Bearing Fault Diagnosis of Split Attention Network Based on Deep Subdomain Adaptation

Abstract

1. Introduction

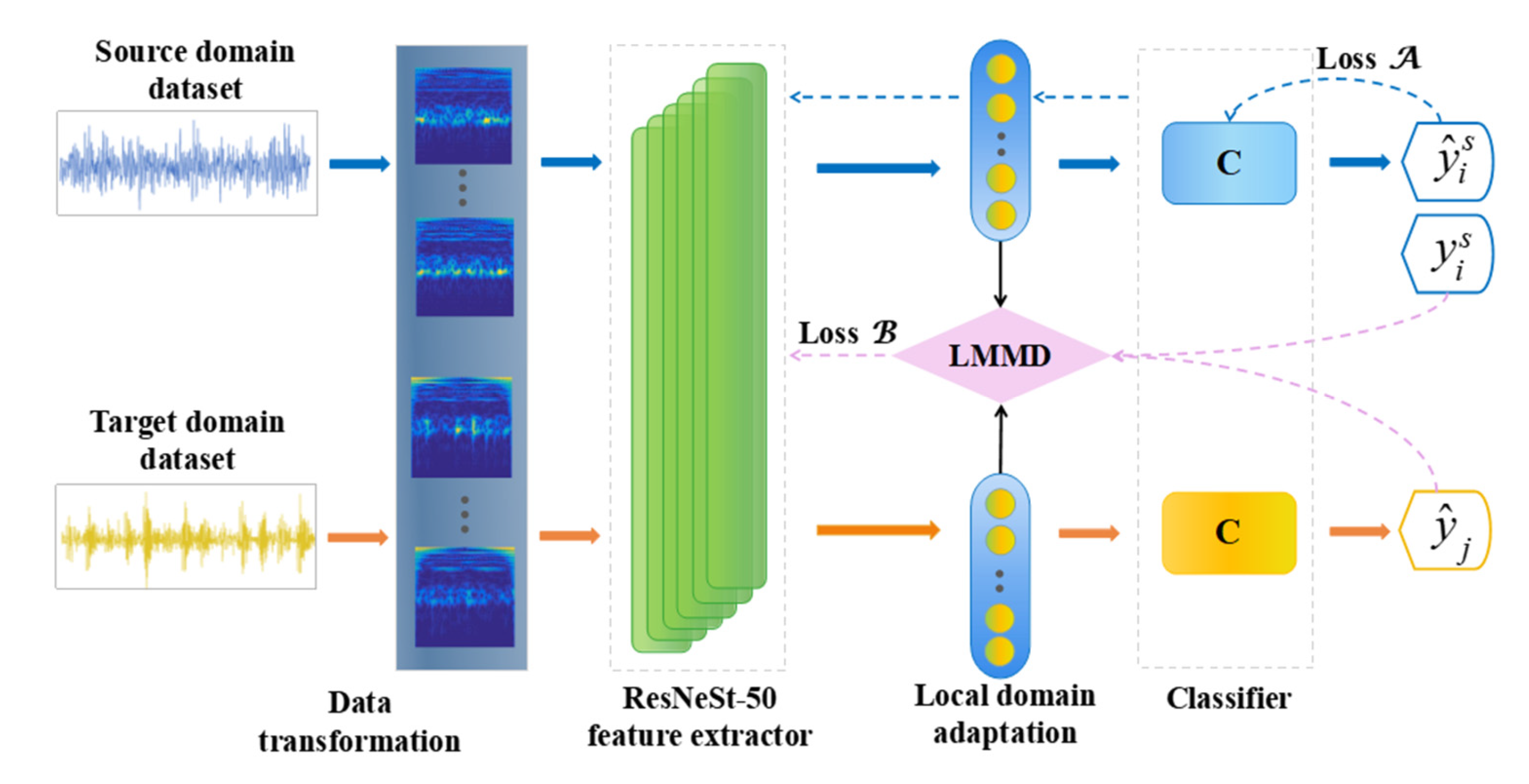

- The vibration signal was transformed into a time-frequency graph by continuous wavelet transform as the learning object of the network. Compared with the one-dimensional vibration signal, the time-frequency graph can not only provide the time-domain and frequency-domain characteristics of the fault, but also avoid the network to learn the single dimensional characteristics and affect the diagnosis accuracy.

- The split attention module was introduced into the feature extraction network, and the multi-channel structure and attention mechanism were adopted to enrich the feature map diversity and improve the ability of the network to learn fault features.

- LMMD was used to measure the difference of relevant subdomains in the source domain and target domain data, and the distribution of relevant subdomains under the same category was adjusted to capture the fine-grained information of each category, so as to achieve the subdomain alignment.

- The method performance was compared to several widely used intelligent bearing fault diagnosis methods, and its effectiveness was verified.

2. Related Works

2.1. Problem Description

2.2. ResNeSt-Split Attention Network

2.3. Subdomain Adaptation

3. Method

3.1. The SPDSAN Diagnostic Process

3.2. Target Optimization

- Minimizing the difference of between the real and the predicted label of the source domain sample. This will increase the classifier accuracy when diagnosing the source domain sample.

- Minimize the LMMD of between the source and the target domain.

4. Experiment and Analysis

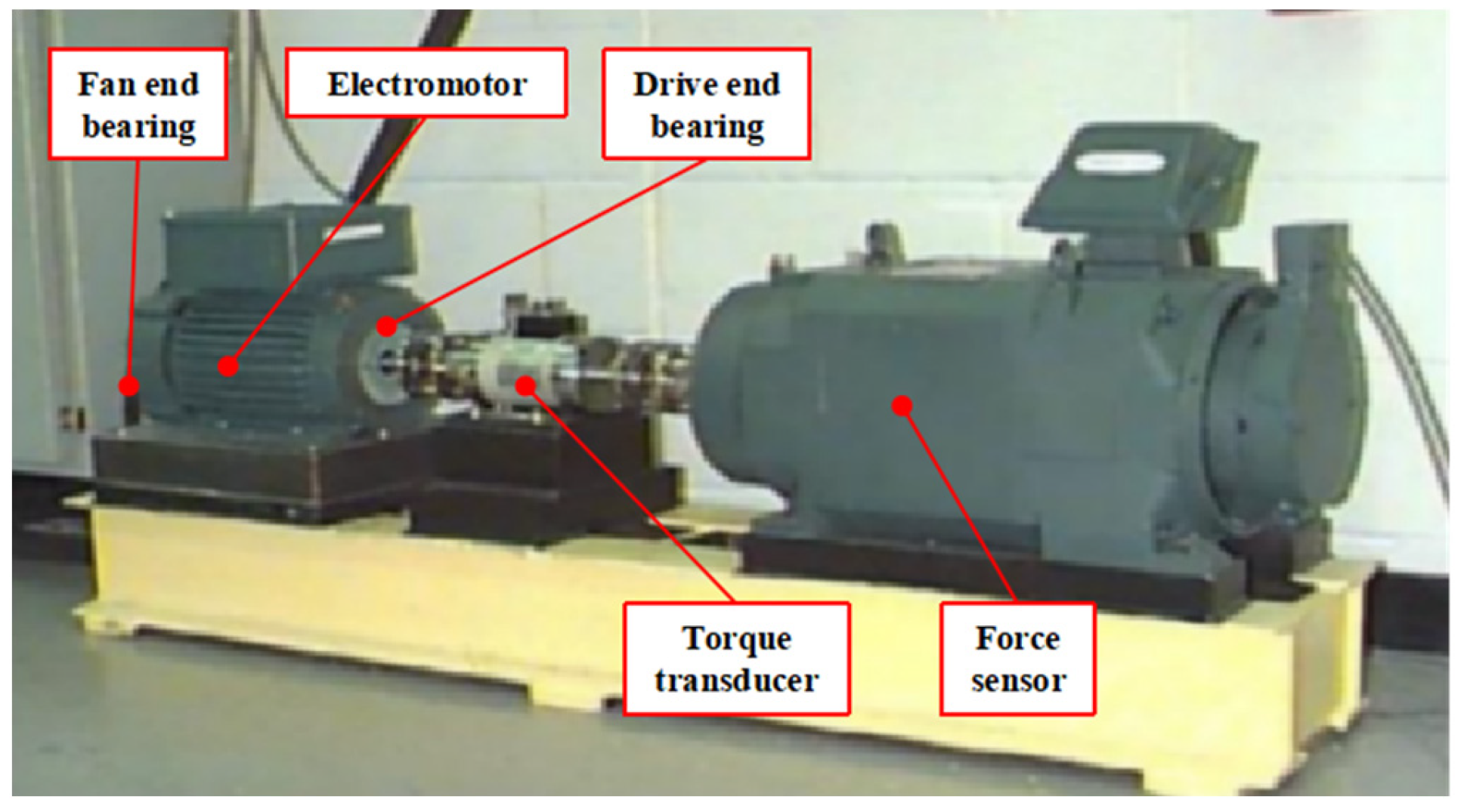

4.1. Introduction to the Fault Datasets

4.2. Build Experimental Datasets

| Healthy State | Fault Size | 0 HP | 1 HP | 2 HP | 3 HP | All |

|---|---|---|---|---|---|---|

| NA | 0 | 486 | 966 | 968 | 968 | 3388 |

| 0.1778 | 241 | 242 | 243 | 244 | 970 | |

| IF | 0.3556 | 242 | 242 | 242 | 242 | 968 |

| 0.5334 | 243 | 242 | 242 | 242 | 969 | |

| 0.1778 | 242 | 243 | 241 | 244 | 970 | |

| OF | 0.3556 | 242 | 242 | 242 | 242 | 968 |

| 0.5334 | 243 | 242 | 243 | 242 | 970 | |

| 0.1778 | 244 | 241 | 242 | 242 | 969 | |

| BF | 0.3556 | 242 | 243 | 242 | 243 | 970 |

| 0.5334 | 242 | 242 | 243 | 243 | 970 | |

| All | ---- | 2667 | 3145 | 3148 | 3152 | 12,112 |

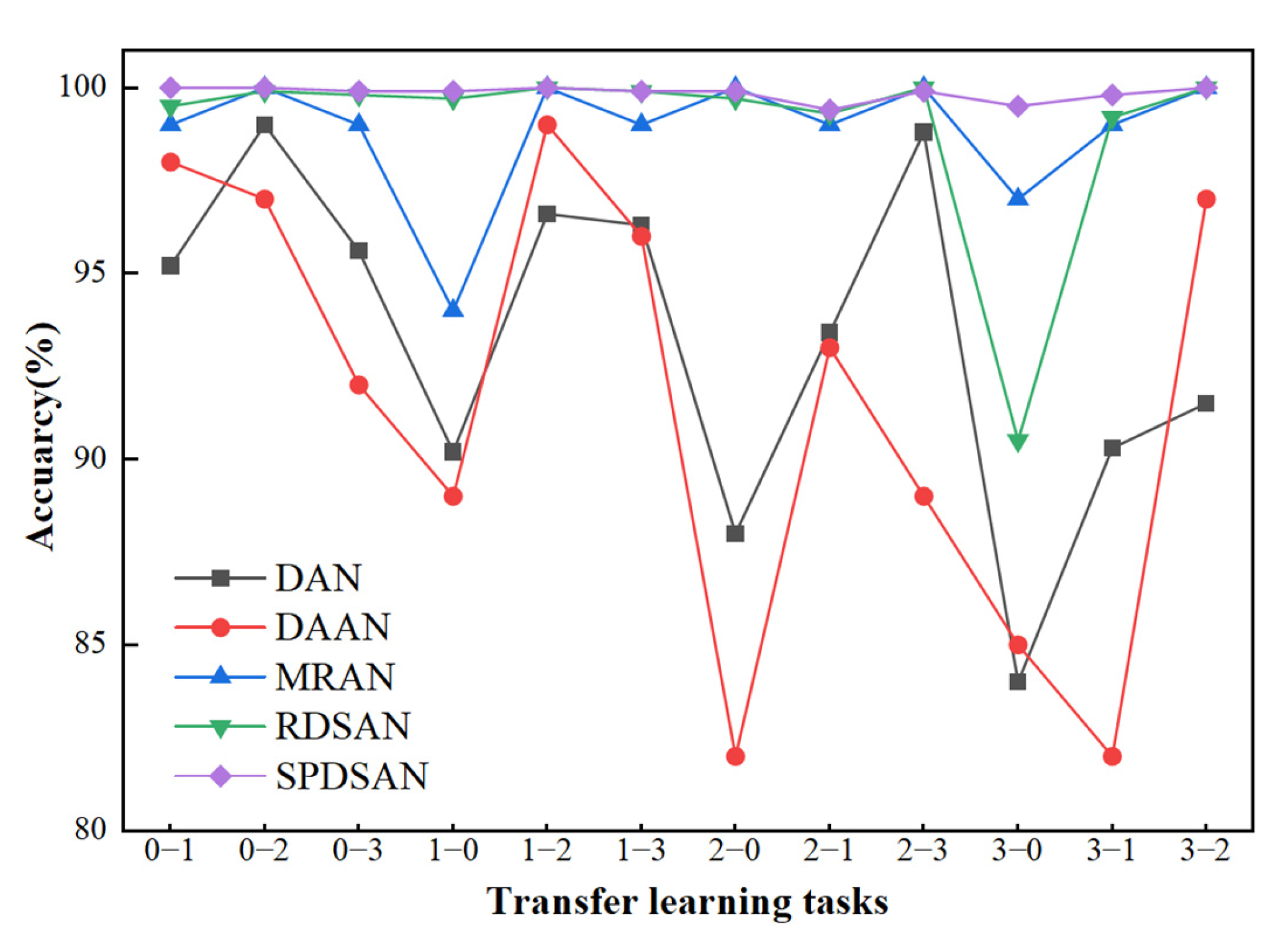

4.3. The Experimental Contrast

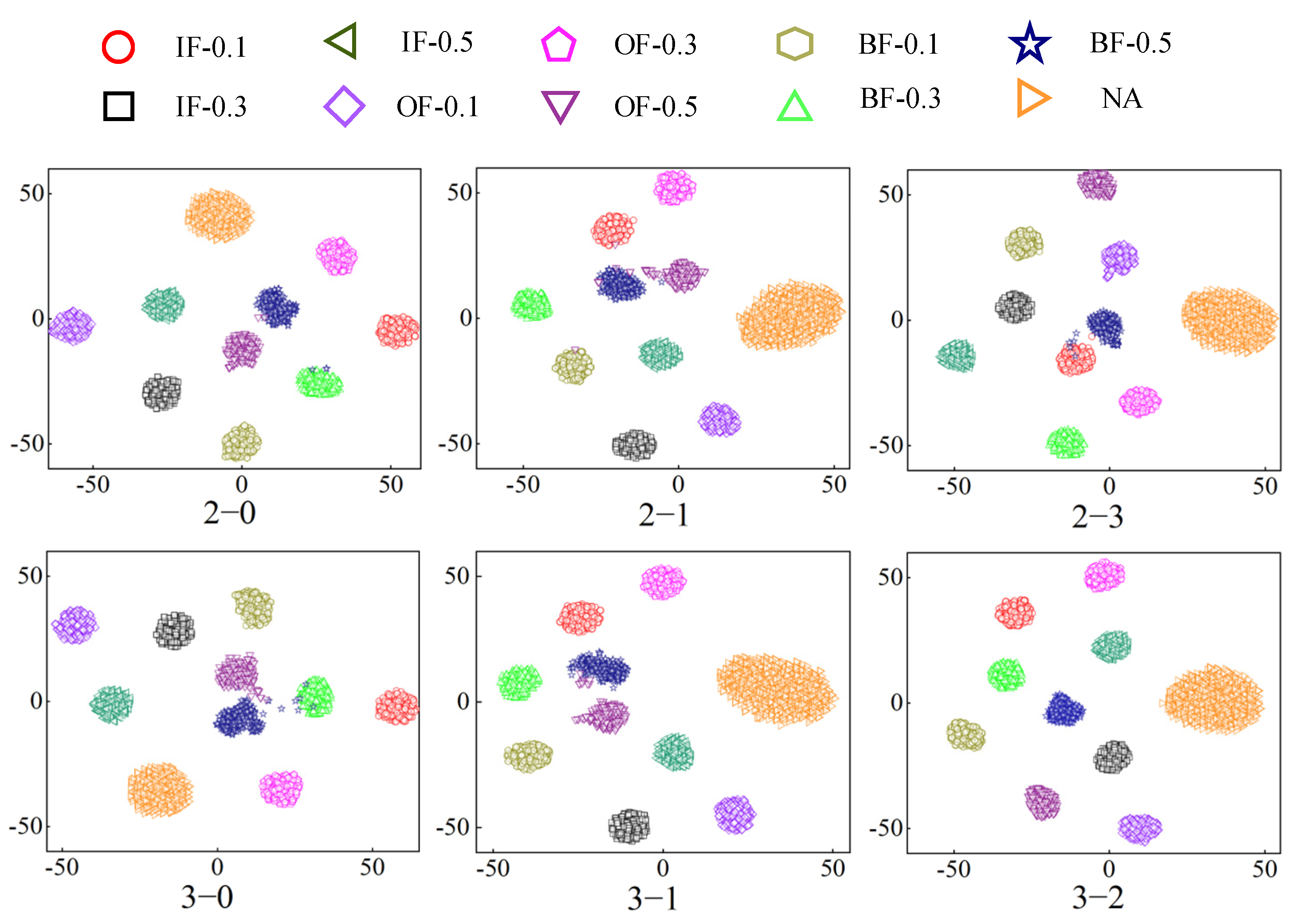

4.4. Feature Visualization

5. Conclusions

- Compared with ResNet, ResNeSt, which integrates multi-channel and split-attention mechanisms, can more fully learn the transferable fault features in samples. This facilitates subsequent transfer learning tasks.

- In the domain adaptation layer, the subdomain alignment method is used to reduce the distribution difference between the and the , and to reduce the misdiagnosis caused by the small subdomain distance caused by the global alignment. Therefore, it is only necessary to train the network with samples under one working condition to complete the fault diagnosis under all working conditions

- The comparison and analysis of different experimental results show that the proposed method has good generalization and robustness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qin, Y.F.; Shi, X.J. Fault Diagnosis Method for Rolling Bearings Based on Two-Channel CNN under Unbalanced Datasets. Appl. Sci. 2022, 12, 8474. [Google Scholar] [CrossRef]

- George, G.; Theodore, L.; Chrysostomos, D.S.; Vassilis, K. Bearing fault detection based on hybrid ensemble detector and empirical mode decomposition. Mech. Syst. Signal Process. 2013, 41, 510–525. [Google Scholar] [CrossRef]

- Ambrożkiewicz, B.; Litak, G.; Georgiadis, A.; Meier, N.; Gassner, A. Analysis of Dynamic Response of a Two Degrees of Freedom (2-DOF) Ball Bearing Nonlinear Model. Appl. Sci. 2021, 11, 787. [Google Scholar] [CrossRef]

- Huang, F.Y.F.; Chen, K.K.; Ma, H.; Li, X.; Han, H.Z.; Zhao, Z.F. Meshing and dynamic characteristics analysis of spalled gear systems: A theoretical and experimental study. Mech. Syst. Signal Process. 2020, 139, 106640. [Google Scholar] [CrossRef]

- Hu, B.Q.; Liu, J.; Zhao, R.Z.; Xu, Y.; Huo, T.L. A New Fault Diagnosis Method for Unbalanced Data Based on 1DCNN and L2-SVM. Appl. Sci. 2022, 12, 9880. [Google Scholar] [CrossRef]

- Arkadiusz, S.; Jacek, C.; Piotr, J. Detection of cylinder misfire in an aircraft engine using linear and non-linear signal analysis. Measurement 2021, 174, 108982. [Google Scholar] [CrossRef]

- Wang, H.T.; Guo, Y.Q.; Shi, L.C.; Pu, L.D.; Nie, Y.W.; Wu, W. Mathematical Problems in Engineering Research on Composite Fault Separation of Rolling Bearing Based on Functional Mixing Decoupling Model. Math. Probl. Eng. 2022, 2022, 9037709. [Google Scholar] [CrossRef]

- Almounajjed, A.; Sahoo, A.K.; Kumar, M.K. Diagnosis of stator fault severity in induction motor based on discrete wavelet analysis. Measurement 2021, 182, 109780. [Google Scholar] [CrossRef]

- Wu, J.; Guo, P.F.; Cheng, Y.W.; Zhu, H.P.; Wang, X.B.; Shao, X.Y. Ensemble Generalized Multiclass Support-Vector-Machine-Based Health Evaluation of Complex Degradation Systems. IEEE/ASME Trans. Mechatron. 2020, 25, 2230–2240. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Pan, H.Y.; Cheng, J.; Cheng, J.S. Non-parallelleast squares support matrix machine for rolling bearing fault diagnosis. Mech. Mach. Theory 2020, 145, 103676. [Google Scholar] [CrossRef]

- Sharanya, S.; Venkataraman, R. An intelligent Context Based Multi-layered Bayesian Inferential predictive analytic framework for classifying machine states. J. Ambient. Intell. Humaniz. Comput. 2020, 12, 7353–7361. [Google Scholar] [CrossRef]

- Vyas, N.S.; Satishkumar, D. Artificial neural network design for fault identification in a rotor-bearing system. Mech. Mach. Theory 2000, 36, 157–175. [Google Scholar] [CrossRef]

- Lei, Y.G.; Jia, F.; Lin, J.; Xing, S.B.; Ding, S.X. An Intelligent Fault Diagnosis Method Using Unsupervised Feature Learning Towards Mechanical Big Data. IEEE Trans. Ind. Electron. 2016, 63, 3137–3147. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Wang, Y.Z.; Wu, J.; Deng, C.; Hu, K. Sensor data-driven structural damage detection based on deep convolutional neural networks and continuous wavelet transform. Appl. Intell. 2021, 51, 5598–5609. [Google Scholar] [CrossRef]

- Wang, N.N.; Ma, P.; Zhang, H.L.; Wang, C. Fault diagnosis of rolling bearings based on multi-scale deep convolutional network feature fusion. China J. Sol. Energy 2022, 43, 351–358. [Google Scholar] [CrossRef]

- Wu, Y.C.; Zhao, R.Z.; Jin, W.Y.; Xing, Z.Y. Fault Identification Method Based on Convolutional Neural Network for Data Imbalance. China Vib. Test Diagn. 2022, 42, 299–307, 408. [Google Scholar] [CrossRef]

- Wang, Q.; Deng, L.F.; Zhao, R.Z. Based on improved one-dimensional convolutional neural networks of the rolling bearing fault recognition. China J. Vib. Shock. 2022, 9, 216–223. [Google Scholar] [CrossRef]

- Yang, B.; Lei, Y.G.; Jia, F.; Xing, S.B. An intelligent fault diagnosis approach based on transfer learning from laboratory bearings to locomotive bearings. Mech. Syst. Signal Process. 2019, 122, 692–706. [Google Scholar] [CrossRef]

- Yang, B.; Lei, Y.H.; Jia, F.; Li, N.P.; Du, Z.J. A Polynomial Kernel Induced Distance Metric to Improve Deep Transfer Learning for Fault Diagnosis of Machines. IEEE Trans. Ind. Electron. 2019, 67, 9747–9757. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Zhong, Q.; Huang, R.Y.; Liao, Y.X.; Li, J.P.; Li, W.H. Mechanical Intelligent fault Diagnosis based on Enhanced Migration Convolutional Neural Network. China J. Mech. Eng. 2021, 57, 96–105. [Google Scholar] [CrossRef]

- Cheng, C.; Zhou, B.T.; Ma, G.J.; Wu, D.R.; Yuan, Y. Wasserstein distance based deep adversarial transfer learning for intelligent fault diagnosis with unlabeled or insufficient labeled data. Neurocomputing 2020, 409, 35–45. [Google Scholar] [CrossRef]

- Gai, J.X.; Xue, X.F.; Wu, J.Y.; Nan, R.X. Cooperative spectrum sensing method based on deep convolutional neural network. China J. Electron. Inf. Technol. 2021, 43, 2911–2919. [Google Scholar] [CrossRef]

- He, K.M.; Zhang, X.Y.; Ren, S.Q.; Jian, S. Deep Residual Learning for Image Recognition. CoRR 2016, 12, 770–778. [Google Scholar] [CrossRef]

- Pan, Y.B.; Hong, R.J.; Chen, J.; Feng, J.S.; Wu, W.W. Performance degradation assessment of wind turbine gearbox based on maximum mean discrepancy and multi-sensor transfer learning. Struct. Health Monit. 2021, 20, 118–138. [Google Scholar] [CrossRef]

- Yaroslav, G.; Victor, S.L. Unsupervised Domain Adaptation by Backpropagation. CoRR 2014, 37, 1180–1189. [Google Scholar] [CrossRef]

- Case Western Reserve University Bearing Data Center Website. Available online: https://engineering.case.edu/bearingdatacenter/download-data-file (accessed on 1 April 2022).

- Zhang, L.; Liu, Y.Y.; Zhou, J.M.; Luo, M.X.; Pu, S.X.; Yang, X.T. An Imbalanced Fault Diagnosis Method Based on TFFO and CNN for Rotating Machinery. Sensors 2022, 22, 8749. [Google Scholar] [CrossRef]

- Li, Q.; Huang, Q.Y.; Yang, T.; Zhou, Y.; Yang, K.; Song, H. Internal defects inspection of arc magnets using multi-head attention-based CNN. Measurement 2022, 202, 111808. [Google Scholar] [CrossRef]

- Long, M.S.; Wang, J.M. Learning Transferable Features with Deep Adaptation Networks. CoRR 2015, 37, 97–105. [Google Scholar] [CrossRef]

- Yu, C.H.; Wang, J.D.; Chen, Y.Q.; Huang, M.Y. Transfer Learning with Dynamic Adversarial Adaptation Network. CoRR 2019, 38, 778–786. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Zhuang, F.Z.; Wang, J.D.; Chen, J.W.; Shi, Z.P.; Wu, W.J.; He, Q. Multi-representation adaptation network for cross-domain image classification. Neural Netw. 2019, 119, 214–221. [Google Scholar] [CrossRef]

- Laurens, V.D.M.; Geoffrey, H. Visualizing Data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

| Serial Number | Healthy State | Fault Size/mm |

|---|---|---|

| NA | Normal | 0 |

| IF-0.1 | Inner ring fault | 0.1778 |

| OF-0.1 | Outer ring fault | 0.1778 |

| BF-0.1 | Ball bearing fault | 0.1778 |

| IF-0.3 | Inner ring fault | 0.3556 |

| OF-0.3 | Outer ring fault | 0.3556 |

| BF-0.3 | Ball bearing fault | 0.3556 |

| IF-0.5 | Inner ring fault | 0.5334 |

| OF-0.5 | Outer ring fault | 0.5334 |

| BF-0.5 | Ball bearing fault | 0.5334 |

| Methods/Task | 0-1 | 0-2 | 0-3 | 1-0 | 1-2 | 1-3 | 2-0 | 2-1 | 2-3 | 3-0 | 3-1 | 3-2 | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DAN | 95.2 | 99.0 | 95.6 | 90.2 | 96.6 | 96.3 | 88.0 | 93.4 | 98.8 | 84.0 | 90.3 | 91.5 | 93.2 |

| DAAN | 98.0 | 97.0 | 92.0 | 89.0 | 99.0 | 96.0 | 82.0 | 93.0 | 89.0 | 85.0 | 82.0 | 97.0 | 91.6 |

| MRAN | 99.0 | 100 | 99.0 | 94.0 | 100 | 99.0 | 100 | 99.0 | 100 | 97.0 | 99.0 | 100 | 98.8 |

| RDSAN | 99.5 | 99.9 | 99.8 | 99.7 | 100 | 99.9 | 99.7 | 99.3 | 100 | 90.5 | 99.2 | 100 | 98.9 |

| SPDSAN | 100 | 100 | 99.9 | 99.9 | 100 | 99.9 | 99.9 | 99.4 | 99.9 | 99.5 | 99.8 | 100 | 99.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Pu, L. Bearing Fault Diagnosis of Split Attention Network Based on Deep Subdomain Adaptation. Appl. Sci. 2022, 12, 12762. https://doi.org/10.3390/app122412762

Wang H, Pu L. Bearing Fault Diagnosis of Split Attention Network Based on Deep Subdomain Adaptation. Applied Sciences. 2022; 12(24):12762. https://doi.org/10.3390/app122412762

Chicago/Turabian StyleWang, Haitao, and Lindong Pu. 2022. "Bearing Fault Diagnosis of Split Attention Network Based on Deep Subdomain Adaptation" Applied Sciences 12, no. 24: 12762. https://doi.org/10.3390/app122412762

APA StyleWang, H., & Pu, L. (2022). Bearing Fault Diagnosis of Split Attention Network Based on Deep Subdomain Adaptation. Applied Sciences, 12(24), 12762. https://doi.org/10.3390/app122412762