Abstract

The possibility of using pozzolanic materials as a partial substitute for Portland cement (PC) to develop mortars and concretes promotes environmental and economic benefits. The present paper includes an in-depth investigation into the characterization of natural pozzolans from Guatemala for the valorization of these materials. An exhaustive physico-chemical characterization of the starting materials was first carried out. Second, an analysis of the pozzolanic reactivity of both pozzolans was performed using an evolution test of the pH and electrical conductivity measurements and a Frattini test. Finally, pastes and mortars were manufactured with pozzolans T and R as a substitute for PC. The results of the pH and electrical conductivity measurements confirmed that natural pozzolans can be classified as low-reactivity. The Frattini test and the thermogravimetric analysis confirmed the pozzolanic behavior of natural pozzolans at 28 curing days. In the cement pastes, lime fixation was positive for a long curing period, which demonstrated that these pozzolans had medium–long-term pozzolanic activity, similar to fly ash (FA). The results were confirmed by mechanical assays. The mortars with 15%, 25%, and 35% substitutions of cement for pozzolans had strength gain percentages of around 13–15% at 90 curing days.

1. Introduction

The geological complexity of Guatemala’s topography has favored the existence of many volcanoes, which have mainly generated lots of pumice and volcanic ash layers. Approximately 25% of Guatemala’s area can be considered a volcanic area rich in pozzolanic materials. The large number of these materials and their distribution throughout the territory make them affordable to low-income populations.

Guatemala imported 57.8 M USD of cement in 2020, while it exported 11.7 M USD of cement. Cement was the 66th most imported product in Guatemala [1]. Not all cements have the same composition, and the proportion of clinker, gypsum, and other materials depends on the plant characteristics and the materials available in each country. Guatemala has the largest limestone and volcanic deposits in Central America [2]. In the last few decades, Guatemala’s cement industry has used pozzolanic material to manufacture cement because volcanic activity produces a large amount of natural pozzolanic deposits [3].

Volcanic pozzolans (VPs) consist of a vitreous or partially crystallized material composed mainly of silica (SiO2) and alumina (Al2O3) with little or no hydraulicity properties. Volcanic materials are formed during volcanic eruptions and can undergo metamorphical processes over time. This type of material is considered to be natural pozzolan, according to American Standard ASTM C618-19 [4]. Once finely divided, in the presence of water and ordinary temperatures, it chemically reacts with Ca(OH)2 (commercial lime or the portlandite produced during cement hydration) to form compounds with cementitious properties and low solubility [5]. Natural pozzolans (e.g., volcanic ash, tuff, diatomaceous earth, calcined clays, and shales) form a wide range of materials with pozzolanic properties that are commonly used as substitutes for cement clinker in mortars and concretes [6,7,8].

The fabrication of clinker to produce Portland cement (PC) generates about 8–9% of anthropogenic CO2 emissions [9]. Manufacturing cements with lower clinker contents favors the reduction of cement-industry-derived emissions. In Europe, different types of cement are being manufactured, for which variable amounts of clinker are used and range from 94–80% clinker for type II/A cements to 20% clinker for type V/B cements. The latter may contain 31–49% natural pozzolans [10].

Different authors have studied using VP as supplementary materials [11,12,13,14,15]. Al-Fadala et al. [11] investigated VP from Saudi Arabia and demonstrated that the binder´s compressive strength decreased with a rising VP percentage. However, the binder with VP whose percentages ranged from 10% to 20% met the limits specified in ASTM C595 and ASTM C1157. Wilson et al. [14] studied a less common method of measuring reactivity. These authors examined reactivity following nano-indentation methods. They observed that a conversion of part of the C-S-H into C-A-S-H occurred when replacing cement with a natural pozzolan because of portlandite consumption. They also noted the distribution of unreacted pozzolan particles throughout the mixture with beneficial mechanical strength properties. Hossain and Lachemi [15] employed VP at a proportion of 50% to fabricate self-compacting concrete. They demonstrated that the setting time increased as the VP percentage in the mixture increased, while the heat of material hydration decreased, which is an interesting aspect for large-volume mass concrete implementation. The concrete containing 50% VP reached 15 MPa after 28 curing days. This strength is sufficient for some applications. The chloride resistance was better in the mixtures containing VP because of pore refinement, which takes place due to the pozzolanic reaction.

The consulted bibliography contains some articles that have employed materials deriving from volcanic activity as aggregates to manufacture mortars or concrete [16,17]. In one of these research works, the authors pointed out that employing a fraction less than 0.5 mm for concrete manufacturing leads to positive results if the material is washed to eliminate any organic compounds present in volcanic materials [16].

In recent years, a new use of volcanic materials has been found as part of the so-called alkali-activation cements. Mixtures with good mechanical performance and durability can be achieved with this new type of material [18,19,20].

Since the last century, major volcanoes in Guatemala have been subject to numerous research works. Volcanic material is abundant and easily exploited to be produced and used as an active mineral additive in cements, mortars, and concretes. This has prompted studies on eruptive outbreaks in Guatemala [21], focusing on the volcanic belt in this country. Accordingly, some volcanic material sand quarries have been evaluated [22] by determining their selection based on factors, such as their chemical and mineralogical compositions, which are essential attributes closely linked to the main reaction products.

Employing pozzolans as active additions mixed with PC was only considered in the 1980–1990s in Guatemala, and it was not until the 1990s when the production of blended cements began in line with requirements of international standards, which set the pozzolanic content at about 15%. The present research work studied the pozzolanic reactivity of two natural materials of volcanic origin. For a complete study, different methodologies were carried out in pastes and mortars of cement and lime binders.

2. Materials, Equipment, and Methods

2.1. Materials

The studied pozzolans came from volcanic ash deposits in two regions of Guatemala and were named according to the initial letter of the sampling place: Sample T (from Tecpan town) and sample R (from El Rancho town). These deposits are near eruptive areas in the country. Tecpan is a town of the department of Chimaltenango. The samples were collected at 2347 m above sea level (W 90° 58′32.8″, N 14° 45′23.7″). El Rancho is a town of the department of El Progreso. In this case, the samples were collected at 350 m above sea level (W 90° 01′12.6″, N 14° 54′46.4″)

These sites were chosen, among other reasons, for their easy access, uniformity of material, volume, and location close to rural and urban areas. Natural pozzolans were collected, dried, and ground by a mill ball to obtain a representative sample of adequate fineness.

To manufacture the lime–pozzolan pastes and to assay the pH and conductivity, calcium hydroxide (or lime) with 95% purity was used and supplied by Panreac Quimica SLU. The mortars and pastes of cement were manufactured with CEM II/A-L 32.5 N, supplied by Cemex (Buñol, Spain). The proportion of limestone in cement was 13%, and the cement had a mean particle diameter of 20.58 µm. Siliceous sand, supplied by Sílices Carrion S.L. (Liria, Valencia, Spain), was used to prepare the mortars. The sand had a fineness modulus of 4.1 and its humidity percentage was below 0.1%.

2.2. Equipment

The particle size distribution of the samples (Laser diffraction analysis, ADL) was determined by a Mastersizer 2000 laser granulometer from Malvern Instruments. Tests were carried out in aqueous suspensions. The chemical composition of VP and cement was determined by X-ray fluorescence (XRF) using a Philips Sequential MagicPro spectrometer (model PW2400) equipped with a rhodium tube and a beryllium window. X-ray diffraction (Brucker AXS D8 Advance) was utilized to analyze the mineralogy of VP (XRD spectra were taken from 10° to 70° 2θ at 20 mA and 40 kV with an angle step of 0.02°). The pH and electrical conductivity measurements were taken with a Micro PH2001 and Micro CM2201, both supplied by Crison.

The thermogravimetric analysis (TGA) of VP was carried out using Mettler-Toledo TGA850 equipment within a heating range of 35–1000 °C and at a heating rate of 20 °C/min using a 70 µL alumina crucible in an inert atmosphere of dry air and an air flow of 75 mL/min. Hydrated pastes were characterized under the following conditions: 35–600 °C temperature range, 10 °C/min heating rate, sealed–pinholed aluminum crucible, and nitrogen atmosphere of 75 mL/min. The VP materials were observed by scanning electron microscopy (SEM; JEOL JSM-6300) equipped with an energy-dispersive X-ray for the microanalysis.

A universal machine (IBERTEST) was employed to measure the compressive strength in compliance with the requirements set by Standard UNE-EN 196-1:2018 [23]. The capacity of the compressive machine is 60,000 kN.

2.3. Methods

To determine the quantity of insoluble residue present in VP, the method specified in Standard UNE-EN 196-2 [24] was followed. According to this method, the sample was first attacked with HCl and finally with KOH. The insoluble residue represented the part of the material that was not reactive because it did not dissolve in the alkaline medium.

The technique followed for the electrical conductivity and pH measurements to monitor the pozzolanic reaction progress in the saturated lime/pozzolan mixtures was proposed by Tashima et al. [25]. In this method, the electrical conductivity and pH of the aqueous suspension of different Ca(OH)2/VP mixtures were measured for 7 days at 60 °C. In a 100 mL Erlenmeyer flask, 50 mL of deionized water was added at the following Ca(OH)2/VP proportions: 0.5:9.5, 1.0:9.0, 1.5:8.5, 2.0:8.0, 2.5:7.5, 3.0:7.0, and 0.0:10.0 (the last sample was employed to measure pozzolan’s contribution to electrical conductivity). The total amount of solid mass was 1 g.

The pozzolanicity test Is a standard method specified in EN196-5 [26]. Samples were prepared by mixing PC and VP with 15%, 25%, 35%, 45%, and 55% replacements. After preparation, the mixture was left in a closed polyethylene bottle at 40 °C for 8–15 days. After this time, the solution was filtered and analyzed by titration for CaO and OH−.

For the TGA analysis, the Ca(OH)2/VP pastes were prepared by mixing 6.7 g of hydrated lime with 13.3 g of pozzolan (1:2 mass ratio) and 14 g of water (water/binder ratio of 0.7). These pastes were cured at 20 °C and 40 °C. The PC/pozzolan pastes were prepared by mixing 7.5 g of cement and 2.5 g of pozzolan (25% replacement) at a water/binder ratio of 0.4. An additional control paste with only PC was prepared. These pastes were cured at 20 °C.

The methodology and study of mortar properties were conducted in accordance with the European UNE-EN standard [23]. The mixtures were initially prepared using the CEM II/A-L 32.5N type with 15%, 25%, and 35% (by weight) replacements of cement with VP, as summarized in Table 1. The blended cement mortars´compressive strength was measured after 28, 90, and 180 curing days. Cement mortars were prepared at a water/binder ratio of 0.47 (binder was the sum of CEM II and VP). Several mortars with 25% replacement (CEM II+25%R and CEM II+25%T series) were prepared at different w/b ratios: 0.41, 0.44, 0.47, 0.50, and 0.53. A set of mortars was also prepared using limestone filler instead of VP at the same replacement percentage (CEM II+25%LF series). The doses of the mortars are summarized in Table 2, where the letter X represents the quantity of limestone filler (LF) or pozzolan R or T added to the mixtures. The compressive strength was obtained at 28 and 90 curing days. The fresh mortars´ workability was evaluated according to Standard UNE EN1015-3 [27].

Table 1.

Mortar doses for the mixtures with different pozzolan percentages.

Table 2.

Mortar doses for the mortars with different w/b ratios.

3. Results and Discussion

3.1. Physico-Chemical Characterization of Volcanic Pozzolans (VPs)

The first part of the results obtained in this research work focuses on the complete characterization of the starting materials.

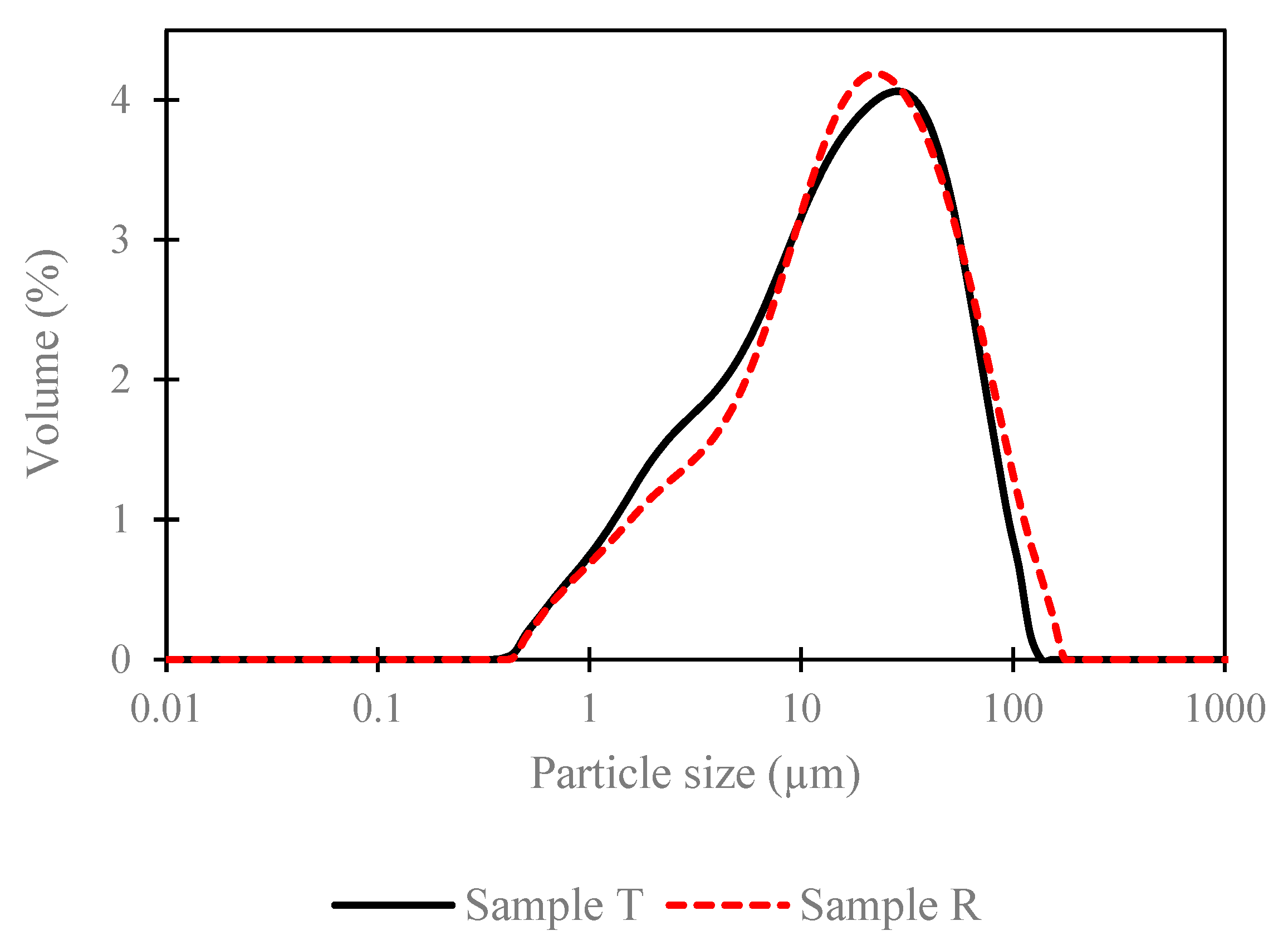

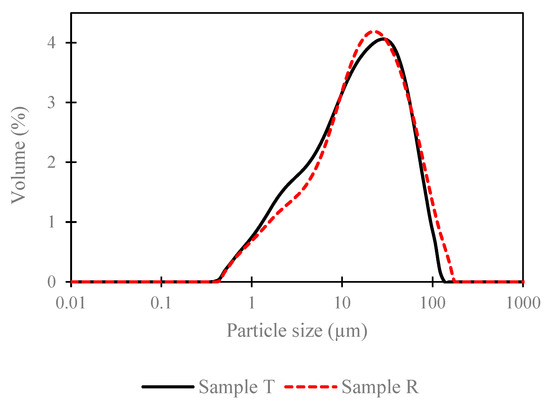

The mean particle diameters and parameters of the particle size distribution for the pozzolanic materials are summarized in Table 3. The diameters of the two pozzolans were similar and came very close to the value for PC (20.58 µm), although they were slightly higher. The granulometric curves for the two VP samples are presented in Figure 1. Both were similar and presented a unimodal aspect.

Table 3.

Mean particle diameters and distribution parameters for the VP samples.

Figure 1.

Granulometric curves of VP.

X-ray fluorescence (XRF) was used to determine the chemical composition of natural pozzolans T and R. The contents of oxides are shown in Table 4; the table shows that the two samples had a high silica (SiO2) content (T = 70.49% and R = 72.06%). This is a decisive oxide for classifying something like pozzolanic material. In addition, a significant alumina (Al2O3) percentage (T = 13.57% and R = 12.67%) appeared. The contents of calcium and iron oxides were very low. The cement composition is included in the same table because it was the material that was also used to manufacture the pastes and mortars.

Table 4.

Chemical composition (%) for VPs and cement CEM II/A-L.

The sums of the three acid oxides (SiO2 + Al2O3 + Fe2O3) for the T and R pozzolanic reactivity evaluations were 85.89% and 85.87%, respectively. These values represented an oxide content that was potentially reactive and above 75%. This composition fell within the normal ranges published in the bibliography; for example, the quantity of SiO2 in this type of natural pozzolan varies between 40–70% [28].

The loss on ignition (LOI*) was less than 5%, which fell within the acceptable values for pozzolanic materials. However, the insoluble residue (IR) was slightly over 40%, indicating that a very large part of the material was crystalline and insoluble in both acid and alkaline media. Specifically, the values obtained from the IR were 40.8% and 42.25% for T and R, respectively. This could severely limit their pozzolanic reactivity.

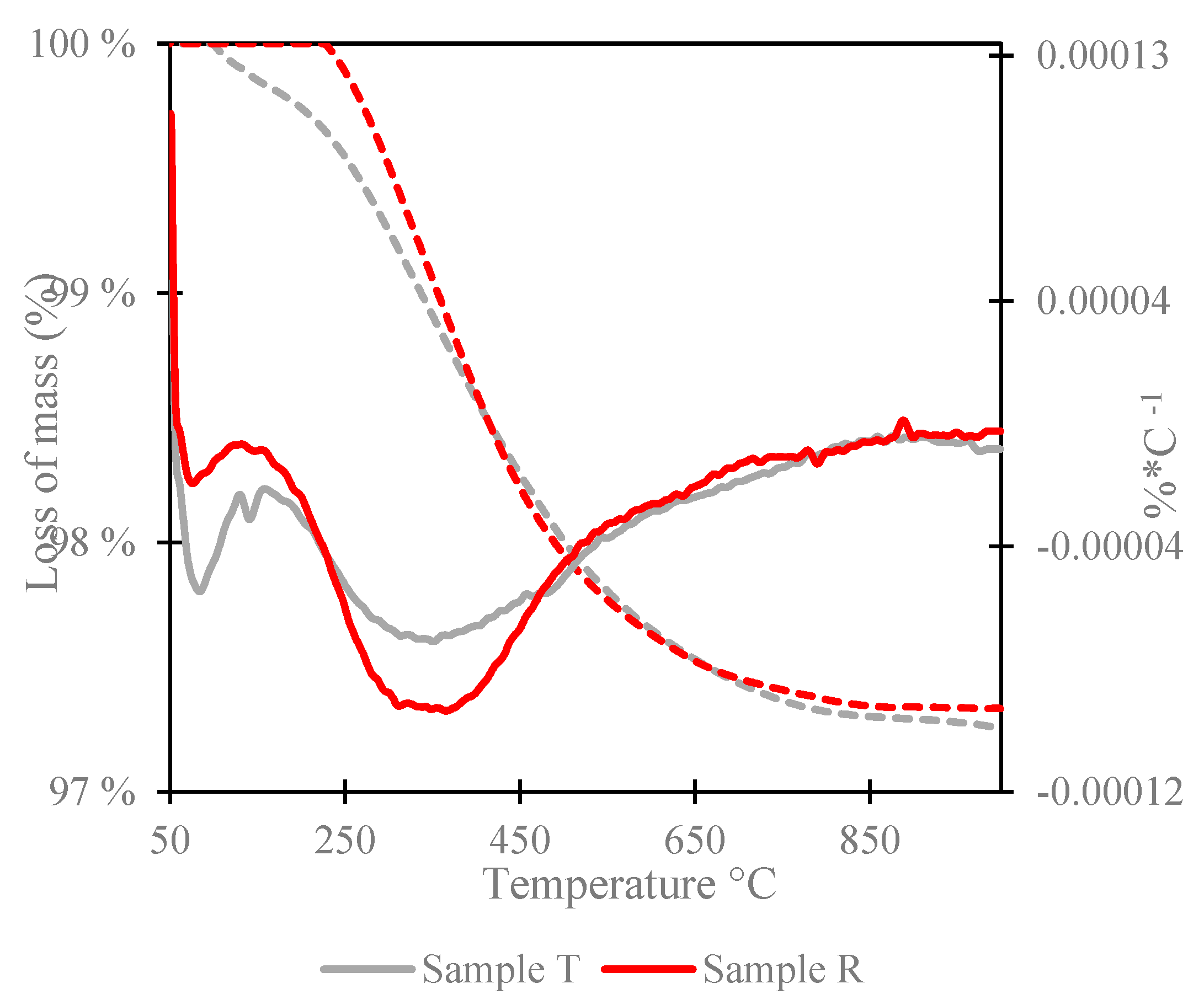

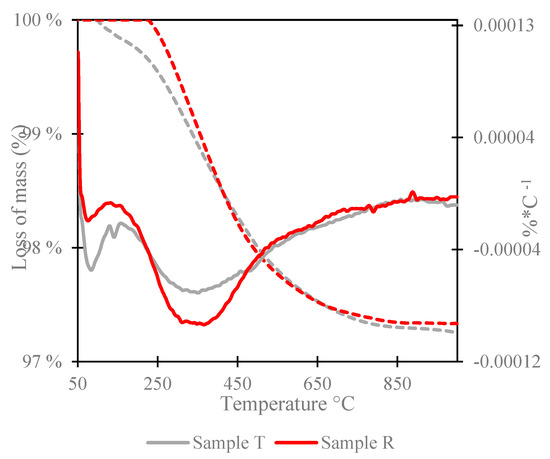

In Figure 2, the TGA and DTG curves of the VP samples are plotted. On the TGA curves, continuous loss of mass can be observed within the 250–700 °C range. The presence of carbonates was not detected in both samples. Some minor losses were associated with humidity, and probably with either the hydroxyl groups of a clay-type material that can decompose or the amorphous silica itself (decomposition of the silanol groups).

Figure 2.

TGA (dotted lines) and DTG (solid lines) curves of the natural pozzolans.

The losses within the 35–1000 °C range were 2.91% and 2.87% for sample T and sample R, respectively. These losses were very slight, showing that they were stable when the temperature increased, and they fell within the same range as the LOI values obtained in other characterization analyses (see Table 4).

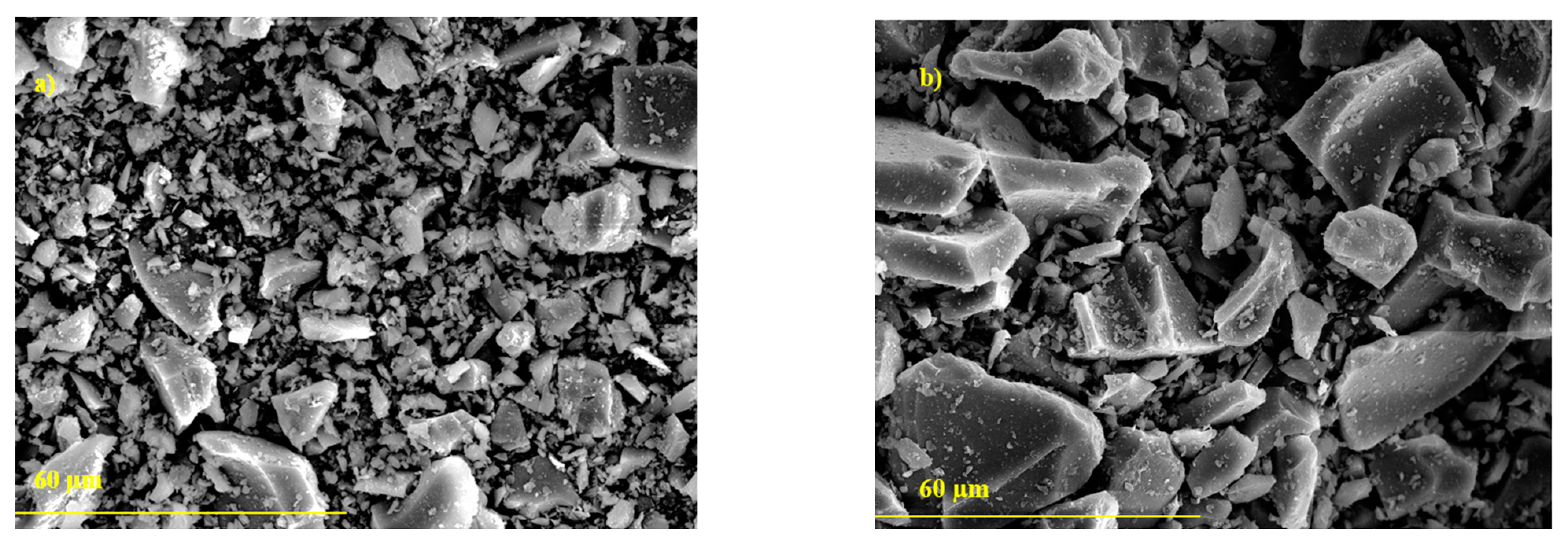

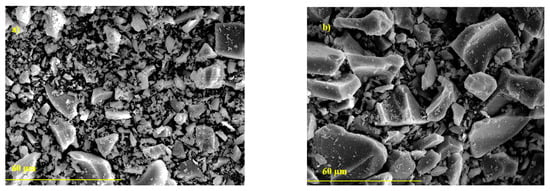

Scanning electron microscopy (SEM) was used to study the morphology and texture of the natural pozzolan particles. The micrographs are shown in Figure 3.

Figure 3.

SEM micrographs at 1000 magnification: (a) Sample T; (b) Sample R.

As shown in Figure 3, both pozzolans were composed of different-sized irregular-shaped particles with several fractured faces and smooth textures. Some particles displayed slight roughness. Their structure did not appear porous, and the particles were dense and compact. These images are like those found by other authors who have studied this type of material [29].

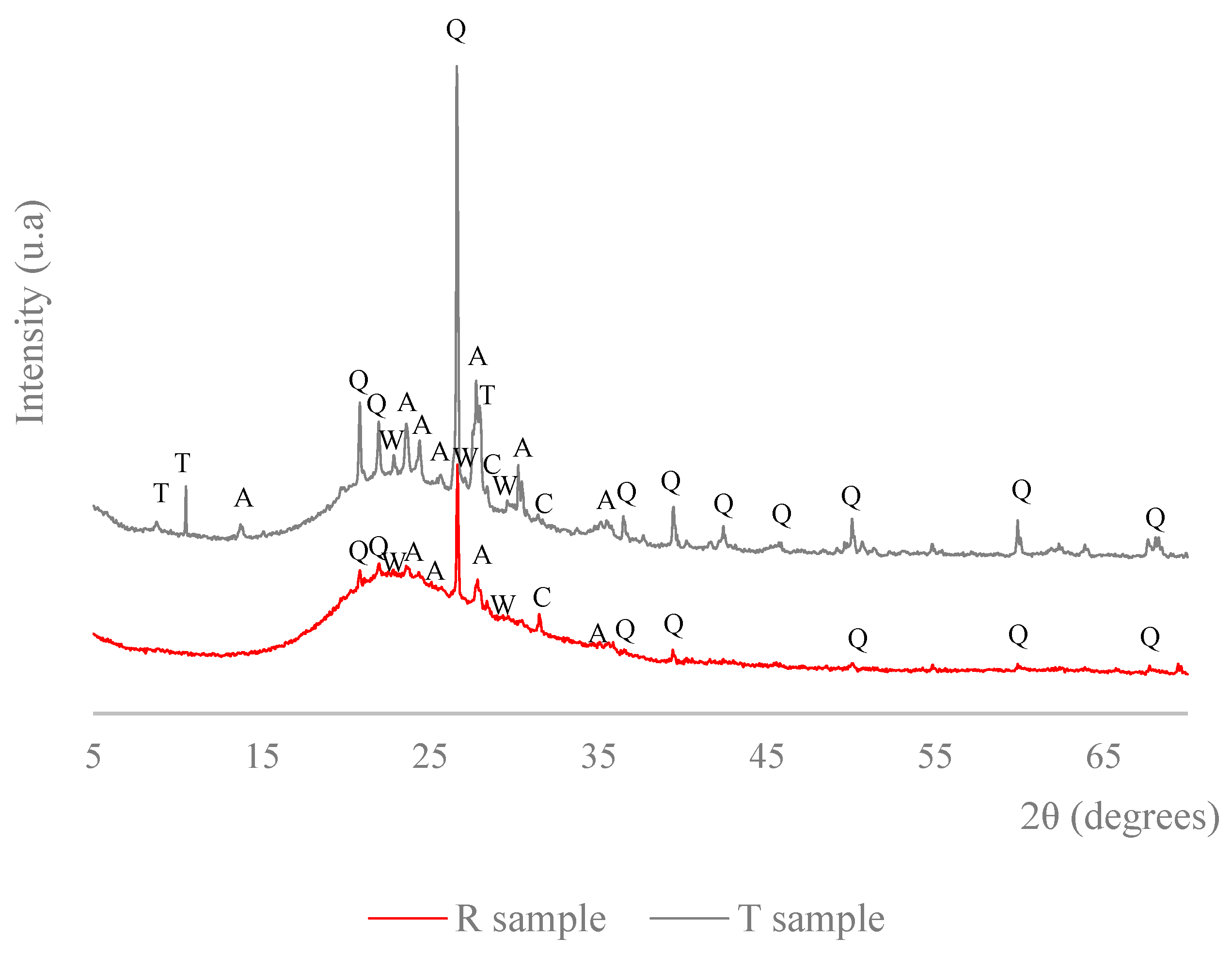

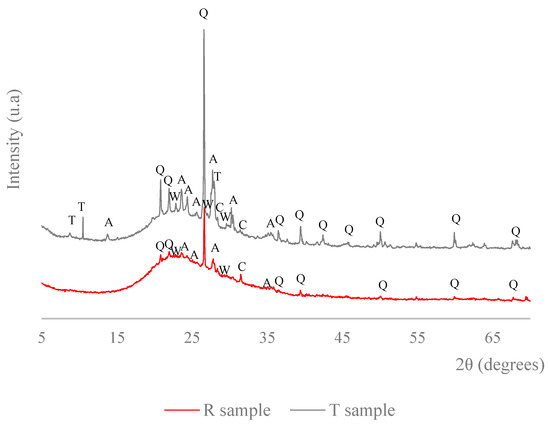

Finally, Figure 4 shows the diffractograms for samples T and R. The most notable aspect was the deviation of the baseline within the 2θ = 15°–30° range, suggesting the presence of a significant quantity of amorphous compounds. Several peaks corresponding to different crystalline substances can be observed. The most important one was quartz (Q, SiO2 PDFcard 331161) in both samples.

Figure 4.

X-ray diffractograms of T and R.

Sample T also had small amounts of cristobalite (C, SiO2 PDFcard 391425), probably due to the crystallization of silica at a high temperature during the eruption process and tremolite (T, Ca2Mg5Si8O22 (OH)2 PDFcard 130 437, a zeolite). It also exhibited small amounts of albite (A, NaAlSi3O8 PDFcard 090466, a feldspar) and wollastonite (W, CaSiO3 PDFcard 100489, a calcium silicate). In sample R, the baseline deviation was greater and could be interpreted as a higher content of amorphous compounds. However, the IR data shown in Table 4 indicate no significant difference with sample T. In this case, tremolite was not present, and the albite peaks and wollastonite were less intense. The displayed crystalline phases are typical of natural pozzolanas of volcanic origin [28].

In short, it can be concluded that both pozzolans contained significant amounts of amorphous material, which may be interesting for pozzolanic reactivity development. Because of the chemical composition of volcanic ash, it can also be stated that the amorphous material will consist mainly of silicon oxide. Most of the crystalline material (which is unreactive) of pozzolans is constituted by quartz.

3.2. Pozzolanic Activity

3.2.1. Electrical Conductivity Test

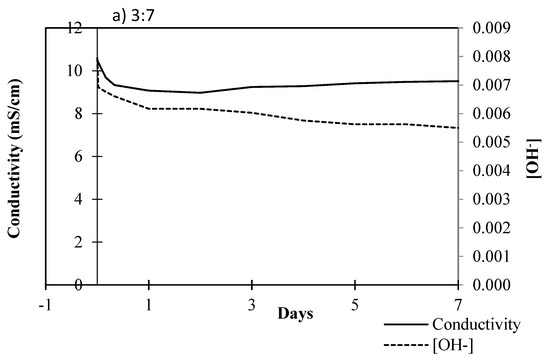

During the electrical conductivity test, suspensions were continuously shaken inside a thermal bath to facilitate the pozzolanic reaction process. Flasks were covered with parafilm paper to avoid carbonation and water loss by evaporation. Data collection was performed at 0 h, 0.5 h, 4 h, 8 h, and 24 h, and then every day for 6 more days.

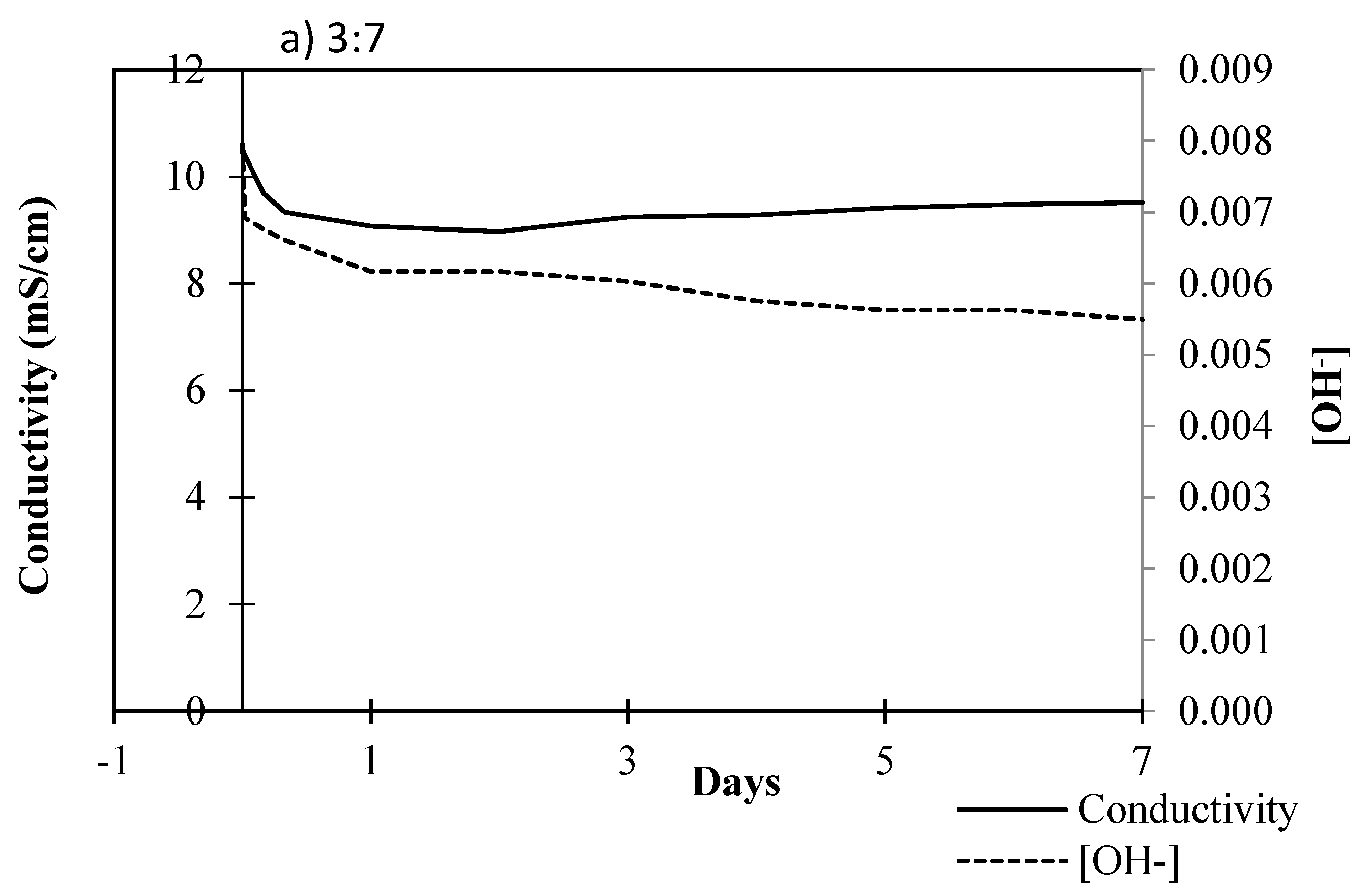

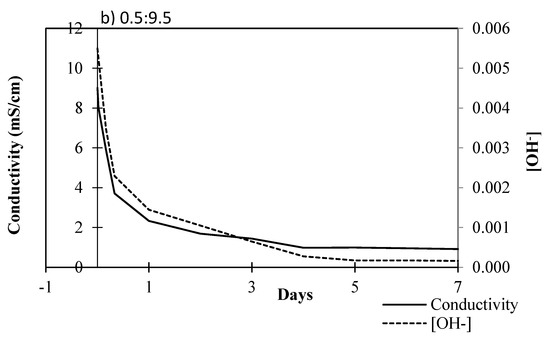

The values of electrical conductivity and the [OH−] concentration of the samples tested at 60 °C for the 3.0:7.0 and 0.5:9.5 lime ratios of sample T are shown in Figure 5. For the 3.0:7.0 sample, no significant change was observed in the curves of the electrical conductivity and [OH−] concentration (the suspension was saturated in calcium hydroxide). A considerable change in the conductivity and [OH−] concentration curves for the 0.5:9.5 sample occurred on the first test days, which demonstrates that the suspension was unsaturated.

Figure 5.

Electrical conductivity and [OH−] concentration measurements for sample T at 60 °C: (a) 3:7 and (b) 0.5:9.5 lime:pozzolan ratios (Sample T).

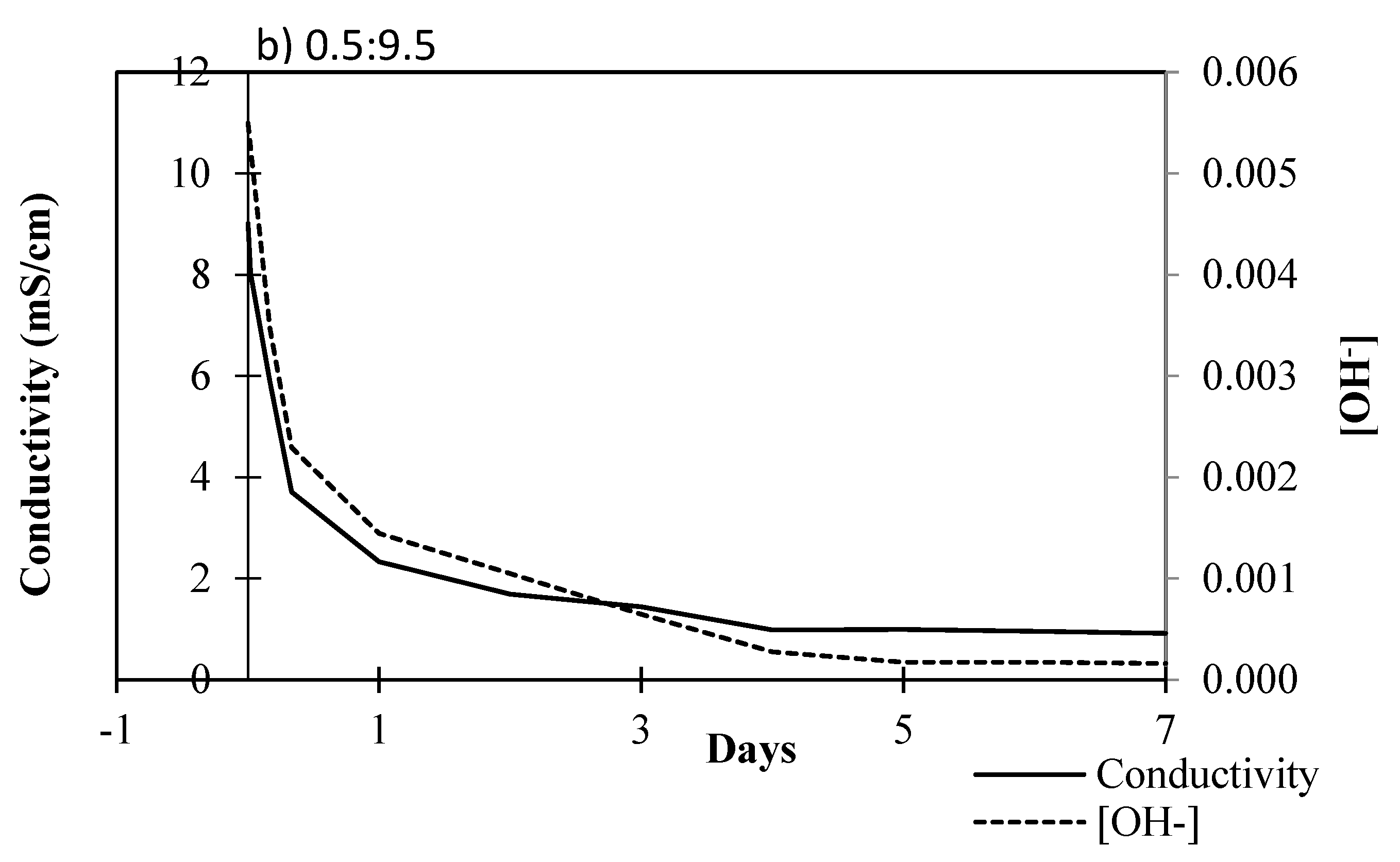

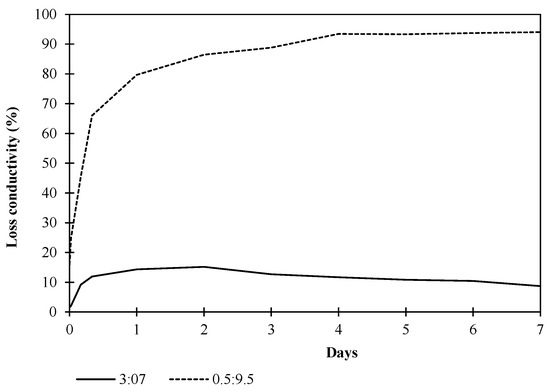

The comparison of these two mixtures is represented in terms of loss of electrical conductivity in Figure 6, which was calculated according to [25].

Figure 6.

Loss of electrical conductivity for sample T at 60 °C.

The loss of electrical conductivity showed a much better comparison among suspensions. The sample with the 0.5:9.5 ratio displayed significant conductivity loss because of the achieved unsaturation, while there was no significant loss for the 3:7 ratio. Hence, it was continuously saturated in Ca(OH)2. According to Tashima et al., suspensions whose electrical conductivity loss is over 30% (Lc = 30%) correspond to solutions that are unsaturated in calcium hydroxide [25].

The conductivity loss percentage was calculated according to Equations (1) and (2):

- Co:

- Initial electrical conductivity of the calcium hydroxide suspension before adding pozzolan;

- Ct:

- Electrical conductivity value measured in the CH/P suspension at time t;

- Cpuz:

- Electrical conductivity of the water/pozzolan suspension (0.0:10.0 mixture).

It should be noted that, throughout the experiment, the Cpuz values never exceeded 1 mS/cm. Hence, the conductivity loss correction was negligible and allowed the Ci and Ct values to be analogous.

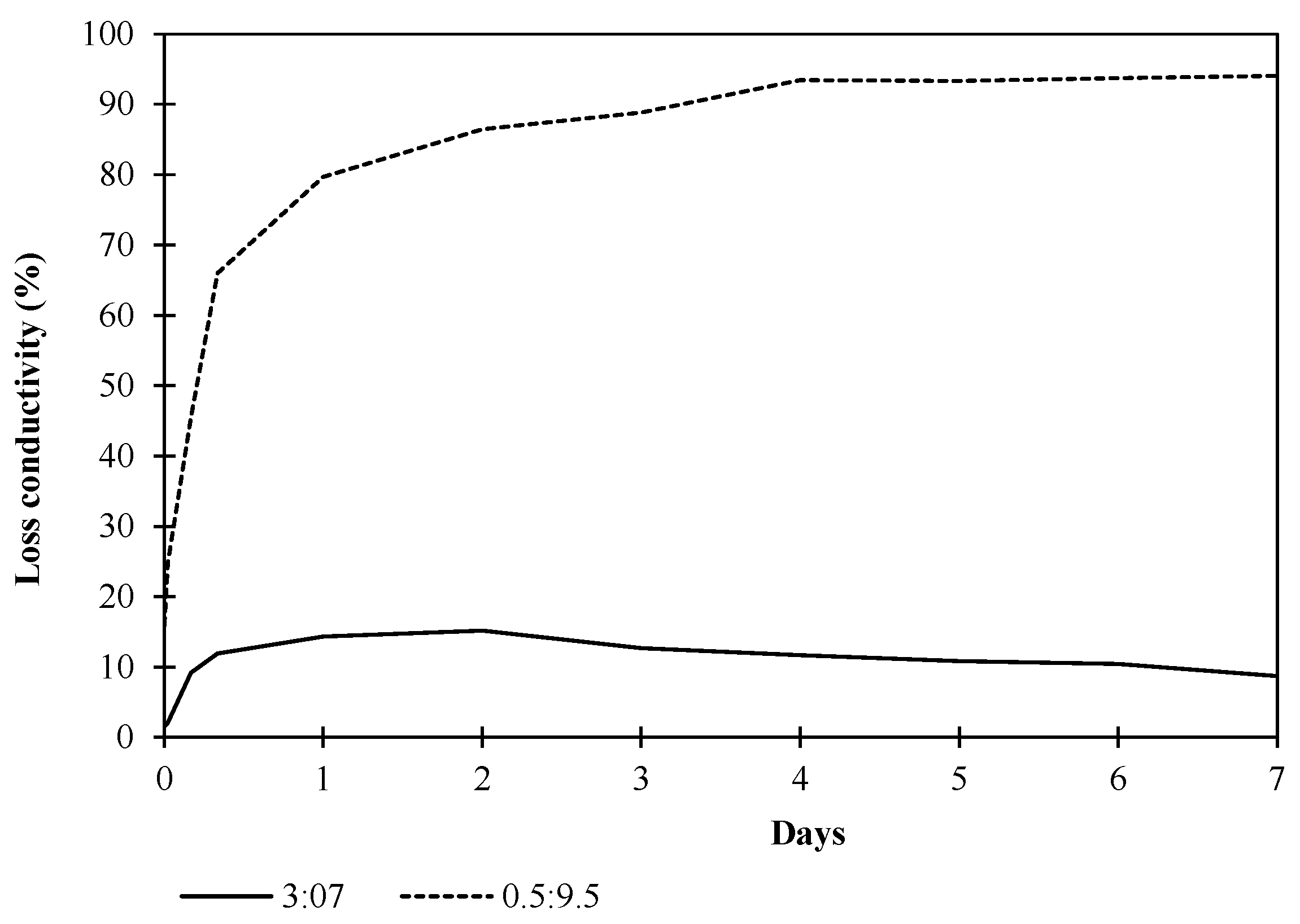

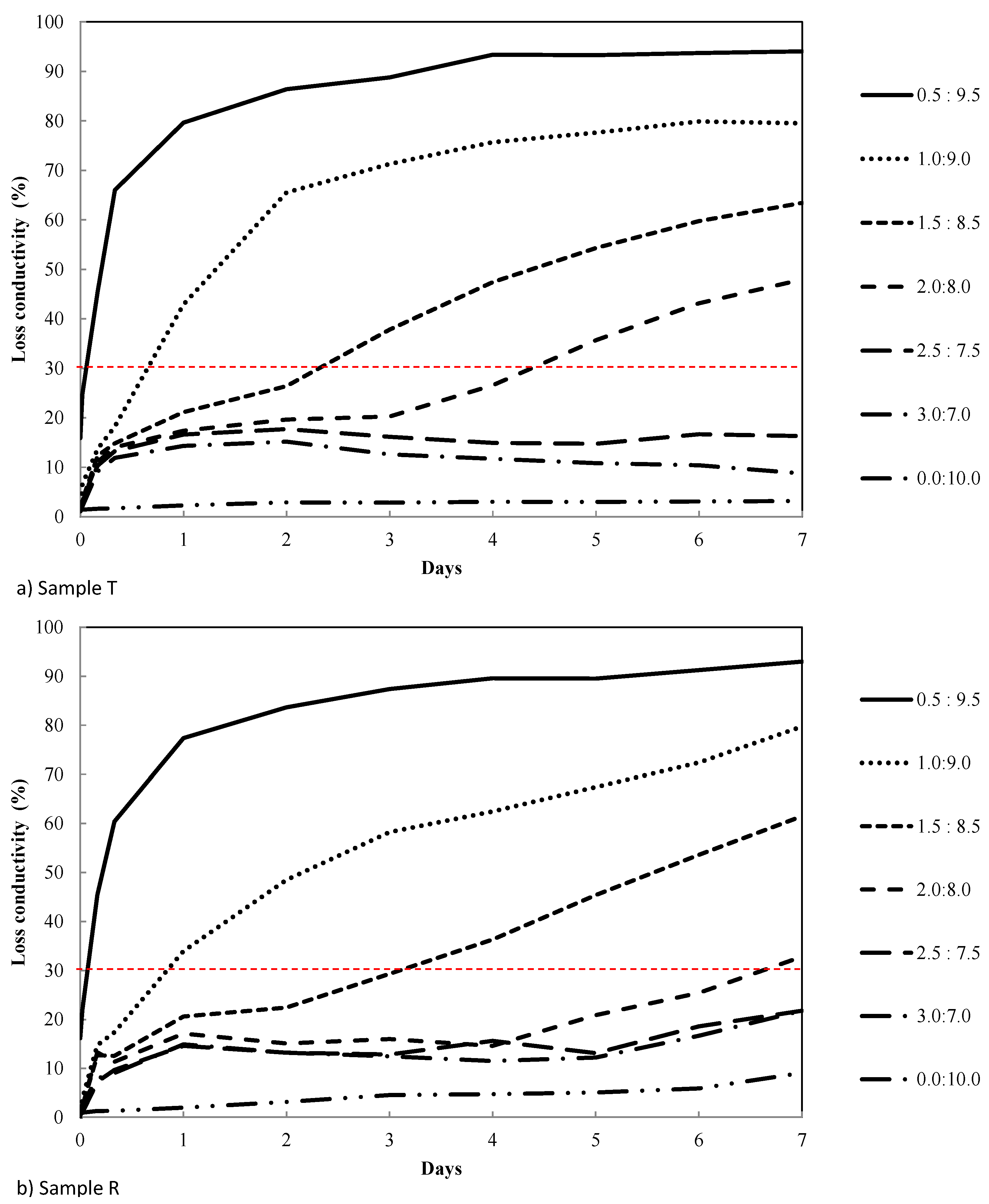

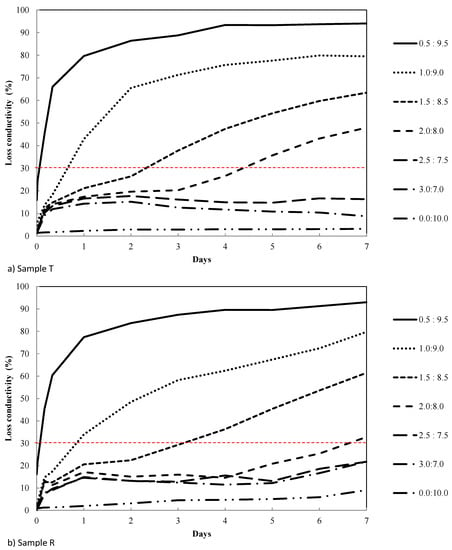

According to Figure 7, the suspensions with excess calcium hydroxide did not exhibit significant changes in electrical conductivity loss. These values remained practically constant throughout testing. Significant variation appeared in the suspensions that reached unsaturation, which were 2.0:8.0; 1.5:8.5; 1.0:9.0, and 0.5:9.5. In the saturated suspensions, they were 3.0:7.0 and 2.5:7.5, and remained so throughout testing. The electrical conductivity loss data are summarized in Table 5 for the 60 °C temperature after 7 days to compare samples T and R.

Figure 7.

Electrical conductivity loss at 60 °C for pozzolans.

Table 5.

Electrical conductivity loss (%) at 60 ° C and 7 days of testing.

According to M. Tashima et al. [25], samples R and T can be classified as low-reactivity pozzolanic materials.

3.2.2. Pozzolanicity Test (Frattini)

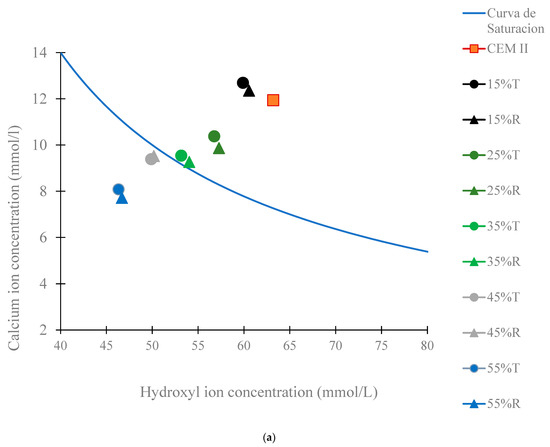

Pozzolanicity can be determined by comparing the hydroxyl ion and calcium ion concentrations in an aqueous solution in contact with hydrated cement after a stated period of time. The calcium hydroxide standard solubility curve was used according to UNE-EN 196-5 [26]. Cement is considered to have pozzolanicity when the experimental points are below the saturation curve [26].

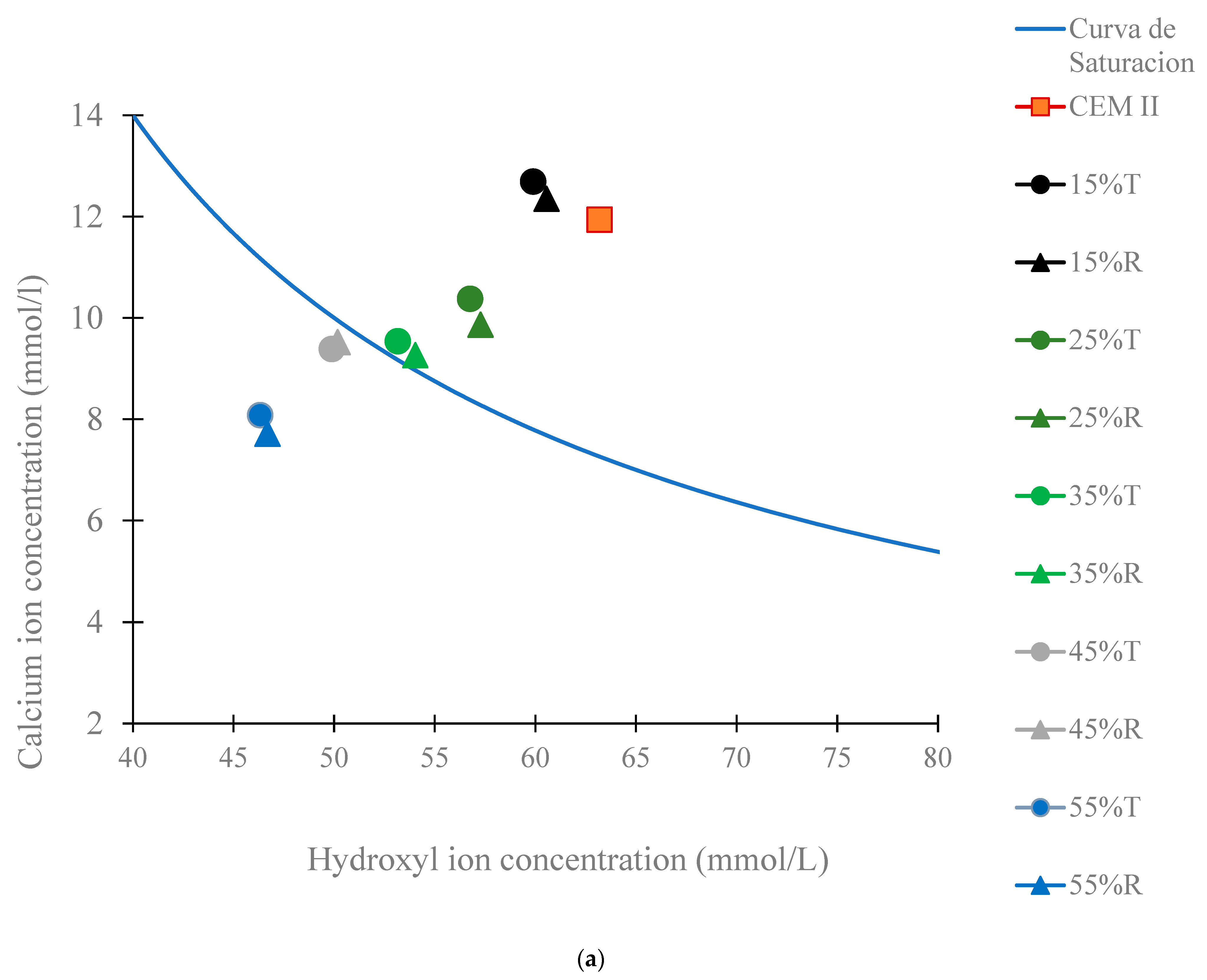

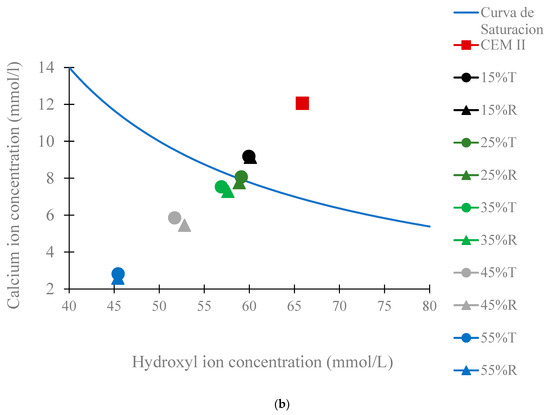

In the present study, cement was replaced at different ratios (0%, 5%, 25%, 35%, 45%, and 55%) with both pozzolans (T and R). The pozzolanicity after 8 and 15 days is shown in Figure 8.

Figure 8.

Pozzolanicity test results for CEM II/A-L 32.5N and the 15%, 25%, 35%, 45%, and 55% replacements with pozzolans T and R: (a) 8 days and (b) 15 days of testing.

The samples that accomplished the pozzolanicity test were the cements with the 45% and 55% replacements for 8 test days (Samples T and R). For 15 testing days, the cements with 25%R and with the 35%, 45%, and 55% replacements (Samples T and R) met the pozzolanicity test. Given the reactivity obtained in the electrical conductivity test, not all of the percentages fulfilled the test at 8 days. Similar results at the same testing time have been obtained by other authors when testing various types of pozzolans of volcanic origin [30]. These results confirm that these natural pozzolans present sufficient reactivity to prepare pozzolanic CEM IV cements, although sample R may be slightly more reactive than sample T.

3.2.3. Thermogravimetric Analysis

This part is subdivided into two parts: (a) hydrated lime pastes cured at 20 °C and 40 °C, tested for curing times of 7, 28, and 90 days with a 1:2 CH/VP weight ratio; and (b) cement pastes cured at 20 °C for 28 and 90 curing days using a control paste (only cement II) and the pastes with the 25% replacement (either T or R).

(a) Hydrated lime/pozzolan (CH/VP) pastes

To calculate the hydrated lime fixation (fixed lime), the calcium hydroxide dehydroxylation mass loss was measured and corresponded to the reaction:

The fixed lime content was in accordance with the calcium hydroxide initially dosed in the sample. Therefore, Equation (3) was used to calculate the percentage [31]:

where

- CHO:

- the initial amount of calcium hydroxide present in the paste;

- CHP:

- the amount of calcium hydroxide present in the CH/VP paste for a given curing time.

The amount of calcium hydroxide present in the paste was calculated by stoichiometry with Equation (4):

where

- H:

- loss of mass due to the calcium hydroxide dehydroxylation present in the paste;

- PMH:

- water molecular weight;

- PMCH:

- calcium hydroxide molecular weight.

Furthermore, the combined water in the formed hydrates (CSH, CAH, and CASH) was calculated, which indicates the associated amount of water with hydration products, to simultaneously provide an approximation of the percentage of the formed hydration products.

The water percentage associated with the hydrates (PH) present in the paste was calculated using Equation (5):

where

- PT:

- the total percentage of mass loss;

- PCH:

- percentage of mass loss due to lime dehydroxylation.

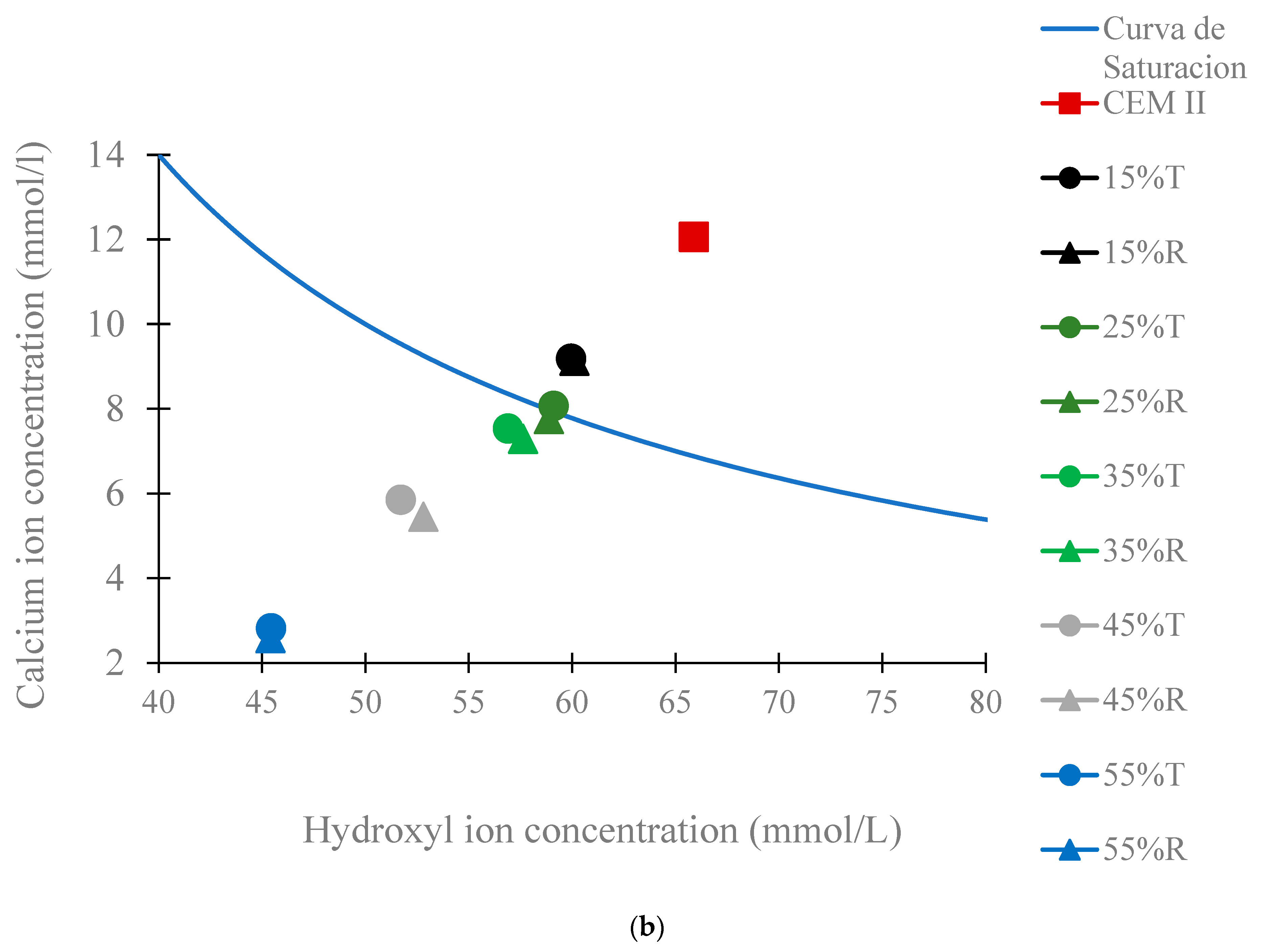

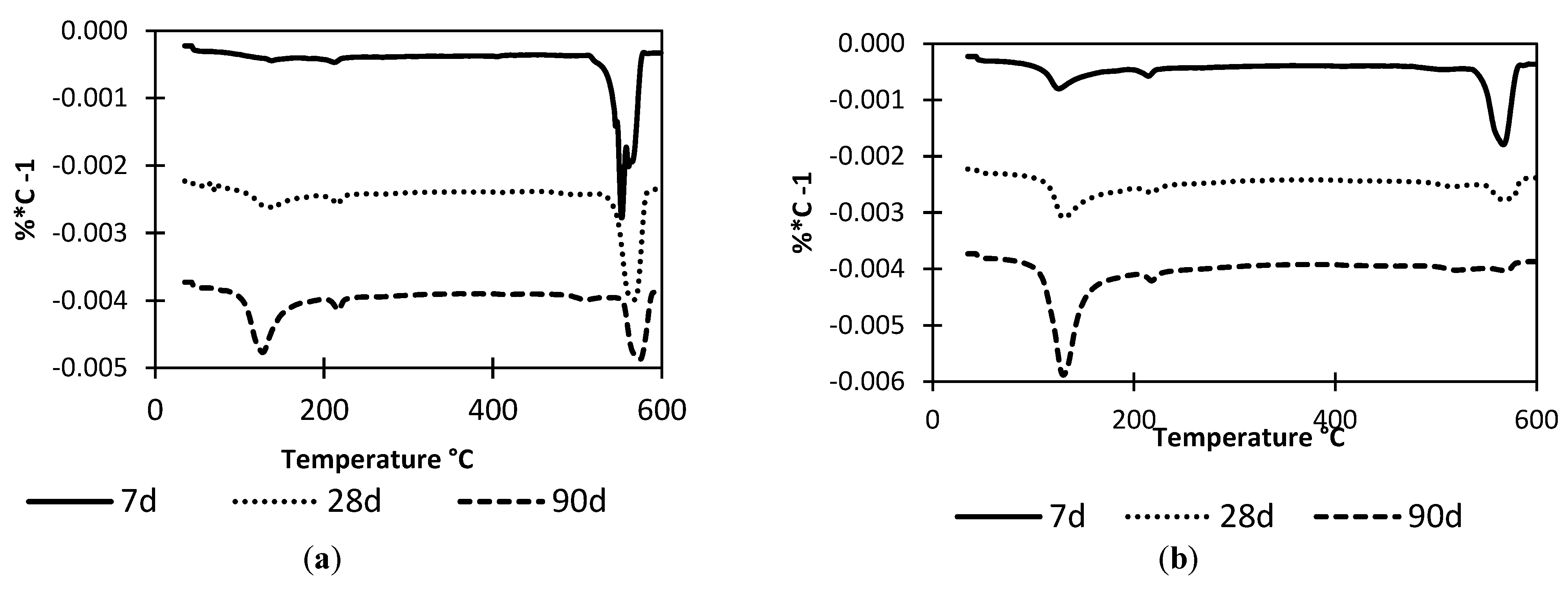

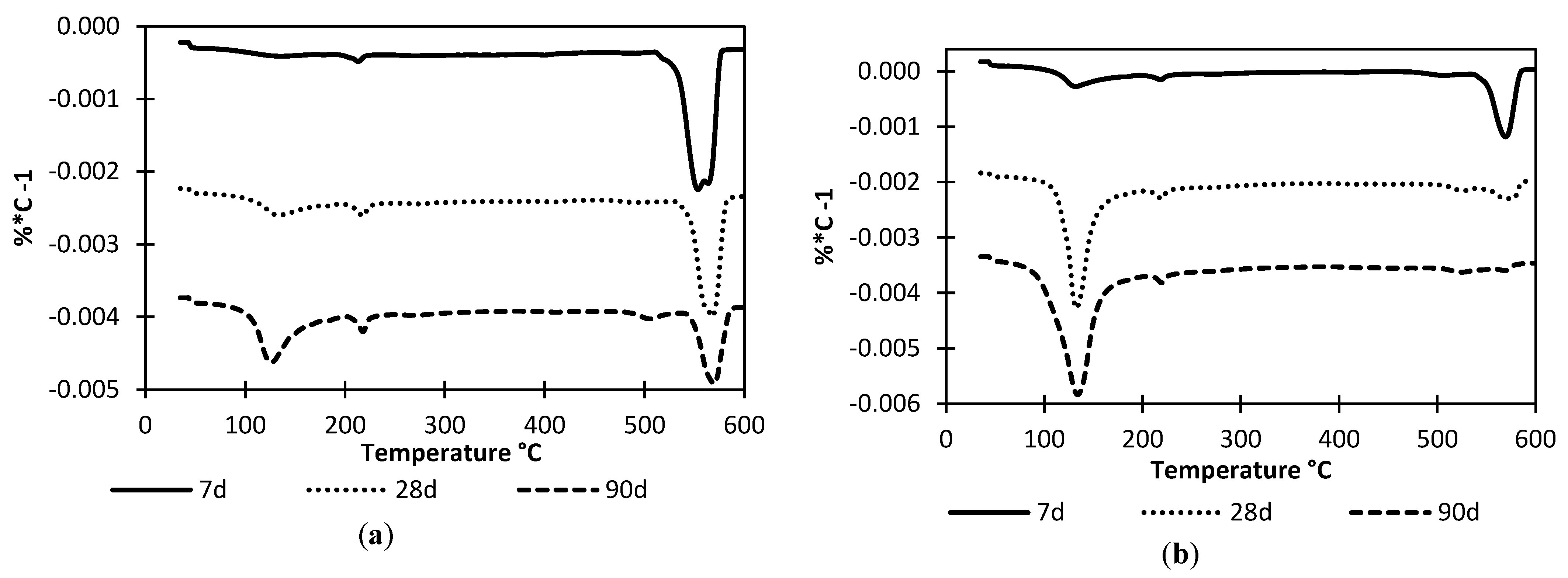

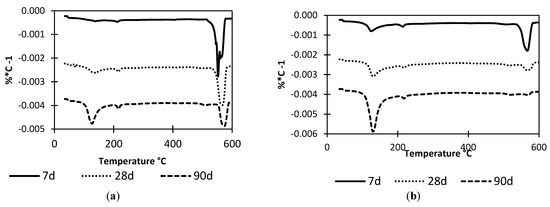

The DTG curves for the 1:2 CH/VP pastes after 7, 28, and 90 days at the 20 °C and 40 °C curing temperatures are presented in Figure 9 and Figure 10 for the T and R samples, respectively.

Figure 9.

DTG curves for the 1:2 CH/T pastes after 7, 28, and 90 days at curing temperatures of: (a) 20 °C and (b) 40 °C.

Figure 10.

DTG curves for the 1:2 CH/R pastes after 7, 28, and 90 days at curing temperatures of: (a) 20 °C and (b) 40 °C.

A predominant peak from the dehydroxylation of calcium hydroxide was observed for both pozzolans on the DTG curves at the 20 °C curing temperature, regardless of the number of days, and was thus higher than the hydrate decomposition peaks (CSH, CAH, and CASH). It can be concluded that, at this temperature, the CH/VP mixtures took considerable time to consume calcium hydroxide via the pozzolanic reaction. The reaction had already begun because the peaks corresponding to CSH, CAH, and CASH had clearly developed at 28 and 90 days.

The peaks corresponding to hydrates rose to 40 °C as a result of the increasing pozzolanic reaction rate. At this curing temperature, most of the calcium hydroxide had been consumed after 90 days, thus demonstrating the relationship between the increase in the curing temperature and the pozzolanic reaction. Table 6 presents the values of total mass loss, dehydroxylation of calcium hydroxide loss, lime fixation percentages, and combined water in hydrates (PH) for all the mixtures, which were calculated from the aforementioned equations in the introduction to this subsection. No significant differences in the behavior of both pozzolans were found.

Table 6.

Total mass loss values, dehydroxylation mass loss, CH percentage in the reacted sample (CHP), and fixed percentage of hydrated lime and water combined in hydrates (PH) for the lime:pozzolan mixtures with a weight ratio of 1:2 at curing times of 7, 28, and 90 days at 20 °C and 40 °C.

Bakolas and Aggelakopoulou [31] studied a lime-natural pozzolans system with different ratios between both materials. They obtained a greater lime fixation value than the present research work (80% lime fixation at 90 curing days at ambient temperature). The thermogravimetry values confirmed VP reactivity for long curing times.

(b) Cement/pozzolan (PC/VP) pastes

In these systems, the PC reaction with water showed a sequence of processes that produced hydration cementing products (Ettringite, CSH, CAH, and CASH) and portlandite. In the presence of pozzolanic materials, this released portlandite can form new hydration products, such as some of those formed during cement hydration. It is essential to note that two reactions simultaneously occurred: cement hydration and the pozzolanic reaction.

Fixed lime depends on calcium hydroxide, which produces hydration in the control paste. Therefore, by calculating the fixed lime percentage in cement pastes, Equation (6) could be used [32]:

where

- CHC:

- the amount of CH in the control pastes for a given curing time;

- CHP:

- the amount of CH present in the paste with the volcanic pozzolan at the same curing time;

- C%:

- the proportion of cement present in the paste (expressed per unit).

The corresponding TG curves were analyzed. The total mass loss, portlandite dehydroxylation mass loss, and combined water in hydrates were obtained. Table 7 summarizes these values, and also the Ca(OH)2 present in the reacted pastes and the fixed lime percentages, which were calculated from the aforementioned equations in the introduction to this subsection.

Table 7.

Total mass loss, dehydroxylation mass loss, Ca(OH)2 present in the paste, fixed lime percentage, and water in the hydrated compounds for the cement:pozzolan mixtures with the 25% replacement at 28 and 90 days of curing at 20 °C.

The results obtained with the analysis of the PC/VP pastes showed a negative fixed lime percentage at 28 days, which indicates that the pozzolanic additions acted as a filler for that curing time and accelerated cement hydration [33]. This behavior is typical of FA pastes at early curing times. Therefore, pozzolan particles are useful primarily as a nucleating agent, where cement hydration products are precipitated. In this way, cement continues to hydrate and the amount of portlandite present in the matrix increases.

At 90 days, the fixed lime values were positive. This suggests a significant contribution of the pozzolanic reaction. It also means that the pozzolanic reaction is slow and its chemical effects are evident for long curing times.

The percentage of water associated with hydrates for the control paste and the pastes with the 25% replacements at 28 days of curing at 20 °C indicated that pozzolan acted as a filler for a short period of time. For this reason, all the pastes had similar combined water contents in the cementing hydrates. For longer curing times (90 days), the significant increase in the cementing hydrates for the PC/VP pastes can be attributed to the pozzolanic reaction products.

3.3. Properties of Mortars: PC/VP Systems’ Workability and Compressive Strength

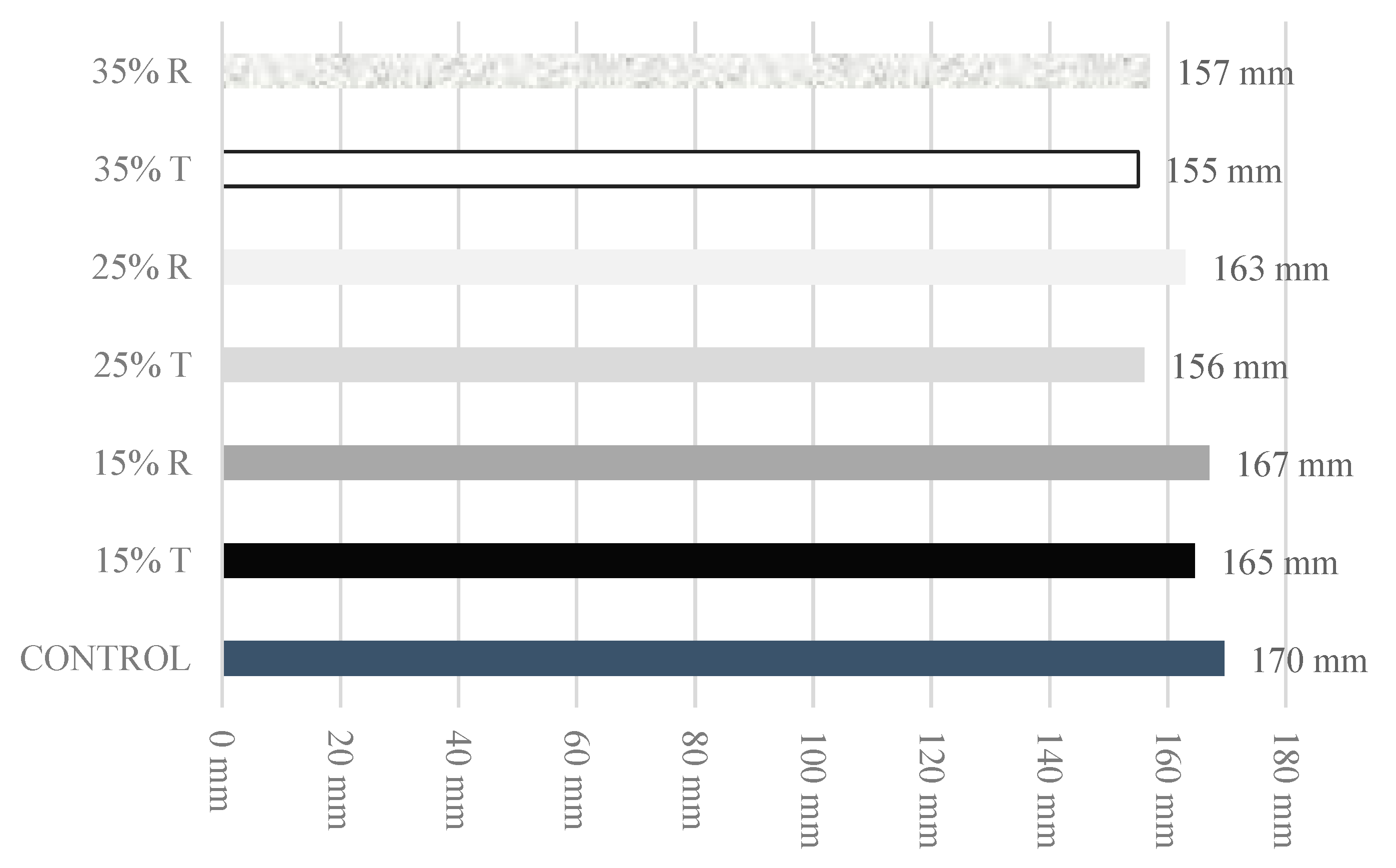

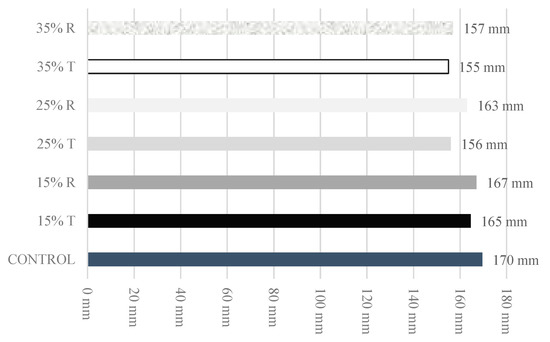

Replacing PC with pozzolan reduces workability, which is due to the pozzolan particles´ irregular shape. The results of workability with a water/binder of 0.47 are shown in Figure 11 (see Table 1).

Figure 11.

Workability of the control mortar and pozzolan-containing mortars (25% replacement) for a water/binder ratio of 0.47.

As shown in Figure 11, replacing cement with VP reduced mortar workability. This behavior is consistent with that in the consulted literature, which reported that the angular shapes of the natural pozzolans´ particles caused loss of workability.

The compressive strength results for each prepared mortar at curing times of 28, 90, and 180 days for 15%, 25%, and 35% cement replacements are presented in Table 8. In any case, the mortars containing pozzolan never exceeded the strengths of the control mortars.

Table 8.

Compression test results of the samples with a water/binder ratio of 0.47 at 28, 90, and 180 days of curing.

In order to determine the contribution of the natural pozzolans to strength development because of pozzolanic activity, the percentage of strength gain (SG%)% was calculated [34]. This parameter is defined by Equation (7):

where

Rcs is the compressive strength of the mortar with pozzolan replacement;

Rcc is the compressive strength of the control mortar;

S% is the proportion of cement in the mortar with substitution (expressed per unit; e.g., for the mortar with the 25% replacement, S% = 0.75).

As can be seen in Table 9, there was a slight strength gain in the early curing days, particularly for the highest replacement percentage (35%). The higher the number of curing days, the higher the strength gained in all of the substitutions. Therefore, it can be concluded that further strength gains were obtained with longer curing times and greater strength gains occurred at higher replacement percentages.

Table 9.

Strength gain results (SG%) of the mortars with a water/binder ratio of 0.47 at 28, 90, and 180 curing days.

Yildirim et al. [35] studied mixtures by replacing cement with VP at a percentage of 45%. The authors concluded that, at early curing times, decreases in the compressive strength values were much more pronounced. The low–medium pozzolanic reactivity of this type of material can, therefore, be confirmed.

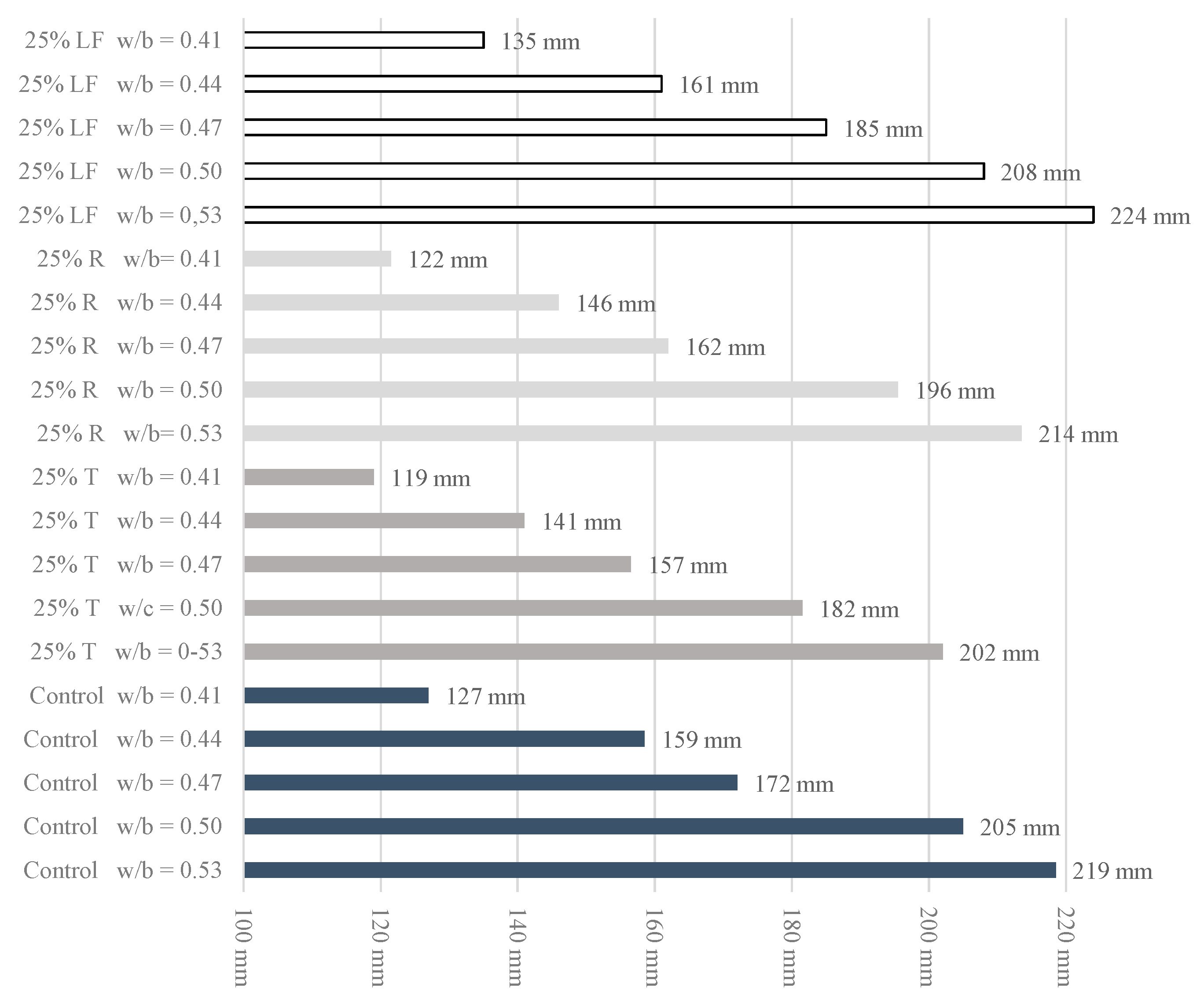

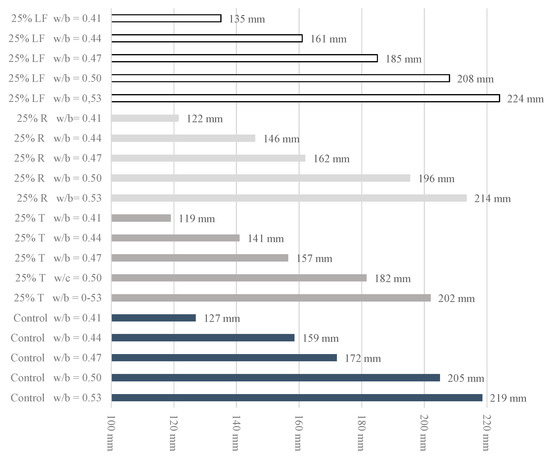

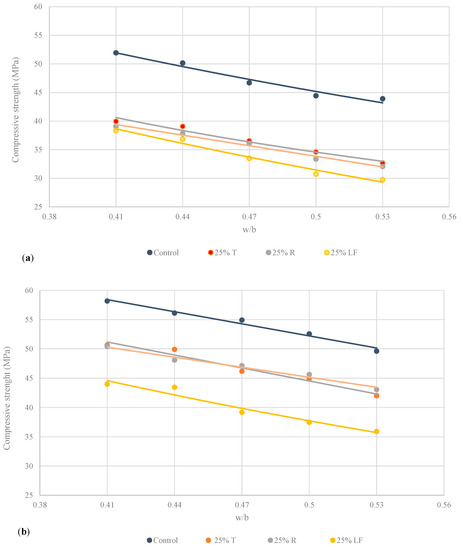

The new studied doses for the mortars with different water/binder ratios are shown in Table 2. The w/b ratios of 0.53, 0.50, 0.44, and 0.41 were studied, together with the data from the previous section corresponding to the w/b ratio of 0.47, completing the study. In this case, the behavior of the two pozzolans systems with the 25% PC replacement was analyzed, and their behavior was compared with that of the corresponding mixtures using LF as an inert addition.

A workability analysis was performed, as shown in Figure 12. The same pattern of reduced workability in all the cement replacements with substitutions for VP was observed for the control mortar values, unlike the mortars with filler substitutions, whose workability increased in relation to the control mortars.

Figure 12.

Workability of the control mortars and the mortars with the 25% replacement: studying the effect of the water/binder ratio (0.53, 0.50, 0.47, 0.44, and 0.41).

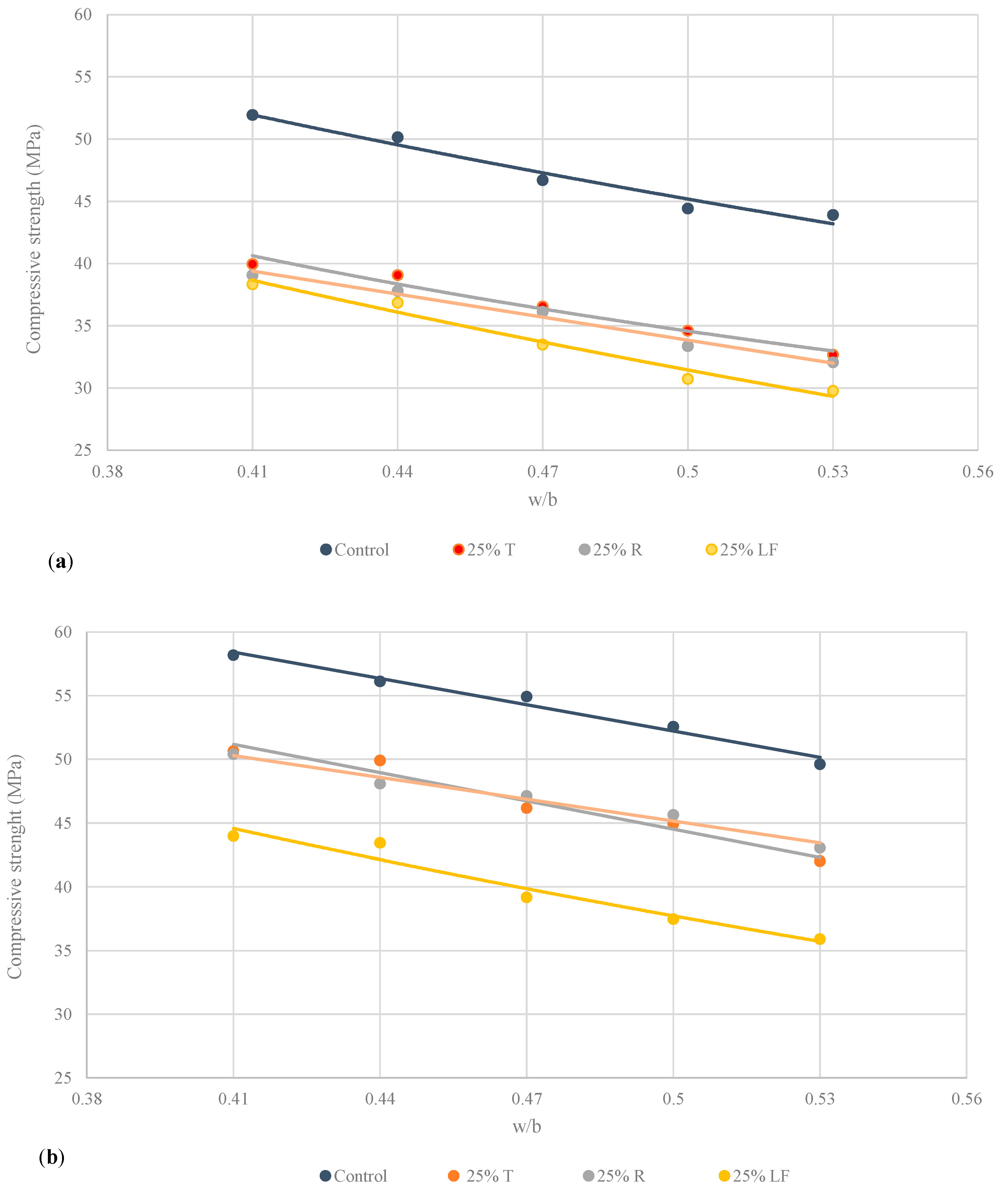

In Figure 13, the compressive strength of the control mortars and the mortars with the 25% replacement (T, R, LF) for the selected w/b ratios at 28 and 90 curing days is shown. After 28 curing days, the compressive strength of all the mortars decreased when the w/b ratio increased. The pozzolan-substituted mortars’ behavior at this curing time showed lightly greater strength development than that of the mortars with LF substitution. However, the differences among them were not very significant, reaffirming that pozzolans interacted mainly in the cement matrix as a filler or an inert addition for short curing times.

Figure 13.

Compressive strength of the control mortars and the mortars with the 25% replacement at different w/b ratios (0.53, 0.50, 0.47, 0.44, and 0.41): (a) 28 curing days and (b) 90 curing days.

Figure 13b shows that the pozzolanic reaction occurred at 90 curing days. Therefore, although the pozzolan-replaced test specimens did not reach the controls’ strength, the strength increased favorably compared with the LF replacements, which had a merely physical effect on the cement matrix. After 90 curing days, the pozzolanic effect contributed significantly to all of the mortars containing R and T (c.a. 6–7 MPa higher).

4. Conclusions

After carrying out studies on both the physical–chemical and pozzolanic reactivity of the natural pozzolans of volcanic origin from Guatemala, it can be concluded that:

- Chemically speaking, both VPs (T and R) were aluminosilicate-based in nature, with contents of potentially reactive acid oxides (SiO2, Al2O3, and Fe2O3) exceeding 85%, and their resulting LOI was acceptable (<5%). However, low reactivity was determined because a large part of the pozzolan was insoluble in acid and basic media (>40%);

- X-ray diffraction analysis confirmed the presence of not only the amorphous phase, but also crystalline phases, such as quartz, tremolite, or albite;

- The electrical conductivity measurements showed low pozzolanic reactivity, which, in this case, resulted in sample T having slightly higher reactivity than sample R;

- The Frattini test showed that the developed systems containing pozzolan at the 25–55% substitution levels could be labeled as CEM IV cements;

- The TGA confirmed the pozzolanic activity of VP: in the cement pastes, VP acted as a filler and yielded negative fixed portlandite values at early curing time. At the long-term curing time (90 days), the fixed portlandite values were positive and came close to 5–6%. The pozzolanic reactivity was enhanced in the hydrated lime pastes, mainly for the 40 °C curing temperature;

- For mortars, the workability decreased for the VP-containing systems. This behavior was due to the irregular-shaped pozzolan particles;

- The compressive strengths of the mortars containing 15–35% VP do not reach those in the control mortars. However, at 90 days, the pozzolanic effect is evidenced compared to LF. No significant differences appear between samples R and T.

It can be generally concluded that VP showed limited reactivity, but a manifest pozzolanic character. This allows it to be used in lime–pozzolan mortars or PC/VP concrete with satisfactory results.

Author Contributions

Conceptualization, O.M.S., LS. and J.P.; methodology, O.M.S., J.P. and M.V.B.; formal analysis, J.M., M.V.B. and L.S.; investigation, All the authors; writing—original draft preparation, O.M.S. and L.S.; writing—review and editing, All the authors; visualization, J.P. and J.Q.; supervision, O.M.S., J.P., L.S. and J.Q.; funding acquisition, J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Adsideo Cooperacion 2012 (Centro de Cooperación al Desarrollo UPV).

Institutional Review Board Statement

It is not applicable.

Informed Consent Statement

It is not applicable.

Acknowledgments

We wish to thank the Adsideo Cooperación 2012 program (Centro de Cooperación al Desarrollo de la Universitat Politècnica de València) for funding the Project “Characterization of pozzolans of volcanic origin from Guatemala: possibilities of use in prefabricated materials for the construction and rehabilitation of social housing”. We would also to thank the Mayanet project (“Erasmus Mundus Programme Action 2- Lot 8 Latin America”), especially Elena Taulet from the OAI of the Universitat Politècnica de València.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Available online: https://oec.world (accessed on 1 January 2020).

- Raventós, P.; Zolezzi, S. Cement in Central America: Global players in a local industry. J. Bus. Res. 2016, 69, 388–394. [Google Scholar] [CrossRef]

- Torres, S.; García, E.; Velásquez, L.; Díaz, R.; Martirena, F. Production of limestone-calcined clay cement in Guatemala. In Proceedings of the International Conference of Sustainable Production and Use of Cement and Concrete, Dalian, China, 20–23 September 2019; pp. 85–92. [Google Scholar] [CrossRef]

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Pacheco Torgal, F.; Jalali, S. Binders and concretes. In Eco-efficient Construction and Building Materials; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Celik, K.; Jackson, M.D.; Mancio, M.; Meral, C.; Emwas, A.-H.; Mehta, P.K.; Monteiro, P.J.M. High-volume natural volcanic pozzolan and limestone powder as partial replacements for portland cement in self-compacting and sustainable concrete. Cem. Concr. Compos. 2019, 45, 136–147. [Google Scholar] [CrossRef]

- Ahmad, S.; Mohaisen, K.O.; Adekunle, S.K.; Al-Dulaijan, S.U.; Maslehuddin, M. Influence of admixing natural pozzolan as partial replacement of cement and microsilica in UHPC mixtures. Constr. Build. Mater. 2019, 198, 437–444. [Google Scholar] [CrossRef]

- Díaz-Loya, I.; Juenger, M.; Seraj, S.; Minkara, R. Extending supplementary cementetitious material resources: Reclaimed and remediated fly ash and natural pozzolans. Cem. Concr. Compos. 2019, 101, 44–51. [Google Scholar] [CrossRef]

- Costa, D.; Quattrone, M.; Souza, J.F.T.; Punhagui, K.R.G.; Pacca, S.A.; John, V.M. Potential CO2 reduction and uptake due to industrialization and efficient cement use in Brazil by 2050. J. Ind. Ecol. 2021, 25, 344–358. [Google Scholar] [CrossRef]

- UNE-EN 197-1; Cement. Part I: Composition, Specifications and Conformity Criteria for Common Cements. AENOR: Madrid, Spain, 2011.

- Al-Fadala, S.; Chakkamalayath, J.; Al-Bahar, A.; Al-Aibini, A.; Ahmed, S. Significance of performance based specifications in the qualification and characterization of blended cement using volcanic ash. Const. Build. Mater. 2017, 144, 532–540. [Google Scholar] [CrossRef]

- Játiva, A.; Ruales, E.; Etxeberria, M. Volcanic ash as a sustainable binder material: An extensive review. Materials 2021, 14, 1302. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Wang, K.-T.; Tang, Q.; Nzeukou, A.N.; Billong, N.; Melo, U.C.; Cui, X.M. Review on the use of volcanic ashes for engineering applications. Resour. Conserv. Recycl. 2018, 137, 177–190. [Google Scholar] [CrossRef]

- Wilson, W.; Rivera-Torres, J.M.; Sorelli, L.; Durán-Herrera, A.; Tagnit-Hamou, A. The micromechanical signature of high-volume natural pozzolan concrete by combines statistical nanoindentation and SEM-EDS analyses. Cem. Concr. Res. 2017, 91, 1–12. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Lachemi, M. Fresh, mechanical, and durability characteristics of self-consolidating concrete incorporating volcanic ash. J. Mater. Civ. Eng. 2010, 22, 651–657. [Google Scholar] [CrossRef]

- Contrafatto, L. Recycled Etna volcanic ash for cement, mortar and concrete manufacturing. Const. Build. Mater. 2017, 151, 704–713. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Magbool, H.M.; Amran, M.; Mijarsh, M.J.A.; Almalki, A. Performance of high-strenght green concrete under the influence of curing methods, volcanic pumice dust, and hot weather. Arch. Civ. Mech. Eng. 2022, 22, 134. [Google Scholar] [CrossRef]

- Djon, L.; Ndjock, B.I.; Elimbi, A.; Cyr, M. Rational utilization of volcanic ashes based on factors affecting their alkaline activation. J. Non-Cryst. Solids. 2017, 463, 31–39. [Google Scholar] [CrossRef]

- Almalkawi, A.T.; Hamadna, S.; Soroushian, P. One-part alkali activated cement based volcanic pumice. Const. Build. Mater. 2017, 152, 367–374. [Google Scholar] [CrossRef]

- Adewumi, A.A.; Ariffin, M.A.M.; Yusuf, M.O.; Maslehuddin, M.; Ismail, M. Effect of sodium hydroxide concentration on strength and microstructure of alkali-activated natural pozzolan and limestone powder mortar. Const. Build. Mater. 2021, 271, 121530. [Google Scholar] [CrossRef]

- Bohnenberger, O.H. Los focos eruptivos cuaternarios de Guatemala. Inst. Centroam. Investig. Y Tecnol. Ind. Guatemala 1969, 1960, 23–24. [Google Scholar]

- Quiñonez, F.J.; Rosales, V.R. Evaluación Física de Muestras de Materiales Volcánicos de Guatemala para Uso en la Producción de Aglomerantes. Elev. LACCEI Lat. Am. Caribb. Conf. Eng. Technol. 2013, 30, 1–2. [Google Scholar]

- UNE-EN 196-1; Methods of Testing Cement. Part 1. Determination of Strength. AENOR: Madrid, Spain, 2018.

- UNE-EN196-2; Methods of Testing Cement. Part 2: Chemical Analysis of Cement. AENOR: Madrid, Spain, 1996.

- Tashima, M.M.; Soriano, L.; Monzó, J.; Borrachero, M.V.; Akasaki, J.L.; Payá, J. New method to assess the pozzolanic reactivity of mineral admixtures by means of pH and electrical conductivity measurements in lime: Pozzolan suspensions. Mater. Constr. 2014, 64, e032. [Google Scholar] [CrossRef]

- UNE-EN196-5; Methods of testing cement. Part 5: Pozzolanicity test for pozzolanic cement. AENOR: Madrid, Spain, 2011.

- UNE-EN1015-3; Methods of Test for Mortar for Masonry. Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). AENOR: Madrid, Spain, 2000.

- Robayo-Salazar, R.A.; Mejía de Gutiérrez, R. Natural volcanic pozzolans as an available raw material for alkali-activated materials in the foreseeable future: A review. Const. Build. Mater. 2018, 189, 109–118. [Google Scholar] [CrossRef]

- Pavlidou, E. Systematic analysis of natural pozzolans from Greece suitable for repair mortars. J. Therm. Anal. Calorim. 2012, 108, 671–675. [Google Scholar] [CrossRef]

- Estifanos, S.; Abay, A.; Hagos, M.; Mebrahtu, G. Assessing the aptitude of vesicular volcanic rocks as pozzolanic sources for supplementary cementitious materials. Bull. Eng. Geol. Environ. 2019, 78, 1607–1616. [Google Scholar] [CrossRef]

- Bakolas, A.; Aggelakopoulou, E. Pozzolanic activity of natural pozzolan-lime pastes and physicomechanical characteristics. J. Therm. Anal. Calorim. 2019, 135, 2953–2961. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Velázquez, S. Evaluation of the pozzolanic activity of fluid catalytic cracking catalyst residue (FC3R). Thermogravimetric analysis studies on FC3R-Porland cement pastes. Cem. Concr. Res. 2003, 33, 603–609. [Google Scholar] [CrossRef]

- Soriano, L.; Payá, J.; Monzó, J.; Borrachero, M.V.; Tashima, M.M. High strength mortars using ordinary Portland cement-fly ash-fluid catalytic cracking catalyst residue ternary system (OPC/FA/FCC). Const. Build. Mater. 2016, 106, 228–235. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Peris, E.; Gonzáles-López, E. Mechanical treatments of fly ashes. Part III: Studies on strength development of ground fly ashes (GFA)—Cement mortars. Cem. Concr. Res. 1997, 27, 1365–1377. [Google Scholar] [CrossRef]

- Yildirim, G.; Dundar, B.; Alam, B.; Yaman, I.O.; Sahmaran, M. Role of nanosilica on the early-age performance of natural pozzolan-based blended cement. ACI Mater. J. 2018, 115, 969–980. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).