Effect of Shelf Aperture Ratio on the Temperature Distribution of an Open Refrigerated Display Cabinet

Abstract

Featured Application

Abstract

1. Introduction

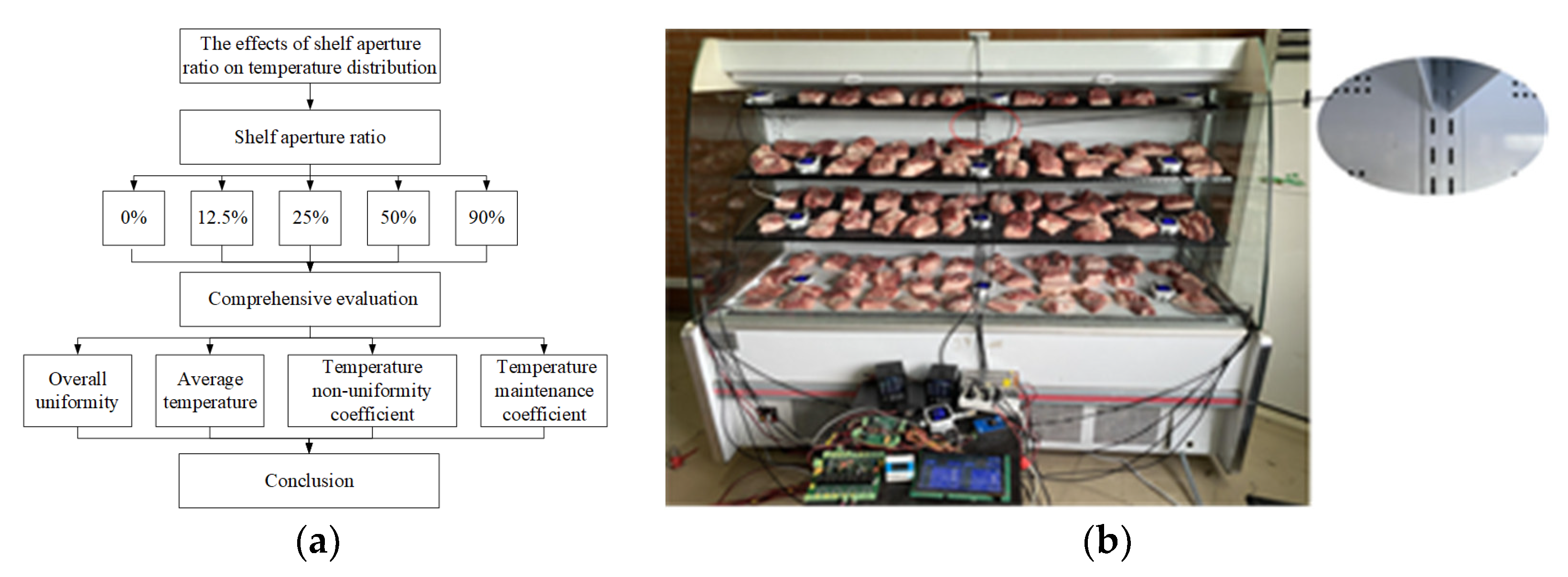

2. Materials and Methods

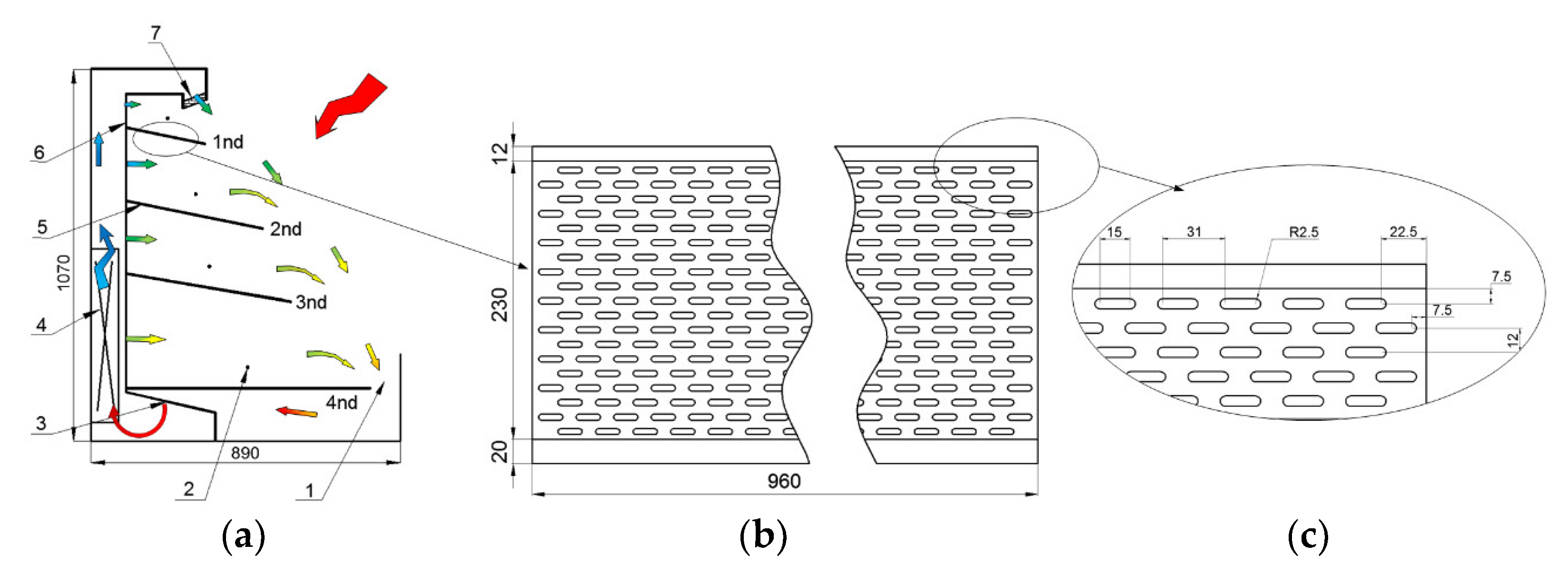

2.1. Structure of the Display Cabinet

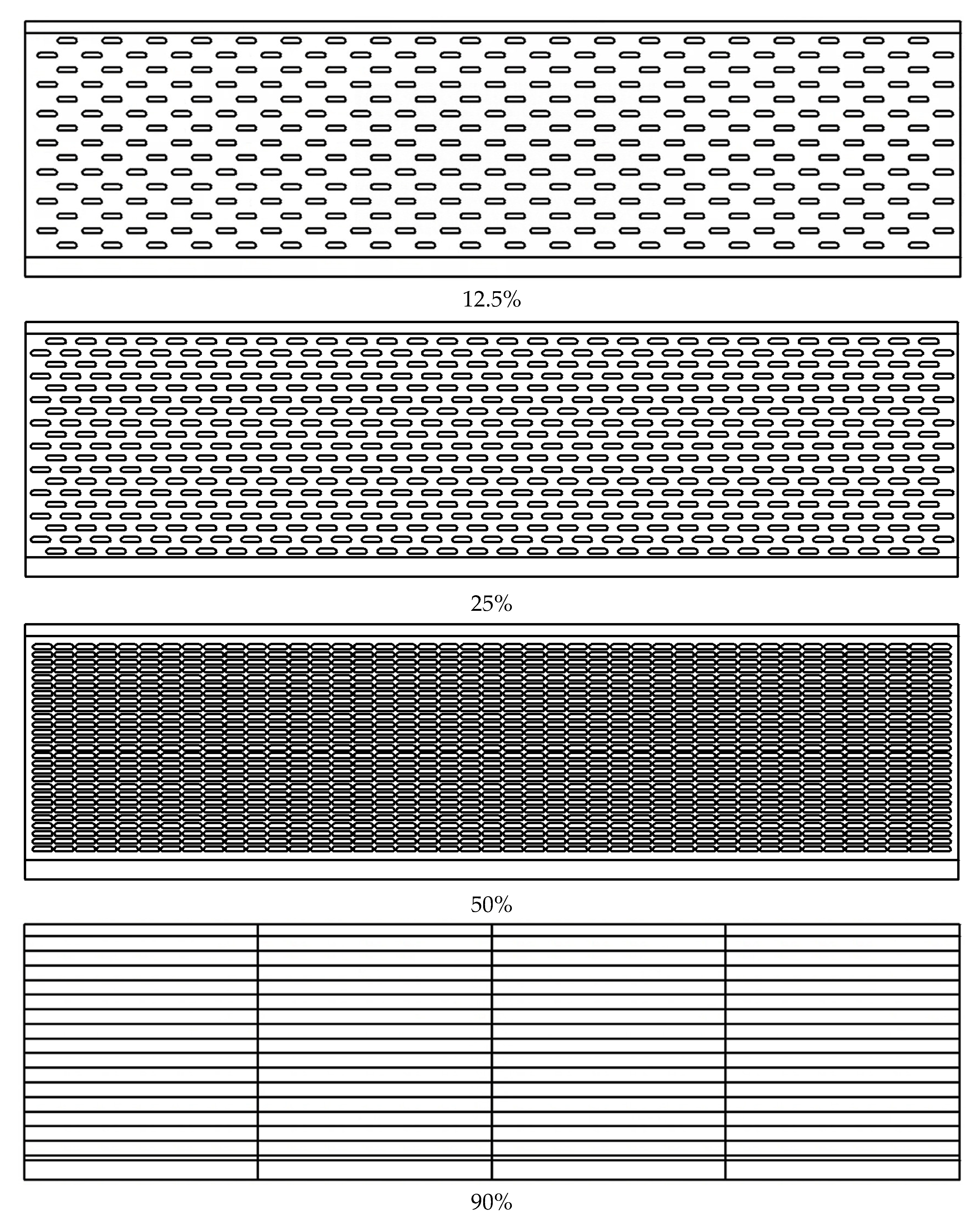

2.2. Test Levels

2.3. Test Method

2.3.1. Processing Steps

2.3.2. Statistical Methods

3. Results

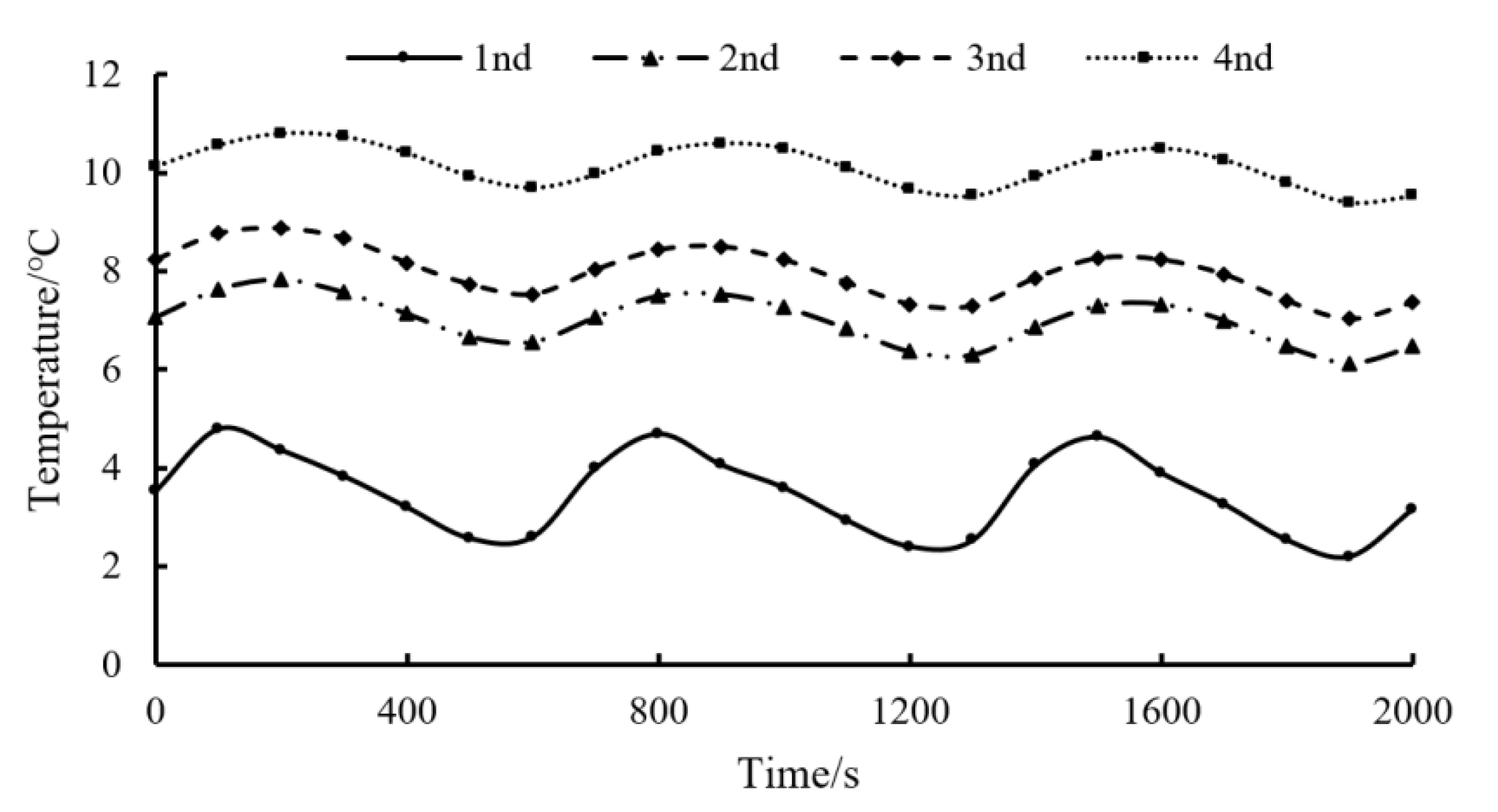

3.1. Temperature Distribution in the Cabinet (0%)

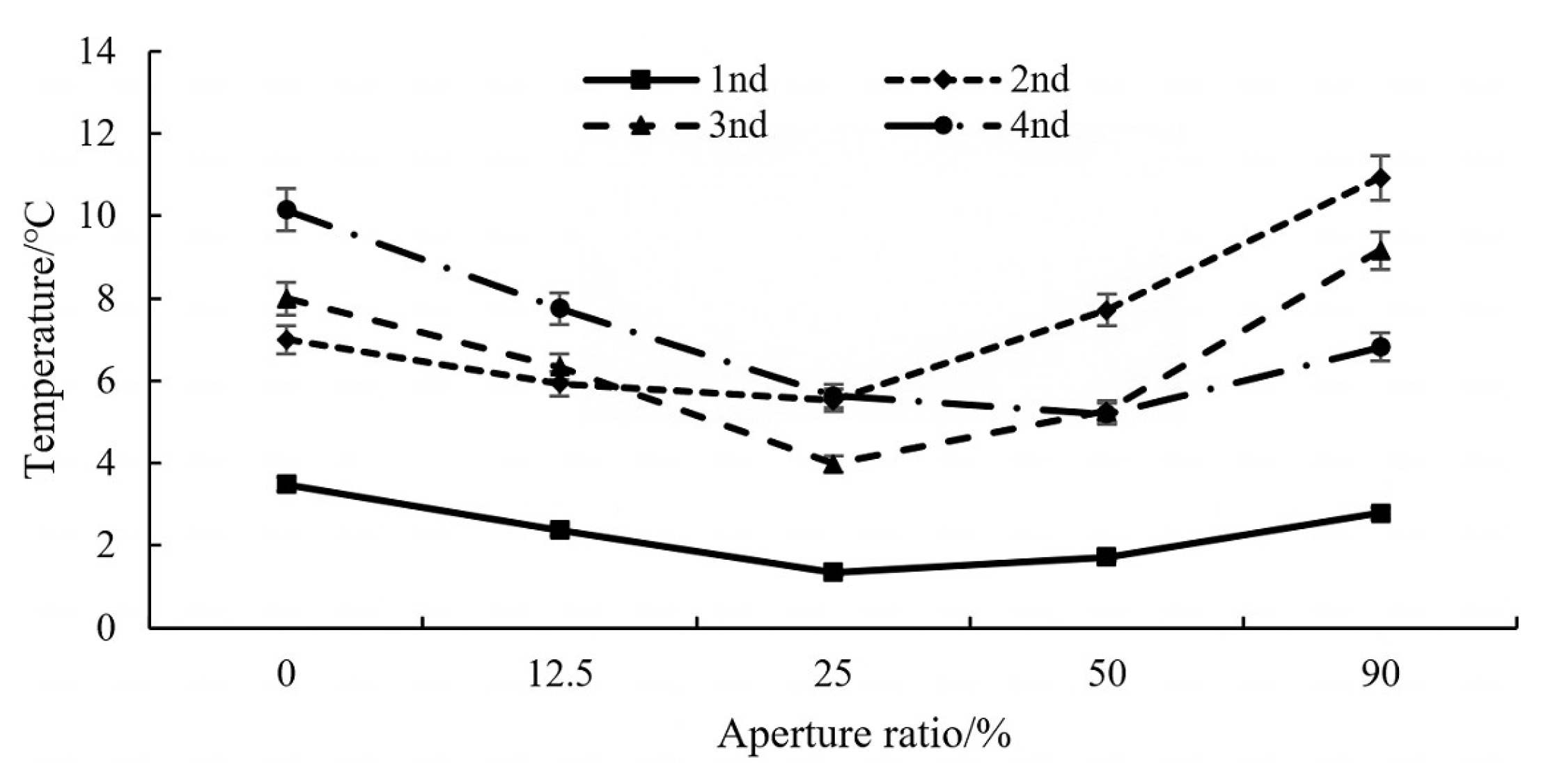

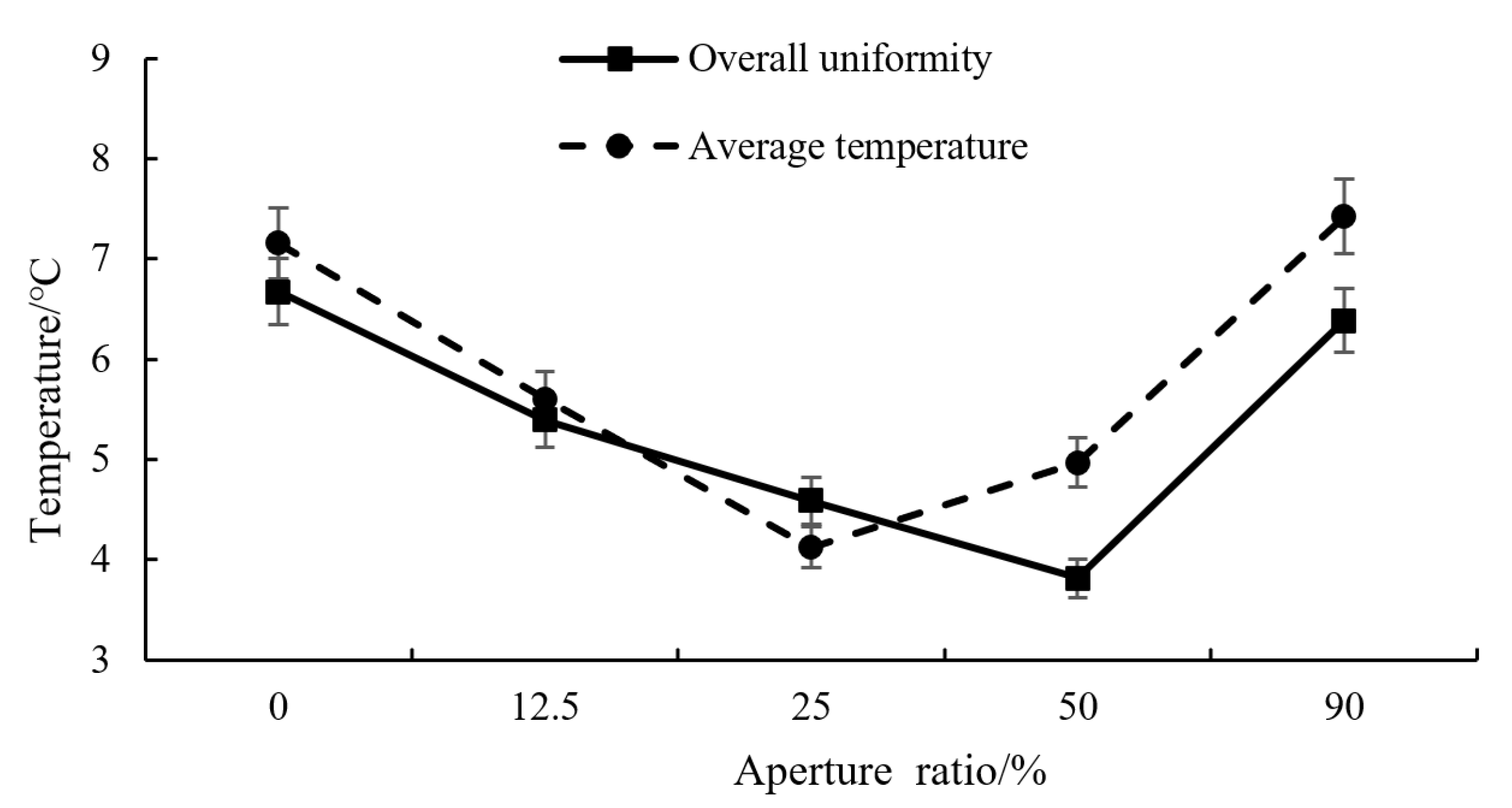

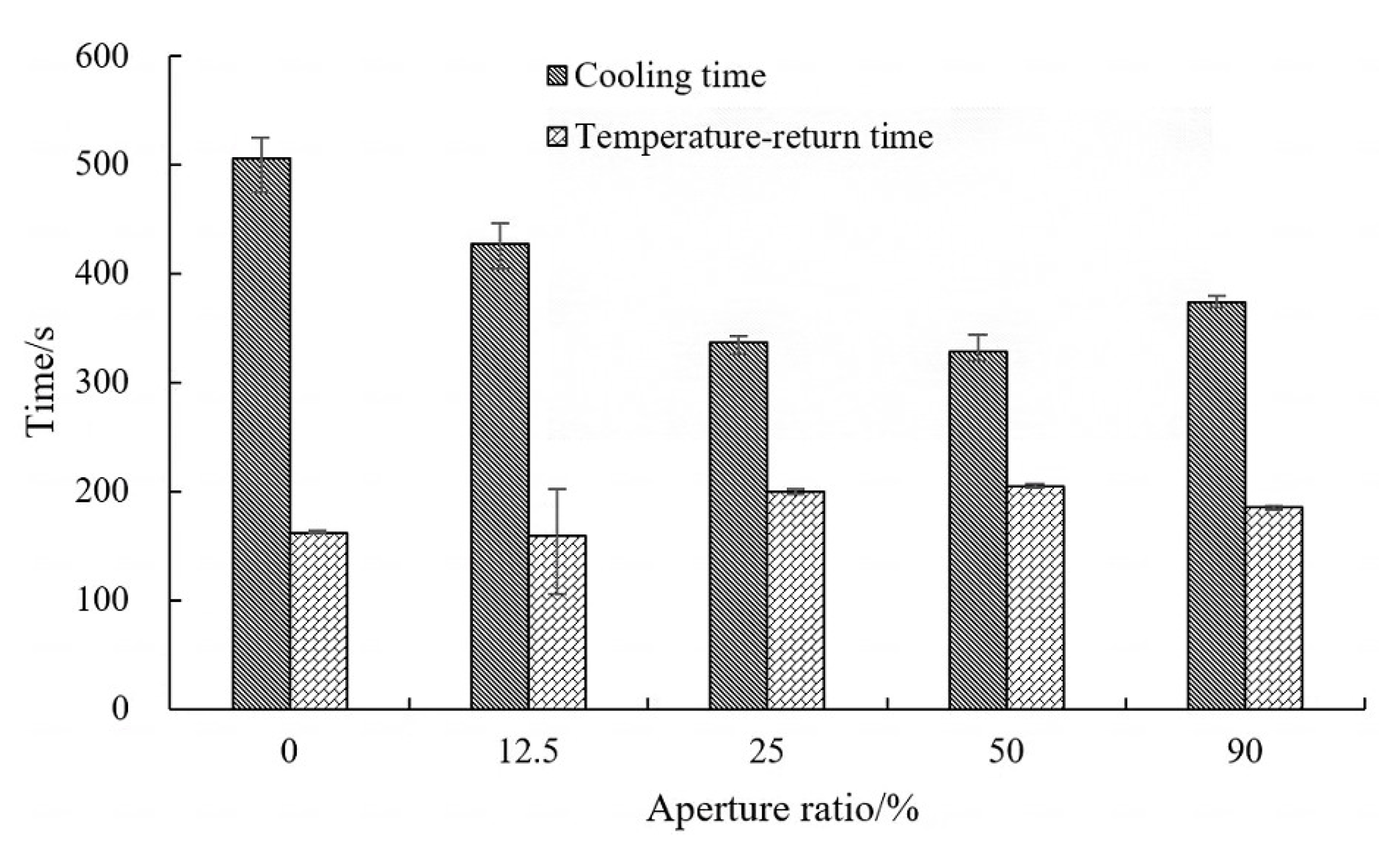

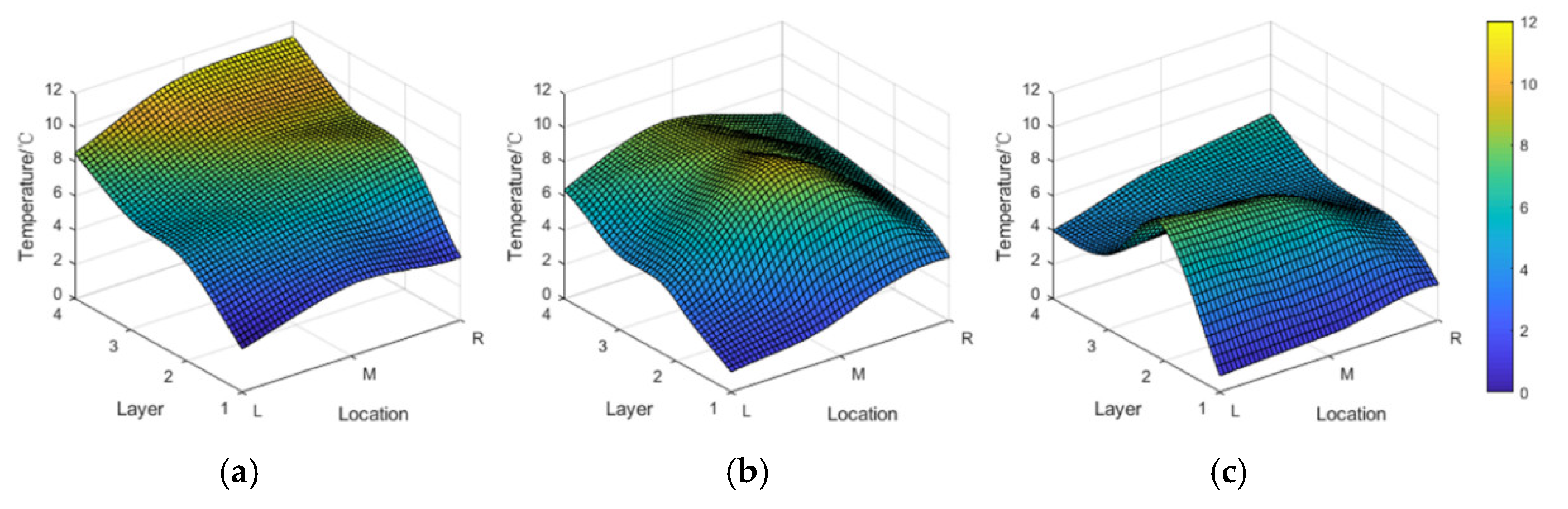

3.2. Influence of Different Aperture Ratios on the Temperature in the Cabinet

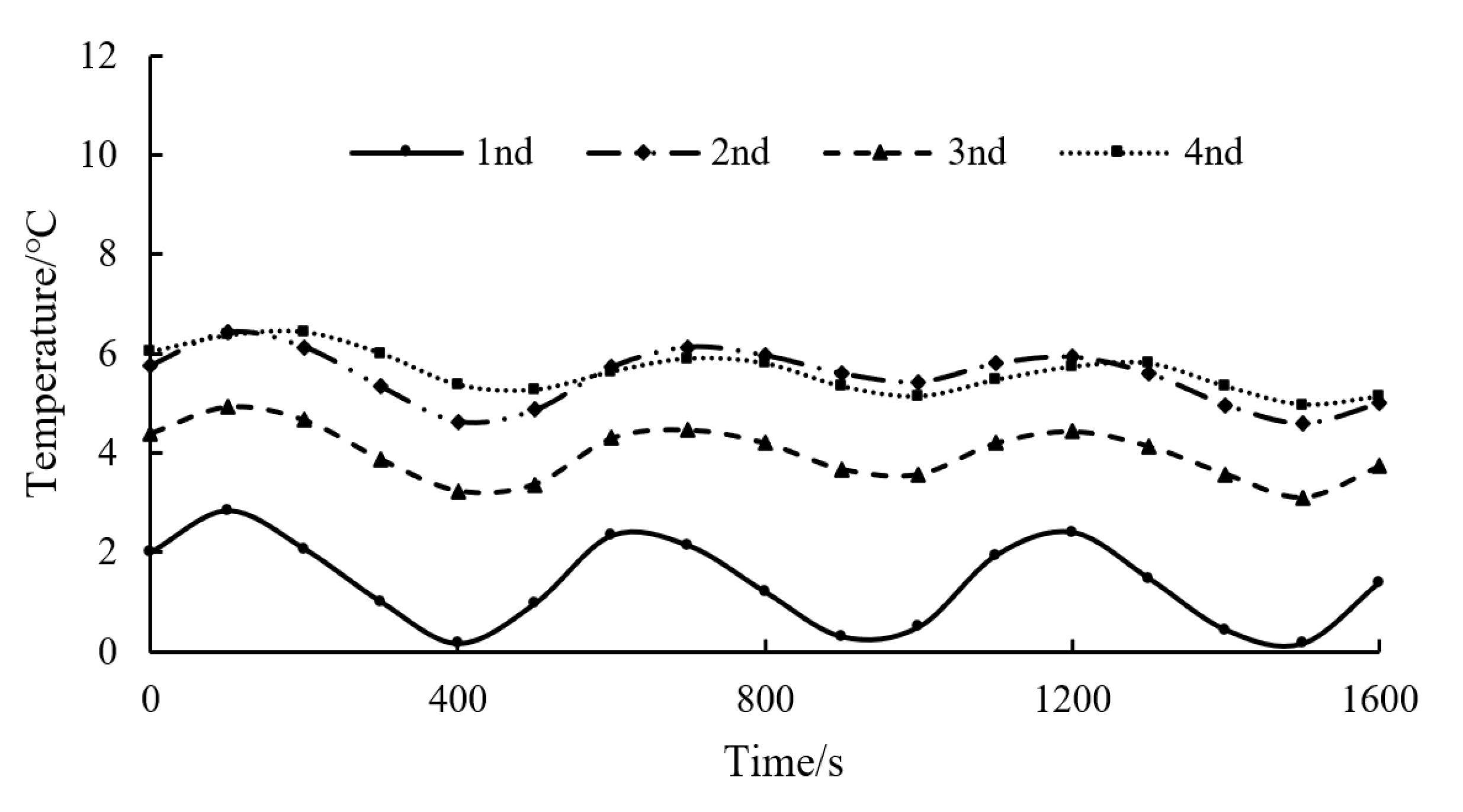

3.3. Temperature Distribution inside the Cabinet (25%)

4. Discussion

5. Conclusions

- (1)

- When the shelf aperture ratio was 0%, the lowest temperature in the cycle operation cabinet appeared in the first layer at 2.2 °C; the highest temperature occurred in the fourth layer at 10.9 °C. The first-layer to fourth-layer shelf temperatures inside the cabinet showed a trend of layer-by-layer increase. The temperature stratification phenomenon was more serious, and the maximum temperature difference in the cabinet was 7.4 °C.

- (2)

- As the aperture ratio increased from 0% to 90%, the average maximum temperature in the cabinet decreased from 10.2 °C to 5.6 °C and then rose to 10.9 °C. The minimum temperature difference in the cabinet was 4.3 °C, and the corresponding aperture ratio was 25%. At this time, the average temperature in the cabinet was 4.1 °C, the average temperature difference was 4.3 °C, the non-uniformity coefficient was 4.9, and the temperature maintenance coefficient was 0.59. Through comprehensive evaluation, 25% was determined to be the optimum aperture ratio for the open refrigerated display cabinet shelf.

- (3)

- For the 25% shelf aperture ratio compared with 0%, the temperature distribution in the cabinet showed a great improvement. The highest temperature in the cabinet decreased from the original 10.9 °C to 6.5 °C, and the temperature difference decreased from the original 7.4 °C to 5.4 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A. Shelf Design Drawing of Different Aperture Ratio

References

- Qiu, X.; Zhao, Y.; Fan, B.; Meng, Q. Research Progress on Open Refrigerated Display Cabinets. J. Refrig. Technol. 2020, 43, 55–59. [Google Scholar]

- Yanli, L.; Cao, X.; Wu, X.; Meng, Z. Numerical simulation of temperature distribution of food packages on open-type horizontal display cabinet. J. Zhengzhou Univ. Light Ind. Nat. Sci. 2013, 28, 1–6. [Google Scholar]

- Xiadong, J. Honeycomb Design Optimization of Multi-deck Refrigerated Display Cabinet Using CFD Simulation. Intern. Combust. Engine Parts 2018, 16, 200–203. [Google Scholar]

- Pei, Y.; Liu, J.; Liu, Z.; Lv, Y. Influence of shelf’s length on performance of refrigerated display cabinet. Refrig. Air-Cond. 2018, 18, 10–14. [Google Scholar]

- Gill, C.O.; Jones, T.; Houde, A. The temperature and ages of packs of beef displayed in multi-shelf retail cabinets. Food Control. 2003, 14, 145–151. [Google Scholar] [CrossRef]

- Bahman, A.; Rosarlo, L.; Rahman, M. Analysis of energy savings in a supermarket refrigeration System. Appl. Energy 2012, 98, 11–21. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, X. The analysis and research on energy efficiency standards and energy-saving technology for commercial refrigerator. Refrig. Technol. 2015, 4, 8–12. (In Chinese) [Google Scholar]

- Meng, X.; Yu, B.; Wang, F. A mathematical model of air curtain and air flow and heat transfer in vertical multi-shelf display cabinet. Fluid Mach. 2001, 2, 50–52. [Google Scholar]

- Stribling, D.; Tassou, S. A two-dimensional CFD model of a refrigerated display case. Ashrae Trans 1997, 104, 88–94. [Google Scholar]

- Foster, A.M.; Swain, M.J.; Barrett, R.; D’agaro, P.; James, S.J. Effectiveness and optimum jet velocity for a plane jet air curtain used to restrict cold room infiltration. Int. J. Refrig. 2006, 29, 692–699. [Google Scholar] [CrossRef]

- Rossetti, A.; Minettoo, S.; Marinetti, S. Numerical modelling and validation of the air flow maldistribution in the cooling duct of a horizontal display cabinet. Appl. Therm. Eng. 2015, 87, 24–33. [Google Scholar] [CrossRef]

- Zhen, B.; Wang, L. Optimization of design parameters of air outlets for horizontal open food refrigerated display cabinets. Sci. Technol. Food Ind. 2016, 37, 273–276. (In Chinese) [Google Scholar]

- Wu, X.; Chang, Z.; Yuan, P.; Lu, Y.; Ma, Q.; Yin, X. The optimization and effect of back panel structure on the performance of refrigerated display cabinet. Food Control 2014, 40, 278–285. [Google Scholar] [CrossRef]

- Jouhara, H.; Nannou, T.; Ghazal, H.; Kayyali, R.; Tassou, S.; Lester, S. Temperature and energy performance of open refrigerated display cabinets using heat pipe shelve. Enegry Procedia 2017, 123, 273–280. [Google Scholar] [CrossRef]

- Sun, J.; Tsamos, K.M.; Tassou, S.A. CFD comparisons of open type refrigerated display cabinets with without air guiding strips. Energy Procedia 2017, 123, 54–61. [Google Scholar] [CrossRef]

- Li, W. Study on Cold Storage and Heat Transfer Characteristics of a Composite Shelf Filled with Phase Change Materials. Ph.D. Thesis, Zhengzhou Institute of Light Industry, Zhengzhou, China, 2016. [Google Scholar]

- Lu, Y.L.; Zhang, W.H.; Yuan, P.; Xue, M.D.; Qu, Z.G.; Tao, W.Q. Experimental study of heat transfer intensification by using a novel combined shelf in food refrigerated display cabinets (Experimental study of a novel cabinets). Appl. Therm. Eng. 2010, 30, 85–91. [Google Scholar] [CrossRef]

- Feng, X.; Chen, J.; Mu, J. CFD optimization of double air Curtain in vertical display cabinet. J. Refrig. 2001, 2, 32–36. [Google Scholar]

- Axell, M.; Fahlen, P. Design Criteria for Energy Efficient Vertical Air Curtains in Display Cabinets. In Proceedings of the 21st International Congress of Refrigeration, Washington, DC, USA, 17–22 August 2003; International Institute of Refrigeration: Paris, France, 2003. [Google Scholar]

- Guo, Y.; Lu, S. Introduction to Fluid Mechanics; Science Press: Beijing, China, 2016. [Google Scholar]

- Li, Y.; Xue, W.; Jin, J.; Hu, J.; Qiu, Y.; Tao, F. Current status and development trend of cold chain logistics for pork of Hangzhou. J. Food Saf. Qual. 2017, 8, 1757–1762. [Google Scholar]

- Kang, H.; Xiao, H. The economic impacts of recent pork price increase in China caused by the African swine fever. Res. Agric. Mod. 2020, 41, 493–501. [Google Scholar]

- Cheng, X.; Liu, S. SWOT analysis of imported meat cold chain logistics development environment in Xi’an international land port. Econ. Res. Guide 2017, 315, 175–176. [Google Scholar]

- Xie, R.; Tang, H.; Tao, W.; Liu, G.; Liu, K.; Wu, J. Optimization of cold-plate location in refrigerated vehicles based on simulation and test of no-load temperature field. Trans. Chin. Soc. Agric. Eng. 2017, 33, 290–298, (In Chinese with English Abstract). [Google Scholar]

- Zeng, Z.; Wei, X.; Lü, E.; Liu, Y.; Yi, Z.; Guo, J. Numerical simulation and experimental verification of temperature and humidity in centralized ventilated delivery pigsty. Trans. Chin. Soc. Agric. Eng. 2020, 36, 210–217, (In Chinese with English Abstract). [Google Scholar]

- Chaomuang, N.; Flick, D.; Denis, A.; Laguerre, O. Influence of operating conditions on the temperature performance of a closed refrigerated display cabinet. Int. J. Refrig. 2019, 103, 32–41. [Google Scholar] [CrossRef]

- Evans, J.A.; Swain MV, L. Performance of retail and commercial refrigeration systems. In Proceedings of the IIR International Cold Chain Conference, Cambridge, UK, 29–31 March 2010. [Google Scholar]

- Laguerre, O.; Hoang, M.H.; Osswald, V.; Flick, D. Experimental study of heat transfer and air flow in a refrigerated display cabinet. J. Food Eng. 2012, 113, 310–321. [Google Scholar] [CrossRef]

- Gaspar, P.D.; Gonçalves, L.; Pitarma, R. Detailed CFD modelling of open refrigerated display cabinets. Model Simul. Eng. 2012, 2012, 9. [Google Scholar] [CrossRef]

| Aperture Ratio | 0% | 12.5% | 25% | 50% | 90% |

|---|---|---|---|---|---|

| Non-uniformity coefficient | 3.7 | 4.7 | 4.9 | 4.6 | 4.5 |

| Temperature maintenance coefficient | 0.32 | 0.37 | 0.59 | 0.62 | 0.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, J.; Guo, J.; Wei, X.; Zeng, Z.; Lü, E. Effect of Shelf Aperture Ratio on the Temperature Distribution of an Open Refrigerated Display Cabinet. Appl. Sci. 2022, 12, 10296. https://doi.org/10.3390/app122010296

Xia J, Guo J, Wei X, Zeng Z, Lü E. Effect of Shelf Aperture Ratio on the Temperature Distribution of an Open Refrigerated Display Cabinet. Applied Sciences. 2022; 12(20):10296. https://doi.org/10.3390/app122010296

Chicago/Turabian StyleXia, Jingjing, Jiaming Guo, Xinyu Wei, Zhixiong Zeng, and Enli Lü. 2022. "Effect of Shelf Aperture Ratio on the Temperature Distribution of an Open Refrigerated Display Cabinet" Applied Sciences 12, no. 20: 10296. https://doi.org/10.3390/app122010296

APA StyleXia, J., Guo, J., Wei, X., Zeng, Z., & Lü, E. (2022). Effect of Shelf Aperture Ratio on the Temperature Distribution of an Open Refrigerated Display Cabinet. Applied Sciences, 12(20), 10296. https://doi.org/10.3390/app122010296