Deep Learning Based Inversion of Locally Anisotropic Weld Properties from Ultrasonic Array Data

Abstract

1. Introduction

2. Methods

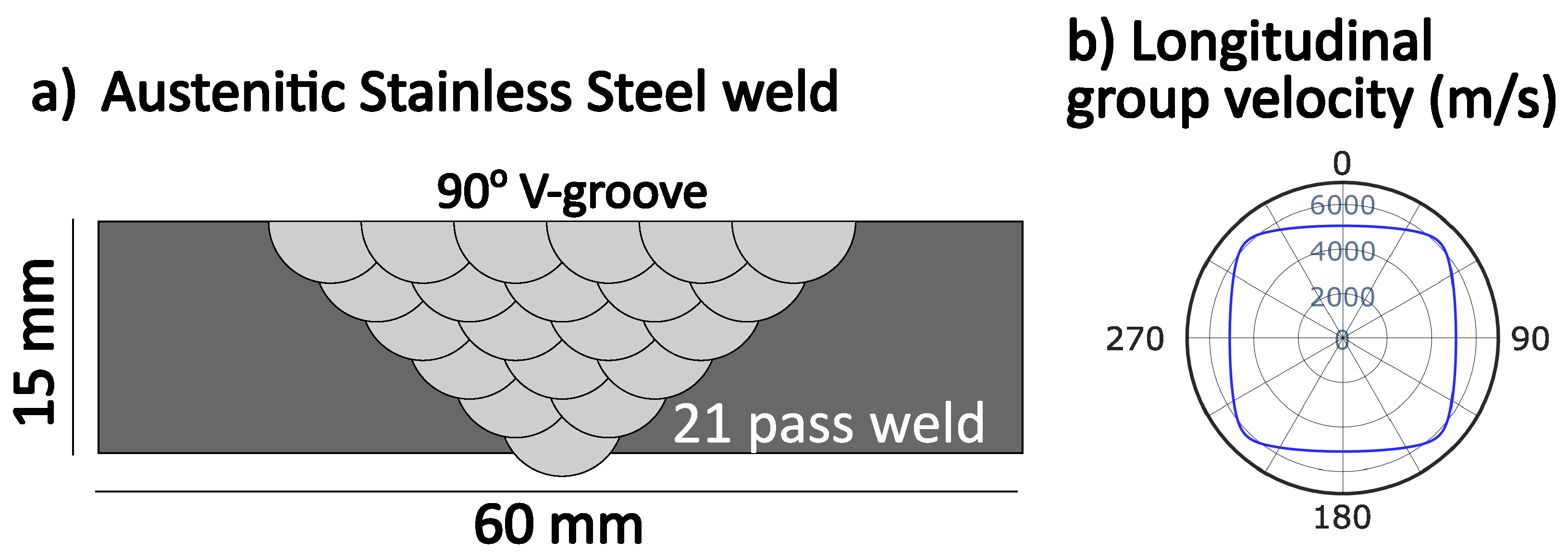

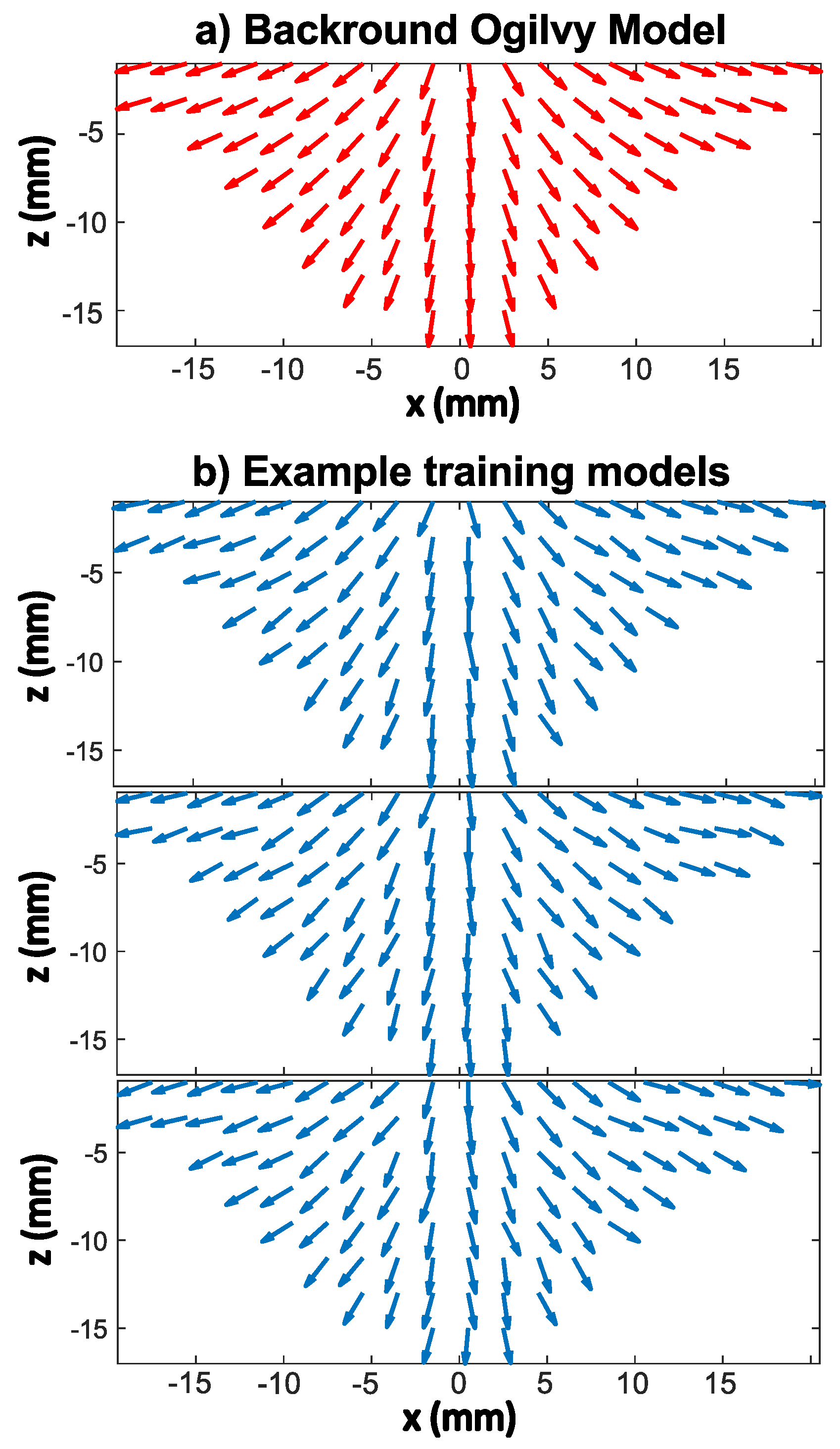

2.1. Weld Models

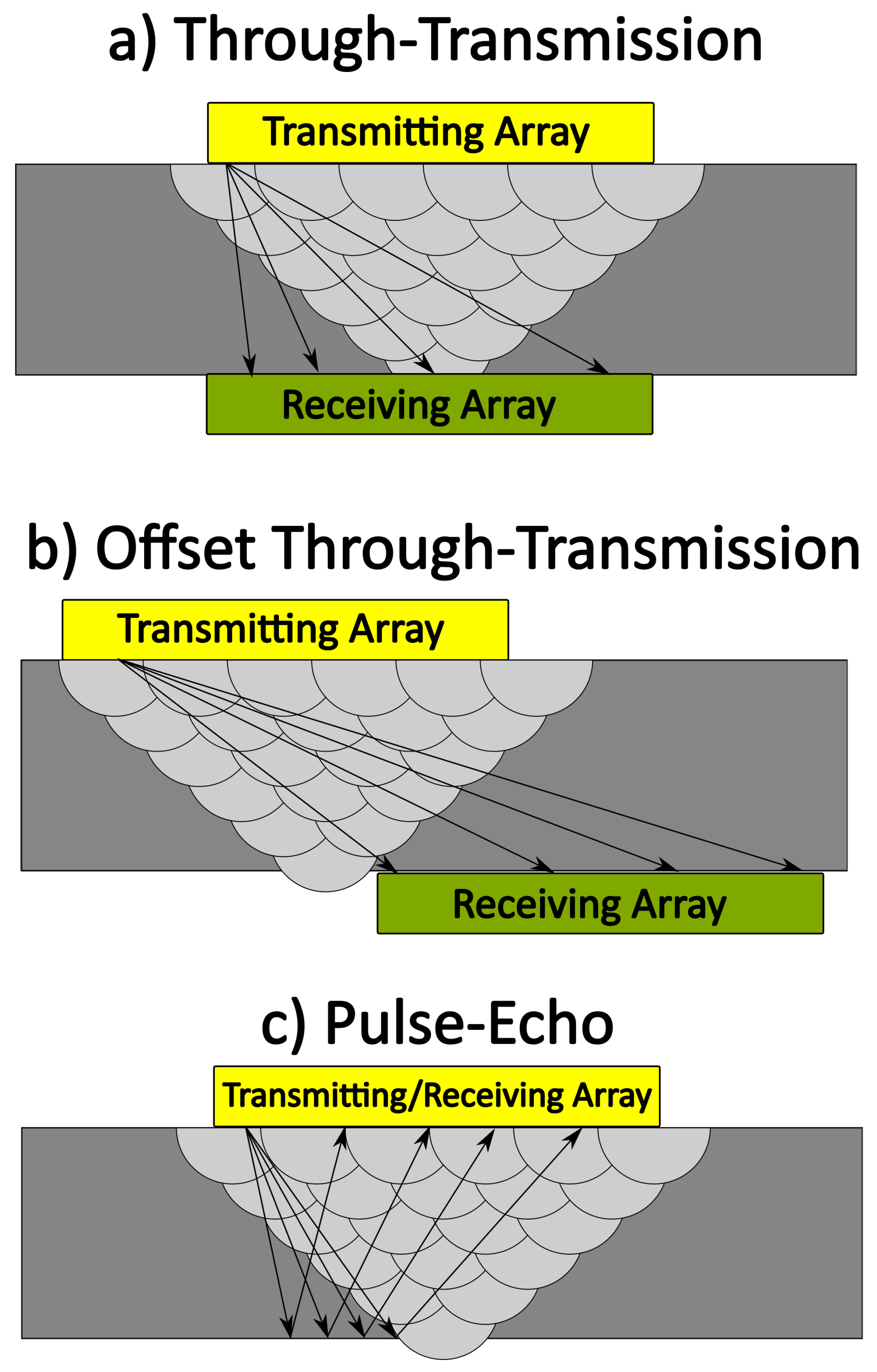

2.2. Data Acquisition Geometry

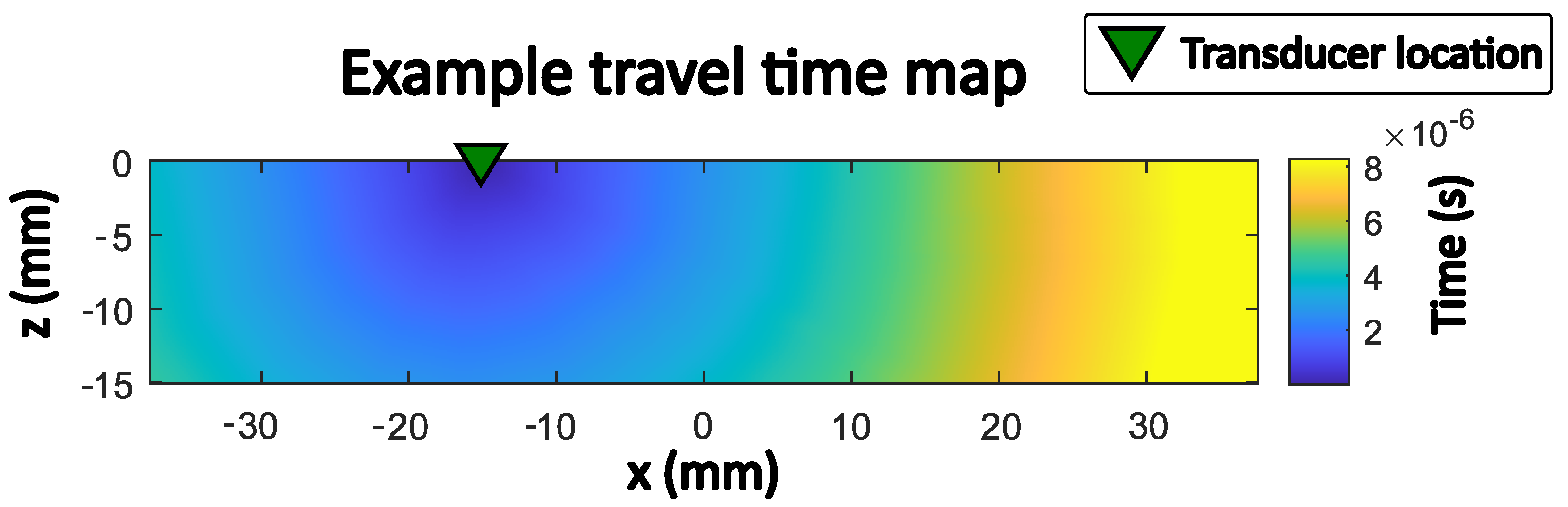

2.3. Forward Models

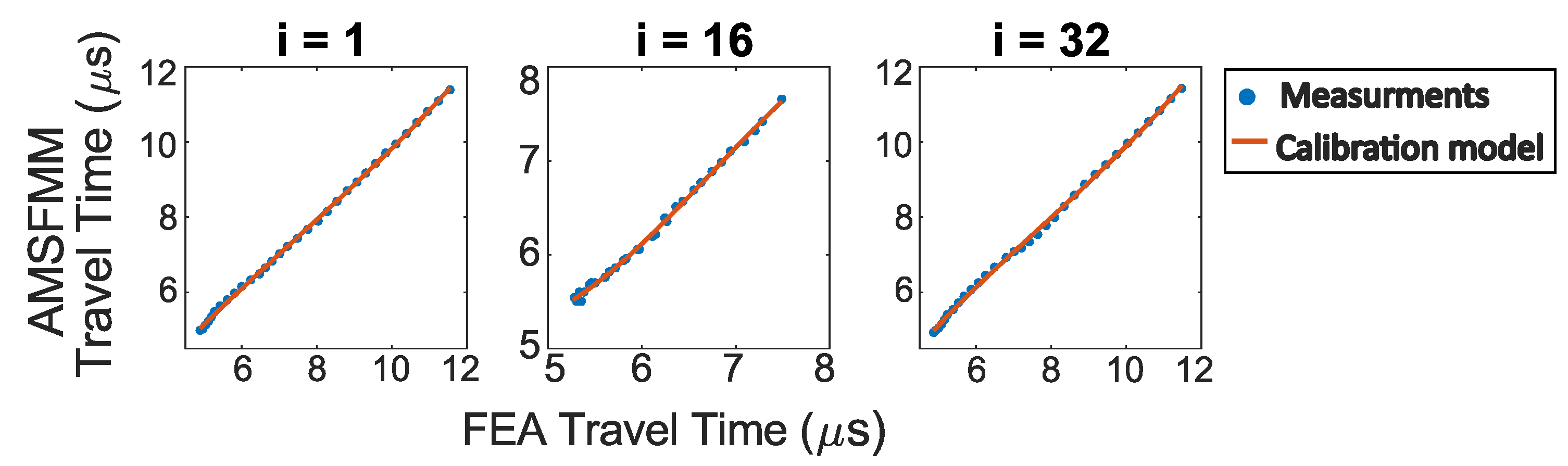

2.4. Data Calibration

2.5. Deep Neural Networks

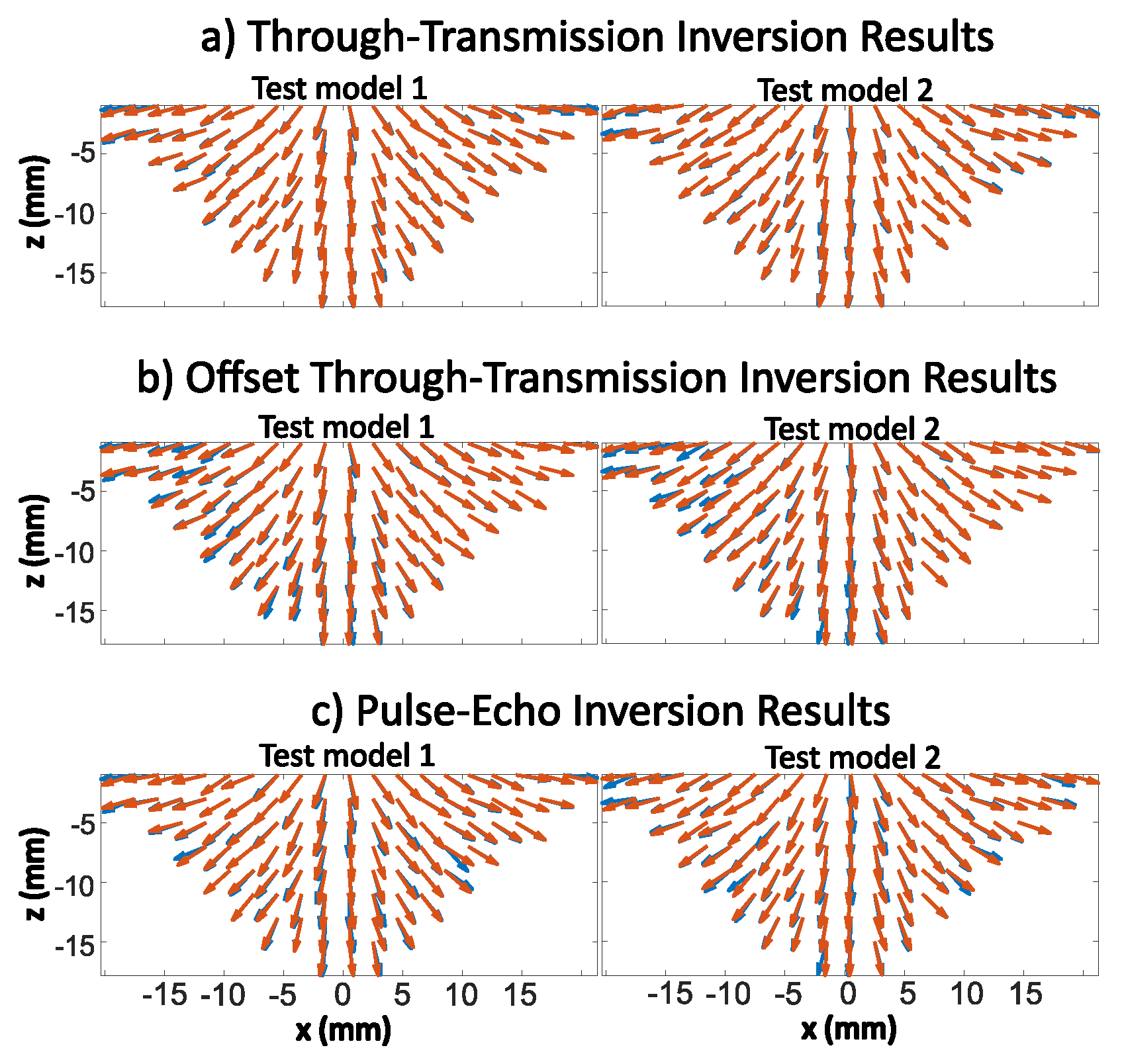

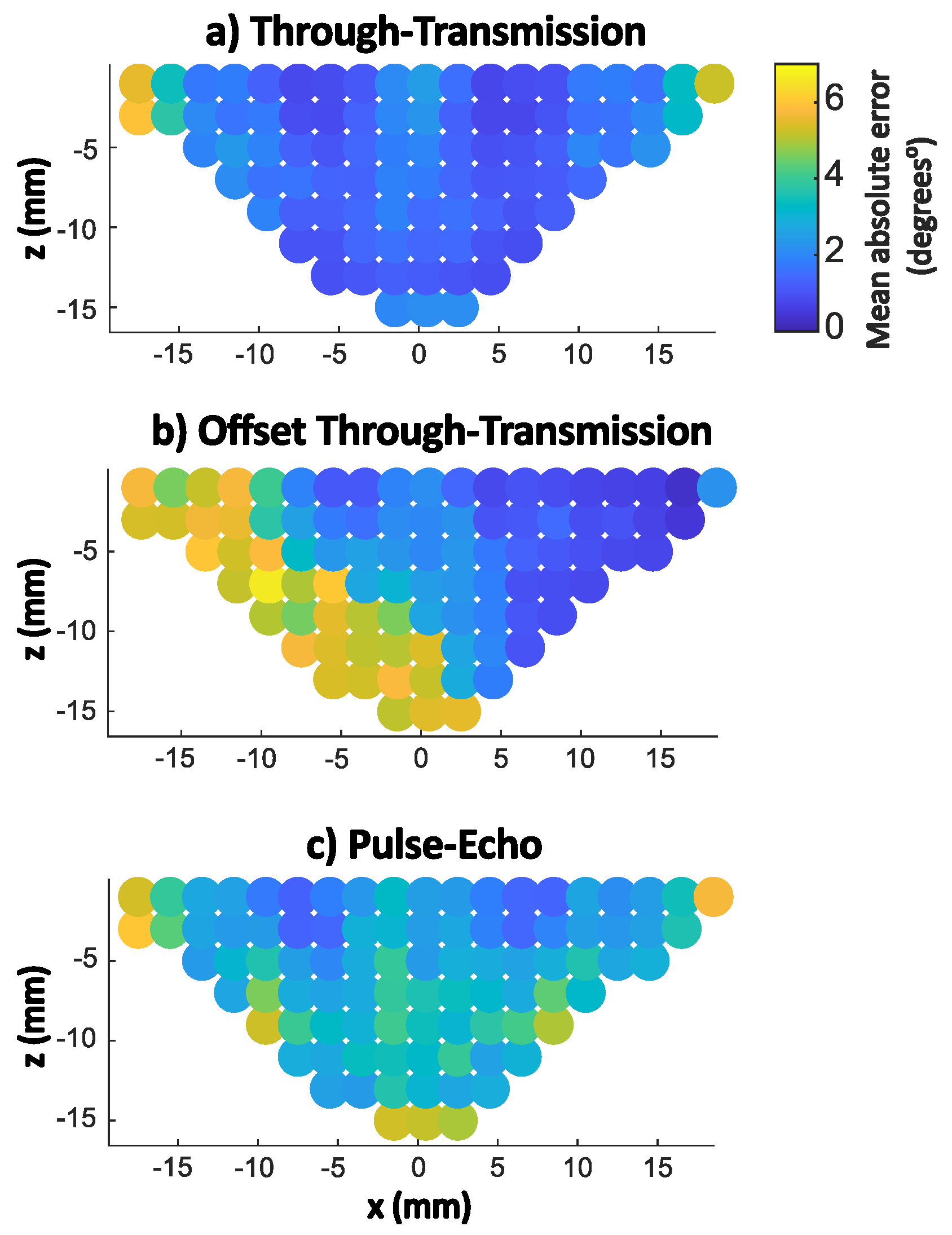

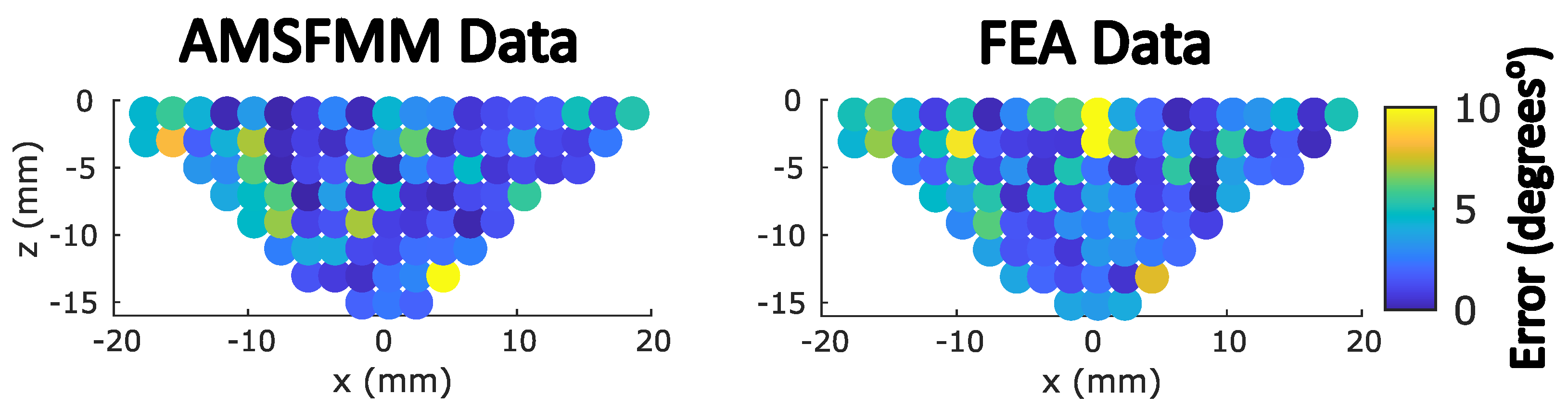

3. Results

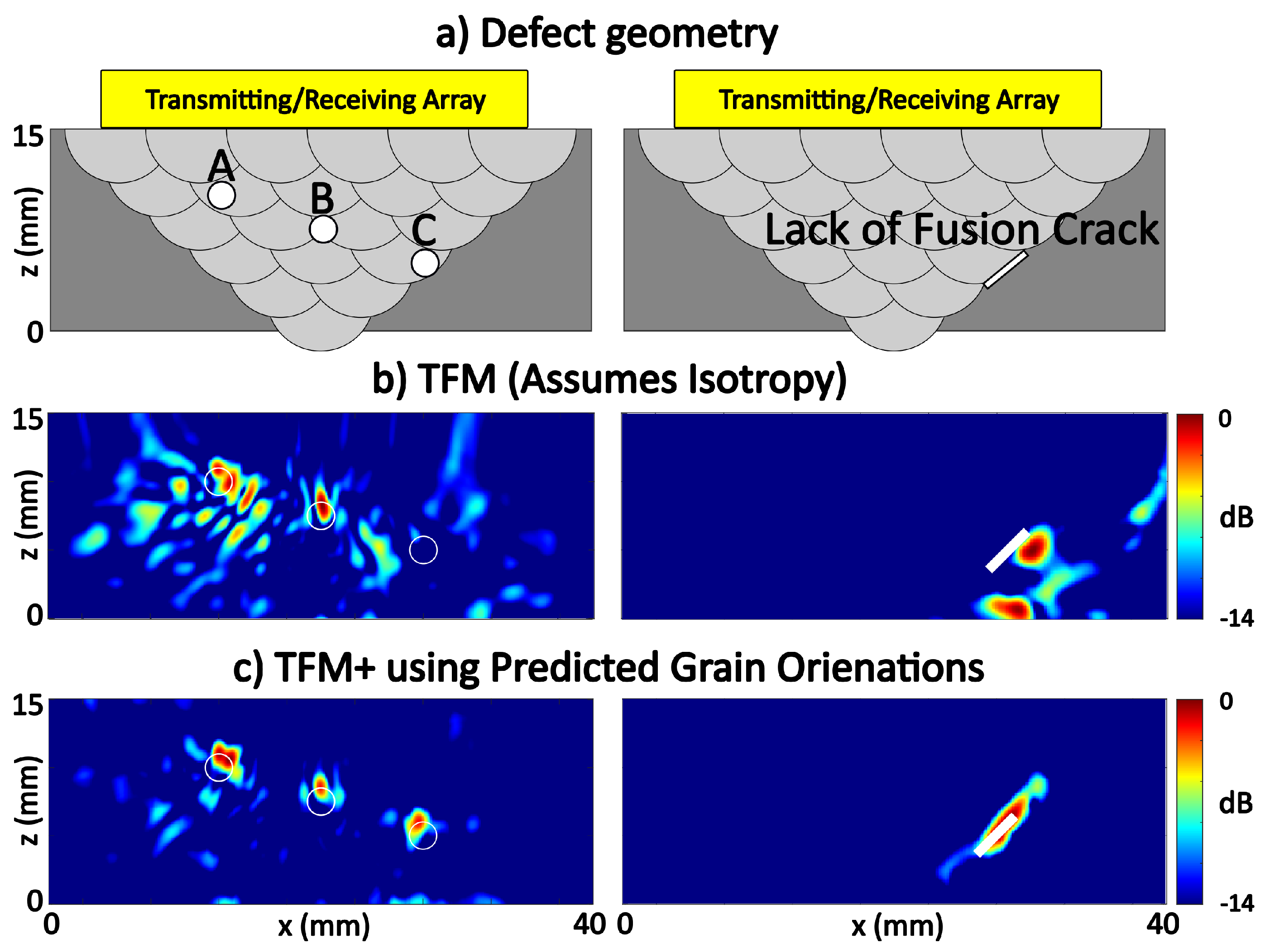

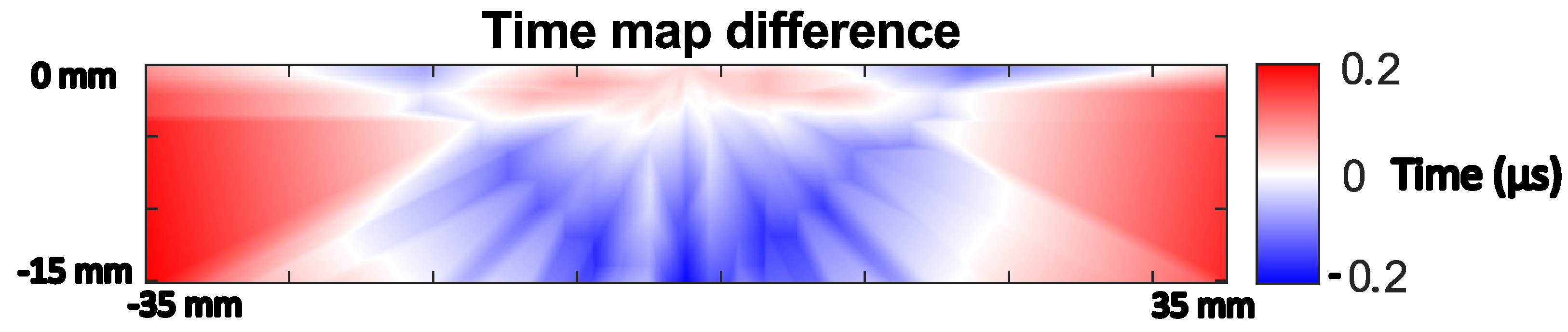

TFM Reconstruction Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Holmes, C.; Drinkwater, B.W.; Wilcox, P.D. Post-processing of the full matrix of ultrasonic transmit–receive array data for non-destructive evaluation. NDT & E Int. 2005, 38, 701–711. [Google Scholar]

- Connolly, G.; Lowe, M.; Temple, J.; Rokhlin, S. The application of Fermat’s principle for imaging anisotropic and inhomogeneous media with application to austenitic steel weld inspection. Proc. R. Soc. A Math. Phys. Eng. Sci. 2009, 465, 3401–3423. [Google Scholar] [CrossRef]

- Zhang, J.; Hunter, A.; Drinkwater, B.; Wilcox, P. Monte Carlo inversion of ultrasonic array data to map anisotropic weld properties. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 2487–2497. [Google Scholar] [CrossRef] [PubMed]

- Tant, K.M.M.; Galetti, E.; Mulholland, A.; Curtis, A.; Gachagan, A. Effective grain orientation mapping of complex and locally anisotropic media for improved imaging in ultrasonic non-destructive testing. Inverse Probl. Sci. Eng. 2020, 1–25. [Google Scholar] [CrossRef]

- Tant, K.M.M.; Galetti, E.; Mulholland, A.; Curtis, A.; Gachagan, A. A transdimensional Bayesian approach to ultrasonic travel-time tomography for non-destructive testing. Inverse Probl. 2018, 34, 095002. [Google Scholar] [CrossRef]

- Nageswaran, C.; Carpentier, C.; Tse, Y. Microstructural quantification, modelling and array ultrasonics to improve the inspection of austenitic welds. Insight-Non-Destr. Test. Cond. Monit. 2009, 51, 660–666. [Google Scholar] [CrossRef][Green Version]

- Chassignole, B.; Villard, D.; Dubuget, M.; Baboux, J.; Guerjouma, R.E. Characterization of austenitic stainless steel welds for ultrasonic NDT. In Proceedings of the AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2000; Volume 509, pp. 1325–1332. [Google Scholar]

- Gueudré, C.; Le Marrec, L.; Moysan, J.; Chassignole, B. Direct model optimisation for data inversion. Application to ultrasonic characterisation of heterogeneous welds. NDT & E Int. 2009, 42, 47–55. [Google Scholar]

- Sharples, S.; Clark, M.; Somekh, M. Spatially resolved acoustic spectroscopy for fast noncontact imaging of material microstructure. Opt. Express 2006, 14, 10435–10440. [Google Scholar] [CrossRef]

- Abrahams, I.; Wickham, G. The propagation of elastic waves in a certain class of inhomogeneous anisotropic materials. I. The refraction of a horizontally polarized shear wave source. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1992, 436, 449–478. [Google Scholar]

- Spies, M. Analytical methods for modeling of ultrasonic nondestructive testing of anisotropic media. Ultrasonics 2004, 42, 213–219. [Google Scholar] [CrossRef]

- Harvey, G.; Tweedie, A.; Carpentier, C.; Reynolds, P. Finite element analysis of ultrasonic phased array inspections on anisotropic welds. In Proceedings of the AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2011; Volume 1335, pp. 827–834. [Google Scholar]

- Moysan, J.; Apfel, A.; Corneloup, G.; Chassignole, B. Modelling the grain orientation of austenitic stainless steel multipass welds to improve ultrasonic assessment of structural integrity. Int. J. Press. Vessel. Pip. 2003, 80, 77–85. [Google Scholar] [CrossRef]

- L’huillier, P.; Chassignole, B.; Oudaa, M.; Kerhervé, S.; Rupin, F.; Fouquet, T. Investigation of the ultrasonic attenuation in anisotropic weld materials with finite element modeling and grain-scale material description. Ultrasonics 2017, 78, 40–50. [Google Scholar] [CrossRef]

- Bodin, T.; Sambridge, M. Seismic tomography with the reversible jump algorithm. Geophys. J. Int. 2009, 178, 1411–1436. [Google Scholar] [CrossRef]

- Zhang, X.; Curtis, A. Variational full-waveform inversion. Geophys. J. Int. 2020, 222, 406–411. [Google Scholar] [CrossRef]

- Bai, C.; Huang, G.; Li, X.; Zhou, B.; Greenhalgh, S. Ray tracing of multiple transmitted/reflected/converted waves in 2-D/3-D layered anisotropic TTI media and application to crosswell traveltime tomography. Geophys. J. Int. 2013, 195, 1068–1087. [Google Scholar] [CrossRef][Green Version]

- Zhu, H.; Komatitsch, D.; Tromp, J. Radial anisotropy of the North American upper mantle based on adjoint tomography with USArray. Geophys. J. Int. 2017, 211, 349–377. [Google Scholar] [CrossRef]

- Lebedev, S.; Van Der Hilst, R.D. Global upper-mantle tomography with the automated multimode inversion of surface and S-wave forms. Geophys. J. Int. 2008, 173, 505–518. [Google Scholar] [CrossRef]

- Guasch, L.; Agudo, O.; Tang, M.; Nachev, P.; Warner, M. Full-waveform inversion imaging of the human brain. NPJ Digit. Med. 2020, 3, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Bernard, S.; Monteiller, V.; Komatitsch, D.; Lasaygues, P. Ultrasonic computed tomography based on full-waveform inversion for bone quantitative imaging. Phys. Med. Biol. 2017, 62, 7011. [Google Scholar] [CrossRef]

- Huthwaite, P.; Simonetti, F. High-resolution imaging without iteration: A fast and robust method for breast ultrasound tomography. J. Acoust. Soc. Am. 2011, 130, 1721–1734. [Google Scholar] [CrossRef]

- Bishop, C.M. Neural Networks for Pattern Recognition; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Earp, S.; Curtis, A.; Zhang, X.; Hansteen, F. Probabilistic neural network tomography across Grane field (North Sea) from surface wave dispersion data. Geophys. J. Int. 2020, 223, 1741–1757. [Google Scholar] [CrossRef]

- Earp, S.; Curtis, A. Probabilistic neural network-based 2D travel-time tomography. Neural Comput. Appl. 2020, 32, 17077–17095. [Google Scholar] [CrossRef]

- Araya-Polo, M.; Jennings, J.; Adler, A.; Dahlke, T. Deep-learning tomography. Lead. Edge 2018, 37, 58–66. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, H.; Gemmeke, H.; Hopp, T.; Hesser, J. Model-data-driven image reconstruction with neural networks for ultrasound computed tomography breast imaging. Neurocomputing 2022, 467, 10–21. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, H.; Gemmeke, H.; Van Dongen, K.W.; Hopp, T.; Hesser, J. Ultrasound transmission tomography image reconstruction with a fully convolutional neural network. Phys. Med. Biol. 2020, 65, 235021. [Google Scholar] [CrossRef] [PubMed]

- Ogilvy, J.A. Ultrasonic beam profiles and beam propagation in an austenitic weld using a theoretical ray tracing model. Ultrasonics 1986, 24, 337–347. [Google Scholar] [CrossRef]

- Holmes, C.; Drinkwater, B.; Wilcox, P. The post-processing of ultrasonic array data using the total focusing method. Insight-Non-Destr. Test. Cond. Monit. 2004, 46, 677–680. [Google Scholar] [CrossRef]

- Connolly, G.; Lowe, M.; Temple, J.; Rokhlin, S. Correction of ultrasonic array images to improve reflector sizing and location in inhomogeneous materials using a ray-tracing model. J. Acoust. Soc. Am. 2010, 127, 2802–2812. [Google Scholar] [CrossRef] [PubMed]

- Dobson, J.; Tweedie, A.; Harvey, G.; O’Leary, R.; Mulholland, A.; Tant, K.; Gachagan, A. Finite element analysis simulations for ultrasonic array NDE inspections. In Proceedings of the AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2016; Volume 1706, p. 040005. [Google Scholar]

- Chassignole, B.; El Guerjouma, R.; Ploix, M.A.; Fouquet, T. Ultrasonic and structural characterization of anisotropic austenitic stainless steel welds: Towards a higher reliability in ultrasonic non-destructive testing. NDT & E Int. 2010, 43, 273–282. [Google Scholar]

- Gueudré, C.; Mailhé, J.; Ploix, M.; Corneloup, G.; Chassignole, B. Influence of the uncertainty of elastic constants on the modelling of ultrasound propagation through multi-pass austenitic welds. Impact on non-destructive testing. Int. J. Press. Vessel. Pip. 2019, 171, 125–136. [Google Scholar] [CrossRef]

- Lhémery, A.; Calmon, P.; Lecœur-Taıbi, I.; Raillon, R.; Paradis, L. Modeling tools for ultrasonic inspection of welds. NDT & E Int. 2000, 33, 499–513. [Google Scholar]

- Wirgin, A. The Inverse Crime. arXiv 2004, arXiv:math-ph/0401050. [Google Scholar]

- Sethian, J.A. Level Set Methods and Fast Marching Methods: Evolving Interfaces in Computational Geometry, Fluid Mechanics, Computer Vision, and Materials Science; Cambridge University Press: Cambridge, MA, USA, 1999; Volume 3. [Google Scholar]

- OnScale. 770 Marshall Street, Redwood City, CA, USA. Available online: https://onscale.com/about-us/ (accessed on 19 November 2021).

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- Singh, J.; Tant, K.M.; Curtis, A.; Mulholland, A.J. Real-time super-resolution mapping of locally anisotropic grain orientations for ultrasonic non-destructive evaluation of crystalline material. Neural Comput. Appl. 2021. [Google Scholar] [CrossRef]

- Bergstra, J.; Komer, B.; Eliasmith, C.; Yamins, D.; Cox, D.D. Hyperopt: A Python library for model selection and hyperparameter optimization. Comput. Sci. Discov. 2015, 8, 014008. [Google Scholar] [CrossRef]

- Kelly, B.; Matthews, T.P.; Anastasio, M.A. Deep learning-guided image reconstruction from incomplete data. arXiv 2017, arXiv:1709.00584. [Google Scholar]

- Stratoudaki, T.; Javadi, Y.; Kerr, W.; Wilcox, P.D.; Pieris, D.; Clark, M. Laser induced phased arrays for remote ultrasonic imaging of additive manufactured components. In Proceedings of the 57th Annual Conference of the British Institute of Non-Destructive Testing, NDT 2018, Nottingham, UK, 10–12 September 2018; pp. 174–182. [Google Scholar]

- Jospin, L.V.; Buntine, W.; Boussaid, F.; Laga, H.; Bennamoun, M. Hands-on Bayesian Neural Networks–a Tutorial for Deep Learning Users. arXiv 2020, arXiv:2007.06823. [Google Scholar]

| Hyperparameter | Through-Transmission (TT) | Offset TT | Pulse-Echo |

|---|---|---|---|

| Learning rate | 5 | 2 | 3.8 |

| Decay rate | 5.4 | 4.4 | 4.5 |

| Nodes in layer 1 | 283 | 220 | 303 |

| Nodes in additional layers | 46 | 48 | 44 |

| Number of layers | 4 | 4 | 4 |

| Activation function | Sigmoid | Sigmoid | Sigmoid |

| Defect A | Defect B | Defect C | |

|---|---|---|---|

| TFM | 11.7 dB | 14.1 dB | 10.5 dB |

| TFM+ | 14.3 dB | 14.1 dB | 15.8 dB |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, J.; Tant, K.; Mulholland, A.; MacLeod, C. Deep Learning Based Inversion of Locally Anisotropic Weld Properties from Ultrasonic Array Data. Appl. Sci. 2022, 12, 532. https://doi.org/10.3390/app12020532

Singh J, Tant K, Mulholland A, MacLeod C. Deep Learning Based Inversion of Locally Anisotropic Weld Properties from Ultrasonic Array Data. Applied Sciences. 2022; 12(2):532. https://doi.org/10.3390/app12020532

Chicago/Turabian StyleSingh, Jonathan, Katherine Tant, Anthony Mulholland, and Charles MacLeod. 2022. "Deep Learning Based Inversion of Locally Anisotropic Weld Properties from Ultrasonic Array Data" Applied Sciences 12, no. 2: 532. https://doi.org/10.3390/app12020532

APA StyleSingh, J., Tant, K., Mulholland, A., & MacLeod, C. (2022). Deep Learning Based Inversion of Locally Anisotropic Weld Properties from Ultrasonic Array Data. Applied Sciences, 12(2), 532. https://doi.org/10.3390/app12020532