Abstract

The article is concerned with energy conservation in the process of cleaning grain. The study aimed to find ways of reducing energy consumption when cleaning food grains by using energy-saving operating modes (ESOM) on the production lines of grain storage facilities. For this purpose, experimental tests were performed which involved studying the effects of physical and chemical properties of grain as well as the influence of various operating modes of the production lines on the specific energy consumption (SEC), which was found to be the most informative indicator for determining ESOM. The mathematical description of the target function was carried out by conducting a multifactorial experiment with the application of the orthogonal central composite design (OCCD) of the second order. Calculations produced a number of mathematical models describing the dependence of the response function on the input parameters. The proposed approach made it possible to obtain the minimum SEC for cleaning food grains and to develop practical recommendations for ways to reduce energy consumption, which resulted in the development of scientifically based SEC standards for a grain cleaning machine.

1. Introduction

The problem of energy conservation, which is extremely urgent globally today, is particularly acute for Ukraine, as it is capable of meeting only 35–40% of energy needs using its own resources. For this reason, energy conservation is a challenging issue that requires the attention of researchers [1,2,3]. One way to address this problem is the use of alternative energy sources converting wind, solar and other types of sustainable energy [4,5,6,7]. The current situation in the energy market makes it necessary to assess energy efficiency and energy use in any production, considering both numerical and qualitative indicators [8,9,10].

The aim of the study is to determine whether it is possible to reduce energy consumption while cleaning food grains on the production lines of grain storage facilities by using ESOM of the electrical equipment. The SEC while grain cleaning proved to be the most informative indicator for determining ESOM [11].

To attain the aim of the research, the following tasks were solved:

- (1)

- Investigating the influence of physical and chemical properties of grain and operating modes of the production lines on SEC;

- (2)

- Determining the quantitative value of the SEC of the production lines for grain cleaning;

- (3)

- Establishing the correlation between the SEC of grain cleaning process, its productivity and operating modes of the production lines equipment [7];

- (4)

- Carrying out a comparative analysis of theoretical and experimental data.

In conducting the experiments, statistical methods of processing the research results were used. The data obtained from the research allow technical implementation of energy conservation in the process of grain cleaning on the production lines.

Improving the energy efficiency of grain cleaning production lines is a pressing concern. The cost-effectiveness of grain production depends on the use of energy-efficient, resource-saving technology providing a quality workflow [6,12,13].

A number of researchers have laid the foundations for mechanical and technological ways of increasing the efficiency of mechanized complexes for post-harvest grain and seed treatment [14], improving machinery to produce high-quality grain [15] and provided a comprehensive overview and analysis of modern electric motors, as well as modelling methods with the use of a variety of applications [16].

Some authors consider ways of improving the design of the equipment for grain purification and technical ways of improving grain separators, one of which is a vibrating centrifuge separator in which a linear induction motor is used as a vibratory drive. This type of motor enables energy-efficient electric vibration motion with adjustable vibration parameters [17].

To determine the flow around characteristics of an air-sieve scalper separator, a method was developed [18] which allows making adjustments when determining the optimal values of characteristics and modes of operation of a pneumatic system [19].

The separation parameters and efficiency values were optimized by the researchers [20] who utilized software based on genetic algorithms. The optimum operating parameters of the seed separator for increasing the separation efficiency were determined [21].

Much attention has recently been paid to the workflow of the cross-flow fan in the rotating coordinate system [22,23,24]. The characteristics of the cross-flow fan were substantiated on the basis of the mathematical model of its operation [25,26,27].

One of the objectives in producing quality seeds is the prospect of modelling ways to divide the grain into fractions in the fluidized layer. This would help to optimize the separation parameters and design new working surfaces for their implementation. The influence of the physical and mechanical properties of raw materials must be considered in the modelling process [28].

Research was also carried out with grain cleaning machines of various configurations. A grain cleaning machine with a linear induction motor [29] is proposed instead of the traditional mechanical drive [30]. Energy consumption is reduced through the work of an impulse drive [31]. At the same time, the technological characteristics of different crops, including the various physical and mechanical properties of the crop being cleaned, can be regulated in a broad range [32,33]. A number of research papers were aimed at reducing the energy consumption of the grain cleaning process [34,35,36].

Much attention is paid nowadays to improving the designs for pneumatic grain transporters [37,38]. This is a new direction in grain cleaning workflow.

Another increasingly popular, although not widely used in post-harvest grain treatment, method is the use of discrete elements in modelling [39] along with dynamic numerical modelling [40]. In calculating the power of electric motors, the SEC method is applied [41,42]. It is recommended to develop and analyse the mathematical models of electricity consumption [43] and optimize the operating modes of electrical equipment [13].

The review of literature shows that the researchers focused their work on post-harvest grain treatment and improvements to the configuration of individual machines, while insufficient attention was paid to energy-related parameters of the process. In order to address energy conservation issues, the problems of optimization of the entire process must first be solved [44]. This requires a sufficient amount of information on energy consumption of the entire grain cleaning process, namely the entire production line instead of individual machines composing the production line [45].

2. Materials and Methods

The experimental studies were conducted on the most typical grain cleaning machine in southern Ukraine, ZAV-20, on farms whose activity area corresponded to the main production area of the region, with the highest level of farm organization, its characteristics and technical operation of the electrical equipment, as well as a reliable and uninterrupted power supply.

The experiment was conducted during the busy period of grain storage facilities, in June through August, under different production conditions, with the existing loads and operating time of the machines.

A portable stand was developed to study the specific electricity consumption of grain cleaning in a production environment, which included an active and reactive energy meters box and a portable measuring set (accuracy class 0.2). The stand did not disrupt the production workflow of the grain cleaning production lines in experimental studies and ensured compliance with safety regulations. The stand included an automatic switch for the emergency disconnection of the machine’s production line [1].

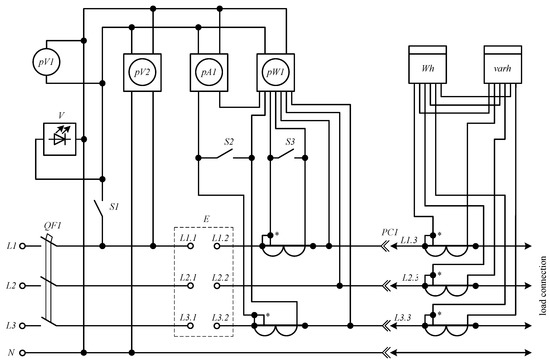

The schematic circuit diagram of the measuring stand is shown in Figure 1.

Figure 1.

Schematic circuit diagram of the measuring stand: *—generator clamp (connects to power supply).

In addition to electrical parameters, the operating time and performance of the production line over the investigated period of time were measured. A minimum of three repetitions were performed during the experiment. The duration of each repetition was at least 15 min.

In the course of the experiment, when cleaning food grain on a ZAV-20 grain-cleaning unit with a capacity of 20 t/h on one production line without disc separators, grain batches with different moisture and dockage, which were determined in the control laboratory of physical and mechanical properties of grain, were weighed. The cleaning time was measured by a stopwatch, and the electrical parameters—current, power and voltage—were measured using the stand. The Active and Reactive Energy Meters measured the electricity consumption for cleaning each grain batch. Then the SEC for cleaning each batch was determined. Similar experiments were conducted for two production lines without disc separators.

In order to reduce the number of experiments and increase their reliability, the method of active experimental planning was used [7]. This method enables quantitative evaluation of the influence of any given factor on the electrical consumption under multifactorial exposure. In addition, this method can be used to find the optimum value of energy consumption.

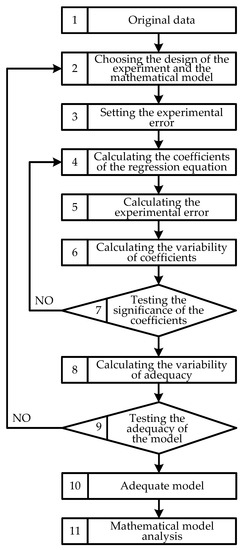

The algorithm of conducting the research by method of active design of the experiment is presented in graphic form in Figure 2.

Figure 2.

Algorithm of conducting the research by method of active design of the experiment.

Preliminary experiments were conducted to estimate the factors that significantly affect energy consumption. They were performed in accordance with the basic experimental research methodology [7].

By using the random balance method, the experiments were set up by the given design, and a number of significant factors were identified from the total number of factors and their interactions using the analysis of a priori information about the object of the study [46]; insignificant factors including hygroscopicity, looseness, interparticle space and freshness of the grain were screened out, while significant ones were distinguished: the machine’s capacity, grain humidity and grain dockage. A full factorial experiment was then conducted.

An experiment in which all possible combinations of levels of the factors are represented is called a full factorial experiment (FFE). If each factor varies at two levels, the FFE will be of type, where n is the number of factors. The total number of basic tests in FFE is determined by the following formula.

The resulting data were processed using Microsoft Excel and Mathcad application software.

3. Results

The issue of optimizing the process of cleaning food grains on the production lines of grain dispensers is to find such modes of operation of the grain cleaning production lines, which result in the minimum SEC within the range of changes of input parameters. The process of cleaning food grains on the production lines without disc separators was investigated.

A multifactorial experiment [8] is appropriate for determining the influence of factors on the optimization criteria of the grain cleaning process on the production lines of grain storage facilities. The theory and practice of its design are characterized by a high level of development and make it possible to obtain, with a minimum number of tests, a credible mathematical model of the object of the research and, in solving the problem of optimization, to determine the optimal conditions of its functioning.

The relationship between the SEC and performance is non-linear, so second-order designs were used to obtain the regression equation. The selection of factors, ranges and the range of variation are based on the analysis of a priori information. The variation limits of the factors under investigation were adopted, considering the technical characteristics of the machines and the technological constraints conditioned by the production of high-quality grains [15]. The variables are: x1—the machine’s capacity, (Q), t/h; x2—grain humidity, (Hum), % and x3—grain dockage, (Doc), %. The specific electricity consumption (Wsp), kW·h/t, was selected as a response function. The Box–Wilson orthogonal central composite design (OCCD) of the second order [15] was used to mathematically describe the specific electricity consumption.

A number of mathematical models describing the response function’s dependence on input parameters were derived from the calculations.

Factor levels and factor variability intervals were taken for ZAV-20 with one production line without disc separators (Table 1).

Table 1.

Factor levels and factor variability intervals for ZAV-20 (one production line without disc separators).

A regression equation was obtained to calculate the specific electricity consumption depending on the productivity, humidity and dockage for the ZAV-20 grain-cleaning machine with one production line without disc separators both in dimensionless form:

and in natural values of the factors:

Similar studies were performed on two production lines with no disc separators (Table 2).

Table 2.

Factor levels and factor variability intervals for ZAV-20 (two production lines without disc separators).

A regression equation was obtained to calculate the specific electricity consumption depending on the capacity, humidity and dockage for the ZAV-20 grain-cleaning machine with two production lines without disc separators both in dimensionless form:

and in natural values of the factors:

After obtaining an adequate mathematical model of the second order, the coordinates of the optimum were determined.

For one production line without disc separators, the second order regression Equation (1) is differentiated for each factor and is set to zero:

By solving the system of equations, centre coordinates were obtained in coded units:

which correspond to the following values of the factors and target functions in physical units:

Q = 9.86 t/h; Hum = 12.4%; Doc = 2.6%; Wsp = 2.06 kW⋅h/t

For two production lines without disc separators, the regression equation of the second order (3) is differentiated for each factor and is set to zero:

By solving the system of equations, centre coordinates were obtained in coded units:

which correspond to the following values of factors and target functions in physical units:

Q = 15.7 t/h; Hum = 12.1%; Doc = 3.1%; Wsp = 1.43 kW⋅h/t

4. Discussion

The SEC on the production lines was obtained while cleaning wheat of varying humidity within the range of 11–17%.

The experimental research on ZAV-20 has shown that with a 1% increase in grain humidity the SEC of production lines increases by an average of 10–12%, as the weight by volume of grain decreases with an increase in grain humidity. At the same time, the capacity of the production line decreases by an average of 0.3–0.5 t/h. The SEC for cleaning one ton of seeds is higher than for cleaning one ton of food grain by an average of 18–20%.

The workflow of post-harvest processing of food grains and seed grains is carried out through systems of machines and installations, which can be distinguished as main and supporting ones [47].

The main machines gradually process the raw material to final product status. These are the separating machines. Supporting machines do not change the quality of grain but are used to help the main ones. These include transporters and car lifts.

While building the production lines, only the passport capacity of machines is considered, which is indicated when working with wheat of normal humidity (up to 15%) and average dockage (up to 5%). The actual dockage of the grain arriving for cleaning includes straw impurities—up to 8%, weed seeds—up to 5% and soil—up to 2%.

The operating experience of the ZAV-20 grain-cleaning machine [1] shows that, as a rule, the capacity of grain cleaning equipment is below nominal values by 30–60%. The reason for the low capacity lies in organizational, technical and technological deficiencies. Organizational and technical deficiencies can be addressed as operating experience is gained and the equipment of the grain cleaning operating line is upgraded. The decline in the capacity of the operating line for technological reasons is mainly related to the probability of grain flow and the grain cleaning process. One of the main factors limiting the machine’s capacity is the quality of grain cleaning, which in turn influences the uniformity of the machine load. The obtained data indicate that 50% of ZAV’s operating capacity is used.

Large deviations from the nominal values for loading the electric motors of individual ZAV machines (17–57% in power, 44–90% in current) indicate the need for further improvements in the design of the machines and possible coordination of their operating performance [1].

It has been established that the actual capacity of the production lines is lower than the nominal capacity of any of the machines forming it. It decreases with an increase in the number of machines in the production line and the variability coefficient of its performance.

The key and indispensable factor for the most economical operation of the production line is the same nominal capacity of all the machines and mechanisms connected in a series and forming the line. Otherwise, the production line capacity will be determined by the machine with the lowest nominal performance.

The experimental data underwent a thorough analysis. The influence of many production and physical factors on the specific electricity consumption can be considered by utilizing mathematical tools and using probability theory and mathematical statistics involving the application of computer software.

Based on the calculations, mathematical models were obtained that relate the specific energy input to the production line capacity, humidity and grain dockage (Equations (2) and (4)).

Through the regression equations obtained from this stage of the research, it is possible to determine the SEC of grain cleaning by different technological schemes with varying physical and mechanical properties of grain. This enables grain cleaning with minimum SEC.

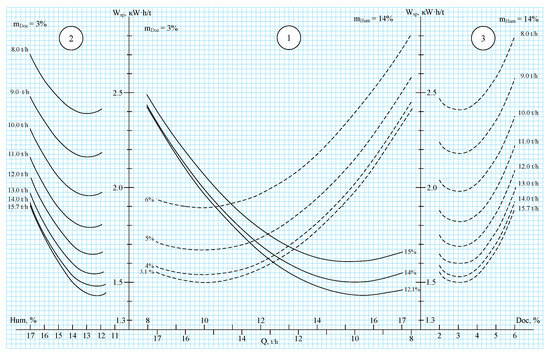

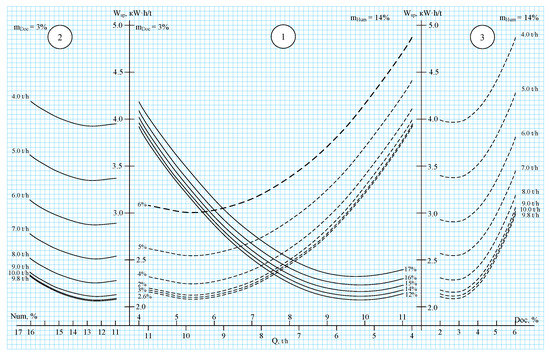

For each grain cleaning production line of the ZAV-20 machine, nomograms of electric consumption are proposed (Figure 3 and Figure 4) which are characterized by legibility and convenience in selecting the optimum load of production lines with the minimum SEC (Quadrant 1) at different humidity and dockage values.

Figure 3.

Nomograms of energy consumption for ZAV-20 (two production lines without disc separators).

Figure 4.

Nomograms of energy consumption for ZAV-20 (one production line without disc separators).

By known values of humidity (Quadrant 2) and dockage of the grain (Quadrant 3) and the minimum specific electricity consumption, the optimum load of the production line is determined.

Figure 3 shows an example of using the nomogram for the ZAV-20 grain-cleaning machine in the grain cleaning process on two production lines without disc separators, while Figure 4 demonstrates the nomogram for one production line without disc separators.

According to the BAT Directorate, a number of threshold indicators have been introduced in some industries to strengthen the application of energy efficiency standards. Such an indicator in the grain cleaning process is the specific electricity consumption [48].

The BAT Directorate indicates the practical application of specific methods that provide a basis for achieving threshold indicators in economic solutions of the issues [48]. Such a method in the grain cleaning process is the scientifically based method for the rate setting of energy consumption that was developed [49] and used in the present paper to address energy conservation issues.

An important factor affecting the efficiency of the use of electrified energy resources is the electricity consumption standard [50]. The latter is known to serve as a criterion in the evaluation of electrical consumption. Sometimes those standards were unavailable. In addition, the lack of scientific evidence on the extent to which a given factor affected energy performance made it very difficult to adjust the standards that are inevitable as a result of changes in technology conditions. If the standards do not correspond to the optimal ESOM, their mobilization role will be reduced or even exclude, and the standards will not be an incentive for energy conservation.

The issues of energy intensity of grain cleaning processes at grain stations and their correlation with technological factors were not considered at all in previous studies or were of a secondary nature. Moreover, in a number of instances, the random nature of electrical loads was not taken into account, so the probability theory, mathematical statistics and experiment planning methods were not used when assessing the electrical performance of grain stations. As a result, the nature of the relationship between the electric power indicators of grain stations remained insufficiently studied. The method of power rationing in the system of processing and storage of grain crops described in [48] proved to be the most suitable for grain stations. However, the developed norms of SEC for processing enterprises are not suitable for grain stations, since grain stations are equipped with technological equipment different from the equipment of these enterprises. The proposed norms [46] cannot be used when rationing the SEC for the ZAV-20 grain-cleaning unit, which represents a unified production line.

In determining the SEC for grain cleaning, it is necessary to take into account the purpose of the grain, the condition of the grain material and the capacity of the grain cleaning equipment.

It has been established that the energy consumption reported in the technical publications differs by a factor of 2–3 for the same grain cleaning units and ranges between 1.1 and 3.7 kW·h/t [51], as different authors propose different definitions of the SEC. This indicates that the methodology for determining the SEC requires further development.

The conducted research resulted in the development of scientifically based SEC standards for grain cleaning production schemes using the ZAV-20 grain-cleaning machine [49,50] (Table 3).

Table 3.

Comparative data of electricity consumption rates for grain cleaning on the production lines of ZAV-20 grain-cleaning unit.

The scientifically justified standards (minimum SEC) for post-harvest grain treatment for various technological circuits, obtained by experimental planning (Table 3), are lower than those presented in [51] by 5.9–34%.

The obtained scientifically justified SEC rates were discussed and approved by the Technical Council of Zaporizhia Oblast, Melitopol District Department of Agriculture and Velyikolepetykhsky District Administration of Agriculture of Kherson Oblast, as evidenced by the certificates of the implementation of the research results.

The recommended scientifically justified energy consumption standards are intended for Planning and Economic Departments of the Oblast Directorates of Agriculture for the planning and control of electricity consumption for the processes of grain cleaning on the production lines of the grain storage facilities of the South of Ukraine. Similar studies are being carried out for other grain cleaning units produced by the industry.

5. Conclusions

As a result of the experimental studies, dependencies have been obtained in the form of regression equations of the specific electricity consumption in terms of production line capacity, grain humidity and grain dockage, which allow enhancing the grain cleaning mode. Thus, for two production lines without disc separators, a minimum of 1.43 kW·h/t of electricity has been obtained at a capacity of 15.7 t/h, humidity of 12.1% and dockage of 3.1%; for one production line without disc separators, these indicators are as follows: 2.06 kW·h/t with a capacity of 9.8 t/h, humidity of 12.4% and dockage of 2.6%.

Experimental studies have shown that the disagreement in theoretical and experimental data does not exceed 8–10%, with a strong correlation (r = 0.9–0.98) between the operating modes of power-driven electrical equipment as well as physical and mechanical properties of grain and the specific electricity consumption.

A comparison of theoretical and experimental data has determined a sufficient degree of justification for the relationship between the SEC of the grain cleaning process on the production lines with grain properties, equipment condition and operating modes.

As practical recommendations for implementing energy-saving modes of electromechanical grain cleaning systems on grain terminals, nomograms have been developed which allow defining the operating modes of the production line.

Author Contributions

Conceptualization, M.P.; methodology, M.P. and V.N.; project administration, O.B., S.H. and S.K.; validation, O.M., O.K. and E.M.; investigation, M.P. and O.M.; data curation, S.H., S.K. and O.K.; writing—original draft preparation, O.B., M.P. and V.N.; writing—review and editing, O.S., S.H. and E.M.; visualization, O.B. and V.N.; supervision, O.B. and V.N.; funding acquisition, O.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Postnikova, M.V. Energy-Saving Modes of Operation of Electromechanical Grain Processing Systems at Grain Stations. Ph.D. Thesis, Tavria State Agrotechnological University, Melitopol, Ukraine, 2011. [Google Scholar]

- Havrysh, V.; Nitsenko, V.; Bilan, Y.; Streimikiene, D. Assessment of optimal location for a centralized biogas upgrading facility. Energy Environ. 2019, 3, 462–480. [Google Scholar] [CrossRef]

- Havrysh, V.; Nitsenko, V.; Perevozova, I.; Kulyk, T.; Vasylyk, O. Alternative Vehicle Fuels Management: Energy, Environmental and Economic Aspects. In Advanced Energy Technologies and Systems I. Studies in Systems, Decision and Control; Zaporozhets, A., Ed.; Springer: Cham, Switzerland, 2022; Volume 395, pp. 91–115. [Google Scholar]

- Qawaqzeh, M.Z.; Szafraniec, A.; Halko, S.; Miroshnik, O.; Zharkov, A. Modelling of a household electricity supply system based on a wind power plant. Prz. Elektrotech. 2020, 96, 36–40. [Google Scholar] [CrossRef]

- Szafraniec, A.; Halko, S.; Miroshnik, O.; Figura, R.; Zharkov, A.; Vershkov, O. Magnetic field parameters mathematical modelling of wind-electric heater. Prz. Elektrotech. 2021, 97, 36–41. [Google Scholar]

- Halko, S.; Suprun, O.; Miroshnyk, O. Influence of Temperature on Energy Performance Indicators of Hybrid Solar Panels Using Cylindrical Cogeneration Photovoltaic Modules. In Proceedings of the 2021 IEEE 2nd KhPI Week on Advanced Technology (KhPIWeek), Kharkiv, Ukraine, 13–17 September 2021; pp. 132–136. [Google Scholar]

- Nitsenko, V.; Mardani, A.; Streimikis, J.; Shkrabak, I.; Klopov, I.; Novomlynets, O.; Podolska, O. Criteria for Evaluation of Efficiency of Energy Transformation Based on Renewable Energy Sources. Montenegrin J. Econ. 2018, 14, 237–247. [Google Scholar] [CrossRef]

- Bazaluk, O.; Havrysh, V.; Nitsenko, V. Energy Efficiency of Inland Waterways Transport for Agriculture: The Ukraine Case Study. Appl. Sci. 2021, 11, 8937. [Google Scholar] [CrossRef]

- Bazaluk, O.; Havrysh, V.; Fedorchuk, M.; Nitsenko, V. Energy Assessment of Sorghum Cultivation in Southern Ukraine. Agriculture 2021, 11, 695. [Google Scholar] [CrossRef]

- Bilan, Y.; Nitsenko, V.; Havrysh, V. Energy aspect of vertical integration in agriculture. Rynek Energii 2017, 5, 98–110. [Google Scholar]

- Nazar’jan, G.N.; Postnikova, M.V.; Karpova, A.P. Solving Optimization Problems for Research Objects by Planning a Mathematical Experiment; Ljuks: Melitopol, Ukraine, 2012. [Google Scholar]

- Kalinichenko, A.; Havrysh, V.; Nitsenko, V. Alternative Vehicle Fuel Management: Impact on Energy Security Indicators. In Infrastructure and Environment; Krakowiak-Bal, A., Vaverkova, M., Eds.; Springer: Cham, Switzerland, 2019; pp. 367–374. [Google Scholar]

- Postnikova, M.; Mikhailov, E.; Nesterchuk, D.; Rechina, O. Energy Saving in the Technological Process of the Grain Grinding. In Modern Development Paths of Agricultural Production; Nadykto, V., Ed.; Springer: Cham, Switzerland, 2019; pp. 395–403. [Google Scholar]

- Podpryatov, G.I.; Rozhko, V.I.; Skaletskaya, L.F. Technology of Storage and Processing of Crop Products; Ahrarna Osvita: Kyiv, Ukraine, 2014; p. 393. [Google Scholar]

- Paraschiv, G.; Manole, C. Explaining the phenomenon of separation into fractions of a mixture of particulate matter by applying the principle of minimum energy. INMATEH-Agric. Eng. 2015, 45, 65–70. [Google Scholar]

- Bilgin, B.; Liang, J.; Terzic, M.V.; Dong, J.; Rodriguez, R.; Trickett, E.; Emadi, A. Modeling and Analysis of Electric Motors: State-of-the-Art Review. IEEE Trans. Transp. Electrif. 2019, 5, 602–617. [Google Scholar] [CrossRef] [Green Version]

- Linenko, A.; Khalilov, B.; Kamalov, T.; Tuktarov, M.; Syrtlanov, D. Effective technical ways to improve the vibro-centrifugal separator electric drive for grain cleaning. J. Agric. Eng. 2021, 52, 1136. [Google Scholar] [CrossRef]

- Mikhailov, E.; Postnikova, M.; Zadosnaia, N.; Afanasyev, O. Methodological Aspects of Determining Parameters of a Scalper-Type Air-Sieved Separator Airflow. In Modern Development Paths of Agricultural Production; Nadykto, V., Ed.; Springer: Cham, Switzerland, 2019; pp. 133–137. [Google Scholar]

- Nesterenko, A.V.; Leshchenko, S.M.; Vasylkovskyi, O.M.; Petrenko, D.I. Analytical assessment of the pneumatic separation quality in the process of grain multilayer feeding. INMATEH–Agric. Eng. 2017, 53, 65–70. [Google Scholar]

- Konopka, S.; Choszcz, D.J.; Markowski, P. Optimization of the Separation Parameters and Indicators of Separation Efficiency of Buckwheat Seeds. Sustainability 2017, 9, 2134. [Google Scholar] [CrossRef] [Green Version]

- Mudarisov, S.G.; Badretdinov, I.D. Numerical implementation of a mathematical model of the technological process of the diametric fan in a rotating coordinate system. News Int. Acad. Agrar. Educ. 2013, 17, 79–83. [Google Scholar]

- Nitsenko, V.; Kotenko, S.; Hanzhurenko, I.; Mardani, A.; Stashkevych, I.; Karakai, M. Mathematical Modeling of Multimodal Transportation Risks. In Proceedings of the Fourth International Conference on Soft Computing and Data Mining (SCDM 2020), Melaka, Malaysia, 22–23 January 2020; Ghazali, R., Nawi, N., Deris, M., Abawajy, J., Eds.; Springer: Cham, Switzerland, 2020; Volume 978, pp. 439–447. [Google Scholar]

- Kotenko, S.; Nitsenko, V.; Hanzhurenko, I.; Havrysh, V. The Mathematical Modeling Stages of Combining the Carriage of Goods for Indefinite, Fuzzy and Stochastic Parameters. Int. J. Integr. Eng. 2020, 12, 173–180. [Google Scholar] [CrossRef]

- Saitov, V.E.; Farafonov, V.G.; Gataullin, R.G.; Saitov, A.V. Research of a diametrical fan with suction channel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 457, 012009. [Google Scholar] [CrossRef]

- Mudarisov, S.G.; Badretdinov, I.D. Substantiation of the parameters of the diametrical fan based on a mathematical model of the process of its operation. In Proceedings of the International Scientific-Practical Conference in the Framework of the XXIII International Specialized Exhibition “AgroComplex-2013”, Ufa, Russia, 12–15 March 2013; pp. 363–367. [Google Scholar]

- Bazaluk, O.; Kotenko, S.; Nitsenko, V. Entropy as an Objective Function of Optimization Multimodal Transportations. Entropy 2021, 23, 946. [Google Scholar] [CrossRef]

- Bredykhin, V.; Gurskyi, P.; Alfyorov, O.; Bredykhina, K.; Pak, A. Improving the Mechanical-Mathematical Model of Grain Mass Separation in A Fluidized Bed. East.-Eur. J. Enterp. Technol. 2021, 3, 79–86. [Google Scholar]

- Linenko, A.; Tuktarov, M.; Aipov, R.; Baynazarov, V. Analysis of pulsed operating mode of linear induction drive of grain cleaning machine. In Proceedings of the International Conference “Actual Issues of Mechanical Engineering” 2017 (AIME 2017), Tomsk, Russia, 27–29 July 2017; Volume 133, pp. 420–424. [Google Scholar]

- Aipov, R.; Linenko, A.; Badretdinov, I.; Tuktarov, M.; Akchurin, S. Research of the Work of the Sieve Mill of a Grain-cleaning Machine with a Linear Asynchronous Drive. Math. Biosci. Eng. 2020, 17, 4348–4363. [Google Scholar] [CrossRef]

- Cieślik, S. Mathematical Modelling of the Dynamics of Linear Electrical Systems with Parallel Calculations. Energies 2021, 14, 2930. [Google Scholar] [CrossRef]

- Badretdinov, I.; Mudarisov, S.; Tuktarov, M.; Dick, E.; Arslanbekova, S. Mathematical modelling of the grain material separation in the pneumatic system of the grain-cleaning machine. J. Appl. Eng. Sci. 2019, 17, 529–534. [Google Scholar] [CrossRef]

- Bazaluk, O.; Havrysh, V.; Nitsenko, V. Energy and Environmental Assessment of Straw Production for Power Generation. E3S Web Conf. 2021, 228, 01010. [Google Scholar] [CrossRef]

- Kharchenko, S.; Kovalishin, S.; Zavgorodniy, A.; Kharchenko, F.; Mikhaylov, Y. Effective sifting of flat seeds through sieve. INMATEH–Agric. Eng. 2019, 58, 17–26. [Google Scholar]

- Panasiewicz, M.; Zawislak, K.; Kusinska, E.; Sobczak, P. Purification and separation of loose material in pneumatic system with vertical air stream. TEKA Kom. Motoryz. Energetyki Rol. 2008, 8, 171–176. [Google Scholar]

- Choszcz, D.J.; Reszczyński, P.S.; Kolankowska, E.; Konopka, S.; Lipiński, A. The Effect of Selected Factors on Separation Efficiency in a Pneumatic Conical Separator. Sustainability 2020, 12, 3051. [Google Scholar] [CrossRef] [Green Version]

- Bortolaia, L.A.; Andrighetto, P.L.; Benatti, M. Technical evaluation of a suction pneumatic grain conveyor. Cienc. Rural 2008, 38, 526–529. [Google Scholar] [CrossRef]

- Kroulík, M.; Hůla, J.; Rybka, A.; Honzík, I. Pneumatic Conveying Characteristics of Seeds in a Vertical Ascending Airstream. Res. Agric. Eng. 2016, 62, 56–63. [Google Scholar] [CrossRef] [Green Version]

- Boac, J.M.; Ambrose, R.P.K.; Casada, M.E.; Maghirang, R.G.; Maier, D.E. Applications of Discrete Element Method in Modeling of Grain Postharvest Operations. Food Eng. Rev. 2014, 6, 128–149. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.H.; Wang, Z.Y.; Liu, Q.; Ma, P.F. Design and Simulation Research on Mechanical Ventilation System for Small Underground Granary. In Advanced Materials Research; Trans Tech Publications, Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 2148, pp. 875–877. [Google Scholar]

- Soldatenko, L.S.; Ostrovkyi, I.A. Improvement of the collector output device of the disk separators. Grain Prod. Mix. Fodd. 2019, 19, 48–50. [Google Scholar] [CrossRef]

- Soldatenko, L.S.; Hornishnyi, O.V. Clarification of the methods used for calculating power of sieve separators. Grain Prod. Mix. Fodd. 2018, 18, 47–50. [Google Scholar] [CrossRef]

- Kupchuk, I.M.; Solona, O.V.; Derevenko, I.A.; Tverdokhlib, I.V. Verification of the mathematical model of the energy consumption drive for vibrating disc crusher. INMATEH-Agric. Eng. 2018, 55, 113–120. [Google Scholar]

- Jiang, S.-L.; Zhang, L. Energy-Oriented Scheduling for Hybrid Flow Shop with Limited Buffers through Efficient Multi-Objective Optimization. IEEE Access 2019, 7, 34477–34487. [Google Scholar] [CrossRef]

- Abdel-Hadi, A.; Salem, A.R.; Abbas, A.I.; Qandil, M.; Amano, R.S. Study of energy saving analysis for different industries. ASME J. Energy Resour. Technol. 2021, 143, 052101. [Google Scholar] [CrossRef]

- Yastrebov, P.P. Use and Rationing of Electricity in Grain Processing and Storage; Kolos: Moscow, Russia, 1973. [Google Scholar]

- Postnikova, M.V. Development of scientifically substantiated norms of energy consumption while grain processing at grain points. In Visnyk Natsionalnoho Tekhnichnoho Universytetu “KhPI”. Problemy Avtomatyzovanoho Elektropryvodu. Teoriia i Praktyka; NTU KHPI: Kharkiv, Ukraine, 2008; Volume 30, pp. 511–512. [Google Scholar]

- Koval, V.; Mikhno, I.; Hajduga, G.; Gaska, K. Economic efficiency of biogas generation from food product waste. E3S Web Conf. 2019, 100, 00039. [Google Scholar] [CrossRef] [Green Version]

- OECD. Best Available Techniques for Preventing and Controlling Industrial Pollution, Activity 2: Approaches to Establishing Best Available Techniques (BAT) around the World, Environment, Health and Safety, Environment Directorate; OECD: Moscow, Russia, 2018. [Google Scholar]

- Didur, V.A.; Masjutkin, E.P.; Postnikova, M.V.; Maslovskij, V.A. Scientific substantiation of specific energy consumption during grain cleaning by the method of mathematical experiment planning. Pratsi Inst. Elektr. NAN Ukr. 2008, 19, 94–98. [Google Scholar]

- Mykhailov, Y.; Zadosna, N.; Postnikova, M.; Pedchenko, G.; Khmelovskyi, V.; Bondar, M.; Ionichev, A.; Kozdęba, M.; Tomaszewska-Górecka, W. Energy assessment of the pneumatic sieve separator for agricultural crops. Agric. Eng. 2021, 25, 147–155. [Google Scholar] [CrossRef]

- Postnikova, M.V. The current state of control of electricity consumption at grain facilities. Pratsi Tavr. Derzh. Agric. Univ. 2013, 13, 148–152. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).