Are Sustainable Aviation Fuels a Viable Option for Decarbonizing Air Transport in Europe? An Environmental and Economic Sustainability Assessment

Abstract

:1. Introduction

2. Materials and Methods

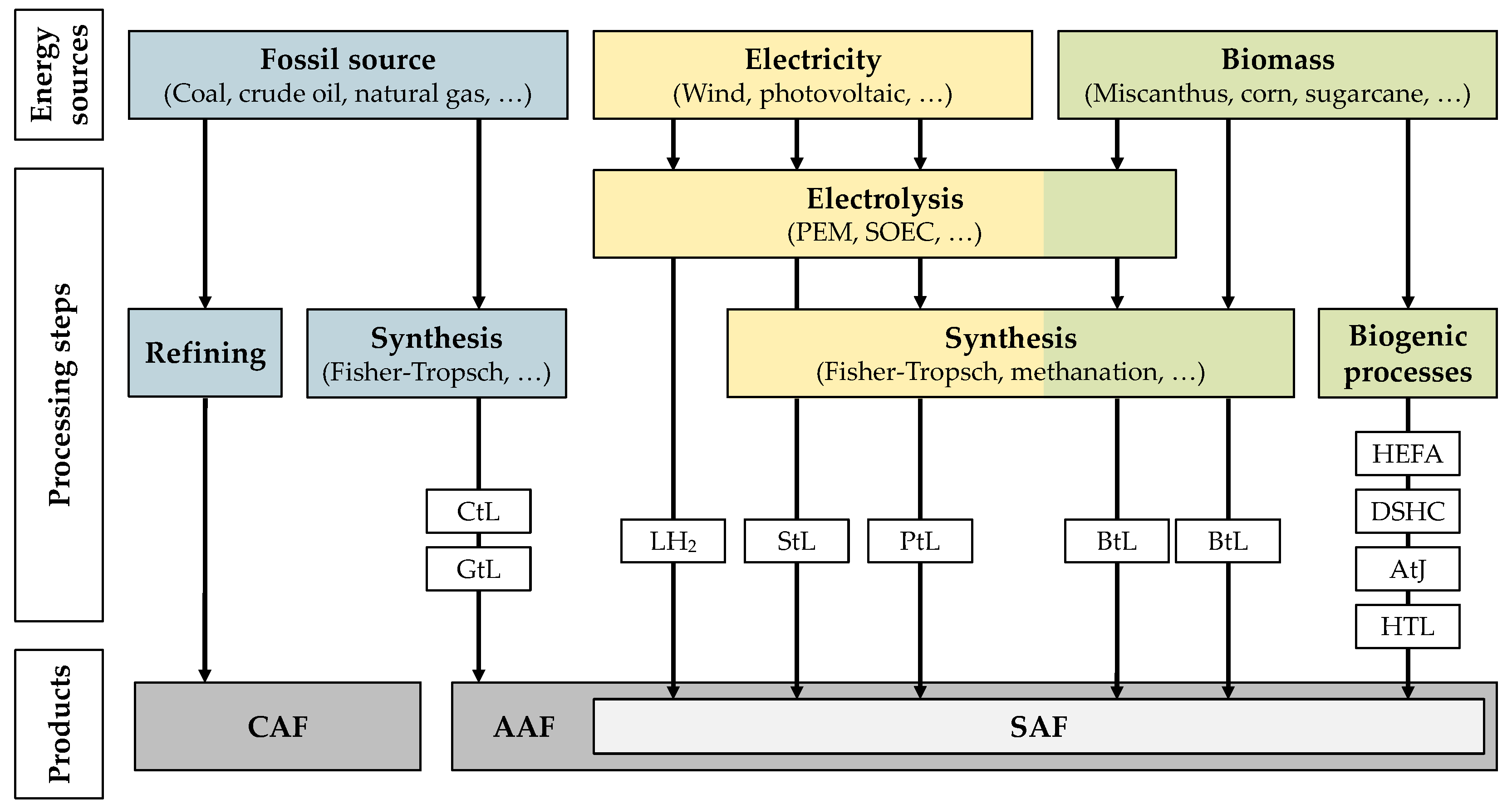

2.1. Aviation Fuels and Previous Sustainability Studies

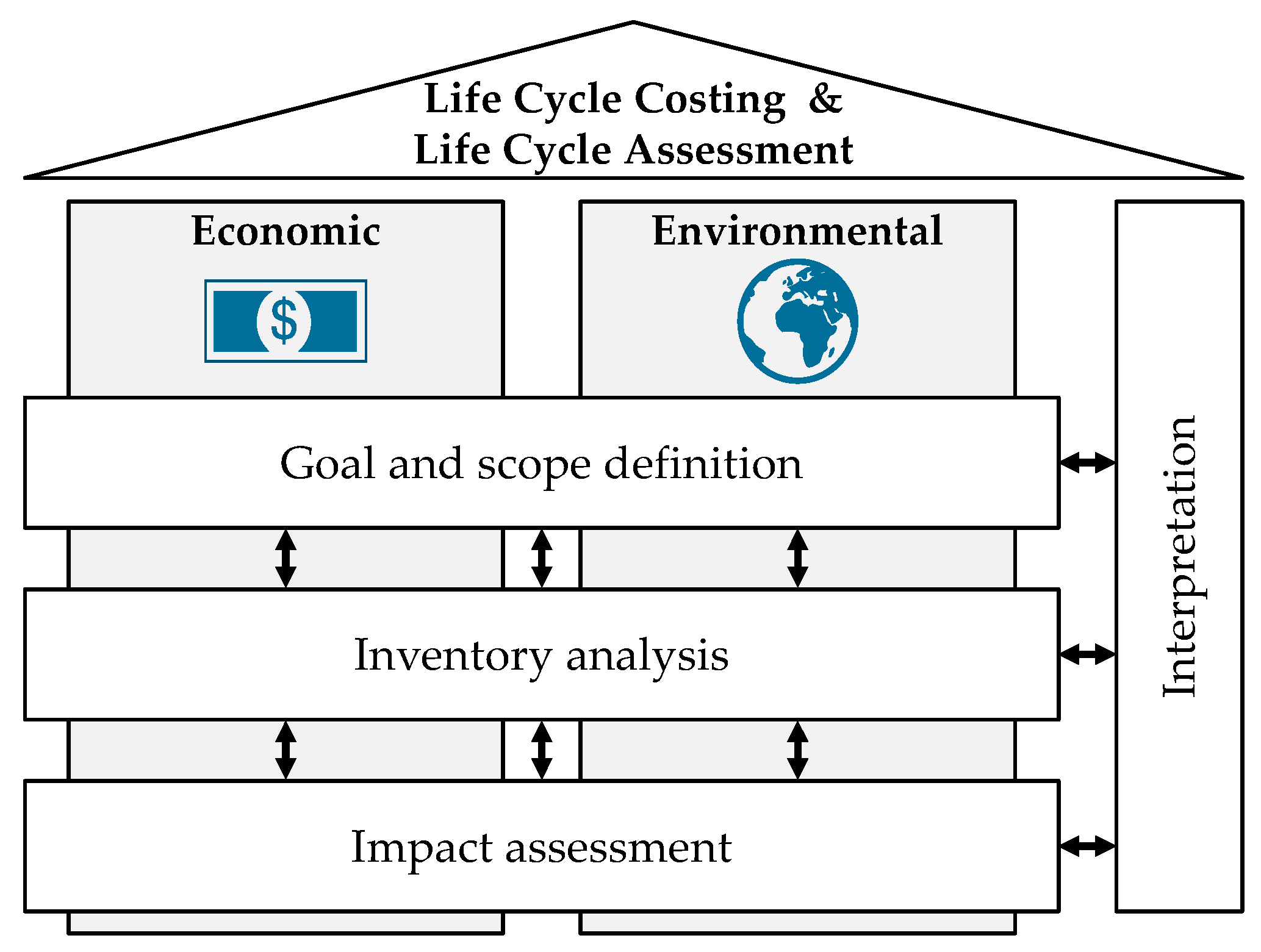

2.2. Assessment Method

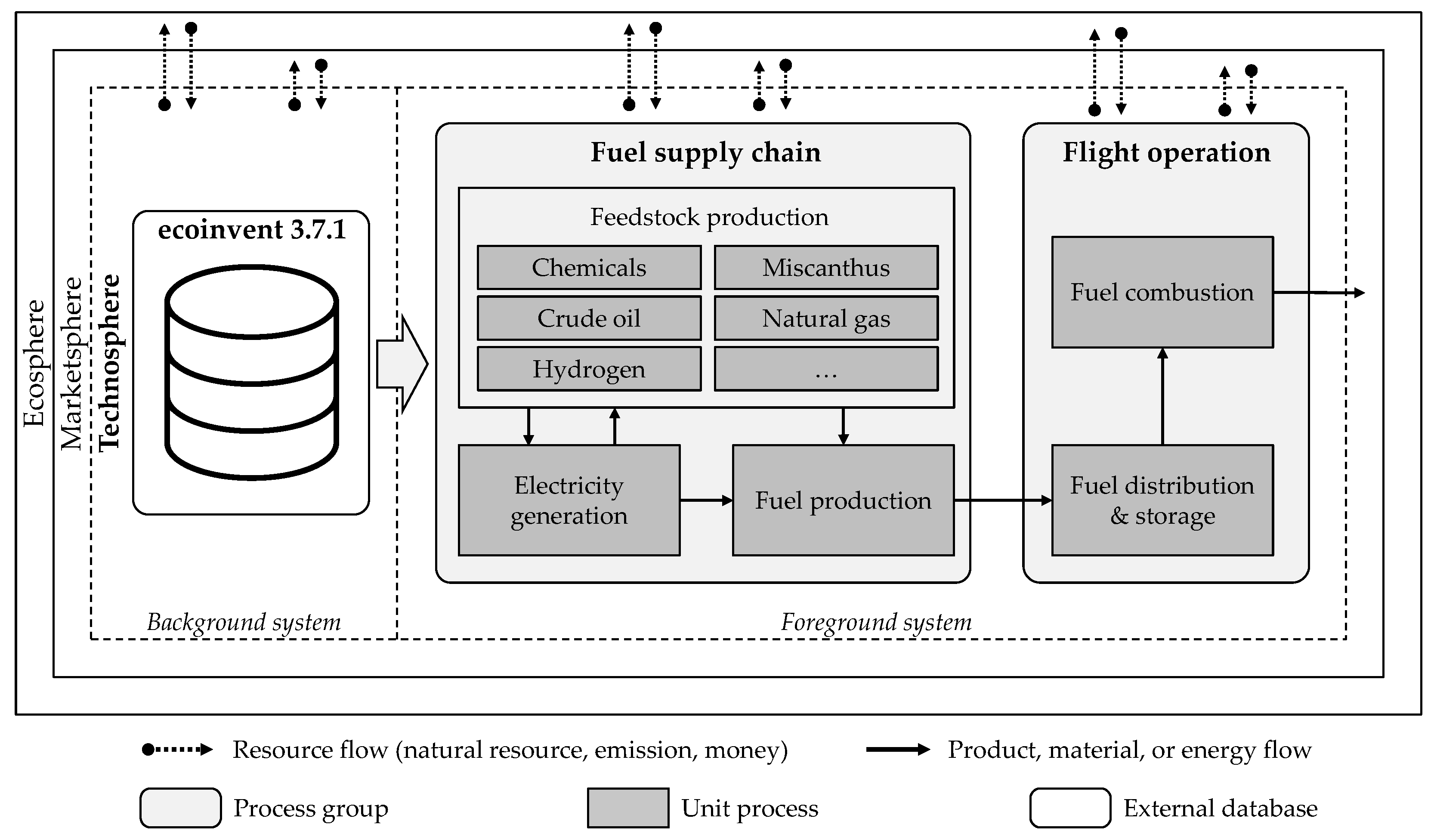

2.3. System Definition

3. Results

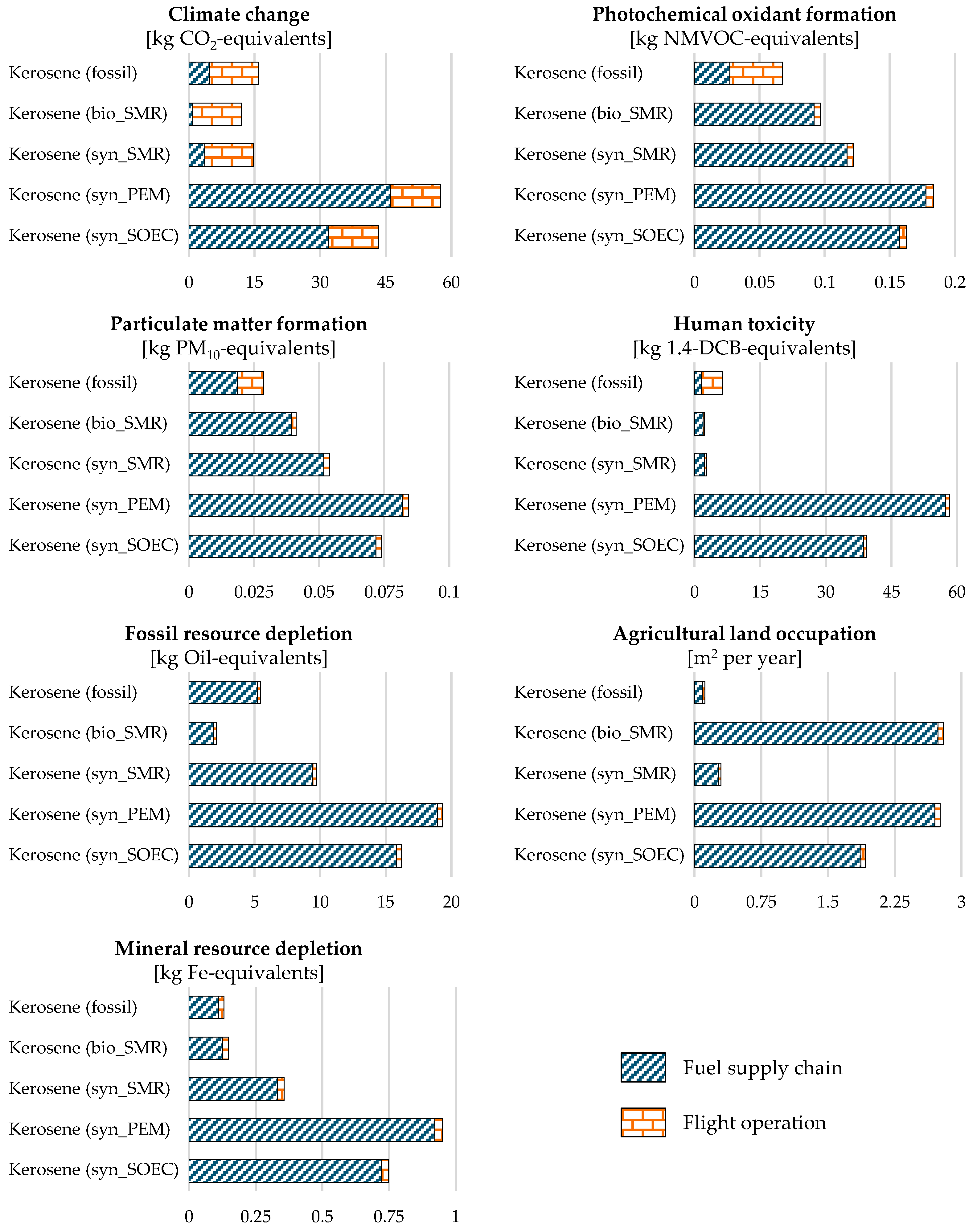

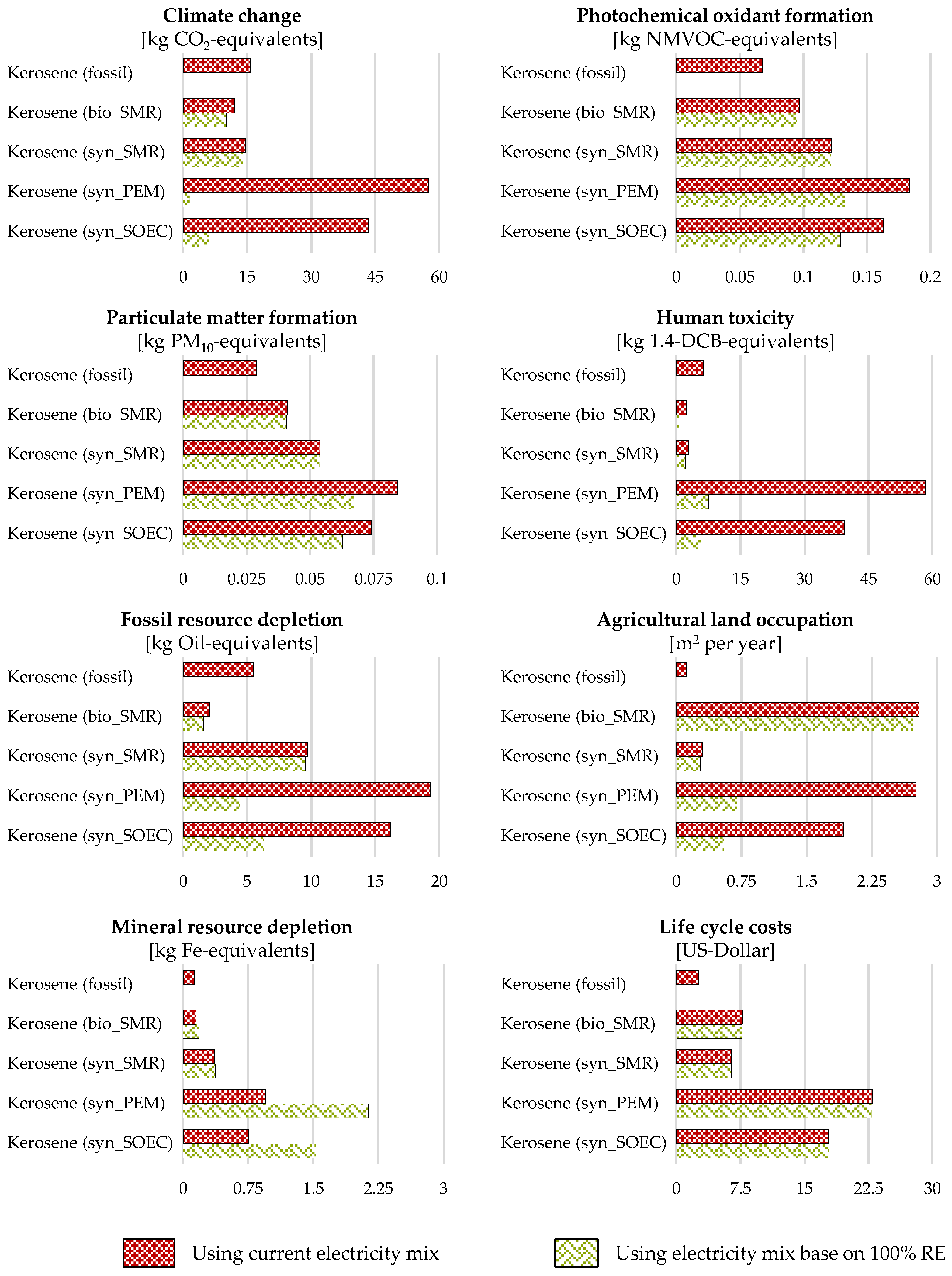

3.1. Overview of Impact Assessment Results

3.2. Detailed Analysis of the Environmental Impacts

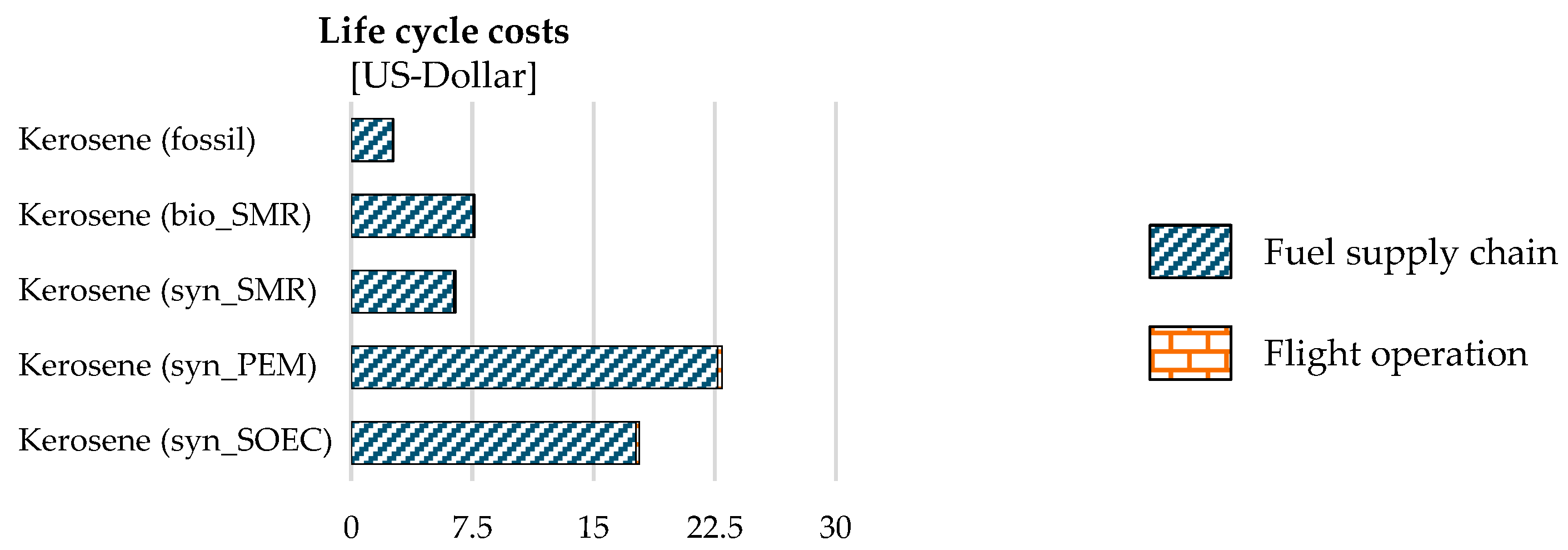

3.3. Detailed Analysis of the Economic Impact

3.4. Influence of Using Electricity Based on Renewable Energy in Production

4. Discussion

5. Conclusions and Outlook

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AAF | Aviation alternative fuel |

| ALO | Agricultural land occupation |

| AtJ | Alcohol-to-jet |

| BtL | Biomass-to-liquid |

| CAF | Conventional aviation fuel |

| CC | Climate change |

| CO2 | Carbon dioxide |

| CORSIA | Carbon Offsetting and Reduction Scheme for International Aviation |

| CtL | Coal-to-liquid |

| DSHC | Direct sugar to hydrocarbons |

| EU ETS | European Union Emission Trading System |

| FRD | Fossil resource depletion |

| FTS | Fisher–Tropsch synthesis |

| GHG | Greenhouse gas |

| GtL | Gas-to-liquid |

| HEFA | Hydroprocessed esters and fatty acids |

| HT | Human toxicity |

| HTL | Hydrothermal liquefaction |

| LC | Life cycle costs |

| LCA | Life cycle assessment |

| LCC | Life cycle costing |

| LCI | Life cycle inventory |

| LH2 | Liquid hydrogen |

| MRD | Mineral resource depletion |

| NOx | Nitrogen oxides |

| PEM | Polymer electrolyte membrane electrolysis |

| pkm | Passenger kilometer traveled |

| PMF | Particulate matter formation |

| POF | Photochemical oxidant formation |

| PtL | Power-to-liquid |

| RE | Renewable energy |

| SAF | Sustainable aviation fuel |

| SMR | Steam methane reforming |

| SOEC | Solid oxide electrolysis |

| StL | Sun-to-liquid |

References

- International Transport Forum. ITF Transport Outlook 2019; OECD Publishing: Paris, France, 2019. [Google Scholar]

- Airbus, S.A.S. Cities, Airports & Aircraft; Airbus: Blagnac Cedex, France, 2019. [Google Scholar]

- Boeing. Commercial Market Outlook: 2019–2038; Boeing: Seattle, WA, USA, 2019. [Google Scholar]

- Gössling, S.; Humpe, A.; Fichert, F.; Creutzig, F. COVID-19 and pathways to low-carbon air transport until 2050. Environ. Res. Lett. 2021, 16, 034063. [Google Scholar] [CrossRef]

- European Union Aviation Safety Agency (EASA); European Environmental Agency (EEA); EUROCONTROL. European Aviation Environmental Report 2019; EASA, EEA, EUROCONTROL: Luxembourg, 2019. [CrossRef]

- Gnadt, A.R.; Speth, R.L.; Sabnis, J.S.; Barrett, S.R.H. Technical and environmental assessment of all-electric 180-passenger commercial aircraft. Prog. Aerosp. Sci. 2019, 105, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Jungbluth, N.; Meili, C. Recommendations for calculation of the global warming potential of aviation including the radiative forcing index. Int. J. Life Cycle Assess. 2019, 24, 404–411. [Google Scholar] [CrossRef]

- Lee, D.S.; Fahey, D.W.; Skowron, A.; Allen, M.R.; Burkhardt, U.; Chen, Q.; Doherty, S.J.; Freeman, S.; Forster, P.M.; Fuglestvedt, J.; et al. The contribution of global aviation to anthropogenic climate forcing for 2000 to 2018. Atmos. Environ. 2021, 244, 117834. [Google Scholar] [CrossRef]

- Andruleit, H.; Meßner, J.; Pein, M.; Rebscher, D.; Schauer, M.; Schmidt, S.; von Goerne, G. Status, Daten und Entwicklungen der globalen Energieversorgung. Z. Für Energ. 2018, 42, 179–191. [Google Scholar] [CrossRef]

- Mensen, H. Handbuch der Luftfahrt, 2nd ed.; Springer Vieweg: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-34401-5. [Google Scholar]

- ICAO. Annex 16 CORSIA; ICAO: Montréal, QC, Canada, 2018; Volume IV, ISBN 9789292586119. [Google Scholar]

- European Commission. Flightpath 2050: Europe’s Vision for Aviation; European Comission: Brussels, Belgium, 2014. [Google Scholar] [CrossRef]

- Kumar, N.; Möller, U.; Tang, S.; Chiarini, P. Flightpath 2050 Goals; ACARE: Brussels, Belgium, 2020. Available online: https://www.acare4europe.org/sria/flightpath-2050-goals (accessed on 15 September 2021).

- Advisory Council for Aviation Research and Innovation in Europe (ACARE). Strategic Research & Innovation Agenda; ACARE: Brussels, Belgium, 2012; Volume 1, pp. 79–100. [Google Scholar]

- Barke, A.; Thies, C.; Popien, J.L.; Melo, S.P.; Cerdas, F.; Herrmann, C.; Spengler, T.S. Life cycle sustainability assessment of potential battery systems for electric aircraft. Procedia CIRP 2021, 98, 660–665. [Google Scholar] [CrossRef]

- ICAO. Electric, Hybrid, and Hydrogen Aircraft—State of Play; ICAO: Montréal, QC, Canada, 2019; pp. 124–130. [Google Scholar]

- Fend, T.; Roeb, M. Solare Thermochemische Wasserspaltung. 2020. Available online: https://www.dlr.de/sf/desktopdefault.aspx/tabid-9315/22259_read-51105/ (accessed on 15 September 2021).

- Melo, S.P.; Barke, A.; Cerdas, F.; Thies, C.; Mennenga, M.; Spengler, T.S.; Herrmann, C. Sustainability Assessment and Engineering of Emerging Aircraft Technologies—Challenges, Methods and Tools. Sustainability 2020, 12, 5663. [Google Scholar] [CrossRef]

- Schmidt, P.; Batteiger, V.; Roth, A.; Weindorf, W.; Raksha, T. Power-to-Liquids as Renewable Fuel Option for Aviation: A Review. Chem. Ing. Tech. 2018, 90, 127–140. [Google Scholar] [CrossRef]

- Han, J.; Elgowainy, A.; Cai, H.; Wang, M.Q. Life-cycle analysis of bio-based aviation fuels. Bioresour. Technol. 2013, 150, 447–456. [Google Scholar] [CrossRef]

- Gomez Jimenez, I. Feasibility Study on the Use of Sustainable Aviation Fuels. 2017, p. 38. Available online: https://www.icao.int/environmental-protection/Documents/FeasabilityStudy_BurkinaFaso_Report-Web.pdf (accessed on 15 September 2021).

- ICAO. Agenda Item 1: Developments in Research and Certification of Aviation Alternative Fuels; ICAO: Montréal, QC, Canada, 2017. [Google Scholar]

- ICAO. Agenda Item 1: Developments in Research and Certification of Aviation Alternative Fuels STATUS; ICAO: Montréal, QC, Canada, 2017. [Google Scholar]

- Bley, T. Analyse und Vergleich Ökologischer und Sozioökonomischer Umweltwirkungen Verschiedener Kraftstoffvarianten für die Verwendung im Luftverkehr. Master’s Thesis, Technische Universität Braunschweig, Braunschweig, Germany, 2021. [Google Scholar] [CrossRef]

- Farokhi, S. Future Propulsion Systems and Energy Sources in Sustainable Aviation, 1st ed.; Wiley & Sons: Hoboken, NJ, USA, 2020; ISBN 978-1-119-41499-5. [Google Scholar]

- Berger, A.; Hirschl, B.; Bluhm, H.; Ehrenstein, U.; Heinbach, K.; Dunkelberg, E. Systematik im Power-to-X-Ansatz—Identifikation, Charakterisierung und Clusterung der Power-to-X-Technologien. Z. Energ. 2020, 44, 177–193. [Google Scholar] [CrossRef]

- Roth, A.; Sizmann, A.; Jeßberger, C. Report on Compilation, Mapping and Evaluation of R&D Activities in the Field of Conversion Technologies of Biogenic Feedstock and Biomass-Independent Pathways; Bauhaus Luftfahrt e.V.: Munich, Germany, 2016. [Google Scholar]

- Kolosz, B.W.; Luo, Y.; Xu, B.; Maroto-Valer, M.M.; Andresen, J.M. Life cycle environmental analysis of “drop in” alternative aviation fuels: A review. Sustain. Energy Fuels 2020, 4, 3229–3263. [Google Scholar] [CrossRef]

- Fasihi, M.; Bogdanov, D.; Breyer, C. Techno-Economic Assessment of Power-to-Liquids (PtL) Fuels Production and Global Trading Based on Hybrid PV-Wind Power Plants. Energy Procedia 2016, 99, 243–268. [Google Scholar] [CrossRef] [Green Version]

- Fischer, F.; Tropsch, H. The Synthesis of Petroleum at Atmospheric Pressures from Gasification Products of Coal. Brennstoff-Chemie 1926, 7, 97–104. [Google Scholar]

- Horschig, T.; Penke, C.; Habersetzer, A.; Batteiger, V. Regional Feedstock Potentials and Preference Regions for HTL Projects. 2020. Available online: www.hyflexfuel.eu (accessed on 15 September 2021).

- Nationale Organisation Wasserstoff-und Brennstoffzellentechnologie. Factsheet: Übersicht und Einordnung Alternativer Kraftstoffe Kraftstoffe im Fokus der NOW; NOW GmbH: Berlin, Germany, 2021. [Google Scholar]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4, 024008. [Google Scholar] [CrossRef]

- Cox, B.; Jemiolo, W.; Mutel, C. Life cycle assessment of air transportation and the Swiss commercial air transport fleet. Transp. Res. Part D Transp. Environ. 2018, 58, 1–13. [Google Scholar] [CrossRef]

- Gutiérrez-Antonio, C.; Gómez-Castro, F.I.; de Lira-Flores, J.A.; Hernández, S. A review on the production processes of renewable jet fuel. Renew. Sustain. Energy Rev. 2017, 79, 709–729. [Google Scholar] [CrossRef]

- Doliente, S.S.; Narayan, A.; Tapia, J.F.D.; Samsatli, N.J.; Zhao, Y.; Samsatli, S. Bio-aviation Fuel: A Comprehensive Review and Analysis of the Supply Chain Components. Front. Energy Res. 2020, 8, 110. [Google Scholar] [CrossRef]

- Staples, M.D.; Malina, R.; Suresh, P.; Hileman, J.I.; Barrett, S.R.H. Aviation CO2 emissions reductions from the use of alternative jet fuels. Energy Policy 2018, 114, 342–354. [Google Scholar] [CrossRef]

- Rye, L.; Batten, D. Alternative aviation fuel feedstock: The microalgae solution. In Proceedings of the ICAS 2012, Brisbane, Australia, 23–28 September 2011; pp. 1–7. [Google Scholar]

- Hileman, J.I.; Stratton, R.W. Alternative jet fuel feasibility. Transp. Policy 2014, 34, 52–62. [Google Scholar] [CrossRef]

- Neuling, U.; Kaltschmitt, M. Techno-economic and environmental analysis of aviation biofuels. Fuel Process. Technol. 2018, 171, 54–69. [Google Scholar] [CrossRef]

- Johanning, A.; Scholz, D. Comparison of the potential environmental impact improvements of future aircraft concepts using life cycle assessment. In Proceedings of the 5th CEAS Air & Space Conference, Delft, The Netherlands, 7–11 September 2015; pp. 1–16. [Google Scholar]

- Koroneos, C.; Dompros, A.; Roumbas, G.; Moussiopoulos, N. Advantages of the use of hydrogen fuel as compared to kerosene. Resour. Conserv. Recycl. 2005, 44, 99–113. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Life cycle evaluation of hydrogen and other potential fuels for aircrafts. Int. J. Prod. Res. 2017, 42, 10722–10738. [Google Scholar] [CrossRef]

- Sürer, M.G.; Arat, H.T. State of art of hydrogen usage as a fuel on aviation. Eur. Mech. Sci. 2018, 2, 20–30. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Schau, E.M.; Lehmann, A.; Traverso, M. Towards Life Cycle Sustainability Assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef] [Green Version]

- Ness, B.; Urbel-Piirsalu, E.; Anderberg, S.; Olsson, L. Categorising tools for sustainability assessment. Ecol. Econ. 2007, 60, 498–508. [Google Scholar] [CrossRef]

- Zimmermann, A.W.; Wunderlich, J.; Müller, L.; Buchner, G.A.; Marxen, A.; Michailos, S.; Armstrong, K.; Naims, H.; McCord, S.; Styring, P.; et al. Techno-Economic Assessment Guidelines for CO2 Utilization. Front. Energy Res. 2020, 8, 31. [Google Scholar] [CrossRef] [Green Version]

- Reddy, K.R.; Sadasivam, B.Y.; Adams, J.A. Social Sustainability Evaluation Matrix (SSEM) to Quantify Social Aspects of Sustainable Remediation. In Proceedings of the 2014 International Conference on Sustainable Infrastructure, Long Beach, CA, USA, 6–8 November 2014; pp. 831–841. [Google Scholar]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Klöpffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- UNEP/SETAC. Towards a Life Cycle Sustainability Assessment: Making Informed Choices on Products; UNEP/SETAC Life Cycle Initiative: Paris, France, 2011. [Google Scholar]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2012, 15, 281–299. [Google Scholar] [CrossRef]

- Keller, H.; Rettenmaier, N.; Reinhardt, G.A. Integrated life cycle sustainability assessment—A practical approach applied to biorefineries. Appl. Energy 2015, 154, 1072–1081. [Google Scholar] [CrossRef]

- Thies, C.; Kieckhäfer, K.; Spengler, T.S. Activity analysis based modeling of global supply chains for sustainability assessment. J. Bus. Econ. 2021, 91, 215–252. [Google Scholar] [CrossRef]

- Grubert, E. The Need for a Preference-Based Multicriteria Prioritization Framework in Life Cycle Sustainability Assessment. J. Ind. Ecol. 2017, 21, 1522–1535. [Google Scholar] [CrossRef] [Green Version]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; van Zelm, R. ReCiPe 2008: A life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Ministerie van VROM: Den Haag, The Newtherland, 2013. [Google Scholar]

- Rebitzer, G.; Hunkeler, D. Life cycle costing in LCM: Ambitions, opportunities, and limitations. Int. J. Life Cycle Assess. 2003, 8, 253–256. [Google Scholar] [CrossRef]

- Hunkeler, D.; Lichtenvort, K.; Rebitzer, G. Environmental Life Cycle Costing; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Moreau, V.; Weidema, B.P. The computational structure of environmental life cycle costing. Int. J. Life Cycle Assess. 2015, 20, 1359–1363. [Google Scholar] [CrossRef]

- Heijungs, R.; Settanni, E.; Guinée, J. Toward a computational structure for life cycle sustainability analysis: Unifying LCA and LCC. Int. J. Life Cycle Assess. 2013, 18, 1722–1733. [Google Scholar] [CrossRef] [Green Version]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Raffinerie Heide. Energising the North; Raffinerie Heide GmbH: Hemmingstedt, Germany, 2017. [Google Scholar]

- 3N Centre of Experts for Renewable Resources Lower Saxony. Biogas in Lower Saxony; 3N Centre of Experts: Werlte, Germany, 2014. [Google Scholar]

- Van Der Giesen, C.; Kleijn, R.; Kramer, G.J. Energy and climate impacts of producing synthetic hydrocarbon fuels from CO2. Environ. Sci. Technol. 2014, 48, 7111–7121. [Google Scholar] [CrossRef]

- Rutkowski, M.; Penev, M.; Saur, G.; Steward, D. Current Central Hydrogen from Natural Gas with CO2 Capture and Sequestration: NREL. 2018. Available online: https://www.nrel.gov/hydrogen/assets/docs/current-central-natural-gas-with-co2-sequestration-v3-2018.20210104.xlsm (accessed on 30 September 2021).

- DeSantis, D.; James, B.; Saur, G. Hydrogen Production from Central PEM Electrolysis: NREL. 2019. Available online: https://www.nrel.gov/hydrogen/assets/docs/current-central-pem-electrolysis-2019-v3-2018.xlsm (accessed on 30 September 2021).

- James, B.; DeSantis, D.; Moton, J.; Saur, G. Current Central Hydrogen Production from Solid Oxide Electrolysis: NREL. 2018. Available online: https://www.nrel.gov/hydrogen/assets/docs/current-central-solid-oxide-electrolysis-v3-2018.xlsm (accessed on 30 September 2021).

- ECSPP. An Overview of the Pipeline Networks of Europe. 2006. Available online: https://chemicalparks.eu/europe/pipeline-networks (accessed on 15 September 2021).

- Lufthansa Group. LH-Factsheet-Sustainability-2020. 2020, pp. 1–22. Available online: https://www.lufthansagroup.com/media/downloads/en/responsibility/LH-Factsheet-Sustainability-2020.pdf (accessed on 15 September 2021).

- Braun-Unkhoff, M.; Riedel, U.; Wahl, C. About the emissions of alternative jet fuels. CEAS Aeronaut. J. 2017, 8, 167–180. [Google Scholar] [CrossRef] [Green Version]

- Turner, D.; Xu, H.; Cracknell, R.F.; Natarajan, V.; Chen, X. Combustion performance of bio-ethanol at various blend ratios in a gasoline direct injection engine. Fuel 2011, 90, 1999–2006. [Google Scholar] [CrossRef]

- Mutel, C. Brightway: An open source framework for Life Cycle Assessment. J. Open Source Softw. 2017, 2, 236. [Google Scholar] [CrossRef]

- Fraunhofer ISE. German Net Electricity Generation in First Half of 2021: Decline in Renewables Due to Weak Winds; Fraunhofer ISE: Freiburg im Breisgau, Germany, 2021. [Google Scholar]

- Jacobson, M.Z.; Delucchi, M.A.; Bauer, Z.A.F.; Goodman, S.C.; Chapman, W.E.; Cameron, M.A.; Bozonnat, C.; Chobadi, L.; Clonts, H.A.; Enevoldsen, P.; et al. 100% Clean and Renewable Wind, Water, and Sunlight All-Sector Energy Roadmaps for 139 Countries of the World. Joule 2017, 1, 108–121. [Google Scholar] [CrossRef] [Green Version]

- Klein, B.C.; Chagas, M.F.; Junqueira, T.L.; Rezende, M.C.A.F.; Cardoso, T.d.F.; Cavalett, O.; Bonomi, A. Techno-economic and environmental assessment of renewable jet fuel production in integrated Brazilian sugarcane biorefineries. Appl. Energy 2018, 209, 290–305. [Google Scholar] [CrossRef]

- Schneider, S.; Bajohr, S.; Graf, F.; Kolb, T. State of the Art of Hydrogen Production via Pyrolysis of Natural Gas. ChemBioEng Rev. 2020, 7, 150–158. [Google Scholar] [CrossRef]

- Barke, A.; Thies, C.; Melo, S.P.; Cerdas, F.; Herrmann, C.; Spengler, T.S. Socio-economic life cycle assessment of future aircraft systems. Procedia CIRP 2020, 90, 262. [Google Scholar] [CrossRef]

| Abbreviation | Description |

|---|---|

| Kerosene (fossil) | Fossil kerosene based on crude oil produced by refinery processes |

| Kerosene (bio_SMR) | Biokerosene based on miscanthus produced by steam methane reforming and Fisher–Tropsch synthesis |

| Kerosene (syn_SMR) | Synthetic kerosene based on hydrogen produced by steam methane reforming and Fisher–Tropsch synthesis |

| Kerosene (syn_PEM) | Synthetic kerosene based on hydrogen produced by polymer electrolyte membrane electrolysis and Fisher–Tropsch synthesis |

| Kerosene (syn_SOEC) | Synthetic kerosene based on hydrogen produced by solid oxide electrolysis and Fisher–Tropsch synthesis |

| Dimension | Impact Category | Unit |

|---|---|---|

| Environmental | Climate change (CC) | kg CO2-eq. |

| Fossil resource depletion (FRD) | kg Oil-eq. | |

| Particulate matter formation (PMF) | kg PM10-eq. | |

| Agricultural land occupation (ALO) | m2 per year | |

| Photochemical oxidant formation (POF) | kg NMVOC-eq. | |

| Human toxicity (HT) | kg 1.4-DCB-eq. | |

| Mineral resource depletion (MRD) | kg Fe-eq. | |

| Economic | Life cycle costs (LC) | US-Dollar |

| Dimension | Impact Category | Unit | Per 100 Passenger Kilometers Traveled | ||||

|---|---|---|---|---|---|---|---|

| Kerosene (Fossil) | Kerosene (bio_SMR) | Kerosene (syn_SMR) | Kerosene (syn_PEM) | Kerosene (syn_SOEC) | |||

| Environmental | CC | kg CO2-eq. | 15.7960 | 11.9856 | 14.7195 | 57.5965 | 43.3410 |

| FRD | kg Oil-eq. | 5.4647 | 2.0757 | 9.7122 | 19.3292 | 16.1859 | |

| PMF | kg PM10-eq. | 0.0288 | 0.0412 | 0.0539 | 0.0843 | 0.0740 | |

| ALO | m2 per year | 0.1180 | 2.7944 | 0.2988 | 2.7630 | 1.9225 | |

| POF | kg NMVOC-eq. | 0.0678 | 0.0967 | 0.1221 | 0.1836 | 0.1629 | |

| HT | kg 1.4-DCB-eq. | 6.3265 | 2.3085 | 2.7208 | 58.3424 | 39.3755 | |

| MRD | kg Fe-eq. | 0.1320 | 0.1469 | 0.3564 | 0.9510 | 0.7482 | |

| Economic | LC | US-Dollar | 2.5905 | 7.6675 | 6.4417 | 22.9424 | 17.8238 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barke, A.; Bley, T.; Thies, C.; Weckenborg, C.; Spengler, T.S. Are Sustainable Aviation Fuels a Viable Option for Decarbonizing Air Transport in Europe? An Environmental and Economic Sustainability Assessment. Appl. Sci. 2022, 12, 597. https://doi.org/10.3390/app12020597

Barke A, Bley T, Thies C, Weckenborg C, Spengler TS. Are Sustainable Aviation Fuels a Viable Option for Decarbonizing Air Transport in Europe? An Environmental and Economic Sustainability Assessment. Applied Sciences. 2022; 12(2):597. https://doi.org/10.3390/app12020597

Chicago/Turabian StyleBarke, Alexander, Timo Bley, Christian Thies, Christian Weckenborg, and Thomas S. Spengler. 2022. "Are Sustainable Aviation Fuels a Viable Option for Decarbonizing Air Transport in Europe? An Environmental and Economic Sustainability Assessment" Applied Sciences 12, no. 2: 597. https://doi.org/10.3390/app12020597

APA StyleBarke, A., Bley, T., Thies, C., Weckenborg, C., & Spengler, T. S. (2022). Are Sustainable Aviation Fuels a Viable Option for Decarbonizing Air Transport in Europe? An Environmental and Economic Sustainability Assessment. Applied Sciences, 12(2), 597. https://doi.org/10.3390/app12020597