Study on the Non-Steady-State Wear Characteristics and Test of the Flow Passage Components of Deep-Sea Mining Pumps

Abstract

:1. Introduction

2. Methods: Modeling and Numerical Calculation Method

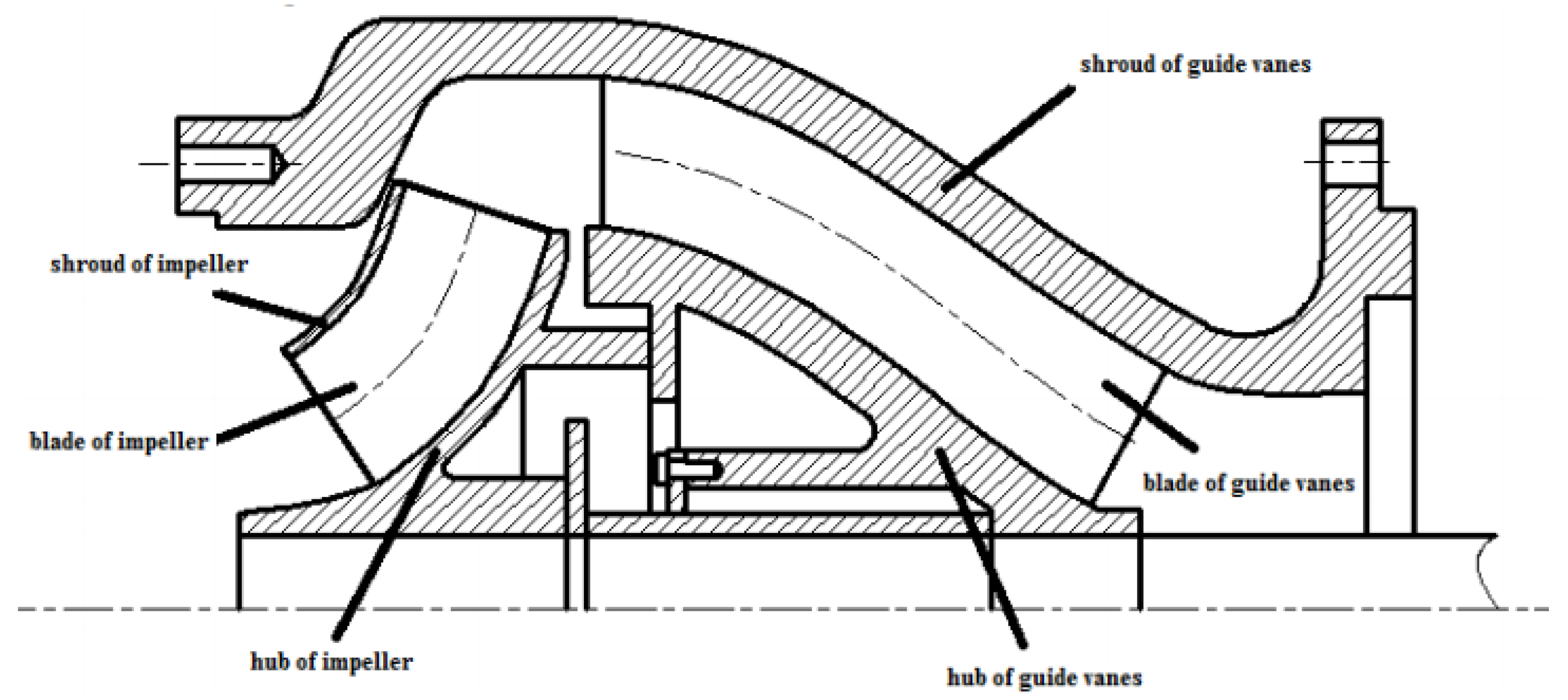

2.1. Three-Dimensional Modeling

2.2. Numerical Calculation Strategy

2.2.1. Numerical Calculation Method

2.2.2. Boundary Conditions

2.3. Selection of the Wear Model

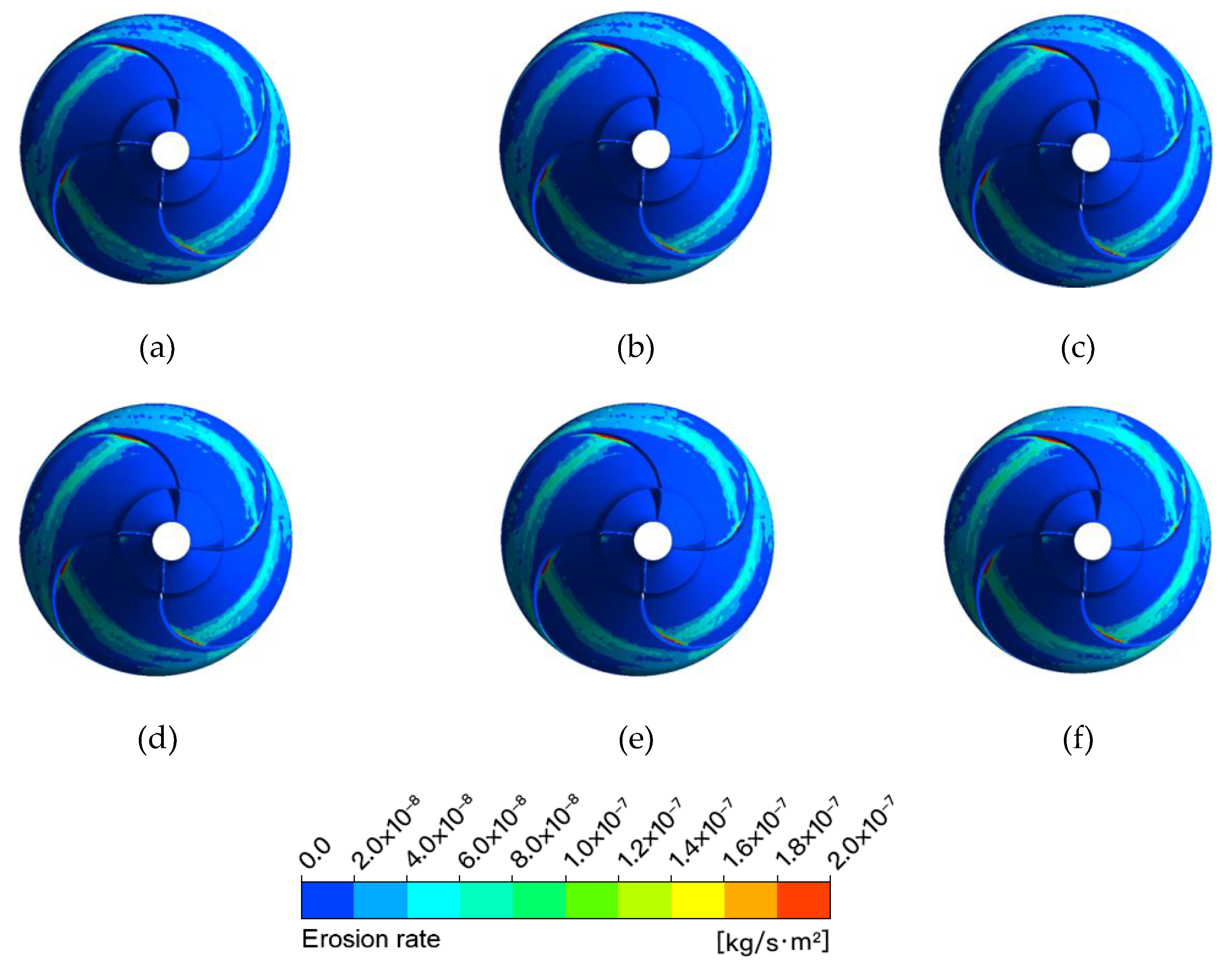

3. Results: Analysis of the Non-Steady-State Wear

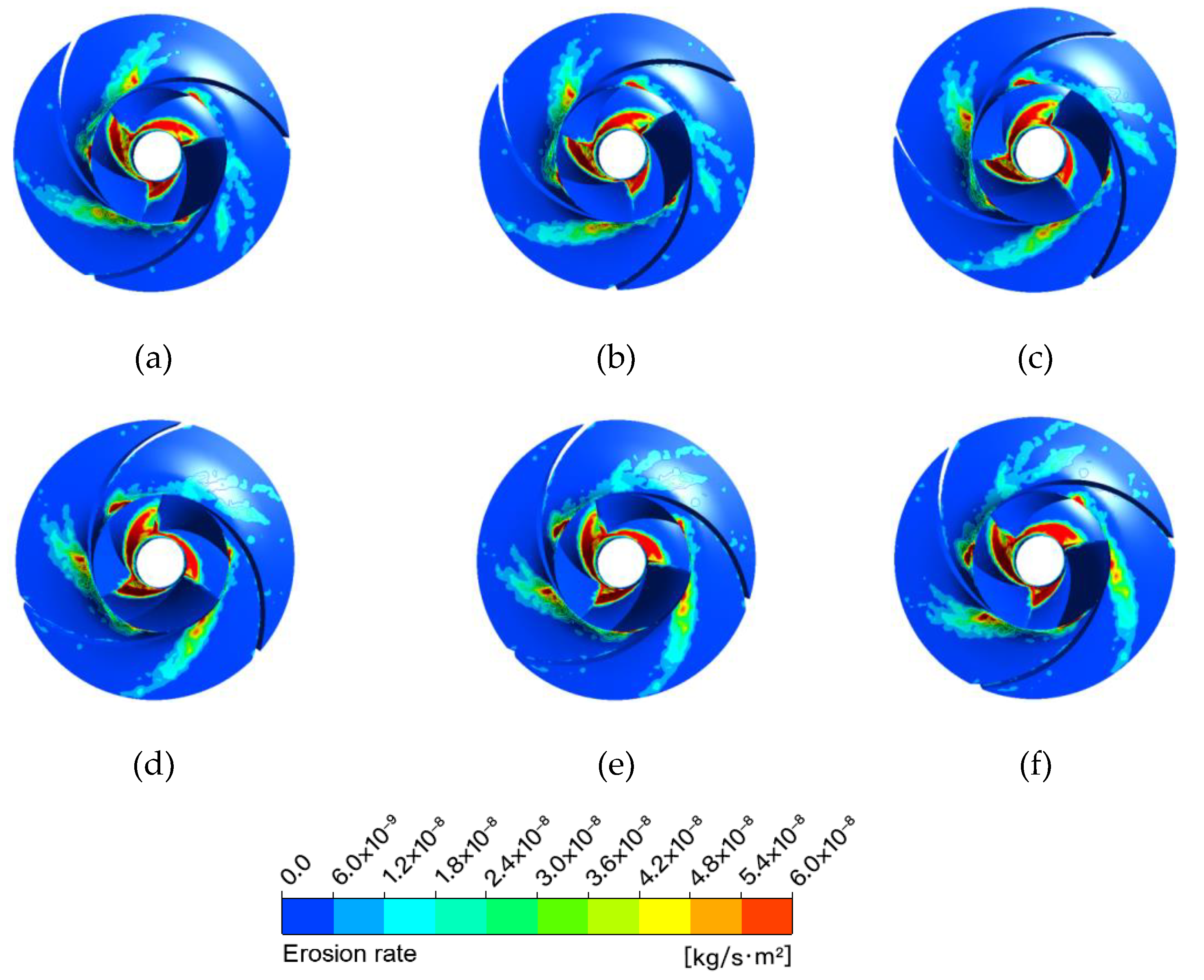

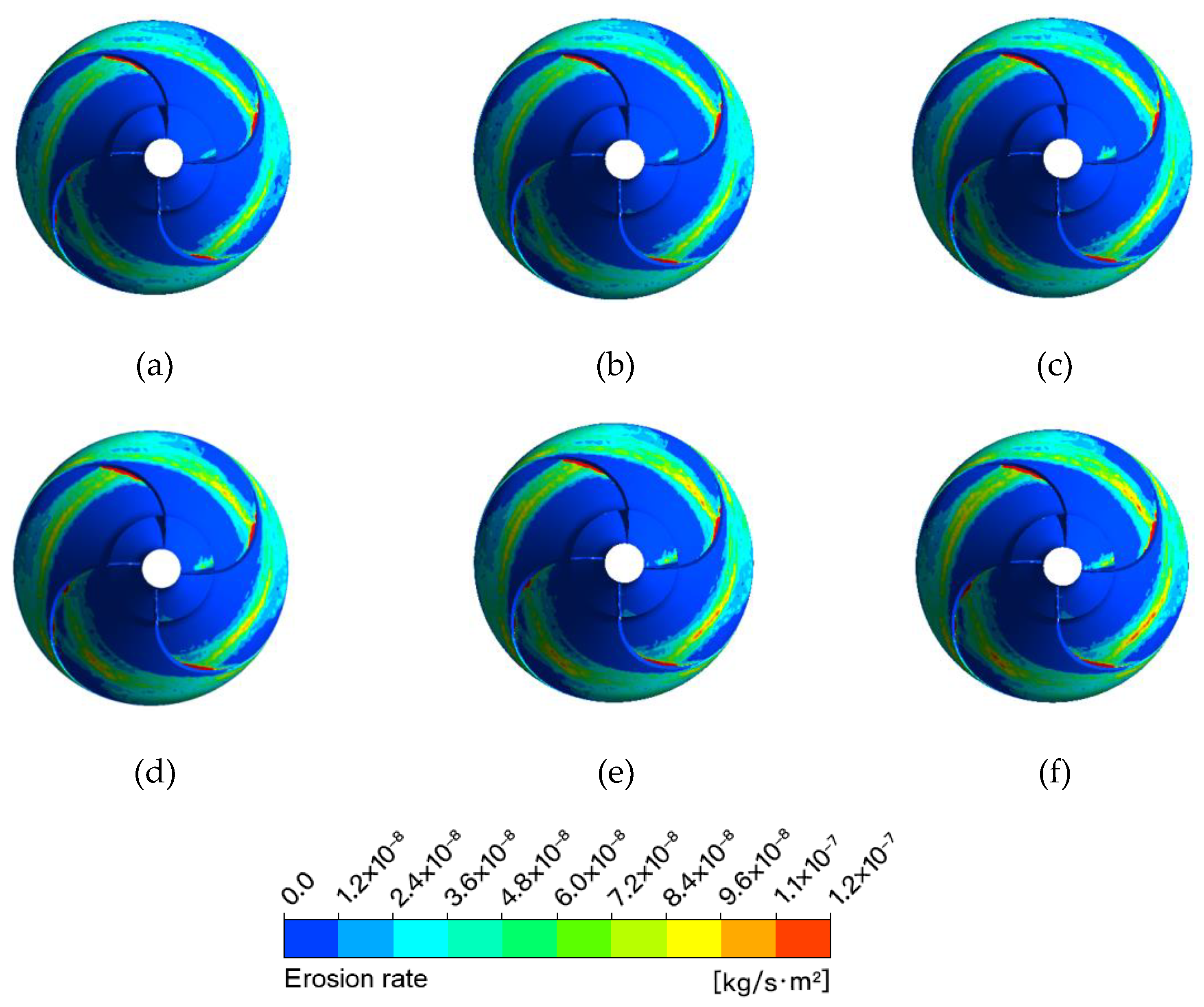

3.1. Low Flow Rate Condition

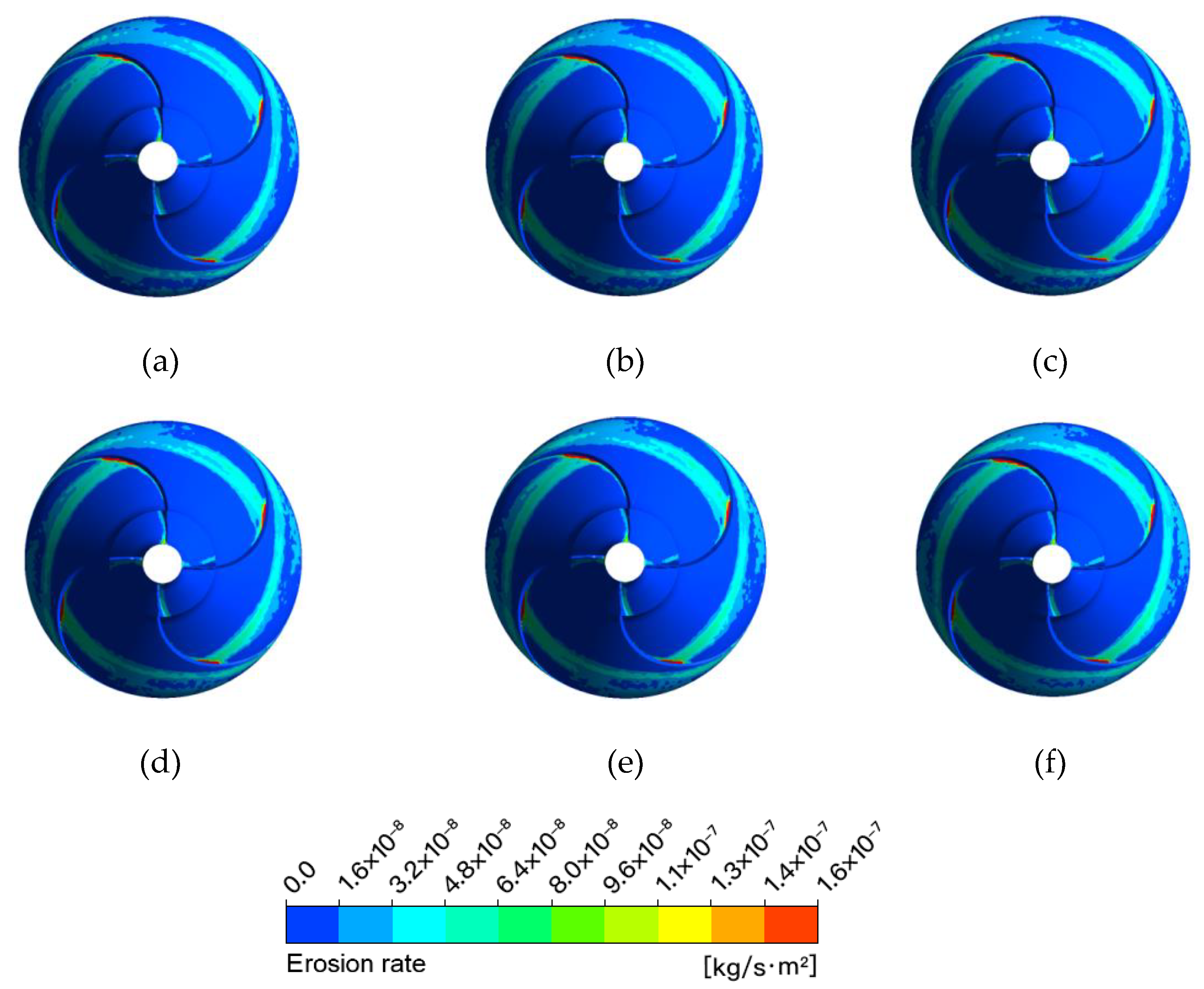

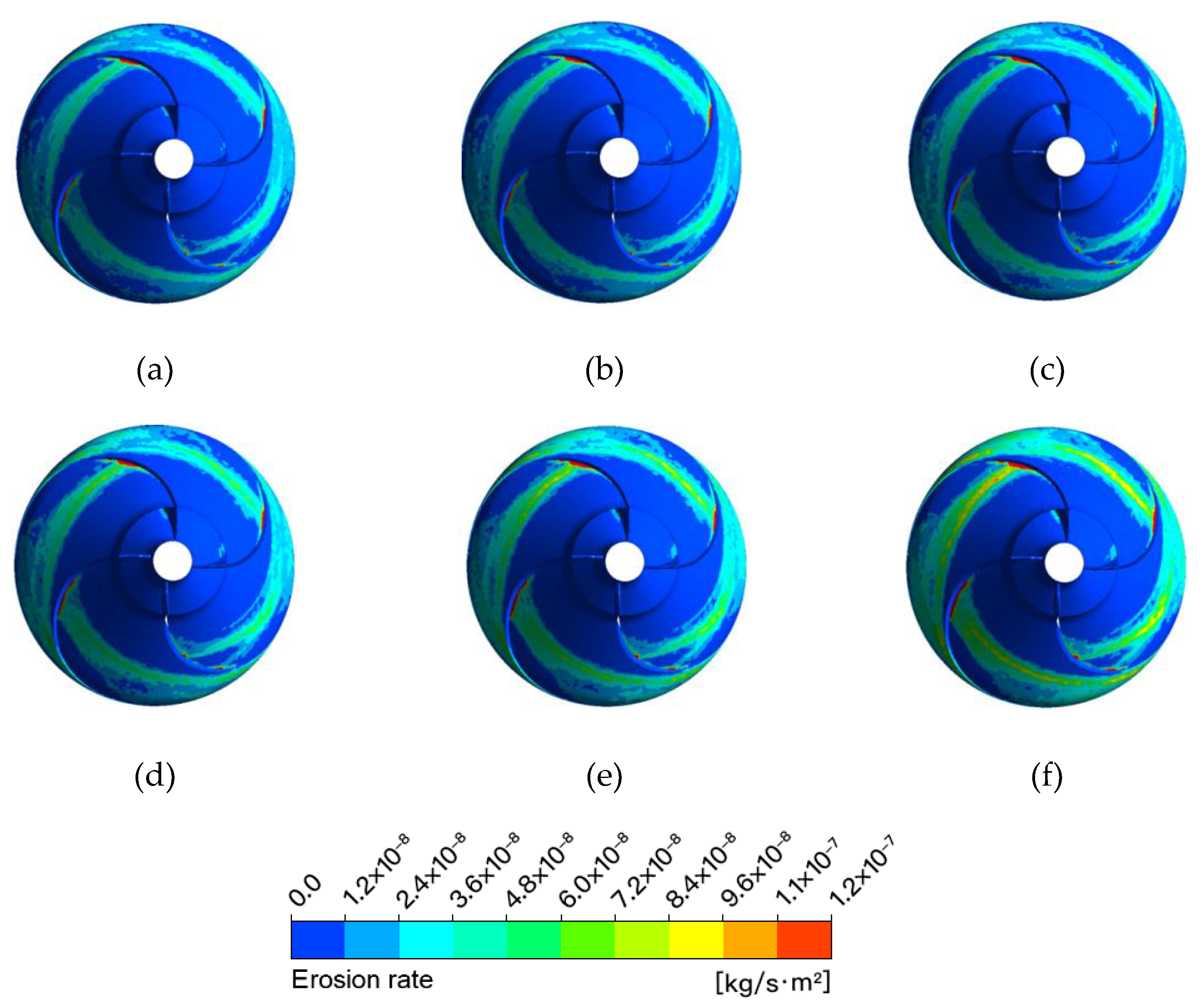

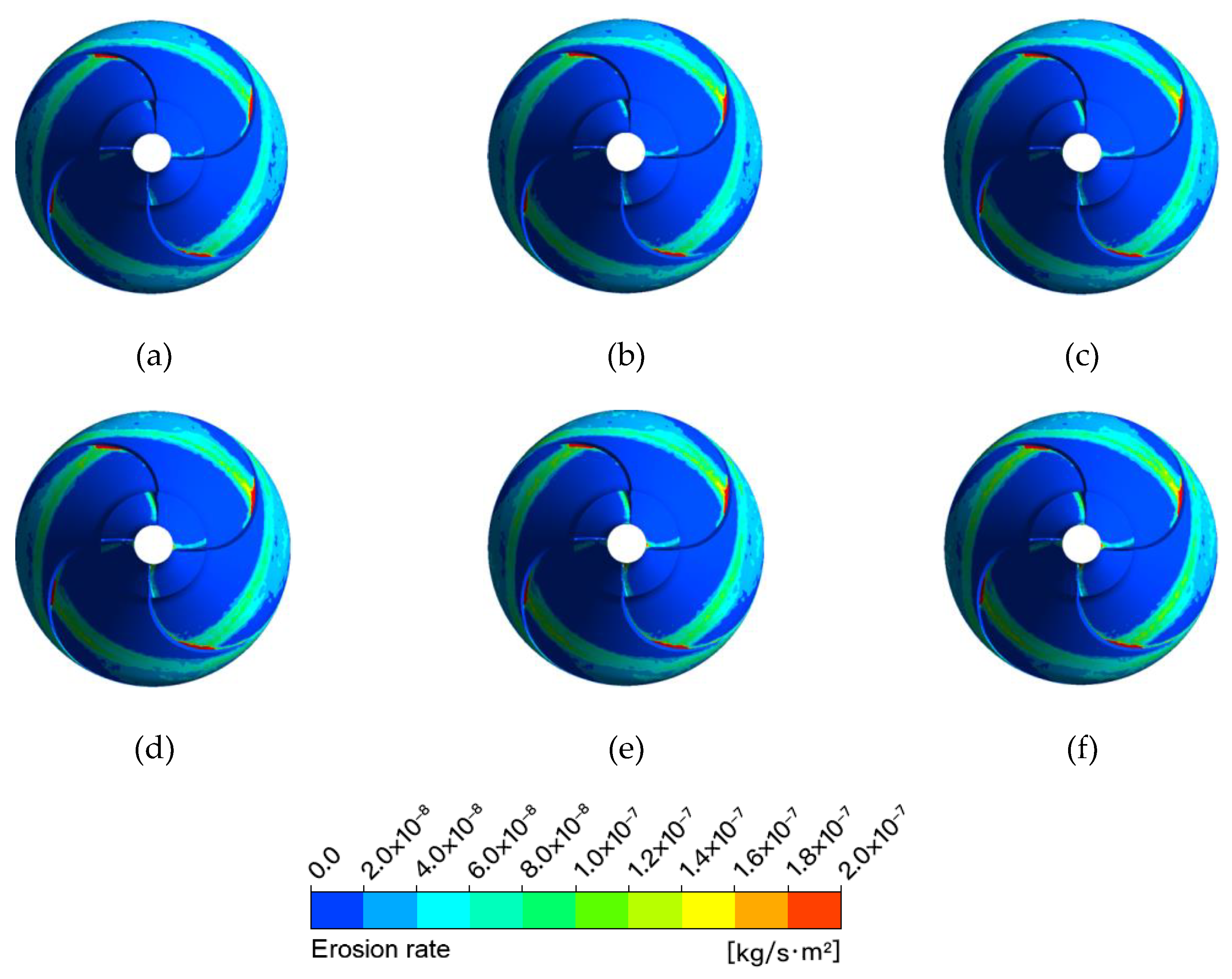

3.2. Design Flow Rate Conditions

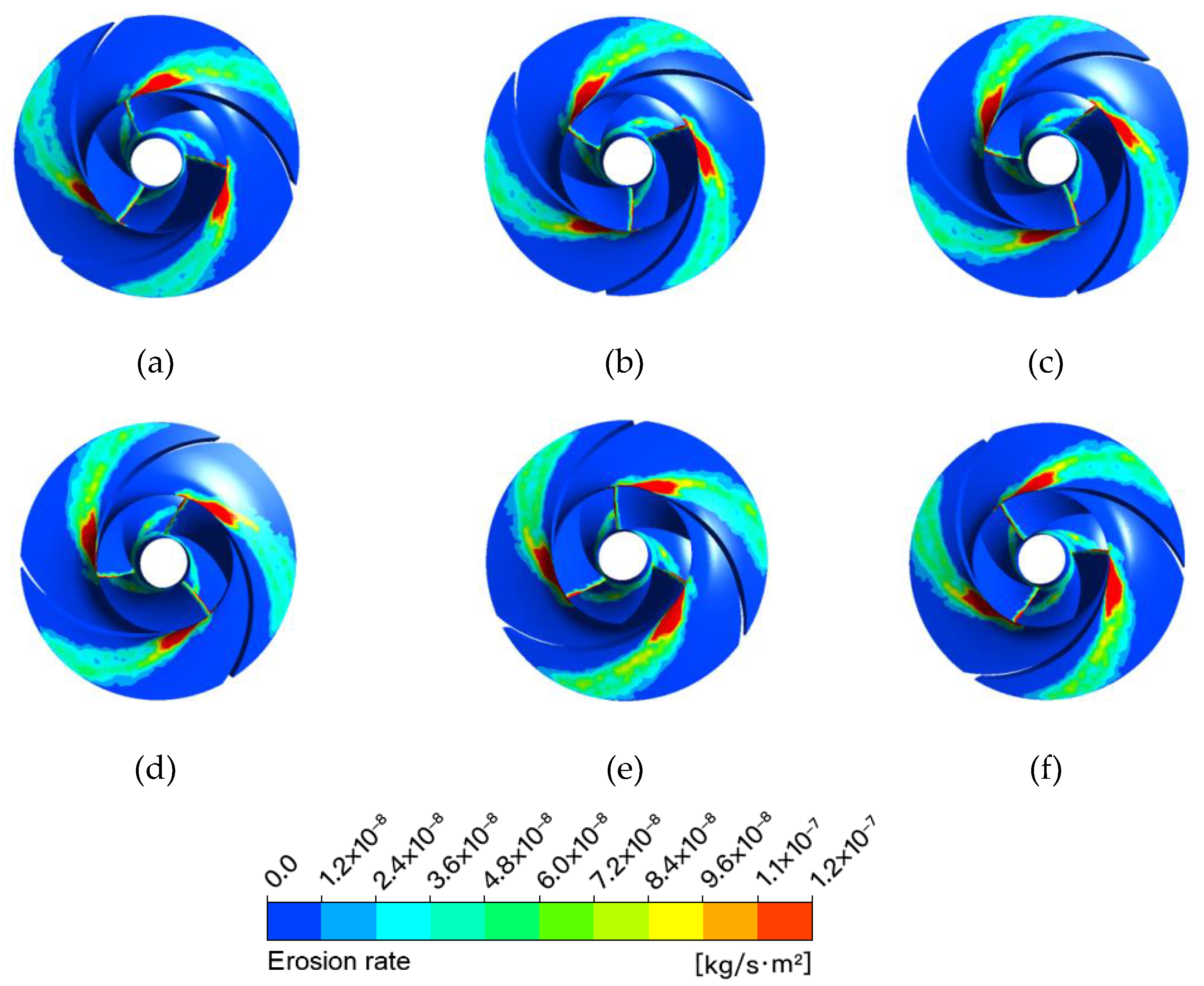

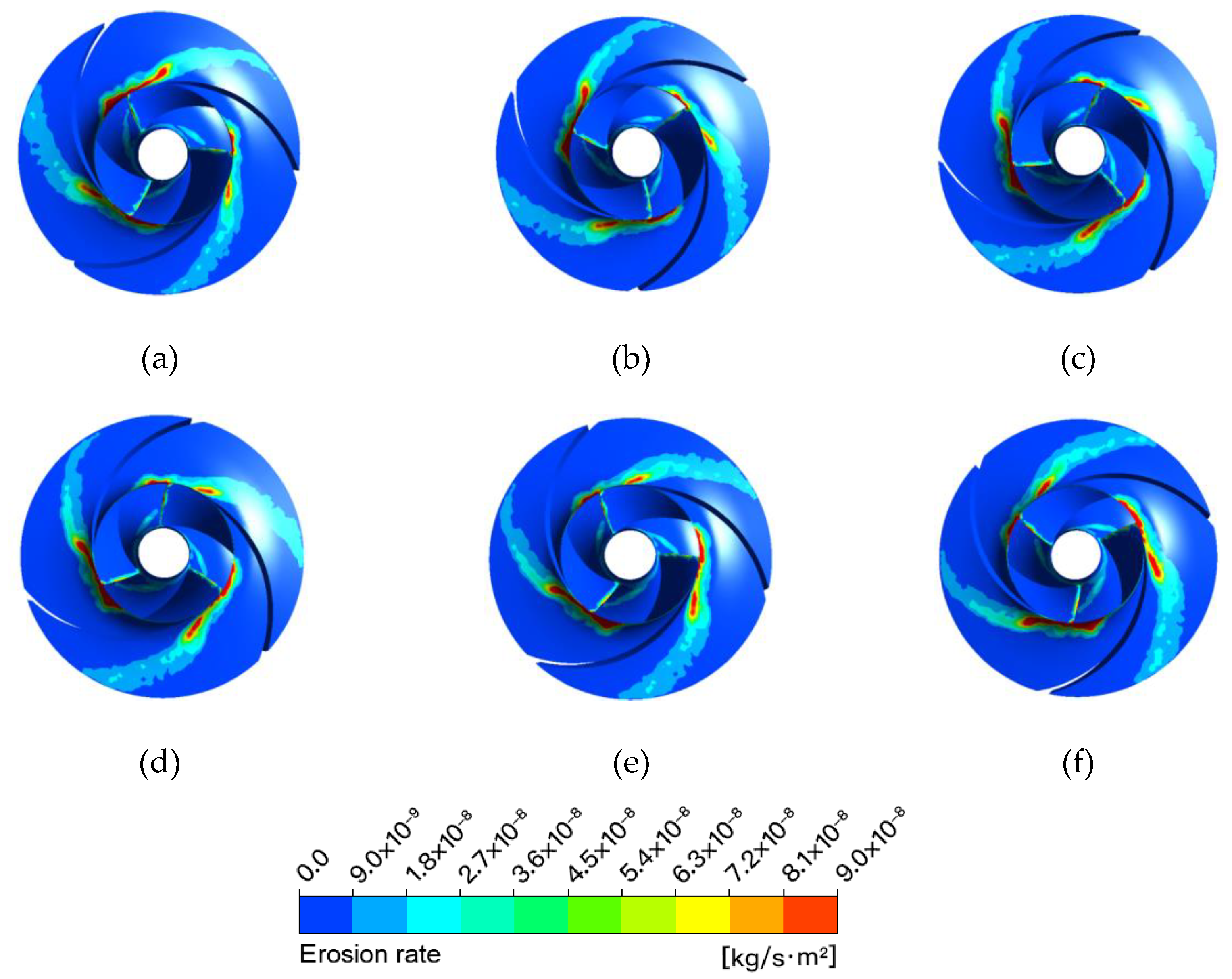

3.3. High Flow Rate Condition

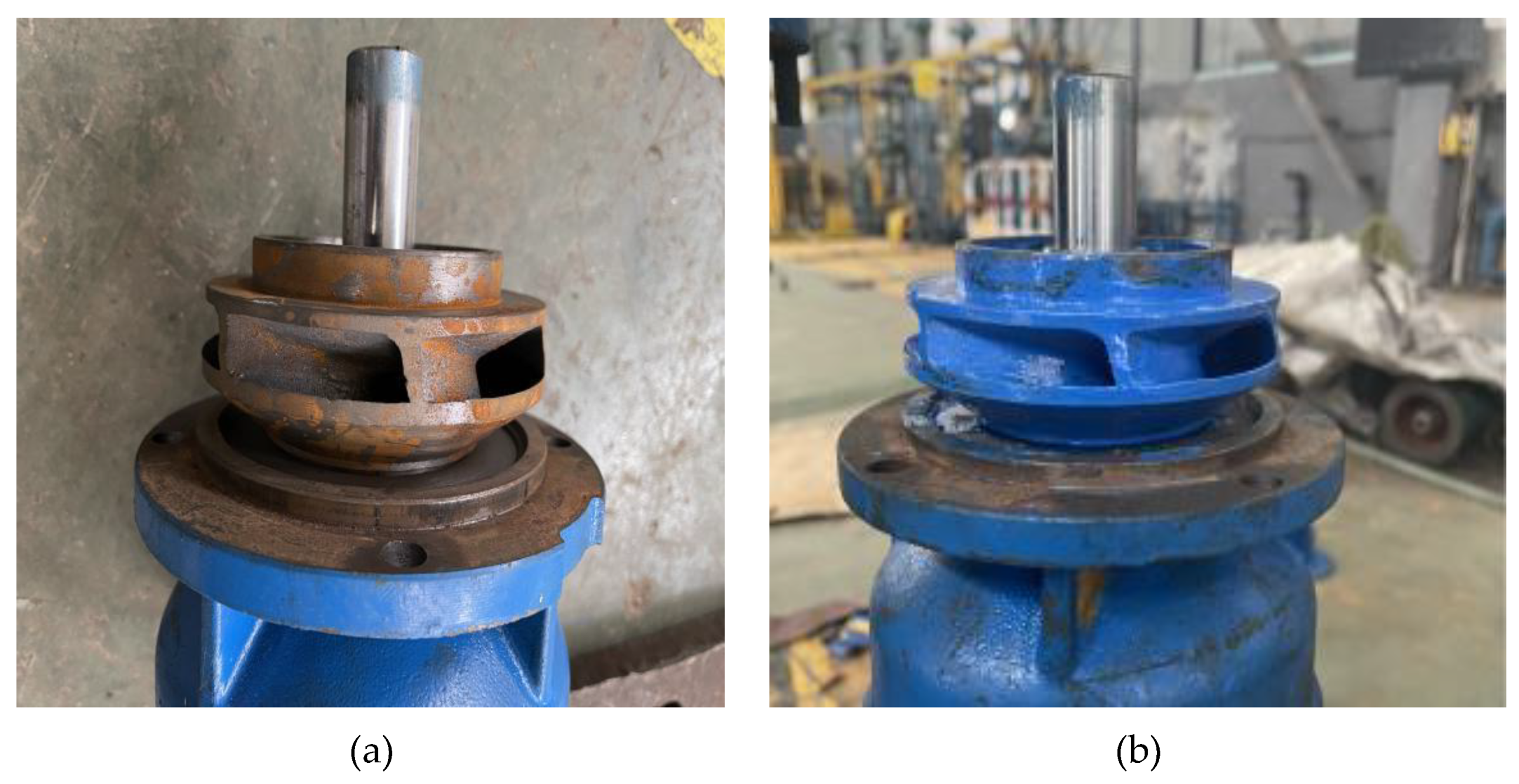

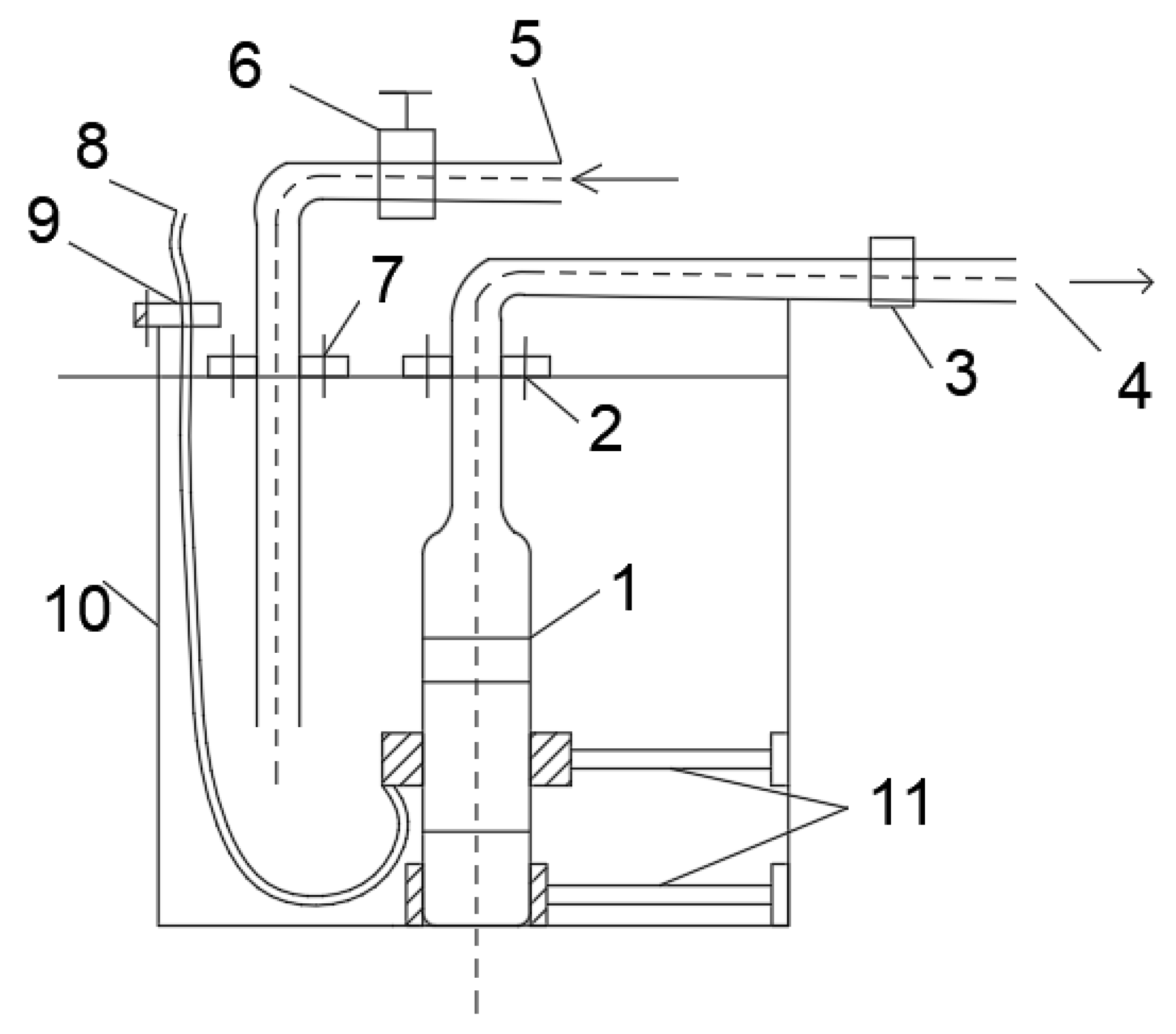

4. Test: Wear Test Verification

4.1. Testing Principle

4.2. Comparative Analysis of the Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, H.X.; Yang, W.X.; Kang, R. A correlation for sand erosion prediction in annular flow considering the effect of liquid dynamic viscosity. Wear 2018, 404–405, 1–11. [Google Scholar] [CrossRef]

- Xu, H.; Zhou, Y.; Yang, F. Analysis on influences of feeding flow rate on flow characteristics in deep-sea ore hydraulic transport equipment. J. Drain. Irrig. Mach. Eng. 2019, 37, 618–624. [Google Scholar]

- Liu, S.-J.; Wen, H.; Zou, W.-S.; Hu, X.-Z.; Dong, Z. Deep-Sea Mining Pump Wear Prediction Using Numerical Two-Phase Flow Simulation. In Proceedings of the 2019 International Conference on Intelligent Transportation, Big Data & Smart City (ICITBS), Changsha, China, 12–13 January 2019; pp. 630–636. [Google Scholar]

- Peng, G.; Chen, Q.; Bai, L.; Hu, Z.; Zhou, L.; Huang, X. Wear mechanism investigation in a centrifugal slurry pump impeller by numerical simulation and experiments. Eng. Fail. Anal. 2021, 128, 105637. [Google Scholar] [CrossRef]

- Noon, A.A.; Kim, M.H. Erosion wear on centrifugal pump casing due to slurry flow. Wear 2016, 364–365, 103–111. [Google Scholar] [CrossRef]

- Tarodiya, R.; Gandhi, B.K. Hydraulic performance and erosive wear of centrifugal slurry pumps—A review. Powder Technol. 2017, 305, 27–38. [Google Scholar] [CrossRef]

- Peng, G.; Fan, F.; Zhou, L.; Huang, X.; Ma, J. Optimal hydraulic design to minimize erosive wear in a centrifugal slurry pump impeller. Eng. Fail. Anal. 2020, 120, 105105. [Google Scholar] [CrossRef]

- Song, X.J.; Yao, R.; Shen, Y.B.; Bi, H.; Zhang, Y.; Du, L.; Wang, Z. Numerical Prediction of Erosion Based on the Solid-Liquid Two-Phase Flow in a Double-Suction Centrifugal Pump. J. Mar. Sci. Eng. 2021, 9, 836. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wan, S.; Nguyen, V.B.; Zhang, Y.-W. A numerical study on the effect of particle shape on the erosion of ductile materials. Wear 2014, 313, 135–142. [Google Scholar] [CrossRef]

- Takaffoli, M.; Papini, M. Numerical simulation of solid particle impacts on Al6061-T6 Part II: Materials removal mechanisms for impact of multiple angular particles. Wear 2012, 296, 648–655. [Google Scholar] [CrossRef]

- Grant, G.; Tabakoff, W. Erosion Prediction in Turbomachinery Resulting from Environmental Solid Particles. J. Aircr. 2012, 12, 471–478. [Google Scholar] [CrossRef]

- Arabnejad, H.; Mansouri, A.; Shirazi, S.; McLaury, B.S. Development of mechanistic erosion equation for solid particles. Wear 2015, 332-333, 1044–1050. [Google Scholar] [CrossRef]

- Huang, X.; Yang, S.; Liu, Z.; Yang, W.; Li, Y. Numerical simulation of prediction in centrifugal pump based on particle track model. Trans. Chin. Soc. Agric. Mach. 2016, 47, 35–41. [Google Scholar]

- Nguyen, V.; Nguyen, Q.B.; Zhang, Y.-W.; Lim, C.Y.H.; Khoo, B.C. Effect of particle size on erosion characteristics. Wear 2016, 348, 126–137. [Google Scholar] [CrossRef]

- Peng, W.; Cao, X. Numerical simulation of solid particle erosion in pipe bends for liquid–solid flow. Powder Technol. 2016, 294, 266–279. [Google Scholar] [CrossRef]

- Wang, R.; Guan, Y.; Jin, X.; Tang, Z.; Zhu, Z.; Su, X. Impact of Particle Sizes on Flow Characteristics of Slurry Pump for Deep-Sea Mining. Shock. Vib. 2021, 2021, 6684944. [Google Scholar] [CrossRef]

- Wang, Z.; Qian, Z. Effects of concentration and size of silt particles on the performance of a double-suction centrifugal pump. Energy 2017, 123, 36–46. [Google Scholar] [CrossRef]

- Liao, J.; Lai, X.D.; Zhang, W.M. Numerical analysis of internal flow field of centrifugal pump based on solid-liquid two-phase flow. J. Eng. Therm. Energy Power 2017, 32, 95–99+139–140. [Google Scholar]

- Shen, Z.; Chu, W.; Li, X.J.; Dong, W. Sediment erosion in the impeller of a double-suction centrifugal pump—A case study of the Jingtai Yellow River Irrigation Project, China. Wear 2019, 422–423, 269–279. [Google Scholar] [CrossRef]

- Serrano, R.O.P.; Santos, L.P.; Viana, E.M.F.; Pinto, M.A.; Martinez, C.B. Case study: Effects of sediment concentration on the wear of fluvial water pump impellers on Brazil’s Acre River. Wear 2018, 408–409, 131–137. [Google Scholar] [CrossRef]

- López, A.; Stickland, M.; Dempster, W. Modeling erosion in a centrifugal pump in an Eulerian-Lagrangian frame using OpenFOAM®. Open Eng. 2015, 5, 105–124. [Google Scholar] [CrossRef]

- Li, Y.W.; Liu, S.J.; Hu, X.Z. Rotating speed’s influence on performance of deep-sea lifting motor pump based on DEM-CFD. Mar. Georesour. Geotecnol. 2019, 37, 979–988. [Google Scholar] [CrossRef]

- Zhou, L.; Han, C.; Bai, L.; Li, W.; El-Emam, M.A.; Shi, W. CFD-DEM bidirectional coupling simulation and experimental investigation of particle ejections and energy conversion in a spouted bed. Energy 2020, 211, 118672. [Google Scholar] [CrossRef]

- Huang, R.F.; Wang, Y.W.; Du, T.Z.; Luo, X.; Zhang, W.; Dai, Y. Mechanism analyses of the unsteady vortical cavitation behaviors for a waterjet pump in a non-uniform inflow. Ocean Eng. 2021, 233, 108798. [Google Scholar] [CrossRef]

- Su, X.H.; Huang, S.; Zhang, X.; Yang, S. Numerical research on unsteady flow rate characteristics of pump as turbine. Renew. Energy 2016, 94, 488–495. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, X.K.; Gao, B.; Xia, B. DDES analysis of the unsteady wake flow and its evolution of a centrifugal pump. Renew. Energy 2019, 141, 570–582. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, X.; Gao, B.; Wang, X.; Xia, B. Effects of modifying the blade trailing edge profile on unsteady pressure pulsations and flow structures in a centrifugal pump. Int. J. Heat Fluid Flow 2019, 75, 227–238. [Google Scholar] [CrossRef]

- Zhang, N.; Jiang, J.X.; Gao, B.; Liu, X. DDES analysis of unsteady flow evolution and pressure pulsation at off-design condition of a centrifugal pump. Renew. Energy 2020, 153, 193–204. [Google Scholar] [CrossRef]

- Liu, S.J.; Liu, C.; Dai, Y. Status and progress on researches and developmengts of deep ocean mining equipmengts. J. Mech. Eng. 2014, 50, 8–18. [Google Scholar] [CrossRef]

- Kang, Y.J.; Liu, S.J.; Zou, W.S.; Zhao, H.; Hu, X. Design and analysis of an innovative deep-sea lifting motor pump. Appl. Ocean Res. 2018, 82, 22–31. [Google Scholar] [CrossRef]

- Wen, H.; Liu, S.-J.; Zou, W.-S.; Hu, X.-Z.; Dong, Z. Effects of Particle Diameter on Erosion Wear Characteristic of Deep-Sea Mining Pump. In Proceedings of the 2019 International Conference on Intelligent Transportation, Big Data & Smart City (ICITBS), Changsha, China, 12–13 January 2019; pp. 507–512. [Google Scholar]

- Zhao, R.-J.; Zhao, Y.-L.; Zhang, D.-S.; Li, Y.; Geng, L.-L. Numerical Investigation of the Characteristics of Erosion in a Centrifugal Pump for Transporting Dilute Particle-Laden Flows. J. Mar. Sci. Eng. 2021, 9, 961. [Google Scholar] [CrossRef]

| b | c | x | y | w | z |

|---|---|---|---|---|---|

| −13.3 | 7.85 | 1.09 | 0.125 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, S.; Hu, X. Study on the Non-Steady-State Wear Characteristics and Test of the Flow Passage Components of Deep-Sea Mining Pumps. Appl. Sci. 2022, 12, 782. https://doi.org/10.3390/app12020782

Hong S, Hu X. Study on the Non-Steady-State Wear Characteristics and Test of the Flow Passage Components of Deep-Sea Mining Pumps. Applied Sciences. 2022; 12(2):782. https://doi.org/10.3390/app12020782

Chicago/Turabian StyleHong, Shunjun, and Xiaozhou Hu. 2022. "Study on the Non-Steady-State Wear Characteristics and Test of the Flow Passage Components of Deep-Sea Mining Pumps" Applied Sciences 12, no. 2: 782. https://doi.org/10.3390/app12020782

APA StyleHong, S., & Hu, X. (2022). Study on the Non-Steady-State Wear Characteristics and Test of the Flow Passage Components of Deep-Sea Mining Pumps. Applied Sciences, 12(2), 782. https://doi.org/10.3390/app12020782