Path Planning Based on NURBS for Hyper-Redundant Manipulator Used in Narrow Space

Abstract

:1. Introduction

- (1)

- It can strictly guarantee that the end of the robot arm is on the cubic B-spline path curve with high accuracy, and the cubic B-spline trajectory G2 is continuous, ensuring smooth movement.

- (2)

- Solve the pose of the robot arm through the UCR parallel joint drive equation, with high accuracy and fast efficiency.

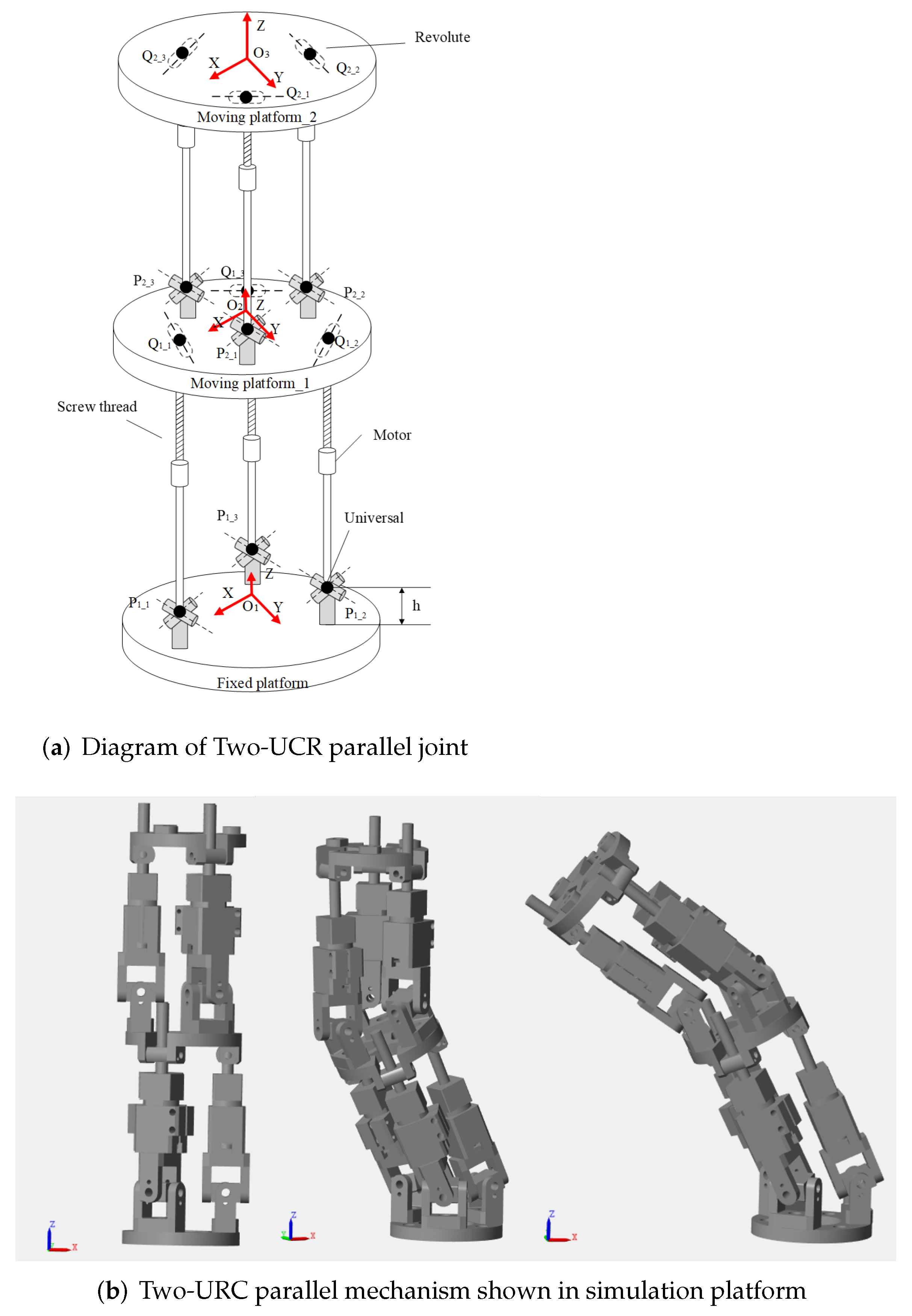

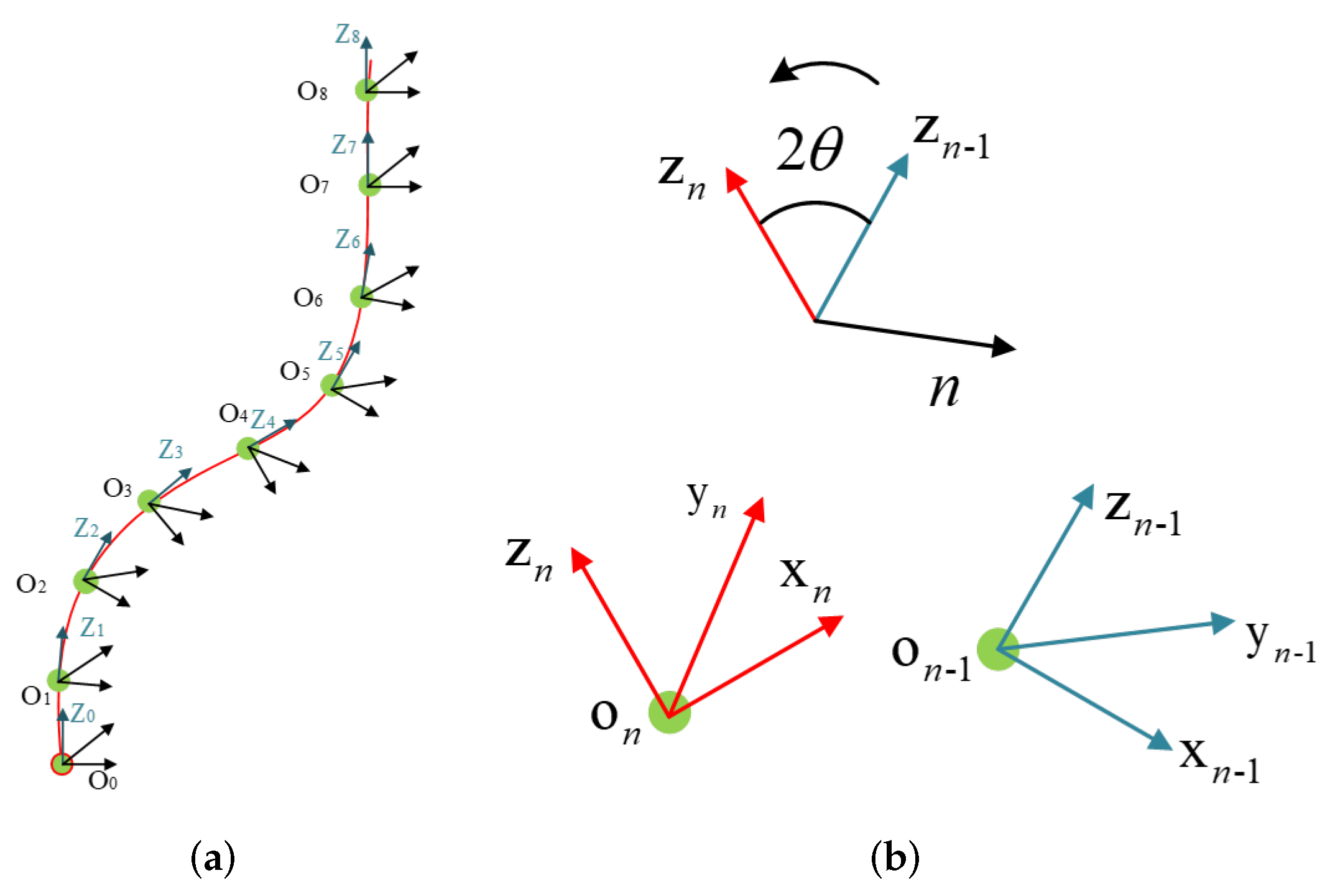

2. Kinematics Modeling and Workspace Analysis of UCR Parallel Mechanism

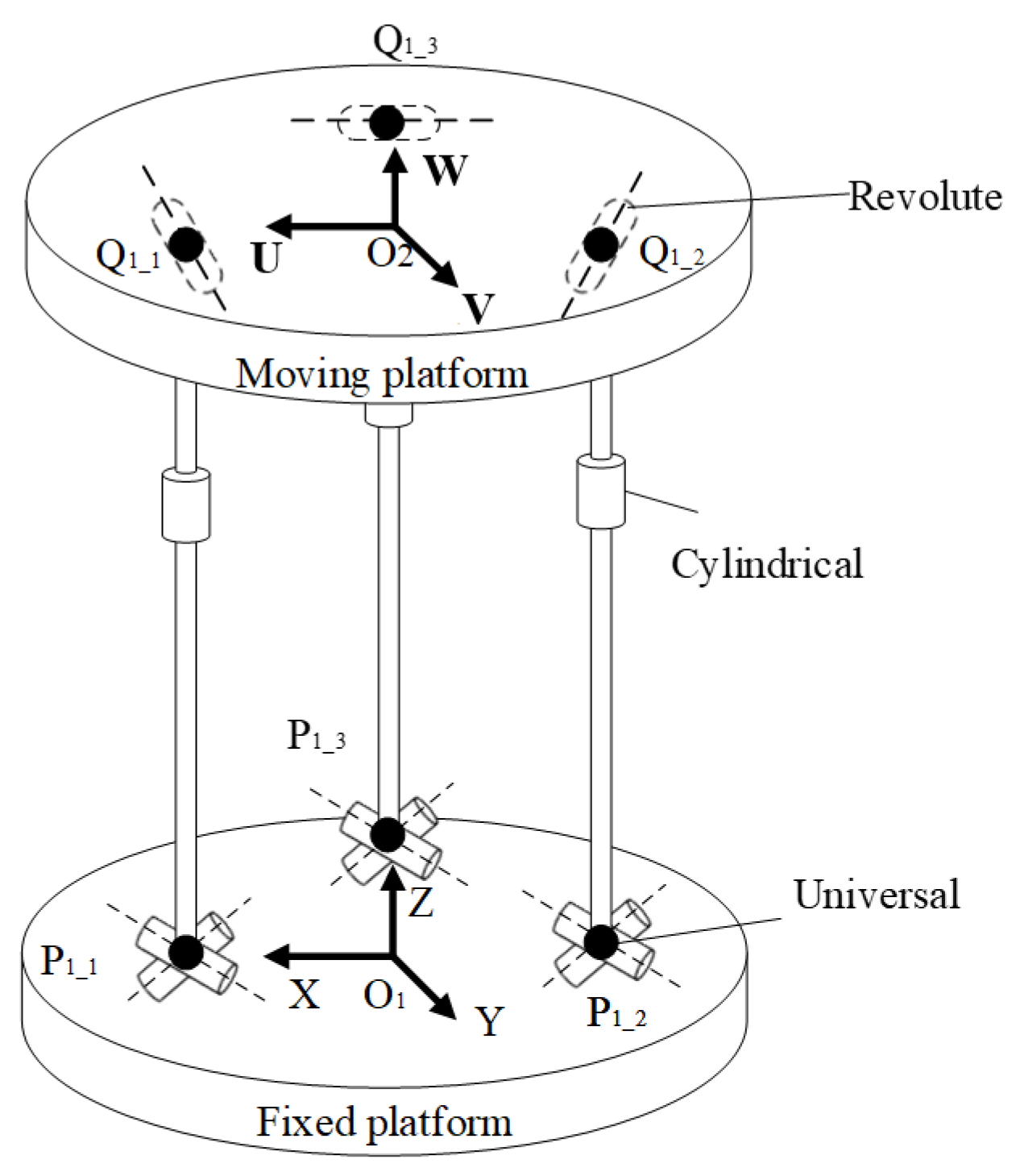

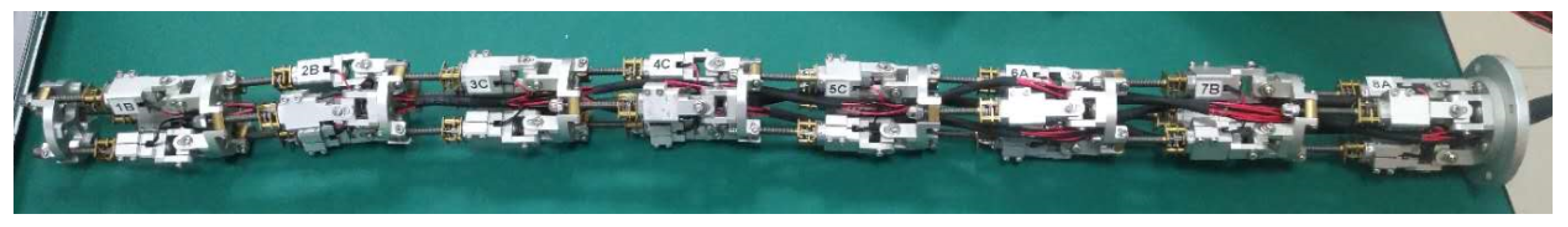

2.1. Introduction of UCR Parallel Mechanism

2.2. Kinematics Modeling of UCR Parallel Mechanism

- (1)

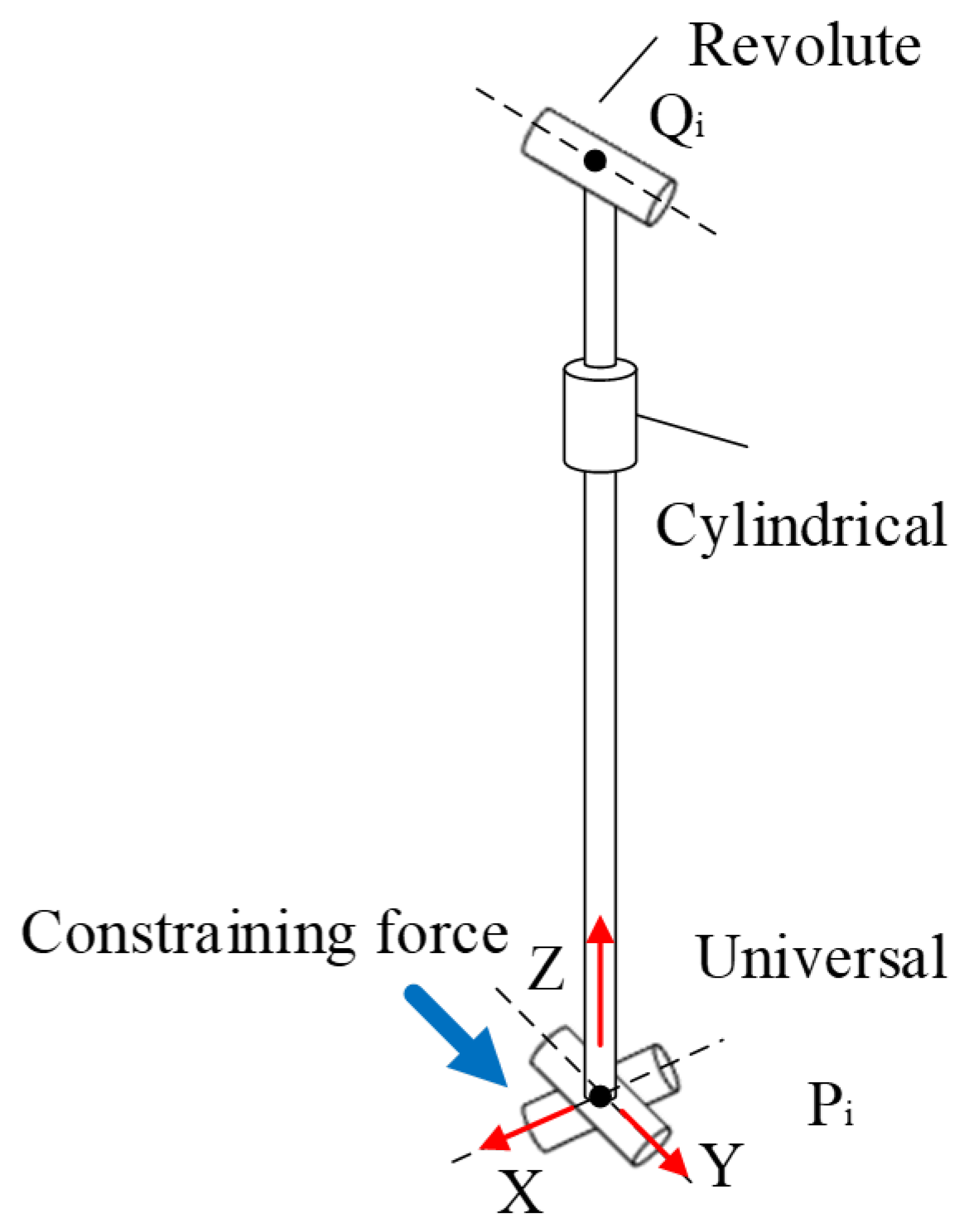

- The driven model of UCR parallel mechanism

- (2)

- The constraint model of UCR parallel mechanism

- (3)

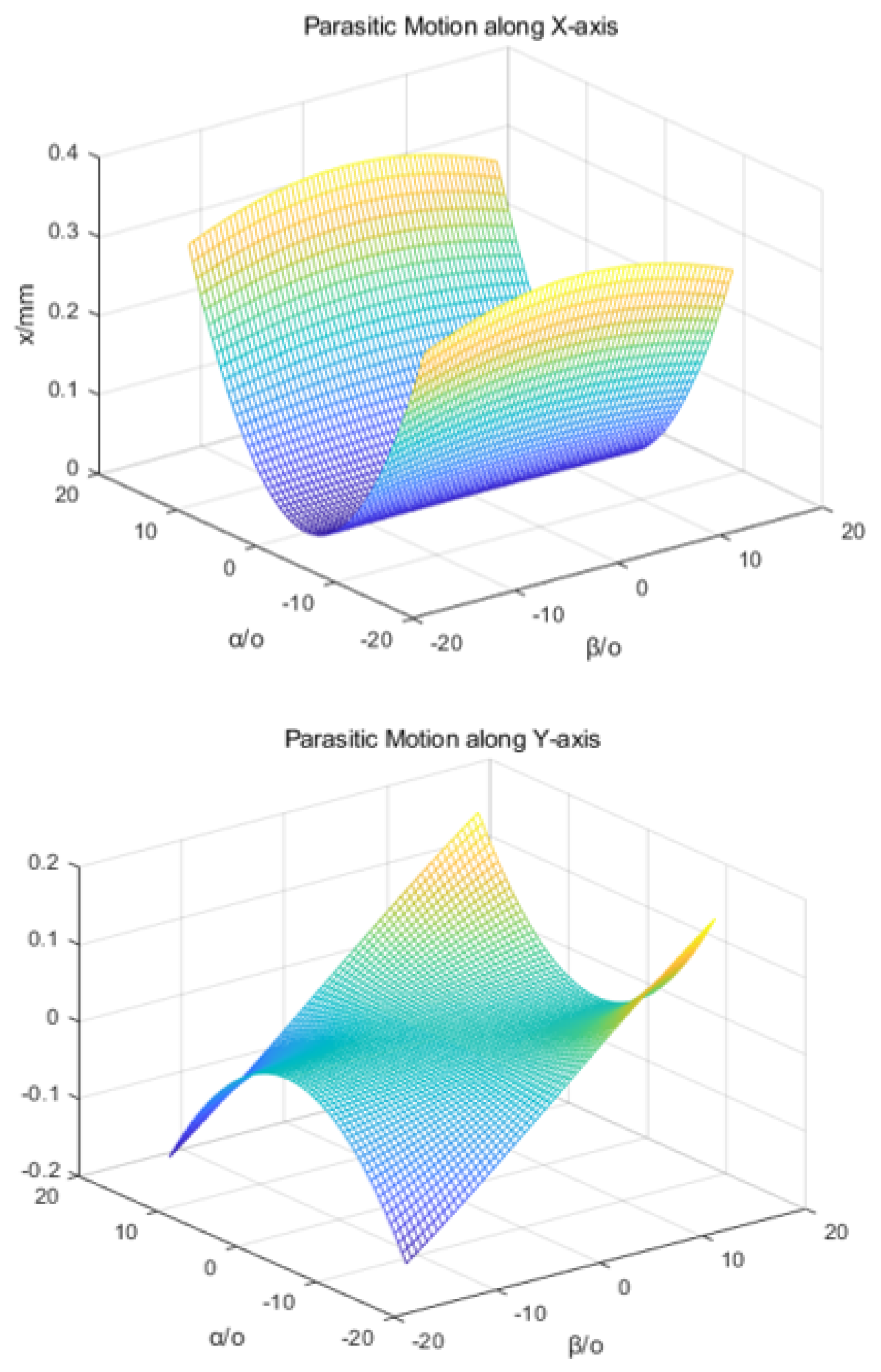

- The parasitic motion of UCR parallel mechanism

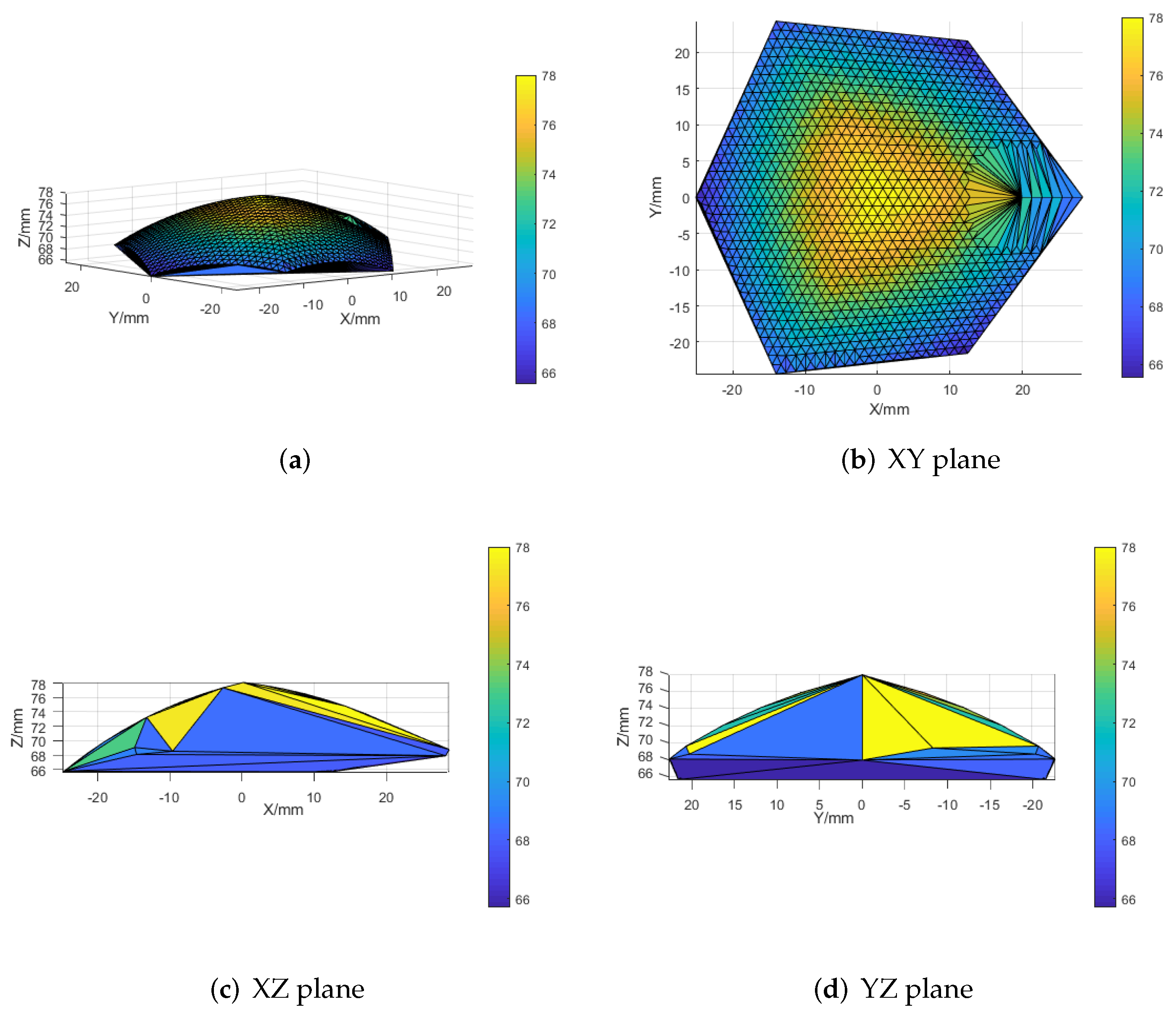

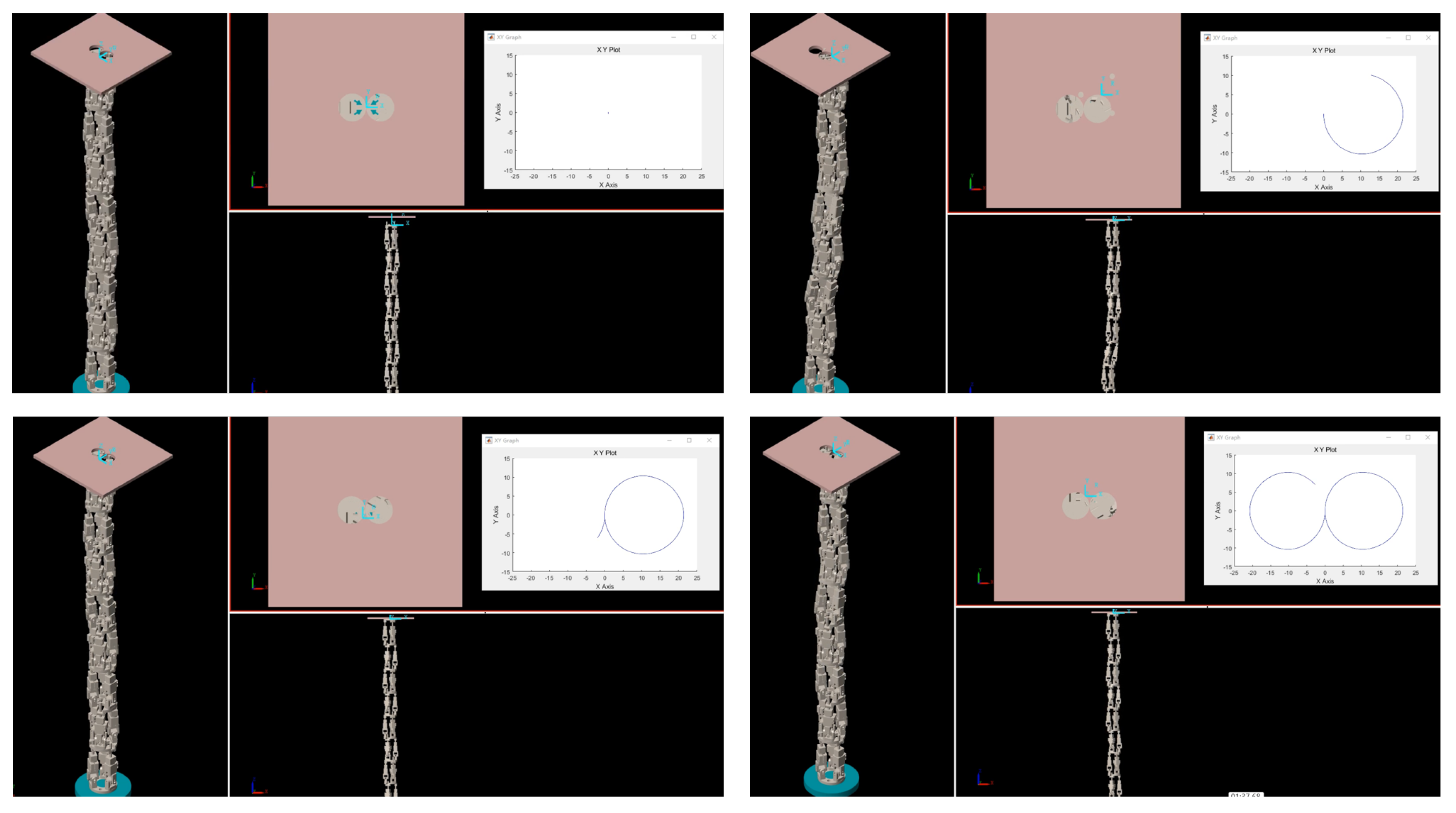

2.3. Workspace Analysis Based on Simulation

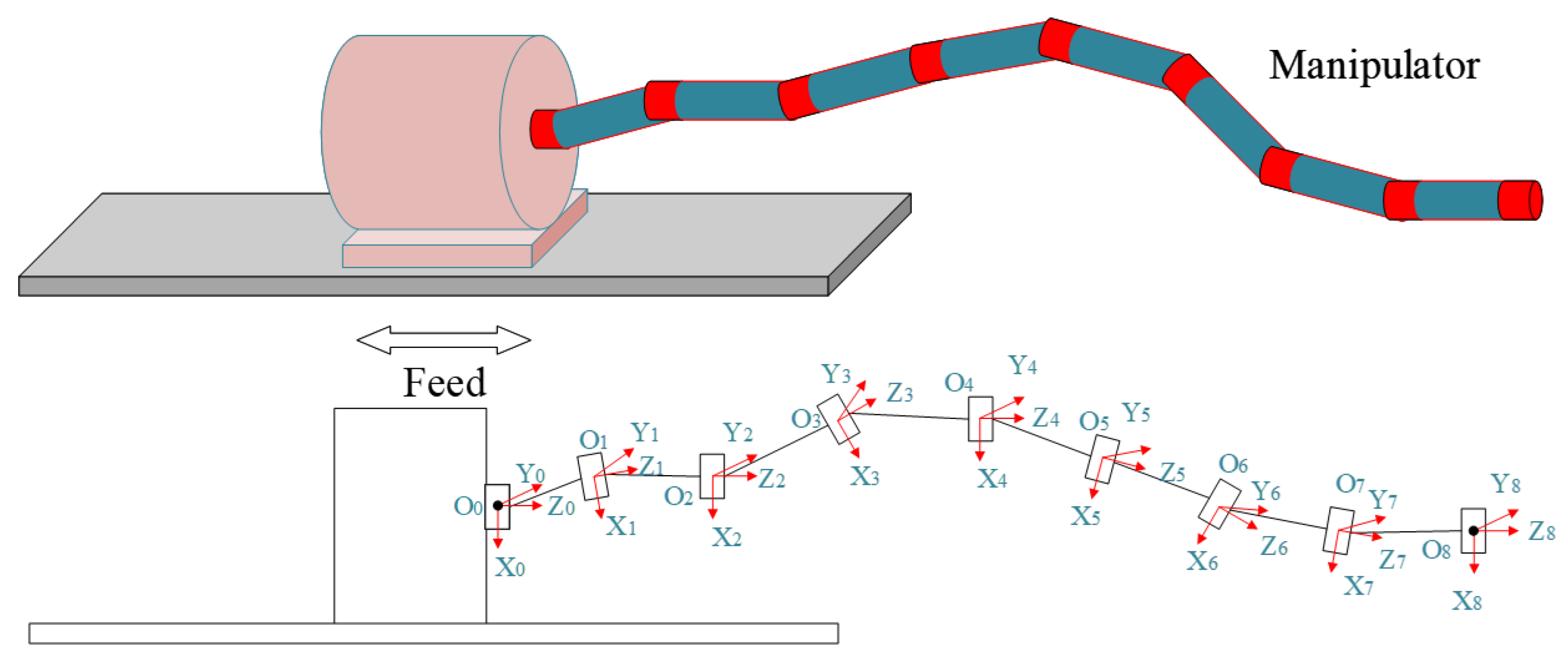

3. Kinematics Modeling of the Manipulator

3.1. Kinematics Modeling of the Manipulator

3.2. Kinematics Modeling of Double-UCR Parallel Mechanisms

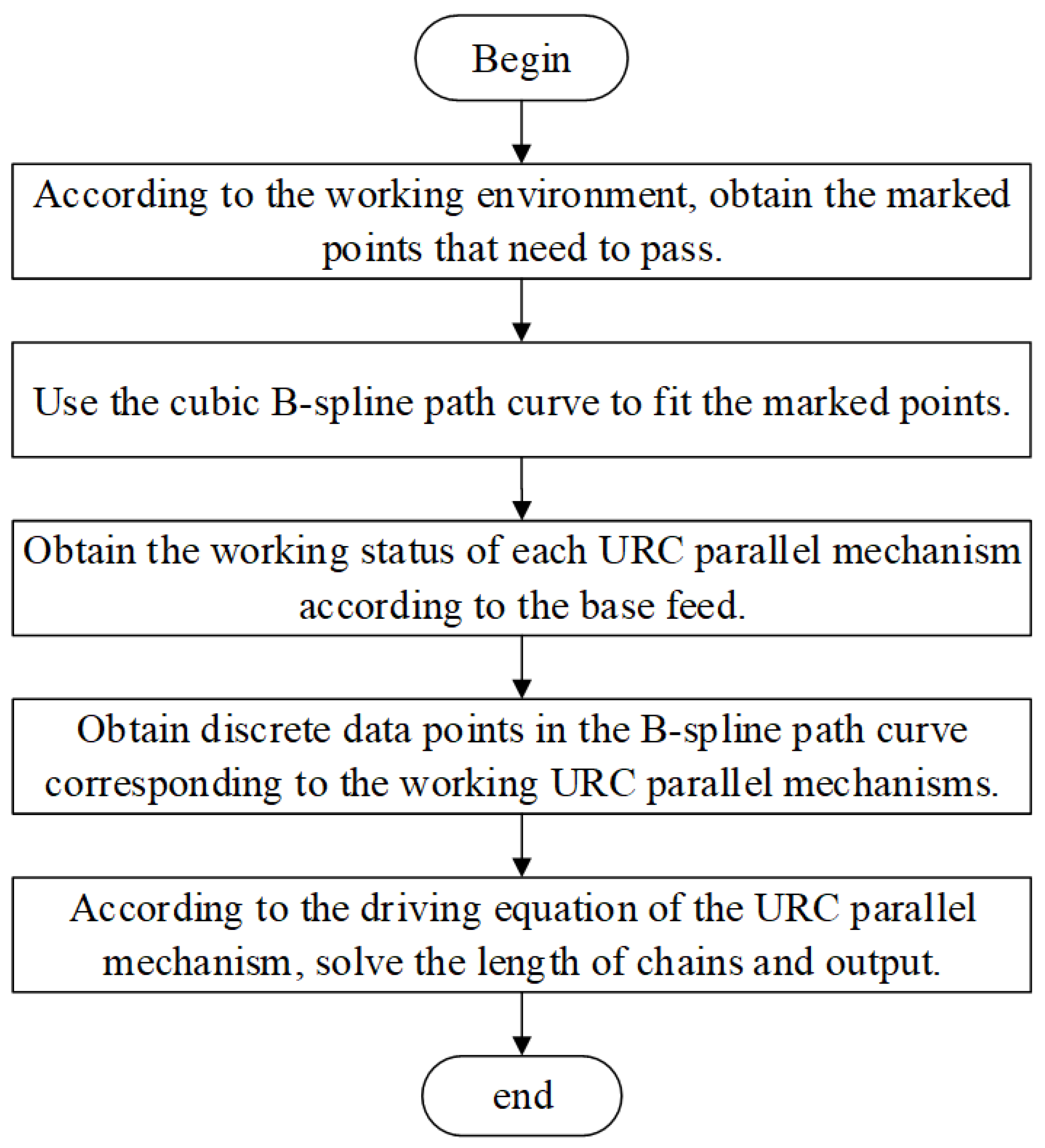

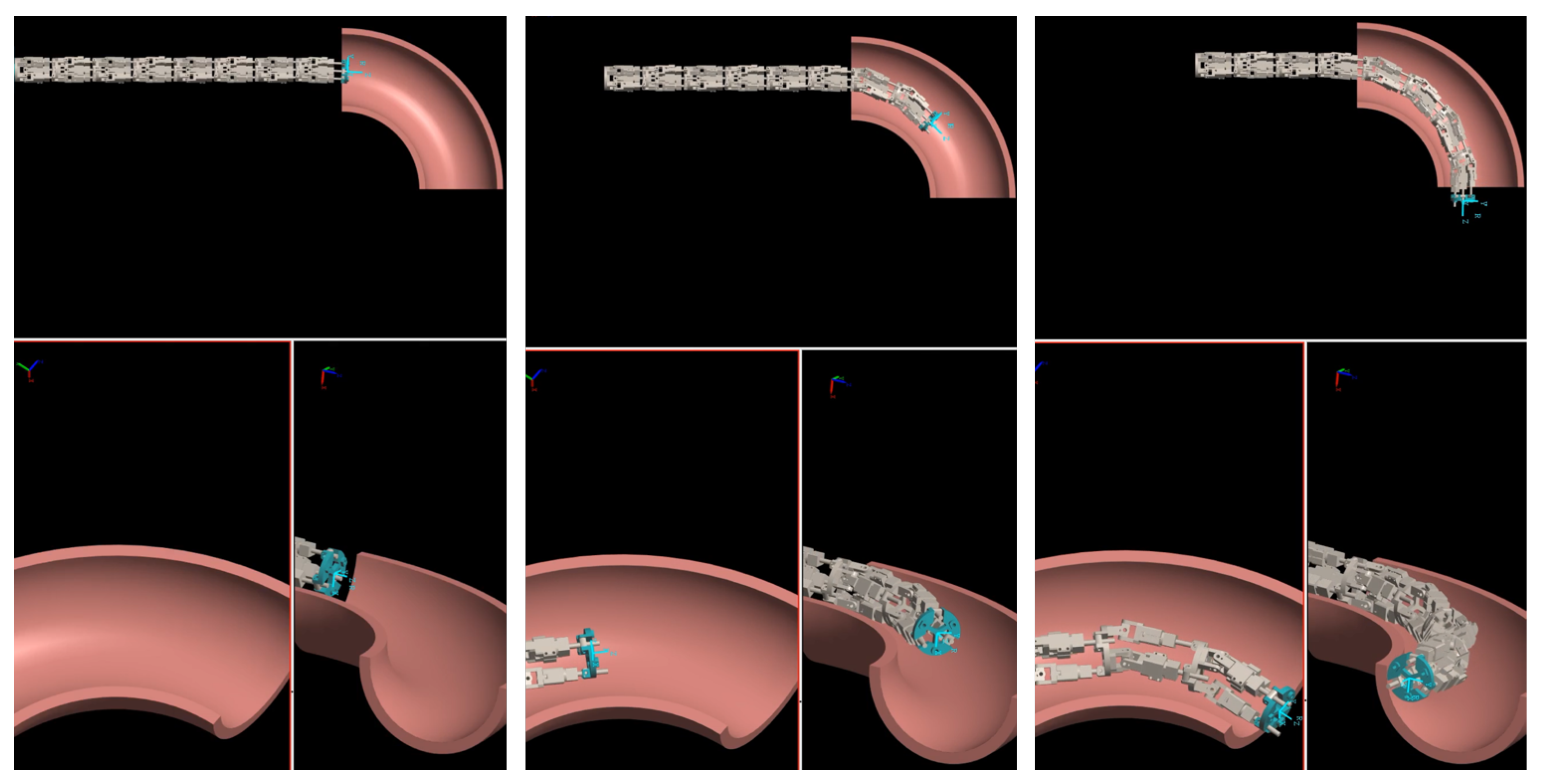

4. The Tip-Following B-Spline Path Planning

- (1)

- Compute the rotation matrix between two adjacent discrete points.

- (2)

- Determine the parity of the index of the UCR parallel mechanism. If the index is an odd number, use the driving equation CalDrivingLength_1() to compute the length of chains; if the index is even, use the driving equation CalDrivingLength_2() to compute the length of three chains.

| ine FUNCTION: CalDrivingLength_1 |

| INPUT: Transformation matrix of moving platform |

| The distance between and |

| OUTPUT: ,, The length of the three chains |

| BEGIN |

| 1. call Translate |

| 2. |

| 3. |

| 4. |

| 5. Output , , |

| END |

| ine |

| ine FUNCTION: CalDrivingLength_2 |

| INPUT: Transformation matrix of two moving platforms |

| OUTPUT: The length of the three chains |

| BEGIN |

| 1. call Translate |

| 2. |

| 3. |

| 4. |

| 5. Output , , |

| END |

| ine |

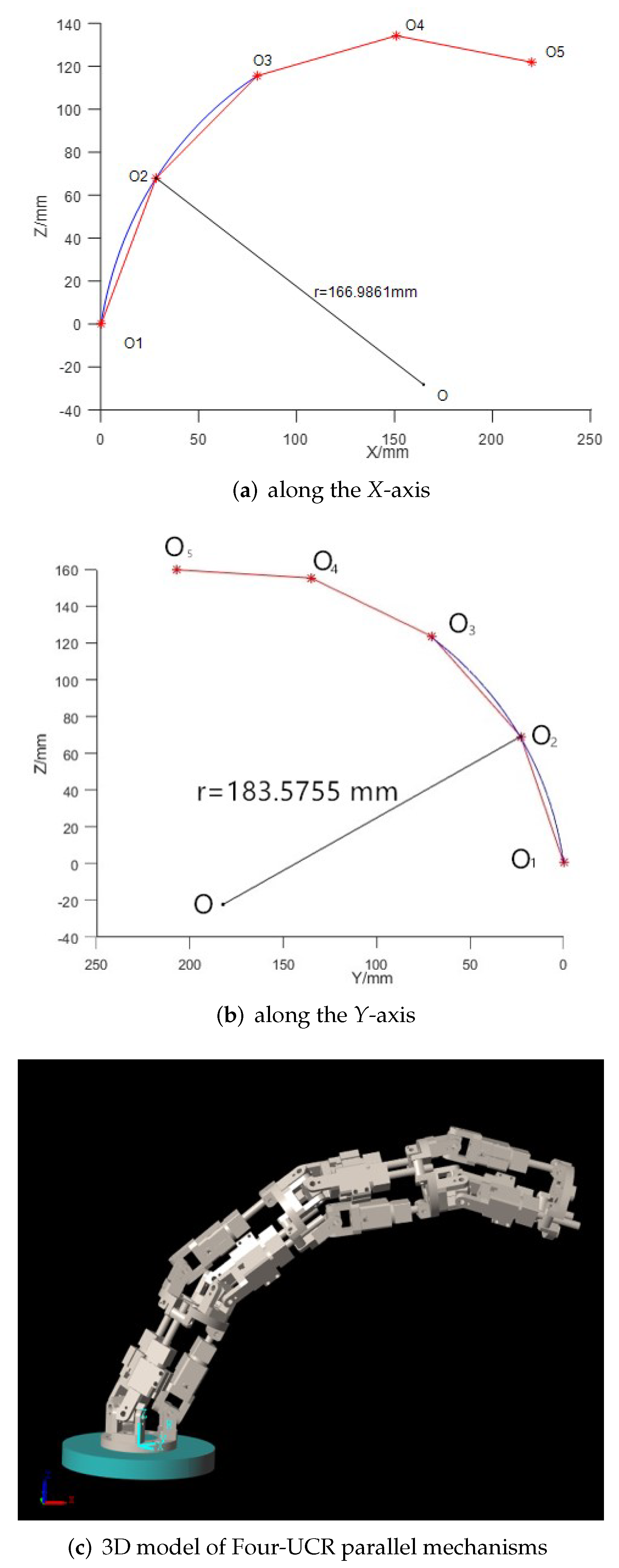

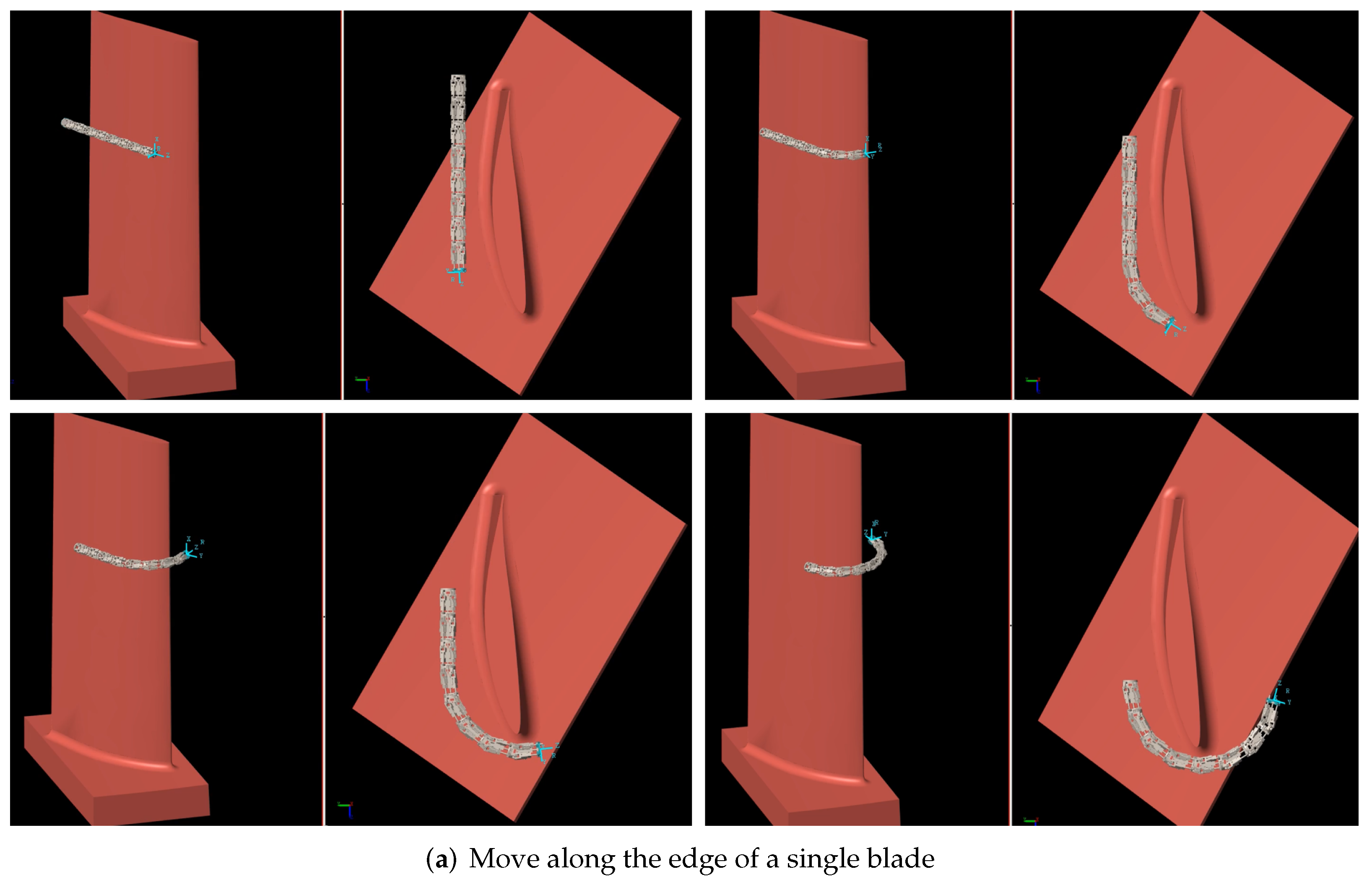

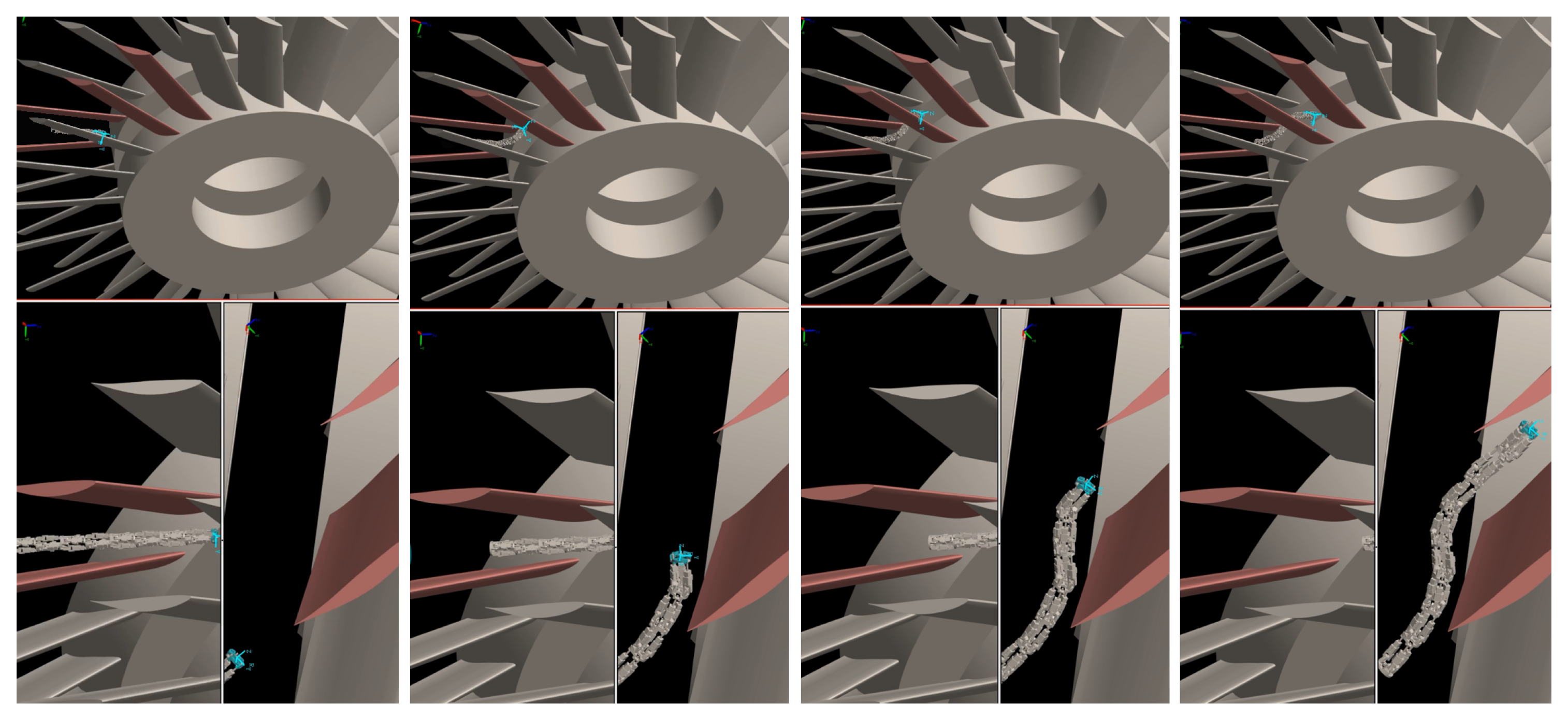

5. Simulations and Experiments

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Freitas, R.A., Jr.; Healy, T.J.; Long, J.E. Advanced automation for space missions. J. Astronaut. Sci. 1982, 30, 221. [Google Scholar]

- Heemskerk, C.J.M.; Visser, M.; Vrancken, D. Extending ERA’s capabilities to capture and transport large payloads. In Proceedings of the 9th ESA Workshop on Advanced Space Technologies for Robotics and Automation, Noordwijk, The Netherlands, 28–30 November 2006; pp. 1–8. [Google Scholar]

- Cruijssen, H.J.; Ellenbroek, M.; Henderson, M.; Petersen, H.; Verzijden, P.; Visser, M. The European Robotic Arm: A HighPerformance Mechanism Finally on Its Way to Space; NASA: Washington, DC, USA, 2014.

- Boumans, R.; Heemskerk, C. The European robotic arm for the international space station. Robot. Auton. Syst. 1998, 23, 17–27. [Google Scholar]

- Kingsley, D.A.; Quinn, R.D.; Ritzmann, R.E. A cockroach inspired robot with artificial muscles. In Proceedings of the 2006 IEEE/RSJ International Conference on on Intelligent Robots and Systems (IROS), Beijing, China, 9–15 October 2006; pp. 1837–1842. [Google Scholar]

- Luk, B.L.; Cooke, D.S.; Galt, S.; Collie, A.A. Intelligent legged climbing service robot for remote maintenance applications in hazardous environments. Robot. Auton. Syst. 2005, 53, 142–152. [Google Scholar]

- Saunders, A.; Goldman, D.I.; Full, R.J.; Buehler, M. The rise climbing robot: Body and leg design. In Proceedings of the Unmanned Systems Technology VIII, International Society for Optics and Photonics, Kissimmee, FL, USA, 17–20 April 2006; Volume 6230, p. 623017. [Google Scholar]

- Lovchik, C.S.; Diftler, M.A. The robonaut hand: A dexterous robot hand for space. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation, Detroit, MN, USA, 10–15 May 1999; Volume 2, pp. 907–912. [Google Scholar]

- Yu, D.Y.; Sun, J.; Ma, X.R. Suggestion on development of Chinese space manipulator technology. Spacecr. Eng. 2007, 16, 1–8. [Google Scholar]

- Laryssa, P.; Lindsay, E.; Layi, O.; Marius, O.; Nara, K.; Aris, L.; Ed, T. International space station robotics: A comparative study of ERA, JEMRMS and MSS. In Proceedings of the 7th ESA Workshop on Advanced Space Technologies for Robotics and Automation, Noordwijk, The Netherlands, 19–21 November 2002; pp. 1–8. [Google Scholar]

- Zhang, K.F.; Zhou, H.; Wen, Q.P.; Zhang, K.F. Review of the development of robotic manipulator for international space station. Chin. J. Space Sci. 2010, 30, 612–619. [Google Scholar]

- Sun, L.; Haiyan, H.U.; Mantian, L.I. A Review on Continuum Robot. Jiqiren/Robot 2010, 32, 688–694. [Google Scholar]

- Dong, X.; Raffles, M.; Guzman, S.C.; Axinte, D.; Kell, J. Design and analysis of a family of snake arm robots connected by compliant joints. Mech. Mach. Theory 2014, 77, 73–91. [Google Scholar]

- He, J.; Liu, R.; Wang, K.; Shen, H. The mechanical design of snake-arm robot. In Proceedings of the IEEE International Conference on Industrial Informatics, Beijing, China, 25–27 July 2012; pp. 758–761. [Google Scholar]

- Peng, J.; Xu, W.; Liu, T.; Yuan, H.; Liang, B. End-effector pose and arm-shape synchronous planning methods of a hyper-redundant manipulator for spacecraft repairing. Mech. Mach. Theory 2021, 155, 104062. [Google Scholar]

- Rone, W.S.; Ben-Tzvi, P. Mechanics Modeling of Multisegment Rod-Driven Continuum Robots. J. Mech. Robot. Trans. ASME 2014, 6, 041006. [Google Scholar]

- Li, Z.; Ren, H.; Chiu, P.W.Y.; Du, R.; Yu, H. A novel constrained wire-driven flexible mechanism and its kinematic analysis. Mech. Mach. Theory 2016, 95, 59–75. [Google Scholar]

- Yukisawa, T.; Nishikawa, S.; Niiyama, R.; Kawahara, Y.; Kuniyoshi, Y. Ceiling continuum arm with extensible pneumatic actuators for desktop workspace. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018. [Google Scholar]

- Ma, L.; Huang, M.; Yang, S.; Wang, R. An Adaptive Localized Decision Variable Analysis Approach to Large-Scale Multiobjective and Many-Objective Optimization. IEEE Trans. Cybern. 2021, 99, 1–13. [Google Scholar]

- Jia, L.; Huang, Y.; Chen, T.; Guo, Y.; Yin, Y.; Chen, J. MDA+RRT: A general approach for resolving the problem of angle constraint for hyper-redundant manipulator. Expert Syst. Appl. 2021, 193, 116379. [Google Scholar]

- Cao, Y.; Shang, J.; Liang, K.; Fan, D.; Ma, D.; Tang, L. Review of soft-bodied robots picking. J. Echanical Eng. 2014, 48, 25–33. [Google Scholar]

- Choset, H.; Henning, W. A follow-the-leader approach to serpentine robot motion planning. J. Aerosp. Eng. 1999, 12, 65–73. [Google Scholar]

- Chirikjian, G.S.; Burdick, J.W. An obstacle avoidance algorithm for hyper-redundant manipulators. In Proceedings of the Robotics and Automation, Cincinnati, OH, USA, 13–18 May 1990; pp. 625–631. [Google Scholar]

- Conkur, E.S. Path following algorithm for highly redundant manipulators. Robot. Auton. Syst. 2003, 45, 1–22. [Google Scholar]

- Andersson, S.B. Discretization of a continuous curve. IEEE Trans. Robot. 2008, 24, 456–461. [Google Scholar]

- Palmer, D.; Cobos-Guzman, S.; Axinte, D. Real-time method for tip following navigation of continuum snake arm robots. Robot. Auton. Syst. 2014, 62, 1478–1485. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, J.; Wang, B.; Cui, K.; Dai, Z. Path Planning Based on NURBS for Hyper-Redundant Manipulator Used in Narrow Space. Appl. Sci. 2022, 12, 1314. https://doi.org/10.3390/app12031314

Duan J, Wang B, Cui K, Dai Z. Path Planning Based on NURBS for Hyper-Redundant Manipulator Used in Narrow Space. Applied Sciences. 2022; 12(3):1314. https://doi.org/10.3390/app12031314

Chicago/Turabian StyleDuan, Jinjun, Bingcheng Wang, Kunkun Cui, and Zhendong Dai. 2022. "Path Planning Based on NURBS for Hyper-Redundant Manipulator Used in Narrow Space" Applied Sciences 12, no. 3: 1314. https://doi.org/10.3390/app12031314

APA StyleDuan, J., Wang, B., Cui, K., & Dai, Z. (2022). Path Planning Based on NURBS for Hyper-Redundant Manipulator Used in Narrow Space. Applied Sciences, 12(3), 1314. https://doi.org/10.3390/app12031314