Abstract

Warm-Mix-Asphalt (WMA) allows aggregates to be coated with asphalt binder at a temperature lower than the Hot-Mix-Asphalt (HMA) temperatures by using additives that make the asphalt mixtures more workable and the asphalt binder viscosity reduced. Due to the cost and environmental advantages of WMA, it is now more frequently employed in the mixtures of asphalt pavement. WMA with two percentages of zeolite (0.3% and 0.5%) is used in this research. The optimum asphalt content of WMA mixtures has a lower value compared to the HMA mixture. According to Marshall Stability’s findings, the HMA has a higher value of stability, whereas the WMA mixtures for both percentages of zeolite have a lower value of stability. WMA mixture with 0.5% zeolite has a higher Marshall Flow value, which is followed by zeolite at 0.3% and the lower value of flow was for HMA. The resilient modulus for both HMA and WMA was determined. The findings indicate that, for the two percentages of zeolite, the resilience modulus of the WMA mixtures was lower than that of the HMA. Additionally, the findings indicate that the WMA has a high potential resistance against rutting that competes with the HMA mixture.

1. Introduction

One of the most significant issues and obstacles that people globally must overcome is the environment, including global warming and energy use [1,2]. Significant fuel and energy use, which results in pollutant emissions, is a factor with flexible pavement, which largely uses HMA [2]. Warm-mix asphalt (WMA) was created by road builders and pavement scientists to replace hot-mix asphalt (HMA) to lessen these environmental issues [1]. There are numerous challenges in asphalt pavements [3], and it is necessary to create bitumen with improved properties in comparison to traditional asphalt binder [4]. Now, it is possible to prepare the HMA at lower temperatures without impacting the performance of the mixture by making use of a variety of products that can lower the temperature. Up to 20% of production, temperatures can be decreased by these innovative items. Because there is more knowledge on climate change, transportation industry infrastructure professionals have been searching for ways to enhance current systems to protect natural resources and reduce energy emissions [5].

Numerous benefits of warm mix asphalt include the reduction of energy use, fuel burn emissions, and volatiles produced by heated asphalt binder at the paving site’s manufacturing facility [6]. WMAs have several advantages compared with HMAs, although the advantages of WMA mixtures rely on the production process. It is therefore challenging to categorize various benefits [7]. However, warm-mix asphalt has the following advantages [8]:

- Benefits for the environment because it was found that WMA’s lower production temperature might greatly have fewer pollutants, gases, odors, and fume emissions, which would minimize global warming.

- It makes it possible to use more waste resources, like recycled asphalt pavement (RAP) and slower bitumen aging.

- Longer haul distances, quicker pavement cooling, and improved workability are advantages of paving since bitumen viscosity is lower at paving temperature.

- Benefits for the economy include lower energy use and lower wear on asphalt plants owing to lower temperatures. Because WMA uses 20–75% less energy during manufacture than HMA does, using it can result in lower production costs.

- Additionally, it was shown that energy consumption is influenced by production temperature, the energy source, moisture content, and fuel type, heat capacity of the material.

- The asphalt mixture’s compacted state and workability are enhanced since WMA’s additives make the asphalt binder less viscous.

Using a WMA mixture could enable cold-weather paving because the mixing temperature of the mixture is closer to that of the surrounding air The reduction in combined heat is hence less extreme. Because paving and compaction can be done with greater time as well as longer hauling distances as a result of the closeness of the temperatures, the paving season is prolonged [9,10,11].

The WMA plants can be situated close to cities because they produce no noise, fumes, or pollutants. Additionally, if the plants were located at an appropriate distance from the construction sites, non-attainment areas might be paved [12,13,14].

Additionally, because of the slight temperature differential and the shorter cooling period following construction, traffic lanes can be opened sooner [15,16]. This is especially desired when rehabilitating airports and heavily traveled roadways [16].

Zeolites, organic additives, chemical modifiers, and foaming devices are the four different kinds of WMA technology [17]. Technologies for warm mix asphalt have been utilized successfully in Europe for more than ten years. The effectiveness of WMA in the lab and the field has been the subject of numerous investigations. In the USA, WMA has received attention from many state DOTs. When it comes to performing research on various WMA technologies, At Auburn University, the National Center for Asphalt Technology (NCAT) has been a pioneer. Many innovations, including Sasobit, Evotherm, and Zeolite have been investigated in the lab [16]. NCAT conducted in situ investigations in numerous states between 2006 and 2010 in collaboration with each state’s DOT. They have discovered generally encouraging results in their performance assessment of WMA combinations.

The NCHRP project 09-43 was carried out to offer suggestions for mixed design methods for WMA [18]. The main outcome of the research effort was that a standalone WMA mix design technique was not required. According to the NCHRP 09-43, the project’s investigation of the content of the binder, HMA and WMA mixtures made with similar aggregates and binders did not have significantly different average design binder contents [19].

Bennert et al. [20] estimated the compatibility and workability of WMA mixes. A comparison of the Superpave Gyratory Compactor and Marshall compactor’s compaction rates revealed that mixes with greater levels of WMA additions compacted more readily than a control mixture without WMA additives when the mixture temperature was reduced to below (110–115) °C.

Mixing temperatures which has lower value could cause more water to get trapped in the aggregate Due to concerns about an increase in moisture-induced damage, this raises a red flag, questioning how well these blends perform in the field. These problems are exacerbated by WMA techniques that add chemicals or foam to mixtures to boost moisture content. Additionally, lower mixing temperatures will cause the mixes to become less oxidatively hardened, although this diminished hardening may increase the mixes’ resistance to rutting [17].

In the case of WMA with zeolites, Woszuk [21] stated that the findings of the chemical and physical tests are consistent the stiffness of the mix, its resistance to water, and its resistance to rutting. These measurements unquestionably depend on the materials being utilized (the asphalt, aggregate type, and zeolite), in addition to the testing procedure and parameters, at least in part.

Alumino-silicates of alkali metals make up the synthetic zeolite which is known as Aspha-min. About twenty percent of the product comprises water that is released when the temperature rises. Zeolite can absorb and lose water without damaging its crystal structure. It is usually used by a percentage of weight-based of 0.3 percent by the total mix weight. Synthetic zeolite releases a low amount of water when the temperature is high, approximately between (100–200) °C, which causes a little asphalt binder volume increase which leads to a depression in the value of viscosity [22].

The rutting distress can be defined as the distortion of the surface of the asphalt pavement due to the applied load [23]. Reduced temperature results in less oxidative binder hardening, which could result in more rutting and less stability in hot weather [24]. Despite this fact, the earlier lab tests and the observations in the field show that the mixes of WMA have rutting performance comparable to the mixes of HMA [25].

Woszuk [21] stated that multi-factor variance research revealed that the inclusion of zeolite has no impact on the modulus of stiffness and wheel-tracking of mixed asphalt. The findings of the HMA samples compacted at 149 °C were compared, and it was discovered that the resistance o rutting had increased and WMA with zeolite compacted at 129 °C in conjunction with PG 58-28 alone and limestone aggregate. The stiffness modulus value was related to the type of asphalt being used. The type of aggregate and asphalt employed, as well as the compaction temperature, to a lesser extent, determined the resistance to rutting [25].

The asphalt binder aging tends to be reduced as a result of the WMA mixture’s low compaction temperature. The density improvement of the compacted mixtures may somewhat counterbalance this drop, which could tend to increase the possibility of rutting [26]. Hurley and Prowell [25,27] evaluated the WMA using the Asphalt Pavement Analyzer (APA) test and showed the applicability of using zeolite and synthetic wax in different processes. The findings indicate that the rutting potential of the asphalt mixtures is not increased by including these elements.

Although utilizing WMA technology can greatly contribute to environmentally friendly building practices, Iraqi mixtures must be assessed using well-known WMA methods to produce the performance data required to construct asphalt concrete pavements with WMA. Most Iraqi roads are paved with HMA mixtures, and WMA mixtures are rarely used, so the purpose of this study is to evaluate a laboratory study’s performance and suitability to determine whether zeolite may be used in conventional pavement and environmental conditions typically found in Iraq in comparison to the HMA using (0.3 and 0.5) percent of zeolite by total mix weight and using local Iraqi paving materials. The two mixtures, HMA and WMA, for the two percentages of zeolite will be assessed using the Marshall Stability, Marshall Flow, resilient modulus, and rutting tests.

2. Materials and Methods

Asphalt binder, aggregate, and mineral filler are local Iraqi materials that were employed in this research. To form the WMA, the zeolite was used in two percentages (0.3 and 0.5) % by the mixture weight The zeolite material, mineral filler, coarse and fine aggregate, and asphalt binder’s physical characteristics are presented in Table 1, Table 2, Table 3 and Table 4.

Table 1.

Physical characteristics of the asphalt binder.

Table 2.

Physical properties of aggregate.

Table 3.

Cement mineral filler physical properties.

Table 4.

Zeolite physical properties.

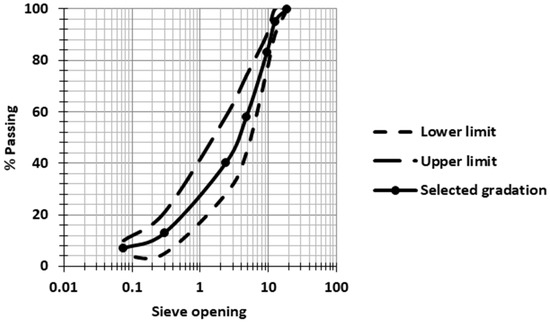

A wearing layer aggregate grade with a nominal maximum aggregate sieve size of 12.5 mm is used to grade the aggregate. Figure 1 and Table 5 present the selected gradation and limitations according to Iraqi specifications (SCRB, 2003) [28].

Figure 1.

Grading of aggregate per Iraqi SCRB standards [28].

Table 5.

Selected gradation of aggregate.

2.1. Preparation of Specimens

Cylindrical samples were prepared for HMA and WMA specimens with Marshall specimen dimension, which is (100 mm × 63.5 mm) (diameter × height) The device of Marshall compactor was used for compacting the samples by applying 75 blows on each face of the specimen according to the ASTM D6926-10 specification. The temperature of mixing and compacting ranges of HMA samples was specified by measuring the viscosity of asphalt binder at 135 °C and 165 °C based on ASTM D2493 using the method of Equiviscous [29]. The temperatures for mixing and compacting were set to be equivalent to the viscosities of the asphalt binder, which were 0.17 ± 0.02 Pas. sec. and 0.28 ± 0.03 Pas. sec., which were (155 and 145) respectively.

In this investigation, a mixture of WMA was compacted at 120 °C after mixing at 135 °C to maintain homogeneity. Based on the literature, experts, and the relevant recommendations of the WMA technology makers, these temperatures were chosen [16,17,29,30,31,32,33]. This method is consistent with the WMA design approach outlined in NCHRP Report 714 [34]. This drop in temperature causes the bitumen’s viscosity to decrease, and after crystallization, the bitumen becomes more rigid, which improves the asphalt’s resistance to deformation.

The amount of the optimum asphalt binder content is determined using the volumetric properties of the WMA blends. This will increase the efficiency of the additives of warm mix and lessen the effect of aging [17,35,36].

2.2. Resilient Modulus Test (Mr)

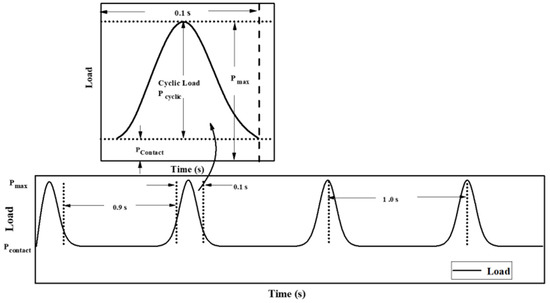

By employing this test, a non-destructive test, to calculate the stress-strain asphalt specimens’ behavior, the elastic properties of the mixture can be determined. The findings of the Mr test provide a fundamental constitutive relationship between the stiffness and stress condition of the pavement material, which may be used in the multilayer pavement systems structural analysis and the methodologies of pavement design. Based on the ASTM D7369-20 [37] specification, the resilient modulus test is applied for both the WMA mixture and the HMA mixture. The samples were tested at the following temperatures: 20, 25, 30, and 40 °C. Using a Marshall compactor, a cylindrical specimen of 100 mm in diameter and 63.5 mm in height was created. The specimen should be conditioned to the test temperature before testing and placed in a temperature chamber. A temperature chamber that is included with the test apparatus is used to condition specimens before testing. Repeated load is applied to the conditioned cylindrical sample, which has a haversine shape, as presented in Figure 2. The applied load, as shown in the figure, had a 1 Hz frequency and was applied for 0.1 s of load time and 0.9 s of a rest period.

Figure 2.

Typical load-time cycles with rest periods during Mr test.

2.3. Wheel Track Test

In a roller compactor device, slab specimens measuring (400, 300, 50) mm were created to be tested in a wheel track device to determine the depth of rutting according to BS EN 12697-22:2020. Before testing the slab, it should be put in the control cabinet of temperature for two hours to condition the slab at the temperature test, which is 40 °C. The test time is continued for 10,000 cycles of loading or till the rut depth reaches 20 mm, whichever is shorter.

3. Results and Discussions

3.1. Mechanical Properties

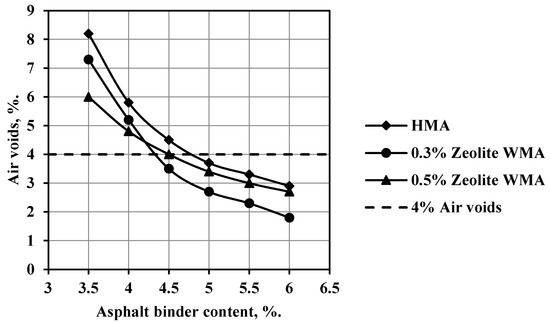

The Marshall technique is used to compute the optimum amount of the content of asphalt binder for the two mixtures HMA and WMA with 4% air voids as the standard for establishing this number. Fifty-four Marshall cylindrical samples were prepared and divided into eighteen samples of asphalt mixture, three for each asphalt content, to take the mean value of the air voids. The relationship between the air spaces and the asphalt binder contents is shown in Figure 3.

Figure 3.

Optimum asphalt binder content for 4% air voids.

Figure 3 demonstrates that the optimum amount of the asphalt binder content for HMA and WAM with 0.3% and 0.5% zeolite is 4.7%, 4.3%, and 4.5%, respectively. The WMA that contains 0.3% zeolite has the lowest value of asphalt binder content.

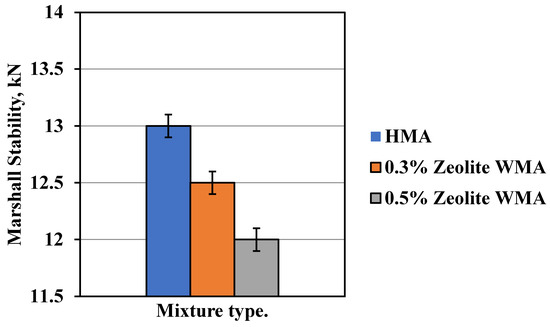

Investigations of the mechanical properties of the WMA and HMA were conducted by using the test of Marshall Stability and flow using ASTM D6927-10 specification. To determine the average value for Marshall Stability and Flow, three of the nine cylinder-shaped Marshall specimens were constructed for each type of asphalt mixture. Figure 4 presents the Marshall Stability for both hot and warm mixtures. The figure shows that both mixtures HMA and WMA have a significant value of stability which is higher than 8 kN, the minimum required value for the wearing asphalt layer according to Iraqi specifications [28], which is a good indication for the WMA. The highest value of stability is for the HMA, followed by the 0.3% zeolite WMA and the lowest value was for the 0.5% zeolite WMA because the Marshall Stability is highly affected by the mixing and compaction temperatures. This result complies with Vaitkus et al. [25] and Almusawi [38]. From the error bars presented in the figure, the results are reliable and no overlaps between the error bars for all results that’s means there is a significant difference between the Marshall Stability of the two types of mixtures (WMA and HMA).

Figure 4.

Results of Marshall Stability.

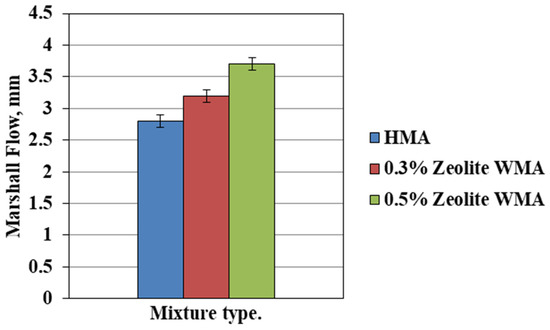

Figure 5 presents the Marshall flow, and the required range of the flow is (2–4) mm according to Iraqi specifications [13]. As presented in the figure, the flow values for all mix types are within the required range of the flow and are considered satisfactory. The figure shows that the HMA has the lowest Marshall Flow value, and the increase in zeolite additive concentration increases the flow values. The result complies with Vaitkus et al. [39]. Error bars demonstrate the validity of the data, and as there are no overlaps between the bars, the WMA and HMA flow mixtures differ significantly from one another.

Figure 5.

Marshall Flow results.

3.2. Resilient Modulus Test (Mr) Results

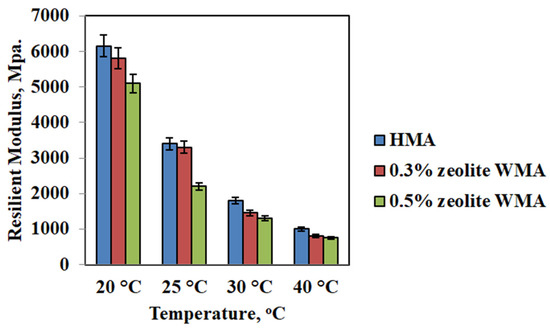

Figure 6 displays the findings of the resilient modulus values for the 12 prepared cylindrical specimens, which are tested at four test temperatures (20, 25, 30, and 40) °C subjected to a haversine waveform of 1 Hz frequency which has 0.1 s loading duration and 0.9 s rest period. As seen in the figure, a temperature rise has a considerable impact on the resilient modulus. The findings show that the WMA mixtures of two percentages of zeolite have the lowest value of resilient modulus, whereas the HMA mixture has a greater value of the resilient modulus which means that the WMA mixture is affected greatly by the temperature increase like the HMA mixture. The WMA mixture that has 0.3% zeolite shows a higher value of the resilient modulus than the 0.5% zeolite specimen. Despite this result, the WMA shows a good resilient modulus that can compete with the HMA. The aggregate skeleton of the compacted specimen may be a reason for this result. The HMA specimen compacted at a higher compaction temperature than the WMA specimens. Given that loads can be transferred from one aggregate to another more successfully with a more durable aggregate skeleton or aggregate-aggregate connection, the foaming effect of zeolite addition results in a low increase in the asphalt binder volume, which enables sufficient coating of the surface of aggregate during the mixing process at a lower temperature and may raise the modulus of the asphalt mixture. The higher resilient modulus leads to thinner asphalt layers in the first phase of the design, which produces a more economical pavement design. This result complies with Vaiana [40].

Figure 6.

Resilient modulus result values.

There is no statistical difference, as seen in Figure 6, between HMA and 0.3% of zeolite WMA at low temperatures (20 and 25) °C whereas the 0.5% zeolite WMA mixture has a significant difference from HMA and 0.3% zeolite WMA mixture. At higher temperatures (30 and 40) °C there is a significant difference between the HMA mixture and the WMA mixtures and no significant difference between the two percentages of zeolite.

3.3. Results of the Wheel Track Test

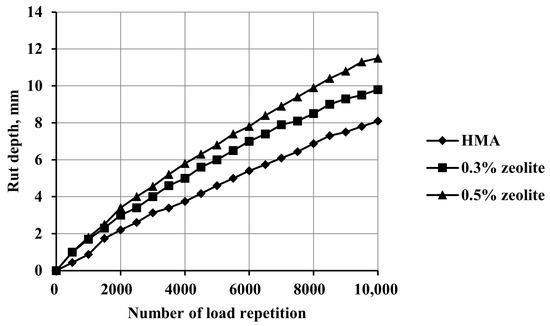

Figure 7 shows the wheel track results for the three slab samples of the HMA mixture and the two percentages of zeolite WMA mixtures to determine the depth of rutting for the WMA and HMA laboratory mixtures. A 40 °C test temperature was used for the experiment. The slab specimen test continued until the depth of rutting reached 20 mm, or the cycles of the loaded wheel reached cycles, whichever happened before. For all examined slab specimens, the rut depth rose as the cycle load increased, as seen in the figure.

Figure 7.

Rut depth result values at 40 °C.

The HMA mixtures show a better rutting resistance than the WMA of two percentages of zeolite because the rut depth is lower than the WMA samples. Despite this result, the WMA shows good resistance to rutting that competes with the HMA. Although the mixing and compaction temperatures of the WMA samples are lower than those of the HMA sample, the addition of zeolite has enhanced the mixture’s compactibility and workability and reduced the air voids contents. Additionally, the asphalt binder volume slightly increases when the zeolite is added, which enables proper coating of the surface of the aggregate at a lower temperature when mixing. For all these reasons, the WMA appears to be competing with HMA. This result complies with Xie et al. [41], Wen [42], Piccone, et al. [43], and Asmael [44].

It is recommended to use 0.3% zeolite for generating WMA since it has a lesser rut depth than 0.5% zeolite. It can be concluded from the wheel track test that the WMA mixture has a good rutting resistance performance as compared with HMA mixtures.

4. Conclusions

This study compares WMA mixes to HMA mixes commonly used in Iraq and evaluates WMA utilizing two zeolite percentages (0.3% and 0.5%) by weight of the whole mix. The research’s findings led to the following conclusions:

- The optimum asphalt binder content decreases by using zeolite to produce the WMA mixtures. The reduction is more sensible when using 0.3% of zeolite; the reduction is 0.4% compared to the HMA mixture. This reduction can be considered a benefit in the initial cost of the production of the WMA by using a zeolite additive.

- All mixtures satisfied the Iraqi specification limits of Marshall Stability and flow. HMA has a more Marshall Stability value than the WMA, whereas the flow value is lower than the WMA.

- The resilient modulus of the WMA shows lower values than the HMA.

- Statistically, there is no difference between HMA and 0.3% of zeolite WMA at low temperatures (20 and 25) °C, whereas the 0.5% zeolite WMA mixture has a significant difference from HMA and 0.3% zeolite WMA mixture.

- At high temperatures (30 and 40 °C), there is a substantial difference between the HMA combination and the WMA mixtures, but there is no significant difference between the two zeolite percentages.

- The rut depth for WMA is greater than the HMA for both zeolite percentages. Despite this result, the WMA mixtures show a good performance for both two percentages of zeolite. Rutting resistance performance for the WMA mixture competes with the HMA mixture, indicating that the WMA mixture has good resistance to rutting.

- In all test findings, 0.3% content of zeolite performed better than 0.5% content of zeolite, so it is recommended to use the 0.3% zeolite for the production of WMA mixtures in Iraq.

Author Contributions

Conceptualization, M.Y.F.; methodology, M.M.H. and M.Y.F.; validation, M.M.H. and M.Y.F.; formal analysis, M.Y.F.; investigation, M.M.H.; resources, M.M.H.; data curation, M.M.H.; writing—original draft preparation, M.M.H.; writing—review and editing, M.M.H. and M.Y.F.; visualization, M.M.H.; supervision, M.Y.F.; project administration, M.M.H.; funding acquisition, Not applicable. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that have been used are confidential.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Milad, A.; Babalghaith, A.M.; Al-Sabaeei, A.M.; Dulaimi, A.; Ali, A.; Reddy, S.S.; Bilema, M.; Yusoff, N.I.M. A Comparative Review of Hot and Warm Mix Asphalt Technologies from Environmental and Economic Perspectives: Towards a Sustainable Asphalt Pavement. Int. J. Environ. Res. Public Health 2022, 19, 14863. [Google Scholar] [CrossRef] [PubMed]

- Alsolieman, H.A.; Babalghaith, A.M.; Memon, Z.A.; Al-Suhaibani, A.S.; Milad, A. Evaluation and Comparison of Mechanical Properties of Polymer-Modified Asphalt Mixtures. Polymers 2021, 13, 2282. [Google Scholar] [CrossRef] [PubMed]

- Akram, H.A.; Hilal, M.M.; Fattah, M.Y. Numerical Simulation of the Effect of Repeated Load and Temperature on the Behavior of Asphalt Layers. Eng. Technol. J. 2022, 40, 769–778. [Google Scholar] [CrossRef]

- Fakhri, M.; Ghanizadeh, A.R.; Omrani, H. Comparison of Fatigue Resistance of HMA and WMA Mixtures Modified by SBS. Procedia—Soc. Behav. Sci. 2013, 104, 168–177. [Google Scholar] [CrossRef]

- Vega-Araujo, D.; Martinez-Arguelles, G.; Santos, J. Comparative life cycle assessment of warm mix asphalt with recycled concrete aggregates: A Colombian case study. Procedia CIRP 2020, 90, 285–290. [Google Scholar] [CrossRef]

- Goh, S.W.; You, Z. Resilient Modulus and Dynamic Modulus of Warm Mix Asphalt. In GeoCongress 2008: Geosustainability and Geohazard Mitigation; American Society of Civil Engineers: New York, NY, USA, 2008; pp. 1000–1007. [Google Scholar]

- Abdulkhabeer, W.N.; Fattah, M.Y.; Hilal, M.M. Characteristics of asphalt binder and mixture modified with waste polypropylene. Eng. Technol. J. 2021, 39, 1224–1230. [Google Scholar] [CrossRef]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Aurilio, R.M.; Aurilio, M.; Baaj, H. The Effect of a Chemical Warm Mix Additive on the Self-Healing Capability of Bitumen. J. Test. Eval. 2021, 50, 1775–1782. [Google Scholar]

- Hasan, M.R.M.; You, Z.; Yang, X. A comprehensive review of theory, development, and implementation of warm mix asphalt using foaming techniques. Constr. Build. Mater. 2017, 152, 115–133. [Google Scholar] [CrossRef]

- Ranieri, V.; Kowalski, K.J.; Berloco, N.; Colonna, P.; Perrone, P. Influence of wax additives on the properties of porous asphalts. Constr. Build. Mater. 2017, 145, 261–271. [Google Scholar] [CrossRef]

- Kristjansdottir, O. Warm Mix Asphalt for Cold Weather Paving; University of Washington: Washington, DC, USA, 2006. [Google Scholar]

- Capitão, S.D.; Picado-Santos, L.G.; Martinho, F. Pavement engineering materials: Review on the use of warm-mix asphalt. Constr. Build. Mater. 2012, 36, 1016–1024. [Google Scholar] [CrossRef]

- Goh, S.W.; You, Z.; Van Dam, T.J. Laboratory evaluation and pavement design for warm mix asphalt. In Proceedings of the 2007 Mid-Continent Transportation Research Symposium, Ames, IA, USA, 16–17 August 2007; pp. 1–11. [Google Scholar]

- Zaumanis, M. Warm mix asphalt investigation. In Climate Change, Energy, Sustainability and Pavements, Green Energy and Technology; Gopalakrishnan, K., Steyn, W., Harvey, J., Eds.; Green Energy and Technology Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Hurley, G.C.; Prowell, B.D. Evaluation of Potential Processes for Use in Warm Mix Asphalt. J. Assoc. Asph. Paving Technol. 2006, 75, 41–90. [Google Scholar]

- Malladi, H.; Ayyala, D.; Khosla, N.P.; Tayebali, A.A. Laboratory Evaluation of Warm Mix Asphalt Mixtures for Moisture and Rutting Susceptibility. ASCE J. Mater. Civ. Eng. 2015, 27, 04014162. [Google Scholar] [CrossRef]

- Bonaquist, R. NCHRP Report 691: Mix Design Practices for Warm Mix Asphalt; Transportation Research Board of the National Academies: Washington, DC, USA, 2011. [Google Scholar]

- Advanced Asphalt Technologies, LLC. NCHRP Report 714: Special Mixture Design Considerations and Methods for Warm Mix Asphalt: A Supplement to NCHRP Report 673: A Manual for Design of Hot Mix Asphalt with Commentary; Transportation Research Board of the National Academies: Washington, DC, USA, 2012. [Google Scholar]

- Bennert, T.; Reinke, G.; Mogawer, W.; Mooney, K. Assessment of workability and compactability of warm-mix asphalt. Transp. Res. Rec. J. Transp. Res. Board 2010, 2180, 36–47. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. A Review of the Application of Zeolite Materials in Warm Mix Asphalt Technologies. Appl. Sci. 2017, 7, 293. [Google Scholar] [CrossRef]

- Middleton, B.; Forfylow, R.W. Evaluation of Warm-Mix Asphalt Produced with the Double Barrel Green Process. Transp. Res. Rec. 2009, 2126, 19–26. [Google Scholar] [CrossRef]

- Hatem, N.S.; Hilal, M.M.; Fattah, M.Y. Finite Element Simulation of Repeated Loading Test of Asphalt Concrete. Eng. Technol. J. 2022, 40, 661–667. [Google Scholar] [CrossRef]

- Vargas-Nordcbeck, A.; Timm, D.H. Rutting characterization of warm mix asphalt and high RAP mixtures. Road Mater. Pavement Des. 2012, 13, 1–20. [Google Scholar] [CrossRef]

- Hurley, G.C.; Prowell, B.D. Evaluation of Aspha-Min® Zeolite for Use in Warm Mix Asphalt; NCAT Report; National Center for Asphalt Technology: Auburn, AL, USA, 2005. [Google Scholar]

- Prowell, B.D.; Hurley, G.C.; Crews, E. Field performance of warm-mix asphalt at National Center for Asphalt Technology test track. J. Transp. Res. Board 2007, 1998, 96–102. [Google Scholar] [CrossRef]

- Hurley, G.C.; Prowell, B.D. Evaluation of Sasobit for Use in Warm Mix Asphalt; NCAT Report; National Center for Asphalt Technology: Auburn, AL, USA, 2005; pp. 1–27. [Google Scholar]

- SCRB, General Specification for Roads and Bridges. Section R/9, Hot-Mix Asphalt Concrete Pavement, State Corporation of Roads and Bridges; Ministry of Housing and Construction: Baghdad, Iraq, 2003. [Google Scholar]

- Wasiuddin, N.M.; Selvamohan, S.; Zaman, M.M.; Guegan, M. Comparative Laboratory Study of Sasobit and Aspha-Min Additives in Warm-Mix Asphalt. Transp. Res. Rec. J. Transp. Res. Board 2007, 1998, 82–88. [Google Scholar] [CrossRef]

- Damm, K.; Abraham, J.; Butz, T.; Hildebrand, G.; Riebsehl, G. Asphalt Flow Improvers as Intelligent Fillers for Hot Asphalts—A New Chapter in Asphalt Technology. J. Appl. Asph. Bind. Technol. 2002–2004, 2, 36–69. [Google Scholar]

- Abbas, A.R.; Ali, A.W. Mechanical Properties of Warm Mix Asphalt Prepared Using Foamed Asphalt Binders; FHWA Report No: FHWA/OH-2011/06; Ohio Department of Transportation: Columbus, OH, USA, 2011. [Google Scholar]

- Mo, L.; Li, X.; Fang, X.; Huurman, M.; Wu, S. Laboratory investigation of compaction characteristics and performance of warm mix asphalt containing chemical additives. Constr. Build. Mater. 2012, 37, 239–247. [Google Scholar] [CrossRef]

- Almusawi, A.; Sengoz, B.; Topal, A. Investigation of Mixing and Compaction Temperatures of Modified Hot Asphalt and Warm Mix Asphalt. Period. Polytech. Civ. Eng. 2021, 65, 72–83. [Google Scholar] [CrossRef]

- Special Mixture Design Considerations and Methods for Warm-Mix Asphalt: A Supplement to NCHRP Report 673: A Manual for Design of Hot-Mix Asphalt with Commentary; NCHRP Report 714; Transportation Research Board: Washington, DC, USA, 2012.

- Topal, A.; Sengoz, B.; Kok, B.V.; Yilmaz, M.; Dokandari, P.A.; Oner, J.; Kaya, D. Evaluation of mixture characteristics of warm mix asphalt involving natural and synthetic zeolite additives. Constr. Build. Mater. 2014, 57, 38–44. [Google Scholar] [CrossRef]

- Sengoz, B.; Topal, A.; Gorkem, C. Evaluation of natural zeolite as warm mix asphalt additive and its comparison with other warm mix additives. Constr. Build. Mater. 2013, 43, 242–252. [Google Scholar] [CrossRef]

- D7369-20; Standard Test Method for Determining the Resilient Modulus of Bituminous Mixtures by Indirect Tension Test. ASTM International: West Conshohocken, PA, USA, 2020.

- Vaitkus, A.; Čygas, D.; Laurinavičius, A.; Vorobjovas, V.; Perveneckas, Z. Influence of warm mix asphalt technology on asphalt physical and mechanical properties. Constr. Build. Mater. 2016, 112, 800–806. [Google Scholar] [CrossRef]

- Almusawi, A.; Sengoz, B.; Topal, A. Evaluation of mechanical properties of different asphalt concrete types in relation with mixing and compaction temperatures. Constr. Build. Mater. 2020, 268, 121140. [Google Scholar] [CrossRef]

- Vaiana, R.; Iuele, T.; Gallelli, V. Warm Mix Asphalt with Synthetic Zeolite: A Laboratory Study on Mixes Workability. Int. J. Pavement Res. Technol. 2013, 6, 562–569. [Google Scholar]

- Xie, Z.; Fan, W.; Wang, L.; Shen, J. The effectiveness of warm mix asphalt (WMA) additives affected by the type of aggregate and binder. Int. J. Pavement Res. Technol. 2013, 6, 554–561. [Google Scholar]

- Wen, H.; Wu, S.; Mohammad, L.N.; Zhang, W.; Shen, S.; Faheem, A. Long-Term Field Rutting and Moisture Susceptibility Performance of Warm-Mix Asphalt Pavement. J. Transp. Res. Board 2016, 2575, 103–112. [Google Scholar] [CrossRef]

- Piccone, G.; Loprencipe, G.; Almeida, A.; Fiore, N. Evaluation of the Performance of a Warm Mix Asphalt (WMA) Considering Aged and Unaged Specimens. Coatings 2020, 10, 1241. [Google Scholar] [CrossRef]

- Asmael, N.M.; Fattah, M.Y.; Kadhim, A.J. Exploring the Effect of Warm Additives on Fatigue Cracking of Asphalt Mixtures. J. Appl. Sci. Eng. 2020, 23, 197–205. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).