Abstract

The most well-known and used evaluation system to determine the life cycle of a product, is the life cycle assessment (LCA). In Europe, the use of the life cycle assessment (LCA) to assess the environmental performance of products is becoming commonplace, which is why substantial efforts have been made in the last two decades to develop new life cycle assessment (LCA) methodologies and software. This paper evaluates the life cycle assessment (LCA) for the rehabilitation of a national road sector in Romania. The biggest ecological problem facing mankind is the effect of global warming and climate change associated with this phenomenon, due to the increase of the concentration of pollutants to the atmosphere, and this paper presents the results of the life cycle assessment (LCA) based on a cradle-to-gate approach. For this case study, were used three rehabilitation alternatives. These alternatives and the existing pavement structure were analysed using the GaBi software, Ganzheitlichen Bilanzierung (German for holistic balancing), to assess the environmental impact of global warming, the stratospheric impact of ozone, and the impact on human health. The results obtained in this study illustrate the importance of a life cycle assessment approach for evaluating the sustainability for different designs and for the construction of road rehabilitation options.

1. Introduction

The life cycle analysis of a product or service is a process with high applicability, making it possible to assess the flows of the materials, energy, and waste of a product over the entire life cycle of the product or service, and its impact on the environment. The analysis covers the complete life cycle of a product, process, or activity, including the production of raw materials, manufacturing, transport and distribution, use, reuse, maintenance, recycling of materials, and final disposal or destruction. According to the standard SR EN ISO 14040: 2007 [1], life cycle means “consecutive and interrelated stages of a product system, from the acquisition of raw materials or the generation of natural resources to post-use”.

The life cycle analysis for construction evaluates the impact of a structure over its lifetime. Once the lifespan has been exhausted, the environmental impact is determined by abandoning or removing the pavement structure. Therefore, the environmental impact assessment has become a key factor in the design and the construction of infrastructure works [2,3,4]. After disposal, the materials may be reused whole or in part, if appropriate disposal techniques are applied. This procedure is one of the keys to sustainability. The special features of the construction sector are the large volumes of materials used, the long life of the finished products; the need to consider construction as a whole, rather than to compare alternative materials; and the significant effect of longevity and the need for constructions to repair the environmental loads. A road is different from many other products in that production methods, material consumption, etc., vary significantly both between construction projects and within them [5,6,7]. A significant example may be geotechnical conditions, which may vary depending on the geographical location of the road. Due to various conditions, it was not possible to use a static life cycle assessment model. Cumulative environmental action along with traffic action during the life of the road proved to be high compared to the loads caused by the construction and the maintenance of the pavement itself [8]. On the other hand, traffic loads and road construction are weighted in different ways, so a direct comparison is not completely unequivocal. If the effect of the pavement structure on environmental and traffic actions could be estimated, it could be significant in terms of energy consumption and atmospheric emissions [9]. However, based on current knowledge, the effect of alternative constructions is extremely difficult to estimate. In the past, consideration of the environmental impact and transport sustainability issues has generally been minimal. Recently, the aggravation of environmental burdens has required an urgent reconsideration of the main environmental aspects in the design and construction of roads. According to European Commission [10] estimates, transport accounts for 32% of Europe’s energy consumption and 28% of the total CO2 emissions. To limit climate change and the resulting global temperature increase by below 2 °C, a reduction of at least 60% in greenhouse gas emissions compared to 1990 in the transport sector is needed.

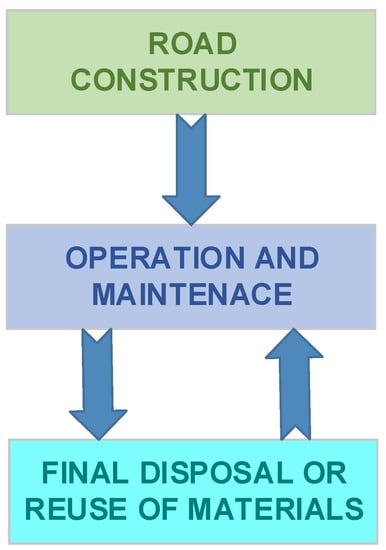

The most well-known and used evaluation system to determine the life cycle of the road sector is the life cycle assessment method [11]. Figure 1 shows the stages of a road, from construction to the end of the service life. Life cycle assessment is an assessment method used to analyse and quantify the impact of pavement structures on the environment throughout the life cycle. This potential impact concerns the use of non-renewable resources, population health, and environmental consequences, useful in decision-making processes for both infrastructure and traffic planning [11,12,13,14,15]. The result contains information on energy consumption and greenhouse gas emissions. There are four distinct steps to be performed in an LCA study [14], namely: goal definition and scope, inventory analysis, impact assessment, and the interpretation of the results. The results are expressed in terms of key environmental factors, namely: energy consumption and greenhouse gas emissions. According to SR EN ISO 104040: 2007 [1], LCA is a tool that “addresses environmental issues and the potential impact on the environment during the life of a product, from the purchase of raw materials, production, use, to recycling and disposal (cradle to gate)”.

Figure 1.

The life cycle of a road.

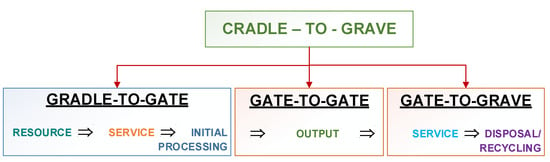

An LCA study can be classified, depending on the considered life cycle period, as presented in Figure 2 [1], into the following:

Figure 2.

LCA classification [1].

- Cradle-to-grave—an evaluation of the life cycle of a product, from the purchase of raw materials to recycling and disposal.

- Cradle-to-gate—an evaluation of the partial life cycle of a product, from the purchase of raw materials to the manufacturing stage, before shipment to the consumer.

- Gate-to-gate—an evaluation of the partial life cycle of a product, which is considered a single process that adds value to the entire production.

- Gate-to-grave—an evaluation of the life cycle of a product, from the purchase of raw materials to recycling or disposal.

In Europe, the use of the life cycle assessment to assess the environmental performance of products is becoming commonplace. As a part of life cycle assessment (LCA), life cycle cost (LCC) is used to assess the economic and environmental performance of products and services. Life cycle cost (LCC) is an analysis technique aimed at quantifying the costs associated with the life cycle of a product or service [16,17]. LCC is not a financial accounting method, but a cost management tool that takes into consideration all the direct costs incurred during the life cycle of a product [18]. In Québec (Canada), the Ministry of Transport has recognized the LCA method as a key element in choosing the pavement [19]. Substantial efforts have been made over the last two decades to develop new LCA methodologies and software, such as GaBi, which was elaborated by the International EP in collaboration with the University of Stuttgart [20,21]. It details the costs, energy, and environmental impact of the supply and refining of each raw material or processed component of a manufactured article [22]. GaBi software combines GaBi databases, created by PE INTERNATIONAL Company, with other commercial databases and regional content. GaBi includes both aggregated database and process database. To design the road life cycle, GaBi database modules were used considering the specific processes and materials for the construction industry [23].

2. Short History

The concept of life cycle analysis first appeared in the 1960s, due to the rapid depletion of fossil fuels, which caused widespread global interest in energy, and it was first used to understand and assess the impact of energy consumption [24]. Big industrial companies in the USA [25] were the initiators of the concept of the life cycle analysis. Its development has focused on the systematic approach used to assess the environmental consequences of a product, process, or activity from a cradle-to-grave perspective. Initially, researchers focused on the energy consumption of existing buildings, capitalizing on their energy-saving potential. Subsequently, it gradually expanded to all aspects of infrastructure construction. Research on road energy consumption also appeared relatively early on, and many research achievements have been applied in practice.

Over time, studies have been conducted in the field of road infrastructure; more precisely, among the first studies on the life cycle analysis of a pavement structure were done in Finland in 1960 by Häkkinen and Mäke [5,26,27]. The study consisted of a comparative analysis between ordinary concrete pavements and asphalt pavements. The authors conclude that when the energy of the raw material for road construction is taken into consideration, the asphalt pavement consumes twice as much energy as the concrete pavement, and if the raw material energy is not included, the energy consumption of these two pavements is equal. In the case of carbon dioxide emissions, ordinary concrete pavement discharges 40–60% more than asphalt pavement [26]. Another comparative study between hot mixed asphalt concrete pavement and continuously reinforced concrete pavement was conducted by Horvath and Hendrickson [26,27] in the United States. They found that in the production stage of materials, the energy consumption of asphalt concrete pavement is about 40% higher than that of continuous reinforced concrete pavement. Most of the environmental indicators of asphalt concrete pavement are better than that of continuous reinforced concrete pavement. Roudebush [28] concluded in his study that the energy value of asphalt pavement is about 90.8% higher than that of concrete pavement. During the production and maintenance of the pavement, the energy value of the asphalt concrete is higher than that of the cement concrete. In Canada, Berthiaume and Bouchard [26] applied energy—the part of the energy that can be transformed into any form of energy—to study the energy consumption and environmental impact of asphalt and cement concrete. Stripple [29], through their study, which included accessory facilities of a highway, concluded that the energy consumption of cement concrete pavements is higher than that of asphalt concrete pavements. Zapata and Gambatese [30], by analysing the energy consumption of asphalt concrete pavements and continuous reinforced concrete pavements, found that the continuous reinforced concrete pavement consumes more energy in the production and construction stage of materials, including the energy consumption of cement production. The energy consumption of cement production is the main factor, while the drying energy consumption of mixed aggregates is a significant factor affecting the energy consumption of asphalt pavement.

Since 1996 until now, at least one study per year has been published that applies the methodology of road life cycle assessment. Although this allowed for the accumulation of knowledge in this field of research, there was no clear evolution of the scientific field during this period. In the current literature for pavement structures, there are contradictory results that occur from the use of different assumptions and the application of LCA methodology. The framework for life cycle environmental assessment is relatively complete after years of research, but there are still many shortcomings in the detailed model and data collection is also in the initial stage. The rehabilitation of pavement structures in terms of life cycle performance has not been studied in the past; the focus was mainly on the performance prediction of new pavements [31,32]. The work produced so far by the International Organization for Standardization (ISO) [33,34,35] has led to a recommendation to use SETAC’s “Code of Practice” as a basis for future work. The European Standardization Organization CEN proposed complying with the ISO recommendations. The LCA framework and theory have been described in the ISO 14040 and ISO 14044 [33,34,35] series standards, which calculate the life cycle in a quantitative framework.

3. Materials and Methods

3.1. General Information about the Analysed Road Sector

The purpose of the study is to outline an overview of the life cycle analysis of a road sector that is part of the Romanian national road DN73, between km 111 + 000 and km 120 + 000. This study took place on the territory of Brașov Country between Tohanu Nou and Râșnov, which connects Muntenia and Transylvania. Knowing the analyses made so far at a national and international level, a study on LCA using GaBi software is presented below. The reconstruction of the old road with new pavement is the most efficient alternative in terms of a negative impact on the environment.

On the road sector mentioned above, an existing rigid pavement with a surface asphalt surface layer was identified, and as presented in Table 1 it consisted of the following.

Table 1.

Existing pavement structure.

The technical class is III Importance category III. The traffic calculation was established based on the average annual daily traffic in standard axles of 115 kN, and was determined using the total number of crossings of the standard axle. The traffic calculation for a prospective period of 15 years, taken in the calculation, was 2.91 m.s.a. (million standard axles—for a heavy traffic load).

3.2. Presentation of the State of Pavement Degradation

The existing degradations on the analysed pavement structure were cracks, alligator cracking, local settlements, and cracks in multiple directions (see Figure 3). Their causes are related to the following [31]:

Figure 3.

Existing pavement structure degradations.

- Insufficient load-bearing capacity for current road traffic;

- Uneven thickness of the pavement structure;

- Inhomogeneity of the structure along the road;

- The small thicknesses of the pavement structure had and still have a negative influence on the frost−thaw behaviours, and an important part of the degradations of the structure being caused by this aspect.

The degradations of the pavement caused by the frost−thaw phenomenon consisted of the following:

- Road bumps caused by water accumulated in freezing areas and turning it into ice lenses;

- Settlements, alligator cracking, and cracks caused by the accumulation of water from melting ice lenses, by softening the supporting ground, and heavy traffic;

- Cracking and tiling of cement concrete slabs.

Structural degradation: the slabs had cracks, blocked joints, and a polished surface, but without unevenness, which that would involve their restoration.

Surface degradations

This type of failure is caused by the following:

- Cracks transmitted to the joints;

- Edge degradation, with a low, medium, and high severity level;

- Swells;

- Polished surfaces;

- Exuded surfaces, with a medium severity level;

- Pinched surfaces with medium and high severity;

- Shoulder failures.

3.3. Rehabilitation Proposals

Based on the degradations observed in the field, the need to carry out intervention works as soon as possible was noted, and several strategies for maintenance and rehabilitation were established, and some of them were selected for the application.

In order to have a unitary behaviour of the pavement structure along the entire width of the road, both the transverse and longitudinal profiles need to be standardized regarding the thickness and load-bearing capacity of the pavement structure.

The following variants are proposed.

3.3.1. First Variant

This operation involves milling the existing asphalt surface to a thickness of about 5 cm, distributing the obtained material across the width of the road platform, and supplementing the thickness of the foundation with a layer of 15 cm of crushed stone or stabilized ballast. Three layers of asphalt mixtures will be placed over the executed foundation, as follows:

- 5 cm MASF 16 or 4 cm MASF 16 according to the project (MASF—fibre-stabilized asphalt mixture)

- 6 cm BAD 20 or 5 cm BAD 25 according to the project (BAD—lightweight asphalt concrete)

- 8 cm AB 31 or 5 or 6 cm AB 2 according to the project (AB—asphalt bitumen mixture).

3.3.2. Second Variant

Complete restoration of the pavement structure, with the basic use of the material resulting from the milling of existing mixtures, and then the transformation of the elastic structure into a semi-rigid pavement structure, according to the one used for the road widening boxes.

3.3.3. Third Variant

Reinforcing the existing structure, which involves the following:

- Repairs of the areas marked with degradation, with a 40% share of the total road surface in the Pitești−Câmpulung sector and 10% of the total road surface in the Câmpulung−Brașov sector;

- Resolving surface degradations, before starting the reinforcement works;

- Execution of a base layer of the mixture AB 2, with a minimum of 12 cm total thickness, laid in two layers of 6 cm thickness each (the first with an equalizing role);

- Laying a geocomposite with a resistance of at least 50 kN/n in both directions, over the first layer of at least 6 cm of the base mixture;

- 5 cm thick bonding layer;

- 4 cm thick wear layer.

For the analysed road sector, the reinforcement of the existing pavement structure was provided according to the third variant proposed above. The drainage of the waters was generally done by removing the ballast foundation from the road widening boxes.

4. Results

4.1. LCA with GaBi

4.1.1. First Step

The first step was to collect important general data about the analysed road sector. It was located on national road 73, km 111 + 000 − km 200 + 000, between Tohanu Nou and Râșnov. According to the technical documentation, the prospective traffic study was 2.91 m.s.a. The pavement structure of the existing road was rigid. The modernization was made according to the third variant of the technical expertise, which consisted of: laying a base layer with a thickness of 6 cm, a bending layer of 5 cm, and a wear layer of 4 cm.

4.1.2. Second Step

The second step was to create modernization alternatives, which helped to present the life cycle assessment of the materials in each alternative, and showed the most efficient option in terms of negative impact on the environment.

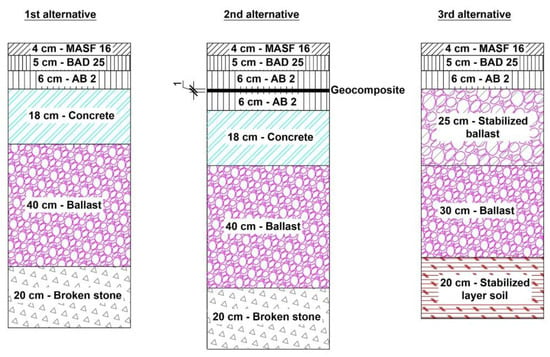

Knowing these data, the following alternatives were examined for the existing pavement structure, and three modernization alternatives respecting the traffic conditions, the technical documentation, and the variants were proposed by the expertise. Thus, the alternatives are presented in Figure 4, and are as follows:

Figure 4.

Alternatives.

- First alternative: Reinforcement, according to the third variant. The laying of three layers of asphalt mixtures.

- Second alternative: Reinforcement with geocomposite, according to the third variant. The laying of the asphalt mix layers over a geocomposite.

- Third alternative: Complete restoration of the pavement structure, according to the second variant.

Transport of materials was not included in the study, but it should be noted that this may be affected by the availability of materials, transport distances, weather conditions, etc. Energy use and related emissions for construction equipment used for initial construction and rehabilitation for all cases were not included. According to the literature, from the studies conducted with EcoConcrete software [7], the contribution of construction equipment to the total energy consumption was only 1% for the initial construction and was even lower for the rehabilitation works. EcoConcrete [7] is a tool that enables the calculation of environmental profiles for ten different European ready mixed and precast concrete products.

The first alternative was to reinforce the existing structure according to the third variant of the technical documentation, without geocomposite, as the modernization did. After the repair of the concrete pavement surfaces, we made a base layer with a thickness of 6 cm (km 111 + 000 − km 112 + 000) or 8 cm (km 113 + 000 − km 120 + 000), a bonding layer of 5 cm, and a wear layer having a thickness of 4 cm.

The second alternative was to reinforce the pavement structure with geocomposite, also according to the third variant of the expertise. After the repair of the concrete pavement surfaces was executed, we added a base layer with a thickness of 6 cm (km111 + 000 − 112 + 000) or 8 cm (km 113 + 000 − 120 + 000), they positioned a geocomposite with the resistance of at least 50 kN/n, and then added another base layer with a thickness of 6 cm (km111 + 000 − 112 + 000) or 8 cm (km 113 + 000 − 120 + 000), respectively; a bonding layer of 5 cm;, and a wear layer of 4 cm.

The third alternative was the complete restoration of the pavement structure, according to the second variant of the expertise. To verify the thickness of the reinforcing road layers, the design was performed with CALDEROM 2000 [36] software to calculate the specific stresses and strains on the road systems, under the static load of the standard axle, and these were verified according to the criteria provided in PD 177/2001 [36] on the load-bearing capacity. Thus, from km 111 + 000 to 112 + 000, the pavement structure was composed of a 30 cm layer of stabilized soil with hydraulic binders, 30 cm of stabilized ballast, 25 cm of stabilized ballast with hydraulic binders, 6 cm base layer, 5 cm bonding layer, and 4 cm wear layer. From km 113 + 000 to 120 + 000, the pavement structure was composed of the following: 30 cm layer of soil form stabilized with hydraulic binders, 30 cm of stabilized ballast, 25 cm of ballast stabilized with hydraulic binders, 8 cm of layer base, 5 cm bending layer, and 4 cm wear layer.

4.1.3. Third Step

The third step was to define the materials and calculate the quantities (volumes). Considering the processes available in the databases, we considered the following hypotheses:

- The MASF 16 layer is assimilated with a layer of asphalt;

- The BAD 25 m layer is assimilated with a layer of asphalt;

- The AB2 layer is assimilated with a layer of asphalt;

- The concrete pavement is assimilated with the C25/30 class of concrete;

- The geocomposite is assimilated with an approximate amount of fibre;

- The stabilized ballast layer is assimilated with a simple ballast layer;

- The stabilized soil layer is assimilated with an assimilated soil road.

The quantities for the existing pavement structure are presented in Table 2.

Table 2.

Quantities (existing pavement structure).

The quantities for the first pavement structure are presented in Table 3.

Table 3.

Quantities (first alternative).

The quantities for the second pavement structure are presented in Table 4.

Table 4.

Quantities (second alternative).

The quantities for the third pavement structure are presented in Table 5.

Table 5.

Quantities (third alternative).

4.1.4. The Negative Impact on the Environment

After defining the materials and calculating the quantities, we started the study using GaBi software. This study applied the “cradle-to-gate” approach. The considered life cycle period was from the resource extraction (cradle) to the factory gate (i.e., before it is transported to the consumer—service to initial processing). After obtaining the results from the GaBi software, the next step was the interpretation of these results. Regarding the negative impact on the environment, we used the following indicators for the global warming potential (climate change midpoint, including biogenic carbon), ozone stratospheric impact (ozone depletion midpoint), and the impact on human health (human toxicity midpoint and cancer effects).

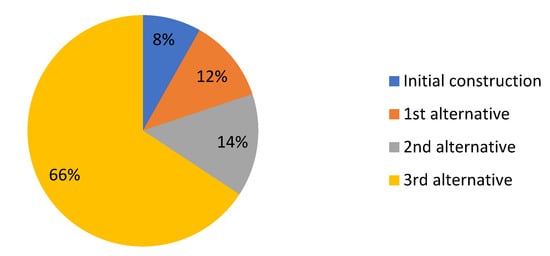

Global warming means an instantaneous increase in the average recorded temperatures of the atmosphere near the ground and water. This currently involves two major issues: reducing greenhouse gas emissions and adapting to the effects of climate change, which are already visible and inevitable. The causes of warming are the greenhouse effect, which is a natural phenomenon through which part of the Earth’s radiation is retained by the Earth’s atmosphere; carbon dioxide, which is the main element that ensures life; methane, which is another chemical element in gaseous form, in which carbon is found in the atmosphere; ozone, which is extremely necessary for life because it reflects the sun’s ultraviolet radiation; eruption of the volcano, which contributes to global warming in two ways, through greenhouse gases and volcanic ash and sulphur aerosols; and anthropogenic effect, which is due to carbon dioxide emissions (burning fossil fuels for transportation, heating, and electricity generation), methane emissions (agricultural activities), and N2O emissions (use of chemical fertilizers and burning fossil fuels) [37]. In terms of road, rail, sea, and air, the transport infrastructure is influenced by the manifestations of extreme weather events, heat waves, heavy snowfalls, storms, floods, increasing slope instability, and the changing geophysical properties of the Earth. Therefore, the design of an adequate infrastructure has an extremely important role in minimizing the causes of global warming. In the case of the current study, according to Table 6, we found that the reinforcement of the pavement structure without a geocomposite (first alternative) was the most efficient from this point of view. In Figure 5, we can see more synthetically the results of the analysis. Thus, compared to the existing road pavement, the impact of global warming is higher for modernization and reconstruction alternatives. This is mainly due to the chemical processes that occur in the execution of asphalt layers, especially in the construction of a new road. As can be seen, the third alternative has the highest impact with a value of 66%. The first alternative has 12% and the second alternative has 14%, with both having an almost similar impact on global warming, due to the similar pavement structure; however, in the second alternative there is an additional base layer AB2, therefore this alternative has a bigger value.

Table 6.

Global warming potential.

Figure 5.

Global warming potential.

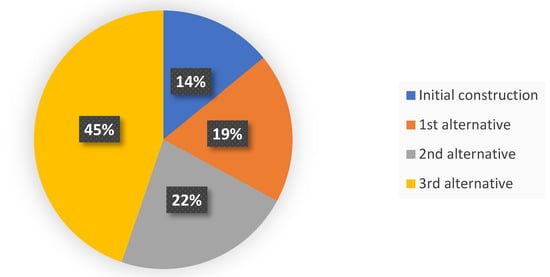

Ozone is a colourless gas that is composed of three oxygen atoms. It is found in the stratosphere, more precisely between 20–30 km above the Earth, where it protects the surface from dangerous ultraviolet (UV) rays. For its measurement, the Dobson [38] unit is used, which is equal to 0.001 atm-cm. According to information published by NASA, the total ozone layer measures 300 Dobson units. A decrease in the number of Dobson units in the ozone layer means less protection against ultraviolet radiation. The causes of this can be chlorine, in the form of table salt; bromine, in various treatments; chlorofluorocarbons (known as Freon), which are used as refrigerants; and smog, created by nitrogen oxides produced by cars, power plants, factories. According to research in recent years, the ozone hole above Antarctica has begun to close, which means that ozone is below 220 Dobson units [39,40]. Concerning the road transport infrastructure, pollution caused through transport has a significant effect on the formation of the ozone hole. The infrastructure of a metropolis-type city leads to increased air pollution and increased noise. This is why the inhabitants of big cities want to move out of town, and so they generally use personal cars to get to work. This factor leads to increased pollution and ozone depletion. The current study is important for obtaining the protection of the ozone layer as much as possible, as well as the increased air quality. According to Table 7, the first alternative (reinforcement of the pavement structure) is the most efficient from this point of view. Figure 6 shows more synthetically the results of the analysis. Here, can be observed that the third alternative is the most unfavourable, with an impact of 45% and its value being approximately equal to the total emissions given in the existing road pavement with 14% impact, and the first alternative having 19% and the second alternative having 22%. This is caused by the production and disposal of nitrogen oxides during new road construction. The first alternative requires the smallest labour force, which means that this variant produces the smallest amount of nitrogen oxide, but it is also more favourable in terms of the stratospheric impact of ozone.

Table 7.

Ozone stratospheric impact.

Figure 6.

Ozone stratospheric impact.

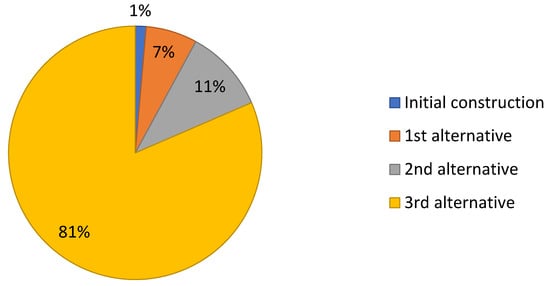

Human health is closely linked to the state of the environment. Clean air and water are essential for people’s lives. Researchers have shown, in recent decades, the climate and nature crisis, which is also due to road construction. Polluted air, noise, and hazardous chemicals have a negative effects on people’s well-being. A study conducted by the World Health Organization (WHO) [41] shows that the quality of the environment is responsible for 12–18% of deaths in the 53 countries of the European region. In Europe, the greatest environmental risk is air pollution, which is closely linked to heart disease, stroke, lung disease, and lung cancer. An estimated 400,000 premature deaths each year in the EU are due to polluted air. The noise of modes of transport, as well as industry, leads to discomfort, sleep disorders, and cardiovascular disease. In terms of hazardous chemicals, in everyday life, people are exposed to a wide range of chemicals, through the air, water, consumer products, and food [41]. These factors show us that before building a road, it is essential to know the current state in terms of human health. According to Table 8, the first alternative (reinforcement of the pavement structure) is the most efficient from this point of view. The fact is also noted in Figure 7. As mentioned above, considering the impact on people’s health, the third alternative, with an impact of 81% on human health, is the most unfavourable, namely the elimination of the old road and the construction of the new road. The most favourable option is the first alternative, with 7%, which requires a reduced workforce, so the hazardous chemicals on human bodies are much lower than the two alternatives. The next favourable option is the second alternative, with 11%.

Table 8.

The impact on human health.

Figure 7.

The impact on human health.

5. Conclusions

As previously mentioned, the purpose of the paper is to study the life cycle assessment of the road sector located on DN 73, between km 111 + 000 — 120 + 000. For the analysis, we used GaBi software [22], which is the most common software in the case of LCA study, and complies with the recommendations of the International Reference Life Cycle Data System (ILCD) Handbook, Recommendations for Life Cycle Impact Assessment in the European Context, European NormsEUR 24571 EN and EN15804: 2012-A1: 2013, as well as the ISO 14040 and 14044 standards [22].

The results obtained with GaBi software considered the following: the potential impact of global warming, the stratospheric impact of ozone, and the impact on human health. These factors are largely influenced by the greenhouse effect, ozone, and carbon dioxide emissions. In this case, the burning of fossil fuels for transport is the element that has the most negative impact on the environment. The results obtained in the analyses in terms of life cycle assessment are presented in Table 9, by performing a ranking from 1 to 3 for each alternative studied.

Table 9.

LCA results.

According to Table 9, we can conclude that the first alternative is the most effective in terms of a negative impact on the environment.

From the results obtained with GaBi software, it can be observed that the ranking of alternatives is the same in all three cases (global warming potential, ozone stratospheric impact, and the impact on human health). The first alternative has the best grade (1), followed by the second alternative with a satisfactory grade (2), and then the third alternative has an insufficient grade (3). The first alternative is the most favourable because it requires a reduced workforce, which leads to the production of small amounts of nitrogen oxides. The first and the second alternatives have almost similar values, which are given by an almost similar pavement structure; in the second alternative, there is an additional base layer AB2, which leads to the production of more nitrogen oxide. The third alternative is the most unfavourable. This is mainly due to the chemical processes that occur in the execution of asphalt layers, especially in the construction of a new road.

From the results obtained in this study, it can be concluded there is a need to apply on time intervention strategies to extend the pavement structure life, and, as can be seen, the third alternative consisting of the construction of a new pavement structure involves the consumption of a large number of bituminous binders and non-renewable granular materials and the release of a large quantity of CO2e (2,170,036.288 kg CO2e) into the atmosphere.

In this case, the burning of fossil fuels for transport is the element that has the most negative impact on the environment. Regarding the results obtained, it can be seen that in order to avoid the depletion of fossil fuels, an evaluation of the impact of energy consumption must be taken into account. Given this information, it can be concluded that such an LCA study is essential for the construction of a road.

Author Contributions

Conceptualization, C.P. and S.G.M.; methodology, C.P. and E.-L.P.; software, M.B.; validation, C.P., S.G.M. and E.-L.P.; formal analysis, M.B.; investigation, C.P., S.G.M., M.B. and E.-L.P.; data curation, C.P.; writing—original draft preparation, M.B.; writing—review and editing, C.P. and E.-L.P.; visualization, C.P. and S.G.M.; supervision, C.P. and S.G.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- ISO 14040:2007; Environmental Management. Life Cycle Assessment. Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Awange, J. Environmental Impact Assessment. Environ. Sci. Eng. 2018, 3, 243–272. [Google Scholar] [CrossRef]

- Fothergill, J.; Barlow, E.; Baxter, M.; Blyth, N.; Harada, R.; Stainton, J. Special Report—The State of Environmental Impact Assessment Practice in the UK Environmental Impact Assessment; Institute of Environmental Management and Assessment: March, UK, 2016. [Google Scholar]

- European Commission. Environmental Impact Assessment of Projects: Guidance on Screening; European Commission: Brussels, Belgium, 2014. [Google Scholar] [CrossRef]

- Jiawen, L.; Hui, L.; Yu, W.; Nailing, G. Integrated Life Cycle Economic and Environmental Impact Assessment for Transportation Infrastructure; Intechopen: London, UK, 2019. [Google Scholar]

- Nicuţă, A.M. Life Cycle Assessment Study for New and Recycled Asphalt Pavements. Bull. Polytech. Inst. Iasi 2011, 61, 81. [Google Scholar]

- Dumitrescu, L.; Maxineasa, S.G.; Simion, I.M.; Taranu, N.; Andrei, R.; Gavrilescu, M. Evaluation of the Environmental Impact of Road Pavements from a Life Cycle Perspective. Environ. Eng. Manag. J. 2014, 13, 449–455. [Google Scholar] [CrossRef]

- Flowerdew, A.D.J.; Hammond, A.; Travers, R. Roads and the Environment; The World Bank: Washington, DC, USA, 1973; Volume 7. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Xiao, F.; Hettiarachchi, C. Project Level Management Decisions in Construction and Rehabilitation of Flexible Pavements. Autom. Constr. 2022, 133, 104035. [Google Scholar] [CrossRef]

- The Adaptation to Climate Changes Effects Guide. Available online: www.meteoromania.ro/anm/images/clima/SSCGhidASC.pdf (accessed on 24 May 2021).

- Condurat, M. Preventing and Reducing the Negative Impact of the Road Transport System on the Environment. Ph.D. Thesis, ”Gheorghe Asachi” Technical University of Iași, Iasi, Romania, 2016. [Google Scholar]

- Dragoslav, D.N. Strategies for Sustainable Pavement Structures. Ph.D. Thesis, ”Gheorghe Asachi” Technical University of Iași, Iasi, Romania, 2017. [Google Scholar]

- Butt, A.A. Life Cycle Assessment of Asphalt Roads: Decision Support at the Project Level. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 11 December 2014. [Google Scholar]

- Jensen, A.A.; Elkington, J.; Christiansen, K.; Hoffmann, L.; Møller, B.T.; Schmidt, A.; van Dijk, F. Life Cycle Assessment (LCA)—A Guide to Approaches, Experiences and Information Sources; European Community: Brussels, Belgium, 1997. [Google Scholar]

- Heidari, M.R.; Heravi, G.; Esmaeeli, A.N. Integrating Life-Cycle Assessment and Life-Cycle Cost Analysis to Select Sustainable Pavement: A Probabilistic Model Using Managerial Flexibilities. J. Clean. Prod. 2020, 254, 120046. [Google Scholar] [CrossRef]

- Heravi, G.; Esmaeeli, A.N. Fuzzy multicriteria decision-making approach for pavement project evaluation using life-cycle cost/performance analysis. J. Infrastruct. Syst. 2014, 20, 04014002. [Google Scholar] [CrossRef]

- Jiang, R.; Wu, P. Estimation of Environmental Impacts of Roads through Life Cycle Assessment: A Critical Review and Future Directions. Transp. Res. Part D Transp. Environ. 2019, 77, 148–163. [Google Scholar] [CrossRef]

- Ventura, A.; Jullien, A. Life cycle assessment applied to road pavements: An analysis of method and results relevancy. In Proceedings of the Sixth International Conference on Maintenance and Rehabilitation of Pavements and Technology Control, Turin, Italy, 8–10 July 2009; pp. 1210–1219. [Google Scholar]

- Nascimento, F.; Gouveia, B.; Dias, F.; Ribeiro, F.; Silva, M.A. A Method to Select a Road Pavement Structure with Life Cycle Assessment. J. Clean. Prod. 2020, 271, 122210. [Google Scholar] [CrossRef]

- PE International, AG. GaBi Manual. 2012, p. 388. Available online: https://gabi.sphera.com/fileadmin/GaBi_Manual/GaBi_6_manual.pdf (accessed on 1 March 2021).

- Di Bari, R.; Jorgji, O. Guidelines and Calculation Methods for Lifecycle Environmental Impact Assessment of Plus Energy Buildings; Cultural-E, 2021. 870072. Available online: https://www.cultural-e.eu/wp-content/uploads/2021/10/CULTURAL-E_D4.5.pdf (accessed on 25 May 2021).

- Available online: https://gabi.sphera.com/international/solutions/life-cycle-assessment (accessed on 1 March 2021).

- McManus, M.C.; Taylor, C.M. The Changing Nature of Life Cycle Assessment. Biomass Bioenergy 2015, 82, 13–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ivanova, N.; Gugleva, V.; Dobreva, M.; Pehlivanov, I.; Stefanov, S.; Andonova, V. Silver Nanoparticles as Multi-Functional Drug Delivery Systems. In Nanomedicines; IntechOpen: London, UK, 2018. [Google Scholar]

- Carlson, A. Life Cycle Assessment of Roads and Pavements. Studies Made in Europe. VTI Rapport 736A. 2011. Available online: https://www.researchgate.net/publication/262874388_Life_cycle_assessment_of_roads_and_pavements_-_Studies_made_in_Europe (accessed on 25 May 2021).

- Santero, N.; Masanet, E.; Horvath, A. Life Cycle Assessment of Pavements: A Critical Review of Existing Research; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2010.

- Zhang, H.; Lepech, M.D.; Keoleian, G.A.; Qian, S.; Li, V.C. Dynamic Life-Cycle Modeling of Pavement Overlay Systems: Capturing the Impacts of Users, Construction, and Roadway Deterioration. J. Infrastruct. Syst. 2010, 16, 299–309. [Google Scholar] [CrossRef] [Green Version]

- Berthiaume, R.; Christian, B. Exergy Analysis of the Environmental Impact of Paving Material Manufacture. Trans. Can. Soc. Mech. Eng. 1999, 23, 187–196. [Google Scholar] [CrossRef]

- Stripple, H. Life Cycle Assessment of Road: A Pilot Study for Inventory Analysis, 2nd ed.; Swedish National Road Administration: Borlänge, Sweden, 2001. [Google Scholar]

- Zapata, P.; Gambatese, J.A. Energy consumption of asphalt and reinforced concrete pavement materials and construction. J. Infrastruct. Syst. 2005, 11, 9–20. [Google Scholar] [CrossRef]

- Abaza, K.A. Empirical Markovian-Based Models for Rehabilitated Pavement Performance Used in a Life Cycle Analysis Approach. Struct. Infrastruct. Eng. Maint. Manag. Life-Cycle Des. Perform. 2017, 13, 625–636. [Google Scholar] [CrossRef]

- Santos, J.; Ferreira, A.; Flintsch, G. A life cycle assessment model for pavement management: Methodology and computational framework. Int. J. Pavement Eng. 2015, 16, 268–286. [Google Scholar] [CrossRef]

- SR EN ISO. 14004:2016; Environmental Management Systems. General Guidelines for Implementation. ISO: Geneva, Switerland, 2016.

- SR EN ISO. 14044:2007; Environmental Management. Life Cycle Assessment. Requirements and Guidelines. ISO: Geneva, Switerland, 2007.

- SR ISO. 14050:2009; Environmental Management—Vocabulary. No. 3533553; ISO: Geneva, Switerland, 2009.

- PD 177:2001; Standard for the Design of the Flexible and Semi-Rigid Pavements—Analytical Method. Search Corporation: Bucharest, Romania, 2001; In Romanian.

- De Horta, O.S.; Carlos, J. Associations of distress and diagnosis of bitumen-surfaced road pavements. In Proceedings of the 5th International Conference on Low-Volume Roads, Raleigh, NC, USA, 19–23 May 1991. [Google Scholar]

- Încăllzirea Globală. Available online: ro.wikipedia.org/wiki/încăllzirea_globală#cite_note-1 (accessed on 24 May 2021).

- NASA Ozone Watch. Available online: https://ozonewatch.gsfc.nasa.gov/facts/SH.html (accessed on 24 May 2021).

- Efectele Metropolelor Asupra Stratului de Ozon. Available online: https://uleiuri-lubrifianti.com.ro/efectele-metropolelor-asupra-stratului-de-ozon/ (accessed on 25 May 2021).

- Environment and Health. Available online: https://www.eea.europa.eu/themes/human/intro (accessed on 25 May 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).