1. Introduction

Space telescopes are developing toward deep space exploration and maneuver to change orbit, with increasing demands on imaging quality, however, they experience changing and complex thermal environments [

1,

2]. The temperature of a telescope directly affects its imaging quality, and a reliable thermal design remains the basis for ensuring the stable operation of the telescope [

3]. The thermal design of telescopes involves the iterative optimization of a large number of parameter combinations, which currently relies on the design experience of engineers and involves a process of repeated attempts. The process is time consuming and it is difficult to find an optimal solution. The development of methods that allow the rapid optimization of the thermal design parameters of telescopes has become an important issue [

4], and techniques of parameter optimization have thus received much attention in recent years.

Scholars have investigated the parameter optimization of space telescopes, but there have been few studies on the optimization of the thermal design parameters of space telescopes. As examples, del Rio et al. [

5] optimized the design parameters of X-ray mirrors using a genetic algorithm (GA) and Zhang et al. [

6] used the inverse of the effective temperature of a star for a given flux density obtained using a stochastic particle swarm optimization algorithm and angular parameters, and solved the problem where the band-pass density of the detector is determined and fixed during the operational phase. Popular parametric optimization methods such as particle swarm algorithms [

7,

8] and genetic algorithms [

9,

10] reveal a better optimization speed and performance than the iterative trial-and-error approach that relies on the engineer. Among these methods, a GA as a global optimization probabilistic algorithm is employed to find an optimal value on the basis of superiority and inferiority and adapts to arbitrary forms of objective functions and constraints. Therefore, GA shows great potential and advantages in the design of thermal parameters of future complex space telescopes. However, these optimization algorithms are combined with traditional physical models to conduct finite element iterative calculations after selecting parameter combinations, which is a time-consuming process of solving partial differential equations that greatly reduces the speed of parameter optimization. The technique of using a surrogate model has attracted attention in recent years for its ability to accelerate the parameter optimization iterations and ensure the accuracy of design at the same time.

A surrogate model [

11,

12,

13] is commonly used for optimization in engineering problems. When the actual problem (involving a high-precision model) is computationally intensive and difficult to solve, a simplified model that is less computationally intensive and fast to solve can be used in place of the original model to accelerate optimization. The surrogate models most commonly used are those of the kriging method [

13], polynomial response surface method [

14], and artificial neural network [

15], which have various industrial applications, including the thermal design of spacecraft. A back-propagation (BP) neural network [

16,

17] is a multilayer feedforward network that can express almost any nonlinear system and is widely used in various fields owing to its excellent fitting ability. As examples, Cui et al. [

18] established a three-component proxy ignition delay prediction model based on a BP neural network, which had a computational speed that was nearly 9 times that of the traditional ignition delay calculation, and Zhao et al. [

19] proposed a surrogate model for computational fluid dynamics simulation based on a GA–BP neural network to predict the concentration of aerosols after diffusion, which solved the problem of the simulation not being achieved in real time when predicting the concentration of diffused gas. Although the BP neural network has a good fitting effect, the setting of the network hyperparameters significantly affects the fitting efficiency and accuracy of the network. The learning rate, initial weights, and thresholds are the parameters that most affect the network performance. The learning rate of the traditional BP network is fixed, regardless of the magnitude of error, always with a fixed learning rate to adjust the weights, etc. If the learning rate is too high, it may not be possible to directly cross the global optimum resulting in a failure to converge. If the learning rate is too low, the loss function changes slowly, there is a large increase in the convergence complexity of the network, and the process is easily trapped in local extremes. In addition, the neural network requires constant iterative updating of weights and thresholds during the computation to perform well [

20,

21]. The initialization of weights and thresholds of traditional BP networks is randomly generated, and during the training process, phenomena such as gradient disappearance and gradient explosion are often encountered. Therefore, proper initialization of the weights can effectively avoid these two issues and improve the model performance and convergence speed.

On the basis of the above analysis, this paper proposes a design method (called SMPO) that uses an improved BP neural network (called GAALBP) to establish a telescope surrogate model and optimizes the model parameters using a GA to optimize the thermal design of a telescope. GAALBP employs a GA to optimize the initial network weights and thresholds, and the learning rate adaptively changes with the error during the training, allowing for the training of a better surrogate model and providing a physical basis for subsequent parameter optimization. The remainder of this paper is organized as follows:

Section 2 details the proposed design methodology of SMPO.

Section 3 describes the application of SMPO to the parameter optimization of the thermal design parameters for a space telescope and compares the results with those obtained using the traditional method of manual parameter optimization.

Section 4 presents the conclusions of the study.

2. Methodology of SMPO

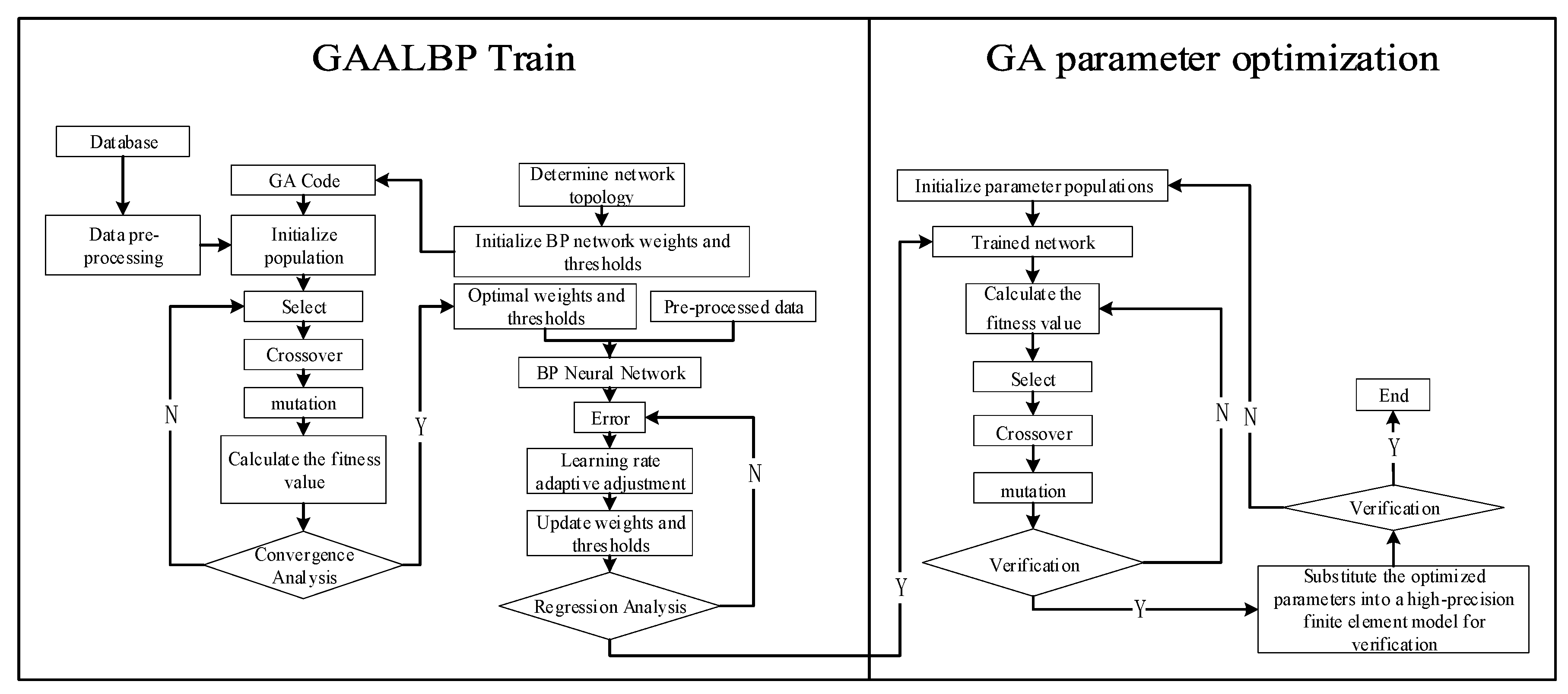

The methodology of SMPO involves building a surrogate model using GAALBP and using a GA to find the best parameters, as shown in

Figure 1.

Part I: GAALBP network training

This paper proposes an improved BP neural network. The improved network uses a GA to optimize the initial weights and thresholds of the network, the best individuals in the population are selected in a winner-takes-all manner [

22], and the coding information of the best individuals is used for the initial weights and thresholds of the network. Therefore, before the training of the network, the GA coding length and fitness value need to be calculated and data preprocessing conducted. The calculations are as follows:

(1) Calculation of the encoding length. The length

S of the GA encoding is derived from the network topology determined by the feature dimensions of the input and output and the numbers of layers and nodes of the hidden layer. The calculation is

where

nin is the number of neurons in the input layer,

N is the number of layers in the hidden layer,

ni is the number of neurons in the hidden layer (

i = 1, 2,…,

N), and

nout is the number of neurons in the output layer.

(2) Calculation of the fitness value. In the training phase of the network, the mean square deviation of the predicted values fitted to the network from the true values is taken as the fitness value of the GA. The maximum fitness value is zero when

Treal and

Tpre are equal. The calculation is

where

Tprei is the predicted temperature,

Treali is the true temperature, and

N is the number of test samples.

(3) Data preprocessing. The input data are normalized to eliminate the effect of variables of different orders of magnitude on the network training. Here, the optimal normalization method [

23] is used to map the data to the range [−1, 1]. The calculation is

where

xmin is the minimum value for the same dimension, and

xmax is the maximum value for the same dimension.

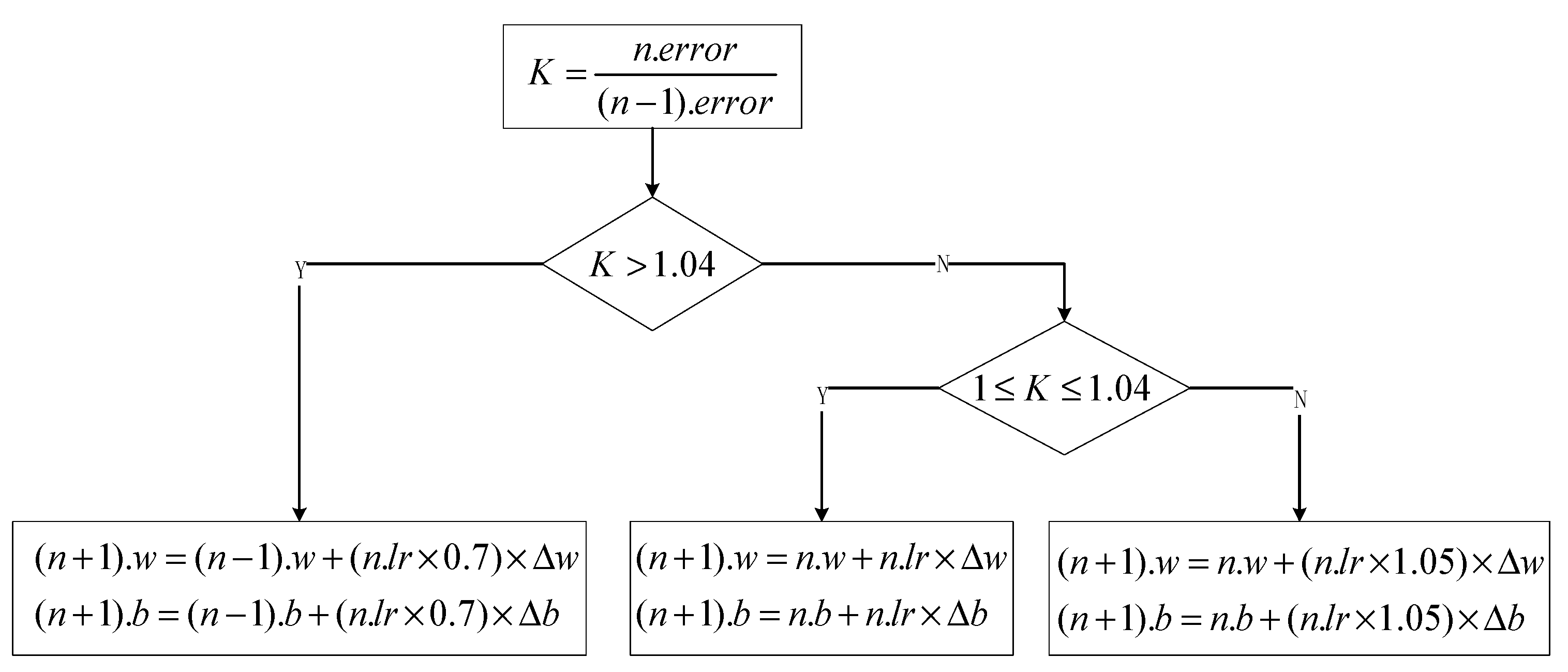

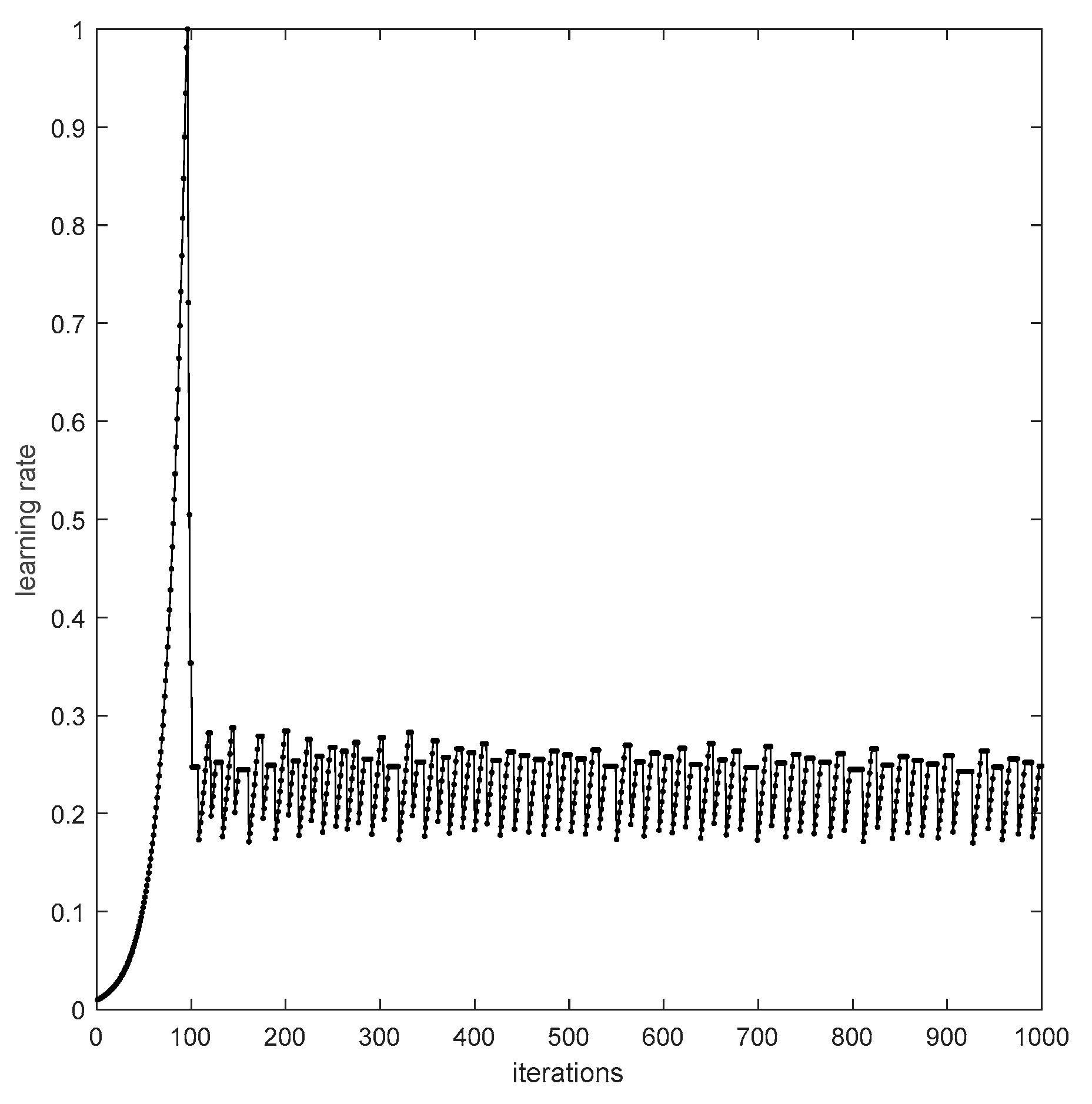

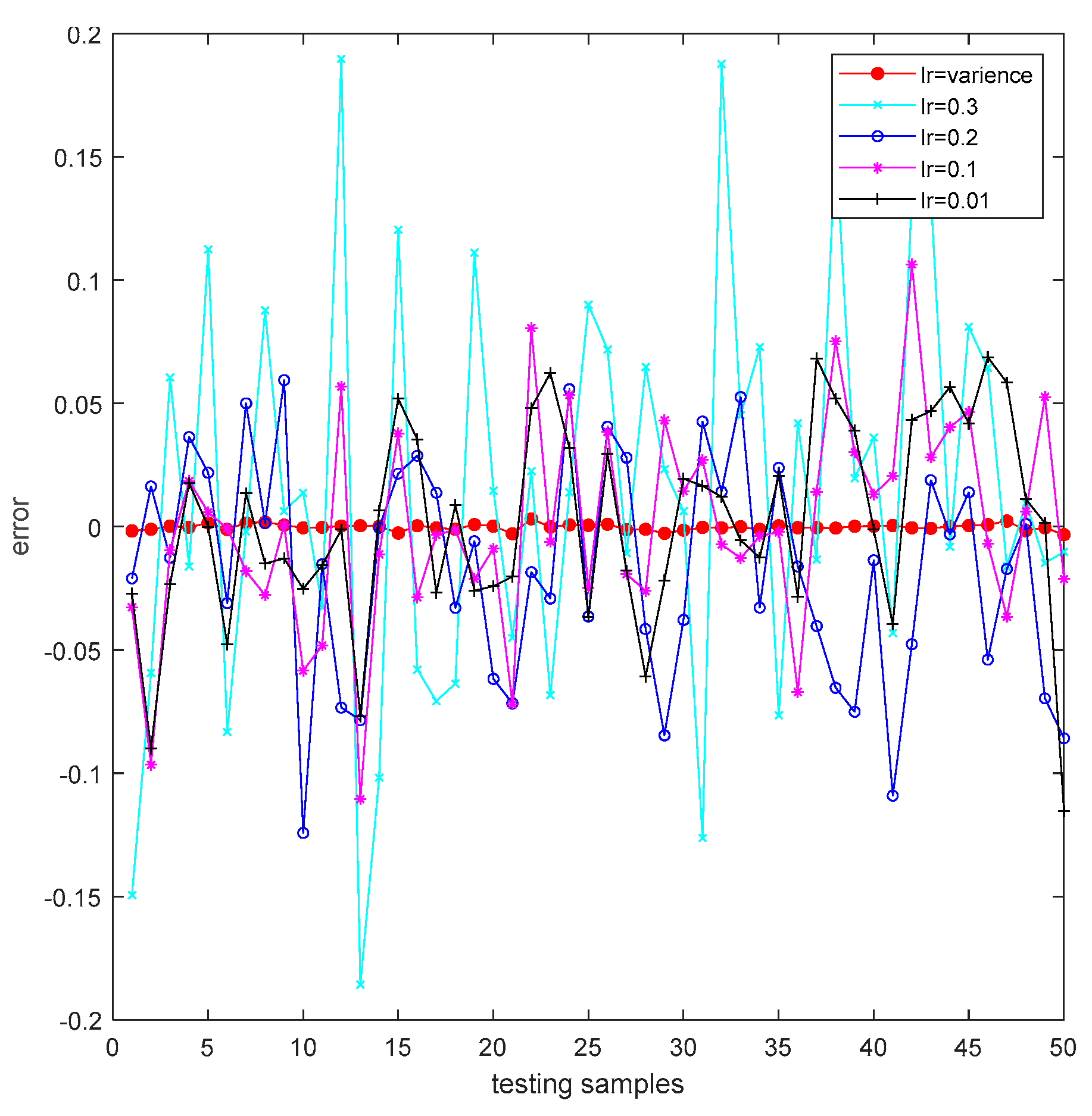

The optimized weights and thresholds are assigned to the BP network, and the input data are used to train the network. During the training process, the learning rate changes adaptively with the relative change in the error, bearing the aim of keeping the learning stable while maintaining the largest possible learning step. If the error increases, a smaller learning rate is used in continuously searching for the direction of the gradient descent, and if the error increases by more than a certain percentage, the weights and thresholds of the previous round are discarded and the learning rate is reduced. This process improves the learning rate, however, when the learning rate is too high and the error reduction is not guaranteed, the learning rate is reduced until stable learning is restored. The improved BP network compensates for drawbacks such as the fixed learning rate of the BP network and can be trained to obtain a better surrogate model. The rule for correcting the learning rate with error is determined by manual debugging, and the method of adaptively adjusting the learning rate is shown in

Figure 2. If the error in the current round increases by more than a factor of 1.04 relative to that in the previous round, the weights and thresholds of the current round are discarded, and the weights and thresholds in the next round are calculated using the values of the previous round, and the learning rate is reduced by a factor of 0.7. If the error in the current round is higher than that in the previous round but by less than a factor of 1.04, then the current weights, thresholds, and learning rate are retained. If the error continues to decrease, the learning rate is increased by a factor of 1.05.

In

Figure 2,

n.error is the error in round

n, (

n − 1)

.error is the error in round (

n − 1);

n.w and

n.b are, respectively, the weight and threshold in round

n; (

n + 1)

.w and (

n + 1)

.b are, respectively, the weight and threshold in round (

n + 1); and ∆

w, ∆

b is the variation calculated from the error using the gradient descent method.

Part II: GA parameter optimization

The GA is used to find the output extrema of the established surrogate model and the optimal solution corresponding to the extrema.

The GA initializes the generated population in the given parameter ranges. By setting the target output value, in the stage of seeking the extreme value, the difference between the target value and the actual output value is found and the negative of its absolute value is used as the fitness value

fit of the GA, and the optimal solution is obtained by selecting the optimal individuals through crossover and mutation operations. Finally, the optimization result is substituted into the high-precision finite element model to verify whether the output satisfies the demand, and if not, the number of population individuals are increased iteratively until the target is met. The fitness value

fit is calculated as

where

Tpre is the predicted temperature and

Treal the true temperature.

4. Conclusions

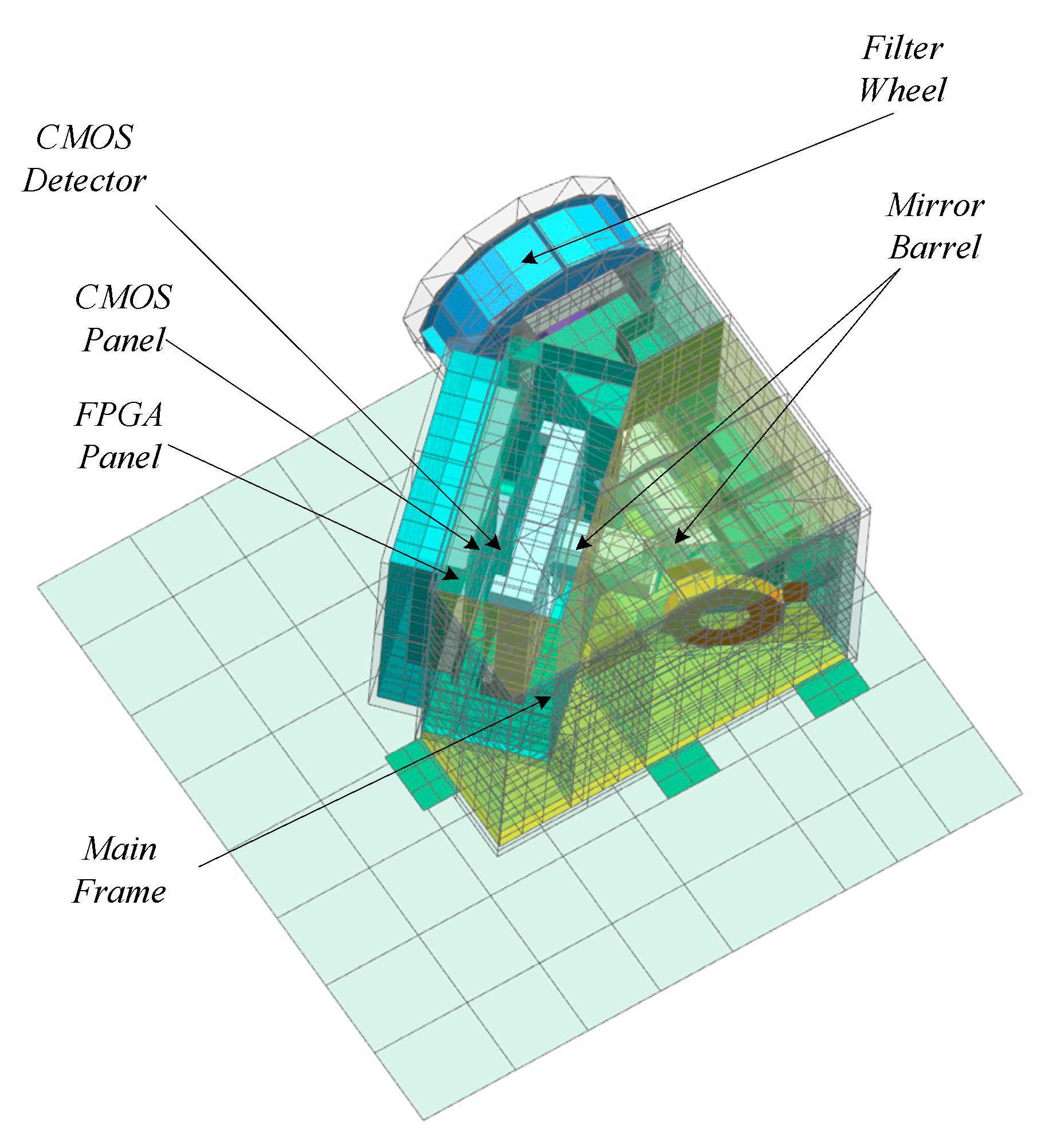

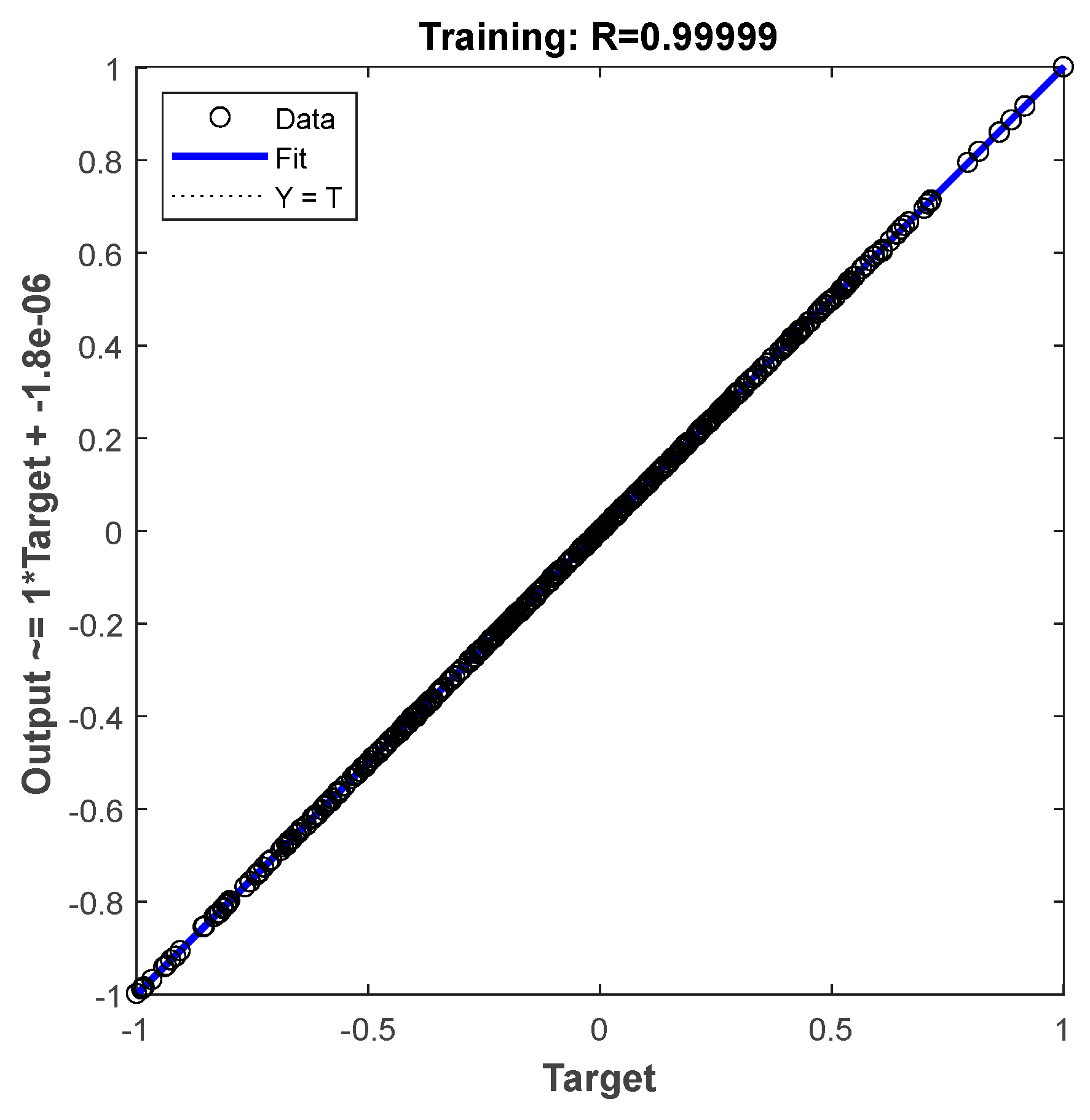

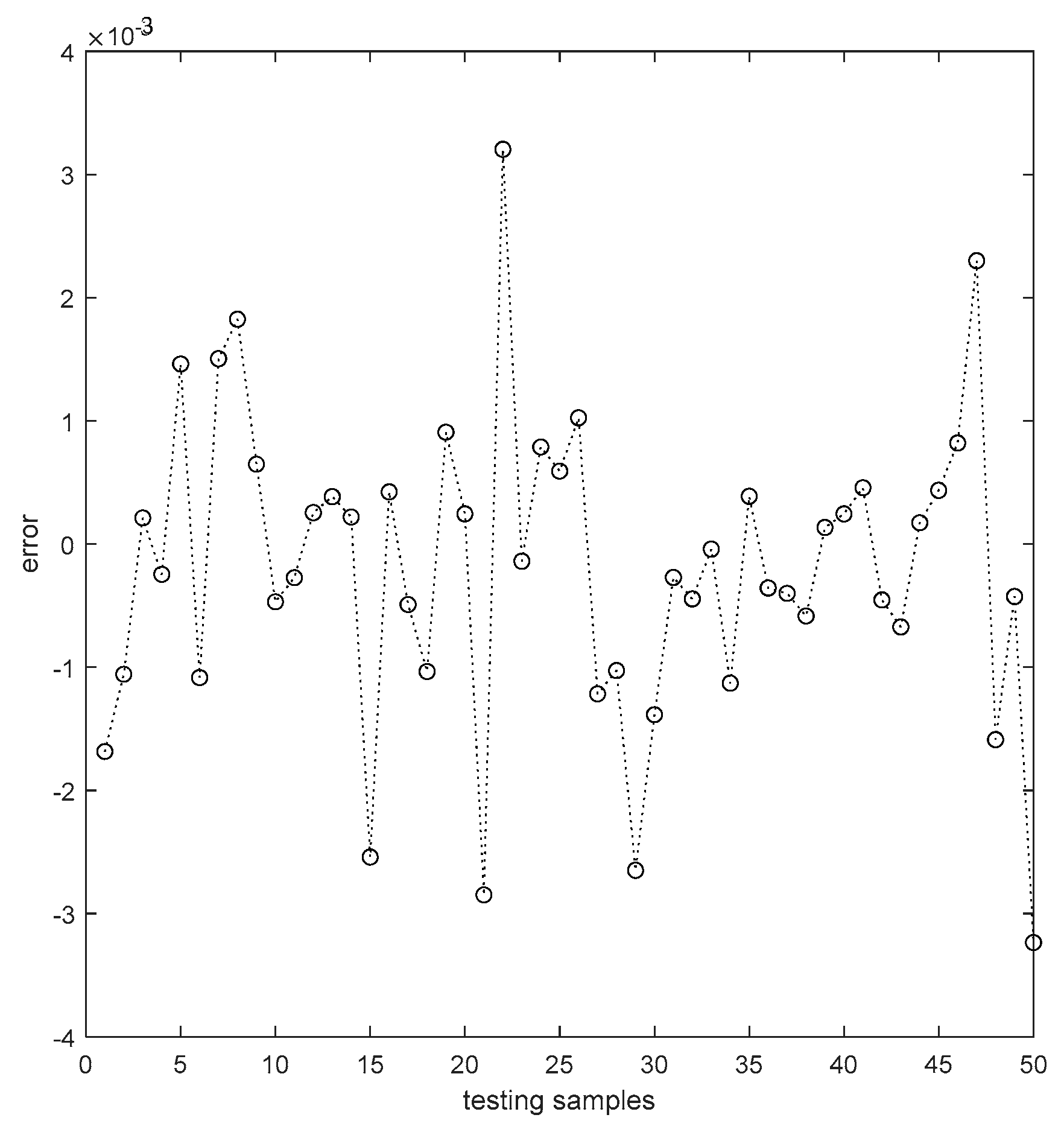

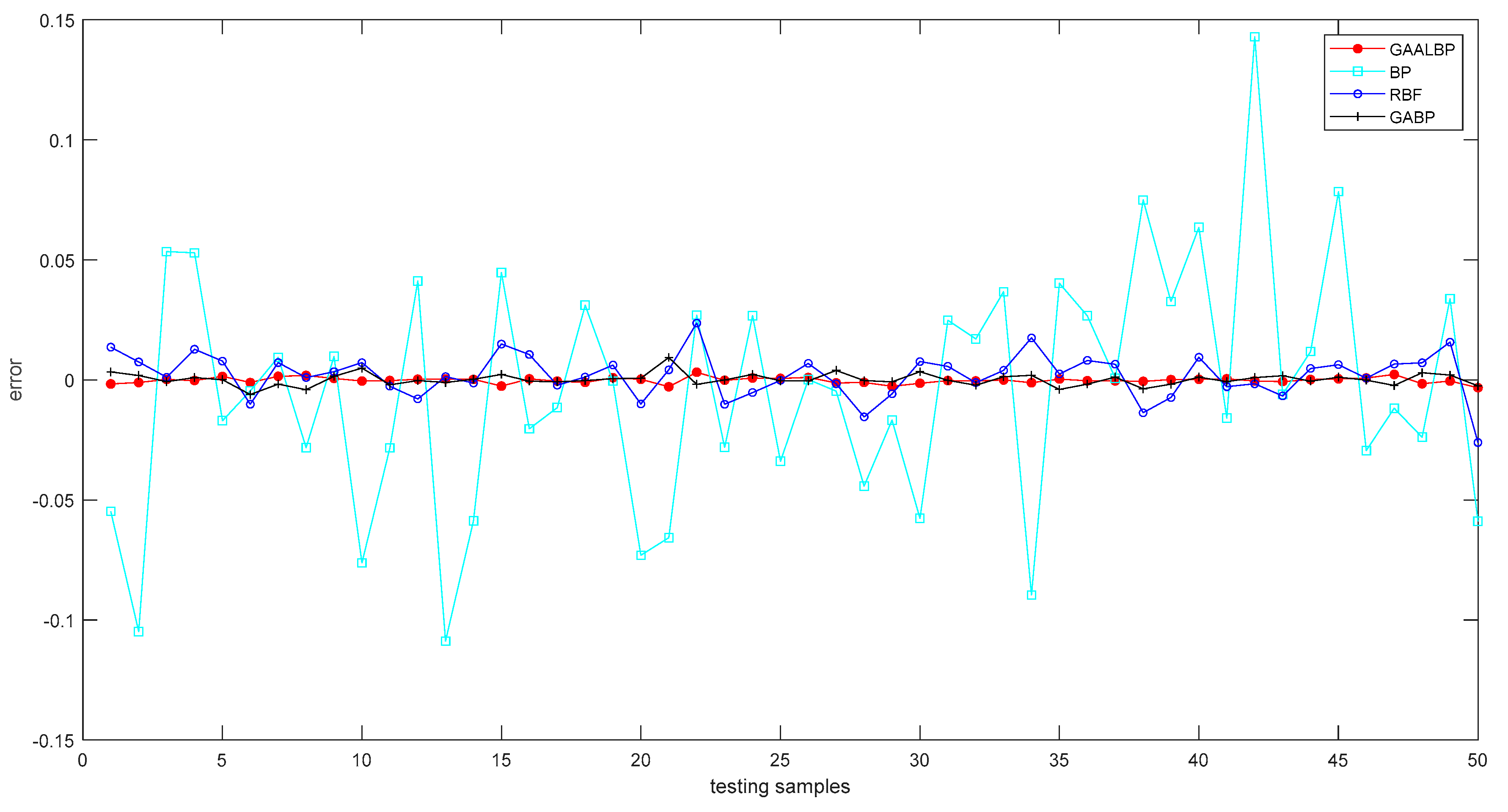

This paper proposes a surrogate model-based method for optimizing the thermal parameters of space telescopes, called SMPO. The method employs a BP neural network surrogate model based on the adaptive learning rate (called GAALBP) so as to bear a lower computational cost than the traditional thermal design approach of solving partial differential equations. Additionally, the proposed method uses a genetic algorithm (GA) to optimize the weights and thresholds of the BP network and thus improves the accuracy of the surrogate model. After the surrogate model is established, the genetic algorithm is used again to optimize the input of the network so that the output of the network approximates the target value.

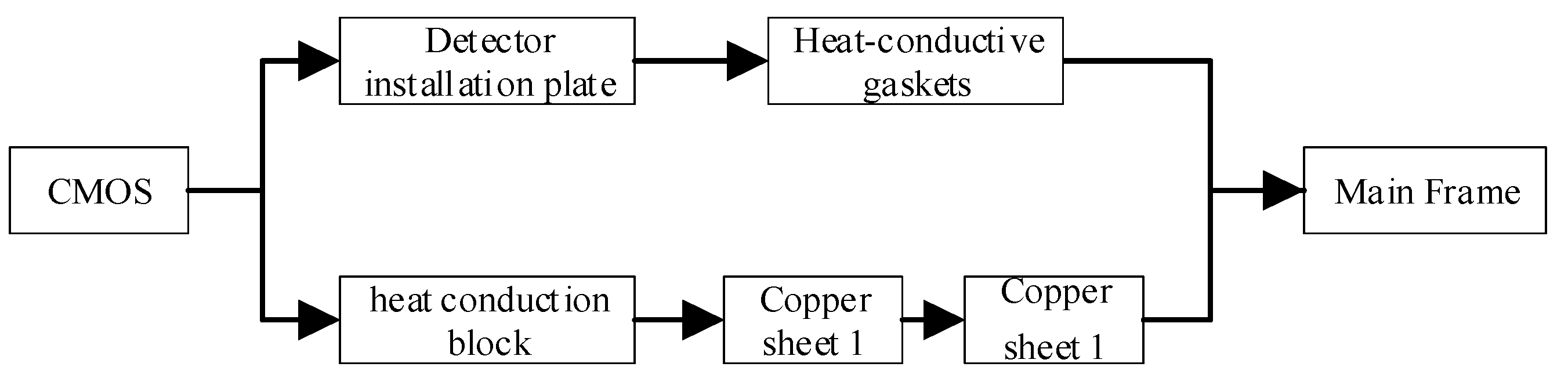

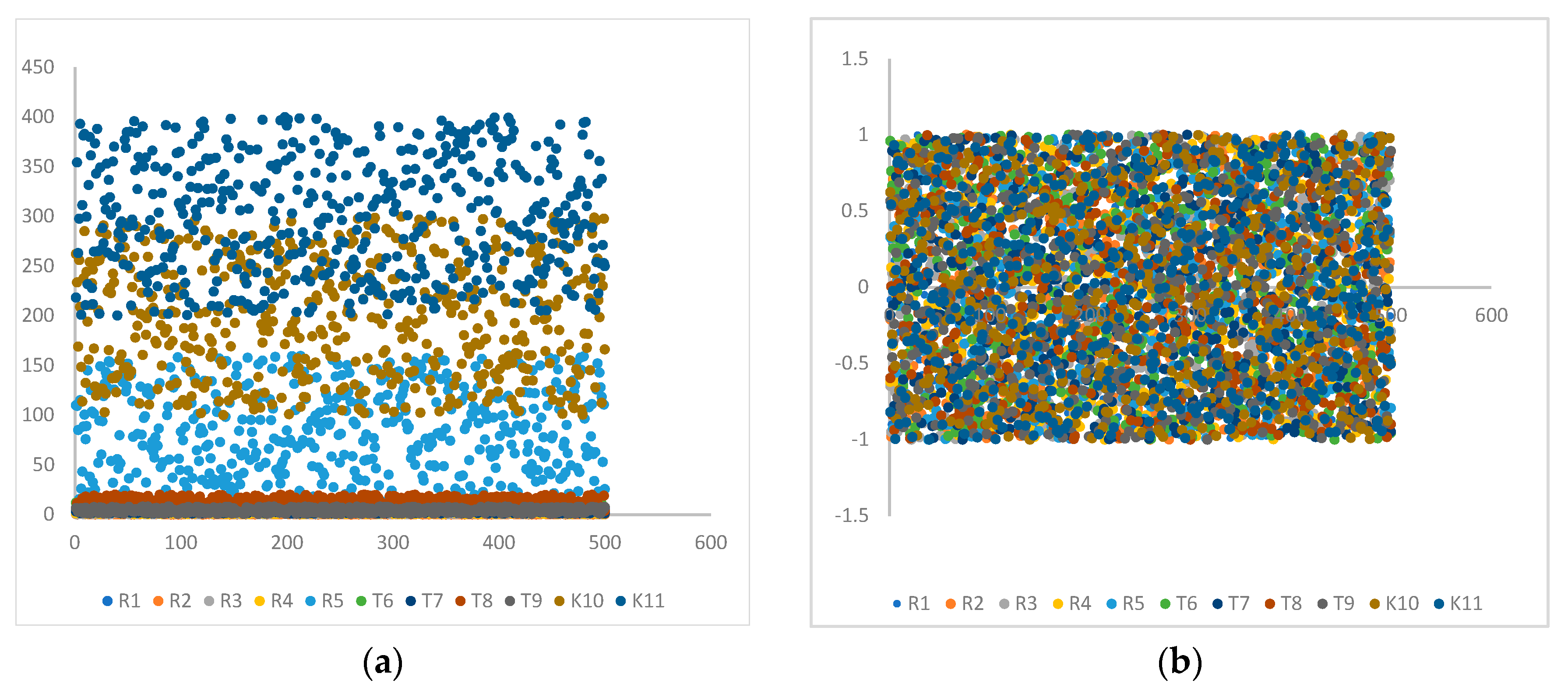

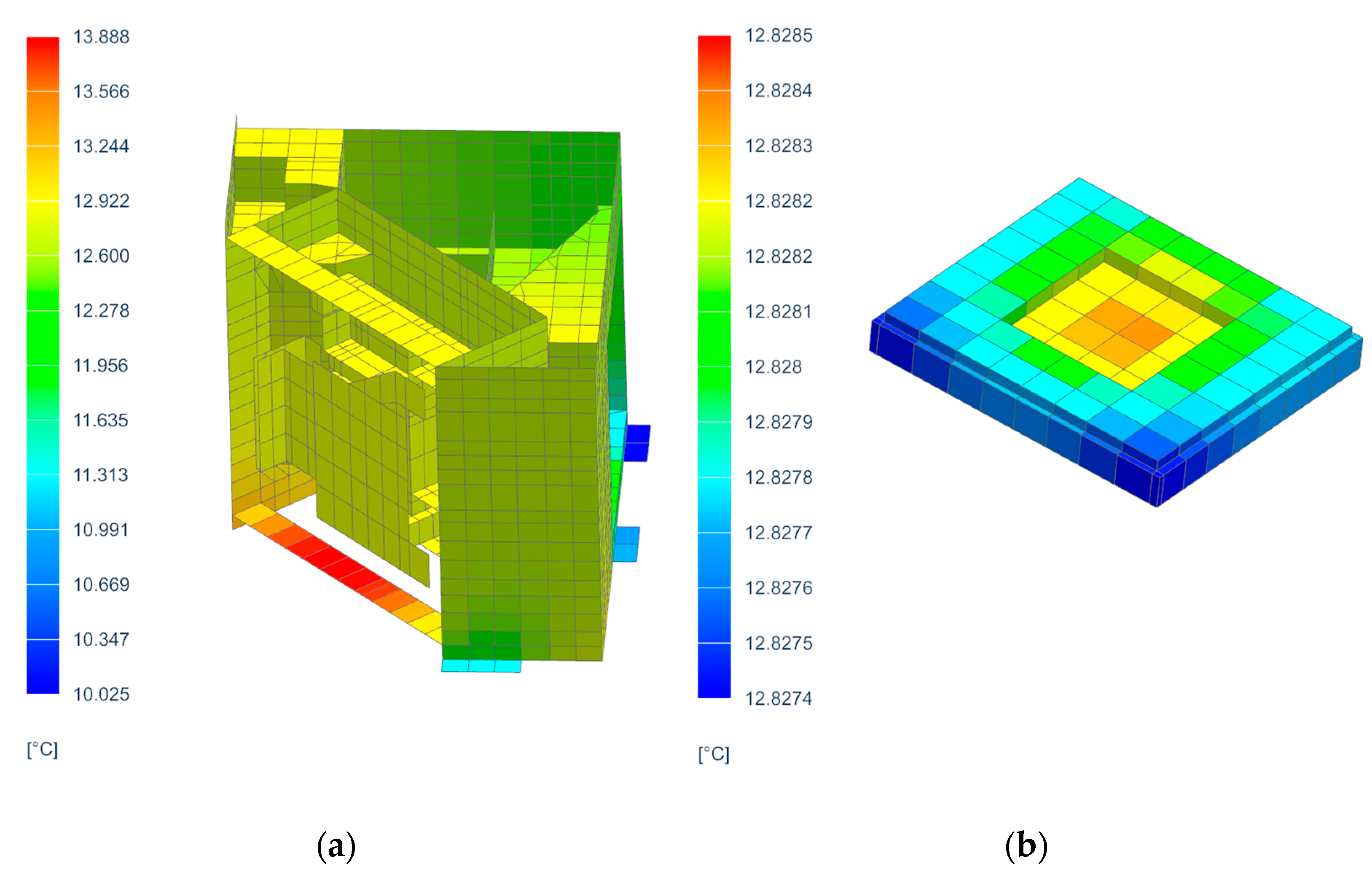

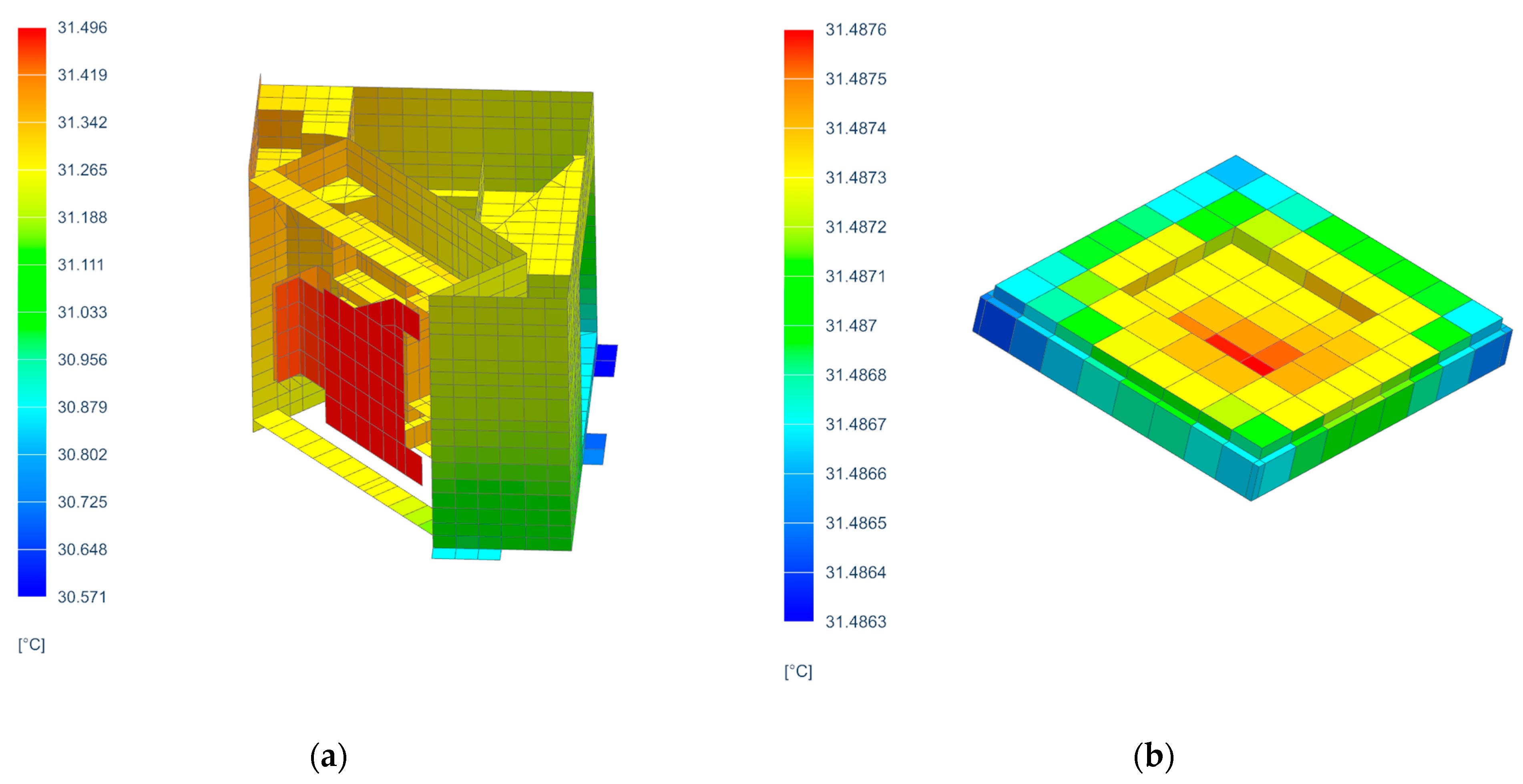

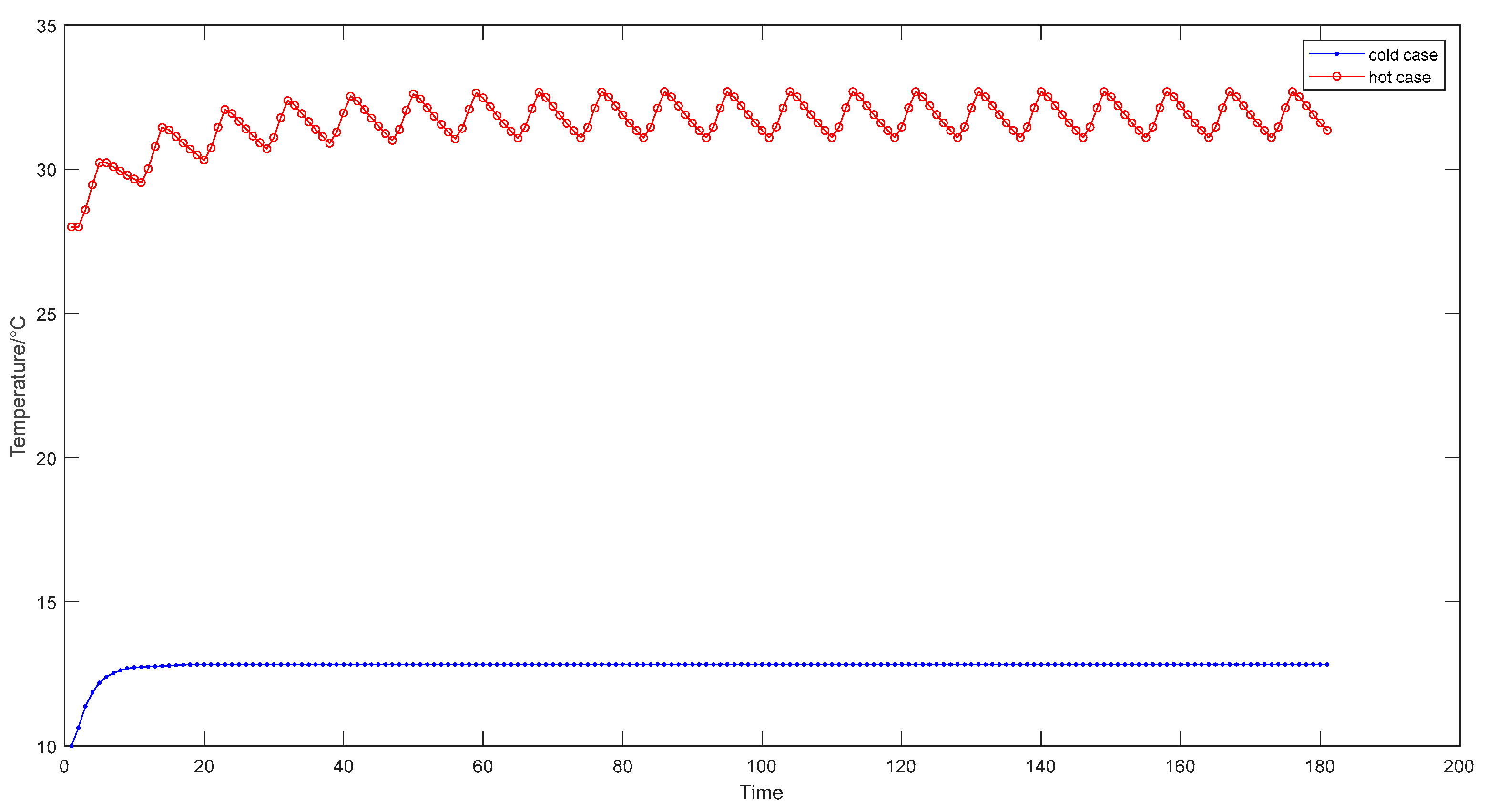

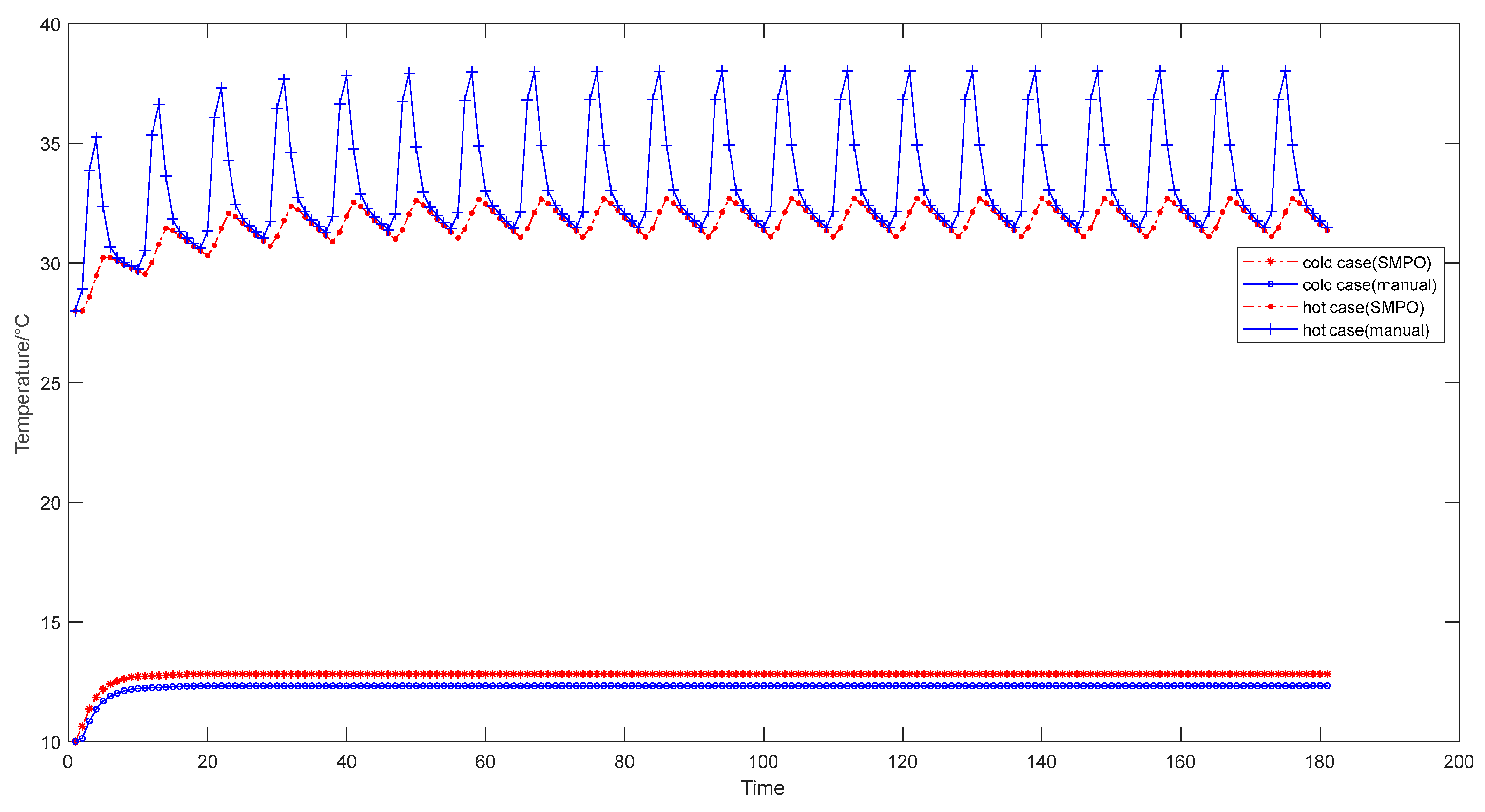

In this paper, we established a thermophysical model of a space telescope (called the ADST), selected 11 parameters of the heat dissipation path of the CMOS detector as indicators to be optimized, applied the GAALBP network surrogate model to approximate the thermophysical model of the ADST, established the mapping relationship between the 11 indicators to be optimized and the temperature of the CMOS, and used a GA to optimize indicators ensuring the output meets CMOS temperature requirements. The theoretical and simulation results reveal that SMPO proposed in the paper outperforms traditional engineer-dependent optimization, in terms of the model evaluation accuracy and higher computational efficiency.

Space telescopes are developing toward the direction of modularization, rapid launch, and short design cycles. Optimization design methods such as those similar to SMPO that can quickly realize multi-parameter intelligence and automation is of particular importance. Moreover, SMPO is an optimization framework and an optimization idea. The rapid optimization process can be transplanted into other models to achieve rapid thermal design and batch implementation. SMPO is applicable to not only the optimization of the thermal design parameters of space telescopes but also post-processing and design optimization in other fields. However, the convergence of SMPO is not particularly stable, and the SMPO optimization framework does not automate the post-processing of data, with manual data conversion still a requirement. Therefore, it remains necessary to further improve the convergence and stability of the SMPO, and to achieve full automation of SMPO.