A Model for Energy Consumption of Main Cutting Force of High Energy Efficiency Milling Cutter under Vibration

Abstract

:1. Introduction

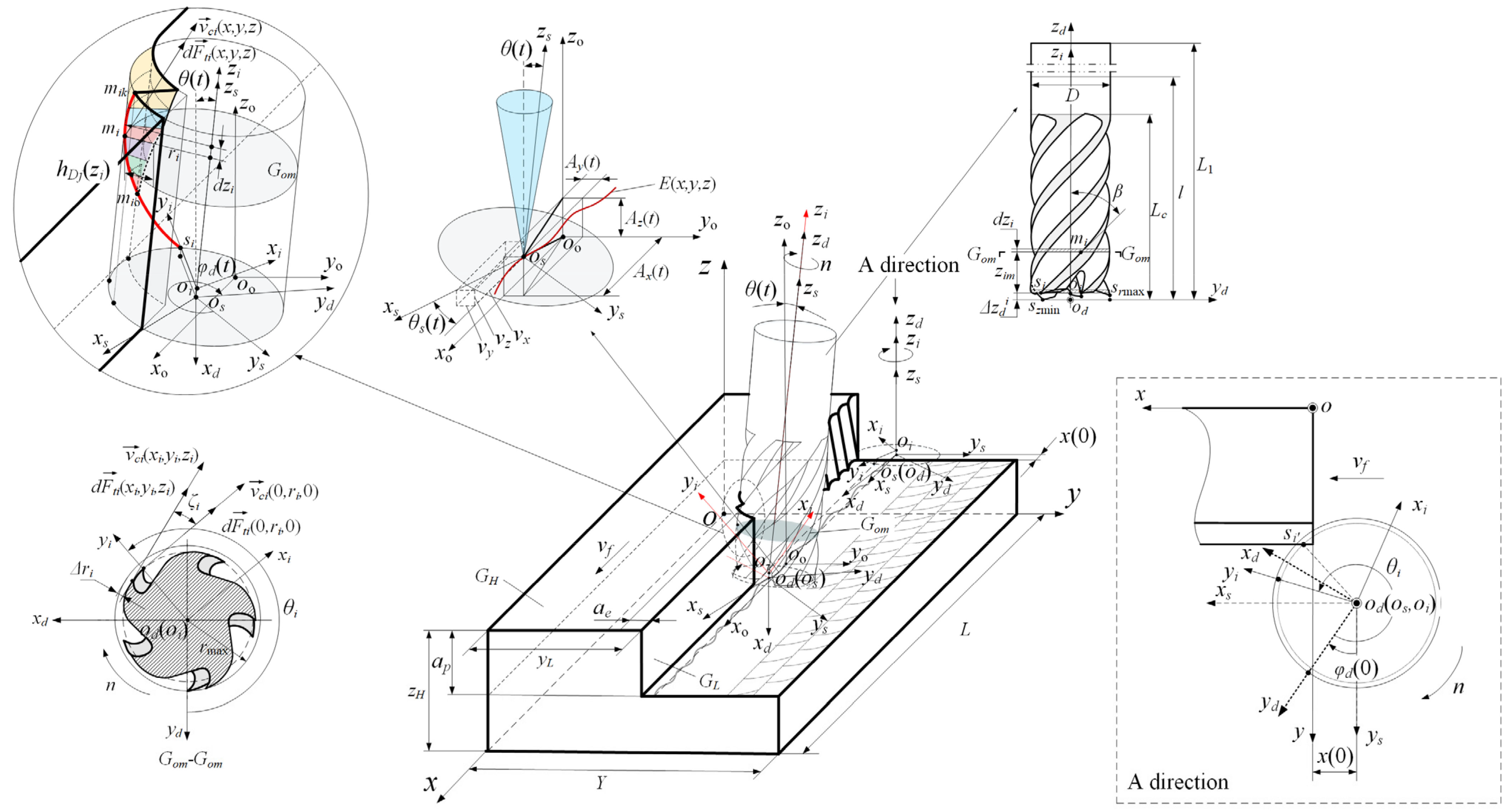

2. Instantaneous Bias of the Main Section of the Milling Cutter under Vibration

3. Solution Method of the Cutter Tooth Instantaneous Cutting Boundary under Vibration

4. Instantaneous Bias of the Main Section of the Milling Cutter under Vibration

5. Identification Method for the Dynamic Characteristics of Energy Consumption of the Milling Cutter Main Cutting Forces

6. Responses and Verification of Energy Consumption of Milling Cutter Main Cutting Force

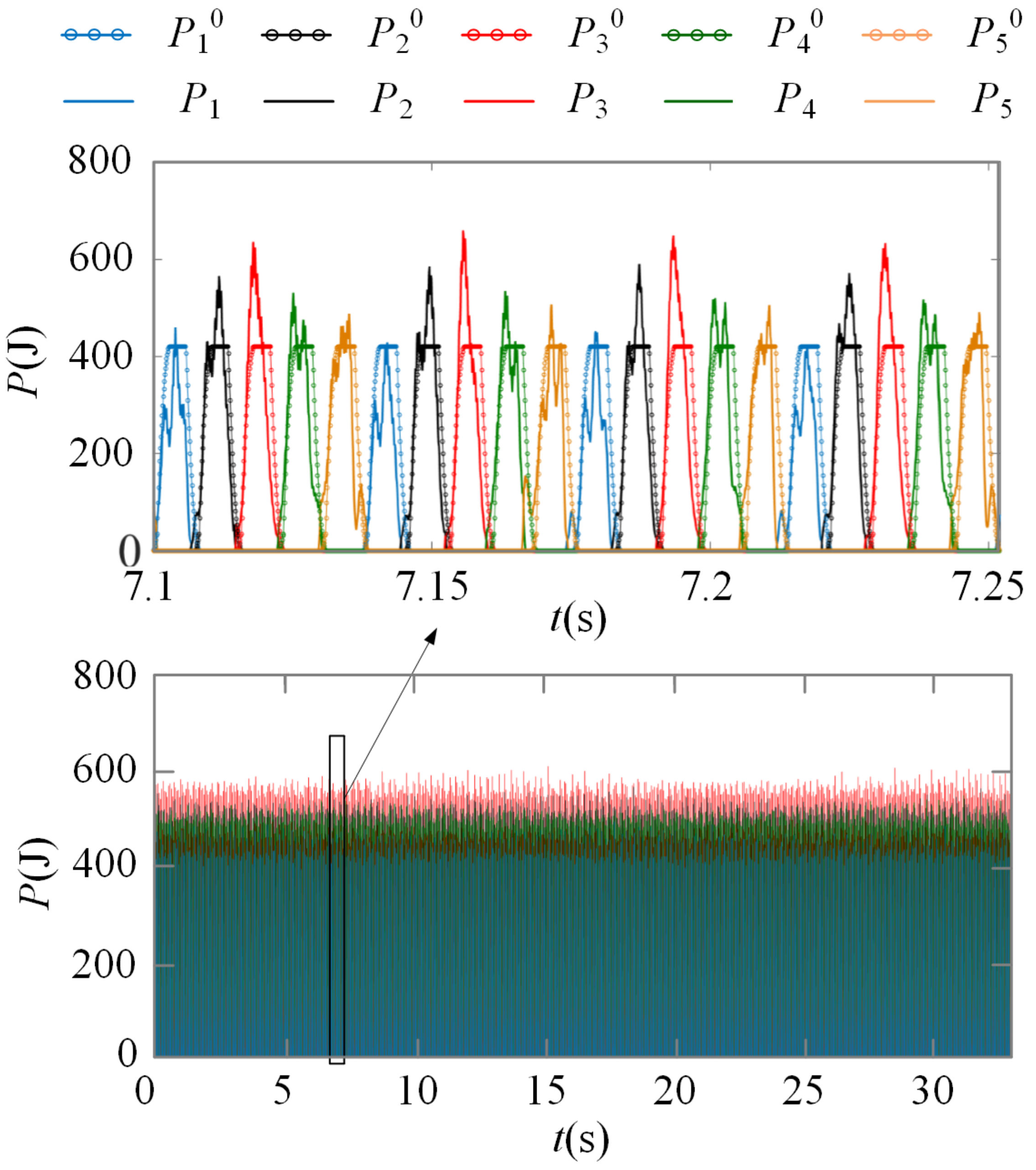

6.1. Responses of Energy Consumption of Milling Cutter Main Cutting Force

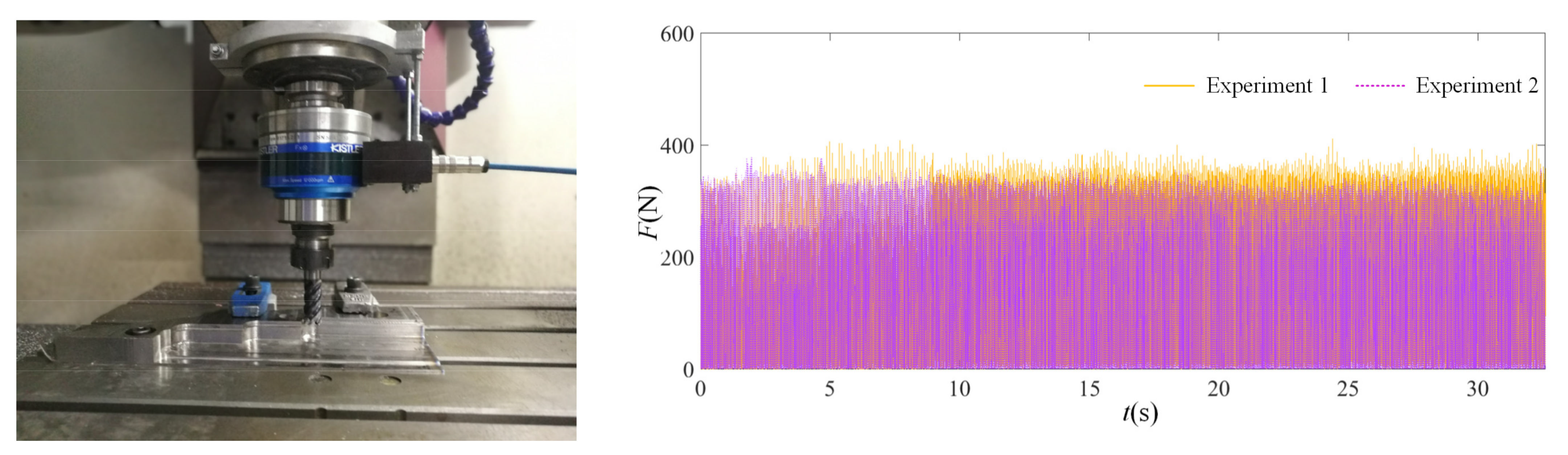

6.2. Verification of Energy Consumption of Milling Cutter Main Cutting Force

7. Conclusions

- The reason the milling cutter posture changes from time to time is milling vibration affects the milling cutter trajectory and bias angle. A model for solving the instantaneous cutting boundary of milling cutter tooth edge under vibration was proposed, the results showed that the milling cutter was displaced due to the influence of milling vibration, besides, the instantaneous cutting boundary was not only affected by the milling vibration during the cutting stage of the current cutter, but also related to the instantaneous pose of the adjacent previous cutter tooth.

- The energy consumption distribution function of instantaneous main cutting force of the cutter teeth was constructed. The analysis results of energy consumption distribution showed that, the variation diversity of the instantaneous cutting speed vector, instantaneous main cutting force vector and instantaneous cutting layer parameters were affected by cutter tooth error and milling vibration. The instantaneous main cutting force energy consumption of each cutter tooth showed obvious differences in the aspects of peak value and changing cycle.

- A method for identifying the dynamics of the energy consumption of the main cutting force of the milling cutter was proposed. The identification results showed that, the instantaneous energy consumption of main cutting force show dynamic changes mainly in its root mean square, while the kurtosis and changing frequency does not change obviously.

- The analysis results of the main cutting force energy consumption responses showed that the energy consumption of the instantaneous main cutting force of the milling cutter were sensitive to the process design variables such as the speed of the milling cutter, the feed per tooth and the tooth error. The validation results of the proposed energy consumption model showed that, the relative errors between the calculation and experimental results were less than 20%, which proved the accuracy of the proposed model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Huang, Z.T.; Yang, J.; Zhang, C.Y.; Zhou, Z.H.; Xie, Y.; Lin, W.W. Energy consumption-oriented numerical control milling process modeling and parameter optimization. Int. J. Chin. J. Mech. Eng. 2016, 27, 9. [Google Scholar]

- Jiang, B.; Zhang, T.; Zhao, P.; Zhao, J.F. Dynamic milling force model for a milling cutter under vibration. Int. J. Adv. Manuf. Technol. 2020, 109, 1–21. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, Z.Q.; Sun, X.D.; Xu, J.X.; Dong, L.L.; Zhu, G.L. Investigation on specific milling energy and energy efficiency in high-speed milling based on energy flow theory. Energy 2020, 192, 116596. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, F.; Liu, P. The energy efficiency acquisition method of the machining process of the tool workpiece double-rotational motion machine tool. Int. J. Chin. J. Mech. Eng. 2018, 489, 1098–1107. [Google Scholar]

- He, Y.; Tian, X.; Li, Y.; Wang, S.; Sutherland, J.W. Modeling machining energy consumption including the effect of toolpath. Int. J. CIRP J. Manuf. Sci. Technol. 2020, 90, 573–578. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Tang, W.; Jia, S.; Liu, Y.; Cao, Y. An investigation into methods for predicting material removal energy consumption in turning. J. Clean Prod. 2018, 193, 128–139. [Google Scholar] [CrossRef] [Green Version]

- Shi, K.N.; Ren, J.X.; Wang, S.B.; Liu, N.; Liu, Z.M.; Zhang, D.H.; Lu, W.F. An improved cutting power-based model for evaluating total energy consumption in general end milling process. J. Clean Prod. 2019, 231, 1330–1341. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, W. Research on integrated modeling of multi-axis simultaneous milling machining dynamics of CNC machine tools. Chin. J. Mech. Eng. 2020, 56, 1. [Google Scholar]

- Bin, J.; Lili, F.; Peiyi, Z.; Zhigang, W.; Junfeng, Z. Identification method for the dynamic distribution characteristics of machining errors in high energy efficiency milling. Int. J. Adv. Manuf. Technol. 2022, 118, 255–274. [Google Scholar] [CrossRef]

- Utsumi, K.; Shichiri, S.; Sasahara, H. Determining the effect of tool posture on cutting force in a turn milling process using an analytical prediction mode. Int. J. Mach. Tools Manuf. 2019, 150, 103511. [Google Scholar] [CrossRef]

- Jun, M.B.G.; Goo, C.; Malekian, M.; Park, S.S. A new mechanistic approach for micro end milling force modeling. J. Manuf. Sci. Eng. 2012, 134, 925–933. [Google Scholar] [CrossRef]

- Warsi, S.S.; Zahid, T.; Elahi, H.; Liaqait, R.A.; Bibi, S.; Gillani, F.; Ghafoor, U. Sustainability-Based Analysis of Conventional to High-Speed Machining of Al 6061-T6 Alloy. Int. J. Appl. Sci. 2021, 11, 9032. [Google Scholar] [CrossRef]

- Cai, S.J.; Yao, B.; Feng, W.; Cai, Z.Q. An improved cutting force prediction model in the milling process with a multi-blade face milling cutter based on FEM and NURBS. Int. J. Adv. Manuf. Technol. 2019, 104, 2487–2499. [Google Scholar] [CrossRef]

- Wan, M.; Wen, D.Y.; Ma, Y.C.; Zhang, W.H. On material separation and cutting force prediction in micro milling through involving the effect of dead metal zone. Int. J. Mach. Tools Manuf. 2019, 146, 103452. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, D.; Chen, B.; Zhang, Y.; Wu, B. Energy Consumption Model for Drilling Processes Based on Cutting Force. Int. J. Appl. Sci. 2019, 9, 4801. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Li, S.; Zhu, K. Generic instantaneous force modeling and comprehensive real engagement identification in micro-milling. Int. J. Mech. Sci. 2020, 176, 105504. [Google Scholar] [CrossRef]

- Li, C.; Zhu, Y.; Li, L. Energy efficiency-oriented multi-objective optimization model of CNC milling parameters. Int. J. Chin. J. Mech. Eng. 2016, 52, 10. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, Y.; Sealy, M.; Liu, Z. Energy consumption and process sustainability of hard milling with tool wear progression. Int. J. Mater. Process. Technol. 2016, 229, 305–312. [Google Scholar] [CrossRef]

- He, K.; Tang, R.; Jin, M. Pareto fronts of machining parameters for trade-off among energy consumption, cutting force and processing time. Int. J. Prod. Econ. 2017, 185, 113–127. [Google Scholar] [CrossRef]

- Wang, L.; Meng, Y.; Ji, W.; Liu, X. Cutting energy consumption modelling for prismatic machining features. Int. J. Adv. Manuf. Technol. 2019, 103, 1654–1667. [Google Scholar] [CrossRef]

| Serial Numbers | Parameters | Parameters Explanation |

|---|---|---|

| 1 | L, Y, zH | The length, width, and height of the workpiece, respectively. |

| 2 | o-xyz | The workpiece coordinate. yL is the distance between the workpiece to be processed side elevation GL and the xoz plane along the y axis. |

| 3 | D | The diameter of the milling cutter. |

| 4 | β | The helix angle of the milling cutter. |

| 5 | Lc | The axial length of the cutting edge of the milling cutter. |

| 6 | l | The overhang of the milling cutter. |

| 7 | L1 | The total length of the milling cutter. |

| 8 | szmin | The lowest cutter tip in the axial direction. |

| 9 | srmax | The cutter tip with the largest radius of the milling cutter. |

| 10 | od-xdydzd | The milling cutter structure coordinate system, od is the center of rotation of the lowest cutter tip in the axial direction; the xd axis is parallel to the direction of the cutting speed at the maximum cutter tip of the radius; the yd axis is parallel to the radial direction of the cutter tip with the maximum radius; zd axis is the rotation axis of the milling cutter and points to the cutter shank. |

| 11 | si | The cutter tip of the ith cutter tooth. |

| 12 | ri | The rotation radius of the ith cutter tooth. |

| 13 | Δri | The radial error of the ith cutter tooth. |

| 14 | Δzdi | The axial error of ith cutter tooth. |

| 15 | oi-xiyizi | The cutter tooth coordinate system, oi is the rotation center of the cutter tip, yi axis is the direction through the origin oi points to the cutter tip, and zi axis is parallel to zd. |

| 16 | θi | The included angle between yi axis and yd axis. |

| 17 | n | The rotational speed of the milling cutter. |

| 18 | vf | The nominal feed speed of the milling cutter. |

| 19 | ae | The cutting width of the milling cutter. |

| 20 | ap | The cutting depth of the milling cutter. |

| 21 | oo-xoyozo | The milling cutter cutting coordinate system without vibration. |

| 22 | Ax(t), Ay(t), Az(t) | The vibration displacement of the milling cutter in three directions of x, y, and z, respectively. |

| 23 | os-xsyszs | The milling cutter cutting coordinate system after the bias of oo-xoyozo caused by milling vibration, oo coincides with od, the xs axis is the direction of the tangent vector of the milling cutter center od motion trajectory, and the zs axis coincides with the zd axis. |

| 24 | os(x, y, z) | The motion trajectory of the coordinate origin os. |

| 25 | vx, vy, vz | The components of the tangent vector of os(x, y, z) along the x axis, y axis, and z axis, respectively. |

| 26 | θ(t) | The angle between zs axis and zo axis at time t. |

| 27 | θs(t) | The angle between xs axis and xo axis. |

| 28 | φsi(t) | The included angle between yi axis and ys axis in xsosys plane. |

| 29 | x(0) | The distance between coordinate origin os and coordinate origin o along x axis when t is 0. |

| 30 | si′ | The first tip point of cutting into the workpiece. |

| 31 | mi | The point on the cutting edge of the ith cutter tooth. |

| 32 | ζi | The lag angle of mi relative to the tip point of the ith cutter tooth. |

| 33 | zim | The axial height of mi in the ith cutter tooth coordinate system. |

| 34 | dzi | The axial height of milling micro-element of mi. |

| 35 | Pom | The main section where mi is located. |

| 36 | mio | The lower boundary of the ith cutter tooth instantaneous cutting. |

| 37 | mik | The upper boundary of the ith cutter tooth instantaneous cutting. |

| 38 | hDj(zi) | The instantaneous cutting layer thickness of mi. |

| 39 | φd(0) | The initial cutting time of the milling cutter. |

| 40 | φd(t) | The instantaneous angle between yd axis and ys axis in xsosys plane. |

| 41 | The cutting speed vector of a point on the cutting edge in the o-xyz | |

| 42 | The cutting speed vector of a point on the cutting edge in the o-xyz. | |

| 43 | The main cutting force vector at a point on the cutting edge in the oi-xiyizi. | |

| 44 | The cutting speed vector of a point on the cutting edge in the oi-xiyizi. | |

| 45 | The main cutting force vector at the tip point of the ith cutter tooth. | |

| 46 | The cutting speed vector at the tip point of the ith cutter tooth. |

| Cutter Tooth Error | Cutter Tooth Number | Cutting Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| i = 1 | i = 2 | i = 3 | i = 4 | i = 5 | n (rpm) | fz (mm/z) | ap (mm) | ae (mm) | |

| Δzid (mm) | 0.051 | 0.008 | 0.000 | 0.012 | 0.022 | 1576 | 0.073 | 10 | 0.5 |

| Δri (mm) | 0.000 | 0.004 | 0.001 | 0.010 | 0.018 | ||||

| Cutter Tooth Error | Cutter Tooth Number | Cutting Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| i = 1 | i = 2 | i = 3 | i = 4 | i = 5 | n (rpm) | fz (mm/z) | ap (mm) | ae (mm) | |

| Δzid (mm) | 0.001 | 0.000 | 0.009 | 0.013 | 0.004 | 1719 | 0.067 | 10 | 0.5 |

| Δri (mm) | 0.029 | 0.010 | 0.018 | 0.039 | 0.000 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, B.; Li, H.; Fan, L.; Zhao, P. A Model for Energy Consumption of Main Cutting Force of High Energy Efficiency Milling Cutter under Vibration. Appl. Sci. 2022, 12, 1531. https://doi.org/10.3390/app12031531

Jiang B, Li H, Fan L, Zhao P. A Model for Energy Consumption of Main Cutting Force of High Energy Efficiency Milling Cutter under Vibration. Applied Sciences. 2022; 12(3):1531. https://doi.org/10.3390/app12031531

Chicago/Turabian StyleJiang, Bin, Haoyang Li, Lili Fan, and Peiyi Zhao. 2022. "A Model for Energy Consumption of Main Cutting Force of High Energy Efficiency Milling Cutter under Vibration" Applied Sciences 12, no. 3: 1531. https://doi.org/10.3390/app12031531

APA StyleJiang, B., Li, H., Fan, L., & Zhao, P. (2022). A Model for Energy Consumption of Main Cutting Force of High Energy Efficiency Milling Cutter under Vibration. Applied Sciences, 12(3), 1531. https://doi.org/10.3390/app12031531