Abstract

To evaluate the performance of wheel coupler formwork support components, the bearing capacity of the horizontal bar, the shear capacity of the wheel, the shear capacity of the sleeve, and the stability bearing capacity of the single- and double-layer vertical poles were investigated through systematic full-scale tests. The feasibility and correctness of the experiment were verified by comparing the results with those of a finite element analysis. The results demonstrated that the weak point of the horizontal bar was the bearing capacity of the weld at the connection between the socket and the horizontal bar. Preventing buckling failure of the weld at the connection between the horizontal bar and the socket was critical to ensure the bearing capacity of the horizontal bar. Under the action of a shearing force, the wheel underwent buckling failure of the welding seam at the connection between the wheel and the vertical pole. With a decreasing number of connecting horizontal bars on the wheel, the shear capacity of the wheel decreased significantly. The shear failure mode of the sleeve was buckling failure. The connection weld did not undergo buckling failure during the load-bearing process, which was basically meeting the serviceability state. The failure of a single-layer vertical pole was typical with lateral displacement buckling, while the double-layer vertical pole did not undergo buckling with lateral displacement.

1. Introduction

In recent years, with the continuous development of the national economy, the construction industry has undergone rapid development. Increasingly complex architectural modelling and diverse functions of structures involve more demanding requirements for construction engineering. Thus, it is necessary to continuously improve technologies for formwork supports, which are important parts of construction technology, and to innovate more specialized techniques for different structural systems for buildings. However, because formwork supports are temporary structures, their importance is often ignored in design and construction processes. At present, there is a lack of research on the performance of steel pipe formwork supports in China. Furthermore, there is no unified standard and specification for steel pipe formwork supports, and this has led to frequent collapses and casualties throughout the country [1,2]. There are many reasons for the collapse of steel pipe formwork supports, mainly due to the lack of thoroughly understanding the theory and calculations of stability, misunderstanding of the theory by technical personnel, and over-reliance on experience when planning construction schemes. There is a need for a new type of wheel coupler formwork support to overcome the shortcomings of traditional fastener formwork supports, which have the advantages of a quick installation and the ability to self-lock and are widely used. Therefore, it is of great significance to study the safety and stability of wheel coupler formwork supports to reduce the frequency of accidents and to ensure safe construction practices [3,4].

The mechanical properties of a wheel coupler formwork support are similar to those of a traditional formwork support; however, because this new type of formwork support has not been widely used, its reliability and mechanical properties have not been studied in detail. Most of the time, engineers refer to the results of domestic and foreign research on traditional fastener types [5,6,7,8,9] and bowl-button formwork supports [10,11,12,13,14]. These results can be used for reference but cannot be directly applied to a wheel coupler framework support. To grasp the mechanical properties of this type of formwork support more accurately and to ensure its safe use in construction, in-depth studies are needed on the mechanical properties of a wheel coupler formwork support.

Scholars have focused their research on the node performance and the stability bearing capacity of the frames of wheel coupler formwork supports. In terms of the node performance, Yang [15] conducted research on the stability bearing capacity of wheel coupler formwork supports, obtained the curve, and compared it with the node stiffness of the traditional type of steel tubular formwork supports with fasteners to determine the stiffness of the semi-rigid connection node. Yang et al. [16,17] obtained the initial stiffness curve by conducting a semi-rigid horizontal force loading experiment on the nodes of wheel coupler formwork supports; the construction process was streamlined by studying the resistance to pull out of a node socket under a normal wedge-tightening state. Wang [18] conducted mechanical performance experiments on nodes in wheel buckle-type and disc-type steel socket formwork supports, obtained the characteristic curves of the respective connecting nodes, conducted numerical simulations on the stress and deformation of the nodes under different loads, and compared the results of simulations and experiments to verify the accuracy of the finite element analysis () model. Chen [19] performed an analysis of a case study of the accidental collapse of formwork supports in Wenzhou. An experimental design was used to improve the rotational stiffness of fastener-type and wheel coupler formwork support nodes, and the experimental data were applied in calculations of actual engineering cases. Comparing the economic benefits of fastener-type and wheel-buckled formwork supports showed that the benefits were greater for wheel-buckled formwork supports. Wang [20] studied the influence of parameters such as the wall thickness of the wheel coupler formwork supports and the thickness of the wheel on the rotational stiffness of the node, verified the credibility of the of the node, and completed a wheel shear experiment. The shear experiment on the straight socket showed that the mechanical properties of the new type of wheel coupler formwork supported nodes that met relevant regulations. Liu et al. [21] conducted rotational stiffness experiments on nodes with different thicknesses and found that the greater the wheel thickness was, the greater the rotational stiffness of the nodes.

In terms of the stability bearing capacity of the frame body, Cheng [22] conducted research on the structural performance of a wheel coupler formwork support. The study included two full-scale experiments on-site with a height of 5 m. The researchers obtained the load—displacement curve of the frame body and performed experiments on the lateral stiffness of the unit. The equivalent spring stiffness was used to consider the influence of the node connection gap on the connection stiffness. Based on this equivalent stiffness, a parametric analysis of the ultimate bearing capacity of the whole was conducted. Yang [13] analysed the impact of sweeping poles, vertical pole spacing, and step distance on the stability bearing capacity of wheel coupler formwork supports. Zhang [23] used axial compression stability experiments to analyse the deformation, instability characteristics, and overall stability of the bearing capacity of 30 experimental pieces of steel pipe used in wheel coupler formwork supports. Liu et al. [24] conducted static failure experiments on four full-scale models to study the instability mechanism and failure mode of wheel coupler formwork supports. The above studies mainly focused on node performance and frame stability; the research has been limited to the stability bearing capacity of main components and vertical poles of wheel coupler formwork support structures.

Therefore, to fully grasp the performance of the members of wheel coupler formwork supports and the stability bearing capacity of the vertical poles, it is particularly important to perform systematic experiments. In this study, experiments were conducted on the eccentric tensile performance of horizontal bar sockets, the bending performance of horizontal bars, the shear capacity of vertical pole wheels and sleeves, and the stability bearing capacity of single- and double-layer vertical poles. The bearing capacity and failure mode of each component of the wheel coupler formwork supports were determined, and the results provided a theoretical basis and technical support for the formulation of relevant specifications and construction schemes of wheel coupler formwork supports.

2. Experimental Analysis of the Bearing Capacity of the Horizontal Bar

The horizontal bar is a component that connects two adjacent vertical poles and ensures the stability of the overall structure. In construction, a vertical pole undergoes bending deformation when the vertical load is increased. Then, the socket at both ends of the horizontal bar is subjected to tension (pressure). In the normal working state of a formwork support structure, the horizontal bar is not affected by the vertical load of the structure. However, the horizontal bar is subjected to a dynamic load due to the construction of pedestrian channels, which results in bending deformation. Through experimental research on horizontal bar bearing capacity, including the shear capacity of the socket on the horizontal bar and the flexural bearing capacity of the horizontal bar, the ultimate bearing capacity and the failure mechanism of the horizontal bar were obtained.

2.1. Eccentric Tensile Properties of the Socket on the Horizontal Bar

2.1.1. Theoretical Value of the Eccentric Tensile Bearing Capacity of the Socket on the Horizontal Bar

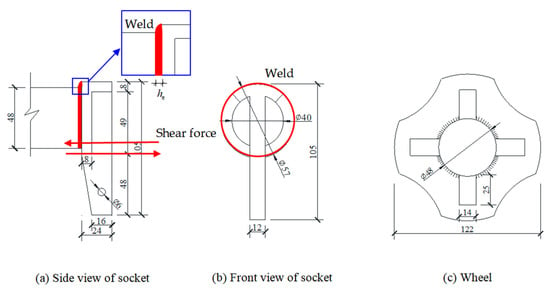

The eccentric tensile bearing capacity of the socket on the horizontal bar is converted into the ultimate bearing capacity of the weld at the connection between the horizontal bar and the socket and the ultimate bearing capacity of the socket under shear. According to the size of the horizontal bar and the socket of the formwork support, the outer diameter of the horizontal bar = 48 mm, the shear area of the socket = 366 mm2, and the weld leg size = 3 mm of the fillet weld connecting the socket and the horizontal bar were obtained. The tensile strength design value of the weld was = 160 N/mm2. The design value of the shear strength of the socket was = 140 N/mm2. The socket weld was a single-sided weld. The geometrical size of connection joints is shown in Figure 1. The tensile (compressive) bearing capacity of the socket was calculated as follows:

Figure 1.

Geometrical size of connection joints.

The value of in Equation (1) is the calculation thickness of the orthogonal fillet weld (mm). When the gap between the two weldments is , . When , , is the weld leg size. In this paper, .

In the experiment, when the socket was subjected to eccentric tensile resistance, a certain bending moment was generated. Thus, the eccentric tensile resistance and ultimate bearing capacity of the socket obtained from the experiment were less than 50.64 kN.

2.1.2. Experimental Design

In this experiment, a horizontal bar specimen 0.6 m in size was used, and five specimens were randomly selected from 50 specimens for the tensile bearing capacity experiment. The main transverse part of the horizontal bar used in the manuscript is a thin-walled cylinder, the main part of the horizontal bar is made of Q235 steel, and the socket parts at both ends of the horizontal bar are cast steel. The tensile force was applied to the socket welded on the horizontal bar through a tensile and compressive testing machine. A force-controlled hierarchical loading method was adopted. Each stage was 5 kN (approximately 1/10 of the theoretical limit), and each stage was loaded for 30 s. When the socket specimen broke or suddenly underwent large deformation, the loading was arrested immediately. The tensile bearing capacity and deformation displacement of the socket were directly collected by the test machine. The experimental device and loading diagram are illustrated in Figure 2.

Figure 2.

Experimental device of socket tension and loading diagram.

2.1.3. Experimental Results and Analysis

At the beginning of the loading experiment, the specimen had no noticeable deformation, and the displacement increased linearly. With increasing load, the deformation of the specimen increased, and there was a slight audible sound of metal failure. As the specimen was loaded to the ultimate load, the deformation of the specimen increased rapidly. When the sound of metal fracture was audible and the load could not continue to increase, the specimen was destroyed, and the loading was stopped immediately. After unloading, observations showed that all the specimens were damaged at the weld seam, i.e., the connection between the socket and the horizontal bar; the horizontal bar was not damaged. The failure morphology of the specimens in this group of experiments is shown in Figure 3.

Figure 3.

Failure mode of sockets on horizontal bars: (a) SJ-1; (b) SJ-2.

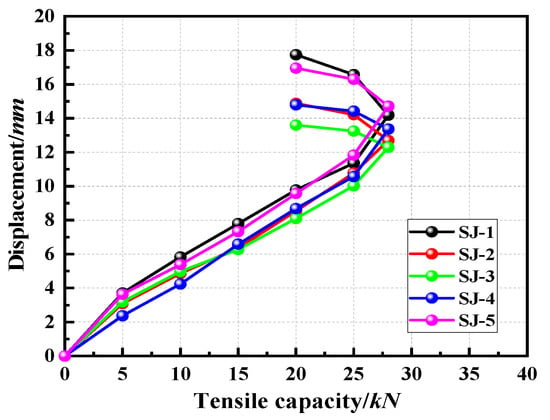

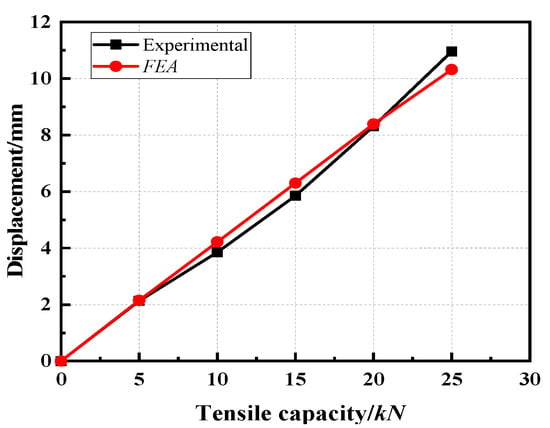

Graphs of the eccentric tensile bearing capacity of the socket on the horizontal bar are shown in Figure 4. The displacement change of horizontal bar socket under tensile force are shown in Table 1. When the socket on the horizontal bar was subjected to eccentric tension, the displacement basically increased linearly. The greater the tension of the socket was, the more obviously the displacement increased. When the load increased gradually, a slight crack formed in the weld at the connection between the socket and the horizontal bar, the tensile bearing capacity of the socket decreased, and the displacement growth rate increased significantly. In summary, according to the experimental observations and data analysis, the failure mode of the socket specimen on the horizontal bar was weld failure, and the failure property was buckling failure. When the bending deformation of the vertical pole of the formwork support caused the sockets at both ends of the horizontal bar to be subjected to eccentric tension (pressure), the bearing capacity of the weld at the connection between the socket and the horizontal bar was low and prone to damage. Therefore, the control of weld quality at horizontal bar connections is key to ensuring safe construction of the formwork support.

Figure 4.

Graphs of the eccentric tensile capacity of sockets on horizontal bars.

Table 1.

Displacement changes of the horizontal bar socket under tensile force.

2.1.4. Finite Element Comparative Analysis of Eccentric Tensile Properties of the Socket on the Horizontal Bar

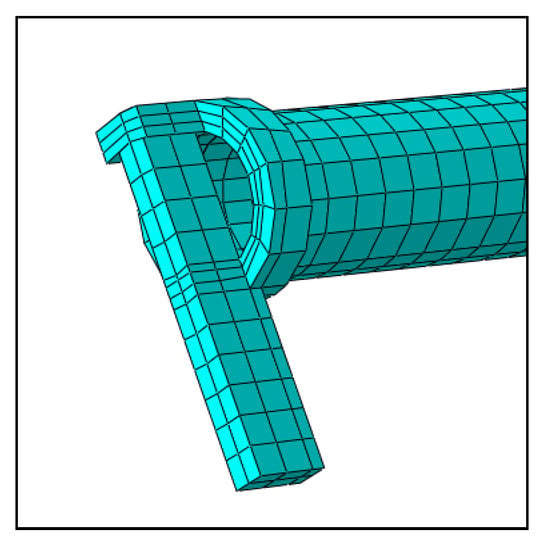

According to the actual size of the socket, a solid model of the socket on the horizontal bar was established using the ABAQUS 6.14. The horizontal bar and the socket were considered as a whole entity, and the weld unit system was ignored. The horizontal bar and the socket, connected with a tie connection, were made of Q235 steel and cast steel, respectively. Due to the complex structure, the socket and the horizontal bar grids were automatically divided. Finer grids were set for the parts prone to stress concentration on the socket. The numerical model is shown in Figure 5. During the construction, with the vertical load increasing, the vertical pole is bent and deformed, such that the sockets at both ends of the horizontal bar are subjected to tension (pressure) and shear force, and the welds at the connection between the horizontal bar and the socket are subjected to tension (pressure). To accurately simulate the sockets’ eccentric tension, an opposite tensile force was imposed on the connection of the sockets and the connecting wheel. The load adopted the step-by-step force control loading method, and the normal construction load was applied; no damage occurred, only the horizontal direction displacement is set for this model, and there is no corner deformation. The translational degrees of freedom must be restricted except for the loading direction, and the rotational degrees of freedom in the loading direction should be restricted. According to the analysis of the numerical simulation results, the stress distribution diagrams were obtained for the sockets at both ends under the normal working load (25 kN), as shown in Figure 6.

Figure 5.

Socket model on the horizontal bar.

Figure 6.

Tensile failure mode of the socket on the horizontal bar.

The stress distribution of the horizontal bar socket under eccentric tension in the normal construction state was obtained from the . According to the results of calculations with ABAQUS, the following conclusions were drawn:

- 1.

- According to the finite element analysis, the deformation and displacement of the sockets on the horizontal bar under normal working conditions were obtained, and the specific values are shown in Table 2.

Table 2. Finite element analysis of the eccentric tension on the sockets on the horizontal bar.

Table 2. Finite element analysis of the eccentric tension on the sockets on the horizontal bar.

The results of the were compared with the average experimental values for the five groups of specimens, as shown in Figure 7. The trends of the simulated and experimental values were basically the same, and the data did not differ significantly. The agreement between the simulation and experimental results in the figure verified the correctness and accuracy of the model.

Figure 7.

Eccentric tensile capacity of sockets on horizontal bars.

- 2.

- Regarding stress distribution, according to the simulation analysis and experimental results, when the socket on the horizontal bar was pulled eccentrically, the stress concentration area was located at the connection between the socket and the horizontal bar. The results of the simulation analysis were in good agreement with the experimental results.

- 3.

- Regarding failure morphology, according to the simulation analysis and experimental results for the eccentric tension of the socket on the horizontal bar, stress concentrations led to plastic deformation at the connection. The plastic deformation increased continuously and eventually led to the loss of the bearing capacity of the specimen. The results showed that under the normal working state of the formwork support, the connection between the socket and the horizontal bar was prone to damage; it was the weak point of the bearing capacity of the horizontal bar of the formwork support.

2.2. Bending Performance of the Horizontal Bar

2.2.1. Experimental Design

In order to obtain the ultimate bearing capacity for the bending performance of the horizontal bar, in this experiment, 0.6 m horizontal bar specimens were selected. In order to ensure steady loading of the horizontal bar, it was simply processed using a testing machine, that is, a steel plate was welded horizontally above the horizontal bar. In the experiment, a universal testing machine was used to apply pressure on the midspan of the horizontal bar and to measure its ultimate flexural bearing capacity. Flexural bearing capacity and midspan vertical displacement of the horizontal bar was directly measured using the testing machine. The experimental apparatus is illustrated in Figure 8. The uniform force loading method was adopted for testing, with a loading speed of 0.2 kN/s. When the vertical deformation of the horizontal bar specimen increased rapidly and the load no longer increased, loading was stopped.

Figure 8.

Experimental device for measuring the bending capacity of a horizontal bar.

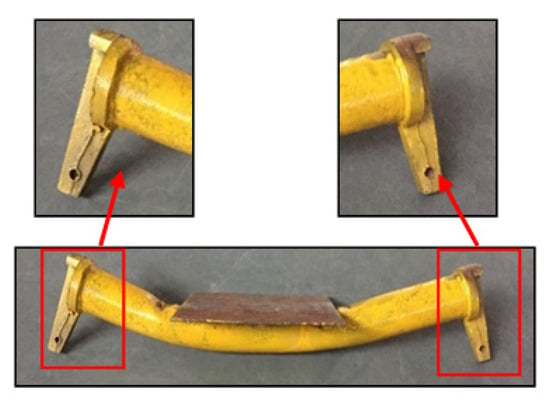

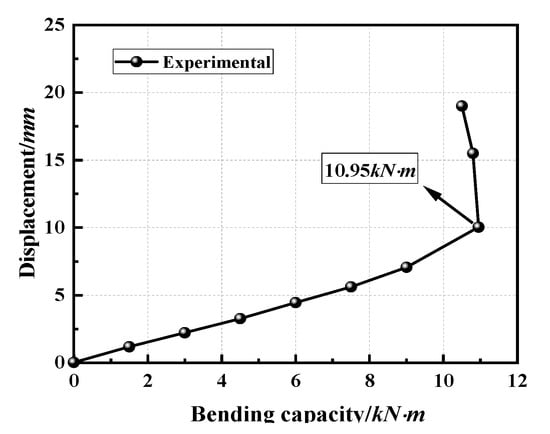

2.2.2. Experimental Results and Analysis

At the beginning of the experimental loading, there was almost no bending deformation of the horizontal bar specimen. When the load increased, the bending deformation began at the midspan of the specimen, but it was relatively slow. As the load continued to increase, the speed of bending deformation of the specimen increased, and the vertical displacement obviously increased obviously. When the midspan vertical displacement of the specimen increased continuously, and the flexural bearing capacity did not change significantly, loading was stopped. At the end of the experiment, observations of the morphology of bending failure of the horizontal bar (Figure 9) showed that plastic bending deformation occurred in the midspan of the specimen and the sockets at both ends were not damaged. There were no cracks in the tube wall of the specimen and the weld seam at the connection between the socket and the horizontal bar. The experimental data for the flexural bearing capacity of the horizontal bar are shown in Figure 10. The vertical deformation of the specimen increased linearly from the initial loading stage to when the flexural bearing capacity reached 9 kN·m. Then, as the bearing capacity increased from 9 kN·m to the ultimate bearing capacity of 10.95 kN·m, the vertical displacement of the midspan increased faster. When the horizontal bar reached its ultimate bending capacity, bending yield occurred in the midspan of the specimen, and local plastic instability occurred as well. This resulted in a continuous decrease in the flexural bearing capacity of the horizontal bar and the continued rapid increase in the vertical displacement of the midspan.

Figure 9.

Bending failure mode of a horizontal bar.

Figure 10.

Bending bearing capacity of a horizontal bar.

According to the experimental behaviour of the horizontal bar and the force analysis of the horizontal bar, three main reasons affected the failure of the horizontal bar: (1) shear failure of the socket, (2) damage of the weld node between the socket and the horizontal bar by tension (compression), and (3) bending failure of the horizontal bar. The theoretical calculation formula was as follows:

When the socket is sheared,

When the welding seam at the connection between the socket and the horizontal bar is under tension (compression),

When the horizontal bar is bent,

From the above experimental conclusions and results of the theoretical calculations, it was clear that the weld bearing capacity at the connection between the socket and the horizontal bar was the lowest among the three influencing factors. Therefore, the welding seam at the connection between the socket and the horizontal bar was the weak point of the bearing capacity of the horizontal bar of the formwork support. In practical engineering, the control of weld quality at the node of a horizontal bar and socket is key to ensuring the bearing capacity of a horizontal bar and plays a vital role in ensuring the safe use of the formwork support.

3. Experimental Analysis of the Bearing Capacity of the Vertical Member

The vertical pole is the main force bearing member of the new wheel coupler formwork support; it plays a vital role in the overall bearing capacity of the formwork support. In this section, we describe the experimental study on the bearing capacity of the vertical pole of the formwork support that includes measurement of the shear capacity of the vertical pole wheel, the shear capacity of the vertical pole sleeve, and the stability bearing capacity of the whole bar. Then, the ultimate bearing capacity and failure mechanism of each part of the vertical pole are obtained.

The horizontal bar and the vertical pole of the new wheel coupler formwork support were connected to the wheel through the socket, that is, the vertical pole was welded to the wheel and connected to the socket at both ends of the horizontal bar; self-locking was achieved through the frictional force. When the horizontal bar was subjected to a dynamic load to generate a bending moment, the socket at both ends acted on the wheel with a downward shear force. Due to different horizontal bar connection conditions, the shear surfaces of the wheel also differed. Due to the vertical load on the vertical pole of the formwork support, the welding seam at the connection between the sleeve and the vertical pole was subjected to shear force. Additionally, the vertical pole of the formwork support was subjected to the vertical load from the formwork above as the main stressed member. Because the vertical pole of the formwork support was a slender pole, it bent and deformed when subjected to axial pressure.

3.1. Experimental Analysis of the Shear Capacity of the Wheel on the Vertical Pole

3.1.1. Theoretical Value of the Wheel Shear Capacity

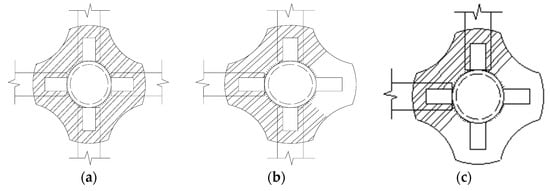

The connection between the vertical pole wheel and the horizontal bar was categorized by three working conditions during the normal construction of the formwork support. First, the wheel was in a four-sided shear state when the vertical pole was the central pole, and the wheel was connected to four horizontal bars. Second, the wheel was in a three-sided shear state when the vertical pole was used as the side pole, and the wheel was connected to three horizontal bars. Third, the wheel was in a two-sided shear state when the vertical pole was a corner pole, and the wheel was connected to two horizontal bars. As shown in Figure 11, the shaded area of each figure is the schematic diagram of the wheel shear zone under different working conditions.

Figure 11.

Schematic diagrams of the wheel shear zone: (a) Central pole; (b) side pole; (c) corner pole.

The ultimate compressive bearing capacity of the wheel under different working conditions was converted into the ultimate bearing capacity of the weld at the connection between the vertical pole and the wheel. The shear capacity of the wheel was calculated by assuming that the wheel was only subjected to shear force without a bending moment. The outer diameter ( = 48 mm) of the formwork support vertical pole, and the weld leg size ( = 6 mm) of the weld connecting the wheel and the vertical pole were obtained. According to the tables, the shear strength design value of the weld was = 160 N/mm2, and the weld of the wheel was double-sided fillet welding. The compressive bearing capacity of the wheel was calculated as follows:

- 1.

- When the four sides of the wheel are sheared,

- 2.

- When the three sides of the wheel are sheared,

- 3.

- When the two sides of the wheel are sheared,

where is the measured weld length under different working conditions.

3.1.2. Experimental Design

The experimental specimen was a new wheel coupler formwork support. Five groups (15) of wheel specimens were randomly selected from numerous specimens, and shear capacity experiments of the wheel disc were conducted under three working conditions. The experiment involved applying pressure on the wheel welded on the vertical pole, measuring the ultimate shear capacity of the wheel, and observing the welding of the wheel and the vertical pole. The ultimate shear capacity and vertical deformation of the wheel were directly measured by using a testing machine. This experiment consisted of three working conditions in five groups of parallel experiments. The experimental device and loading mould are shown in Figure 12. The uniform force loading method was used for loading 10 kN per stage for 120 s per stage.

Figure 12.

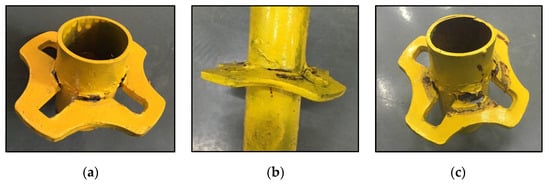

Shear failure mode of wheel: (a) Central pole; (b) side pole; (c) corner pole.

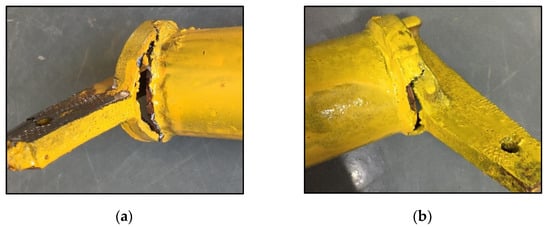

3.1.3. Experimental Results and Analysis

At the beginning of the experimental loading, there was no significant deformation of the wheel in the shear zone, and the vertical displacement increased steadily. With the gradual increase in the applied load, the wheel in the shear zone underwent different degrees of bending deformation, and at the same time, the vertical displacement increased significantly. When the load continued to approach the ultimate load, the vertical displacement of the wheel increased instantaneously, and the load could not continue to increase, which indicated that the specimen was destroyed. After inspection, all the wheel specimens were too large due to the excessive vertical bending deformation in the shear zone. This resulted in the weld fracturing at the connection between the wheel and the vertical pole, and part of the wheel and the vertical pole separated. The failure mode of the specimen is illustrated in Figure 12.

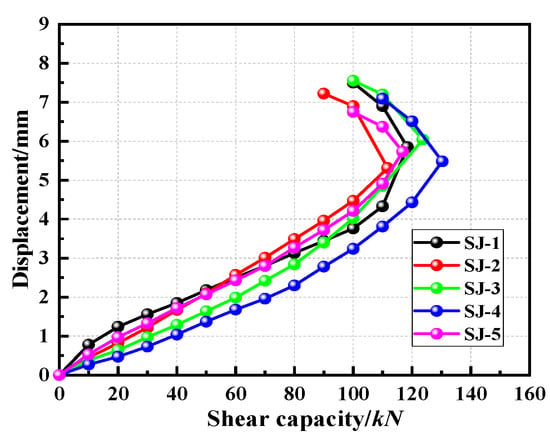

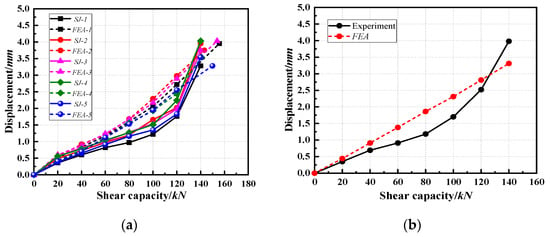

The shear capacity and displacement data for the wheel under the central pole under various working conditions are shown in Figure 13. The ultimate shear capacity under various working conditions was obtained from the experimental data, as shown in Table 3.

Figure 13.

Graphs of the shear capacity of the wheel under central pole conditions.

Table 3.

Ultimate shear capacity under three conditions.

According to the above analysis, the wheel shear capacity of the side pole condition was 24% lower than that of the central pole condition, and the wheel shear capacity of the corner pole condition was 33% lower than that of the side pole condition, with an increasingly obvious decreasing trend. According to the experimental observations, all the failure modes were weld failures, and the failure properties were buckling failures. Therefore, the ultimate shear capacity of the wheel was related to the length and quality of the weld. The longer the length of the weld was, the better the quality and the greater the ultimate bearing capacity.

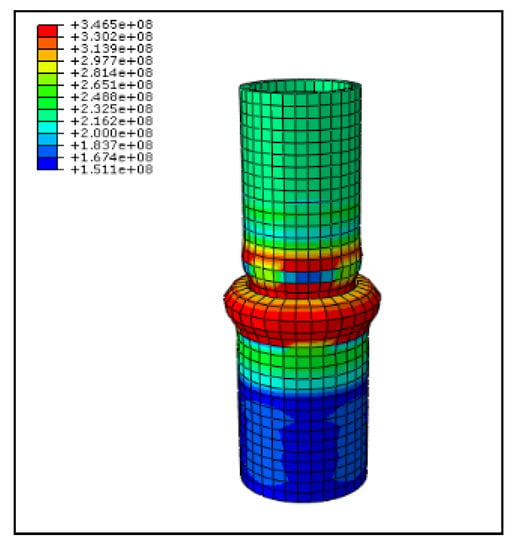

3.1.4. Finite Element Comparative Analysis of the Shear Capacity of the Wheel on the Vertical Pole

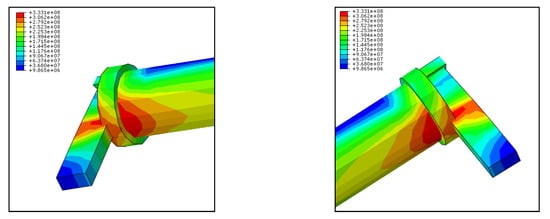

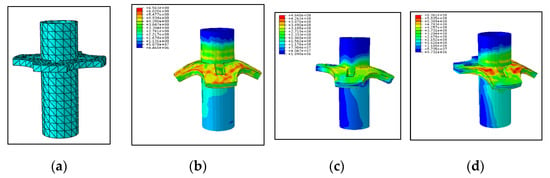

The wheel model was composed of a vertical pole and a wheel, and a solid model was established according to the actual size. The vertical pole and the wheel were entities, and the weld element system was ignored. The vertical pole and the wheel were made of Q235 steel and cast steel, respectively. As shown in Figure 5, the proximate global size was set to 0.05, and the meshing method was set to Sweep. The wheel and the vertical pole grids were automatically divided. The specific numerical model is shown in Figure 14a. In order to make the simulation consistent with the compression experiment of the wheel disk of the formwork support, the connection at the bottom end of the vertical pole was fixed, to limit the translational and rotational degrees of freedom at the upper and lower ends of the vertical pole. A uniform load was applied by using the loading mould; the load was applied in three conditions, and it was uniformly applied on the edge of the wheel disk (the load areas of the central, side, and corner pole wheel disks were 1, ¾, and ½ circles of the wheel disk, respectively). The load adopted the step-by-step force control loading method. According to the experimental value for the failure of the ultimate shear capacity of the wheel, normal values of the construction load were applied to the wheels under three working conditions, that did not damage the model. The applied loads were 100, 80, and 50 kN for wheels under the central, side, and corner pole conditions, respectively. The stress distribution diagrams of three working conditions under normal working loads were obtained from the numerical simulation, as shown in Figure 14.

Figure 14.

Finite element analysis of wheel shear: (a) (b) central pole; (c) side pole; (d) corner pole.

According to the , the stress distribution of the new type of wheel coupler formwork supported the wheel under shear force. According to the results of the ABAQUS calculation, the following conclusions can be drawn:

- The comparison of the results for the wheel shear capacity of the experiment and the finite element analysis showed that the curve fit was accurate (Figure 15), which verified the accuracy of the finite element model.

Figure 15. Finite element analysis of the wheel shear capacity.

Figure 15. Finite element analysis of the wheel shear capacity. - Regarding stress distribution, when the wheel was subjected to shear force, the area of stress concentration was at the connection between the wheel and the vertical pole. The results of the simulation analysis were consistent with the experimental results. Plastic deformation occurred at the joint due to stress concentration. Therefore, when the wheel was sheared, the area prone to damage was the weld between the wheel and the vertical pole.

3.2. Experimental Analysis of the Shear Capacity of the Sleeve on the Vertical Pole

The overlap of the new type of wheel coupler formwork support, at a vertical height, was connected to another vertical pole through a vertical pole sleeve to increase the height. The bearing capacity of the welding seam at the connection of the vertical pole sleeve is a key factor that ensures the bearing capacity of the vertical pole. Therefore, it was necessary to conduct a shear experiment on the vertical pole sleeve.

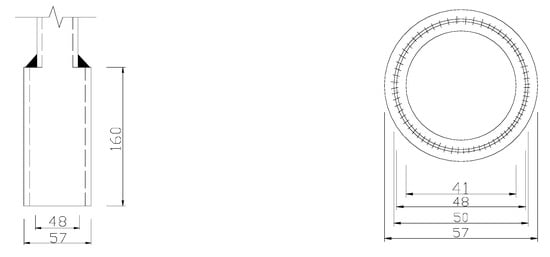

3.2.1. Theoretical Value of Sleeve Shear Capacity

The vertical pole sleeve section had a round annular cross-section, the section size was 58 mm × 4 mm, the sleeve length was 160 mm, and the whole element was formed by unilateral girth welding with the sleeve as well as a vertical pole. According to the measured weld leg size ( = 3 mm) at the connection between the sleeve and the vertical pole, the design value of the shear strength of the weld was = 160 N/mm2, and according to the tables, the socket weld was double-sided girth welding. The shear capacity of the sleeve was calculated as follows:

In actual production, it is impossible for the weld to achieve absolute full welding strength. Perhaps the quality of the weld is poor in some places; thus, the actual shear capacity of the weld is less than the theoretical calculation value.

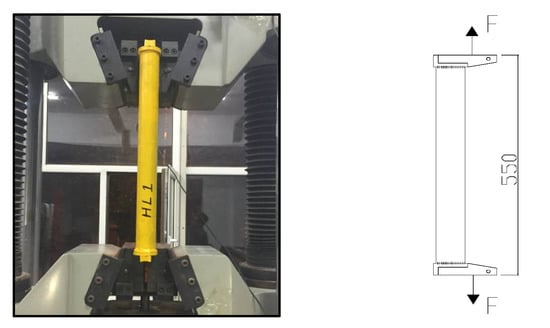

3.2.2. Experimental Design

The sleeve was cut from the whole vertical pole used as the vertical pole sleeve specimen in the experiment. Five specimens were randomly selected for the shear capacity experiment. The geometric sizes of the specimens are shown in Figure 16.

Figure 16.

Dimensions of sleeve specimens.

In this experiment, vertical pressure was applied to the specimen of the vertical pole sleeve with a universal testing machine that applied shear force on the weld of the connection between the vertical pole and the sleeve. The shear capacity of the vertical pole sleeve of the new type of wheel coupler formwork support was measured, and failure characteristics of the sleeve and the vertical pole were observed. The ultimate shear capacity and vertical displacement of the sleeve were collected directly by the testing machine, and five groups of parallel experiments were performed. The experimental device is shown in Figure 17. The uniform force loading method was adopted to ensure that the experimental specimen was in full contact with the testing machine before the actual loading. If there was no relative sliding, then, it was loaded at a uniform speed of 0.5 kN/s. When the sleeve specimen broke or the vertical deformation increased instantaneously, loading was immediately stopped.

Figure 17.

Sleeve shear experimental device.

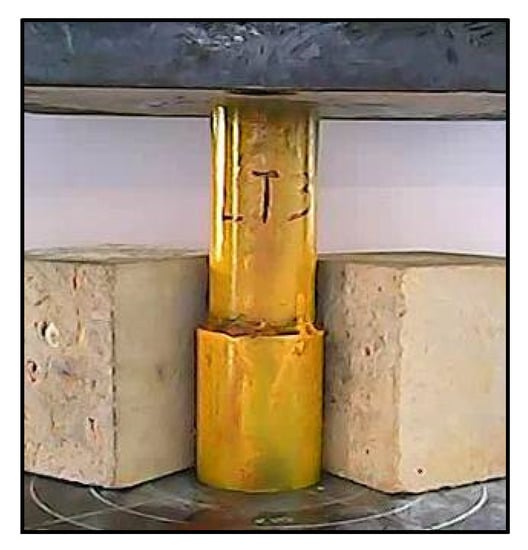

3.2.3. Experimental Results and Analysis

At the beginning of the experimental loading, the displacement of the specimen increased linearly. When the load reached the ultimate load, the vertical displacement of the specimen increased linearly. The load did not continue to increase, but the displacement continued to increase. The experiment was stopped; the vertical pole specimen bending yielded. After unloading, the sleeve and vertical pole connection weld were observed; they were not damaged. The failure morphology of the specimen is shown in Figure 18.

Figure 18.

Shear failure modes of sleeves: (a) SJ-1; (b) SJ-2.

When subjected to a vertical load, the vertical displacement of the sleeve increased linearly during the early and middle stages of loading. In the late loading stage, due to the bending and yielding of part of the main materials near the sleeve weld, the vertical displacement increased significantly until the main material was completely bent and yielded. The experiment showed that the failure mode of the five vertical pole sleeve specimens in this group was the yielded steel; no cracks formed in the weld seam at the connection between the sleeve and the vertical pole. The failure property was a ductile failure. Therefore, this experiment verified that the welding seam at the connection of the vertical pole sleeve was not damaged before the main material, during the normal use of the formwork support, which met the vertical bearing capacity requirements for the vertical pole of the formwork support.

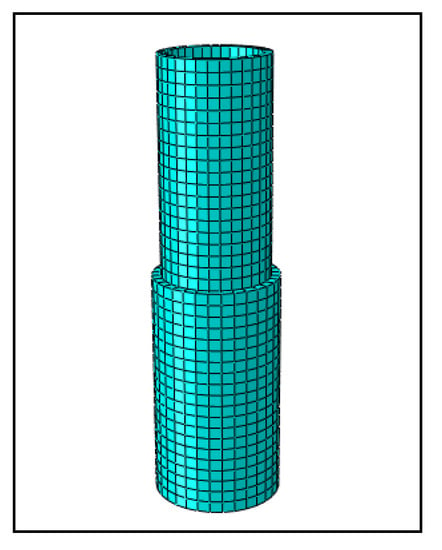

3.2.4. Finite Element Comparative Analysis of the Shear Capacity of the Sleeve on the Vertical Pole

The sleeve model was composed of a vertical pole and a sleeve, and the model was established according to the actual size of the element. The vertical pole and the sleeve were one entity; the weld element unit system was ignored. The vertical pole and the sleeve material were both made of Q235 steel. As shown in Figure 5, the proximate global size was set to 0.02, and the meshing method was set to Sweep. The vertical pole and sleeve grids were automatically divided. The numerical model is shown in Figure 19. In order to make the simulation and the experimental situation the same, the connection at the bottom end of the sleeve was fixed and a vertical uniform load was applied to the upper vertical pole, that is, the lower end of the sleeve restricted the translational and rotational degrees of freedom in three directions. The upper end of the sleeve restricted the translational degrees of freedom in the other two directions except for the vertical directions and restricted all the rotational degrees of freedom at the upper end. The load adopted the step-by-step force control loading method. Vertical displacement control was adopted for this model, and the specimen failure was defined as damaged when the maximum vertical deformation displacement of the specimen reached 5 mm. The deformation displacement of the sleeve under normal working conditions is shown in Figure 20a, and the shear stress diagram of the sleeve is illustrated in Figure 21.

Figure 19.

Model of a sleeve shear.

Figure 20.

Finite element analysis of sleeve shear capacity: (a) Original data; (b) average values.

Figure 21.

Shear stress diagram of a sleeve.

According to the ABAQUS calculation results, the following conclusions can be drawn:

- 1.

- Regarding shear capacity, the results of the were compared with the average values of the five groups of specimens, and Figure 20b was obtained. The trends of the two graphs of the simulated and experimental values were different. The experimental load–displacement curve increased slowly in the middle of the loading period, while the load–displacement curve obtained by the finite element method increased linearly throughout the experiment, which indicated the necessity of establishing the welding unit when studying the shear capacity of the sleeve. However, the results for the ultimate shear capacity were very accurate, which verified the accuracy of the finite element model to predict the ultimate shear capacity of the sleeve.

- 2.

- Regarding stress distribution, according to the simulation analysis and experimental results, when the sleeve was sheared, the stress concentration area was located mainly in the main material near the connection between the sleeve and the vertical pole. The results were consistent for the simulation analysis and experiment.

- 3.

- Regarding failure mode, according to the simulation analysis and experimental results, the sleeve shear failure mode was the result of stress concentration that led to different degrees of plastic buckling deformation of the vertical pole and the sleeve; this buckling eventually led to the loss of bearing capacity by the specimen. The results showed that the bearing capacity of the sleeve was stronger under shear force.

4. Results and Discussion

The stability bearing capacity of the vertical pole, which was the smallest structural unit in the wheel coupler formwork, was studied. The experiments consisted of single- and double-layer vertical pole stability bearing capacity tests. Each experiment was divided into three conditions, namely, stability bearing capacity experiments for the central, side, and corner poles. The variation in the stability bearing capacity of the vertical pole was studied, and the buckling form of the vertical pole was determined.

4.1. Constitutive Experiment

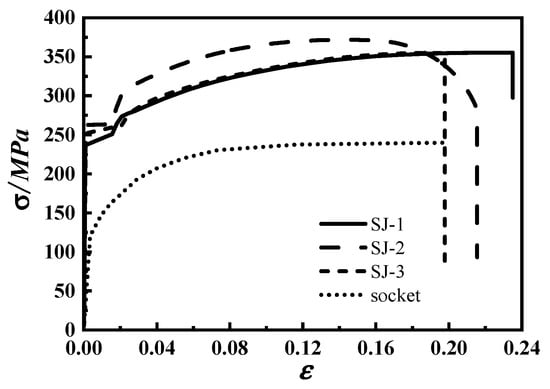

In order to obtain a constitutive model of the steel pipe material, a sample of steel pipe in the experimental specimen was randomly selected. According to the relevant requirements of “Tensile Experimenting of Metallic Materials, Part 1: Experiment Methods at Room Temperature” [25], three standard arc components were made to conduct the tensile experiments. The specimen size is shown in Table 4. The material behaviour test results are shown in Table 5. The constitutive model of the steel pipe and socket interpolation is shown in Figure 22.

Table 4.

Specimen size of the material property experiment.

Table 5.

Material behaviour test results.

Figure 22.

Constitutive model of steel tube and socket.

The stress–strain curve of the test specimen is shown in Figure 22, and the constitutive model of the cast steel used for the socket is also shown in Figure 22. In the following finite element analysis, the material constitutive model was set according to the experimental results. The outer diameter and thickness of the horizontal bar and the vertical pole were set to 50 mm and 3.0 mm, respectively, and the yield strength of the Q235 steel used for the horizontal bar and the vertical pole was 255.52 MPa. The elastic modulus was set to 2.02 × 105 MPa, the density was ρ = 7850 kg/m3, and the Poisson’s ratio was μ = 0.3. The socket and the wheel were made of cast steel, and the constitutive material setting was set according to the socket curve in Figure 22.

4.2. Theoretical Value of the Stability Bearing Capacity of the Vertical Pole

The stability bearing capacity of the single-layer 1.2 m vertical pole axis with constraints at both ends under compression, with calculation length coefficient = 1.0, was calculated; the slenderness ratio was:

According to Figure 21, = 256 MPa. According to = 62.36, the steel structure specification was = 0.795.

- Calculation of the axial compression stability bearing capacity of the double-layer 1.2 m vertical pole: According to = 78.77, = 0.696.

4.3. Experimental Design

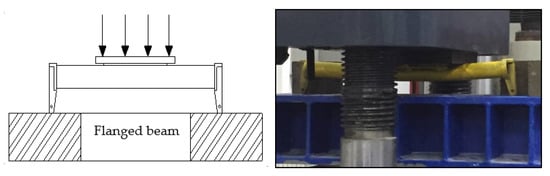

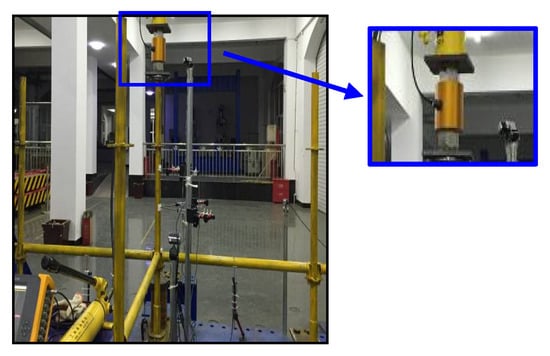

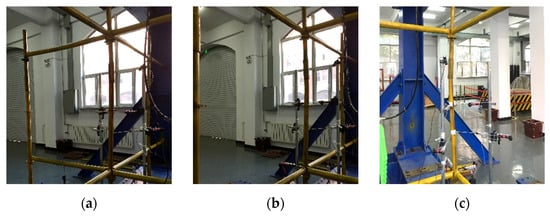

The experimental specimens included several horizontal bars and vertical pole specimens of the new type of wheel coupler formwork support with a size of 1.2 m. The sampling method was adopted from numerous poles, and 36 vertical poles and 27 horizontal bars were randomly selected for assembly under different working conditions. The loading device included a horizontal bar and vertical pole specimens, 50 t hydraulic jacks, a 50 t force transducer, and lateral support bars and bearings, as shown in Figure 23. All the bottom ends of the vertical poles were fixed by the support. The whole device was connected to the counterforce frame through the lateral support bar. The top of the vertical pole was connected to the force sensor by the support. The force sensor was connected to the hydraulic jack, and the axial force on the vertical pole was applied from the top through the hydraulic jack. The load value in the loading process was obtained by the data acquisition instrument. The deformation displacement of the specimen was obtained by the displacement meter through the data acquisition instrument.

Figure 23.

Experimental loading device.

The method of graded loading was adopted, and preloading was conducted before the actual experiment to ensure that the experimental device was correctly assembled. Monotonic loading was performed by loading 10 kN for 30 s per stage. When the load no longer increased, the next loading stage was performed. The load was stopped when the vertical pole specimen of the wheel coupler formwork support could not continue to load, and the displacement continued to increase.

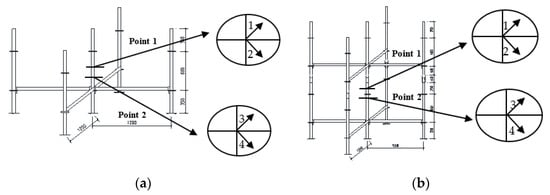

The buckling deformation of the vertical pole was monitored by placing a displacement meter on the vertical pole. Measuring Point 1 was located at the midpoint of the longest free end of the vertical pole specimen, and displacement meters No. 1 and No. 2 were arranged symmetrically along the 45° direction outside the plane of measuring Point 1. Measuring Point 2 was located at the midpoint of the length of the whole vertical pole specimen. The No. 3 and No. 4 displacement meters were symmetrically arranged along the 45° direction outside the plane of measuring Point 2. When the side pole and corner pole experiments were conducted, the position of the displacement meter was unchanged. The arrangement of measuring points in the double-layer stability bearing capacity experiment was the same as that of the single-layer stability bearing capacity experiment. A schematic diagram of the measuring point arrangement is shown in Figure 24.

Figure 24.

Measuring point arrangements: (a) Single-layer experiment; (b) double-layer experiment.

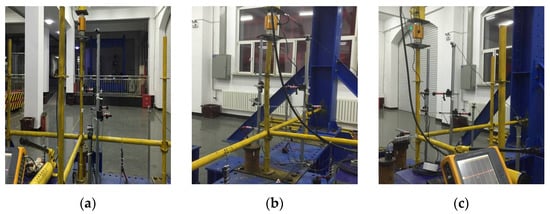

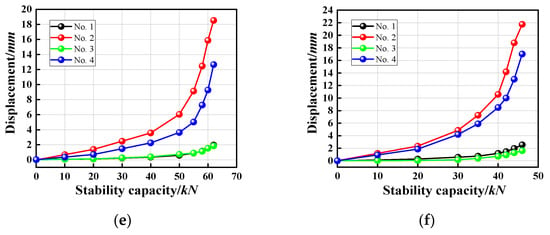

4.4. Experimental Results and Analysis

In the initial stage of experimental loading, there was no significant change in the single- and double-layer vertical poles (central, side, and corner poles). When the load continued to increase, the maximum free end midspan of the single-layer vertical pole specimen first underwent bending deformation, followed by bending deformation of the center of the whole vertical pole specimen. The first bending deformation of the double-layer vertical pole was the vertical pole sleeve connection; when the load did not increase, the vertical pole’s bending deformation continued to increase. The single- and double-layer vertical pole specimens of the formwork support were unstable. The failure modes of the single- and double-layer vertical pole specimens are shown in Figure 25 and Figure 26, respectively.

Figure 25.

Failure modes of single-layer vertical poles: (a) Central pole; (b) side pole; (c) corner pole.

Figure 26.

Failure modes of double-layer vertical poles: (a) Central pole; (b) side pole; (c) corner pole.

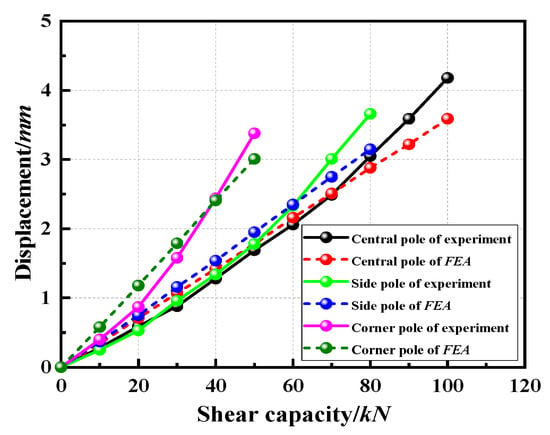

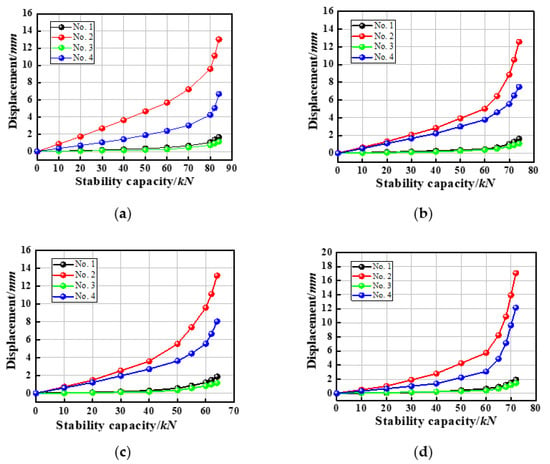

The load–displacement curves of the measuring points are shown in Figure 27. With the continuous increase in load, the trends in horizontal displacement at each measuring point of the single- and double-layer vertical poles were basically the same. The trends for displacements at the No. 1 and No. 3 displacement meters were not prominent. The change in displacement of the No. 2 displacement meter was the most obvious, followed by that of the No. 4 displacement meter. This showed that the maximum deformation displacement of the single- and double-layer vertical poles occurred at the midpoint of the longest free end, that is, near measuring Point 1, and instability occurred along the 45° out of the plane. According to the compression bar stability theory and the Euler formula, the maximum deformation of a slender unstable pole occurs in the middle of the longest free end span of the pole; the vertical pole of the formwork support is considered to be a slender pole. Thus, the experimental results conformed to the relevant theory.

Figure 27.

Load—displacement curves of measuring points: (a) Single-layer central pole; (b) single-layer side pole; (c) single-layer corner pole; (d) double-layer central pole; (e) double-layer side pole; (f) double-layer corner pole.

4.5. Finite Element Analysis and Verification of Stability Bearing Capacity Experiments of Single- and Double-Layer Vertical Poles

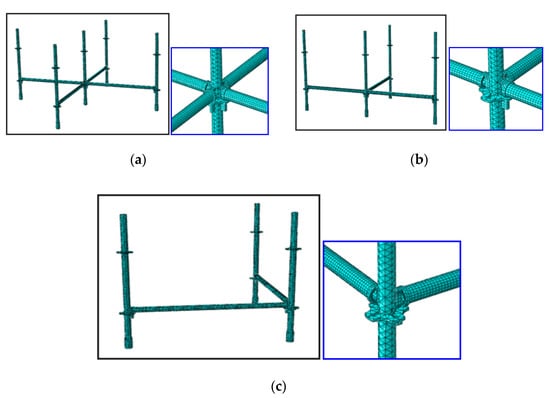

4.5.1. Establishment of the Numerical Model

To more closely model the actual stress state of the formwork support and to better simulate the stress state of the vertical pole of the formwork support, the following basic assumptions were made for the vertical pole model of a formwork support: (1) The connection between the vertical pole and the horizontal bar was a semi-rigid connection, and the bending moment was transmitted between the vertical pole and the horizontal bar. (2) The vertical pole was a continuous, complete vertical pole, and the welding system was ignored. (3) The foundation and the formwork support were connected by hinges, and no bending moment was transmitted, which was more consistent with the actual situation. (4) The roles of scissor supports and inclined bars were ignored, and conservative assumptions were made about the support frame. (5) Considering the geometric nonlinearity of the structure, the critical load was determined according to the stress diagram and load–displacement curve. Additionally, the size of the vertical load was changed, and the calculation of the structure was repeated. Finally, the critical load value was obtained.

According to the size of the formwork support, solid modelling of the single-layer vertical pole of the formwork support was conducted. The vertical pole and horizontal bar with specifications of 1.2 m were used for solid modelling in three working conditions (central, side, and corner poles). Among them, the wheel and vertical pole, the sleeve and vertical pole, and the socket and horizontal bar were considered to be single entities, consistent with the above. The vertical pole, horizontal bar, and sleeve were all set as Q235 steel, and the other components were set as cast steel. The meshing method was set as previously described. The node connection between the vertical pole and the horizontal bar was set up with a surface-to-surface friction connection. The models of the three working conditions are illustrated in Figure 28.

Figure 28.

Finite element model of single-layer vertical pole for calculations of stability bearing capacity: (a) Central pole; (b) side pole; (c) corner pole.

It was important to keep the boundary conditions of the and the experimental analysis consistent. Thus, in the of the stability bearing capacity of single- and double-layer vertical poles in the formwork support, the bottom ends of the other vertical poles that were not affected by the load were fixed. The top ends of the other vertical poles were set as free ends, which limited the out-of-plane translational degree of freedom at the low end and the rotational degree of freedom in the vertical direction, and the load was applied only to the single- and double-layer stressed poles (central, side and corner poles). The displacement control method was adopted in the of the stability bearing capacity of single- and double-layer vertical poles. The maximum vertical displacement of the stressed vertical pole was set to 50 mm, and a uniform axial load was applied at the upper end of the stressed bar.

4.5.2. Finite Element Comparative Analysis

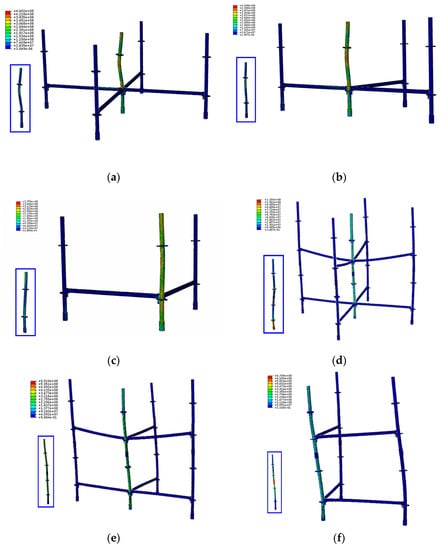

A finite element analysis was performed on the stability bearing capacity of the single- and double-layer vertical poles (central, side, and corner poles) of the new type of wheel coupler formwork support. The vertical pole deformation and stress cloud diagrams for the three working conditions were obtained, as shown in Figure 29.

Figure 29.

Deformation diagrams of single- and double-layer vertical pole structures: (a) Central pole of a single-layer structure; (b) side pole of a single-layer structure; (c) corner pole of a single-layer structure; (d) central pole of a double-layer structure; (e) side pole of a double-layer structure; (f) corner pole of a single-layer structure.

The results for deformation diagrams and stress cloud diagrams showed that single- and double-layer vertical poles in the new wheel coupler formwork supported under axial compression for three working conditions (central, side, and corner poles), and the results were basically consistent with the experimental results. According to the results of ABAQUS calculations, the following conclusions were drawn:

- Regarding the stress analysis, the stress concentration of the single- and double-layer vertical poles occurred in the middle of the longest free end of the vertical pole, i.e., the stress concentration was in the buckled section.

- Regarding the failure mode, according to the simulated results for the failure of the single-layer vertical poles (central, side, and corner poles), all the single-layer vertical poles of the formwork that provided support under three working conditions were unstable and damaged due to buckling of the pole, which was consistent with the failure mode of the axial compression member. However, it was still slightly different from the axial compression member. The reason was that when the pole bent, the loading point was not entirely under axial compression, therefore, a bias developed, that is, the pole underwent vertical and also horizontal displacement.

- Regarding buckling deformation, in the numerical simulation and experiment, the deformation displacement of the buckling section of the double-layer vertical pole of the new wheel coupler formwork support under three working conditions (central, side, and corner poles) was larger than that of the single-layer vertical pole. The free end was longer than the single-layer vertical pole. However, the free length included the vertical pole connecting the sleeve. When the vertical pole was connected to the sleeve, there was a gap between the sleeve and the vertical pole so that the lower vertical pole could rotate under the force. When the height of the formwork support increased, the number of connections between the vertical pole and the sleeve increased, and the accumulated deformation increased, which may have been one of the reasons that it was not conducive to the overall stability of the formwork support.

The experimental and results for the stability bearing capacity of the single- and double-layer formwork supports are compared in Table 6. The predictions of the buckling capacity of the double-layer formwork support vertical pole were very accurate, and the error was basically within 5%. Therefore, the numerical model accurately predicted the buckling capacity of the wheel coupler formwork support in a large range. With a reduction in the number of horizontal bars connected to the vertical pole wheel disk, the stability bearing capacity showed a significant downward trend, especially with increasing layers; the stability bearing capacity decreased the most for the corner pole condition. The failure of a single-layer vertical pole was typical for lateral displacement buckling, while the double-layer vertical pole did not undergo lateral displacement buckling.

Table 6.

Comparative analysis of the stability bearing capacity of the vertical pole.

4.6. Discussion

In recent years, formwork support is often ignored in design and construction processes; there is a lack of research on the performance of steel pipe formwork supports in China. Aiming at the problems of incomplete and unsystematic research on the performance of wheel coupler formwork support components, the bearing capacity of the horizontal bar, the shear capacity of the wheel, the shear capacity of the sleeve, and the stability bearing capacity of the single- and double-layer vertical poles were investigated through systematic full-scale tests. In this paper, the performances of the wheel coupler formwork support components have been improved, but the number of tests was limited due to the lack of test conditions. Subsequent and more comprehensive and systematic experiments would be more conducive to mastering research on the performance of wheel coupler formwork support components and could provide a theoretical basis for the formulation of relevant norms.

5. Conclusions

In this study, we addressed the problems of incomplete and unsystematic research on the performance of wheel coupler formwork support components by performing experiments. Additionally, the bearing capacities and failure modes of horizontal bars, vertical poles, and related components of a wheel coupler formwork support were analysed. The stability bearing capacities of single- and double-layer vertical poles were tested and analysed, and the variation of the stability bearing capacities of vertical poles under different working conditions was determined. The main conclusions were as follows:

- The eccentric tensile failure mode of the horizontal bar socket was buckling failure of the weld, and the bearing capacity was low.

- The bending failure mode of the horizontal bar was the yield strength of the horizontal bar section, which was a ductile failure. No cracks formed in the weld seam at the connection between the socket and the horizontal bar, which verified the stability of the horizontal bar of the formwork support under normal working conditions.

- According to the experimental analysis of the horizontal bar bearing capacity, the weld bearing capacity at the connection between the socket and the horizontal bar was the least among the three influencing factors. Therefore, the weak point of the bearing capacity of the horizontal bar of the formwork support was the weld seam at the connection between the socket and the horizontal bar. In practical engineering, the control of weld quality of the connection between the socket and the horizontal bar is key to ensure the bearing capacity of the horizontal bar and safe use of the formwork support.

- Buckling failure of the weld at the connection between the wheel and the vertical pole occurred under shear force, and the shear capacity of the wheel decreased obviously with decreasing number of horizontal bars connected to the wheel. The sleeve shear failure mode was buckling failure, and the connection weld did not exhibit buckling failure in the bearing process, which basically corresponded to the normal use state.

- The numerical model accurately predicted the buckling capacity of the wheel coupler formwork support over a large range. With a reduction in the number of horizontal bars connected to the vertical pole wheel disk, the stability bearing capacity showed a significant downward trend, especially with increasing layers; the stability bearing capacity decreased the most for the corner pole condition. The failure of a single-layer vertical pole was typical with lateral displacement buckling, while the double-layer vertical pole did not undergo buckling with lateral displacement.

Author Contributions

Conceptualization, Q.C. and J.D.; Data curation, Q.C.; Formal analysis, Q.C.; Funding acquisition, H.L.; Investigation, S.X. and L.T.; Methodology, H.L.; Project administration, M.L.; Resources, H.L.; Software, C.Y.L. and Y.F.; Supervision, H.L.; Validation, Q.C., H.L. and T.K.T.T.; Visualization, J.D.; Writing—original draft, Q.C.; Writing—review & editing, S.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Service Local Project of the Liaoning Provincial Education Department Project: Development of Coal Gangue Insulating Concrete and Industrialization of Energy-saving Construction of Village Houses, grant number LJ2020FWL003 and this work was also supported by the Key R&D Program Project of Liaoning Province: Demonstration of Resource Utilization Project of Coal Gangue in Energy-saving Construction of Village Houses, grant number 2018230008.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request due to restrictions eg privacy or ethical. The data presented in this study are available on request from the corresponding author.

Acknowledgments

We especially thank the structural laboratory of the School of Civil Engineering at Liaoning Technical University for its indispensable support in experiments.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Abbreviations

The list contains the nomenclature employed in the current study.

| Latin Letters | |

| Shear area | |

| D | Outer diameter size |

| Weld leg size | |

| Tensile strength design value | |

| Shear strength design value | |

| Ultimate bearing capacity of welds | |

| Ultimate shear capacity | |

| Ultimate flexural bearing capacity | |

| Measured weld length under different working conditions | |

| Calculation thickness of orthogonal fillet weld | |

| Design value of axial force | |

| Modulus of section | |

| Flexural modulus | |

| Calculated length of vertical pole | |

| Radius of gyration of cross-section | |

| Greek Letters | |

| Effective length factor | |

| Slenderness ratio | |

| Stability coefficient | |

| Others | |

| Finite element analysis | |

| Moment–rotation curve | |

References

- He, Y.; Zhang, L.; Chen, Z.; Li, C.Y. A framework of structural damage detection for civil structures using a combined multi-scale convolutional neural network and echo state network. Eng. Comput. 2022, 22, 1278–1285. [Google Scholar] [CrossRef]

- Yang, L.; Li, S. Quantitative analysis on the importance of events in construction safety accidents. China Saf. Sci. 2010, 20, 105–110. [Google Scholar] [CrossRef]

- Hui, L.; Zheng, X.; Zhang, Z. Risk analysis of high-risk operations in construction by a quantitatively improved JHA method. China Saf. Sci. 2019, 29, 146–151. [Google Scholar] [CrossRef]

- Zhang, M.; Fang, D.; Tong, R. Study on underestimating risks of scaffolders to unsafe behaviors. China Saf. Sci. 2011, 21, 145–150. [Google Scholar] [CrossRef]

- Jia, L.; Liu, H.; Chen, Z. Capacity calculation method of full hall steel tubular scaffold with couplers. Build Struct. 2016, 46, 71–76. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Q.; Wang, X. Experimental and theoretical study on stability behavior of structural steel tube and coupler scaffold without X-bracing. Eng. Struct. 2010, 32, 1003–1015. [Google Scholar] [CrossRef]

- Lu, Z. Experimental and Theoretical Study on Fastener Steel Tube Full Hall Formwork Support System. Ph.D. Thesis, Tianjin University, Tianjin, China, 2010. [Google Scholar]

- Lu, Z.; Chen, Z.; Wang, X. Experimental and theoretical study of the bearing capacity of fastener steel tube full-hall formwork support system. China Civ. Eng. 2012, 45, 49–60. [Google Scholar] [CrossRef]

- Xie, N.; Fu, X.; Wang, L.; Hu, H.; Wu, T. Design method of load and resistance factor for high falsework with couplers. KSCE J. Civ. Eng. 2016, 33, 68–75+104. [Google Scholar]

- Ding, K.; He, X. Force mechanism and progressive collapse of steel tube-coupler scaffold under local load. KSCE J. Civ. Eng. 2018, 22, 2344–2353. [Google Scholar]

- Hua, J.; Yang, Z.; Xue, X.; Huang, L.; Wang, N.; Chen, Z. Bond properties of bimetallic steel bar in seawater sea-sand concrete at different ages. Constr. Build. Mater. 2022, 323, 126539. [Google Scholar] [CrossRef]

- Yi, M.; Li, J.; Chen, Z. Structural behavior of steel tube and coupler scaffolds with stability strengthening details. Int. J. Steel Struct. 2018, 18, 79–95. [Google Scholar]

- Zhang, X. Study on the Performance of the Full Cuplock Steel Tubular Scaffoldings. Master’s Thesis, Chang’an University, Xi’an, China, 2015. [Google Scholar]

- Zhou, K. Experiment and Analysis on Load-Bearing Capacity of Steel Tubular Falsework with Bowl-Button Type Connection. Master’s Thesis, Tianjin University, Tianjin, China, 2010. [Google Scholar]

- Yang, S. The Research on Stability Bearing Capacity of Wheel Coupler Formwork Support. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2011. [Google Scholar]

- Yang, W.; Yang, Y.; Yang, S. Experimental study on connection property of joints of pulley-clip supporting frame. Ind. Constr. 2012, 42, 101–107. [Google Scholar] [CrossRef]

- Yang, W.; Bai, S.; Zeng, K. Analysis of the anti-pull-out performance of the joint plug of the wheel-coupler steel pipe support. Constr. Saf. 2018, 33, 73–77. [Google Scholar]

- Wang, Z. The Experimental Investigation of Socket Type Steel Pipe Scaffold. Master’s Thesis, Hunan University, Changsha, China, 2013. [Google Scholar]

- Chen, M. The Study on the Popularization and Application of the Pulley-Clip High Formwork in Wenzhou. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 2016. [Google Scholar]

- Liu, W.; Yu, H.; Wang, X. The Research on Development and Applied of the New Wheel Buckle Scaffold Support Frame. Master’s Thesis, Hebei University of Science and Technology, Shijiazhuang, China, 2018. [Google Scholar]

- Liu, W.; Yu, H.; Wang, X. Rotational stiffness experiment and numerical analysis of a new type pulley-clip scaffold. Steel Constr. 2018, 33, 26–31. [Google Scholar]

- Cheng, Y. Performance Research of Wheeled-Coupler Type Steel Tubular Scaffolding. Master’s Thesis, South China University of Technology, Guangzhou, China, 2017. [Google Scholar]

- Zhang, H. Study on Stability and Bearing Capacity of Axially Compressed Disk-Pin Joined Steel Tubular Scaffold. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2016. [Google Scholar]

- Liu, W.; Yu, H.; Huang, J. Bearing capacity experiment and finite element analysis of pulley-clip formwork supporting frame. Build Struct. 2022, 43, 219–227. [Google Scholar]

- GB/T 228.1–2010; Metallic Materials—Tensile Experimenting. Part 1: Method of Experiment at Room Temperature. China Standards Press: Beijing, China, 2010.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).