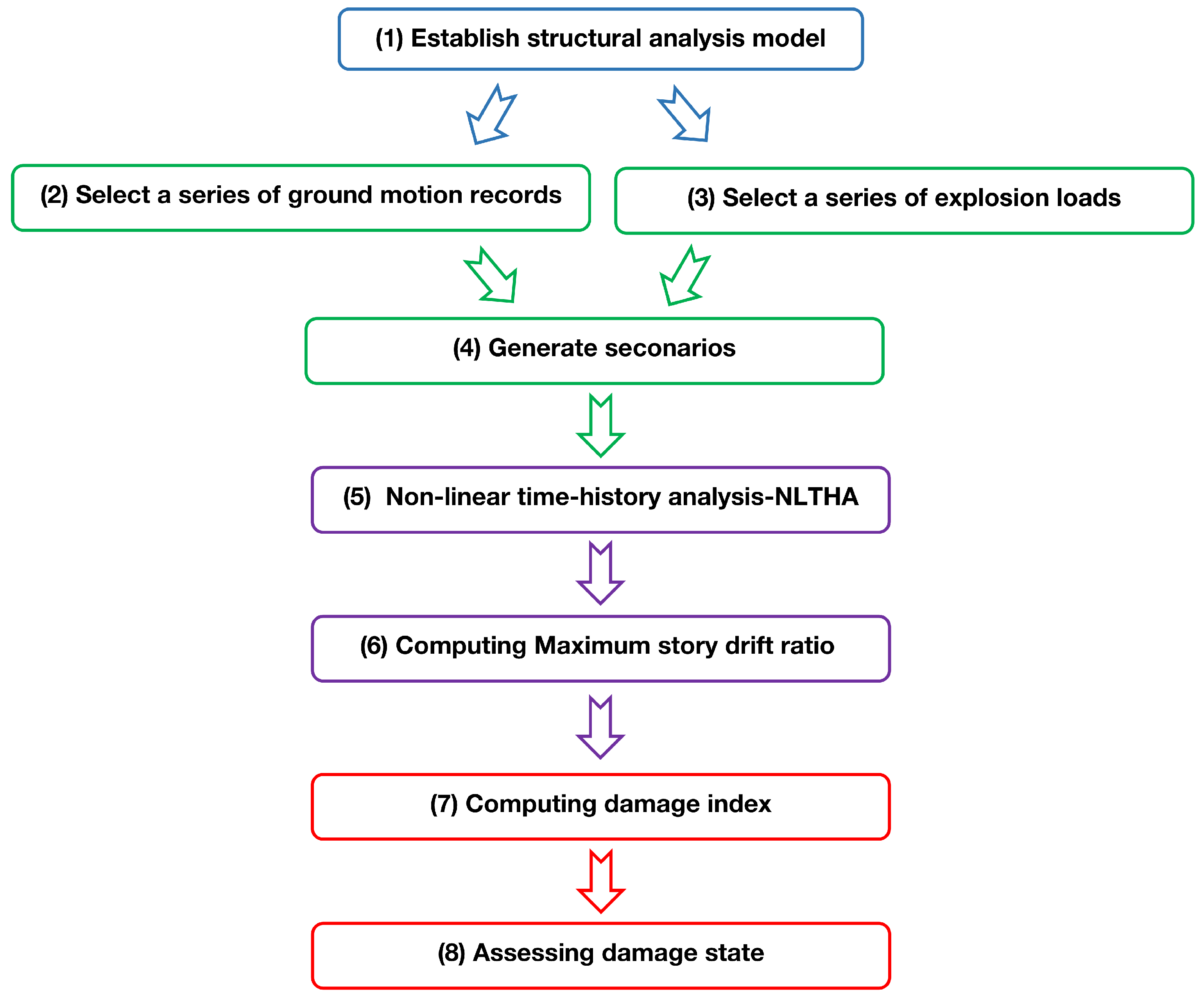

Figure 1.

The framework for damage evaluation of shear wall structures under an earthquake–explosion disaster chain.

Figure 1.

The framework for damage evaluation of shear wall structures under an earthquake–explosion disaster chain.

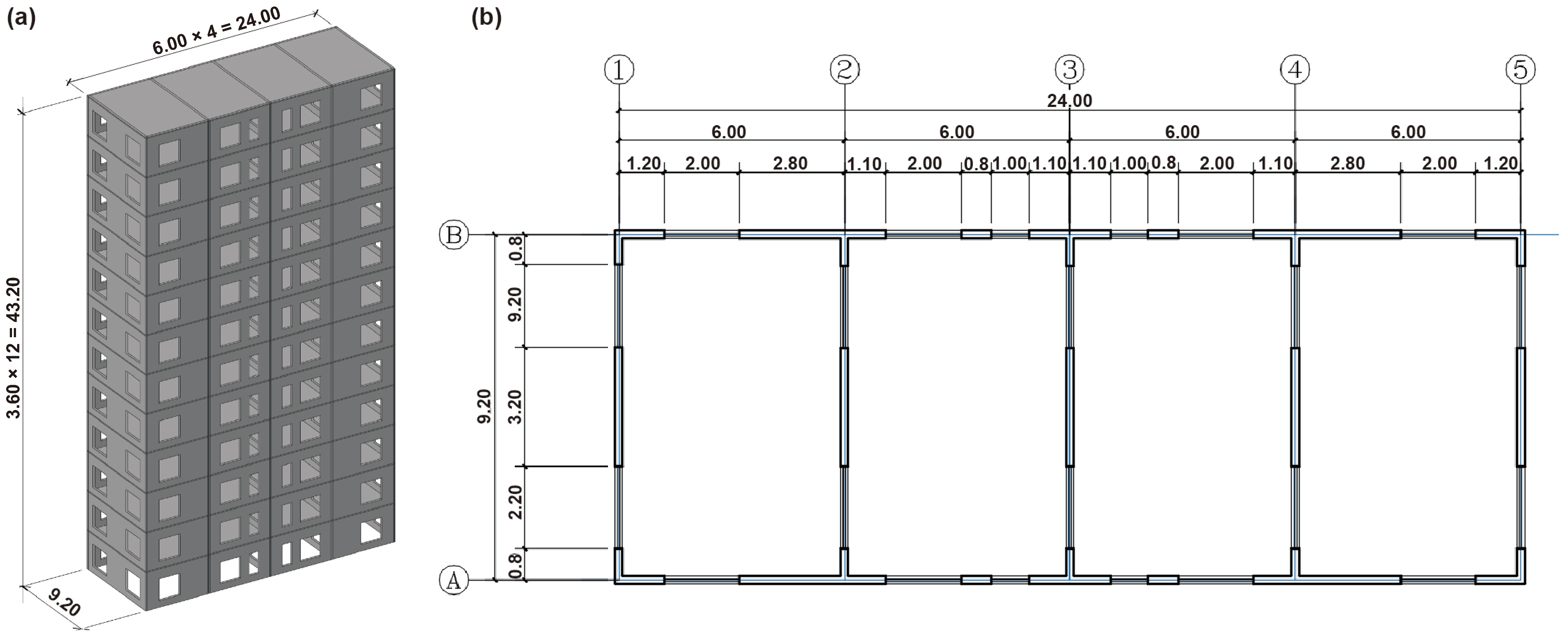

Figure 2.

Schematic diagram of the 12-story shear wall structure: (a) elevation; and (b) plan (Unit: m).

Figure 2.

Schematic diagram of the 12-story shear wall structure: (a) elevation; and (b) plan (Unit: m).

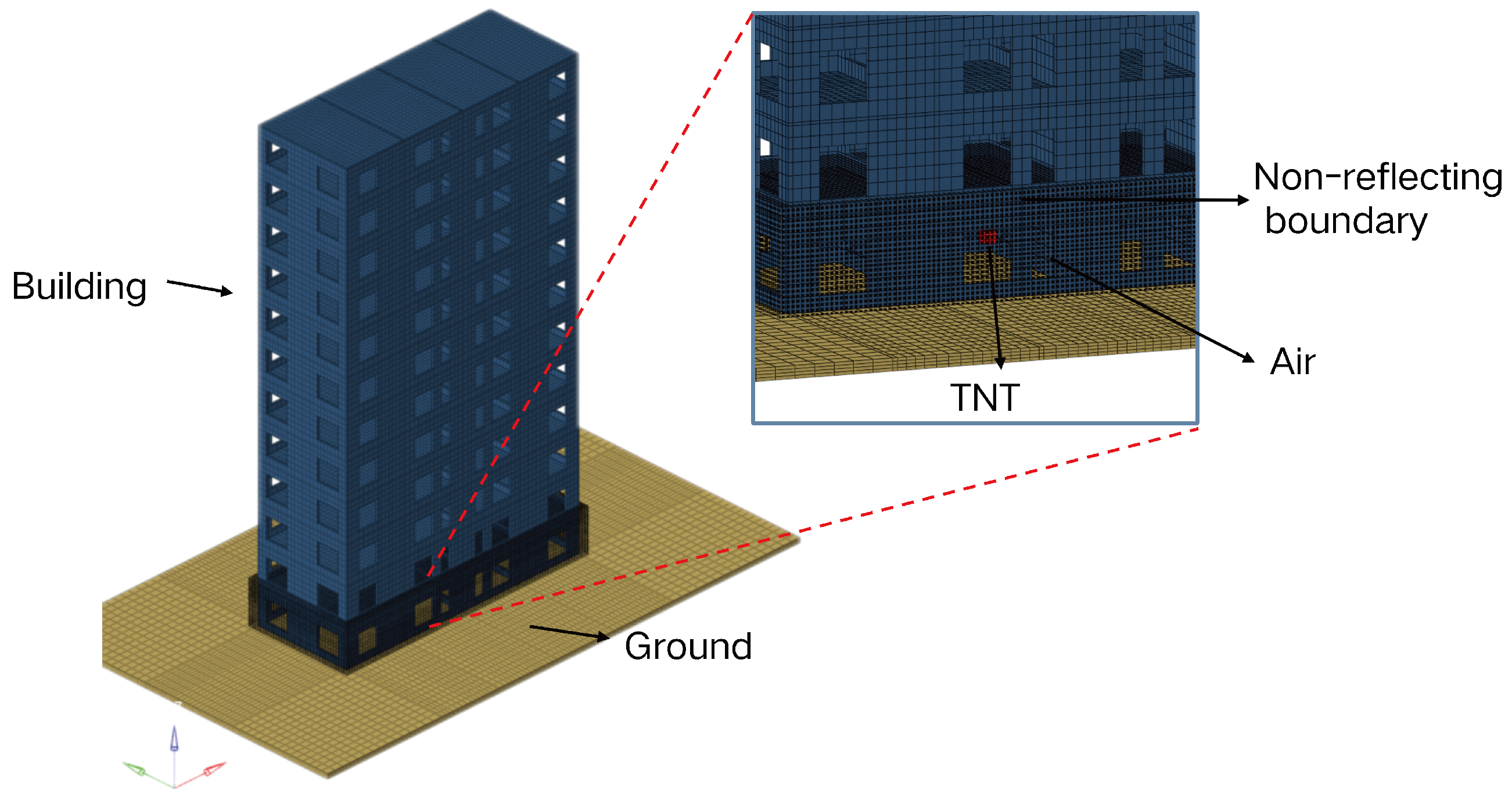

Figure 3.

FE model of the shear wall structure under earthquake–explosion disaster chains.

Figure 3.

FE model of the shear wall structure under earthquake–explosion disaster chains.

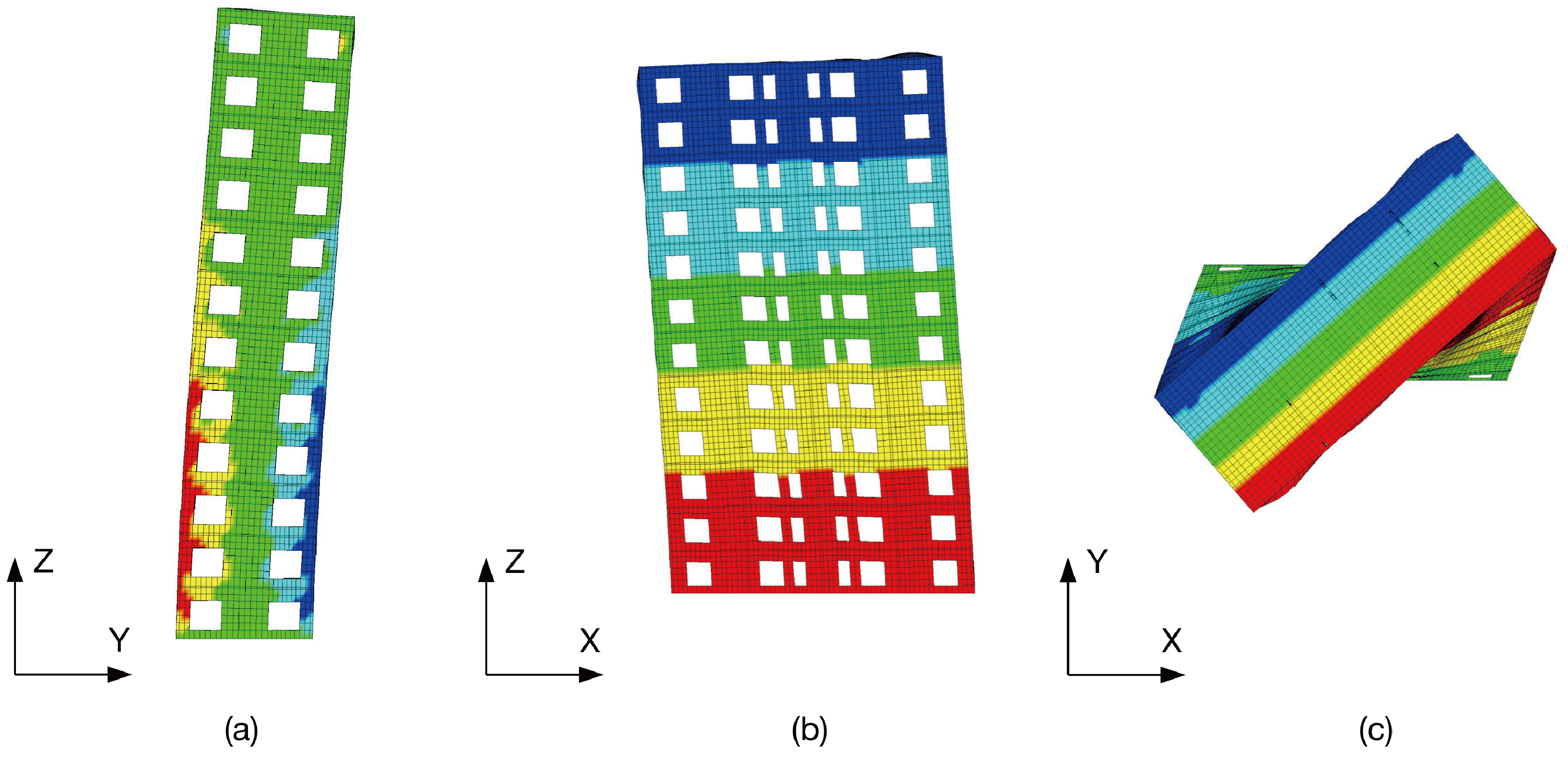

Figure 4.

The first three modes of the shear wall structure: (a) the first order; (b) the second order; and (c) the third order.

Figure 4.

The first three modes of the shear wall structure: (a) the first order; (b) the second order; and (c) the third order.

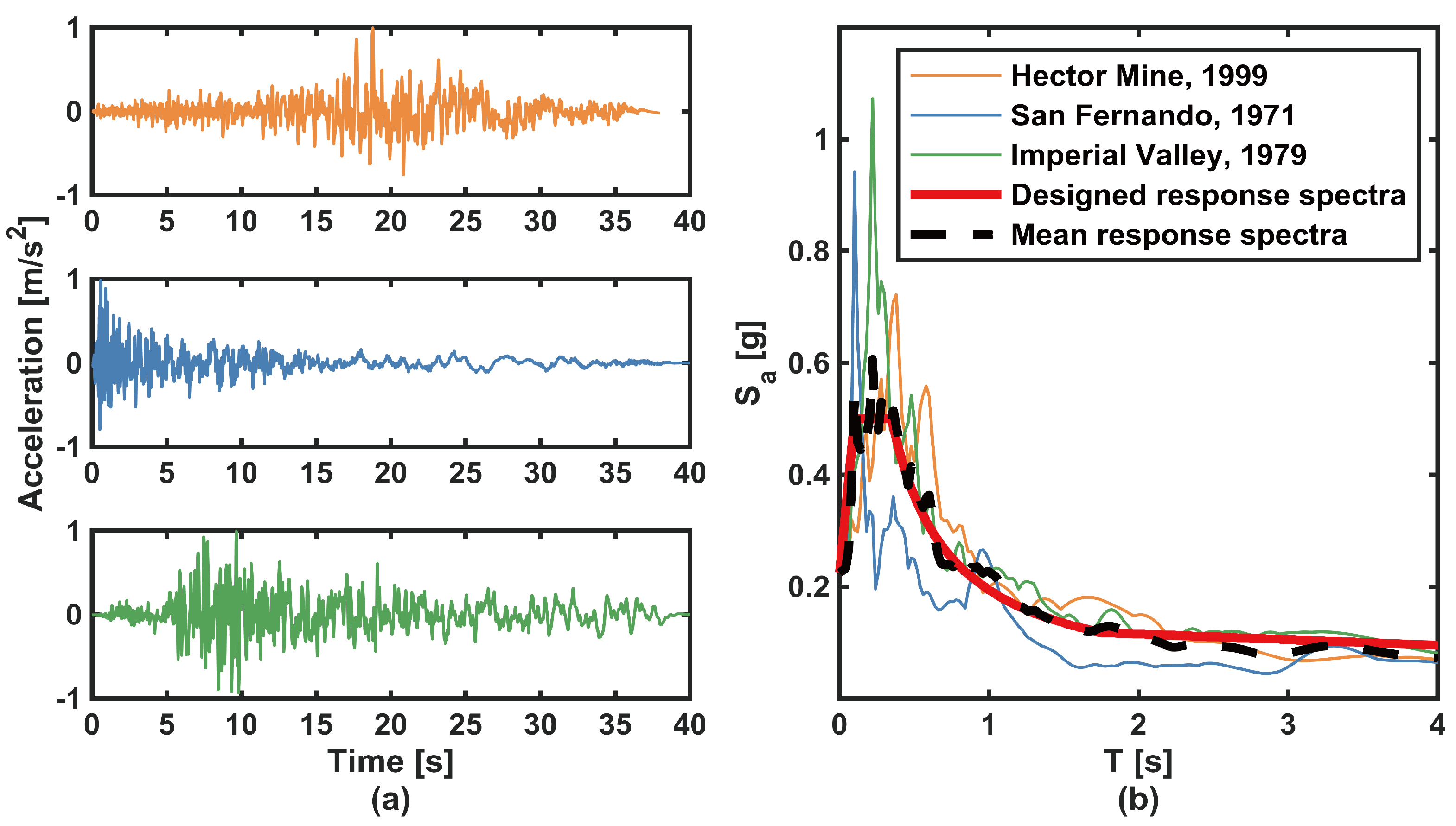

Figure 5.

(a) Spectra of three scaled time history records based on design spectra; and (b) comparison of the designed response spectra and the mean response spectra.

Figure 5.

(a) Spectra of three scaled time history records based on design spectra; and (b) comparison of the designed response spectra and the mean response spectra.

Figure 6.

The sketch of explosion loads acting on the structure: (a) the location of the gas leak; and (b) the location of the explosion.

Figure 6.

The sketch of explosion loads acting on the structure: (a) the location of the gas leak; and (b) the location of the explosion.

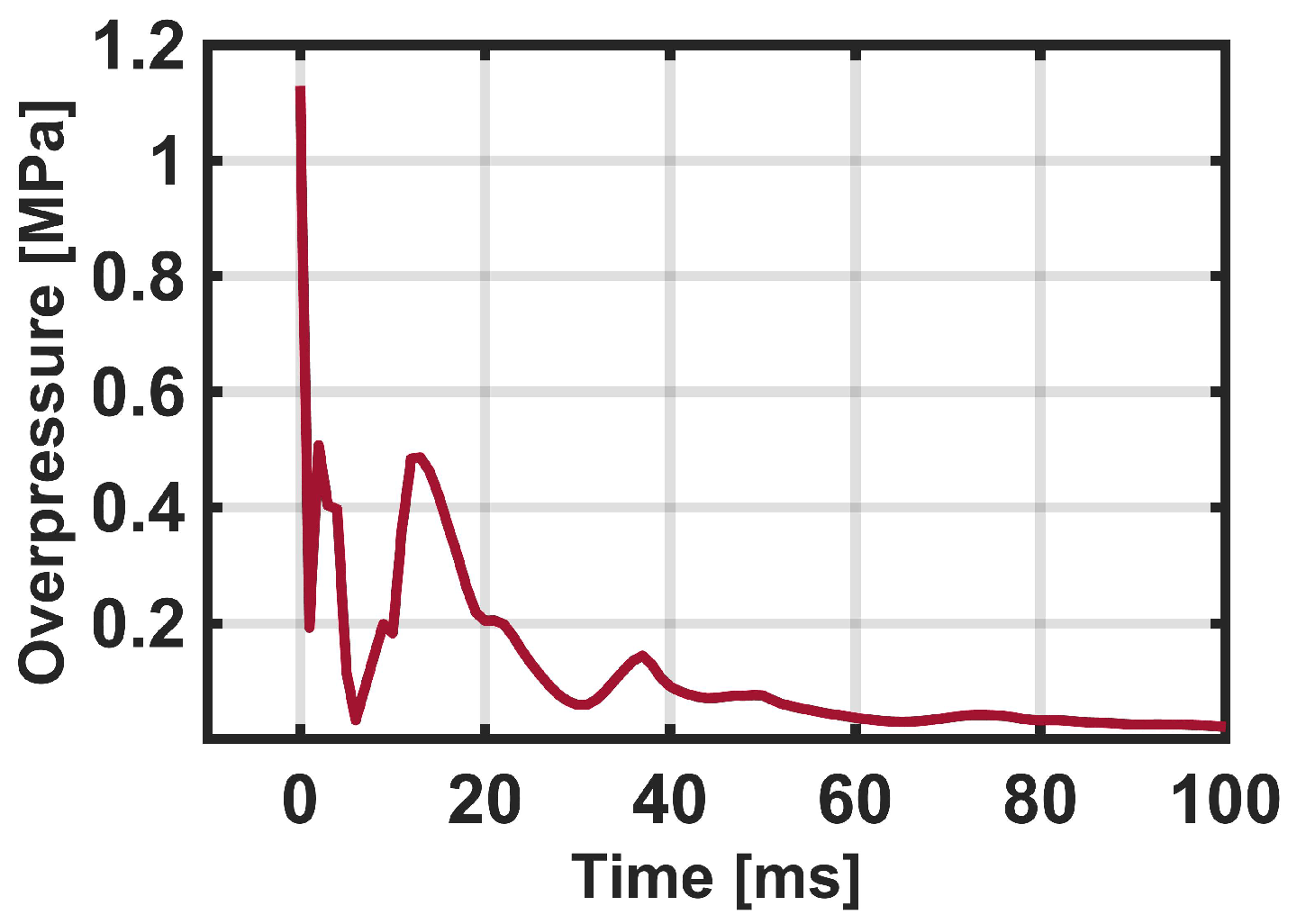

Figure 7.

The overpressure time history of the selected target in series-II.

Figure 7.

The overpressure time history of the selected target in series-II.

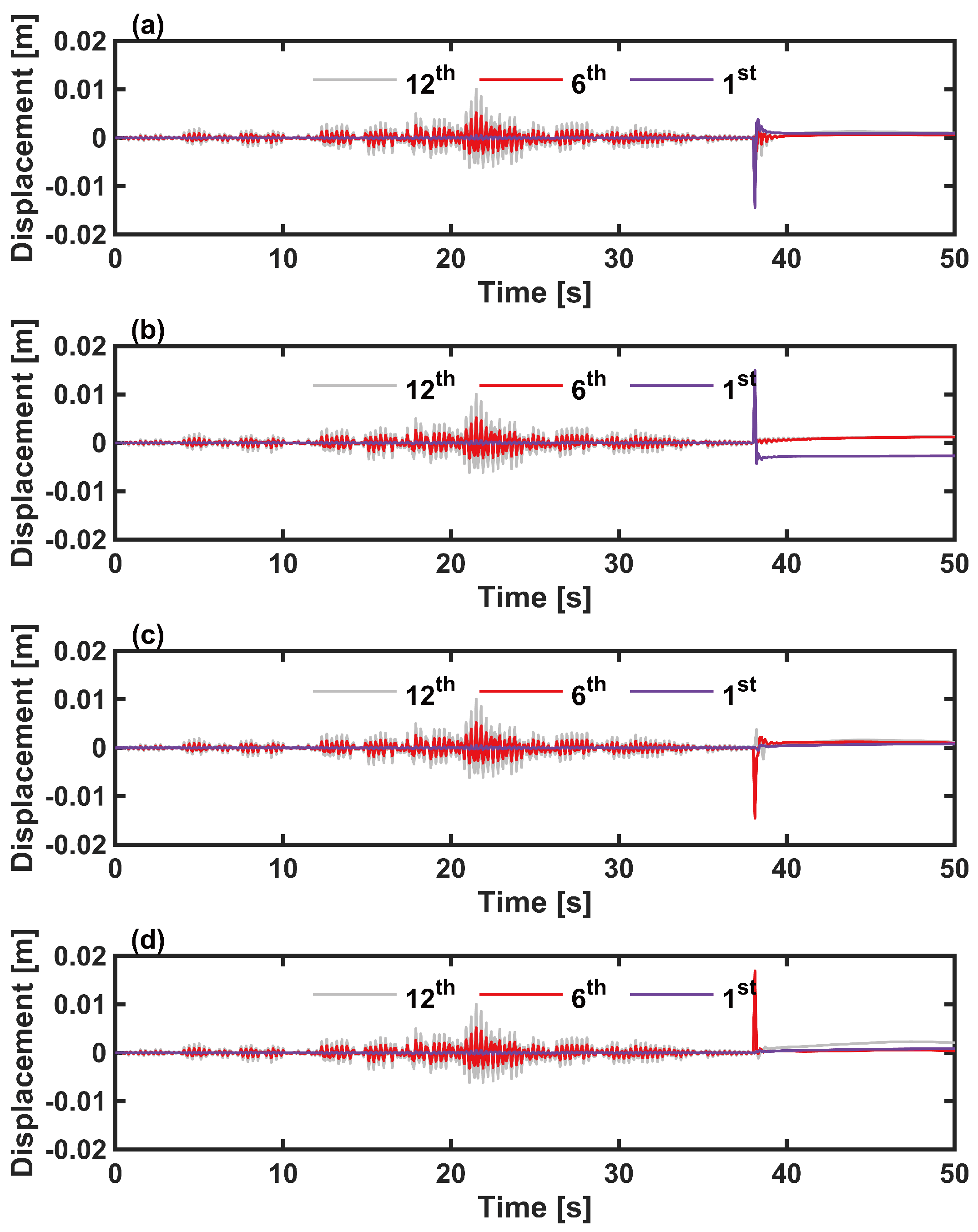

Figure 8.

Displacement time histories of the first, sixth, and twelfth floor under different conditions: (a) case 4; (b) case 7; (c) case 10; and (d) case 13.

Figure 8.

Displacement time histories of the first, sixth, and twelfth floor under different conditions: (a) case 4; (b) case 7; (c) case 10; and (d) case 13.

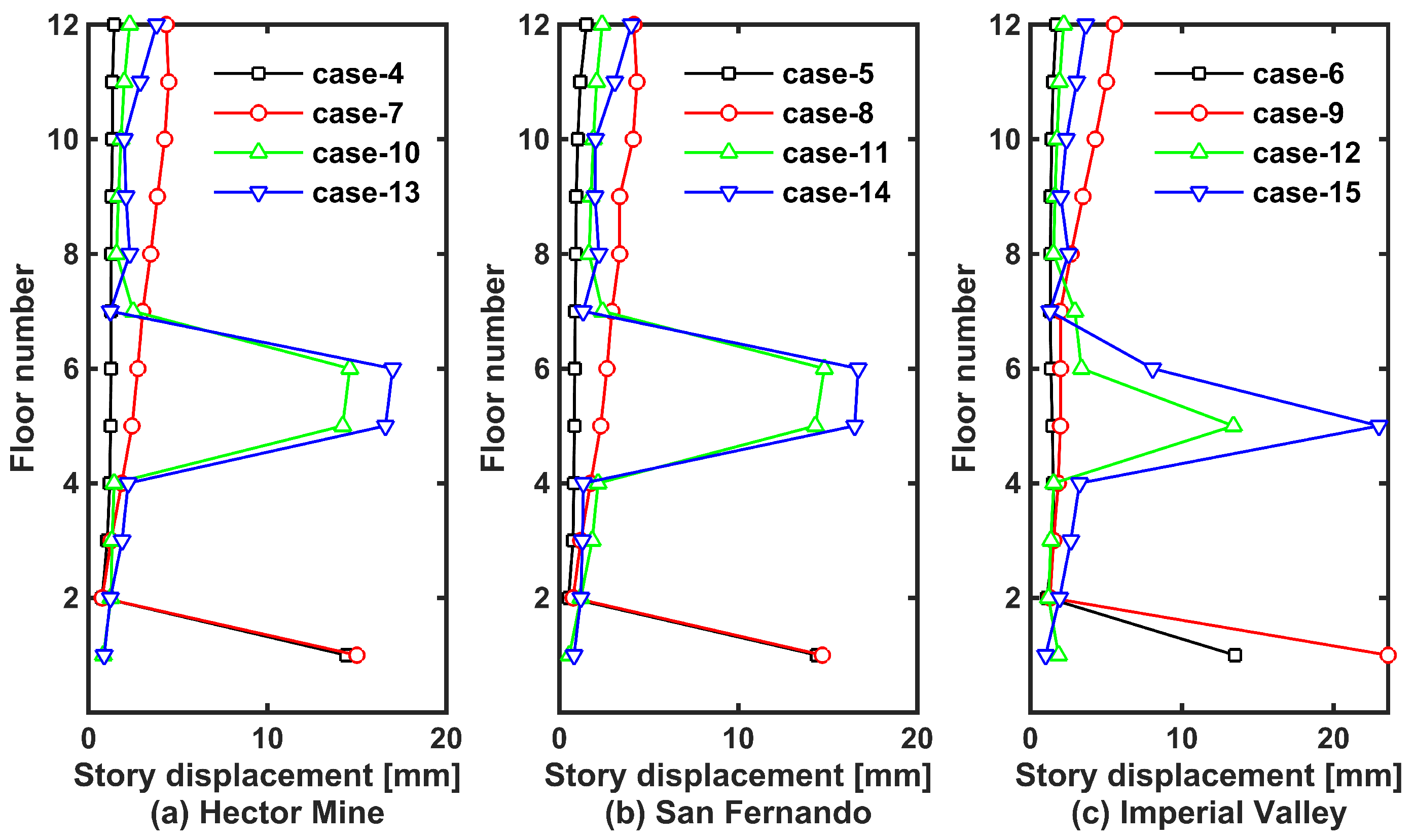

Figure 9.

Peak displacement of each floor.

Figure 9.

Peak displacement of each floor.

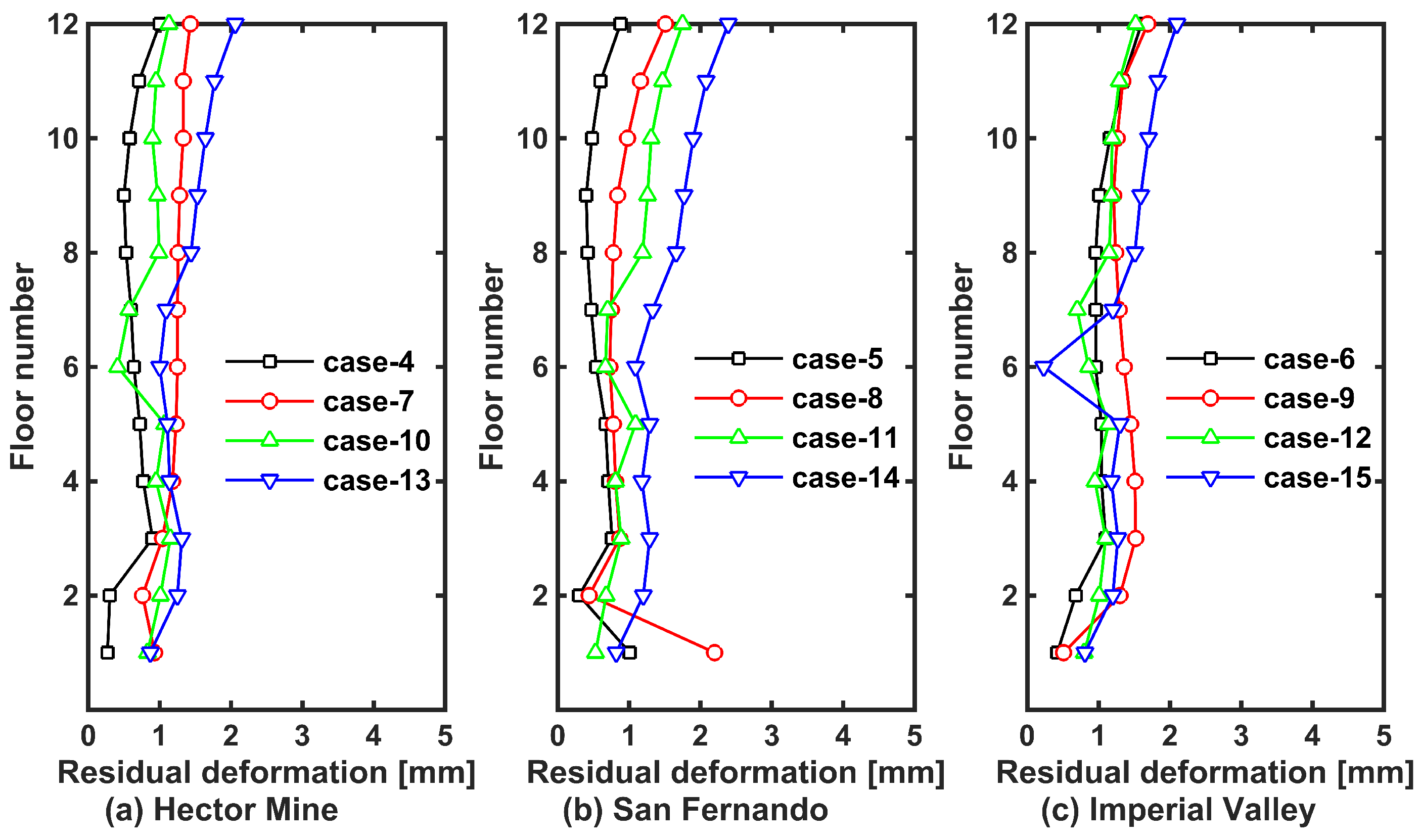

Figure 10.

Distribution of cumulative plastic deformation.

Figure 10.

Distribution of cumulative plastic deformation.

Figure 11.

The damage distribution of shear wall structures under case 4: (a) Damage caused by an earthquake; and (b) Damage caused by an earthquake–explosion disaster chain.

Figure 11.

The damage distribution of shear wall structures under case 4: (a) Damage caused by an earthquake; and (b) Damage caused by an earthquake–explosion disaster chain.

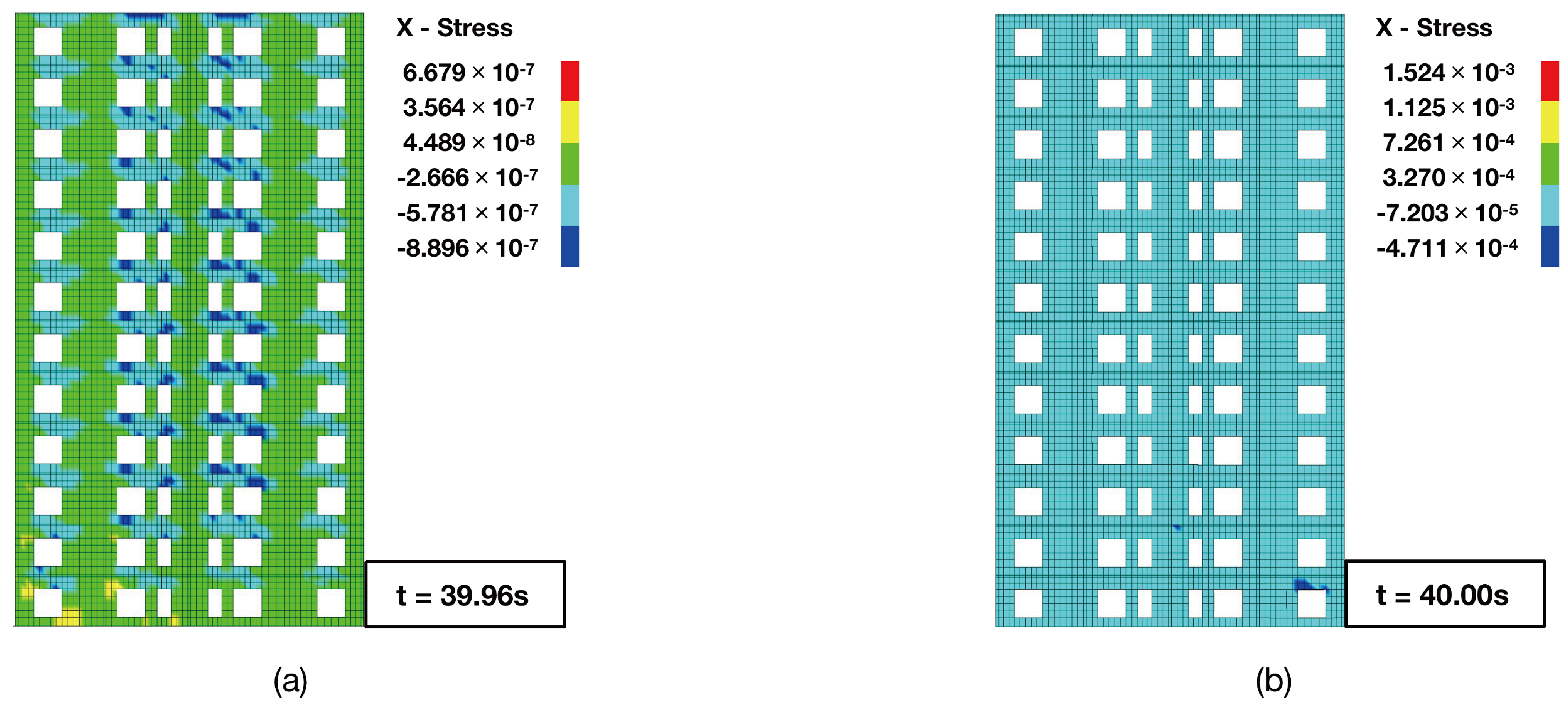

Figure 12.

The stress distribution of shear wall structures under case 4: (a) x-stress caused by an earthquake; and (b) x-stress caused by the earthquake–explosion disaster chain.

Figure 12.

The stress distribution of shear wall structures under case 4: (a) x-stress caused by an earthquake; and (b) x-stress caused by the earthquake–explosion disaster chain.

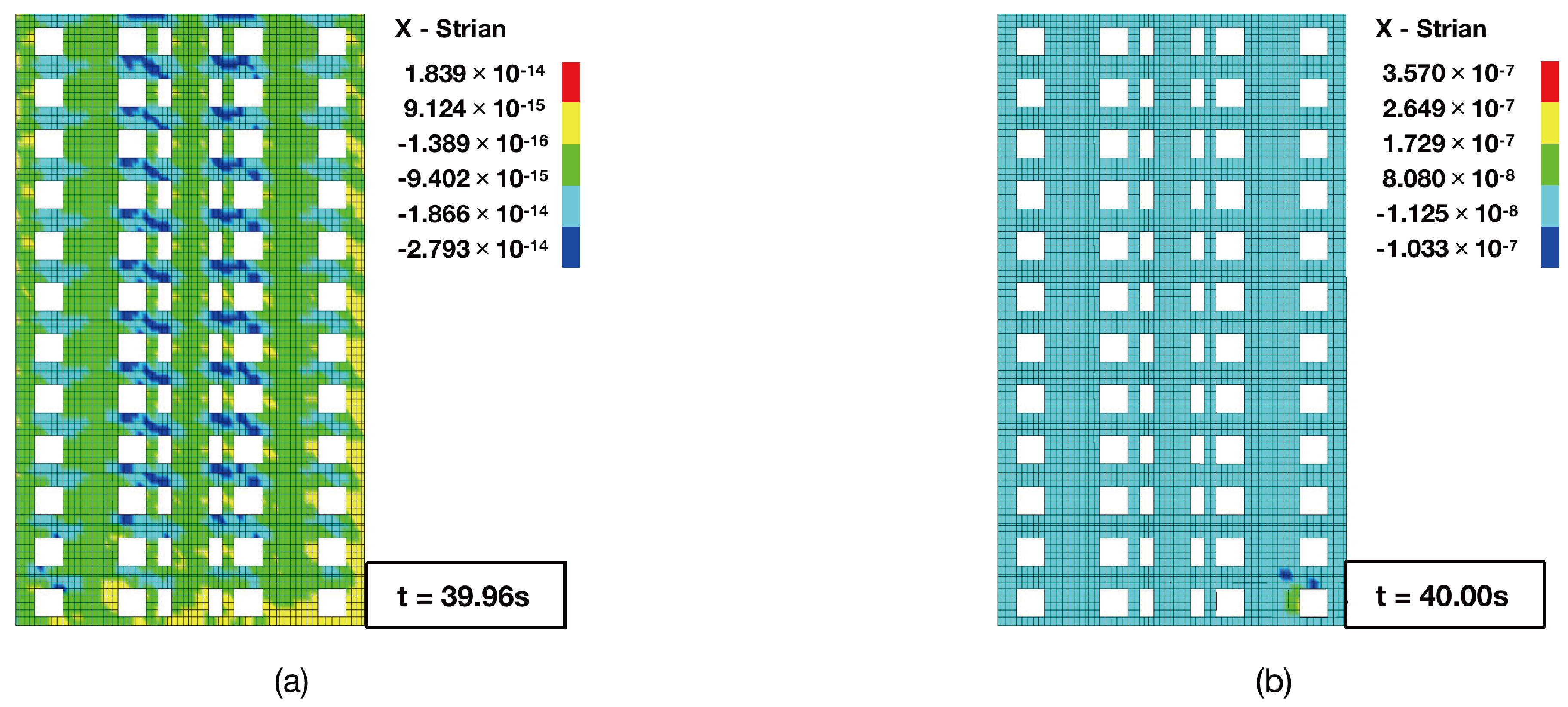

Figure 13.

The strain distribution of shear wall structures under case 4: (a) x-strain caused by an earthquake; and (b) x-strain caused by earthquake–explosion disaster chain.

Figure 13.

The strain distribution of shear wall structures under case 4: (a) x-strain caused by an earthquake; and (b) x-strain caused by earthquake–explosion disaster chain.

Figure 14.

Comparison of the maximum story drift ratio: (a) Hector Mine–blast on the first floor; (b) San Fernando–blast on the first floor; (c) Imperial Valley–blast on the first floor; (d) Hector Mine–blast on the sixth floor; (e) San Fernando–blast on the sixth floor; and (f) Imperial Valley–blast on the sixth floor.

Figure 14.

Comparison of the maximum story drift ratio: (a) Hector Mine–blast on the first floor; (b) San Fernando–blast on the first floor; (c) Imperial Valley–blast on the first floor; (d) Hector Mine–blast on the sixth floor; (e) San Fernando–blast on the sixth floor; and (f) Imperial Valley–blast on the sixth floor.

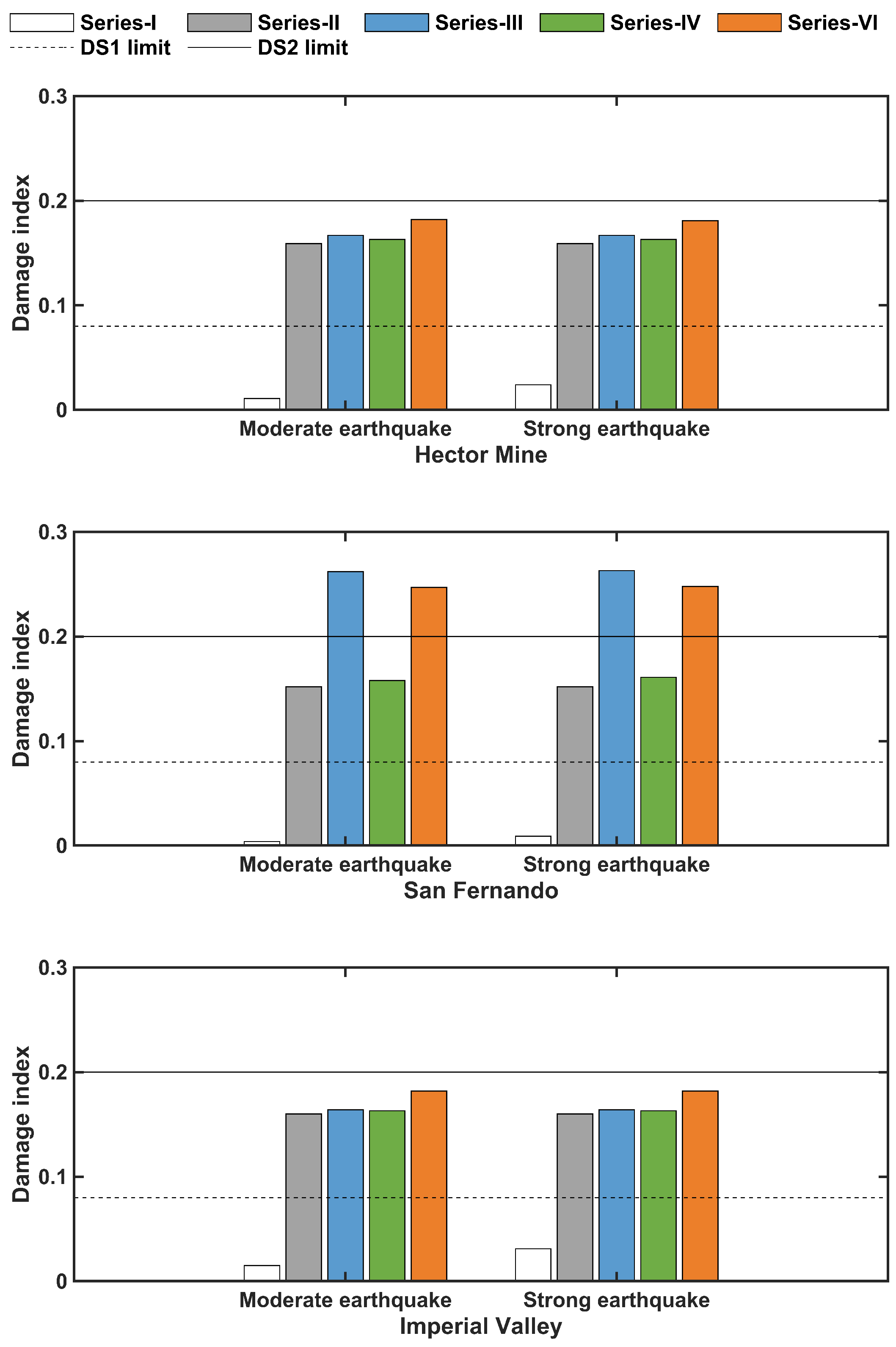

Figure 15.

Distribution of damage index ().

Figure 15.

Distribution of damage index ().

Table 1.

Performance levels, corresponding damage state, and drift limits.

Table 1.

Performance levels, corresponding damage state, and drift limits.

| Performance Level | Damage State | Drift |

|---|

| Fully operational | No damage | <0.2% |

| Operational | Repairable | <0.5% |

| Life safe | Irreparable | <1.5% |

| Near collapse | Severe | <2.5% |

| Collapse | | >2.5% |

Table 2.

Parameters of the constitutive concrete model.

Table 2.

Parameters of the constitutive concrete model.

| Concrete (*MAT_JOHNSON_HOLMQUIST_CONCRETE & *MAT_ADD_EROSION) |

|---|

| Density | G | A | B | C | N | FC | T | EPS0 |

| 2440 kg/m | 14.86 GPa | 0.79 | 1.6 | 0.007 | 0.61 | 0.048 GPa | 4 | 1 s |

| EFMIN | SFMAX | PC | UC | PL | UL | D1 | D2 | K1 |

| 0.01 | 7 | 0.016 GPa | 0.001 | 0.8 GPa | 0.1 | 0.04 | 1 | |

| K1 | K2 | K3 | Failure strain | | | | | |

| 85 GPa | −171 GPa | 208 GPa | 0.01 | | | | | |

Table 3.

Parameters of TNT.

Table 3.

Parameters of TNT.

| TNT (*MAT_HIGH_EXPLOSIVE_BURN & *EOS_JWL) |

|---|

| Initial density | Detonation velocity D | Burst pressure | A | B | | | | |

| 1630 kg/m | 6930 m/s | 21 GPa | 373.8 GPa | 3.747 GPa | 4.15 | 0.9 | 0.35 | 6 × 10 J/m |

Table 4.

Parameters of air.

Table 4.

Parameters of air.

| Air (*MAT_NULL&*EOS_LINEAR_POLYNOMIAL) |

|---|

| Initial density | Initial energy | Pressure cutoff | Dynamic viscosity coefficient | , , , , | , |

| 1.29 kg/m | 2.5 × 10 J/m | 0 | 0 | 0 | 0.4 |

Table 5.

Earthquake events.

Table 5.

Earthquake events.

| Record Number | Events | Date | Station Name | Duration (s) |

|---|

| A_1 | Hector Mine | 16 October 1999 | San Bernardino-N Verdemont Sch | 37.80 |

| A_2 | San Fernando | 9 February 1971 | Maricopa Array #2 | 29.48 |

| A_3 | Imperial Valley | 15 October 1979 | Niland Fire Station | 32.00 |

Table 6.

Fifteen earthquake–blast disaster chains.

Table 6.

Fifteen earthquake–blast disaster chains.

| Series | Explosion Location | Earthquake Record |

|---|

| Hector Mine | San Fernando | Imperial Valley |

|---|

| Series-I | Without explosion | Case 1 | Case 2 | Case 3 |

| Series-II | The corner room on the 1st floor | Case 4 | Case 5 | Case 6 |

| Series-III | The middle room on the 1st floor | Case 7 | Case 8 | Case 9 |

| Series-IV | The corner room on the 6th floor | Case 10 | Case 11 | Case 12 |

| Series-V | The middle room on the 6th floor | Case 13 | Case 14 | Case 15 |

Table 7.

Peak displacement of each floor.

Table 7.

Peak displacement of each floor.

| Series | Case | Floor |

|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|

| Series-II | 4 | 14.4 | 0.76 | 1.04 | 1.18 | 1.23 | 1.25 | 1.25 | 1.26 | 1.28 | 1.33 | 1.33 | 1.43 |

| | 5 | 14.4 | 0.52 | 0.76 | 0.81 | 0.84 | 0.86 | 0.88 | 0.92 | 0.94 | 1.03 | 1.17 | 1.51 |

| | 6 | 13.5 | 1.10 | 1.52 | 1.51 | 1.45 | 1.36 | 1.31 | 1.33 | 1.35 | 1.41 | 1.50 | 1.71 |

| Series-III | 7 | 15.0 | 0.76 | 1.26 | 1.85 | 2.43 | 2.75 | 3.02 | 3.47 | 3.85 | 4.25 | 4.48 | 4.34 |

| | 8 | 14.7 | 0.77 | 1.20 | 1.74 | 2.31 | 2.66 | 2.93 | 3.37 | 3.37 | 4.12 | 4.33 | 4.16 |

| | 9 | 23.6 | 1.30 | 1.54 | 1.84 | 1.98 | 1.99 | 1.98 | 2.68 | 3.47 | 4.28 | 5.01 | 5.55 |

| Series-IV | 10 | 0.83 | 1.25 | 1.31 | 1.43 | 14.2 | 14.6 | 2.49 | 1.56 | 1.67 | 1.81 | 1.99 | 2.30 |

| | 11 | 0.55 | 1.20 | 1.83 | 2.16 | 14.3 | 14.8 | 2.41 | 1.66 | 1.77 | 1.90 | 2.08 | 2.39 |

| | 12 | 1.86 | 1.20 | 1.35 | 1.54 | 13.4 | 3.37 | 2.94 | 1.53 | 1.63 | 1.76 | 1.92 | 2.20 |

| Series-V | 13 | 0.87 | 1.22 | 1.87 | 2.21 | 16.6 | 17.0 | 1.22 | 2.30 | 2.09 | 2.00 | 2.88 | 3.80 |

| | 14 | 0.82 | 1.20 | 1.29 | 1.34 | 16.5 | 16.7 | 1.33 | 2.21 | 1.99 | 2.02 | 3.09 | 4.02 |

| | 15 | 1.01 | 1.93 | 2.67 | 3.25 | 23.0 | 8.07 | 1.29 | 2.52 | 2.01 | 2.38 | 3.06 | 3.65 |

Table 8.

Residual deformation of each floor.

Table 8.

Residual deformation of each floor.

| Series | Case | Floor |

|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|

| Series-II | 4 | 0.27 | 0.30 | 0.90 | 0.77 | 0.72 | 0.64 | 0.60 | 0.53 | 0.50 | 0.58 | 0.71 | 1.00 |

| | 5 | 1.01 | 0.30 | 0.76 | 0.71 | 0.67 | 0.54 | 0.47 | 0.42 | 0.40 | 0.48 | 0.60 | 0.88 |

| | 6 | 0.42 | 0.68 | 1.10 | 1.04 | 1.04 | 0.96 | 0.96 | 0.96 | 1.01 | 1.16 | 1.34 | 1.60 |

| Series-III | 7 | 0.93 | 0.76 | 1.04 | 1.18 | 1.23 | 1.25 | 1.25 | 1.26 | 1.28 | 1.33 | 1.33 | 1.43 |

| | 8 | 2.20 | 0.44 | 0.87 | 0.81 | 0.78 | 0.73 | 0.75 | 0.78 | 0.84 | 0.98 | 1.16 | 1.51 |

| | 9 | 0.51 | 1.30 | 1.52 | 1.51 | 1.45 | 1.36 | 1.29 | 1.24 | 1.21 | 1.26 | 1.34 | 1.69 |

| Series-IV | 10 | 0.83 | 1.01 | 1.15 | 0.95 | 1.07 | 0.41 | 0.57 | 0.99 | 0.97 | 0.90 | 0.95 | 1.13 |

| | 11 | 0.53 | 0.68 | 0.89 | 0.81 | 1.09 | 0.67 | 0.70 | 1.19 | 1.26 | 1.31 | 1.47 | 1.75 |

| | 12 | 0.80 | 1.01 | 1.10 | 0.95 | 1.14 | 0.86 | 0.70 | 1.15 | 1.18 | 1.19 | 1.29 | 1.52 |

| Series-V | 13 | 0.87 | 1.25 | 1.31 | 1.14 | 1.11 | 1.00 | 1.09 | 1.44 | 1.53 | 1.64 | 1.77 | 2.06 |

| | 14 | 0.82 | 1.20 | 1.29 | 1.18 | 1.29 | 1.09 | 1.33 | 1.66 | 1.77 | 1.90 | 2.08 | 2.39 |

| | 15 | 0.81 | 1.20 | 1.27 | 1.18 | 1.30 | 0.23 | 1.20 | 1.51 | 1.59 | 1.70 | 1.83 | 2.10 |

Table 9.

of 15 medium earthquake–blast disaster chains.

Table 9.

of 15 medium earthquake–blast disaster chains.

| Earthquake Record | |

|---|

| Series-I | Series-II | Series-III | Series-IV | Series-V |

|---|

| Hector Mine | 0.0278 | 0.3987 | 0.4167 | 0.4071 | 0.4541 |

| San Fernando | 0.0106 | 0.3791 | 0.6547 | 0.3947 | 0.6173 |

| Imperial Valley | 0.0365 | 0.3993 | 0.4094 | 0.4066 | 0.4552 |

Table 10.

of 15 major earthquake–blast disaster chains.

Table 10.

of 15 major earthquake–blast disaster chains.

| Earthquake Record | |

|---|

| Series-I | Series-II | Series-III | Series-IV | Series-V |

|---|

| Hector Mine | 0.0600 | 0.3980 | 0.4175 | 0.4086 | 0.4530 |

| San Fernando | 0.0783 | 0.3801 | 0.6580 | 0.4037 | 0.6200 |

| Imperial Valley | 0.0233 | 0.4000 | 0.4090 | 0.4064 | 0.4554 |

Table 11.

Damage states, story drift ratio ranges, and damage-index-limit ranges.

Table 11.

Damage states, story drift ratio ranges, and damage-index-limit ranges.

| Damage States | Story Drift Ratios Ranges (%) | Limit Ranges |

|---|

| No damage (DS1) | 0~0.2 | 0~0.08 |

| Repairable (DS2) | 0.2~0.5 | 0.08~0.2 |

| Irreparable (DS3) | 0.5~1.5 | 0.2~0.6 |

| Severe (DS4) | 1.5~2.5 | 0.6~1 |

Table 12.

Damage indexes and damage states of 15 simultaneous medium earthquake–blast disaster chains.

Table 12.

Damage indexes and damage states of 15 simultaneous medium earthquake–blast disaster chains.

| Earthquake Record | and DSs |

|---|

| Series-I | Series-II | Series-III | Series-IV | Series-V |

|---|

| Hector Mine | 0.011 | 0.159 | 0.167 | 0.163 | 0.182 |

| | DS1 | DS2 | DS2 | DS2 | DS1 |

| San Fernando | 0.004 | 0.152 | 0.262 | 0.158 | 0.247 |

| | DS1 | DS2 | DS3 | DS2 | DS3 |

| Imperial Valley | 0.015 | 0.160 | 0.164 | 0.163 | 0.182 |

| | DS1 | DS2 | DS2 | DS2 | DS1 |

Table 13.

Damage indexes and damage states of 15 simultaneous major earthquake–blast disaster chains.

Table 13.

Damage indexes and damage states of 15 simultaneous major earthquake–blast disaster chains.

| Earthquake Record | and DSs |

|---|

| Series-I | Series-II | Series-III | Series-IV | Series-V |

|---|

| Hector Mine | 0.024 | 0.159 | 0.167 | 0.163 | 0.181 |

| | DS1 | DS2 | DS2 | DS2 | DS1 |

| San Fernando | 0.009 | 0.152 | 0.263 | 0.161 | 0.248 |

| | DS1 | DS2 | DS3 | DS2 | DS3 |

| Imperial Valley | 0.031 | 0.160 | 0.164 | 0.163 | 0.182 |

| | DS1 | DS2 | DS2 | DS2 | DS1 |