Analysis of Characteristics of Roof Fall Collapse of Coal Mine in Qinghai Province, China

Abstract

:1. Introduction

2. Materials and Methods

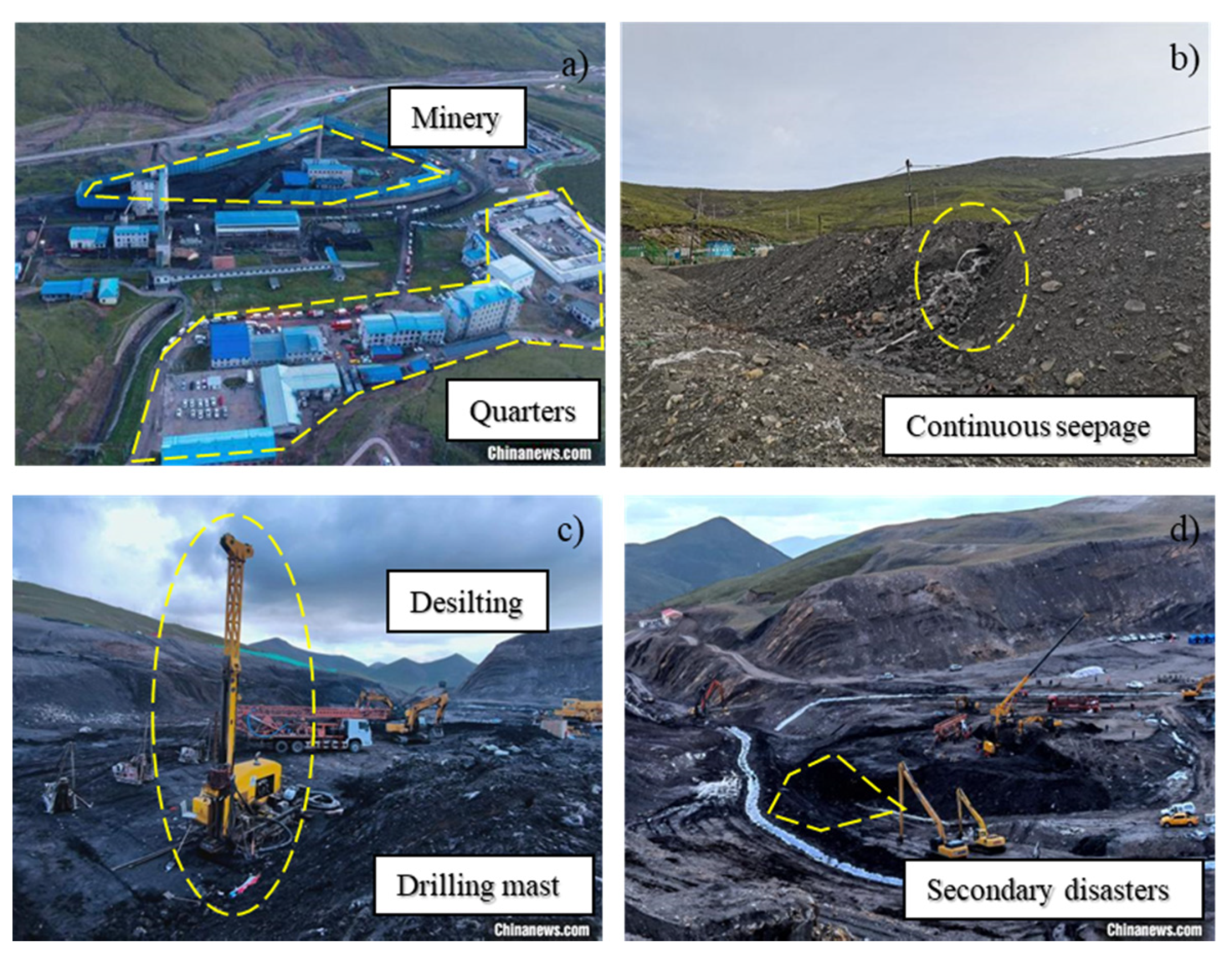

2.1. Overview of Collapse Event

2.2. Data Source

2.3. Recuse Effort

3. Analysis and Discussion

3.1. Environmental Factors

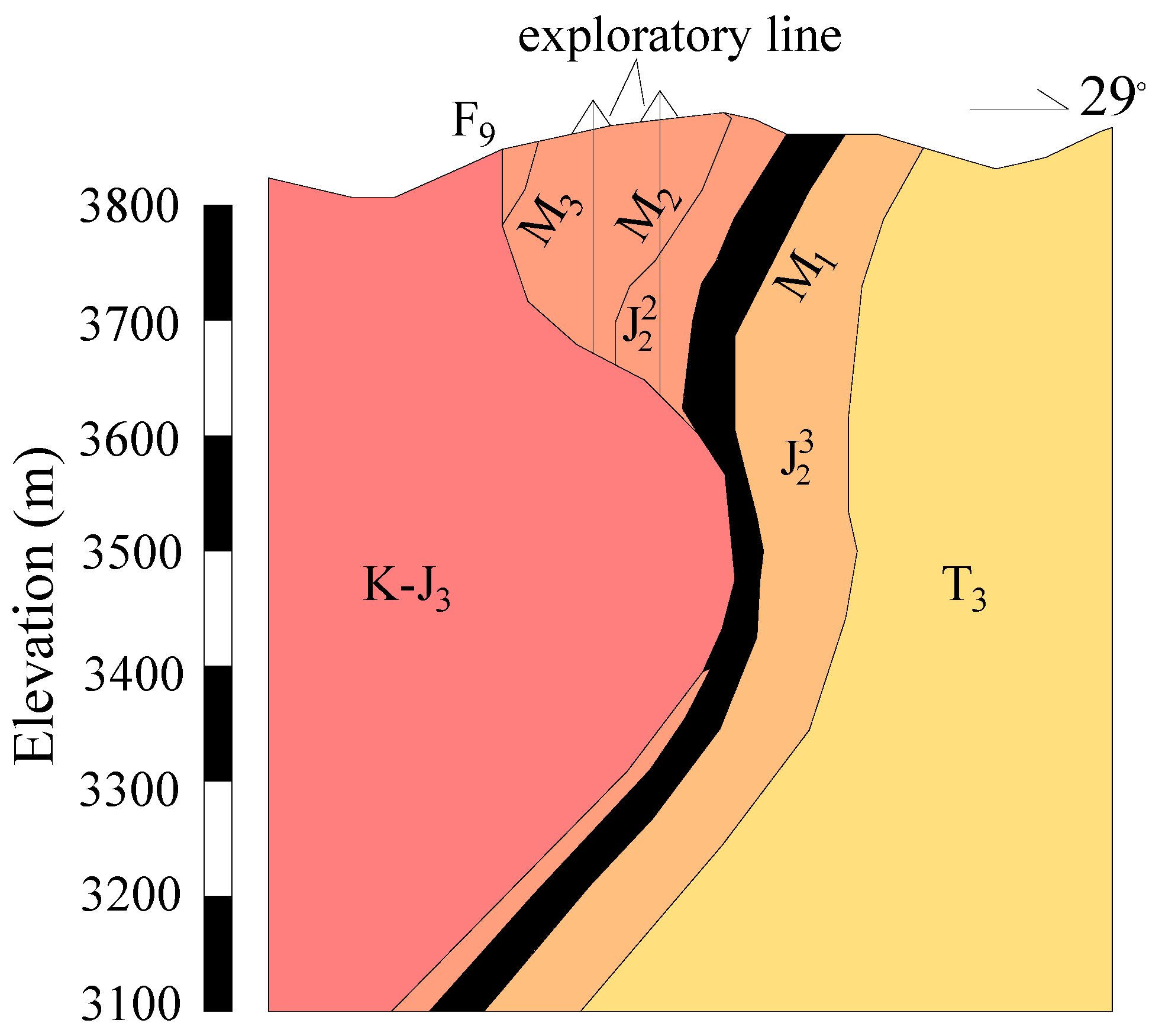

3.1.1. Complex Geological Conditions

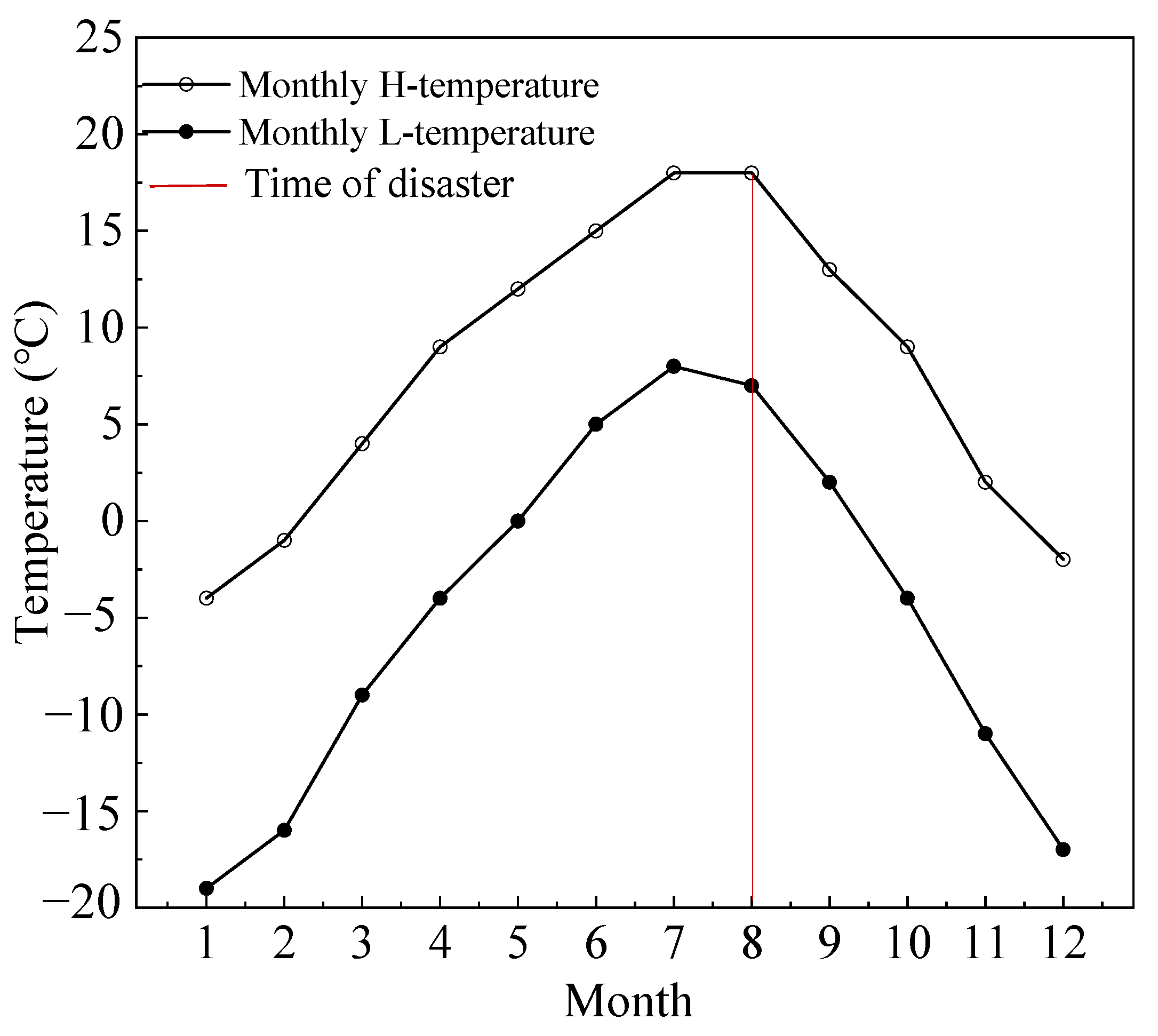

3.1.2. Climate Change

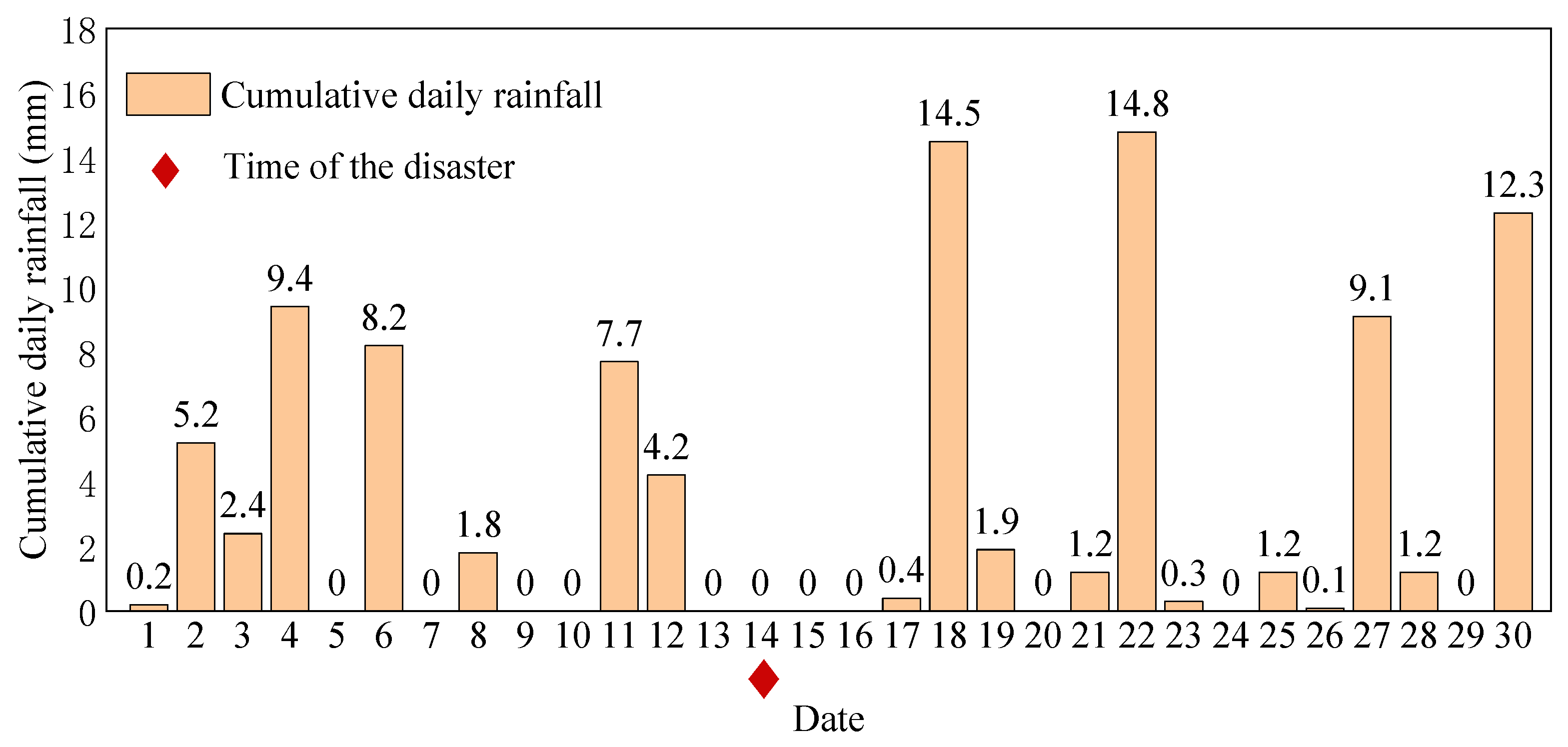

3.1.3. Rainfall

3.2. Extral Factors

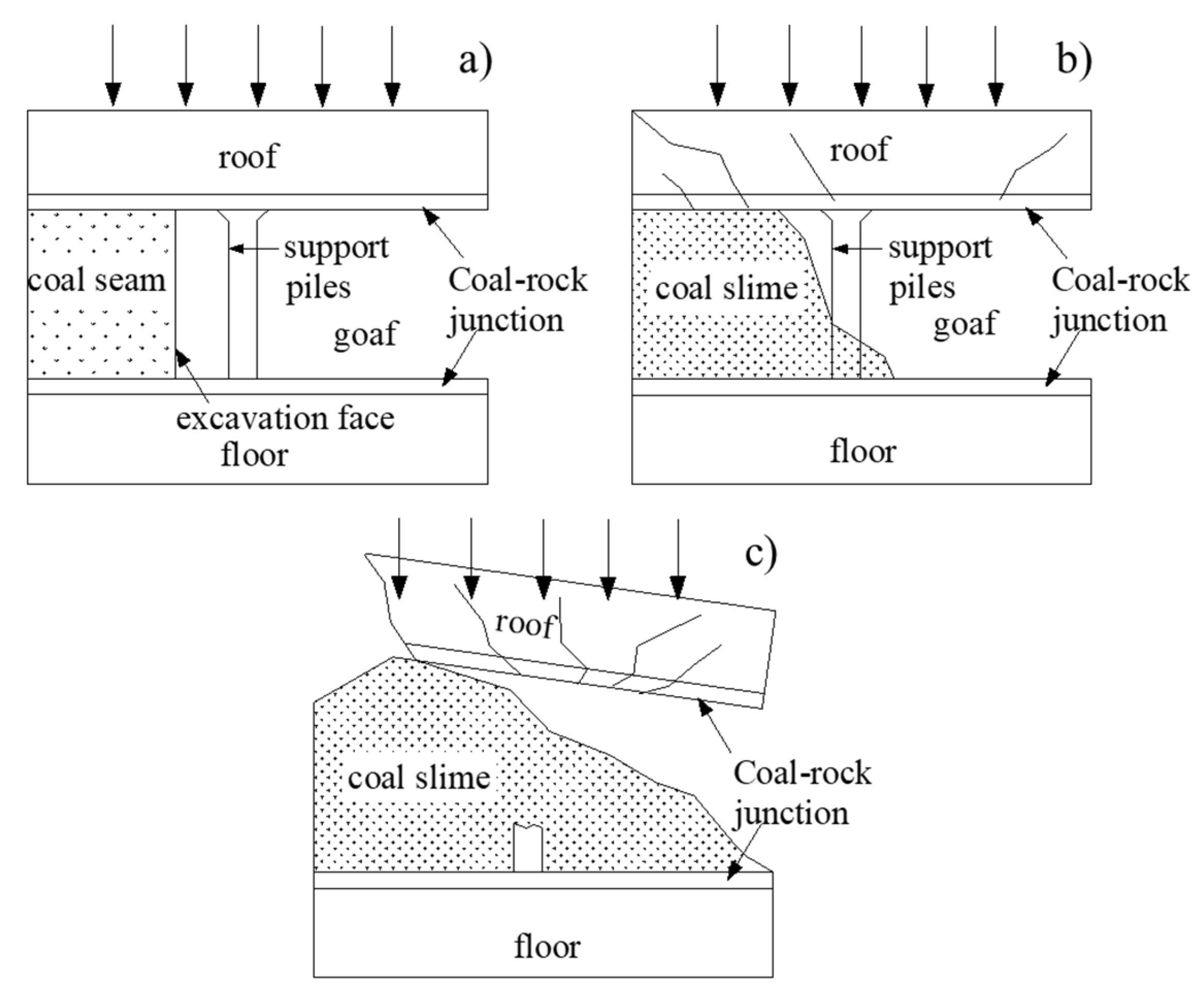

3.2.1. Support Structure

3.2.2. Organization and Management

3.3. Reflections

3.4. Suggestions

4. Concluding Remarks

- The roof fall accident in the Chaidar coal mine in Gangcha County, Qinghai Province, killed 20 people and injured 1. The disaster was caused by the influx of coal slime formed by fissure water and coal dust in the upper part of the coal seam pouring into the working face.

- Complex geological conditions, climate change, rainfall and other environmental factors are important reasons affecting coal mining. In the mining process, the ground pressure changes constantly under different geological conditions, and the mining difficulty is different. Temperature change and rainfall will change the water content of the soil, as well as the runoff direction and runoff of surface water and shallow groundwater, thereby changing the ground pressure of the coal mine roof.

- For roof fall collapse, it is suggested to develop a new ground-pressure-monitoring system. Reasonable support methods shall be adopted during construction. Additionally, it is essential to strengthen training and improve the safety awareness of construction personnel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prusek, S.; Rajwa, S.; Wrana, A.; Krzemien, A. Assessment of roof fall risk in longwall coal mines. Int. J. Min. Reclam. Environ. 2017, 31, 558–574. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.D.; Bai, J.B.; Feng, G.R.; Wang, X.Y. Investigation on the mechanism and control methods for roof collapse caused by cable bolt shear rupture. J. Eng. Fail. Anal. 2021, 130, 105724. [Google Scholar] [CrossRef]

- Lyu, H.M.; Sun, W.J.; Shen, S.L.; Zhou, A. Risk assessment using a new consulting process in fuzzy AHP. J. Constr. Eng. Manag. 2020, 146, 04019112. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Analysis of rock mass dynamic impact influence on the operation of a powered roof support control system. E3S Web Conf. 2018, 29, 1–9. [Google Scholar] [CrossRef]

- Düzgün, H.S.B. Analysis of roof fall hazards and risk assessment for Zonguldak coal basin underground mines. Int. J. Coal Geol. 2005, 64, 104–115. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J. The Impact of the Strength of Roof Rocks on the Extent of the Zone with a High Risk of Spontaneous Coal Combustion for Fully Powered Longwalls Ventilated with the Y-Type System—A Case Study. Appl. Sci. 2019, 9, 5312. [Google Scholar] [CrossRef] [Green Version]

- Yaşlı, F.; Bolat, B. A Bayesian Network Analysis for Occupational Accidents of Mining Sector BT. In Proceedings of the International Symposium for Production Research 2018; Durakbasa, N.M., Gencyilmaz, M.G., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 781–799. [Google Scholar]

- Song, G.; Wang, Z.; Ding, K. Evaluation of the face advance rate on ground control in the open face area associated with mining operations in Western China. J. Geophys. Eng. 2020, 17, 390–398. [Google Scholar] [CrossRef]

- Shen, S.L.; Wang, Z.F.; Cheng, W.C. Estimation of lateral displacement induced by jet grouting in clayey soils. Géotechnique 2017, 67, 621–630. [Google Scholar] [CrossRef]

- Atangana Njock, P.G.; Shen, S.L.; Zhou, A.; Modoni, G. Artificial neural network optimized by differential evolution for predicting diameters of jet grouted columns. J. Rock Mech. Geotech. Eng. 2021, 13, 1500–1512. [Google Scholar] [CrossRef]

- Tubis, A.; Werbińska-Wojciechowska, S.; Wroblewski, A. Risk Assessment Methods in Mining Industry—A Systematic Review. Appl. Sci. 2020, 10, 5172. [Google Scholar] [CrossRef]

- Xinhua Daily Telegraph. The Death Toll of Roof Fall Accident in Dengfeng Coal Mine in Henan Province Rose to 12. Available online: http://www.xinhuanet.com/mrdx/2017-01/07/c_135962368.htm (accessed on 16 January 2022). (In Chinese).

- Tencent News. The Cause of the Coal Mine Roof Fall Accident in Shuozhou, Shanxi Province Was Announced, Killing 10 People. Available online: https://news.qq.com/a/20170123/022609.htm (accessed on 16 January 2022). (In Chinese).

- Liu, W.B. “11.11” Major Roof Accident in Hongyang No. 3 Mine of Shenyang Coking Coal Mine. Mod. Group 2019, 4, 29. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=67747176504849574852485149&from=Qikan_Search_Index (accessed on 16 January 2022). (In Chinese).

- Global Network. A Roof Fall Accident Occurred in a Coal Mine in Shenmu City, Shaanxi Province, Killing all 21 Trapped Miners. Available online: https://baijiahao.baidu.com/s?id=1622489749531651842&wfr=spider&for=pc (accessed on 16 January 2022). (In Chinese).

- Global Network. Preliminary Investigation on 6 Deaths Caused by Roof Fall in Ningwu Coal Mine, Shanxi Province: It is Related to Insufficient Anchoring Force. Available online: https://baijiahao.baidu.com/s?id=1636906902610407192&wfr=spider&for=pc (accessed on 16 January 2022). (In Chinese).

- Guangxi News Network. Nandan Major Mining Accident Investigation Results Announced: The Heads of Many Enterprises Were Sentenced and 18 Public Officials Were Dealt with. Available online: http://www.gxnews.com.cn/staticpages/20201208/newgx5fcec5c8-19986953.shtml (accessed on 16 January 2022). (In Chinese).

- Chinanews. Five People Were Killed in a Coal Mine Roof Accident in Yunnan. The Cause of the Accident Is Being Investigated. Available online: https://www.chinanews.com/sh/2020/03-01/9109525.shtml (accessed on 16 January 2022). (In Chinese).

- Xinhua Net. The Search and Rescue of the “May 26” Roof Fall Accident in Xin’an Coal Mine of Shandong Jujube Mining Group Ended and Three People Were Killed. Available online: http://www.xinhuanet.com/2021-06/08/c_1127541348.htm (accessed on 16 January 2022). (In Chinese).

- Lyu, H.M.; Zhou, W.H.; Shen, S.L.; Zhou, A. Inundation risk assessment of metro system using AHP and TFN-AHP in Shenzhen. Sustain. Cities Soc. 2020, 56, 102103. [Google Scholar] [CrossRef]

- Kardani, N.; Zhou, A.; Shen, S.L.; Nazem, M. Improved prediction of slope stability using a hybrid stacking ensemble method based on finite element analysis and field data. J. Rock Mech. Geotech. Eng. 2021, 13, 188–201. [Google Scholar] [CrossRef]

- Zheng, Q.; Lyu, H.M. Risk assessment of geohazards along Cheng-Kun railway using fuzzy AHP incorporated into GIS, Geomatics. Nat. Hazards Risk 2021, 12, 1508–1531. [Google Scholar] [CrossRef]

- Lin, S.S.; Zhang, N.; Zhou, A.; Shen, S.L. Time-series prediction of shield movement performance during tunneling based on hybrid model. Tunn. Undergr. Space Technol. 2022, 119, 104245. [Google Scholar] [CrossRef]

- Lyu, H.M.; Shen, S.L.; Zhou, A.; Yang, J. Risk assessment of mega-city infrastructures related to land subsidence using improved trapezoidal FAHP. Sci. Total Environ. 2020, 717, 135310. [Google Scholar] [CrossRef]

- Liu, X.X.; Shen, S.L.; Zhou, A.; Xu, Y.S. Non-linear spring model for backfill grout-consolidation behind shield tunnel lining. Comput. Geotech. 2021, 136, 104235. [Google Scholar] [CrossRef]

- Shen, S.L.; Wang, Z.F.; Yang, J.; Ho, C.E. Generalized approach for prediction of jet grout column diameter. J. Geotech. Geoenviron. Eng. 2013, 139, 2060–2069. [Google Scholar] [CrossRef]

- Chai, J.C.; Shen, S.; Ding, W.Q.; Zhu, H.H.; Cater, J.P. Numerical investigation of the failure of a building in Shanghai, China. Comput. Geotech. 2014, 55, 482–493. [Google Scholar] [CrossRef]

- Elbaz, K.; Shen, S.L.; Zhou, A.; Yin, Z.Y.; Lyu, H.M. Prediction of disc cutter life during shield tunneling with AI via the incorporation of a genetic algorithm into a GMDH-type neural network. Engineering 2021, 7, 238–251. [Google Scholar] [CrossRef]

- Chin, Y.T.; Chen, J. Foundation Pit Collapse on 8 June 2019 in Nanning, China: A Brief Report. Safety 2019, 5, 68. [Google Scholar] [CrossRef] [Green Version]

- Shen, S.L.; Atangana Njock, P.G.; Zhou, A.; Lyu, H.M. Dynamic prediction of jet grouted column diameter in soft soil using Bi-LSTM deep learning. Acta Geotech. 2021, 16, 303–315. [Google Scholar] [CrossRef]

- Shen, S.L.; Lyu, H.M.; Lu, L.H.; Li, G.; Hu, B.B. Automatic control of groundwater balance to combat dewatering during construction of a metro system. Autom. Constr. 2021, 123, 103536. [Google Scholar] [CrossRef]

- Lyu, H.M.; Shen, S.L.; Zhou, A.; Yang, J. Perspectives for flood risk assessment and management for mega-city metro system. Tunn. Undergr. Space Technol. 2019, 84, 31–44. [Google Scholar] [CrossRef]

- Wang, Z.F.; Shen, S.L.; Modoni, G.; Zhou, A. Excess pore water pressure caused by the installation of jet grouting columns in clay. Comput. Geotech. 2020, 125, 103667. [Google Scholar] [CrossRef]

- Wu, H.N.; Shen, S.L.; Chen, R.P.; Zhou, A. Three-dimensional numerical modelling on localised leakage in segmental lining of shield tunnels. Comput. Geotech. 2020, 122, 103549. [Google Scholar] [CrossRef]

- Lyu, H.M.; Sun, W.J.; Shen, S.L.; Arulrajah, A. Flood risk assessment in metro systems of mega-cities using a GIS-based modeling approach. Sci. Total Environ. 2018, 626, 1012–1025. [Google Scholar] [CrossRef]

- Wang, Z.F.; Shen, S.L.; Modoni, G. Enhancing discharge of spoil to mitigate disturbance induced by horizontal jet grouting in clayey soil: Theoretical model and application. Comput. Geotech. 2019, 111, 222–228. [Google Scholar] [CrossRef]

- Shen, S.L.; Wu, H.N.; Cui, Y.J.; Yin, Z.Y. Long-term settlement behavior of metro tunnels in the soft deposits of Shanghai. Tunn. Undergr. Space Technol. 2014, 40, 309–323. [Google Scholar] [CrossRef]

- Zhang, K.; Shen, S.L.; Zhou, A.; Yin, Z.Y. Evolutionary hybrid neural network approach to predict shield tunneling-induced ground settlements. Tunn. Undergr. Space Technol. 2020, 106, 103594. [Google Scholar] [CrossRef]

- Lyu, H.M.; Shen, S.L.; Zhou, A. The development of IFN-SPA: A new risk assessment method of urban water quality and its application in Shanghai. J. Clean. Prod. 2021, 282, 124542. [Google Scholar] [CrossRef]

- Chinanews. Direct Access to Qinghai Chaidar Coal Mine Mud Collapse Rescue Site. Available online: http://www.chinanews.com/sh/2021/08-14/9543607.shtml (accessed on 16 January 2022). (In Chinese).

- People’s Daily Online. Rescue of Roof Fall Accident in Chaidar Coal Mine: Race Against Time and Do Everything Possible. Available online: http://qh.people.com.cn/n2/2021/0816/c378418-34869916.html (accessed on 16 January 2022). (In Chinese).

- Chinanews. Visit the Rescue Site of the Roof Collapse Accident in Chaidar Coal Mine, Qinghai Province. Available online: http://www.chinanews.com/sh/2021/08-16/9544840.shtml (accessed on 16 January 2022). (In Chinese).

- Chinanews. Visit Rescue Site of Chaidar Coal Mine Accident in Qinghai Province. Available online: http://www.chinanews.com/tp/hd2011/2021/08-16/996822.shtml (accessed on 16 January 2022). (In Chinese).

- People’s Daily Online. Coal Mine Roof Caving Accident in Qinghai: Race against Time to Rescue 900 People. Available online: http://qh.people.com.cn/n2/2021/0815/c378418-34868307.html (accessed on 16 January 2022). (In Chinese).

- Wen, H.J. Structural Assemblage Forms in Cetar Minefield, Reshui, Qinghai. Coal Geol. China 2006, 18, 14–16. Available online: https://d.wanfangdata.com.cn/periodical/ChlQZXJpb2RpY2FsQ0hJTmV3UzIwMjEwOTA5Eg96Z210ZHoyMDA2MDMwMD (accessed on 16 January 2022). (In Chinese).

- Huo, C.S.; Wang, S.Z.; Wang, Y.K.; Xv, S.F.; Gao, G.B. Influence of nappe structure on coal seam and selection of mining method in qaidar coalfield. Qinghai Guotu Jinglue 2007, 1, 46–47. (In Chinese) [Google Scholar] [CrossRef]

- Cao, W.; Sheng, Y. Permafrost environment problems and countermeasures in the process of coal mining. Hydrogeol. Eng. Geol. 2013, 5, 91–96. (In Chinese) [Google Scholar]

- Wang, Y.J.; Guan, Q.C.; Duan, S.R. Investigation and analysis on the geological environment problems of Chaidar coal mine. Miner. Explor. 2018, 9, 1031–1036. (In Chinese) [Google Scholar] [CrossRef]

- Beijing Business Today. What happened to Qinghai Chaidar Coal Mine. Available online: https://www.bbtnews.com.cn/2021/0815/407052.shtml (accessed on 16 January 2022). (In Chinese).

- Lin, S.S.; Shen, S.L.; Zhang, N.; Zhou, A. An extended TODIM-based model for evaluating risks of excavation system. Acta Geotechnica. 2021, in press. [Google Scholar] [CrossRef]

- Farid, M.; HosseinAbadi, M.M.; Yazdani-Chamzini, A.; Yakhchali, S.H.; Basiri, M.H. Developing a new model based on neuro-fuzzy system for predicting roof fall in coal mines. Neural Comput. Appl. 2012, 23, 129–137. [Google Scholar] [CrossRef]

- Zhang, N.; Zhou, A.; Pan, Y.T.; Shen, S.L. Measurement and prediction of tunnelling-induced ground settlement in karst region by using expanding deep learning. Measurement 2021, 183, 109700. [Google Scholar] [CrossRef]

- Yan, T.; Shen, S.L.; Zhou, A.; Lyu, H.M. Construction efficiency during shield tunnelling in soft deposit of Tianjin. Tunn. Undergr. Space Technol. 2021, 112, 103917. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, S.L.; Zhou, A.; Jin, Y.F. Application of LSTM approach for modelling stress-strain behavior of soil. Appl. Soft Comput. 2021, 100, 106959. [Google Scholar] [CrossRef]

- Gao, J.C.; Ma, H.W.; Wang, C.W.; Xue, X.S.; Yao, Y. Structure design and motion planning of bolt mesh transport robot for coal mine tunneling. Coal Eng. 2021, 53, 175–180. (In Chinese) [Google Scholar] [CrossRef]

- Mark, C.; Stephan, R.C.; Agioutantis, Z. Analysis of Mine Roof Support (AMRS) for US Coal Mines. Min. Metall. Explor. 2020, 37, 1899–1910. [Google Scholar] [CrossRef]

| Date | Site | Casualties | References |

|---|---|---|---|

| 4 January 2017 | Defeng County of Henan province | 12 deaths | [12] |

| 17 January 2017 | Shuozhou City of Shanxi province | 10 deaths | [13] |

| 11 November 2017 | Shenyang City of Liaoning province | 10 deaths and 1 injury | [14] |

| 12 January 2019 | Shenmu County of Shaanxi province | 21 deaths | [15] |

| 19 June 2019 | Ningwu County of Shanxi province | 6 deaths | [16] |

| 28 October 2019 | Nandan County of Guangxi province | 2 deaths and 11 missing | [17] |

| 29 February 2020 | Qujing City of Yunnan province | 5 deaths | [18] |

| 26 May 2021 | Weishan County of Shandong province | 3 deaths and 3 injuries | [19] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-J.; Zhao, L.-S.; Xu, Y.-S. Analysis of Characteristics of Roof Fall Collapse of Coal Mine in Qinghai Province, China. Appl. Sci. 2022, 12, 1184. https://doi.org/10.3390/app12031184

Wang Y-J, Zhao L-S, Xu Y-S. Analysis of Characteristics of Roof Fall Collapse of Coal Mine in Qinghai Province, China. Applied Sciences. 2022; 12(3):1184. https://doi.org/10.3390/app12031184

Chicago/Turabian StyleWang, Ya-Jie, Lin-Shuang Zhao, and Ye-Shuang Xu. 2022. "Analysis of Characteristics of Roof Fall Collapse of Coal Mine in Qinghai Province, China" Applied Sciences 12, no. 3: 1184. https://doi.org/10.3390/app12031184

APA StyleWang, Y.-J., Zhao, L.-S., & Xu, Y.-S. (2022). Analysis of Characteristics of Roof Fall Collapse of Coal Mine in Qinghai Province, China. Applied Sciences, 12(3), 1184. https://doi.org/10.3390/app12031184