Highlights

What are the main findings?

- Compared with the mixed-effects and the fixed-effects models, the random-effects model is the most suitable form to predict the asphalt pavement surface texture.

- The cumulative standard axle loads (CSAL), the monthly average humidity (MAH), the monthly rainfall (MR), the coarse aggregate ratio (CA), and the fine aggregate fine ratio (FAF) are negatively correlated with surface texture. The monthly average temperature (MAT) and the fine aggregate coarse ratio (FAC) are positively correlated with surface texture.

What is the implication of the main finding?

- The panel data analysis model is established for predicting asphalt pavement surface texture

- The significance of each influencing factor on asphalt pavement surface texture is determined

Abstract

The surface texture of asphalt pavement is of enormous importance to skid resistance. To investigate the degradation tendency of surface texture related to the skid resistance, four years of sensor measured texture depth (SMTD) panel data measured from 19 pavement structures including 4 types of surface asphalt layer are used to develop a surface texture prediction model. The panel data-based prediction model takes into account the dependence on time scale, diversified road sections, traffic factors, environmental factors, and the Bailey method-based aggregate gradation parameters. The regression and prediction capability of the surface texture model is evaluated from both short and long-term perspective. The results indicated that the random-effects model is the most suitable form to characterize the degradation of surface texture. The cumulative standard axle loads (CSAL), monthly average humidity (MAH), and the Bailey method-based aggregate gradation parameters (the coarse aggregate ratio (CA), the fine aggregate coarse ratio (FAC), and the fine aggregate fine ratio (FAF)) have significant influences on the sensor measured texture depth. The time scale of the input sensor measured texture depth (SMTD) data has influence on the accuracy of the surface texture prediction model; therefore, long-term data series can ensure the robustness of long-term prediction. The results of this study can benefit the material design, construction, maintenance of asphalt pavement, and its evaluation pavement for longer service life.

1. Introduction

Road traffic accidents closely relate to driver, traffic, weather and road conditions [1,2]. According to statistics, traffic accidents caused by insufficient pavement skid resistance account for about 10% of the total [3], while improving the level of surface textures and pavement friction has a clear benefit on the reduction of accident rates [4]. However, under the combined action of traffic loads and adverse weather conditions, the pavement skid resistance performance degrades over time. Therefore, the prediction of long-term asphalt pavement skid resistance is essential for road safety.

In order to study the surface textures and pavement friction degradation of asphalt pavement, full-scale instrumented track tests have been carried out in a few countries. Among them, the American AASHTO test road has been tested since 1958. After two years of real traffic loading and the application of total 1.1 million axle loads, the friction coefficients decreased from 0.72 and 0.63 to 0.44 and 0.22, respectively, for the flexible pavement and the rigid pavement [5]. Based on the National Center for Asphalt Technology (NCAT) test track constructed in 2000, the friction coefficient and the skid number on several road sections were measured using a dynamic friction tester and a locking wheel anti-skid trailer [6]. Subsequently, a surface shot peening treatment was proposed to improve the long-term skid resistance of the asphalt pavement [7]. The Minnesota Department of Transportation began construction of MnROAD in 1991 and opened the full-scale pavement research facility to live traffic in 1994. The skid number on asphalt pavement road sections was measured using the lock wheel anti-skid trailer, and a relationship among the skid numbers, service time, and loading conditions was established [8]. In China, RIOHTrack was built in November, 2015, aiming at verifying the design and construction of long-life pavement. Based on the RIOHTrack, Wu et al. (2020) carried out a correlation analysis of British pendulum number (BPN) test value and mean texture depth measured by te sand patch method (MTD) test value. They found that there is a linear growth law between the two indicators, and the correlation coefficient reaches 0.99 [9]. Wang et al. (2018) reported the variation of sideways force coefficient (SFC) and sensor measured texture depth using a laser method (SMTD) measured on RIOHTrack during 2017, but they did not establish a prediction model to characterize these indicators [10]. Liao (2019) proposed exponential and logarithmic functions with regard to the short-term prediction of SFC by considering the influencing factors of load level and loading cycle numbers [11].

Up to now, the research based on full-scale accelerated pavement testing has mainly focused on the comparison of friction among different road sections and the degradation trend of skid resistance. There is no surface texture model that considers the aggregate factors based on the aggregate gradation parameters from the Bailey method. The main factors considered in surface texture modeling need to be further improved. Generally, the existing surface texture models for asphalt pavement take into account the influences from the traffic volume (the cumulative standard axle loads) [12]. The Bailey method provides a promising approach for the design of asphalt mixtures and the evaluation of aggregate packing and voids. It can realize the optimal design of a dense skeleton interlocking anti-skid wearing course and improve the pavement surface textures and the skid resistance [13]. Therefore, the aggregate parameters considered in the Bailey method can be taken as the important influencing factors to predict the sensor measured texture depth in the surface texture model, namely, the coarse aggregate ratio (CA), the fine aggregate coarse ratio (FAC), and the fine aggregate fine ratio (FAF).

In this study, a random-effects panel data-based prediction model is developed to evaluate the asphalt pavement surface texture in terms of SMTD. The data are collected from 19 asphalt pavement structures in RIOHTrack including 4 types of surface asphalt layers (denoted as SAC13-65%, SAC13-70%, SMA13-75%, and PAC13-80%). From year 2016 to 2020, data collection has been continuously performed to gather SMTD data as well as the relevant data of loading and environmental conditions. Based on panel data analysis (PDA), the key factors affecting the surface texture of asphalt pavement are clarified, and the relationship between the surface texture and these factors are revealed. The regression results, the short and long-term prediction accuracy of the proposed model are evaluated with the SMTD panel data across various time scales.

2. RIOHTrack Test

2.1. Overview of Full-Scale Track

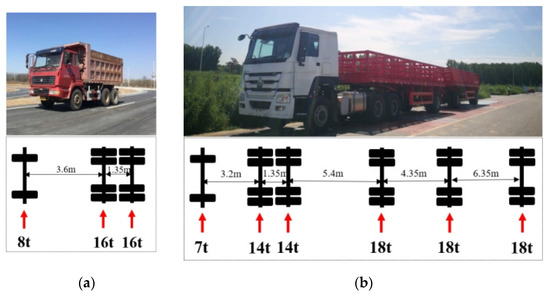

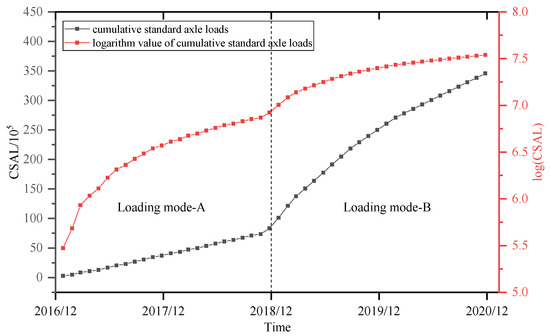

RIOHTrack is a 2038 m long, 10.5 m wide, full-scale testing loop with 2 lanes. There are 19 types of asphalt pavement structures, named STR1 to STR19, which contain diversified asphalt pavement structures and construction materials [14]. Four types of asphalt concretes are used as the upper layer asphalt materials, as shown in Table 1. The construction of RIOHTrack project was completed in November 2015. The asphalt road sections testing began in December 2016. After that, two types of loading modes have been applied, which are mode-A starting from December 2016 to December 2018, and mode-B starting from January 2019 until 2020, as shown in Figure 1. In this study, the conversion to standard axle load (80 kN) from mode-A and mode-B is carried out first. Up to December 2020, 35 million times the standard axle load has been applied to the testing loop. Equivalent axle load conversions are conducted according to different loading modes in Figure 1. The variation of cumulative standard axle loads (CSAL) and logarithm of cumulative standard axle loads (log(CSAL)) during RIOHTrack testing is shown in Figure 2. It can be clearly seen that the cumulative standard axle loads (CSAL) and the logarithm of cumulative standard axle loads (log(CSAL)) have increased significantly since December 2018.

Table 1.

Asphalt upper layer information and pavement structure number of RIOHTrack.

Figure 1.

Loading modes of RIOHTrack. (a) Loading mode-A. (b) Loading mode-B.

Figure 2.

Cumulative standard axle loads (CSAL) applied during RIOHTrack testing.

2.2. Measured Parameters of Full-Scale Track

Table 2 shows the test methods that can be used to obtain the skid resistance indicators. The test data from the RIOHTrack include the sideways force coefficient (SFC), the British pendulum number (BPN), the mean texture depth (MTD) measured by the sand patch method, and the mean texture depth measured by a laser method (SMTD) [15]. The current study focuses on the surface texture depth measured using vehicle-carried lasers, following the Chinese standard procedures (JTG/T E61-2014). The laser texture depth meter is composed of a range sensor, a longitudinal distance sensor, and a high-speed signal acquisition and data processing system. By using a multi-functional pavement condition measuring vehicle as shown in Figure 3, the sensor measured texture depth data can be collected very efficiently [16].

Table 2.

Test methods for the characterization of skid resistance.

Figure 3.

Multifunctional vehicle equipped with a laser texture depth tester.

The vehicle-carried laser texture depth meter is an instrument that uses the laser range and distance sensors to automatically and quickly detect the pavement surface texture [22]. It projects a beam of infrared laser onto the pavement surface, and the scattered signal is received by a light collector soon afterwards. The elevation data of the pavement texture are saved and then used to calculate the sensor measured texture depth (in the unit of mm). Assuming that the length of road where the SMTD is measured is D, the calculation formula of SMTD is [23]:

2.3. Degradation of Surface Texture

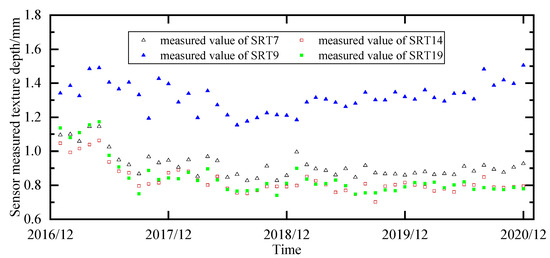

Figure 4 shows the variations of sensor measured texture depth by laser method (SMTD) in typical asphalt pavement sections of RIOHTrack from December 2016 to December 2020. During the first year, large SMTD fluctuations can be observed, and the SMTD value temporarily increased at the early stage. This is mainly because the asphalt content in the upper layer is slightly higher than the optimum value of the mixture design [15]; thus, free asphalt would be formed in the pavement surface, filling in the voids between the surface aggregate particles. This asphalt is then wearing thin upon traffic load applications, so that the surface particles are exposed, and the SMTD is increased at the early stage. The subsequent decrease of SMTD test value is attributed to the compaction of the asphalt mixture under the heavy vehicle loads. It is also noted that slight fluctuations in SMTD still exist even at later stage, which might be caused by the gradual spalling of the mixture on the pavement surface [15].

Figure 4.

Field measured SMTD in typical asphalt pavement sections.

It is seen from Figure 4 that the SRT-9 section paved with PAC13-80% mixture shows the largest SMTD value, which is generally greater than 1.2 mm. The second-largest SMTD value is observed on the SRT-7 section paved with SAC13-70% mixture, which is generally greater than 0.9 mm. The SMTD value measured from the SRT-14 section (paved with SAC13-65%) is very close to that measured from the SRT-19 section (paved with SMA13-75%). The reason is that the STR-9 section uses a distinct mixture type of porous asphalt concrete (PAC13-80%), which was designated to provide water drainage and resistance to both raveling and deformation. Thus, the SMTD measured on STR-9 showed the largest value. It is also worth mentioning that compared with SAC13-65% mixture, SAC13-70% mixture has a higher 4.75-mm sieve passing percentage that results in less wear-resistant and greater SMTD [15].

3. Generation of Surface Texture Panel Data

3.1. Introduction of Panel Data Analysis

Panel data is a two-dimensional data set that contains time series data and cross section data [24]. A dataset containing T observation periods and N objects is denoted as yit. The subscript i denotes the number of objects (N), and the subscript t denotes the number of observation periods (T). Accordingly, the dataset of the i-th object across T observation periods is expressed as , which is called the time series panel data in the i-th longitudinal cross section. The dataset of N objects across the t-th observation period is expressed by , which is called the transversal section panel data in the t-th observation period.

Currently, the panel data analysis method is less used for the characterization of pavement performance. Theoretically, this method is of benefit in understanding and predicting the short and long-term surface texture of asphalt pavement, since it extends the sample data and can provide more accurate and effective estimates. Using the panel data analysis method, three basic types of models can be established, i.e., mixed-effects (ME), fixed-effects (FE), and random-effects (RE) models [25]. Lee [26] developed a random-effects panel data model to assess the international roughness index (IRI) of asphalt pavement. The model obtained a good result for the key factors affecting asphalt pavement IRI. Guo [27] proposed a mixed-effects IRI prediction model for asphalt pavement. Compared with an earlier developed time series model, this mixed-effects panel data model has a higher precision in the long-term prediction. Taking the skid number as the indicator, Zhan [28] developed a random-effects panel data model to predict the skid resistance of asphalt pavement. The regression between the predicted and the measured results was fitted with the R2 coefficient of 0.74. Based on the LTPP test road, Li [29] developed a fixed-effects panel data model using the skid number as the indicator of skid resistance. A satisfactory fitting performance was provided by this model since the R2 reached 0.94. Therefore, the performance prediction model of asphalt pavement developed by the panel data analysis is satisfactory for the pavement roughness prediction using IRI as the indicator and the skid resistance prediction using skid number as the indicator.

The sensor measured texture depth data collected from full-scale asphalt pavement track is a typical kind of panel data, which contains two dimensions, i.e., the time series data and the cross section data. Compared with single time series data, the panel dataset contains dynamic performance variations in different asphalt pavement sections. The surface texture panel data of RIOHTrack contains the time series data from January 2017 to December 2020, and the cross section series data of 19 pavement structures (Table 3). For a certain month, the panel data is the cross section data containing 19 road sections; as for a certain road section, the panel data is the time series data of this road section across 48 months. The panel data processed in this study is composed of 19 individuals and 48 months. Accordingly, the panel data of each unknown influencing factor contains 19 individuals and 48 months; thus, a total of 912 observations should be considered.

Table 3.

Summary of influencing factors of surface texture panel data model.

A general form of surface texture panel data analysis model is as follows:

where, i is the number of road sections (i = 1, 2, …, N), t is the month for the surface texture test (t = 1, 2, …, T), yit is the sensor measured texture depth value in the i-th road section and the t-th month, xkit is the value of the k-th influencing factor in the i-th road section and the t-th month, is a parameter to be estimated, is a term of random error, is called the individual effect value, which is a characteristic value reflecting the difference between different road sections of the same pavement type caused by material, structure, construction, and measurement. It does not change with time. is the time effect value, a characteristic value reflecting the time difference that does not change with the road section. is the mixed random error component for the i-th road section and the t-th month.

As mentioned earlier, the three basic forms of panel data model are mixed-effects, fixed-effects, and random-effects. When the individual effect and the time effect are 0, the model is classified as the mixed-effects type. When the individual effect or the time effect is considered to directly relate to the influencing factors, the model is classified as the fixed-effects type. When the individual effect and the time effect are not relevant to any factors, the model is classified as the random-effects type. Using the SMTD data collected from RIOHTrack, the three types of panel data models are developed in this study and their applicabilities are evaluated.

3.2. Aggregate Factors Affecting Surface Texture

Kane and Edmondson (2017) defined the aggregate hardness parameter (AHP) as the sum of average hardness (DMP) and contrast of hardness (CD), and indicated a positive correlation between AHP and the friction coefficient of asphalt pavement [30]. For now, few researchers try to introduce the Bailey method-based aggregate parameters (CA, FAC, and FAF) as the basic factors in the prediction model of surface texture. In this paper, the Bailey method-based aggregate parameters, for the first time, are considered as the influencing factors in the surface texture prediction model.

The Bailey method controls the passing percentages of key sieve size of coarse and fine aggregates through CA, FAC and FAF parameters, so that asphalt mixture can form a dense anti-sliding wear layer with embedded structure. Therefore, the aggregate parameters based on the Bailey method are closely related to the skid resistance [12,30]. Unlike the conventional design methods, the Bailey method uses a different definition of coarse and fine aggregate, taking the sieve size corresponding to 0.22 times of the nominal maximum aggregate size (NMAS) as the critical size that distinguishes the coarse aggregate from the fine aggregate.

The Bailey aggregate gradation parameters include CA, FAC, and FAF ratios [13]. The CA ratio defines the shape of the coarse aggregate portion of the gradation. If the CA ratio is too large, the coarse aggregate skeleton of asphalt mixture cannot be formed; if it is too small, the problems of segregation and insufficient compactness may occur. The FAC ratio describes the interlocking and filling effects of the coarser portion in fine aggregate, and the FAF ratio describes the filling compactness of the finer portion in fine aggregate. The calculation formulas are as follows:

where, CA is the coarse aggregate ratio, FAC is the fine aggregate coarse ratio, FAF is the fine aggregate fine ratio, NMPS is the nominal maximum particle size, PNMPS/2 is the passing percentage of the sieve corresponding to 1/2 nominal maximum particle size, PCS is the key controlling sieve, PPCS is the passing percentage of PCS, P100% is the passing percentage of the maximum sieve, SCS is the first controlling sieve of fine aggregate, TCS is the second controlling sieve for fine aggregate, PSCS is the passing percentage of SCS, and PTCS is the passing percentage of TCS.

3.3. Surface Texture Panel Data

The factors that influence pavement friction forces can be grouped into four categories—pavement surface characteristics, vehicle operational parameters, tire properties, and environmental factors [31]. Pavement surface texture is characterized by the asperities present in a pavement surface, which has a significant impact on the skid resistance [32,33,34]. The main factors affecting the surface texture of asphalt pavement are pavement materials, traffic load and climate environment [35]. Based on a careful analysis of previous research conclusions on asphalt pavement surface texture, 7 influencing factors are chosen for our panel data model, as shown in Table 3. These factors include the cumulative number of axle loads, the monthly average temperature, the monthly average relative humidity, the monthly rainfall, CA, FAC, and FAF. The surface texture panel data set is generated by taking the 7 influencing factors as independent variables (xkit in Equation (4)) and the sensor measured texture depth as dependent variables (yit in Equation (4)), taking into account the time scales of field SMTD data and multi-sections of the same surface asphalt layer.

The data sources of the 7 influencing factors presented in Table 3 are introduced in the following way. Based on the deflection equivalent method, the applied traffic loads are converted into the equivalent axle loads. The axle load conversion index is 4.35 according to Chinese Technical Specifications for Construction of Highway Asphalt Pavements (JTG F40-2017) [36]. The datasets of air temperature, humidity, and rainfall are obtained from the on-site meteorological station [14]. The aggregate parameters CA, FAC, and FAF were calculated based on the Bailey method. For the asphalt mixtures of surface layer, the half sieve, main controlling sieve, first controlling sieve for fine aggregate, and second controlling sieve for fine aggregate are 4.75 mm (NMPS/2), 2.36 mm (PCS), 0.6 mm (SCS), and 0.15 mm (TCS), respectively [11]. The calculated results of CA, FAC, and FAF are shown in Table 4.

Table 4.

Bailey method-based CA, FAC, and FAF ratios calculated for the four types of mixtures.

4. Panel Data Analysis-Based Surface Texture Prediction Model

The procedures for developing a panel data-based surface texture prediction model include three steps: (1) The mixed-effects, fixed-effects, and random-effects models are developed using RIOHTrack mean texture depth measured by laser method (SMTD) data. The F test, LM test, and Hausman test are carried out in sequence to determine the most applicable model among the three types of models. (2) The regression results of the surface texture prediction model based on the SMTD data across different time scales are compared. (3) The influence of the time scales of SMTD data on the accuracy of the surface texture prediction model is analyzed in respect to the short-term and long-term service time. The optimal time scale of the SMTD data for the prediction model is determined.

4.1. Development of Panel Data Analysis-Based Surface Texture Prediction Model

The SMTD data collected from 19 test structures in RIOHTrack between December 2016 to December 2020 are taken as the panel data for analysis. Considering that most environmental factors change periodically, at least one-year panel data should be used as the input of the prediction model. Importantly, the time scale of the input data needs to be determined according to the regression results of the panel data analysis-based prediction model, which will be discussed in detail later. As an analytical example, the surface texture prediction model is developed and evaluated using the first 3 years SMTD panel data (from year 2017 to 2019), and the obtained prediction formulas are presented in Table 5.

Table 5.

Prediction formulas of surface texture model using the first 3 years SMTD panel data.

Table 6 shows the regression results of a panel data analysis-based surface texture prediction model using the first 3 years SMTD panel data. The significance level of each influencing factor, depending on the calculated p value, can be determined from the regression results. The smaller the p value, the more significant the influence of this factor on the surface texture. For the mixed-effects and random-effects models, all these selected influencing factors have a significant impact on the surface texture. For the fixed-effects model, only 4 influencing factors (the cumulative axle loads, monthly average temperature, monthly average humidity, and monthly rainfall) have a significant impact on the surface texture. The regression R2 value of the three models are 0.732, 0.822, and 0.398, respectively. However, it cannot be concluded that the larger the R2 value of regression, the more applicable the model is [28]. Normally, the developed panel data analysis-based models should be examined by F test, LM test, and Hausman test to determine whether these models are qualified. Then we can choose the most applicable model.

Table 6.

Regression results of panel data analysis-based surface texture prediction model using the first 3 years SMTD panel data.

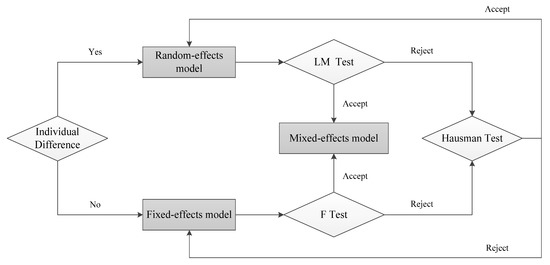

4.2. Examination of Panel Data Analysis-Based Surface Texture Prediction Model

In order to select the most suitable panel data analysis-based model, a series of tests need to be conducted on the model. The flow chart of examining the panel data analysis model is shown in Figure 5. The first step is to judge whether there is individual heterogeneity in the surface texture data set collected from multiple sections of same type of pavement structure. If there is, the panel data analysis model is initially considered to be a random-effects form. Then, the LM test is carried out. If the LM test condition is accepted, the analysis model is recognized as the mixed-effects model. If the LM test condition is rejected, the Hausman test is performed. If there is no individual heterogeneity in the data set from different sections, the panel data analysis model is initially considered to be a fixed-effects form, then the F test is implemented. If the F test condition is accepted, the analysis model is recognized as the mixed-effects model. If the F test condition is rejected, the Hausman test is conducted. The Hausman test is an effective tool to distinguish the fixed-effects model and the random-effects model. If the Hausman test condition is accepted, the analysis model is a random-effects model. Otherwise, it is a fixed-effects model.

Figure 5.

The flow chart of the panel data analysis model examination.

Table 7 shows the results of the panel data analysis model examination. The p value is the probability that the null hypothesis is true, that is, the smaller the p value is, the smaller the probability of the null hypothesis is; the greater the p value is, the greater the probability of the null hypothesis is. It is seen that the p value obtained by LM Test and F test is 0, indicating that these two test conditions are both rejected. The p value obtained by Hausman test is 1, that is, the Hausman test condition is accepted. Therefore, the random-effects model is the most suitable model to predict the asphalt pavement surface texture of RIOHTrack (see Figure 5). Ref. [28] developed a panel data-based skid resistance model using skid number (SN). This model is also a random-effects model and it achieves good results; the regression between the predicted and the measured SN results was fitted with the R2 coefficient of 0.74.

Table 7.

Examination results of panel data analysis-based surface texture model.

The prediction formula of the asphalt pavement surface texture based on the 3 years SMTD panel data is shown in Equation (12). It is clearly seen that the cumulative axle load (CSAL), monthly average humidity (MAH), monthly rainfall (MR), CA and FAF ratios are negatively correlated with the surface texture of asphalt pavement, while the monthly average temperature (MAT) and FAC ratio are positively correlated with the surface texture of asphalt pavement. A fixed-effects type panel data analysis model with respect to skid number variation has been developed in Ref. [28]. The data were taken from the skid number results measured from 255 road sections for 15 years, and it was reported that the annual average rainfall was negatively correlated with skid number, whereas the traffic volume and the annual average humidity were positively correlated with skid number. That is, Ref. [28] concluded a positive correlation between the annual average humidity and the skid number (SN) of asphalt pavement, which is contrary to the panel data analysis model developed in our study. The conclusions in Ref. [28] are contrary to the engineering practice. Practice shows that the higher the humidity is, the lower the skid resistance is. However, the absolute value of the partial coefficient of MAT is very small, and MAT is insensitive to surface texture.

4.3. Influence of Panel Data Time Scale on Surface Texture Prediction Model

The above analysis has led to the random-effects model as the most suitable form of the surface texture model with respect to the indicator of sensor measured texture depth. In the following, the surface texture prediction models using one year, two years, three years, and four years sensor measured texture depth data are developed to clarify the influence of different time scales of sensor measured texture depth data on the regression result, the short-term prediction accuracy, and the long-term prediction robustness of the developed model.

Table 8 shows the prediction formulas of random-effects model based on different time scales of sensor measured texture depth data. It is seen from Table 8 that when different time scales of SMTD data are used to develop the prediction model, the sign of the coefficient in front of each independent variable does not change except for monthly rainfall. The reason may be the high variation of the monthly rainfall measured in the same month of different years. The coefficient in front of each independent variable varies slightly from the one year panel data-based prediction model to the two years panel data-based model, and similarly, from the three years panel data-based prediction model to the four years panel data-based model. Overall, the coefficients in front of these independent variables change very little when different time scales of SMTD data are used to develop the prediction model. It reveals that the SMTD data time scale has minor effect on the significance level of these independent variables.

Table 8.

Prediction formulas of random-effects model using different time scales of SMTD data.

A comparison of the variable significance level of random-effects panel data analysis model using different time scales of SMTD data is shown in Table 9. It is seen from Table 9 that except for the two variables of monthly average temperature (MAT) and monthly rainfall (MR), the obtained p values of other variables are less than 0.1, revealing that the significance levels of CSAL, MAH, CA, FAC, and FAF are basically the same and they have significant effects on asphalt pavement surface texture. With the extension of the time scale of SMTD data, the p value of MAT increases, indicating that the significance level of MAT gradually decreases; the p value of MR decreases, indicating that the significance level of MR gradually increases. Based on 15 years skid number panel data of 255 sections, Ref. [29] developed a fixed-effects model of skid number (SN) considering the annual average precipitation (AAP), the annual average freezing index (AAFI), the annual average humidity (AAH), the annual average daily truck traffic (AADTT), and the service age (AGE). It was concluded that the influences of these five factors on skid number were significant. In our study, the influences of the cumulative standard axle loads (CSAL) and the monthly average humidity (MAH) on surface texture are significant, while the influence of monthly rainfall (MR) on surface texture varies with the time scale of the input panel data. However, monthly data are collected and analyzed in this study, whereas in Ref [29] annual data were analyzed. The influencing factor of freezing index is not considered in this study.

Table 9.

Comparison of the variable significance level of the random-effects model based on different time scales of SMTD data.

Previous studies [27,28] have developed the panel data analysis-based model for the assessment of skid number (SN) using the variables such as annual average temperature and annual rainfall. In this study, the monthly SMTD data are used to generate the panel dataset. The advantage is that a surface texture prediction model with a shorter testing cycle can be provided.

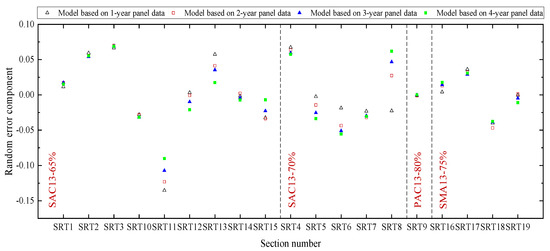

To characterize the individual differences between road sections, the random error component (ui) of the surface texture prediction model using one year, two years, three years, and four years SMTD panel data are calculated (shown in Figure 6). The smaller the random error component, the smaller the individual difference between different road sections. The random error components of different sections of the same pavement structure are different, which is mainly caused by the differences in materials, construction, and measurement. It can be seen from Figure 6 that for the same asphalt pavement structure, the differences between the obtained random error components of panel data analysis models based on different time scales of SMTD data are relatively small, indicating that the time scale of the input panel data has insignificant influence on the random error component of the panel data analysis-based prediction model. The absolute value of the random error component is less than 0.1 mm (except for SRT-11), which is one order of magnitude smaller than the predicted SMTD value. The maximum deviation of the random error component for SRT-11 is 0.14 mm in absolute value. Thus, the individual difference is little affected by the test cycle, and even the model based on the first year data can already reflect the individual difference in surface texture between different road sections. To take into account the influence of random error in the panel data analysis-based prediction model, the obtained random error components across different time scales can be averaged.

Figure 6.

Random error component (ui) of surface texture prediction model based on different time scales of SMTD data.

4.4. Influence of Panel Data Time Scale on Model Regression Results

Table 10 shows the regression results (R2, adjusted R2, and p value) of the random-effects model based on different time scales of SMTD data. R2 is a biased estimator of the multiple correlation coefficient, and the adjusted R2 can take into account the number of independent variables used in the model. It is seen from Table 10 that the adjusted R2 of the model using two years SMTD data is the largest, and the adjusted R2 of the model using four years SMTD data is the smallest. The reason may lie in that the measured SMTD shows a gradual decreasing trend in the first two years, and after that an unusual increase of the measured SMTD is observed. The cause of the SMTD increasing in the third year is unclear [15].

Table 10.

Regression results of random-effects model using different time scales of panel data.

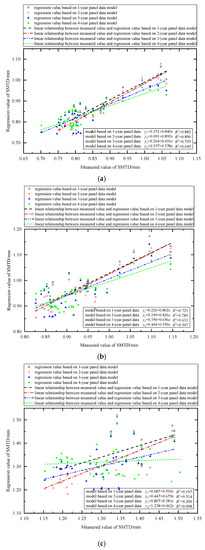

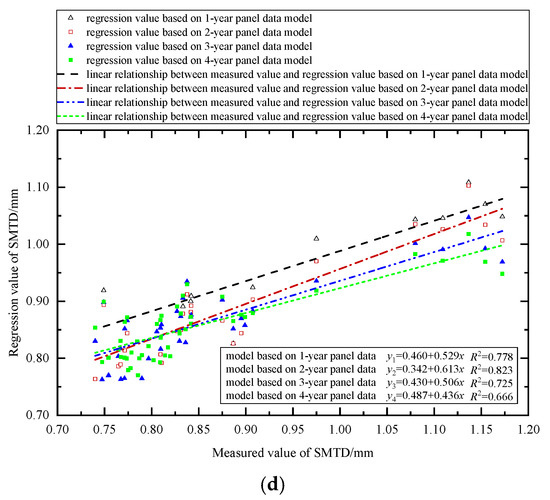

Figure 7 shows the linear fitting relationship between the model regression results based on different time scales of SMTD panel data and the measured data. The panel data analysis-based model shows good regression effects when it is applied on the pavement constructed with the dense-graded asphalt concrete as the asphalt surface layer. For example, when the panel data analysis model is developed using three years panel data, the obtained regression R2 is 0.739 for SAC13-65%, 0.631 for SAC13-70%, and 0.725 for SMA13-75%, respectively. As for porous asphalt concrete PAC13-80%, the obtained R2 is only 0.2. The reason is mainly due to the large dispersion of the field data obtained from the SRT-9 section (the only section paved with PAC13-80%), which leads to a large individual difference of the random-effects panel data model for PAC13-80%. It can be seen from Figure 7a–d that for the same asphalt pavement, the regression coefficient of the panel data analysis-based model based on one year field data is close to that based on two years field data, and the regression coefficient of the model based on three years field data is very close to that based on four years field data. It is indicated that the time scale of the short-term panel data has little effect on the model regression result.

Figure 7.

Linear relationship between the measured data and the regression results of the model based on different time scales of panel data. (a) SRT-14 (Dense-graded asphalt concrete, SAC13-65%). (b) SRT-7 (Dense-graded asphalt concrete, SAC13-70%). (c) SRT-9 (Porous asphalt concrete, PAC13-80%). (d) SRT-19 (Dense-graded asphalt concrete, SMA13-75%).

4.5. Prediction Results of Short-Term Surface Texture

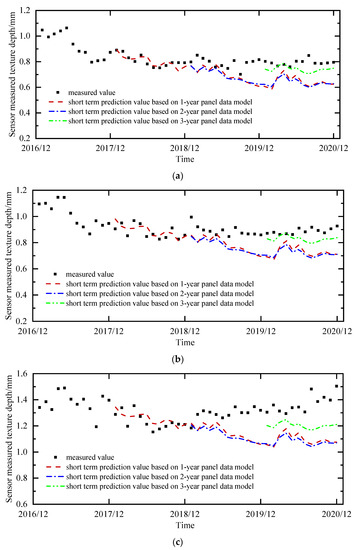

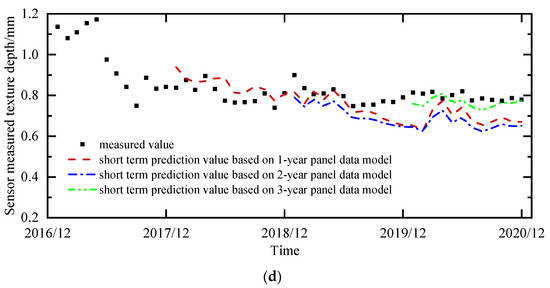

The short-term SMTD development is calculated for three scenarios: (1) predicting the SMTD development from 2018 to 2020 based on the SMTD panel data of 2017; (2) predicting the SMTD development from 2019 to 2020 based on the SMTD panel data from 2017 to 2018; and (3) predicting the SMTD development in 2020 based on the SMTD panel data from 2017 to 2019.

The predicted SMTD results are compared with the field measured SMTD data, as shown in Figure 8. Compared with SRT-14, SRT-7, and SRT-19 sections, the panel data analysis result in terms of short-term SMTD prediction is less accurate for the SRT-9 section. This is because SRT-9 is the only section paved with porous asphalt concrete PAC13-80% (see Table 3) and because of the abnormal increase of SMTD occurring in 2019 [26]. It is seen from Figure 8 that when predicting the SMTD development of the fourth year (2020) based on the SMTD panel data of the first three years (2017 to 2019), the accuracy is relatively high. When the SMTD panel data of the first year (2017) or two years (2017 to 2018) are used to predict the SMTD development of the next one year, the predicted results have a certain deviation from the measured values. Obviously, the longer the time scale of SMTD data used in the model development, the more accurate the model regression and the short-term SMTD prediction.

Figure 8.

Comparison of measured and predicted SMTD based on different time scales of SMTD panel data. (a) SRT-14 (Dense-graded asphalt concrete, SAC13-65%). (b) SRT-7 (Dense-graded asphalt concrete, SAC13-70%). (c) SRT-9 (Porous asphalt concrete, PAC13-80%). (d) SRT-19 (Dense-graded asphalt concrete, SMA13-75%).

4.6. Prediction Results of Long-Term Surface Texture

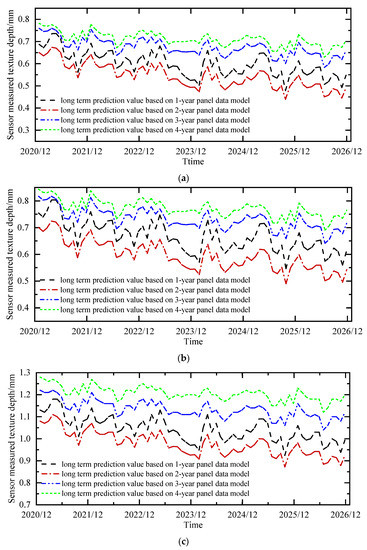

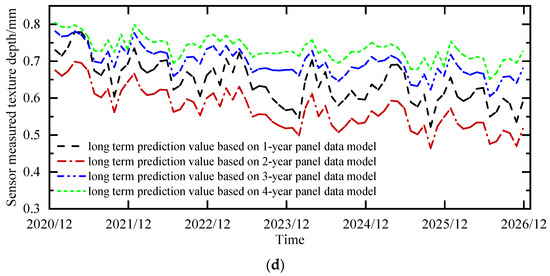

The SMTD development in the long-term (from year 2021 to 2026) is predicted by the model based on the one year (2017), two years (2017 to 2018), three years (2017 to 2019), and four years (2017 to 2020) SMTD panel data. The predicted results are shown in Figure 9. It can be seen that the predicted SMTDs of SRT-14, SRT-7, SRT-9, and SRT-19 display a similar trend in the long-term. However, the prediction model based on only one year SMTD data (year 2017) shows the fastest decrease trend in the long-term, whereas the prediction model based on four years SMTD panel data (from 2017 to 2020) shows the slowest decrease tendency. The longer the scale of input data for the model development, the less the predicted SMTD value decreases. Taking SRT-14 as an example, the SMTD prediction models developed based on one year, two years, three years, and four years panel data are used for long-term prediction, and the SMTD value is reduced by 0.14 mm, 0.16 mm, 0.10 mm, and 0.07 mm, respectively, from year 2021 to 2026. Notably, the input SMTD panel data across a short time scale has difficulty in achieving a high-precision long-term prediction. According to the short-term prediction results (Figure 8), the predicted SMTD development in the fourth year (2020) based on the first three years (2017 to 2019) panel data model agrees well with the measured data, while the prediction models based on one year (2017) or two years (2017 to 2018) panel data provide less accurate results. It can be deduced that the predicted SMTD value by the four years panel data-based model is likely closer to the long-term actual SMTD value. The analysis shows that the longer time scale of SMTD panel data for model development can guarantee the robustness of the model’s long-term prediction ability.

Figure 9.

Predicted SMTD results for year 2021 to 2026 for different time scales of panel data analysis-based model. (a) SRT-14 (Dense-graded asphalt concrete, SAC13-65%). (b) SRT-7 (Dense-graded asphalt concrete, SAC13-70%). (c) SRT-9 (Porous asphalt concrete, PAC13-80%) (d) SRT-19 (Dense-graded asphalt concrete, SMA13-75%).

5. Conclusions

To investigate the degradation tendency of asphalt pavement surface texture, four years of SMTD panel data (characterized by sensor measured texture depth) measured from 19 pavement structures including 4 types of surface asphalt layer were used to develop a surface texture prediction model. For the first time, the Bailey method-based aggregate parameters were considered as the influencing factors in surface texture prediction model. The significant levels of 7 selected influencing factors were determined through a series of panel data analyses. This study proves the feasibility and effectiveness of the panel data analysis method in the evaluation and prediction of the surface texture of a full-scale accelerated pavement testing loop. The results of this study can benefit the material design, construction, maintenance treatment of asphalt pavement, and the evaluation of asphalt pavement performance for better long-term service. The main conclusions are as follows:

- (1)

- The surface texture measured by a laser method (SMTD)-based prediction model for asphalt pavement has been developed using a panel data analysis method. The proposed prediction model takes into account the dependence on time scale of input panel data, diversified road sections, traffic factors, environmental factors, and the Bailey method-based aggregate gradation parameters. Compared with the mixed-effects and the fixed-effects models, the random-effects model is the most suitable form to predict the asphalt pavement surface texture. The random-effects model has good regression effect and prediction accuracy for SMTD.

- (2)

- The impacts of the time scale of input panel data on the significance level of the 7 selected influencing factors for surface texture prediction were investigated. The cumulative standard axle loads (CSAL), monthly average humidity (MAH), CA, FAC, and FAF have significant effects on pavement surface texture prediction, while the significance level of the monthly average temperature (MAT) and monthly rainfall (MR) changes with the extension of time scales of the input data. The cumulative standard axle loads (CSAL), monthly average humidity (MAH), monthly rainfall (MR), CA, and FAF are negatively correlated with SMTD. The monthly average temperature (MAT) and FAC ratio are positively correlated with SMTD.

- (3)

- The regression and prediction ability of the surface texture prediction model based on different time scales of SMTD panel data were evaluated. The prediction model using one year SMTD panel data (year 2017) shows the fastest decrease trend in the long-term (year 2021–2026), whereas the prediction model based on four years SMTD panel data (from year 2017 to 2020) presents the slowest decreasing tendency. The extension of the time scale of input panel data can ensure long-term prediction robustness for the panel data analysis-based surface texture prediction model. It should be noted that the model developed in this work was established and calibrated using the RIOHTrack data; to date, there has not been a large amount of field SMTD test data on asphalt pavements in China or worldwide for developing prediction models.

Author Contributions

Conceptualization, W.H. and Y.W.; Data curation, C.L. and W.G.; Writing—original draft, C.L.; Writing—review & editing, W.H. and Y.W.; Funding acquisition, Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Key R&D Program of China under grant number 2021YFB3202902.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

3rd Party Data Restrictions apply to the availability of these data. Data was obtained from Research Institute of Highway, Ministry of Transport of China and are available from https://www.roadsdata.cn/pages/shujufuwu/index.html with the permission of Research Institute of Highway, Ministry of Transport of China.

Acknowledgments

The authors thank supports from the National Key R&D Program of China under grant No. 2021YFB3202902.

Conflicts of Interest

No potential conflict of interest was reported by the authors.

References

- Goniewicz, K.; Goniewicz, M.; Pawłowski, W.; Fiedor, P. Road accident rates: Strategies and programmes for improving road traffic safety. Eur. J. Trauma Emerg. Surg. 2016, 42, 433–438. [Google Scholar] [CrossRef] [PubMed]

- Wallman, C.G.; Åström, H. Friction Measurement Methods and the Correlation between Road Friction and Traffic Safety; VII eddelande 911A; Swedish National Road and Transport Research Institute: Linkoping, Sweden, 2001. [Google Scholar]

- Wang, W.; Li, Q. Expressway Safety Management; China Communications Press: Beijing, China, 2021. (In Chinese) [Google Scholar]

- Wang, Y. Study on the Relationship between Sliding Resistance of Asphalt Pavement and Its Surface Rough Characteristics. Ph.D. Thesis, Southeast University, Nanjing, China, 2017. (In Chinese). [Google Scholar]

- Highway Research Board of the NAS-NRC Division of Engineering and Industrial Research. The AASHO Road Test Report 7 Summary Report; National Academy of Sciences-National Research Council: Washington, DC, USA, 2018.

- Sarkar MT, A.; Gu, F.; Heitzman, M.; Powell, B. Using shotblasting treatment to improve asphalt pavement friction at the NCAT test track. In Airfield and Highway Pavements; American Society of Civil Engineers: Restion, VA, USA, 2021; Volume 2021, pp. 332–344. [Google Scholar]

- Danoshini, G.; Baqadeem, A.; Al-Shakhrit AK, S.; Jasni, N.E.; Masri, K.A. Statistical analysis of stone mastic asphalt incorporating kenaf fiber. Construction 2021, 1, 12–17. [Google Scholar] [CrossRef]

- Nelson, T.; Akkari, A. Evaluation of Skid Resistance of Turf Drag Textured Concrete Pavements; Minnesota Department of Transportation, Research Services Section: St. Paul, MN, USA, 2011.

- Wu, J.; Wang, X.; Wang, L.; Zhang, L.; Xiao, Q.; Yang, H. Temperature correction and analysis of pavement skid resistance performance based on RIOH track full-scale track. Coatings 2020, 10, 832. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Zhou, X.; Xiao, Q.; Guan, W. Review of researches of RIOHTRACK in 2017. J. Highw. Transp. Res. Dev. 2018, 278, 1–13. (In Chinese) [Google Scholar]

- Liao, Y. Research on Regularity of Skid Resisitance Regradation of Asphalt Pavement Based on Full-Scale Pavement Loop. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2019. (In Chinese). [Google Scholar]

- Xu, X.; Yu, Y.; Yang, J.; Wu, C. Long-term skid resistance evaluation of GAC-16 based on accelerated pavement testing. Adv. Mater. Sci. Eng. 2020, 2020, 1245060. [Google Scholar] [CrossRef]

- Vavrik, W.R.; Pine, W.J.; Carpenter, S.H. Aggregate blending for asphalt mix design Bailey method. Transp. Res. Rec. 2002, 1789, 146–153. [Google Scholar] [CrossRef]

- Huang, X.; Zheng, B. Research status and progress for skid resistance performance of asphalt pavements. China J. Highw. Transp. 2019, 32, 32–49. [Google Scholar]

- Ministry of Transport of the People’s Republic of China. 2017 Annual Technical Report of RIOHTRACK; Ministry of Transport of the People’s Republic of China: Beijing, China, 2018. (In Chinese)

- Wu, J.; Wang, X.; Xiao, Q.; Zhang, L.; Guan, W.; Zhang, C. Temperature correction method of sensor measured texture depth index based on equivalent temperature of asphalt surface layer. Int. J. Pavement Res. Technol. 2021, 14, 450–458. [Google Scholar] [CrossRef]

- ASTM, E274 M-15; Standard Test Method for Skid Resistance of Paved Surfaces Using a Full-Scale Tire. ASTM International: West Conshohocken, PA, USA, 2015.

- BS DD CEN/TS 15901-6-2009; Road and Airfield Surface Characteristics. European Committee for Standardization: Brussels, Belgium, 2009.

- ASTM, E303-93; Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E965-15; Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique. ASTM International: West Conshohocken, PA, USA, 2019.

- JTG/T E61-2014; Specifications of Automated Pavement Condition Survey. China Communications Construction Co., Ltd.: Beijing, China, 2014.

- Xiao, Y.; Wei, Y.; Yan, C.; Liu, Y.; Wang, L. A new data preprocessing method for 3D reconstruction of pavement. International J. Pavement Eng. 2021, 22, 675–689. [Google Scholar] [CrossRef]

- Dou, G. Research of calculation model of pavement texture depth based on profile elevation. J. Highw. Transp. Res. Dev. 2015, 32, 50–56. (In Chinese) [Google Scholar]

- Bai, Z. Econometric Analysis of Panel Data; Nankai University Press: Tianjin, China, 2008. [Google Scholar]

- Lee DGKim, S.-K. Impacts of geographical location and construction type on as-built roughness in highway pavement construction. KSCE J. Civ. Eng. 2005, 9, 447–452. [Google Scholar]

- Lee DGRussell, J.S. Panel data analysis of factors affecting as-built roughness of asphaltic concrete pavements. J. Transp. Eng. 2004, 130, 479–485. [Google Scholar]

- Guo, Y. Prediction of Road Roughness for Asphalt Pavement Considering Maintenance Intervetion. Master’s Thesis, Southeast University, Nanjing, China, 2016. (In Chinese). [Google Scholar]

- Zhan, Y.; Li, Q.J.; Yang, G.; Pittenger, D.M.; Wang, K.C.P.; Zaman, M. Panel data models for pavement friction of major preventive maintenance treatments. Int. J. Geomech. 2019, 19, 04019081. [Google Scholar] [CrossRef]

- Li, Q.J.; Zhan, Y.; Yang, G.; Wang, K.C.P.; Wang, C. Panel data analysis of surface skid resistance for various pavement preventive maintenance treatments using long term pavement performance (LTPP) data. Can. J. Civ. Eng. 2017, 44, 358–366. [Google Scholar] [CrossRef]

- Kane, M.; Edmondson, V. Long-term skid resistance of asphalt surfacings and aggregates’ mineralogical composition: Generalisation to pavements made of different aggregate types. Wear 2020, 454, 203339. [Google Scholar] [CrossRef]

- Hall, J.W.; Smith, K.L.; Titus-Glover, L.; Wambold, J.C.; Yager, T.J.; Rado, Z. Guide for Pavement Friction; NCHRP Web-Only Document 108.; Contractor’s Final Report for NCHRP Project 01-43; Transportation Research Board: Washington, DC, USA, 2009. [Google Scholar]

- Huang, W.; Liang, S.; Wei, Y. Surface deflection-based reliability analysis of asphalt pavement design. Sci. China Technol. Sci. 2020, 63, 1824–1836. [Google Scholar] [CrossRef]

- Huang, W.; Guo, W.; Wei, Y. Prediction of paving performance for epoxy asphalt mixture by its time and time-dependent properties. ASCE’s J. Mater. Civ. Eng. 2020, 32, 04020017. [Google Scholar] [CrossRef]

- Huang, W.; Guo, W.; Wei, Y. Thermal effect on rheological properties of epoxy asphalt mixture and stress prediction for bridge deck paving. J. Mater. Civ. Eng. 2019, 31, 04019222. [Google Scholar] [CrossRef]

- Xiao, S.; Zhao, F.; Zhou, X.; Tian, Y.; Li, J. Spatiotemporal evolution analysis of pavement texture depth on RIOH track using statistical and rescaled range approaches. Constr. Build. Mater. 2022, 338, 127560. [Google Scholar] [CrossRef]

- JTG-F40-2017; Technical Specifications for Construction of Highway Asphalt Pavement. Ministry of Transport of the People’s Republic of China: Beijing, China, 2017.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).