Abstract

Compared with other industries, construction has maintained one of the lowest growth rates in productivity and innovation over the last decades. Moreover, low compliance with schedule targets has remained a common issue throughout projects. Therefore, although methodologies developed have benefited productivity in design, construction and operation, meeting client and project objectives becomes challenging without properly integrating organization, information, systems and processes. This perspective introduces the Virtual Design and Construction (VDC) framework. First, this paper studies and reviews VDC since its creation at the Center for Integrated Facility Engineering (CIFE) of Stanford University in 2001. After that, a comprehensive bibliographical review of the VDC framework is presented and updated with examples of its application in construction projects, delving into its elements: Client Objectives, Project Objectives, Production Objectives, Controllable Factors, Integrated Concurrent Engineering (ICE), Building Information Modeling (BIM) and Project Production Management (PPM). Finally, the main benefits and project outcomes when applying the VDC framework are presented and discussed, followed by the conclusions and recommendations for future research.

1. Introduction

Construction is one of the most impactful sectors globally, contributing 13% to the global Gross Domestic Product (GDP) [1]. However, compared with the 2.8% growth in the overall economy and 3.6% in manufacturing, labor productivity growth in construction has increased by only 1% annually from 1995 to 2014 [1]. Hence, construction is considered one of the most stagnant industries in terms of productivity.

This lagging behind of the construction industry is commonly attributed to a lack of innovation and the nature of the industry. Blayse and Manley (2004) identified six main factors driving or hindering construction innovation: “clients and manufacturers, the structure of production, relationships between individuals and firms within the industry and between the industry and external parties, procurement systems, regulations/standards and the nature and quality of organizational resources” [2] (p. 144).

Moreover, the project-based nature of construction is seen as a hurdle to innovation and improvement because projects are usually short and of small scope in most firms or within the industry [3] and tend to be inappropriate to create the necessary conditions for innovation [2].

This low productivity and innovation in construction have various causes [4]. However, according to industry perspectives, the main barrier to innovation lies in industry fragmentation, described as differences in professional experience, work methods, information systems and other aspects that differ in the sector [4,5]. Furthermore, the inefficient and ineffective exchange of information between projects is a cause and effect of the construction industry’s fragmentation, which is also the consequence of poor collaboration and integration between construction actors and partners [6,7]. Unfortunately, until a few decades ago, no significant qualitative data could convince clients to try to reverse this fragmented condition [8].

The lack of integration in construction dates back to the 19th century, with the division between design and construction. This fact marked the dissociation between them, which had previously depended solely on the builder [5].

Numerous attempts have been made to reverse this situation. However, many of these efforts have focused for several decades on using new technologies to improve the current construction product or process because a greater competitive advantage was perceived when using such tools [9]. Nevertheless, until then, the integration of people represented a less relevant factor. For example, Luiten and Fischer [10] developed a framework for integrating design and construction. Kam and Fischer [11] also indicated the need for integrating available information and resources so that actors and stakeholders can evaluate interdisciplinary alternatives and make correct decisions.

Integrating design, construction and operation represent one of the major challenges in the sector. This challenge motivated the founding of the Center for Integrated Facility Engineering (CIFE) at Stanford University in 1988 and, consequently, the founding of VDC over a decade later as a proposal for a solution to the constant challenges and barriers experienced in the industry.

The origins of VDC and the methods, studies and principles that led to its development and updates are presented in this paper. A background (Section 2) review was carried out, starting with the beginnings of VDC (Section 2.1), followed by the interrelationship between the Product, Organization and Process (POP) components (Section 2.2). Next, the VDC framework is revised (Section 3), including its elements: BIM (Section 3.2), ICE (Section 3.3), PPM (Section 3.4), controllable factors and production objectives (Section 3.5) and client/business and project objectives (Section 3.6). Subsequently, a bibliographic review of VDC applications is depicted through seven successful case studies of VDC implementations in projects (Section 4 and Section 4.1, Section 4.2, Section 4.3, Section 4.4, Section 4.5, Section 4.6 and Section 4.7). Additionally, in Section 4.8, a discussion of production objectives is carried out from 279 VDC professional reports from Scandinavia and Latin America. Finally, the main benefits and project outcomes when applying the VDC framework are discussed in Section 5, followed by the conclusions and the recommendations for future research in Section 6 and Section 7, respectively.

2. Background

2.1. Beginnings of Virtual Design and Construction

VDC is a project management framework developed in 2001 at the Center for Integrated Facility Engineering (CIFE) at Stanford University [12]. VDC aims to improve construction projects’ planning, design, construction and operation through combined management via objectives, collaboration methods, production management and digital technologies. VDC is also a framework that motivates research and development strategies to improve reliability, productivity, innovation and sustainability in construction [13].

VDC’s origin is based on the composition of product, organization and process (POP) models [14,15]. Bicharra et al. [16] stated that construction projects are undertaken due to a client’s specific need. Designers should create a conceptual product solution (product model) based on this requirement. The product model will only become a reality through construction, so the construction plan (process model) is required for project success. Finally, the team should be hired and organized (organization model) to develop product and process models and execute plans to achieve the project’s objectives [16]. Thus, VDC was defined as the use of integrated multidisciplinary performance models of design-construction projects, including the product (building), organization (design–construction–operation team) and work processes, to support explicit and public business objectives [17].

VDC models are virtual in order to be more interactive, flexible and visual, as they can be projected anywhere and in multiple ways by any person involved and based on one’s need [18]. Moreover, these models represent the intentions and behaviors expected in the project [19]. According to CIFE, an integrated approach to such models is necessary to allow professionals to simulate the project in the form of POP to generate a fundamental change in the industry [20].

From a different perspective, a project manager (or team) can and should control three aspects of a project: the design of the product (P) to be built, the organization (O) that undertakes the design and construction and the design-construction process (P) that the organization must follow [12].

Product and process-related concepts, innovation, design, or modeling [9,21] were commonly used before VDC. During its early days, VDC addressed the product model (usually a 3D model) as the graphical representation of information regarding the form/scope of the project. In the case of the process, VDC prioritized 4D modeling, which integrated the spatial-temporal aspect of the project and allowed stakeholders to visualize the general plan or current state of construction [17].

However, one of VDC’s modern approaches is the organization model, which emerged from the need to solve industry fragmentation and integrate design and construction. VDC attributes much of its organizational focus to the influence of the work of Professor Raymond Levitt and his research team’s studies in the Virtual Design Team (VDT) during the 1990s [18]. The VDT model focused on analyzing the performance of a work team, given a particular organizational structure. In addition, VDT allowed for predictive calculations and provided communication tools to achieve the objectives proposed by the organization [22,23,24].

There is also the previous work of Martin Fischer regarding the integration of design and construction. The objectives have varied between defining integration [6], establishing different levels of integration [25] and reducing productivity inefficiencies caused by vertical and horizontal fragmentation in the organization [26].

The interactive workspace research influenced the formalization of VDC [27,28,29,30] as the Extreme Collaboration Method (ECM) [31] developed by NASA’s Jet Propulsion Laboratory (JPL). The ECM proposes the execution of complex projects (such as the design of aeronautical missions) through exhaustive collaboration between those in charge of different areas, with high-performance tools and under the same working space. Furthermore, the ECM has allowed the execution of projects with deadlines of months in only days [16,32]. This relationship of VDC with the ECM is the basis of what CIFE defines as Integrated Concurrent Engineering (ICE).

The following subsection explores POP model concepts in-depth and illustrates how they are interrelated to represent the main aspects of a construction project.

2.2. Interrelationship between POP Components

From its beginnings, VDC has conceptually interrelated product, organization and process in various ways. One of the most widely used and standard representations is in the form of a matrix, in which the components of the POP models are related to the concepts of function, form and behavior [12].

The function, form (also called scope or structure) and behavior terms correspond to the key components of developing a design prototype, a concept developed by John Gero in 1990 [33]. Considering the design of any artifact as an example, the desired requirements for its use are transformed into functions that the artifact itself must fulfill. These functions will be performed by the elements that make up the artifact’s form. Finally, identifying the artifact’s expected and actual behavior is necessary to evaluate its design correctly [33].

Clayton et al. [34] adapted Gero’s concepts to building design through a modeling system incorporating design processes with digital methods and tools. Clayton’s work defined the terms of function, form and behavior adopted from Kunz & Fischer [12] in the following way:

- The function represents the project’s requirement, either due to the design or a specific request from the client.

- The form comprises the design chosen based on the requirement of the function, including all physical and abstract elements of the building, such as equipment, systems and project activities.

- The behavior is composed of the predicted or observed measurements of an aspect or element of the design, such as cost or schedule.

These components are interrelated in a matrix called the POP matrix (Table 1) that represents the interdependence of the POP components, such as the effects of activity in the organization or the physical product, as well as the impact of a design change in the construction process, among other correlations [16].

Table 1.

POP matrix, adapted from the studies by Bicharra et al. [16], Khanzode et al. [20] and Kunz & Fischer [12].

The POP matrix application focuses on segregating a decision’s impact on the entire project [20]. For example, decisions made in construction are often based on the impact of the product, the people involved and the process required.

Kunz & Fischer [18] developed a reference framework to interrelate the POP components, which indicates how the information flow from the client’s requirement and moves toward the product, organization and process models, updated by the feedback cycles they receive over time. Furthermore, this feedback is given interdependently between components and project objectives, influencing client objectives.

Next, the VDC project management framework, its elements and its relationship to the POP model components are presented below.

3. Virtual Design and Construction (VDC)

3.1. VDC Project Management Framework

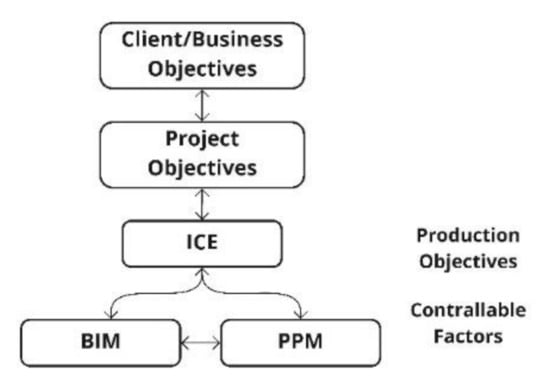

VDC is focused on product, organization and process models and has been taught with the framework presented in Figure 1.

Figure 1.

VDC framework, adapted from Rischmoller et al. [35].

A diagram is obtained through the framework presented in Figure 1 that attributes a specific term (ICE, BIM, PPM) for each element and for the main objectives and production objectives. An organized and hierarchical structure supports the framework to align each element and actor with the client and project objectives.

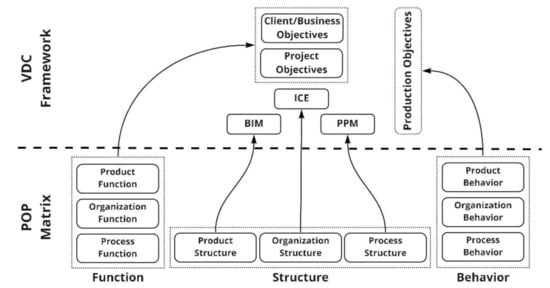

From the POP and the VDC frameworks, the following correlations can be found: the product (P) design is constituted using Building Information Modeling (BIM) and the organization (O) design is developed through the practice of Integrated Concurrent Engineering (ICE) and the process (P) models are developed based on Project Production Management (PPM). Similarly, the objectives are present in both frameworks.

The relationship between POP components and VDC elements is illustrated in Figure 2. The product, organization and process represent the BIM, ICE and PPM elements. The project function column is closely related to the objectives that the project must achieve for the client. Finally, the expected and real behavior will be measured based on the production objectives implemented in each element.

Hence, VDC proposes vital elements for each of the original POP models. However, the framework is not subject to the same elements (ICE, BIM, or PPM) but adapts to today’s technologies, methods and tools. Moreover, Figure 2 demonstrates the consistency in VDC structuring since each framework and element is equivalent, allowing the user to visualize, integrate, simulate, plan, execute and operate a project properly. Finally, the VDC framework enables the project team to exceed the client’s expectations under an integrated, concurrent and collaborative working environment.

Next, the elements BIM, ICE and PPM are explained in the context of the VDC framework.

3.2. Building Information Modeling (BIM)

BIM is possibly one of the most popular terms in the construction industry today, even more after its dissemination in various countries as public policy, such as Peru in 2018 [36,37], Chile in 2019 [38] and the UK in 2016 [39].

It is common to hear different definitions of BIM. Thus, it can be associated with a tool, software, methodology, representative model, project simulation, revolutionary technology, or a modern concept used to generate an image and marketing [40].

In the VDC framework, BIM is focused on supporting product design. Additionally, this element is not limited only to generating the virtual model of the building and resolving incompatibilities. Implementing BIM involves being able to convey project information through 3D/4D models effectively [41], train the modelers and advise the client [42], measuring the cost of resources and impact on the project [43], among other implications. This makes it necessary to contemplate BIM training throughout the Architecture, Engineering and Construction (AEC) undergraduate curricula [44].

The term “BIM+” in the VDC framework is attributed to advanced BIM applications, such as performing 4D planning and scheduling the product or a cost estimate based on the BIM. However, the concept can be extended to more complex and novel uses, such as virtual/augmented reality or robotic process automation [35,45].

Although BIM represents the form/scope of the product, it does not encompass the entire project [46]. Instead, BIM focuses on the tangible elements of the VDC framework, which is considered valuable but limited because management issues are based on a complete product–organization–process interaction [12].

Effective communication and collaboration among designers are critical for the success of a project, something that cannot be achieved by coordination meetings or BIM coordinators alone [47]. The value of BIM as part of VDC resides less in the models themselves than in how much people learn as they create and test the models collaboratively over time, and the interactions that the models invite [35]. Therefore, BIM as part of VDC will be practical only if integrated with ICE sessions and PPM use.

BIM addresses the information management challenges, whereas VDC addresses all the project management issues. BIM allows a better understanding of the project information (for designing, building and operating) through powerful visualization, information integration and automation. Additionally, the BIM application could be extended to support the industrialization process in the AEC industry.

Using the BIM platform, project stakeholders can exchange engineering information in real-time and work together, consequently improving work efficiency, saving resources, reducing costs and achieving sustainable development [48,49]. Furthermore, BIM could also improve automated information analysis for different project phases [50].

Finally, BIM in the VDC framework has a broader meaning as Building Information Management, which can include Building Information Modelling.

3.3. Integrated Concurrent Engineering (ICE)

The organization model in the VDC framework is defined by the practice of ICE, a concept based on the powerful collaboration method promoted by NASA’s Jet Propulsion Laboratory [12].

The application of ICE constitutes the simultaneous (i.e., concurrent) development of interdependent tasks by the actors under highly concentrated coordination efforts [51]. This concept can be applied in two ways: by constant co-location for a defined period by the actors with interdependent tasks, or by conducting ICE sessions to resolve specific project issues efficiently.

Regardless of the type of application, ICE is usually carried out in a workspace equipped with modern collaboration tools [45]. The idea of this place is that those involved can share information and solve problems effectively and directly by working face-to-face with the necessary resources [47,52,53]. Moreover, there is the fundamental use of BIM because the ICE session is one of the main spaces where all participants can interact and learn directly with the models [35].

Working face-to-face does not necessarily imply or mean working in person. The impact of the COVID-19 pandemic on the construction industry, mainly during the first half of 2020, has forced many face-to-face ICE sessions to be carried out virtually, opening the space for the use of big virtual rooms employing the latest tools/technologies available in digital collaborative boards/workspaces.

ICE sessions usually represent the most common application among those who use VDC, as seen in the study by Majumdar et al. [54]. Furthermore, unlike traditional meetings, which often lack proper planning with pre-established time frames and preparation by the members, ICE sessions follow a detailed agenda previously sent to the participants, with clear objectives and estimated times for each topic to be discussed [45,51].

ICE’s success lies in the dramatic reduction in coordination (or response) latency, which is the time that goes by from the moment a request for information or action is made to the completion of that request [51,55]. Similarly, co-location in a small or big room considerably reduces decision latency [47] by having the leading managers, stakeholders and decision-makers present.

ICE provides an environment where all VDC elements (Figure 1) are integrated with measured metrics for the product, organization and process [18].

Finally, ICE is centered on the people who drive the project. The ICE sessions are where the contributions of the project disciplines are integrated by maximizing the concurrency to find the best solution for the client.

3.4. Project Production Management (PPM)

The process design is defined by PPM’s principles, which apply Operations Science to projects viewed as temporary production systems [56]. PPM focuses on the organization and control of project workflows and activities. One of the main applications focuses on analyzing, measuring and introducing planned buffers in these flows, which are of three types: (1) inventory buffers (raw materials, work-in-process and finished goods—transformation occurs before demand), (2) time buffers (contingency times—transformation occurs after demand) and (3) capacity buffers (in-excess labor and equipment capacity—above the average demand).

In addition, PPM focuses on reducing workflow variability, which can be defined as a lag in the quality and quantity of flows (information, materials, labor, equipment, workspace) required to perform a sequence of constructive activities [56,57]. The principles of PPM and Lean Construction—an adaptation of the Lean philosophy introduced by Lauri Koskela in 1992 [58]—share the same origin in Operations Science [35].

Lean principles originated in the compilation of practices and values employed in the Toyota Production System. One of its main objectives is to reduce waste in a production flow and generate greater value for the client [59]. Similarly, Lean Construction aims to create production systems capable of optimizing, reducing, or eliminating workflows and improving delivery times [60].

However, the Project Production Institute (PPI) [61]—the organization that introduced the PPM concept and practice in 2014—highlights the differences with Lean Construction. Although both concepts emerged based on Operations Science (which PPI defines as the study of the transformation of resources to create and distribute goods and services), PPI emphasizes the lack of mathematical support in the approaches of Lean Construction as well as differences in the way PPM and Lean Construction address many concepts related to systems [56].

Within the VDC framework, PPM is placed as the process element. However, VDC has had a connection with Lean Construction long before, using tools such as the Last Planner System [45] and comparing the impact of both methodologies, such as the Lean Project Delivery System [20]. Due to this, VDC combines PPM’s primary focus of activities and physical work with the human component of Lean Construction [35], making integrated use of both for optimal process design.

Finally, PPM allows us to understand the production process as the work in the process due to its ability to model and analyze a sequence of steps/tasks to design the best project production system, with possibly less variability.

3.5. Controllable Factors and Production Objectives (Formerly Production Metrics)

Kunz and Fischer [12] proposed a list of 16 recommended production metrics based on anecdotal information from early VDC practitioners in 2005. In their research, they define metrics (process production metrics) as: “an aspect of project performance that a team can frequently measure (hourly, daily or every week or two) and use to judge how well past management choices (controllable factors) are moving toward the final project outcome objectives” (p. 45). On the other hand, Belsvik et al. [62] explored the most applied metrics in projects based on the literature and semi-structured interviews with a Norwegian contractor, recommending 13 production metrics for VDC projects in the design phase.

Based on the production metrics recommended by Kunz and Fischer [12] and Belsvik et al. [62] and empirical evidence of their application in the construction industry, from 279 VDC reports from Scandinavia and Latin America, Majumdar et al. [63] proposed the list of production metrics presented in Table 2.

Table 2.

List of production metrics, adapted from [63].

An initial base of production objectives (production metrics) is of great value for professionals interested in adequately developing a VCD implementation plan. Individually, each organization must identify the factors to control, process metrics to monitor and use in management, and outcomes by which to evaluate project success [12]. Additionally, regarding production objectives, there are controllable factors and project outcomes to continue following up on the project’s progress. The controllable factors, production objectives and project outcomes are closely interrelated. All the VDC elements measure over time a quantifiable objective, be it the main outcomes of the client/project objective or the production metrics and controllable factors in ICE, BIM and PPM.

Finally, controllable factors are the actions a project team decides to carry out. In contrast, a project team cannot decide on the performance of production objectives (formerly production metrics). Still, they can be measured and followed up to display the project performance during the design, construction and operation phases to determine whether the objectives have been met or not, take decisions and, if needed, correct project directions.

3.6. Client/Business and Project Objectives

The client and project objectives represent an essential part of the construction project since implementation revolves around these at the top of the VDC element hierarchy. The objectives can be linked to controllable factors, production metrics and project objectives [12].

Fischer et al. [7] define client and project objectives, since they specify high-performance buildings as those that meet the client’s objectives during use and operation and at hand-over from the design and construction team to the client. “A high-performing building can only be achieved through a building with integrated building systems, which can only be produced through an integrated process, which depends on an integrated team with the right people, which needs integrated information, i.e., BIM+, to function effectively and efficiently. Simulation and visualization are the primary ways BIM+ informs the integrated team. Collaboration and co-location are the primary ways for the integrated team to integrate processes. Production management methods enable the integrated building system’s productive design, fabrication and construction. Finally, outcome metrics define the performance of the building and validate the integrated building system. This is supported by the appropriate agreement or framework” [7] (p. XXIV).

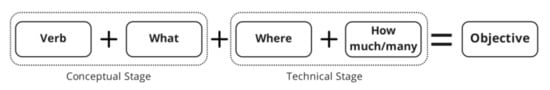

How the client and project objectives are structured may affect their understanding and accomplishment. Figure 3 proposes a simple objective framework to describe an objective precisely. The simple objective framework starts with an “auxiliary verb infinitive plus participle” (whose combination represents a completed action) + “what” (which represents the noun of the objective) + “where” (where the objective is located) + “how much or many” (that represents the quantified goal of the objective). The conceptual stage (“verb” + “what”) may represent the initial client’s needs, while the technical stage specifies how the project should address the client’s needs technically and precisely.

Figure 3.

A simple framework to structure client and project objectives.

Client objectives usually focus on obtaining a usable, operable and sustainable building. In contrast, project objectives are focused on a buildable building with special attention to the safety, quality, schedule, cost, social and environmental aspects.

4. VDC Case Studies

VDC has achieved favorable results in projects worldwide, as one of the methods of global interest for innovators in the industry [18]. This section compiles seven successful case studies of VDC implementations in projects to confirm the benefits perceived in the theoretical foundation of the VDC framework, and a discussion about production metrics (production objectives) from 279 VDC professional reports from Scandinavia and Latin America.

The first case presents the benefits of implementing VDC to manage mechanical, electrical and plumbing (MEP) systems in a large health office project in California, USA. The second and third cases involve large residential building projects from Norway. Additionally, four recent projects carried out in Peru are included: the first one covers replacing a crusher machine and bulk hopper in a mining unit; the second establishes VDC application to develop a conceptual design for civil engineering laboratories; the third focuses on VDC applied to optimize the flow of vehicles during the construction of a building; and the last focuses on increasing the construction industrialization of the main bridge elements (footings, columns and head beams).

4.1. Case Study 1: El Camino Medical Office Building (USA)

The El Camino Medical Office Building (MOB) project decided to implement VDC to coordinate the design and installation of the MEP systems due to the challenges of these disciplines’ technical systems, and to meet the objectives of not exceeding the estimated time and cost. One of the biggest challenges in health projects is correctly designing and assembling the MEP facilities with the least amount of rework. In fact, due to the importance of building facilities in this sector, MEP systems can represent up to 50% of the total project cost. The construction project was a three-story building with 23,000 m2 and began in January 2005, with an estimated duration of 30 months and a contractual budget of $96.9M [64,65].

The VDC framework’s main benefits for this project included zero design changes during MEP installation. In addition, almost 99% of the RFIs (Request for Information) were resolved in the pre-construction phase through the efficient generation and sharing of relevant information. Overall, “due to the use of VDC tools and a fast track approach the team was able to save $9M and 6 months as compared to the traditional process” [64] (p. 337). After these results, the client and the general contractor felt a real added value with VDC, which persuaded them to continue implementing the framework [64].

4.2. Case study 2: Gjønneshagen Residential Project (Norway)

The Gjønneshagen complex is a $41M project comprised of residential houses and apartment blocks comprising 181 homes. The project started in 2012 and used various elements of the VDC framework with previous training of the actors involved to contribute to delivering the buildings on time. One of these was the integrated information provided by BIM, which became a success factor by coordinating and controlling design processes and enabling the procurement of materials directly from the BIM [45].

Lean tools such as pull-planning or the Last Planner System were used. The value of the Last Planner System was enhanced using a common data environment-based application, which allows real-time updating of the schedule modified by the last planner and adding comments and suggestions from the team. Additionally, collaborative concurrent engineering sessions were implemented that contributed to product and process integration [45].

Finally, a six-month reduction in the schedule for the Gjønneshagen complex was achieved, fulfilling the initially proposed objectives.

4.3. Case Study 3: Tiedemannsbyen Felt A Residential Project (Norway)

The ‘Tiedemannsbyen felt A’ residential complex comprises 251 apartments distributed in five blocks, with a total budget of $54M. Although the project was at an early stage during the study of the VDC application, several benefits were found [45].

Unlike common BIM practice (where the project’s BIM coordinator mainly manages the model), in “Tiedemannsbyen felt A”, the same actors and designers who updated the BIM assessed the interferences and extracted information directly from the model. This allowed better control of the integrated information and achieved a higher quality BIM and, consequently, a buildable product. In addition, ICE was implemented both in the big room (co-located people) and in the form of sessions. This environment was also used for other sessions, such as pull-planning or Last Planner. Moreover, the project followed metrics such as Percent Plan Complete (PPC) and model interferences, efficiency and involvement in ICE sessions [45].

Finally, during the initial implementation stage, the benefits included reducing the design timeline by six months and fully integrating the work team.

4.4. Case Study 4: El Brocal Mining Unit (Peru)

El Brocal is a mining unit located in Cerro de Pasco, Peru. The mining plant is in constant production and it is highly counterproductive to have it stopped or inoperative. Therefore, to mitigate any unnecessary loss due to the maintenance and upgrade process, VDC was applied to replace a crushing machine and a bulk hopper based on a design focused on operation and maintenance objectives [66].

Virtual ICE sessions were held with the suppliers, engineering designers and operation and maintenance managers to solve design interferences. Regarding the product, a 3D and 4D BIM were used, the latter being a simulation of disassembling and assembling the structures, and this included non-graphical information needed for the maintenance of the machines. Likewise, pending activities were monitored through PPM to comply with said deliverables [66].

Finally, the outcomes of this implementation were a detailed design for replacing the crushing machine and a bulk hopper within the deadline.

4.5. Case Study 5: Civil Engineering Laboratories (Peru)

The Civil Engineering Laboratories of the University of Lima, Peru, are grouped in a shed with 1440 m2 and were built in 2017 for a budget of $20M approximately. This infrastructure contains nine central laboratories. The first three laboratories (Materials, Soils, Topography and Geomatics) were implemented in 2017 and the remaining six laboratories (Structures, Environmental Engineering, Pavements, Sanitary Engineering, Hydraulics and Hydrology) were implemented in 2021. However, due to the limited space available to install the equipment for the remaining six laboratories, a detailed plan was developed, supported by VDC methodology, to avoid unforeseen issues during installation and operation [67].

The VDC application was developed during 2019–2020 and focused on the conceptual design for the last six labs and the respective purchase order of the equipment before the established end date of 30 December 2020. The conceptual design depended on the equipment definition. Therefore, the design had to consider the appropriate dimensions, spaces, operation, maintenance, use and installation for this equipment [67].

Virtual ICE sessions were developed weekly due to the COVID-19 pandemic restrictions. The laboratory managers, technicians, suppliers and other actors coordinated and resolved issues involving the entire facility management. A detailed BIM was built and managed, integrating the specialties and lab equipment, containing the product’s information on a cloud-based platform. All this was developed through a PPM system focused on solving issues for each session and reaching the desired conceptual design according to the needs [67].

The conceptual design was achieved by solving 100% of the issues. Likewise, the equipment purchase orders were successfully requested one month before the deadline.

4.6. Case Study 6: ‘Centro de Bienestar Universitario’ (Peru)

The ‘Centro de Bienestar Universitario’ is a building of the University of Lima, Peru, of 14,944 m2 built between 2019 and 2022, with a contractual budget of $30M approximately. Various VDC implementations were carried out for different aspects of the project. One of these focused on optimizing the vehicular flow for the entrance and exit of concrete mixers due to the narrow access and exit route of one single lane available at the university.

The main objective of the implementation was to reduce to less than 40 min the non-productive time of entry and exit of concrete mixers, measured by the time that the mixer was on site but not working on concrete pouring. According to this, weekly ICE sessions were implemented and carried out in person to eliminate interferences from the work area and propose solutions to the low performance of the vehicular flow. In addition, a BIM based on a 3D point cloud collected all the information about the terrain and its obstacles, which was updated weekly. Finally, the PPM production system captured each concrete mixer’s entire process and identified the losses’ main points [68].

The outcomes showed a reduction of non-productive time of concrete mixers by 30% through the implementation of this system for measuring, releasing interferences caused by on-site obstacles and optimizing vehicle flow.

4.7. Case Study 7: ‘Ovalo Monitor Bridge’ (Peru)

The ‘Ovalo Monitor Bridge’ project is located at the Monitor Huáscar roundabout, built between 2021 and 2022 in Lima, Peru. With an 870 meter-span and a budget of $21M, this project serves as a bypass with the main purpose of alleviating traffic in the roundabout, which is the intersection between two big town districts [69].

To reduce the execution time of the structural elements, the VDC implementation focused on increasing the industrialization of the bridge elements (footings, columns and head beams) through the design, construction, assembly and installation of prefabricated rebar cages (PRC). ICE sessions were carried out with the main stakeholders involved in delivering the PCR elements to bring solutions, confirm details and make decisions regarding the structural trade. The project’s BIM helped better visualize the pre-assembled PRC elements, those modeled with a minimum of LOD 350. All elements were prefabricated from the information provided by the BIM, with zero rework. Moreover, PPM was focused on tracking the progress of the PRC elements, following up on the status of the industrialization level and the overall time reduction in the structural trade [69].

The VDC implementation outcomes showed a project time saving of 31% in the structural trade by designing, constructing, assembling and installing prefabricated reinforcement cage elements.

4.8. Production Metrics (Production Objectives) from 279 VDC Case Studies Classified into Common Production Metrics Obtained from the Literature (PML)

A conceptual content analysis was performed based on empirical evidence of applying production metrics (production objectives) in the construction industry [63]. This analysis was based on 279 VDC reports from Scandinavia and Latin American professionals in 2019 and 2020.

The study’s main objective was to know the homogeneity and discrepancy of the Production Metrics found in the Literature (PML) for each VDC implementation. The purpose of the research is supported by the fact that, since production metrics are the key element in quantifying and monitoring project performance, there should be a certain level of consensus or standardization in their use [63].

The research results showed a considerable discrepancy in PML reported across professionals. Of the 17 PML (Table 2), three PML (detailed schedule conformance, stakeholder involvement and meeting efficiency) were reported by more than 40% of the professionals. The largest discrepancy was observed in meeting efficiency (Scandinavia: 44%, Latin America: 78%), meeting effectiveness (Scandinavia: 40%, Latin America: 3%) and BIM coordination consistency (Scandinavia: 23%, Latin America: 40%).

Finally, the authors reinforced the need to develop a common vocabulary of production metrics for different project types, sizes and phases so that Architecture, Engineering and Construction (AEC) professionals can track those useful for their specific projects [63].

5. Results and Discussion

The cases studied are presented in Table 3 according to the Product, Organization and Process models and project outcomes. These models are the principles that encompass the fundamental elements of BIM, ICE and PPM.

Table 3.

VDC elements found in the case studies.

The POP structure works regardless of the project type. All seven cases used BIM for the product element. In fact, in the El Camino MOB case, BIM (as it is known and used today) was a newly emerging technology. Although the term ICE was not yet fully established, the “Big Room” fully embraced the concept of ‘co-location’ and reduced latency in this early application of VDC. In addition, neither of the first three projects (case studies from 1 to 3) specified the use of PPM in their process design, since PPM replaced the “Process Management” framework only a few years ago. The Last Planner System was commonly the primary tool regarding the process. On the other hand, the last four projects (case studies from 4 to 7) implemented VDC based on the VDC framework in Figure 1 with all its elements.

Despite the more than 13 years of difference between the El Camino MOB and the Peruvian projects, the concepts and principles of VDC have remained consistent. Therefore, it can be expected that VDC elements and framework may evolve in the near and far future (as they have done for the past 20 years up to the current framework), but the core principle and concepts should remain.

Regarding the project outcomes of the seven case studies, there are tangible positive results and some opportunities for improvement. Unfortunately, the main objectives of cases 2 and 3 were not explicitly specified in the authors’ original text. Therefore, it is essential to define them to have a correct, clear, targeted VDC implementation. On the other hand, although the El Camino MOB did specify the proposed objective, target quantification is necessary because it is essential to evaluate the project’s performance according to the main objectives. Similarly, although PPM was mentioned in the last four projects, a greater emphasis is needed on the properties of the production system, the analysis of buffers and the reduction of variability.

Moreover, there was a significant benefit in terms of cost and schedule (or other benefits according to the client objective) by using the VDC framework, showing the effectiveness and the complete interrelation between elements, contributing to the general knowledge and spreading of the VDC principles and concepts focused on the integration of the product, organization and process to achieve better project results.

In addition to Product, Organization and Process models, it is important to define and monitor the project progress throughout production objectives. The work done by Majumdar et al. [63] gives us an important starting point to define proven production objectives (production metrics) based on previous VDC implementation experiences. Later, the same research group, Majumdar et al. [54], extended the production metrics studies to categorize them into the three VDC elements: ICE, BIM and PPM. The results show that production metrics categorized as ICE were reported by more than 80% of Scandinavian and Latin-American professionals and PPM by more than 65%. However, a disparity was found for production metrics categorized as BIM, with 30% of the Scandinavian professionals reporting them, in contrast to 91% of the Latin-American professionals.

6. Conclusions

Like a technology, an ideology, or the construction industry, VDC is a living framework that evolves while maintaining its core principles and concepts. Its specific application and evolution will depend on the current level of technology, the new tendencies to systematize processes and how the organization of a project is managed. This paper focused on the solid foundations and models on which VDC was founded by CIFE back in 2001 (product, organization, process) and how they have shaped the VDC elements and framework (such as BIM, ICE and PPM) to bring a solution to the constant challenges encountered in the construction industry.

Seven successful case studies support this claim, achieving expected benefits related to cost and schedule (as client objectives). Likewise, the bibliographical review and results analysis corroborated the interdependence in the VDC elements and their direct relationship with the original POP model.

A proven production objective list was also shared as a starting point for new VDC implementations. Finally, VDC demonstrates through academia and practice its myriad benefits in managing projects and integrating teams to obtain the best outcomes in construction.

7. Future Recommendation

This research showed that VDC case studies primarily focused on projects in the design and construction phases. Therefore, extending the research to VDC cases applied to different project phases, such as initial conceptual/proposal development and operation and maintenance phases, is recommended.

Future investigation also could focus on developing a list of controllable factors categorized as per the VDC elements (ICE, BIM and PPM), similar to the production objective studies by Majumdar et al. [63] and Majumdar et al. [54], respectively.

Finally, VDC has been largely applied in different AEC projects by professionals from the industry throughout the VDC Certificate Program, guided by the Stanford Center for Professional Development in collaboration with the Center for Integrated Facility Engineering, Norwegian University of Science and Technology (NTNU), Universidad de Lima and the Swiss University of Applied Sciences and Arts (FHNW). However, just a few of these VDC application cases are shared. Future studies could focus on compiling and sharing the VDC application results broadly.

Author Contributions

Conceptualization, A.A.D.S. and L.A.R.D. and M.F.; methodology, A.A.D.S.; software, J.F.V.Q. and A.D.B.M.; validation, A.A.D.S.; formal analysis, A.A.D.S., J.F.V.Q. and A.D.B.M.; investigation, A.A.D.S., J.F.V.Q. and A.D.B.M.; resources, A.A.D.S.; data curation, A.A.D.S., J.F.V.Q. and A.D.B.M.; writing—original draft preparation, A.A.D.S., J.F.V.Q. and A.D.B.M.; writing—review and editing, A.A.D.S. and L.A.R.D.; visualization, A.A.D.S., J.F.V.Q. and A.D.B.M.; supervision, A.A.D.S.; project administration, A.A.D.S.; funding acquisition, A.A.D.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Scientific Research Institute (IDIC) of Universidad de Lima, grant number AC.06.016.2022.

Data Availability Statement

The data supporting the findings of this study are available within the article.

Acknowledgments

The authors would like to gratefully acknowledge CIFE (Center for Integrated Facility Engineering) at Stanford University and Universidad de Lima for the facilities provided for the investigation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Barbosa, F.; Woetzel, J.; Mischke, J.; Ribeirinho, M.; Sridhar, N.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction: A Route to Higher Productivity; McKinsey Global Institute: San Francisco, CA, USA, 2017. [Google Scholar]

- Blayse, A.M.; Manley, K. Key influences on construction innovation. Constr. Innov. 2004, 4, 143–154. [Google Scholar] [CrossRef]

- Taylor, J.E.; Levitt, R.E. Inter-Organizational Knowledge Flow and Innovation Diffusion in Project-Based Industries. CIFE, WP #089. 2004. Available online: https://stacks.stanford.edu/file/druid:bc506xw2626/WP089.pdf (accessed on 19 October 2022).

- Betts, M.; Brandon, P. Integrated Construction Information; E & FN Spon: London, UK, 2005. [Google Scholar]

- Bowley, M. The British Building Industry: Four Studies in Response and Resistance to Change; Cambridge University Press: Cambridge, UK, 1966. [Google Scholar]

- Fischer, M. Design Construction Integration through Constructibility Design Rules for the Preliminary Design of Reinforced Concrete Structures. In Proceedings of the CSCE/CPCA Structural Concrete Conference, Montreal, QC, Canada, 20–21 March 1989. [Google Scholar]

- Fischer, M.; Ashcraft, H.; Reed, D.; Khanzode, A. Integrating Project Delivery; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Nam, C.; Tatum, C.B. Major characteristics of constructed products and resulting limitations of construction technology. Constr. Manag. Econ. 1988, 6, 133–147. [Google Scholar] [CrossRef]

- Tatum, C.B. Technology and competitive advantage in civil engineering. J. Prof. Issues Eng. 1988, 114, 256–264. [Google Scholar] [CrossRef]

- Luiten, G.; Fischer, M. Opportunities for computer-aided design for construction. Eng. Constr. Archit. Manag. 1998, 5, 127–136. [Google Scholar] [CrossRef]

- Kam, C.; Fischer, M. Capitalizing on early project decision-making opportunities to improve facility design, construction, and life-cycle performance—POP, PM4D, and decision dashboard approaches. Autom. Constr. 2004, 13, 53–65. [Google Scholar] [CrossRef]

- Kunz, J.; Fischer, M. Virtual Design and Construction: Themes, Case Studies and Implementation Suggestions. CIFE Working Paper 097. 2012. Available online: https://stacks.stanford.edu/file/druid:gg301vb3551/WP097_0.pdf (accessed on 19 October 2022).

- Center for Integrated Facility Engineering (CIFE). Available online: https://cife.stanford.edu/ (accessed on 30 June 2020).

- Kunz, J.; Luiten, G.; Fischer, M.; Jin, Y.; Levitt, R. CE4: Concurrent Engineering of Product, Process, Facility, and Organization. Concurr. Eng. 1996, 4, 187–198. [Google Scholar] [CrossRef]

- Kim, J.S.; Fischer, M.A.; Nasrallah, W.; Kunz, J.C.; Levitt, R.E. Concurrent Engineering of Facility, Schedule and Project Organization for Retrofit Projects. In Proceedings of the International Conference on Construction Process Reengineering, Gold Coast, Australia, 14–15 July 1997; pp. 647–658. [Google Scholar]

- Bicharra, A.; Kunz, J.; Ekstrom, M.; Kiviniemi, A. Building a Project Ontology with Extreme Collaboration and Virtual Design & Construction. CIFE, TR #152. 2003. Available online: https://stacks.stanford.edu/file/druid:jr207fd2953/TR152.pdf (accessed on 19 October 2022).

- Kunz, J.; Fischer, M. The scope and role of information technology in construction. J. Constr. Manag. Eng. 2004, 763, 1–18. Available online: https://stacks.stanford.edu/file/druid:jb926sr1126/TR156German.pdf (accessed on 19 October 2022).

- Kunz, J.; Fischer, M. Virtual design and construction. Constr. Manag. Econ. 2020, 38, 355–363. [Google Scholar] [CrossRef]

- Kunz, J.; Levitt, R.; Fischer, M. Management and Leadership Education for Civil Engineers: Teaching Virtual Design and Construction for Sustainability. CIFE, WP #079. 2003. Available online: https://stacks.stanford.edu/file/druid:vq141qm4960/WP079.pdf (accessed on 19 October 2022).

- Khanzode, A.; Fischer, M.; Reed, D.; Ballard, G. A Guide to Applying the Principles of Virtual Design & Construction (VDC) to the Lean Project Delivery Process. CIFE, WP #093. 2006. Available online: https://stacks.stanford.edu/file/druid:bc980bz5582/WP093.pdf (accessed on 19 October 2022).

- Hayakawa, M. Evaluation of Technology in Construction. Center for Integrated Facility Engineering. 1989. Available online: https://stacks.stanford.edu/file/druid:th508qb8281/TR016.pdf (accessed on 19 October 2022).

- Levitt, R.; Cohen, G. The “Virtual Design Team”: Using Computers to Model Information Processing and Communication in Organizations. CIFE, WP #16. 1992. Available online: https://stacks.stanford.edu/file/druid:sf783yf1155/WP016.pdf (accessed on 19 October 2022).

- Jin, Y.; Levitt, R. The Virtual Design Team: A Computational Model of Project Organizations. Comput. Math. Organ. 1996, 2, 171–196. [Google Scholar] [CrossRef]

- Levitt, R.; Thomsen, J.; Christiansen, T.; Kunz, J.; Jin, Y.; Nass, C. Simulating Project Work Processes and Organizations: Toward a Micro-Contingency Theory of Organizational Design. Manag. Sci. 1999, 45, 1479–1495. [Google Scholar] [CrossRef]

- Teicholz, P.; Fischer, M. Technology framework for computer integrated construction. In Proceedings of the Fifth International Conference on Computing in Civil and Building Engineering, Anaheim, CA, USA, 7–9 June 1993; pp. 1139–1146. [Google Scholar]

- Fischer, M.; Tatum, C.B. Partially Automating the Design-Construction Interface: Constructability Design Rules for Reinforced Concrete Structures. In Proceedings of the 6th ISARC, San Francisco, CA, USA, 6–8 June 1989; pp. 127–134, ISSN 2413-5844. [Google Scholar] [CrossRef]

- Johanson, B.; Hanrahan, P.; Winograd, T. Integrating information appliances into an interactive workspace. IEEE Comput. Graph. Appl. 2000, 20, 54–65. [Google Scholar] [CrossRef]

- Fischer, M.; Stone, M.; Liston, K.; Kunz, J.; Singhal, V. Multi-stakeholder collaboration: The CIFE iRoom. In Proceedings of the CIB W78 Conference 2002: Distributing Knowledge in Building, Aarhus School of Architecture and Centre for Integrated Design, Arhus, Denmark, 12–14 June 2002. [Google Scholar]

- Kunz, J.; Fischer, M.; Liston, K.; Singhal, V.; Stone, M. Virtual Design and Construction in the CIFE iRoom. In Proceedings of the 3rd International Conference on Decision-Making in Urban and Civil Engineering (DMinUCE), London, UK, 6–8 November 2002. [Google Scholar]

- Schreyer, M.; Hartmann, T.; Fischer, M.; Kunz, J. CIFE iRoom XT Design & Use. CIFE Technical Report #144. 2002. Available online: https://stacks.stanford.edu/file/druid:pg790hj9996/TR144.pdf (accessed on 19 October 2022).

- Mark, G. Extreme Collaboration. Commun. ACM 2002, 45, 89–93. [Google Scholar] [CrossRef]

- Chachere, J.; Levitt, R.; Kunz, J. Can You Accelerate Your Project Using Extreme Collaboration? A Model Based Analysis. CIFE, TR #154. 2003. Available online: https://stacks.stanford.edu/file/druid:sd007yg8399/TR154.pdf (accessed on 19 October 2022).

- Gero, J. Design Prototypes: A Knowledge Representation Schema for Design. AI Mag. 1990, 11, 26. [Google Scholar] [CrossRef]

- Clayton, M.; Kunz, J.; Fischer, M. Rapid Conceptual Design Evaluation Using a Virtual Product Model. Engineering Applications of Artificial Intelligence. Eng. Appl. Artif. Intell. 1996, 9, 439–451. [Google Scholar] [CrossRef]

- Rischmoller, L.; Reed, D.; Khanzode, A.; Fischer, M. Integration enabled by virtual design & construction as a lean implementation strategy. In Proceedings of the 26th Annual Conference of the International. Group for Lean Construction (IGLC), Chennai, India, 16–22 July 2018; pp. 240–249. [Google Scholar] [CrossRef]

- Almeida, A. BIM en el Perú. RPP Noticias. Available online: https://rpp.pe/columnistas/alexandrealmeida/bim-en-el-peru-noticia-1190692?fbclid=IwAR1QUYsk5Uoz0oPSmz5nmd2xUyE0z5KfjCDAKCM-h6zyKAGx3AinrPVa9tM (accessed on 11 April 2019).

- Ministerio de Economía y Finanzas del Perú. Available online: https://www.gob.pe/mef (accessed on 4 September 2022).

- Planbim Chile. Available online: https://planbim.cl/ (accessed on 4 September 2022).

- Infrastructure and Projects Authority. Government Construction Strategy 2016–2020; Reporting to HM Treasury and Cabinet Office; Infrastructure and Projects Authority: London, UK, 2016.

- Latiffi, A.A.; Brahim, J.; Fathi, M.S. The Development of Building Information Modeling (BIM) Definition. Appl. Mech. Mater. 2014, 567, 625–630. [Google Scholar] [CrossRef]

- Hartmann, T.; Fischer, M. Supporting the constructability review with 3D/4D models. Build. Res. Inf. 2007, 35, 70–80. [Google Scholar] [CrossRef]

- Coates, P.; Arayici, Y.; Koskela, L.; Kagioglou, M. The key performance indicators of the BIM implementation process. In Proceedings of the EG-ICE 2010—17th International Workshop on Intelligent Computing in Engineering, Nottingham, UK, 30 June–2 July 2010; Available online: http://www.engineering.nottingham.ac.uk/icccbe/proceedings/html/79.htm (accessed on 19 October 2022).

- Arayici, Y.; Coates, P.; Koskela, L.; Kagioglou, M. Technology Adoption in the BIM Implementation for Lean Architectural Practice; University of Salford: Manchester, UK, 2011. [Google Scholar] [CrossRef]

- Del Savio, A.A.; Galantini Velarde, K.; Díaz-Garay, B.; Valcárcel Pollard, E. A Methodology for Embedding Building Information Modelling (BIM) in an Undergraduate Civil Engineering Program. Appl. Sci. 2022, 12, 12203. [Google Scholar] [CrossRef]

- Fosse, R.; Ballard, G.; Fischer, M. Virtual Design and Construction: Aligning BIM and Lean in Practice. LC3 2017 Volume II. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; pp. 499–506. [Google Scholar] [CrossRef]

- Rischmoller, L.; Fischer, M.; Kunz, J. A study of virtual design and construction implementation and benefits using a bayesian approach. Rev. Constr. 2012, 11, 74–87. [Google Scholar] [CrossRef]

- Tauriainen, M.; Marttinen, P.; Dave, B.; Koskela, L. The effects of BIM and lean construction on design management practices. Procedia Eng. 2016, 164, 567–574. [Google Scholar] [CrossRef]

- Wang, C.; Cui, B.; Wu, M.; Tang, Y.; Yap, J.B.H.; Zhang, H.; Li, H. Building Information Modeling-Embedded Building Energy Efficiency Protocol for a Sustainable Built Environment and Society. Appl. Sci. 2022, 12, 6051. [Google Scholar] [CrossRef]

- Zheng, Y.; Tang, L.C.M.; Chau, K.W. Analysis of Improvement of BIM-Based Digitalization in Engineering, Procurement, and Construction (EPC) Projects in China. Appl. Sci. 2021, 11, 11895. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, M.; Cho, C.-S.; Park, J.; Kwon, S. Deep Learning-Based PC Member Crack Detection and Quality Inspection Support Technology for the Precise Construction of OSC Projects. Appl. Sci. 2022, 12, 9810. [Google Scholar] [CrossRef]

- Chachere, J.; Kunz, J.; Levitt, R. Observation, Theory, and Simulation of Integrated Concurrent Engineering: Grounded Theoretical Factors that Enable Radical Project Acceleration. CIFE, WP #087. 2004. Available online: https://stacks.stanford.edu/file/druid:dq405zf4697/WP088.pdf (accessed on 19 October 2022).

- Söderberg, A. A Contingency Approach to the Co-Location of Design Team Members. Production Management. 2015. Available online: http://lup.lub.lu.se/student-papers/record/5050343 (accessed on 19 October 2022).

- Dave, B.; Pikas, E.; Kerosuo, H.; Mäki, T. ViBR—Conceptualising a Virtual Big Room through the Framework of People, Processes and Technology. Procedia Econ. Financ. 2015, 21, 586–593. [Google Scholar] [CrossRef]

- Majumdar, T.; Rasmussen, S.G.; Del Savio, A.A.; Johannesdottír, K.; Hjelseth, E.; Fischer, M.A. VDC in Practice: A Preliminary Categorization of Production Metrics Reported in Scandinavia and Latin America. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction (IGLC), Edmonton, Canada, 27–29 July 2022; pp. 1177–1185. [Google Scholar] [CrossRef]

- Chachere, J.; Kunz, J.; Levitt, R. The Role of Reduced Latency in Integrated Concurrent Engineering. CIFE, WP #116. 2009. Available online: https://stacks.stanford.edu/file/druid:bd089dx8723/WP116.pdf (accessed on 19 October 2022).

- Shenoy, R. A Comparison of Lean Construction with Project Production Management. Proj. Prod. Inst. J. 2017, 2, 1–13. Available online: https://projectproduction.org/wp-content/uploads/2017/09/PPI-JOURNAL-PPIPP-A-Comparison-of-Lean-Construction-with-Project-Production-Management.pdf (accessed on 19 October 2022).

- Garcia-Lopez, N.; Fischer, M. A Construction Workflow Model for Analyzing the Impact of In-Project Variability. Construction Research Congress. 2016. Available online: https://ascelibrary.org/doi/abs/10.1061/9780784479827.199 (accessed on 19 October 2022).

- Koskela, L. Application of the New Production Philosophy to Construction. CIFE, TR #72. 1992. Available online: https://stacks.stanford.edu/file/druid:kh328xt3298/TR072.pdf (accessed on 19 October 2022).

- Liker, J.K. The Toyota Way; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Porras, H.; Sánchez, O.; Galvis, J. Lean Construction Phylosophy for the management of construction projects: A current review. Av. Investig. En Ing. 2014, 11, 32–53. Available online: https://revistas.unilibre.edu.co/index.php/avances/article/view/298 (accessed on 19 October 2022).

- Project Production Institute (PPI). Available online: https://projectproduction.org/ (accessed on 5 September 2022).

- Belsvik, M.R.; Lædre, O.; Hjelseth, E. Metrics in VDC Projects. In Proceedings of the 27th Annual Conference of the International. Group for Lean Construction (IGLC), Dublin, Ireland, 3–5 July 2019; pp. 1129–1140. [Google Scholar] [CrossRef]

- Majumdar, T.; Rasmussen, S.G.; Del Savio, A.A.; Johannesdottir, K.; Hjelseth, E.; Fischer, M. A Comparative Analysis of Production Metrics across VDC Implementations. In Proceedings of the Construction Research Congress 2022, Arlington, VA, USA, 9–12 March 2022; Project Management and Delivery, Controls, and Design and Materials. ASCE: Arlington, VA, USA, 2022. [Google Scholar] [CrossRef]

- Khanzode, A.; Fischer, M.; Reed, D. Benefits and lessons learned of implementing building virtual design and construction (vdc) technologies for coordination of mechanical, electrical, and plumbing (mep) systems on a large healthcare project. Itcon 2008, 13, 324–342. Available online: https://www.itcon.org/papers/2008_22.content.04920.pdf (accessed on 19 October 2022).

- DPR Construction. Camino Medical Group Medical Office Building. Retrieved from DPR Construction Projects. 2007. Available online: https://www.dpr.com/projects/camino-medical-group-medical-office-building (accessed on 19 October 2022).

- Bazán Montalto, A. VDC Framework Applied to the ‘El Brocal Mining Unit’ Project; Universidad de Lima, Center for Integrated Facility Engineering (Stanford University), Stanford Center for Professional Development: Lima, Peru, 2020; Available online: https://hdl.handle.net/20.500.12724/16879 (accessed on 23 November 2022).

- Del Savio, A.A. VDC Methodology Applied to the Conceptual Design of Civil Engineering Laboratories; Universidad de Lima, Center for Integrated Facility Engineering (Stanford University): Lima, Peru, 2020; Available online: https://hdl.handle.net/20.500.12724/16867 (accessed on 25 November 2022).

- Vidal Quincot, J.F. VDC Framework Applied to the ‘Centro de Bienestar Universitario’ Project; Universidad de Lima, Center for Integrated Facility Engineering (Stanford University), Stanford Center for Professional Development: Lima, Peru, 2020; Available online: https://hdl.handle.net/20.500.12724/16884 (accessed on 25 November 2022).

- Tuesta, R.; Vicuña, M.; Del Savio, A.A.; Palpan, A.; Valle, E.; Quiroz, F. Prefabricated reinforcement in construction using VDC: Case study Ovalo Monitor Bridge. In Proceedings of the 30th Annual Conference of the International Group for Lean Construction (IGLC), Edmonton, AB, Canada, 27–29 July 2022; pp. 1008–1019. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).