Influence of Ion Implantation on the Wear and Lifetime of Circular Saw Blades in Industrial Production of Wooden Door Frames

Abstract

1. Introduction

2. Materials and Methods

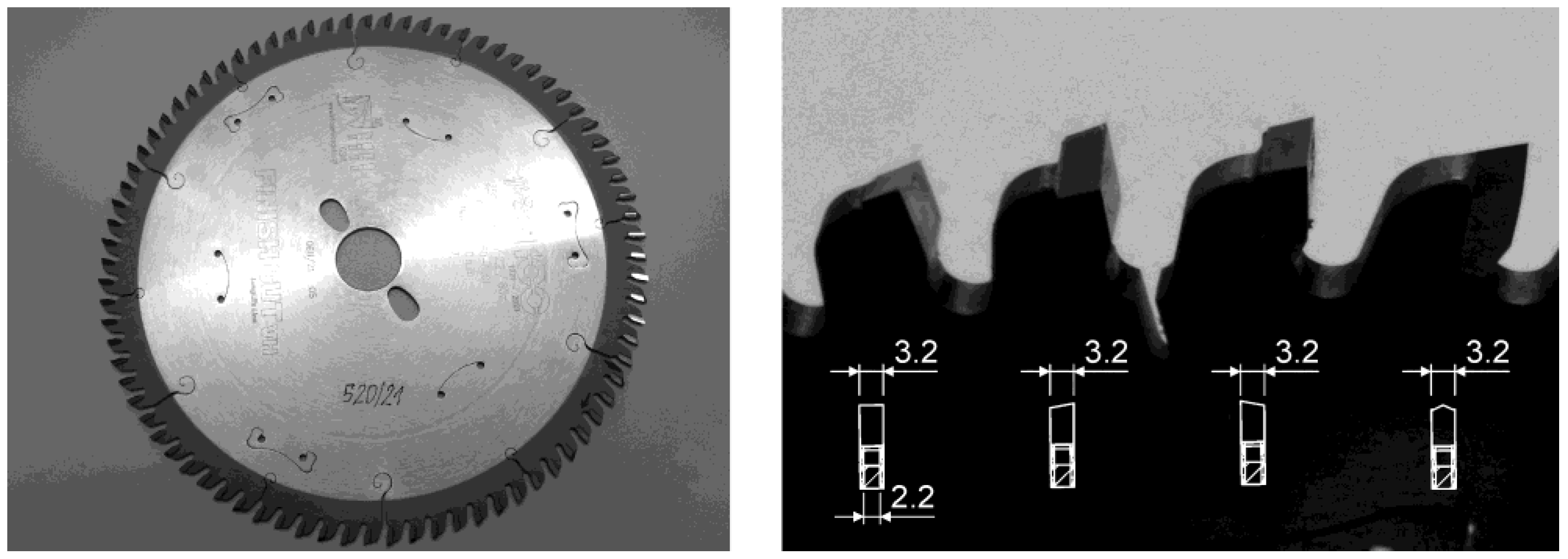

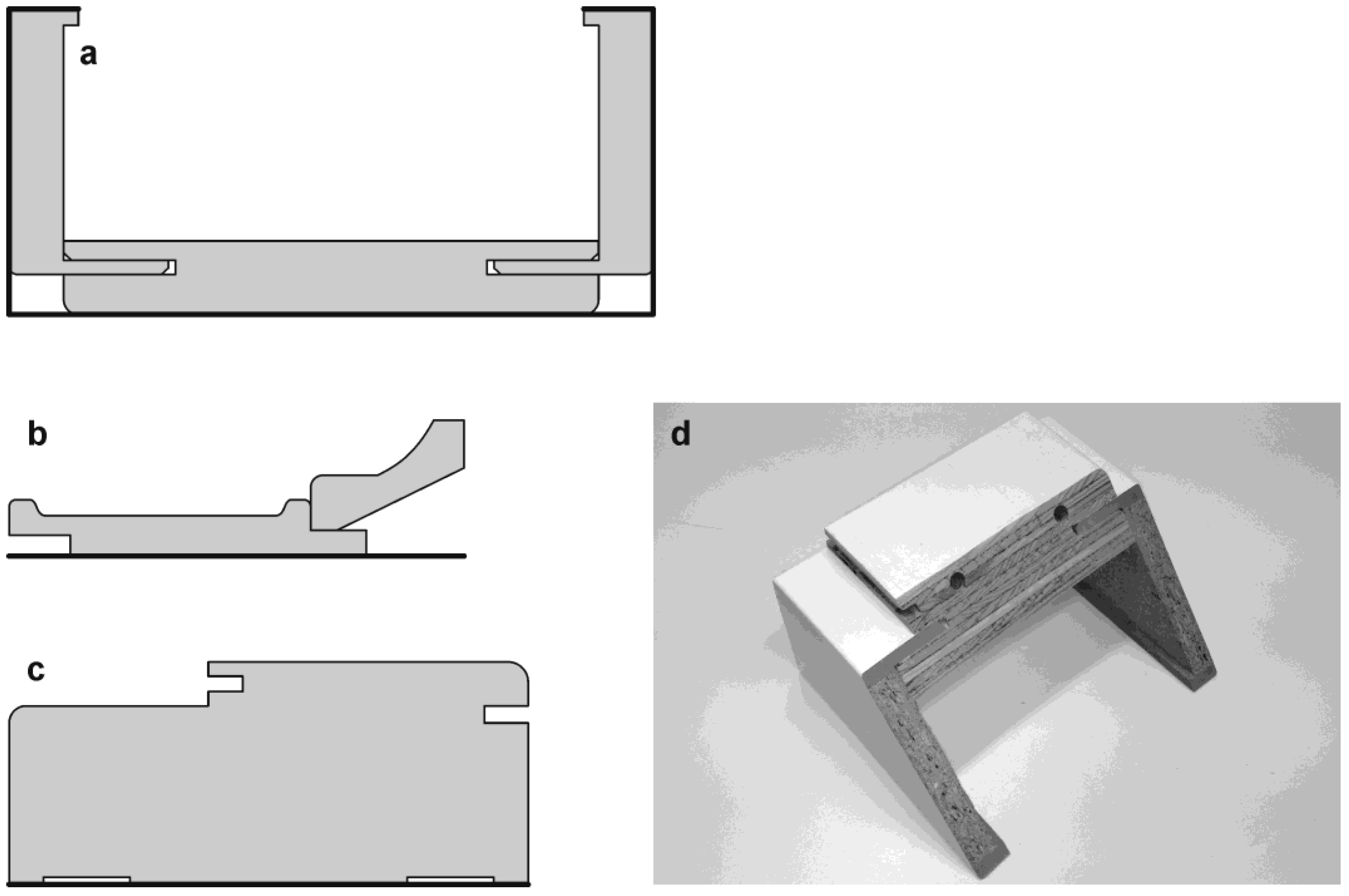

2.1. WC-Co Saw Blades

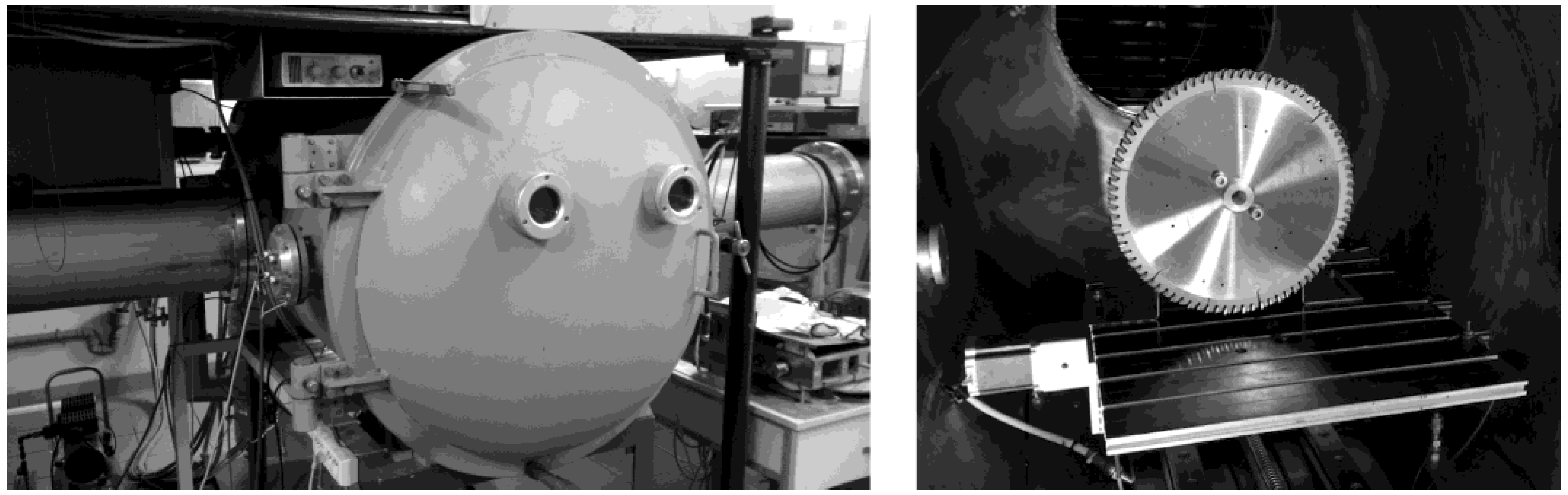

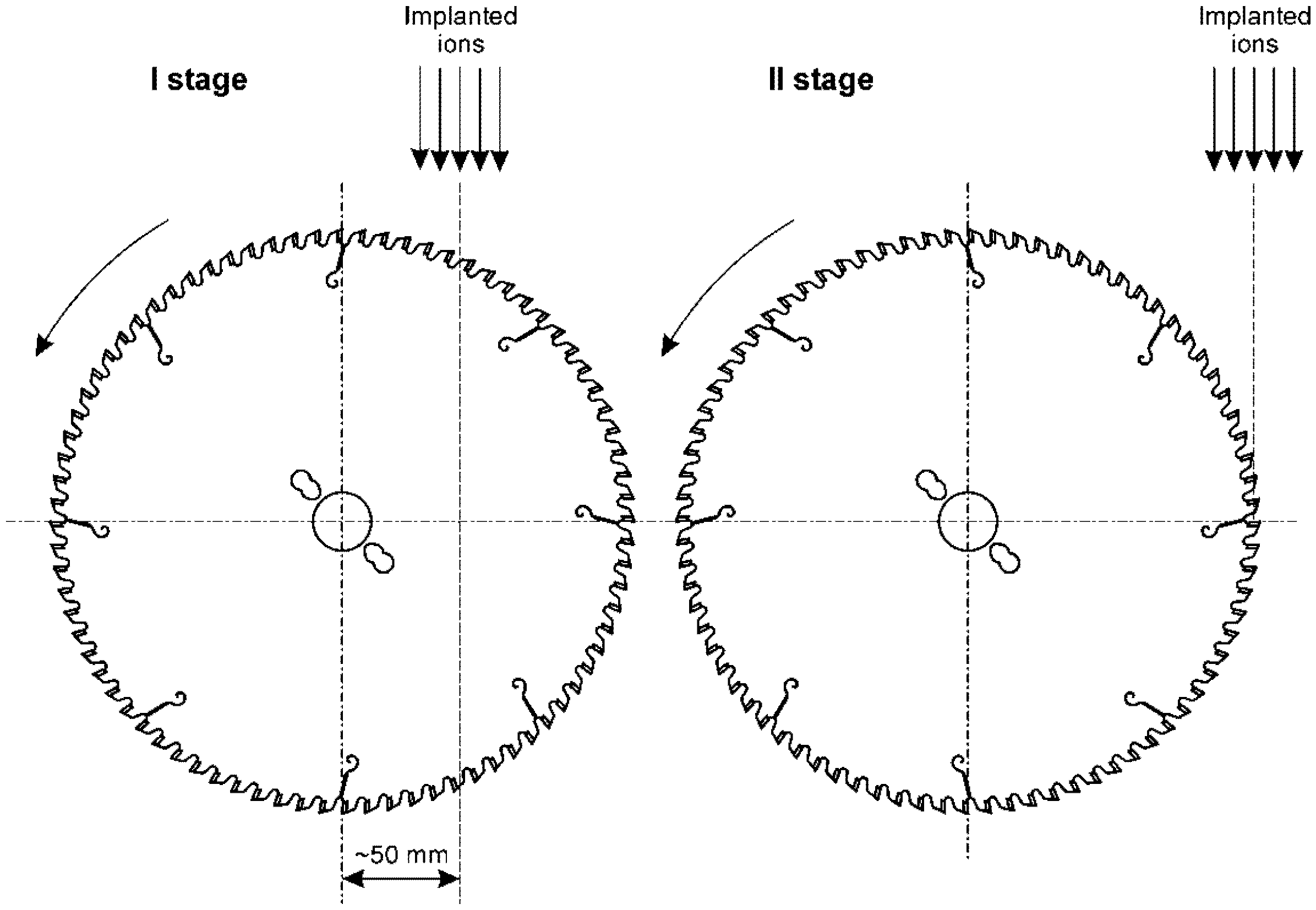

2.2. Nitrogen Ion Implantation

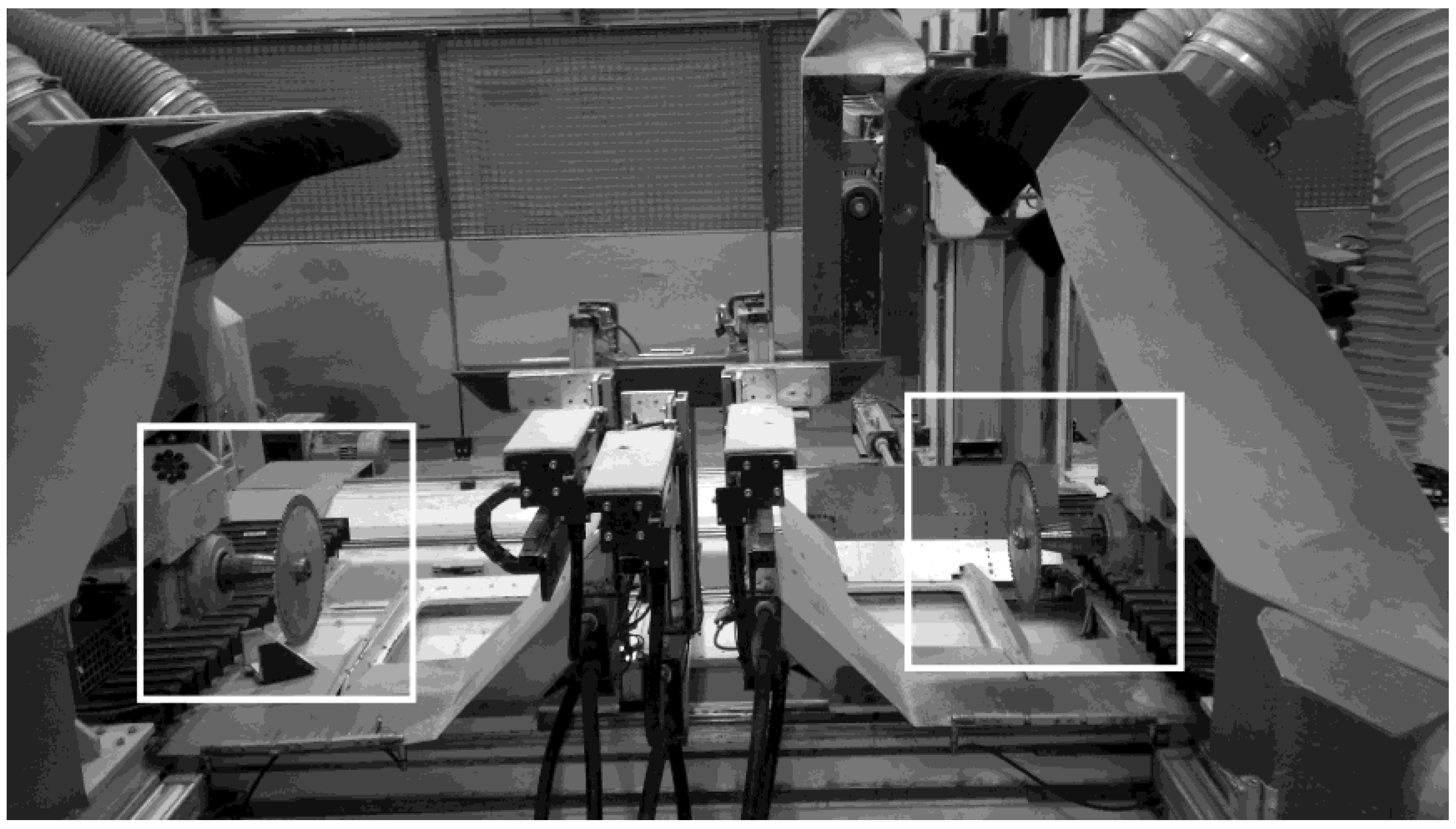

2.3. Industrial Tool Life Tests

2.4. Workpiece

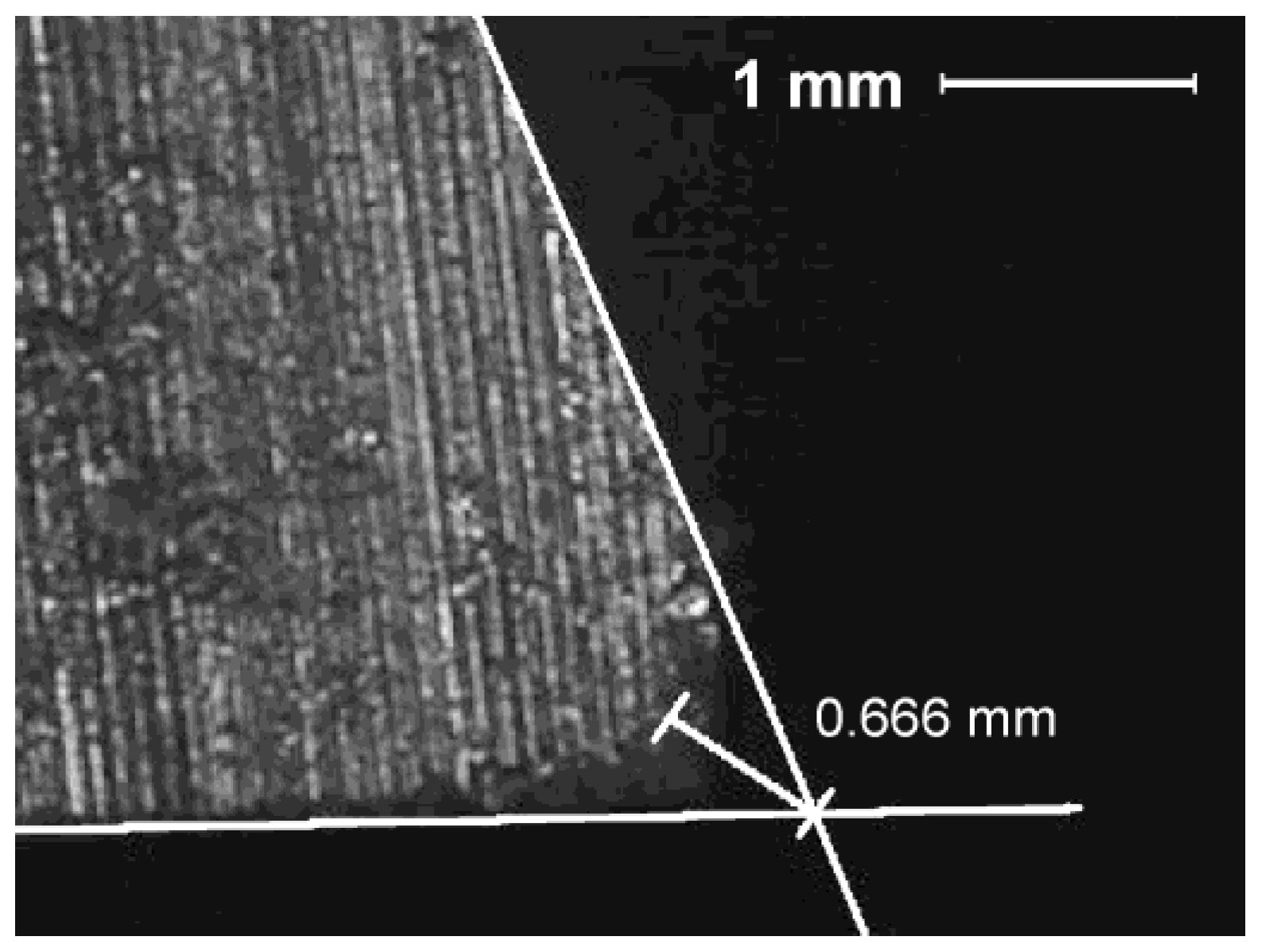

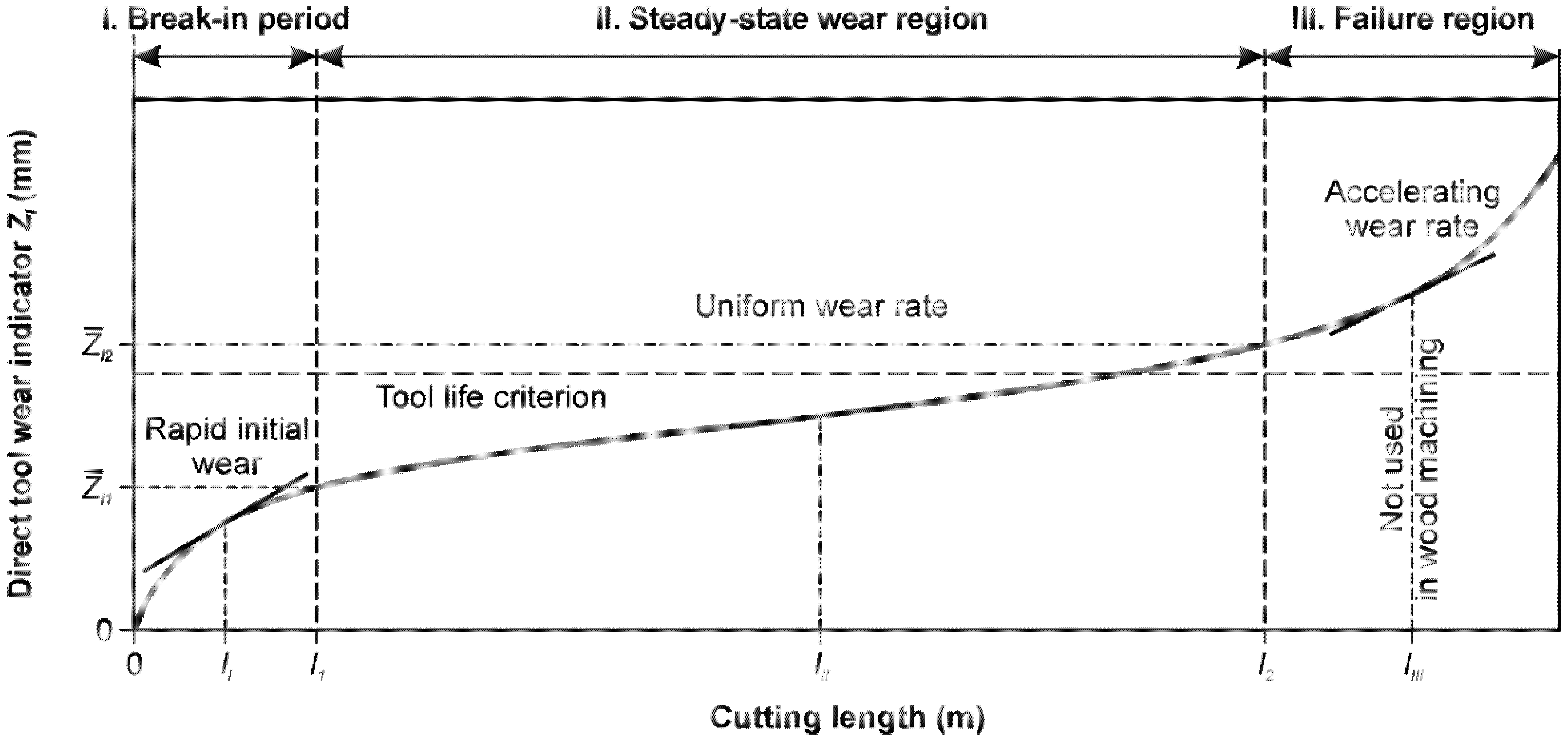

2.5. Tool Wear Measurement and Tool Life Estimation

- —actual wear of a given tooth in (mm),

- —measured wear of a given tooth in (mm),

- —average value of the measured base indicator of new saw teeth in (mm).

- —relative index of tool life,

- —estimated total cutting length of ion-implanted tools in (m),

- —estimated total cutting length of non-treated tools in (m).

2.6. EDS Tests of the Tooth Surface after Machining

3. Results and Discussion

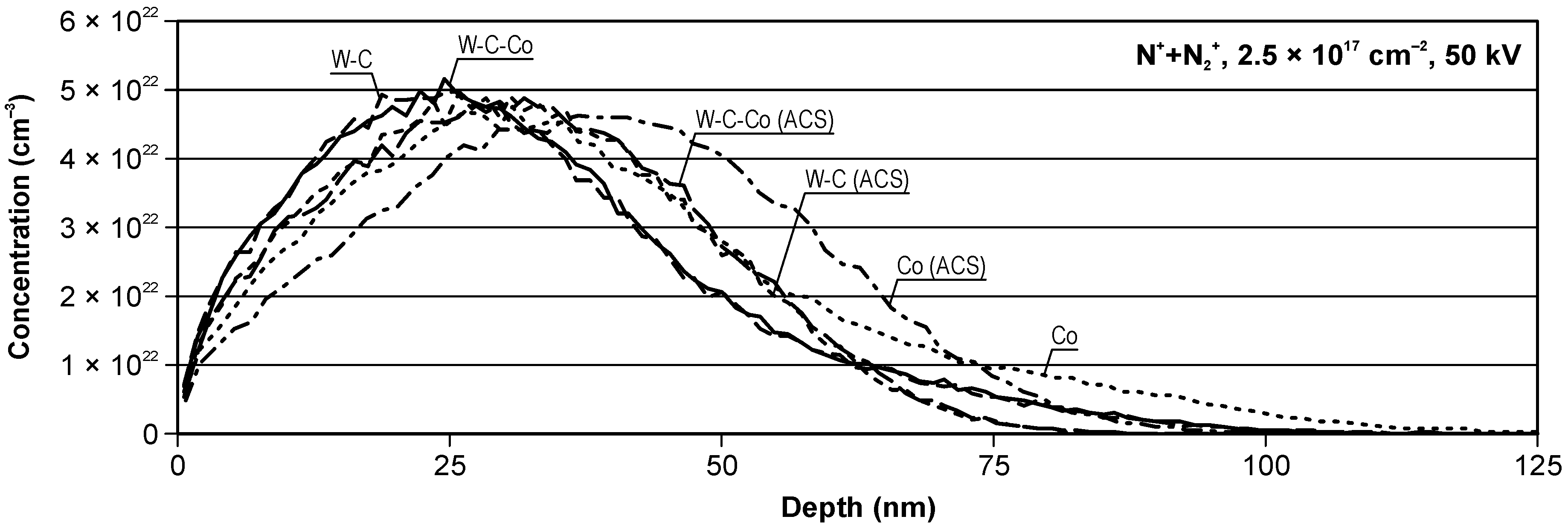

3.1. Results of Modeling Nitrogen Ion Implantation

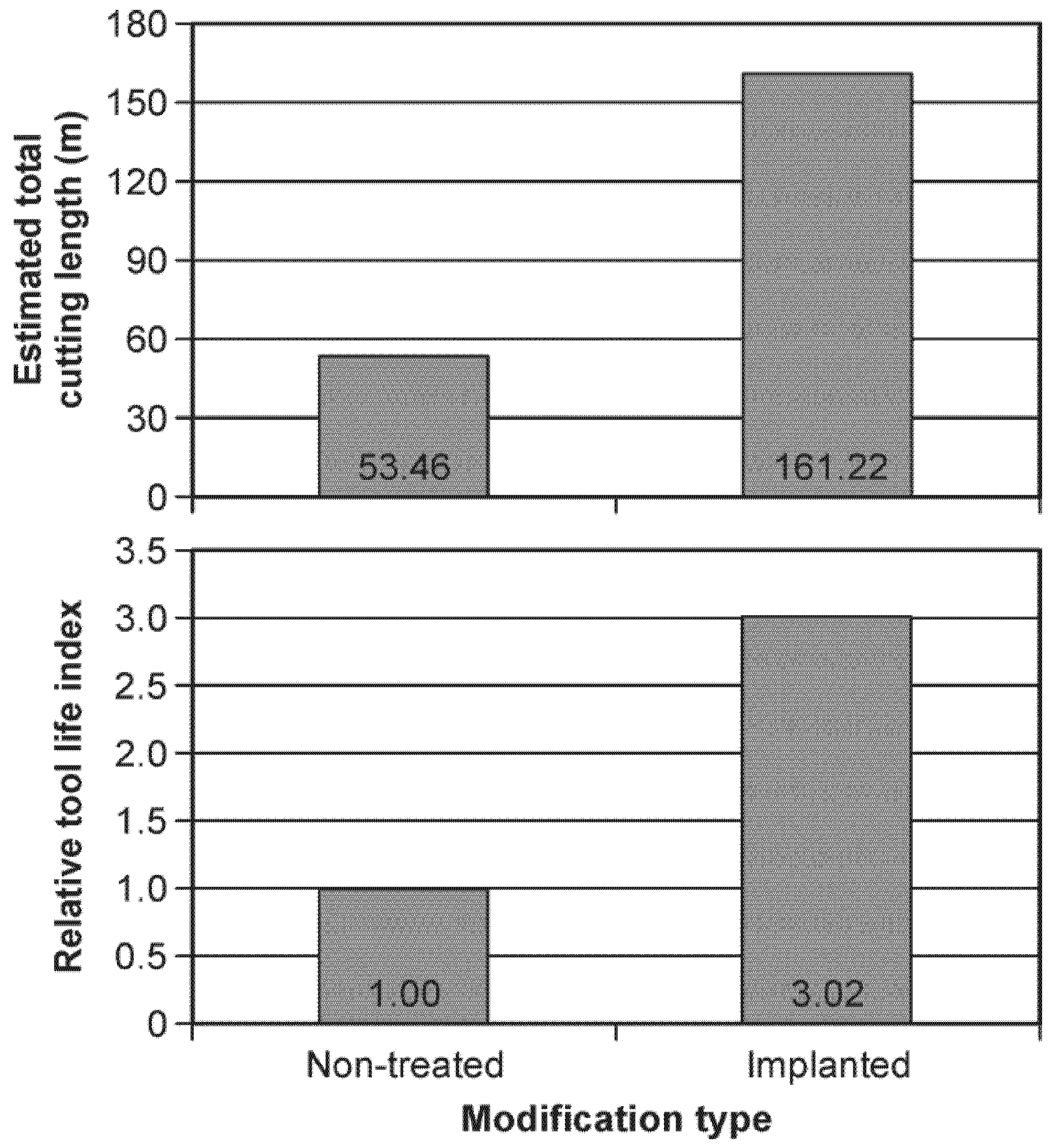

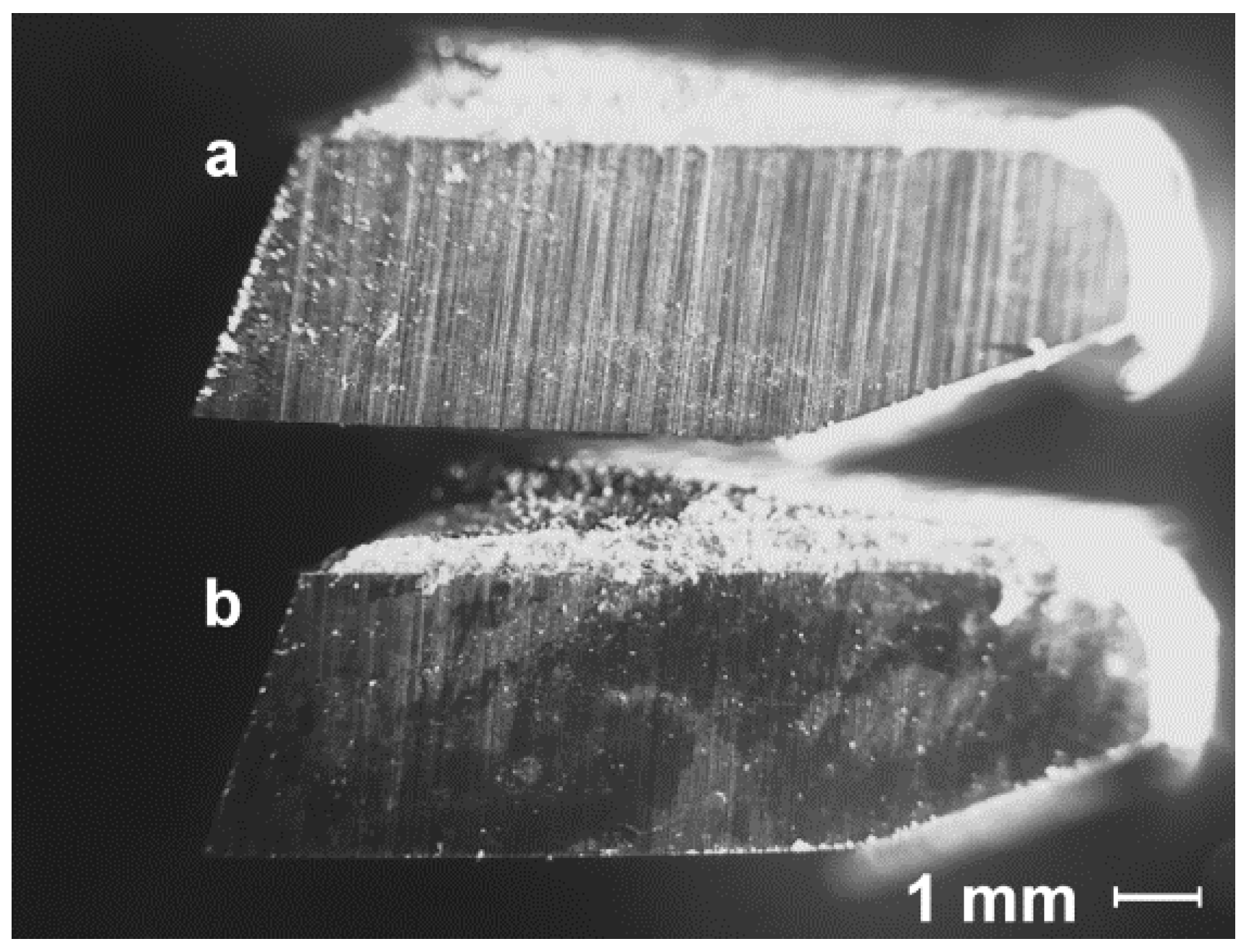

3.2. Wear and Tool Life Analysis

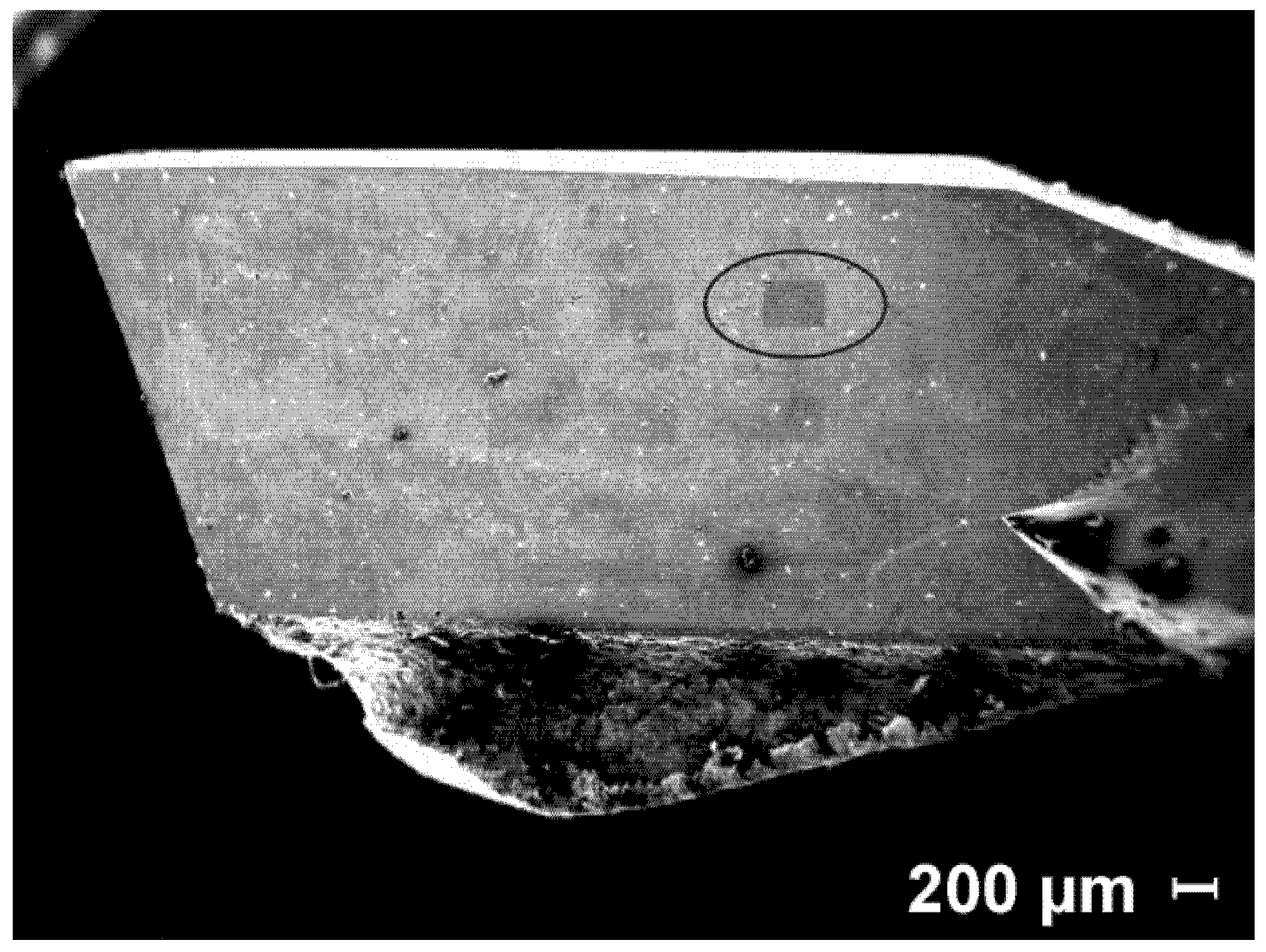

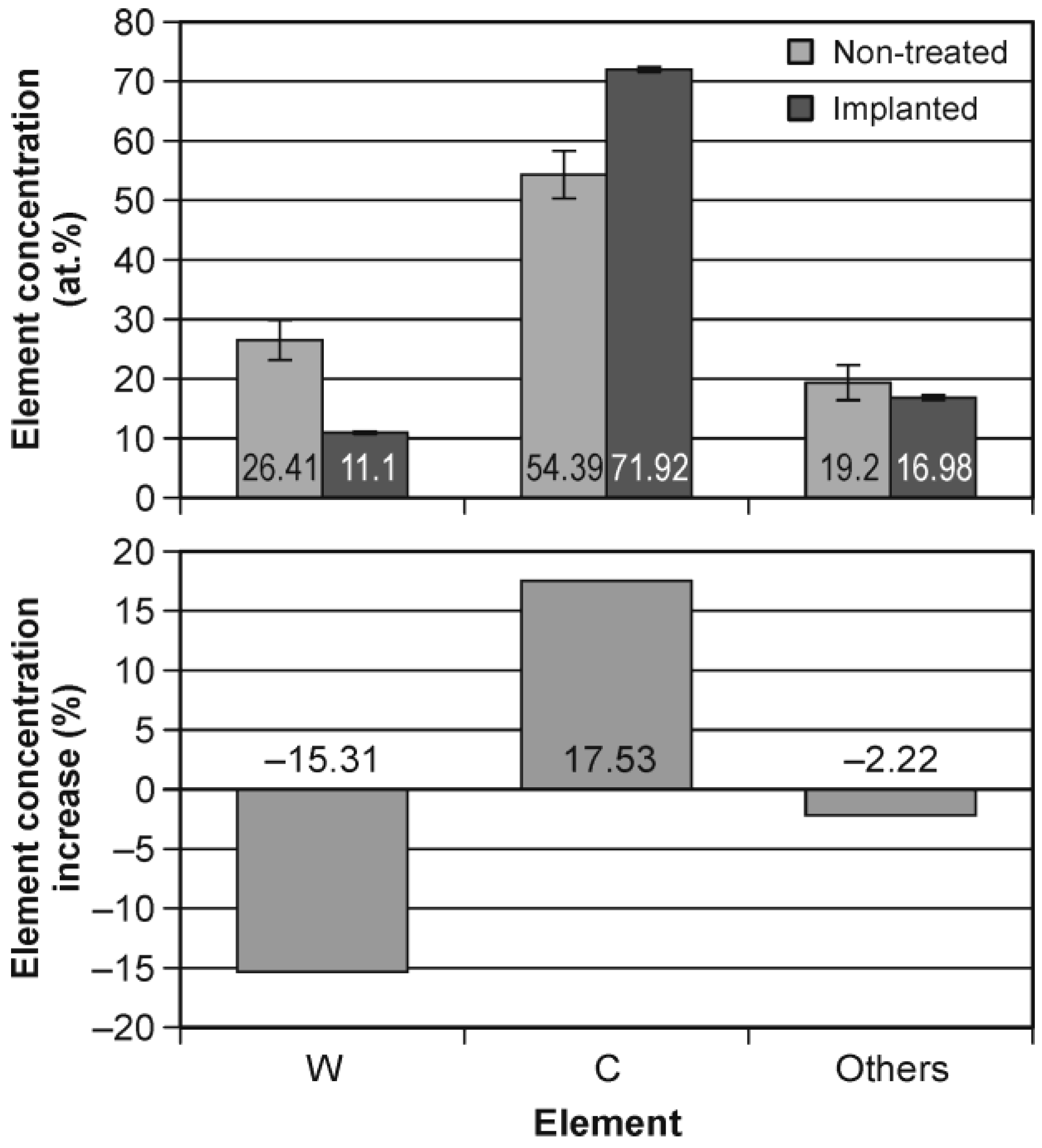

3.3. EDS Analysis

4. Conclusions

- The teeth of circular saw blades made of WC-Co and nitrogen ion-implanted were less worn than the non-treated teeth of circular saw blades in the industrial production of wooden door frames.

- The estimated lifetime, using the linear least squares method, of ion-implanted tools was over three times higher than the lifetime of non-treated tools.

- After tool life tests, secondary structures made of carbon were observed on the surface of ion-implanted tools.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wilkowski, J.; Barlak, M.; Böttger, R.; Werner, Z.; Konarski, P.; Pisarek, M.; Wachowicz, J.; von Borany, J.; Auriga, A. Effect of Nitrogen Ion Implantation on the Life Time of WC-Co Tools Used in Particleboard Milling. Wood Mater. Sci. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Wilkowski, J.; Górski, J. Vibro-Acoustic Signals a Source of Information about Tool Wear during Laminated Chipboard Milling. Wood Res. 2011, 56, 57–66. [Google Scholar]

- Wilkowski, J.; Jegorowa, A.; Barlak, M.; Werner, Z.; Zagórski, J.; Staszkiewicz, B.; Kurek, J.; Kruk, M. Effect of Nitrogen Ion Implantation on the Tool Life Used in Particleboard CNC Drilling. Materials 2022, 15, 3420. [Google Scholar] [CrossRef]

- Wilkowski, J.; Barlak, M.; Werner, Z.; Zagórski, J.; Czarniak, P.; Podziewski, P.; Szymanowski, K. Technical Note: Life-Time Improvement and the Cutting Forces in Nitrogen-Implanted Drills during Wood-Based Material Machining. Wood Fiber Sci. 2019, 51, 209–220. [Google Scholar] [CrossRef]

- Wilkowski, J.; Barlak, M. The Lifetime of Cemented Carbide Blades during Wood-Based Panels Milling. Biul. Inf. OB-RPPD 2018, 3–4, 118–128. [Google Scholar] [CrossRef]

- Zhu, Z.; Guo, X.; Ekevad, M.; Cao, P.; Na, B.; Zhu, N. The Effects of Cutting Parameters and Tool Geometry on Cutting Forces and Tool Wear in Milling High-Density Fiberboard with Ceramic Cutting Tools. Int. J. Adv. Manuf. Technol. 2017, 91, 4033–4041. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Barlak, M.; Wilkowski, J.; Werner, Z. Ion Implantation Changes of Tribological and Corrosion Resistance Properties of Materials Used in Wood Industry. Ann. WULS. For. Wood Technol. 2016, 94, 19–27. [Google Scholar]

- Labidi, C.; Collet, R.; Nouveau, C.; Beer, P.; Nicosia, S.; Djouadi, M.A. Surface Treatments of Tools Used in Industrial Wood Machining. Surf. Coat. Technol. 2005, 200, 118–122. [Google Scholar] [CrossRef]

- Warcholiński, B.; Gilewicz, A.; Szymański, W.; Pinkowski, G.; Olik, R. Improvment of Durability of Engineering Tools for Wood. Inżynieria Powierzchni 2011, 2, 73–80. [Google Scholar]

- Djouadi, M.A.; Beer, P.; Marchal, R.; Sokolowska, A.; Lambertin, M.; Precht, W.; Nouveau, C. Antiabrasive Coatings: Application for Wood Processing. Surf. Coat. Technol. 1999, 116–119, 508–516. [Google Scholar] [CrossRef]

- Barlak, M.; Piekoszewski, J.; Werner, Z.; Pakiela, Z.; Sartowska, B.; Składnik-Sadowska, E.; Walis, L.; Kierzek, J.; Starosta, W.; Kolitsch, A.; et al. The Influence of Distribution of Titanium Alloyed into Carbon Ceramics by the Intense Plasma Pulses on Their Surface Wettability with Liquid Copper. Vacuum 2009, 83, 81–85. [Google Scholar] [CrossRef]

- Nowakowska-Langier, K.; Chodun, R.; Nietubyc, R.; Minikayev, R.; Zdunek, K. Dependence of the Specific Features of Two PAPVD Methods: Impulse Plasma Deposition (IPD) and Pulsed Magnetron Sputtering (PMS) on the Structure of Fe-Cu Alloy Layers. Appl. Surf. Sci. 2013, 275, 14–18. [Google Scholar] [CrossRef]

- Werner, Z.; Barlak, M.; Ratajczak, R.; Konarski, P.; Markov, A.M.; Heller, R. Electron-Beam Pulse Annealed Ti-Implanted GaP. J. Appl. Phys. 2016, 120, 085103. [Google Scholar] [CrossRef]

- Chodun, R.; Nowakowska-Langier, K.; Wicher, B.; Okrasa, S.; Kwiatkowski, R.; Zaloga, D.; Dypa, M.; Zdunek, K. The State of Coating-Substrate Interfacial Region Formed during TiO2 Coating Deposition by Gas Injection Magnetron Sputtering Technique. Surf. Coat. Technol. 2020, 398, 126092. [Google Scholar] [CrossRef]

- Kim, K.; Jeong, H. Steam Condensate Behavior and Heat Transfer Performance on Chromium-Ion-Implanted Metal Surfaces. Int. J. Heat Mass Transf. 2019, 136, 681–691. [Google Scholar] [CrossRef]

- Cherdhirunkorn, B.; Surakulananta, S.; Tangsritrakul, J.; Hall, D.; Intarasiri, S. The Effect of Nitrogen Ion Implantation on the Physical and Dielectric Properties of Cobalt-Doped PZT Ceramics. Results Phys. 2020, 16, 102851. [Google Scholar] [CrossRef]

- Liu, C.X.; Zhang, J.; Lin, S.B.; Yue, Q.Y.; Zheng, R.L.; Guo, J.H. Two-Dimensional Waveguides in Magneto-Optical Glasses Fabricated by Carbon Ion Implantation and Femtosecond Laser Ablation. Opt. Commun. 2021, 495, 127109. [Google Scholar] [CrossRef]

- Kavetskyy, T.; Stebeletska, N.; Borc, J.; Kravtsiv, M.; Graz, K.; Šauša, O.; Švajdlenková, H.; Kleinová, A.; Kiv, A.; Tadeush, O.; et al. Long-Range Effect in Ion-Implanted Polymers. Vacuum 2022, 200, 111038. [Google Scholar] [CrossRef]

- Laput, O.A.; Zuza, D.A.; Vasenina, I.V.; Savkin, K.P.; Kurzina, I.A. Effect of Silver Ion Implantation on Surface Physicochemical Properties of Composite Materials Based on Polylactic Acid and Hydroxyapatite. Vacuum 2020, 175, 109251. [Google Scholar] [CrossRef]

- Wilkowski, J.; Barlak, M. Infinite Life Time of Cutting Tools—Theoretical Considerations in Context of the Relativistic Tribology. Biul. Inf. OB-RPPD 2022, 1–2, 43–58. [Google Scholar] [CrossRef]

- Barlak, M.; Wilkowski, J.; Werner, Z.; Staszkiewicz, B.; Zagórski, J. Increasing Technical Capabilities of the Ion Implanter in Tool Modification Processes. Biul. Inf. OB-RPPD 2022, 1–2, 59–82. [Google Scholar] [CrossRef]

- Barlak, M.; Wilkowski, J.; Werner, Z. Modelling of Nitrogen Implantation Processes into WC-Co Indexable Knives for Wood-Based Material Machining Using Ion Implanters with or without Direct Ion Beam. Ann. WULS For. Wood Technol. 2019, 108, 68–78. [Google Scholar] [CrossRef]

- SRIM. Available online: http://www.srim.org/ (accessed on 28 August 2022).

- SUSPRE. Available online: http://uknibc.co.uk/suspre/ (accessed on 28 August 2022).

- Yeo, S.; Kim, Y. The Enhancement of Wear Resistance for Nitrogen-Implanted Tungsten Carbide. J. Korean Phys. Soc. 2015, 66, 474–477. [Google Scholar] [CrossRef]

- Kupczyk, M.J. Production and Operation of Cutting Tools with Anti-Wear Coatings; Publishing House of Poznań University of Technology: Poznań, Poland, 2009. [Google Scholar]

- Kostetskii, B.I.; Zazimko, O.V. Physicochemical Effect of Environment in Process of Self-Organization of Materials during Friction. Mater. Sci. 1990, 26, 650–656. [Google Scholar] [CrossRef]

- Shpenkov, G.P. Friction Surface Phenomena; Elsevier: Amsterdam, The Netherlands, 1995. [Google Scholar]

- Bakli, B. Surface Phenomena during Adhesion and Friction Interaction; Mashinostroyenie Published House: Moscow, Russia, 1986. [Google Scholar]

- Garunkov, D.N.; Kragelski, I.V. Selective Atomic Transfer. Sci. Discov. Diploma 1968, 41, 52–53. [Google Scholar]

| Acceleration Voltage (kV) | Percentage Charge State Distribution (%) | |

| N2+ | N+ | |

| 67 | 33 | |

| Energy (keV) | ||

| 50 | 25 | 50 |

| Implanted Surface | Peak Volume Dopant Concentration Nmax (cm−3) | Projected Range Rp (nm) | Range Straggling ΔRp (nm) | Skewness | Kurtosis | Sputtering Yield Y (Atoms/Ion) |

|---|---|---|---|---|---|---|

| W-C-Co | 5.17 × 1022 | 31.6 | 37.8 | 0.8574 | 3.6237 | 0.49 |

| (4.89 × 1022) | (31.8) | (32.4) | (0.2732) | (2.5179) | (0.48) | |

| W-C | 4.98 × 1022 | 31.3 | 37.4 | 0.8597 | 3.6271 | 0.48 |

| (4.93 × 1022) | (31.4) | (32) | (0.2936) | (2.5403) | (0.47) | |

| Co | 4.75 × 1022 | 38.1 | 44.8 | 0.826 | 3.4617 | 0.92 |

| (4.63 × 1022) | (38.4) | (36.8) | (0.1878) | (2.5197) | (0.87) |

| Circular Saw Blade | Total Cutting Length (m) | Tool Wear

(mm) |

|---|---|---|

| Non-treated 1 | 131.62 | 0.67 |

| Non-treated 2 | 104.19 | 0.45 |

| Non-treated 3 | 161.32 | 0.48 |

| average | 132.38 | 0.53 |

| Ion-implanted 1 | 131.62 | 0.56 |

| Ion-implanted 2 | 104.19 | 0.45 |

| Ion-implanted 3 | 161.32 | 0.47 |

| average | 132.38 | 0.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilkowski, J.; Barlak, M.; Kwidziński, Z.; Wilczyński, A.; Filipczuk, P.; Pędzik, M.; Drewczyński, M.; Zagórski, J.; Staszkiewicz, B.; Rogoziński, T. Influence of Ion Implantation on the Wear and Lifetime of Circular Saw Blades in Industrial Production of Wooden Door Frames. Appl. Sci. 2022, 12, 10211. https://doi.org/10.3390/app122010211

Wilkowski J, Barlak M, Kwidziński Z, Wilczyński A, Filipczuk P, Pędzik M, Drewczyński M, Zagórski J, Staszkiewicz B, Rogoziński T. Influence of Ion Implantation on the Wear and Lifetime of Circular Saw Blades in Industrial Production of Wooden Door Frames. Applied Sciences. 2022; 12(20):10211. https://doi.org/10.3390/app122010211

Chicago/Turabian StyleWilkowski, Jacek, Marek Barlak, Zdzisław Kwidziński, Adam Wilczyński, Piotr Filipczuk, Marta Pędzik, Marcin Drewczyński, Jerzy Zagórski, Bogdan Staszkiewicz, and Tomasz Rogoziński. 2022. "Influence of Ion Implantation on the Wear and Lifetime of Circular Saw Blades in Industrial Production of Wooden Door Frames" Applied Sciences 12, no. 20: 10211. https://doi.org/10.3390/app122010211

APA StyleWilkowski, J., Barlak, M., Kwidziński, Z., Wilczyński, A., Filipczuk, P., Pędzik, M., Drewczyński, M., Zagórski, J., Staszkiewicz, B., & Rogoziński, T. (2022). Influence of Ion Implantation on the Wear and Lifetime of Circular Saw Blades in Industrial Production of Wooden Door Frames. Applied Sciences, 12(20), 10211. https://doi.org/10.3390/app122010211