Research on the Processing of Microstructures on Silicon Carbide Surfaces Using a Blowing-Assisted Nanosecond Laser

Abstract

1. Introduction

2. Experimental Procedure

2.1. Material

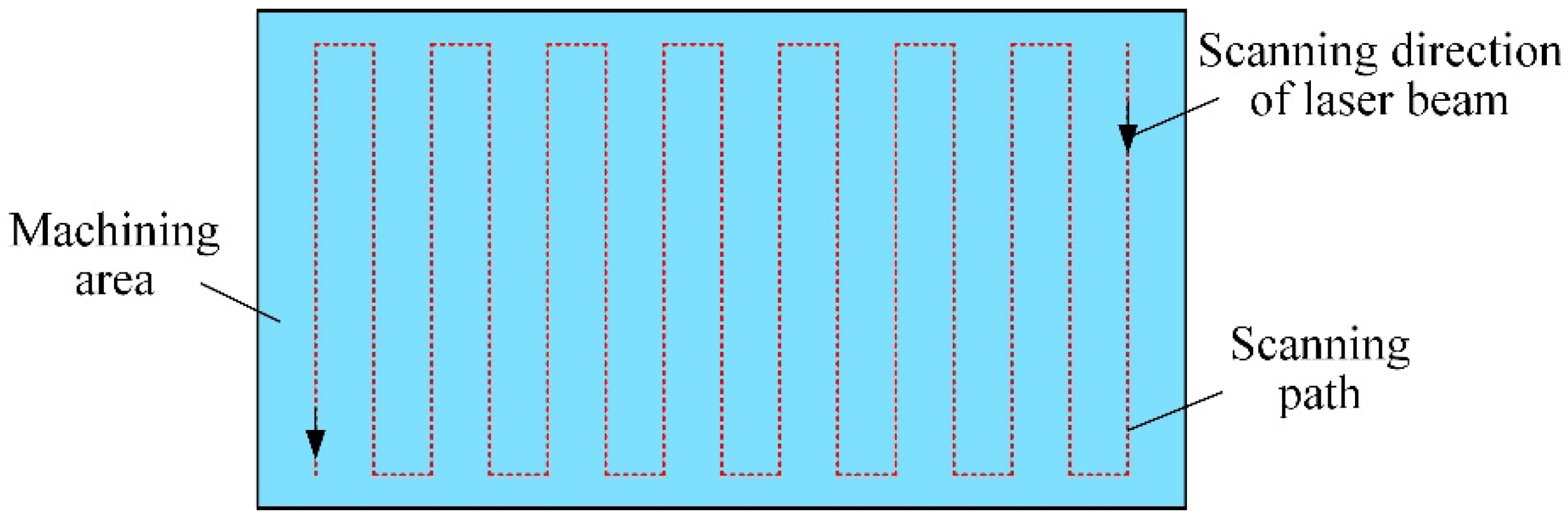

2.2. Description of Blowing-Assisted Laser Processing

2.3. Experimental Design

2.4. Workpiece Measurement

3. Results

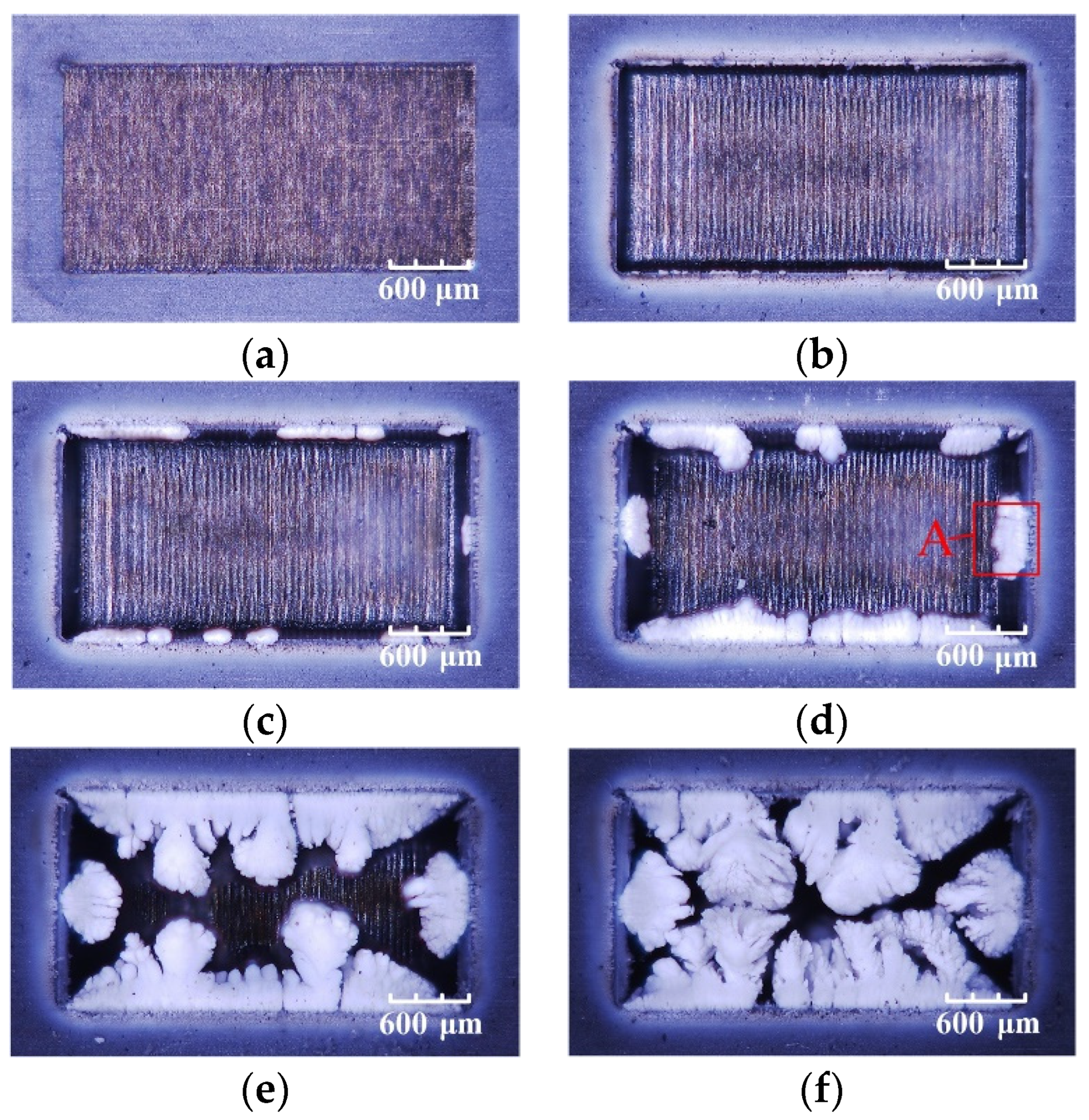

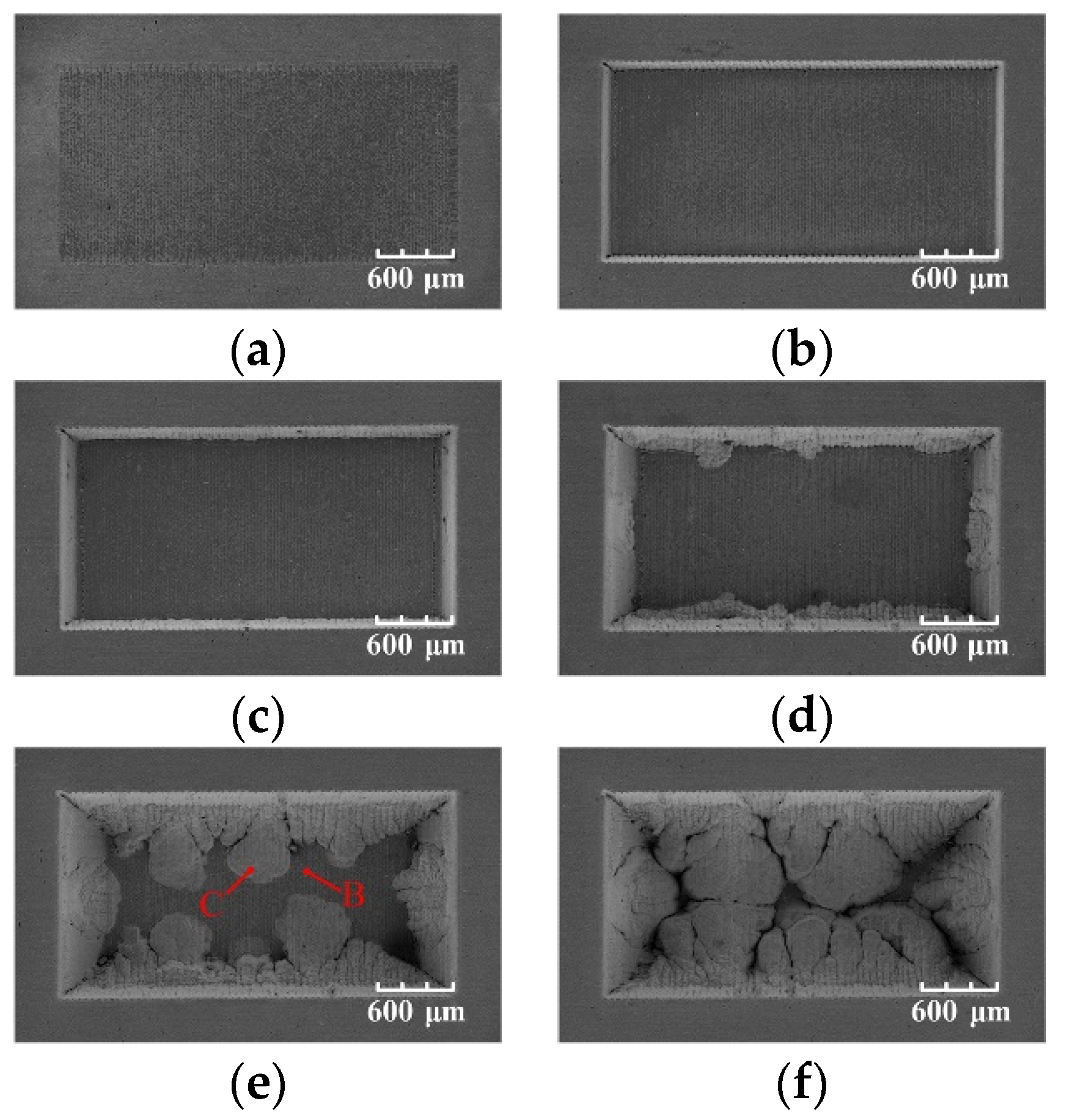

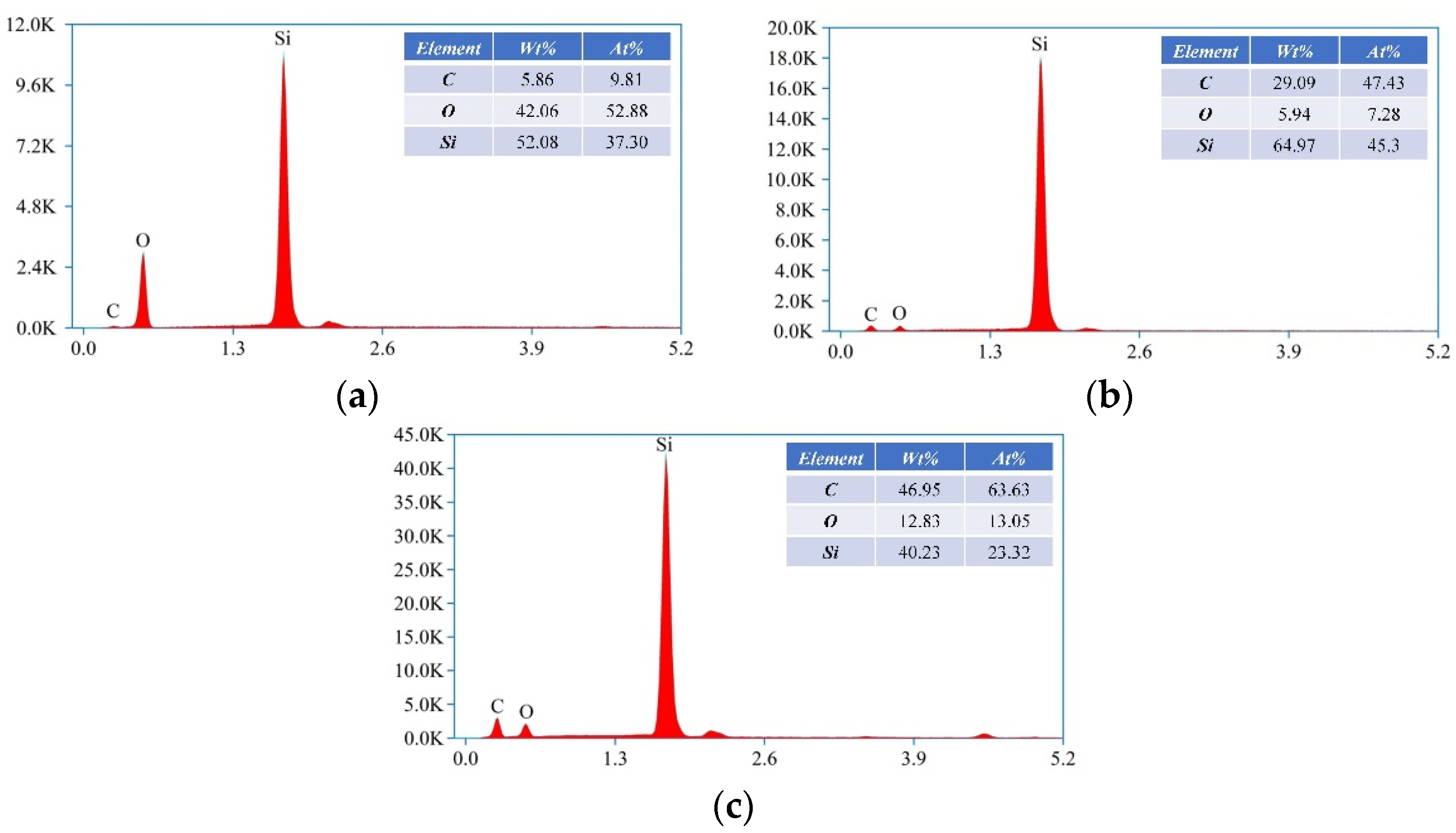

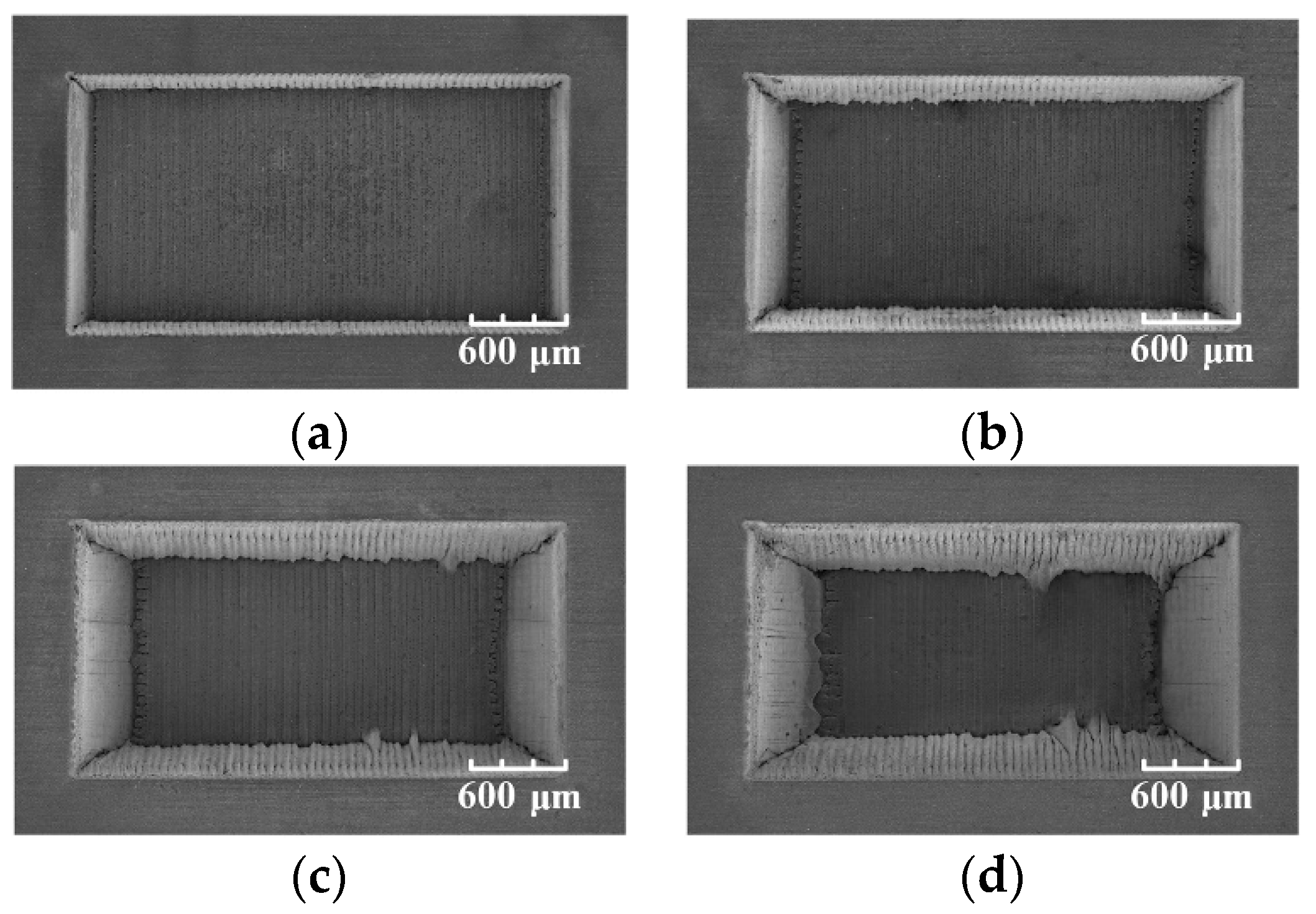

3.1. Groove Structures Processed with Different Scan Times by Conventional Laser Processing

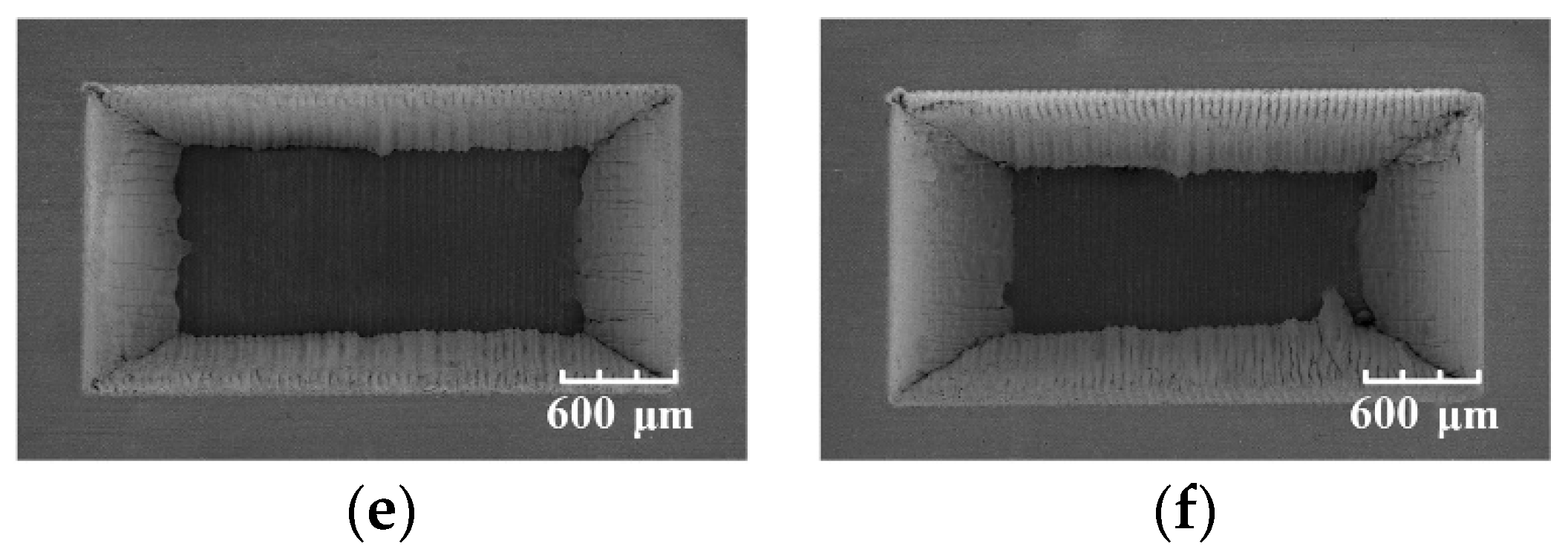

3.2. Groove Structures Processed with Different Processing Times by Blowing-Assisted Laser Processing

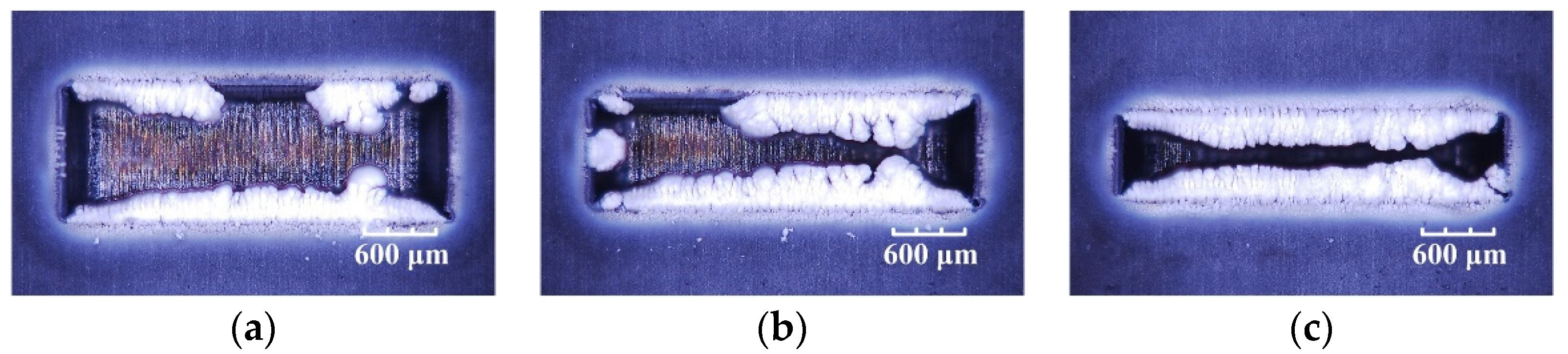

3.3. Grooves of Different Widths Processed by Conventional and Blowing-Assisted Laser Processing

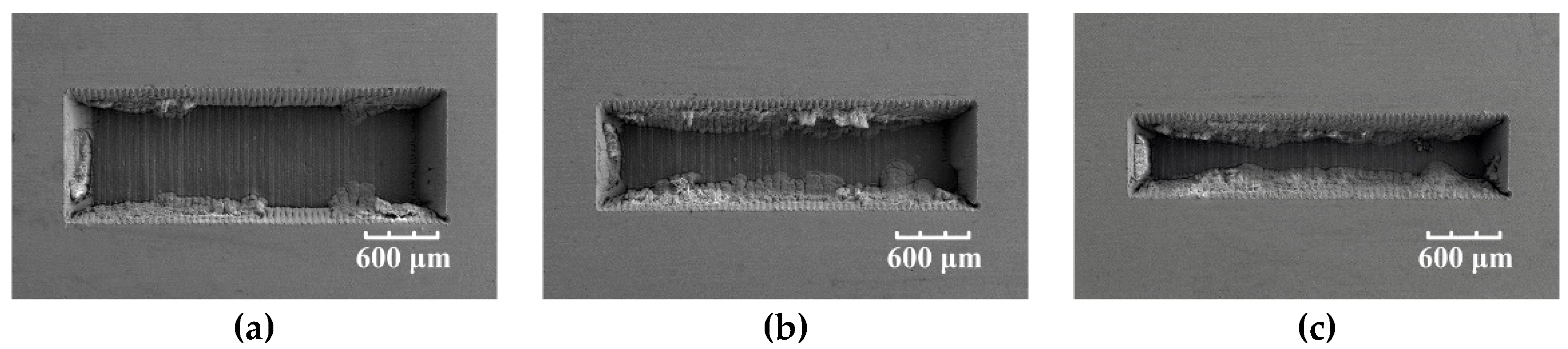

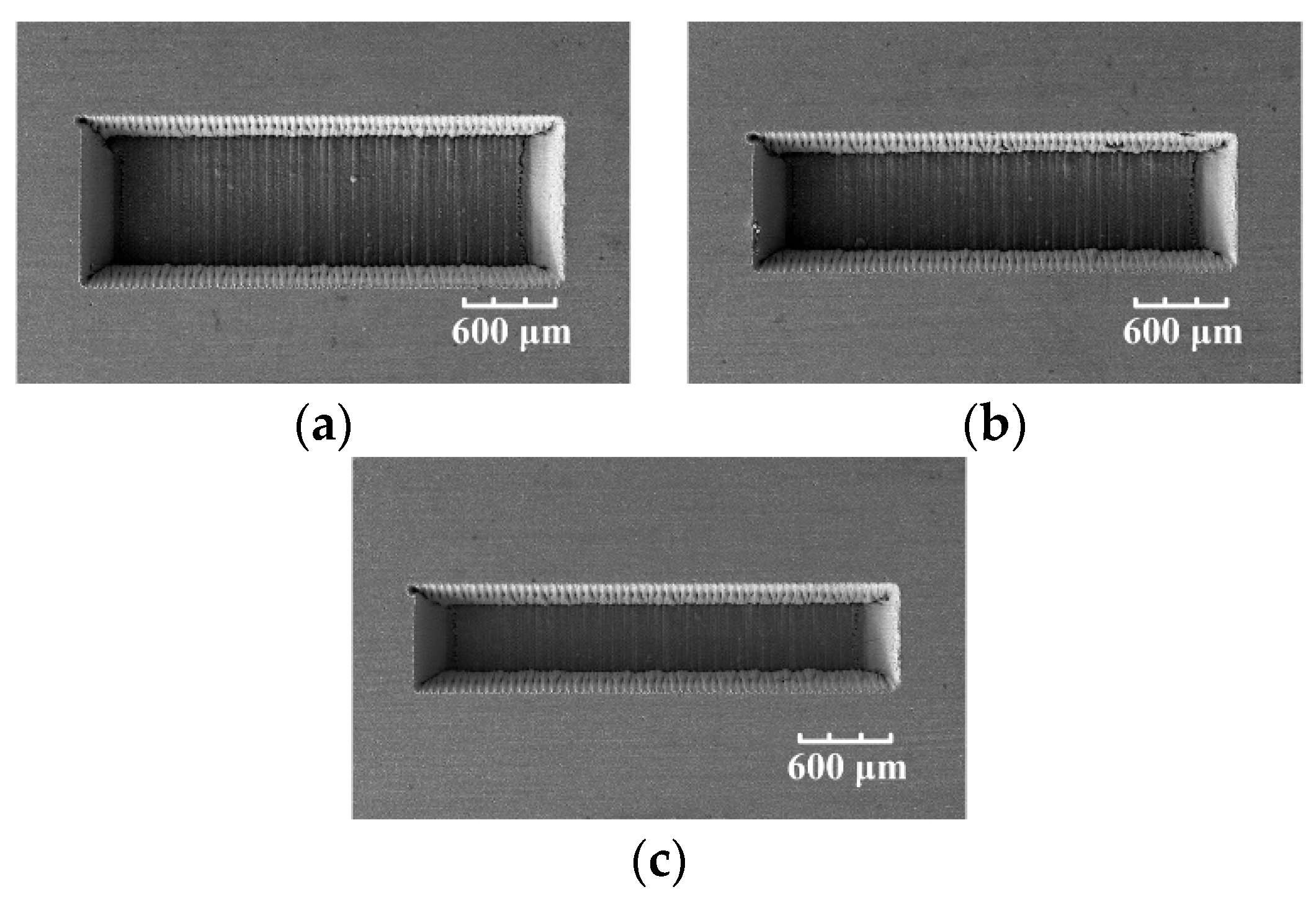

4. Discussion on Array Micro Grooves Processing

5. Conclusions

- (1)

- In conventional laser processing of silicon carbide material, white silicon dioxide products form and accumulate around the processing area with the increase of processing times, which can hinder further material removal and affect the processing quality of groove structures.

- (2)

- Blowing assistance can remove the oxidation products from the processing area to avoid accumulation and improve the laser processing capability of microstructures. Compared with conventional laser processing, blowing-assisted laser processing can machine deeper and narrower groove structures with higher quality.

- (3)

- Array structures of 1 mm × 1 mm × 0.658 mm can be processed on silicon carbide surfaces by a nanosecond laser assisted by blowing.

- (4)

- The influence of blowing on the thermodynamic equilibrium of ablation reactions of silicon carbide requires further analysis in the future.

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Sharma, S.K.; Kumar, B.; Kim, Y.W. Tribological behavior of silicon carbide ceramics—A review. J. Korean Ceram. Soc. 2016, 53, 581–596. [Google Scholar] [CrossRef]

- Gao, S.; Han, Q.k.; Zhang, X.N.; Pennacchi, P.; Chu, F.L. Ultra-high-speed hybrid ceramic triboelectric bearing with real-time dynamic instability monitoring. Nano Energy 2022, 103, 107759. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Yang, X.; Zheng, L.G.; Xue, D.L. High-performance grinding of a 2-m scale silicon carbide mirror blank for the space-based telescope. Int. J. Adv. Manuf. Technol. 2017, 89, 463–473. [Google Scholar] [CrossRef]

- Diaz, O.G.; Luna, G.G.; Liao, Z.; Axinte, D. The new challenges of machining Ceramic Matrix Composites (CMCs): Review of surface integrity. Int. J. Mach. Tools Manuf. 2019, 139, 24–36. [Google Scholar] [CrossRef]

- Kildemo, M. Optical properties of silicon carbide polytypes below and around bandgap. Thin. Solid. Films. 2004, 455, 187–195. [Google Scholar] [CrossRef]

- Abrego Serrano, P.A.; Kim, M.; Kim, D.R.; Kim, D.H.; Kim, G.H.; Ahn, S.H. Spherical mirror and surface patterning on silicon carbide (SiC) by material removal rate enhancement using CO2 laser assisted polishing. Int. J. Precis. Eng. Manuf. 2020, 21, 775–785. [Google Scholar] [CrossRef]

- Pawar, P.; Ballav, R.; Kumar, A. Machining processes of silicon carbide: A review. Rev. Adv. Mater. Sci. 2017, 51, 62–76. [Google Scholar]

- You, K.Y.; Yan, G.P.; Luo, X.C.; Michael, D.G.; Fang, F.Z. Advances in laser-assisted machining of hard and brittle materials. J. Manuf. Process. 2020, 58, 677–692. [Google Scholar] [CrossRef]

- Samant, A.N.; Dahotre, N.B. Laser machining of structural ceramics—A review. J. Eur. Ceram. Soc. 2009, 29, 969–993. [Google Scholar] [CrossRef]

- Pecholt, B.; Gupta, S.; Molian, P. Review of laser microscale processing of silicon carbide. J. Laser. Appl. 2011, 23, 012008. [Google Scholar] [CrossRef]

- Pan, Y.C.; Zhan, Q.L.; Guo, B.; Long, Y.T. High-efficiency machining of silicon carbide Fresnel micro-structure based on improved laser scanning contour ablation method with continuously variable federate. Ceram. Int. 2021, 47, 4062–4075. [Google Scholar] [CrossRef]

- Zhai, Z.Y.; Wang, W.J.; Mei, X.S.; Li, M.; Cui, J.L.; Wang, F.C.; Pan, A.F. Effect of the surface microstructure ablated by femtosecond laser on the bonding strength of EBCs for SiC/SiC composites. Opt. Commun. 2018, 424, 137–144. [Google Scholar] [CrossRef]

- Li, M.J.; Li, S.; Yang, X.J.; Zhang, Y.; Liang, Z.C. Fiber laser cutting of CFRP laminates with single-and multi-pass strategy: A feasibility study. Opt. Laser. Technol. 2018, 107, 443–453. [Google Scholar] [CrossRef]

- Pecholt, B.; Vendan, M.; Dong, Y.Y.; Molian, P. Ultrafast laser micromachining of 3C-SiC thin films for MEMS device fabrication. Int. J. Adv. Manuf. Technol. 2008, 39, 239–250. [Google Scholar] [CrossRef]

- Dong, Y.Y.; Nair, R.; Molian, R.; Molian, P. Femtosecond-pulsed laser micromachining of a 4H–SiC wafer for MEMS pressure sensor diaphragms and via holes. J. Micromech. Microeng. 2008, 035022. [Google Scholar] [CrossRef]

- Tong, Y.G.; Bai, S.X.; Zhang, H.; Ye, Y.C. Laser ablation behavior and mechanism of C/SiC composite. Ceram. Int. 2013, 39, 6813–6820. [Google Scholar] [CrossRef]

- Zhai, Z.Y.; Chen, W.; Zhang, Y.C.; Cui, Y.H.; Zeng, Q.R. Investigations on the oxidation phenomenon of SiC/SiC fabricated by high repetition frequency femtosecond laser. Appl. Surf. Sci. 2020, 502, 144131. [Google Scholar] [CrossRef]

- Jiao, H.W.; Chen, B.; Deng, Z.H. Influence of laser parameters on processing microgrooves of 2.5-dimensional C/SiC composites via nanosecond laser. Int. J. Adv. Manuf. Tech. 2022, 118, 85–101. [Google Scholar] [CrossRef]

- Cheong, H.G.; Chu, C.N.; Kwon, K.K.; Song, K.Y. Micro-structuring silicon compound ceramics using nanosecond pulsed laser assisted by hydrothermal reaction. J. Manuf. Process. 2020, 50, 34–46. [Google Scholar] [CrossRef]

- Iwatani, N.; Doan, H.D.; Fushinobu, K. Optimization of near-infrared laser drilling of silicon carbide under water. Int. J. Heat Mass Transf. 2014, 71, 515–520. [Google Scholar] [CrossRef]

- Khuat, V.; Ma, Y.C.; Si, J.H.; Chen, T.; Chen, F.; Hou, X. Fabrication of through holes in silicon carbide using femtosecond laser irradiation and acid etching. Appl. Surf. Sci. 2014, 289, 529–532. [Google Scholar] [CrossRef]

- Srinivasu, D.S.; Axinte, D.A.; Shipway, P.H.; Folkes, J. Influence of kinematic operating parameters on kerf geometry in abrasive waterjet machining of silicon carbide ceramics. Int. J. Mach. Tool. Manuf. 2009, 49, 1077–1088. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, M.R.; Zhang, T.; Qiao, H.C.; Li, H. Overview on the development and critical issues of water jet guided laser machining technology. Opt. Laser Technol. 2021, 137, 106820. [Google Scholar] [CrossRef]

- Feng, S.C.; Huang, C.Z.; Wang, J.; Zhu, H.T. Material removal of single crystal 4H-SiC wafers in hybrid laser-waterjet micromachining process. Mat. Sci. Semicond. Process. 2018, 82, 112–125. [Google Scholar] [CrossRef]

| Density (g/cm3) | Bending Strength (MPa) | Rockwell Hardness (HRA) | Thermal Conductivity (W/mK) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| 3.12 | 400 | 93 | 148 | 415 |

| Parameter | Conventional | Blowing-Assisted |

|---|---|---|

| Scanning speed | 500 mm/s | |

| Pulse frequency | 20 kHz | |

| Pulse width | 100 ns | |

| The wavelength of laser | 1064 nm | |

| Laser power | 18 W | |

| Scanning processing times | 1, 50, 100, 200, 300, 400 | 100, 200, 300, 400, 500, 600 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Li, J.; He, B.; Yuan, J.; Chen, G. Research on the Processing of Microstructures on Silicon Carbide Surfaces Using a Blowing-Assisted Nanosecond Laser. Appl. Sci. 2022, 12, 11234. https://doi.org/10.3390/app122111234

Zhang S, Li J, He B, Yuan J, Chen G. Research on the Processing of Microstructures on Silicon Carbide Surfaces Using a Blowing-Assisted Nanosecond Laser. Applied Sciences. 2022; 12(21):11234. https://doi.org/10.3390/app122111234

Chicago/Turabian StyleZhang, Suorong, Jian Li, Bin He, Jian Yuan, and Guoyan Chen. 2022. "Research on the Processing of Microstructures on Silicon Carbide Surfaces Using a Blowing-Assisted Nanosecond Laser" Applied Sciences 12, no. 21: 11234. https://doi.org/10.3390/app122111234

APA StyleZhang, S., Li, J., He, B., Yuan, J., & Chen, G. (2022). Research on the Processing of Microstructures on Silicon Carbide Surfaces Using a Blowing-Assisted Nanosecond Laser. Applied Sciences, 12(21), 11234. https://doi.org/10.3390/app122111234