Evaluation of the Physical, Mechanical, and Calorific Properties of Briquettes with or without a Hollow Made of Wheat (Triticum aestivum L.) Straw Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Determination of Density

2.2. Determination of Resistance to Breaking by Compression

2.3. Determination of the Splitting Strength

2.4. Determination of Calorific Value

2.5. Determination of Caloric Density

2.6. Determination of Ash Content

2.7. Determination of Proximate and Elemental Analysis

2.8. Statistical Analysis

3. Results

3.1. Dimensions and Expansion in Diameter after Pressing

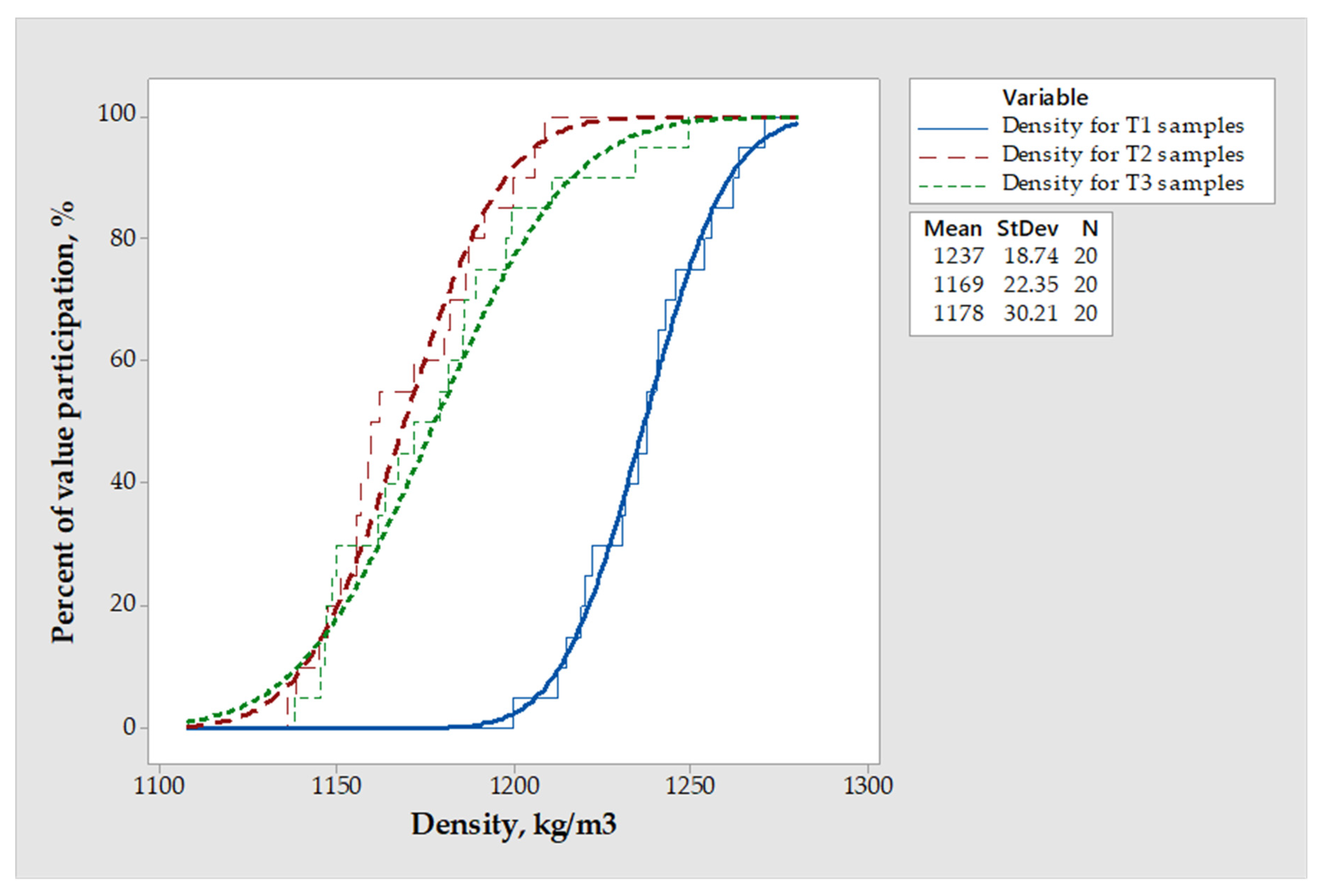

3.2. Density of Briquettes

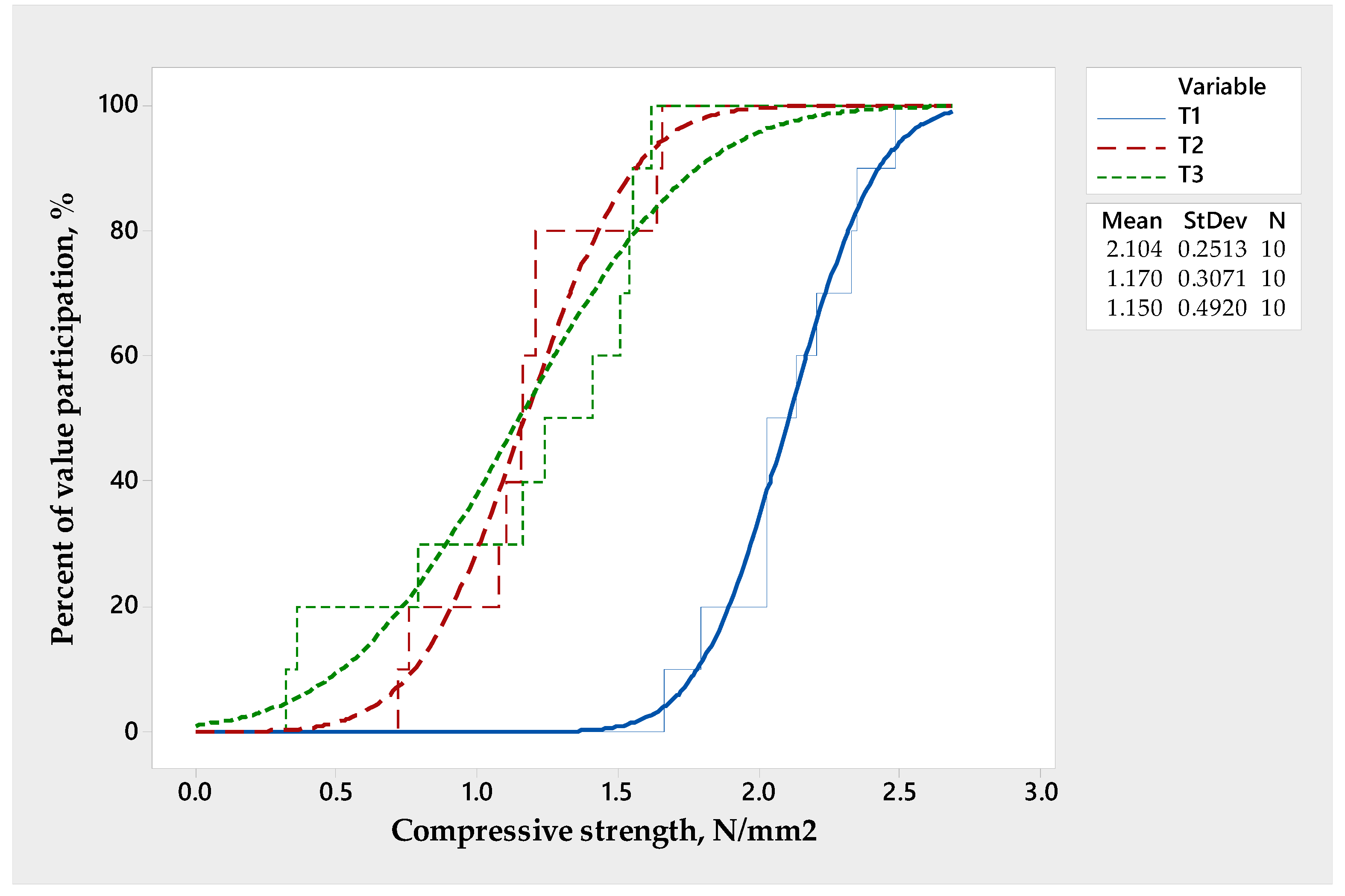

3.3. The Compressive Strength of Briquettes

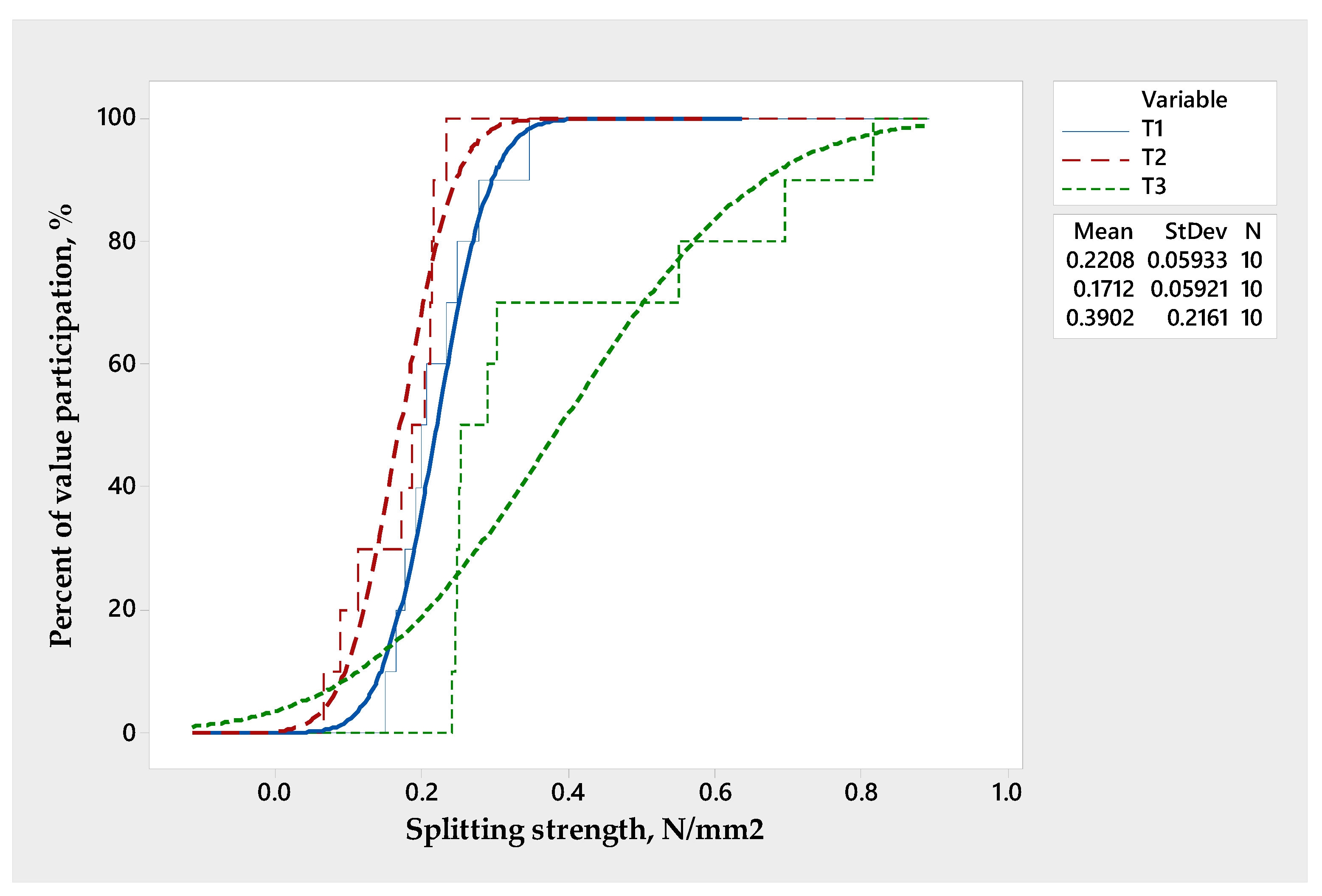

3.4. Splitting Strength

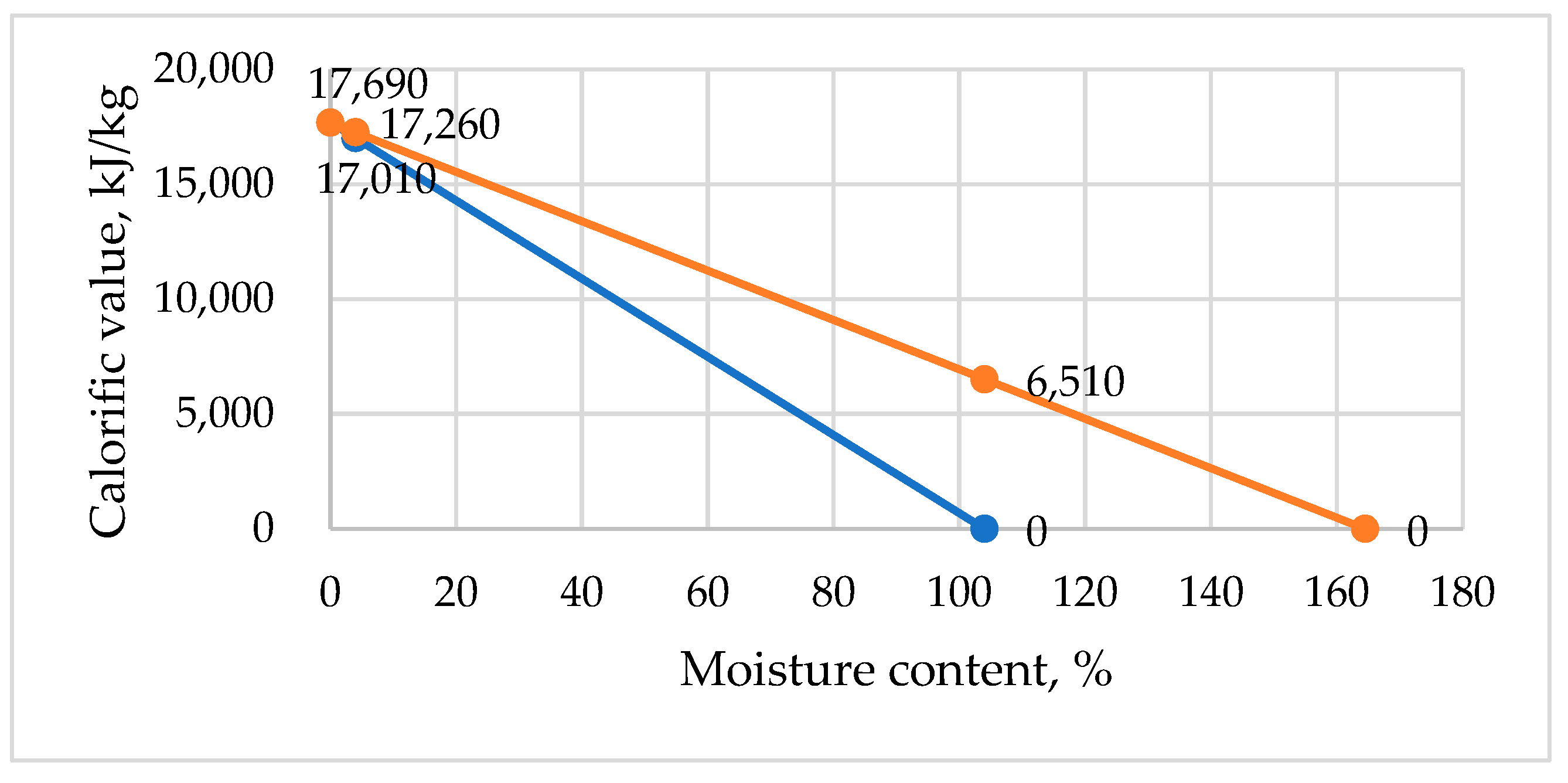

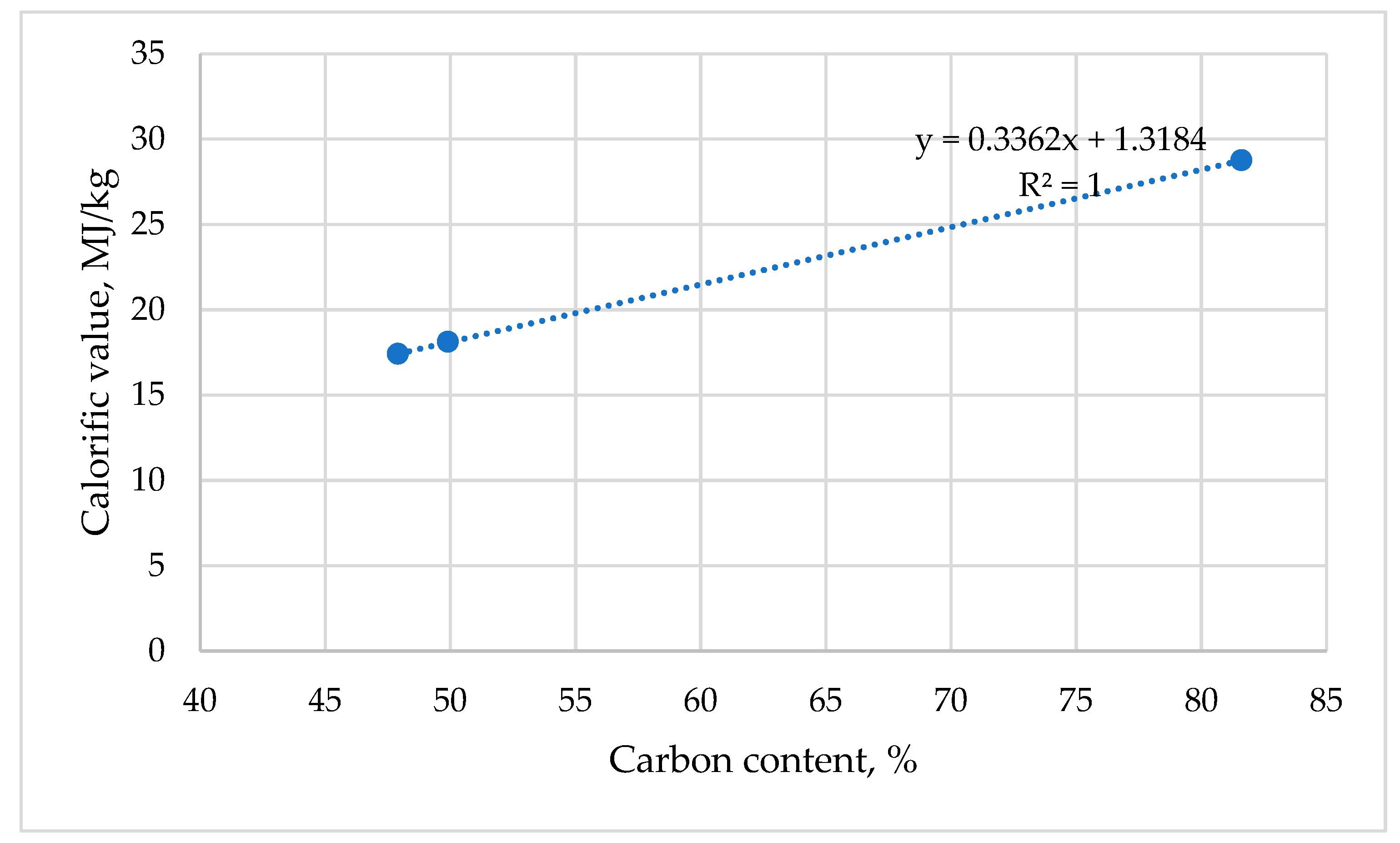

3.5. Calorific Value

3.6. Calorific Density

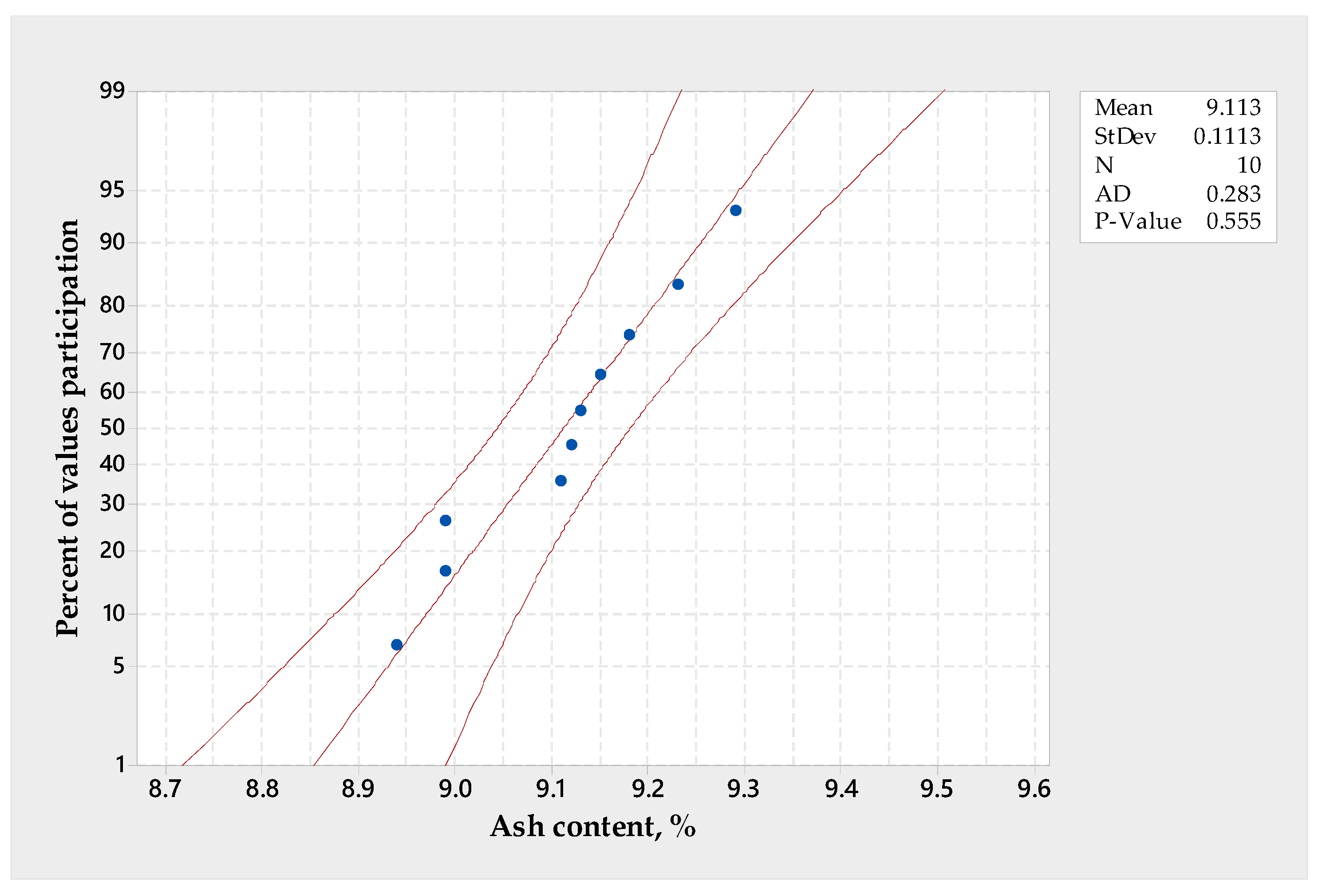

3.7. Ash Content

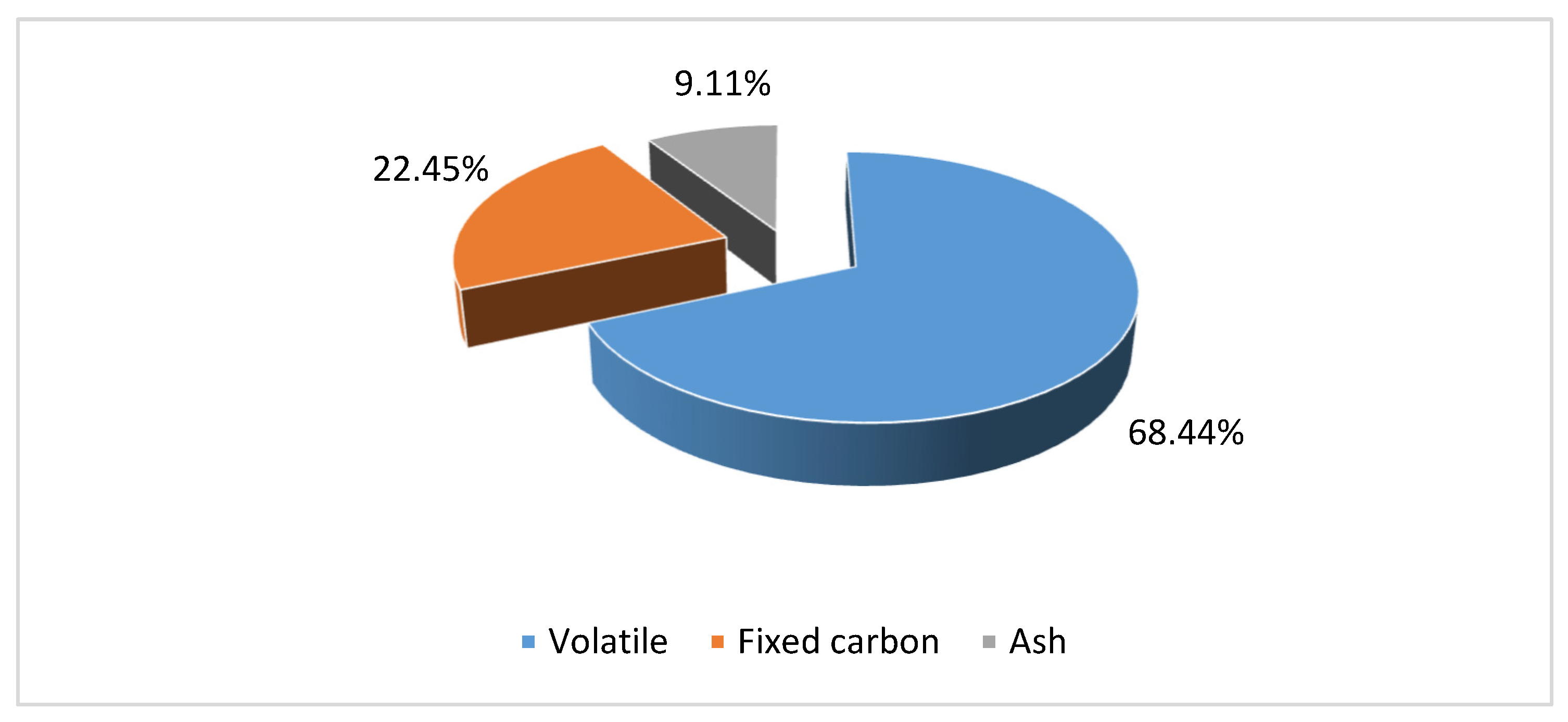

3.8. Volatile Matter, Ash, and Fixed Carbon (EN 15148:2009)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tabarés, J.L.M.; Ortiz, L.; Granada, E.; Viar, F.P. Feasibility Study of Energy Use for Densificated Lignocellulosic Material (briquettes). Fuel 2000, 79, 1229–1237. [Google Scholar] [CrossRef]

- Krajnic, N. Wood Fuel Handbook; Food and Agriculture Organization (FAO) of the United Nations: Pristina, Wikipedia, 2015; Available online: https://large.stanford.edu/courses/2017/ph240/timcheck1/docs/fao-krajnc-2015.pdf (accessed on 23 March 2022).

- Prasertsan, S.; Sajakulnukit, B. Biomass and Bioenergy in Thailand: Potential, Opportunity and Barriers. Renew. Energy 2006, 31, 599–610. [Google Scholar] [CrossRef]

- Boutin, J.P.; Gervasoni, G.; Help, R.; Seyboth, K.; Lamers, P.; Ratton, M.; McCormick, K.; Mundaca, L.; Plepys, A. Alternative Energy Sources in Transition Countries. The Case of Bio-energy in Ukraine. Environ. Eng. Manag. J. 2007, 6, 3–11. [Google Scholar]

- Kim, S.; Dale, B.E. Cumulative Energy and Global Warming Impact from the Production of Biomass for Biobased Products. J. Ind. Ecol. 2003, 7, 147–162. [Google Scholar] [CrossRef]

- Vilcek, J. Bioenergetic potential of agricultural soils in Slovakia. Biomass Bioenergy 2013, 56, 53–61. [Google Scholar] [CrossRef]

- Agropower 2022. Available online: http://www.agropower-energy.ro/index.php?page=agro-biomasa (accessed on 10 May 2022).

- Lundborg, A. A Sustainable Forest Fuel System in Sweden. Biomass Bioenergy 1998, 15, 399–406. [Google Scholar] [CrossRef]

- Lakó, J.; Hancsók, J.; Yuzhakova, T.; Marton, G.; Utasi, A.; Rédey, A. Biomass—A Source of Chemicals and Energy for Sustainable Development. Environ. Eng. Manag. J. 2008, 7, 499–509. [Google Scholar] [CrossRef]

- Ramírez-Ramírez, M.A.; Carrillo-Parra, A.; Ruíz-Aquino, F.; Pintor-Ibarra, L.F.; González-Ortega, N.; Orihuela-Equihua, R.; Carrillo-Ávila, N.; Luján-Álvarez, C.; Rutiaga-Quinones, J.G. Valorization of briquettes fuel using Pinus spp. sawdust from five regions of Mexico. BioResources 2021, 16, 2249–2263. [Google Scholar] [CrossRef]

- ÖNORM M 7135 [2000]; Pellets and Briquettes—Requirements and Test Conditions. Austria Standards Institute: Vienna, Austria, 2000.

- Borowsky, G. Possibilities of Utilisation of Energy Briquettes. 2011. Available online: http://eeeic.org/proc/papers/74.pdf (accessed on 4 June 2022).

- Kazagic, A.; Smajevic, I. Synergy effects of co-firing wooden biomass with Bosnian coal. Energy 2009, 34, 699–707. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Mihăescu, L.; Prisecaru, T.; Oprea, I.; Pîşă, I.; Negreanu, G.; Indrieş, R. Combustion of Pitcoal-wood Biomass Briquettes in a Boiler Test Facility. Environ. Eng. Manag. J. 2008, 7, 595–601. [Google Scholar] [CrossRef]

- Zarringhalam, M.A.; Gholipour, Z.N.; Dorosti, S.; Vaez, M. Physical properties of solid fuel briquettes from bituminous coal waste and biomass. J. Coal Sci. Eng. 2011, 17, 434–438. [Google Scholar] [CrossRef]

- Kostanaki, E.; Vamvuka, D. A comparative reactivity and kinetic study on the combustion of coal-biomass char blends. Fuel 2005, 85, 1186–1193. [Google Scholar] [CrossRef]

- Teuch, O.; Hofeanuer, A.; Troger, F.; From, J. Wood Science Basic properties of specific wood-based materials carbonised in a nitrogen atmosphere. Wood Sci. Technol. 2004, 38, 323–333. [Google Scholar] [CrossRef]

- Chen, W.H.; Cheng, W.Y.; Lu, K.M.; Wuang, Y.P. An Evaluation on Improvement of Pulverized Biomass Property for Solid through Torrefaction. Appl. Energ. 2011, 11, 3636–3644. [Google Scholar] [CrossRef]

- Chen, W.H.; Ye, S.C.; Sheen, H.K. Hydrothermal Carbonization of Sugarcane Bagasse via Wet Torrefaction in Association with Microwave Heating. Bioresource Technol. 2012, 118, 195–203. [Google Scholar] [CrossRef]

- Verma, V.K.; Bram, S.; de Ruyck, J. Small Scale Biomass Systems: Standards, Quality Labeling and Market Driving Factors—An EU Outlook. Biomass Bioenergy 2009, 33, 1393–1402. [Google Scholar] [CrossRef]

- CTI-R 04/5 [2004]; Solid Bio-Combustibles—Characterisation of the Pellet to Fine Energy. Italian Organization for Standardization: Milano, Italy, 2004.

- DIN 51900-1; Determining the Gross Calorific Value of Solid and Liquid Fuels Using the Bomb Calorimeter and Calculation of Net Calorific Value. Part 1: General Information. German National Standard: Berlin, Germany, 2000.

- Gocławski, J.; Korzeniewska, E.; Sekulska-Nalewajko, J.; Kiełbasa, P.; Dróżdż, T. Method of Biomass Discrimination for Fast Assessment of Calorific Value. Energies 2022, 15, 2514. [Google Scholar] [CrossRef]

- Kudasik, M.; Skoczylas, N.; Palla Braga, L.T. Laboratory Studies on Permeability of Coals Using Briquettes: Understanding Underground Storage of CO2. Energies 2022, 15, 715. [Google Scholar] [CrossRef]

- Hívila, M.P.; Marreiro Rogério, S.; Peruchi Lopes, R.; Andersen, S.; Eliziário, S.; Rotella Junior, P. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Dąbrowska, M. Influence of the Die Height on the Density of the Briquette Produced from Shredded Logging Residues. Materials 2021, 14, 3698. [Google Scholar] [CrossRef]

- Lamlom, H.; Savidge, R.A. A reassessment of carbon content in wood: Variation within and between 41 North American species. Biomass Bioenergy 2003, 25, 381–388. [Google Scholar] [CrossRef]

- Būmane, S.; Poiša, L.; Čubars, E.; Platače, R. The analysis of carbon content in different energy crops, NJF 25th Congress Nordic view to sustainable rural development. Crop Sci. Prod. 2015, 25, 156–160. [Google Scholar]

- Garcia, A.M.; Barcia, B.M.J.; Diaz, D.M.A.; Hernandez, J.A. Preparation of Active Carbon from a Comercial Holm-oak Charcoal: Study of Micro-and Meso-porosity. Wood Sci. Technol. 2004, 37, 385–394. [Google Scholar] [CrossRef]

- EN 14774-1:2009; Solid Biofuels. Determination of Moisture Content; Oven Dry Method; Total Moisture. Reference Method. European Committee of Standardization: Brussels, Belgium, 2009.

- DIN 51731 [1996]; Testing of Solid Fuels—Compressed and Untreated Wood—Requirements and Testing. German Institute for Standardization: Berlin, Germany, 1996.

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Plištil, D.; Brožek, M.; Malaták, J.; Roy, A.; Hutla, P. Mechanical Characteristics of Standard Fuel Briquettes on Biomass Basis. Res. Agr. Eng. 2005, 51, 66–72. [Google Scholar] [CrossRef]

- CEN/TC 335 [2004]; Solid Biofuels—Fuels Specification and Classes. European Committee of Standardization: Brussels, Belgium, 2004.

- EN ISO 17225-1: 2014 [2014]; Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements. European Committee of Standardization: Brussels, Belgium, 2014.

- ASTM D3865-12; Standard Test Method for Gross Calorific Value of Coal and Coke. American Society for Testing and Materials: West Conshohocken, PA, USA, 2000.

- ISO 1928:2009; Solid Mineral Fuels. Determining the Gross Calorific Power by Calorimeter Bomb and Calculus of Net Calorific Power. International Organization for Standardization: Geneva, Switzerland, 2009.

- Equilabo, 2012, Catalogue 1200. Parr. Oxygen Bomb Calorimeters and Accessories. Available online: http://www.equilabo.com/Documentation/Calorim%C3%A8tre.pdf (accessed on 8 July 2012).

- Shulga, G.; Betkers, T.; Brovkina, J.; Aniskevicha, O.; Ozolinš, J. Relationship between Composition of the Lignin-based Interpolymer Complex and its Structuring Ability. Environ. Eng. Manag. J. 2008, 7, 397–400. [Google Scholar] [CrossRef]

- ASTM E1755-01; “Standard Method for the Determination of Ash in Biomass” In 2003 Annual Book of ASTM Standards, Volume 11.05. American Society for Testing and Materials, International: Philadelphia, PA, USA, 2003.

- Okello, C.; Pindozzi, S.; Faugno, S.; Boccia, L. Bioenergy potential of agricultural and forest residues in Uganda. Biomass Bioenergy 2013, 56, 515–525. [Google Scholar] [CrossRef]

- Hansen, M.A.T.; Jørgensen, H.; Laursen, K.H.; Schjoerring, J.K.; Felby, C. Structural and chemical analysis of process residue from biochemical conversion of wheat straw (Triticum aestivum L.) to ethanol. Biomass Bioenergy 2013, 56, 572–581. [Google Scholar] [CrossRef]

- Petrovici, V.; Popa, N. Chemistry and Chemical Wood Processing (Romanian language); Lux Libris Print House: Brasov, Romania, 1997. [Google Scholar]

- Pallavi, H.V.; Srikantaswamy, S.; Kiran, B.M.; Vyshnavi, D.R.; Ashwin, C.A. Briquetting Agricultural Waste as an Energy Source. J. Environ. Sci. Comput. Sci. Eng. Technol. 2013, 2, 160–172. [Google Scholar]

- ASTM E872-82(2019); Standard Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- EN 15148:2009; Solid Biofuels—Determination of the Content of Volatile Matter. European Committee of Standardization: Brussels, Belgium, 2009.

- EN 323: 1993; Wood-Based Panels—Determination of Density. European Committee of Standardization: Brussels, Belgium, 1993.

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A. Effect of Species, Particle Size and Compacting Pressure on Relaxed Density and Compressive Strength of Fuel Briquettes. Int. J. Energy Environ. Eng. 2013, 4, 30. [Google Scholar] [CrossRef]

- Sola, O.C.; Atis, C.D. The Effects of Pyrite Ash on the Compressive Strength Properties of Briquettes. KSCE J. Civ. Eng. 2012, 16, 1225–1229. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Rahman, A.N.E.; Masood, M.A.; Prasad, C.S.N.; Venkatesham, M. Influence of Size and Shape on the Strength of Briquettes. Fuel Process. Technol. 1989, 23, 185–195. [Google Scholar] [CrossRef]

- Dhillon, R.S.; von Wuelhlisch, G. Mitigation of Global Warming through Renewable Biomass. Biomass Bioenergy 2013, 48, 75–87. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, Z.; Cai, Z.; Fei, B.; Yu, Y.; Liu, X. Dynamic mechanical thermal analysis of moso bamboo (Phyllostachys heterocycla) at different moisture content. BioResources 2012, 7, 1548–1557. [Google Scholar] [CrossRef][Green Version]

- Kers, J.; Kulu, P.; Aruniit, A.; Laurmaa, V.; Križan, P.; Šooš, L.; Kask, Ü. Determination of physical, mechanical and burning characteristics of polymeric waste material briquettes. Est. J. Eng. 2013, 19, 307–316. [Google Scholar] [CrossRef]

- Demirbas, A. Biomass Resource Facilities and Biomass Conversion Processing for Fuels and Chemicals. Energ. Convers. Manage. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Demirbas, A.; Demirbas, A.S. Briquetting Properties of Biomass Waste Materials. Energ. Source Part A 2004, 26, 83–91. [Google Scholar] [CrossRef]

- Wijaya, N.; Zhang, L.A. Critical Review of Coal Demineralization and Its Implication on Understanding the Speciation of Organically Bound Metals and Submicrometer Mineral Grains in Coal. Energ Fuel. 2011, 25, 1–16. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, H.; Liu, Y.; Dang, H.; Ye, L.; Conejio, A.; Xu, R. Review on biomass metallurgy: Pretreatment technology, metallurgical mechanism and process design. Int. J. Miner. Metall. Mater. 2022, 29, 1133–1149. [Google Scholar] [CrossRef]

- Spirchez, C.; Lunguleasa, A.; Ionescu, C.; Croitoru, C. Physical and calorific properties of wheat straw briquettes and pellets. MATEC Web Conf. 2019, 290, 90110. [Google Scholar] [CrossRef]

| Type | Mean Mass, g | Mean Force, kg | Mean Resistance, N/mm2 | Mean Diameter, mm | Mean Length, mm | Maximum Rows |

|---|---|---|---|---|---|---|

| T1 | 208.1 | 598 | 2.10 | 59.95 | 59.49 | 23 |

| T2 | 297.3 | 501 | 1.16 | 73.22 | 60.38 | 19 |

| T3 | 253.8 | 395 | 1.14 | Dex = 71.12 Din = 26.8 | 60.36 | 17 |

| Materials | Carbon, % | Hydrogen, % | Oxygen, % | Ash Content, % | Calorific Value, MJ/kg |

|---|---|---|---|---|---|

| Wheat straw | 47.8 | 5.1 | 38.1 | 9.1 | 17.402 |

| Beech waste | 49.9 | 6.4 | 43.0 | 0.7 | 18.119 |

| Charcoal | 81.6 | 7.1 | 10.1 | 1.2 | 28.753 |

| No. | Characteristics | Triticum aestivum L. | Fagus sylvatica L. |

|---|---|---|---|

| 1. | Moisture content, % | 10 | 10 |

| 2. | Effective density, kg/m3 | 1.21 | 1.26 |

| 3. | Calorific value CV, MJ/kg | 17.69 | 18.38 |

| 4. | Calorific density, MJ/m3 | 20,679 | 21,856 |

| 5. | Volatile, % | 68.44 | 66.3 |

| 6. | Fixed carbon, % | 23.45 | 32.8 |

| 7. | Compressive strength, N/mm2 | 2.1 | 4.6 |

| 8. | Expansion coefficient, % | 1.6 | 1.8 |

| 9. | Ash content, %, | 9.1 | 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dragusanu, V.; Lunguleasa, A.; Spirchez, C. Evaluation of the Physical, Mechanical, and Calorific Properties of Briquettes with or without a Hollow Made of Wheat (Triticum aestivum L.) Straw Waste. Appl. Sci. 2022, 12, 11936. https://doi.org/10.3390/app122311936

Dragusanu V, Lunguleasa A, Spirchez C. Evaluation of the Physical, Mechanical, and Calorific Properties of Briquettes with or without a Hollow Made of Wheat (Triticum aestivum L.) Straw Waste. Applied Sciences. 2022; 12(23):11936. https://doi.org/10.3390/app122311936

Chicago/Turabian StyleDragusanu, Veronica, Aurel Lunguleasa, and Cosmin Spirchez. 2022. "Evaluation of the Physical, Mechanical, and Calorific Properties of Briquettes with or without a Hollow Made of Wheat (Triticum aestivum L.) Straw Waste" Applied Sciences 12, no. 23: 11936. https://doi.org/10.3390/app122311936

APA StyleDragusanu, V., Lunguleasa, A., & Spirchez, C. (2022). Evaluation of the Physical, Mechanical, and Calorific Properties of Briquettes with or without a Hollow Made of Wheat (Triticum aestivum L.) Straw Waste. Applied Sciences, 12(23), 11936. https://doi.org/10.3390/app122311936