Workforce Learning Curves for Human-Based Assembly Operations: A State-of-the-Art Review

Abstract

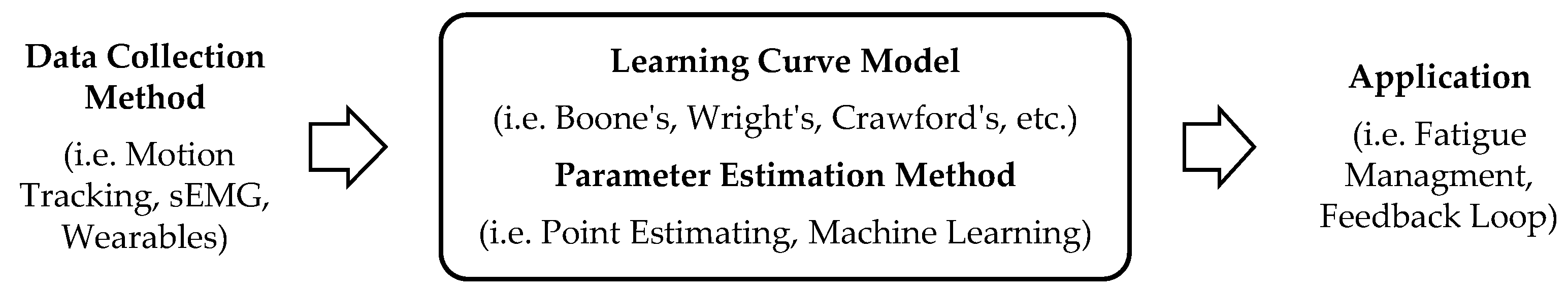

1. Introduction

- RQ1.

- What calculation methods for estimating the learning curve of a worker exist in the recent scientific literature?

- RQ2.

- What other usages are manufacturing enterprises giving to the modern learning curve prediction models according to the recent scientific literature?

- RQ3.

- What data collection and monitoring technologies exist to automatically acquire the data needed to create and continuously update the learning curve of an assembly operator?

2. Theoretical Background

2.1. Manual Assembly Operations

2.2. Learning Curves

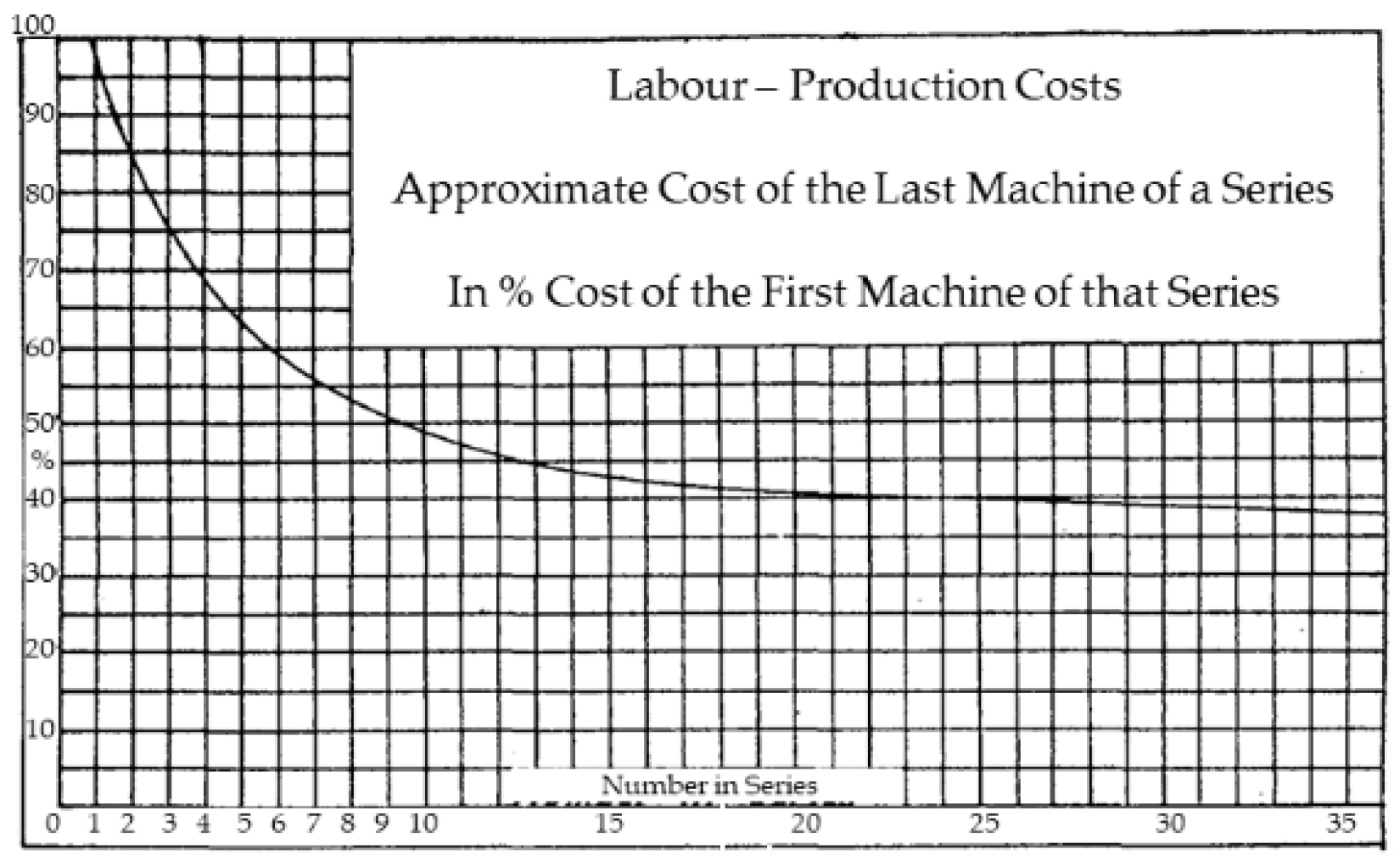

- Cumulative Average Learning Model—Developed in 1936 by Wright [10] who observed that after doubling the produced parts, the production time was reduced by a constant rate. Wright’s learning curve model offers its calculations based on the following Equation (1):which represents the cumulative average cost or time of the first x unit, where A is the theoretical cost or time to produce the first unit, and b is the natural logarithm of the learning curve slope divided by the natural logarithm of 2. From Wright’s observations, the learning curve slope parameter should be 80% to approximate a bomber manufacturing process behaviour (see Figure 1). Multiple variations of his model were created afterwards, accounting for process-specific variables observed by other authors and parameters not considered in his initial model. Some of the more popular examples are the Stanford-B model, Crawford’s unit learning model, and Conaway & Schultz’s plateau model.

- Unit Learning Model—Developed in 1947 by Crawford [12], which base formula is the same as the cumulative average learning model from Wright [10], however, there is a difference in interpretation of the values where represents the individual cost or time of unit x where the rest of the variables remain the same (see Figure 2).

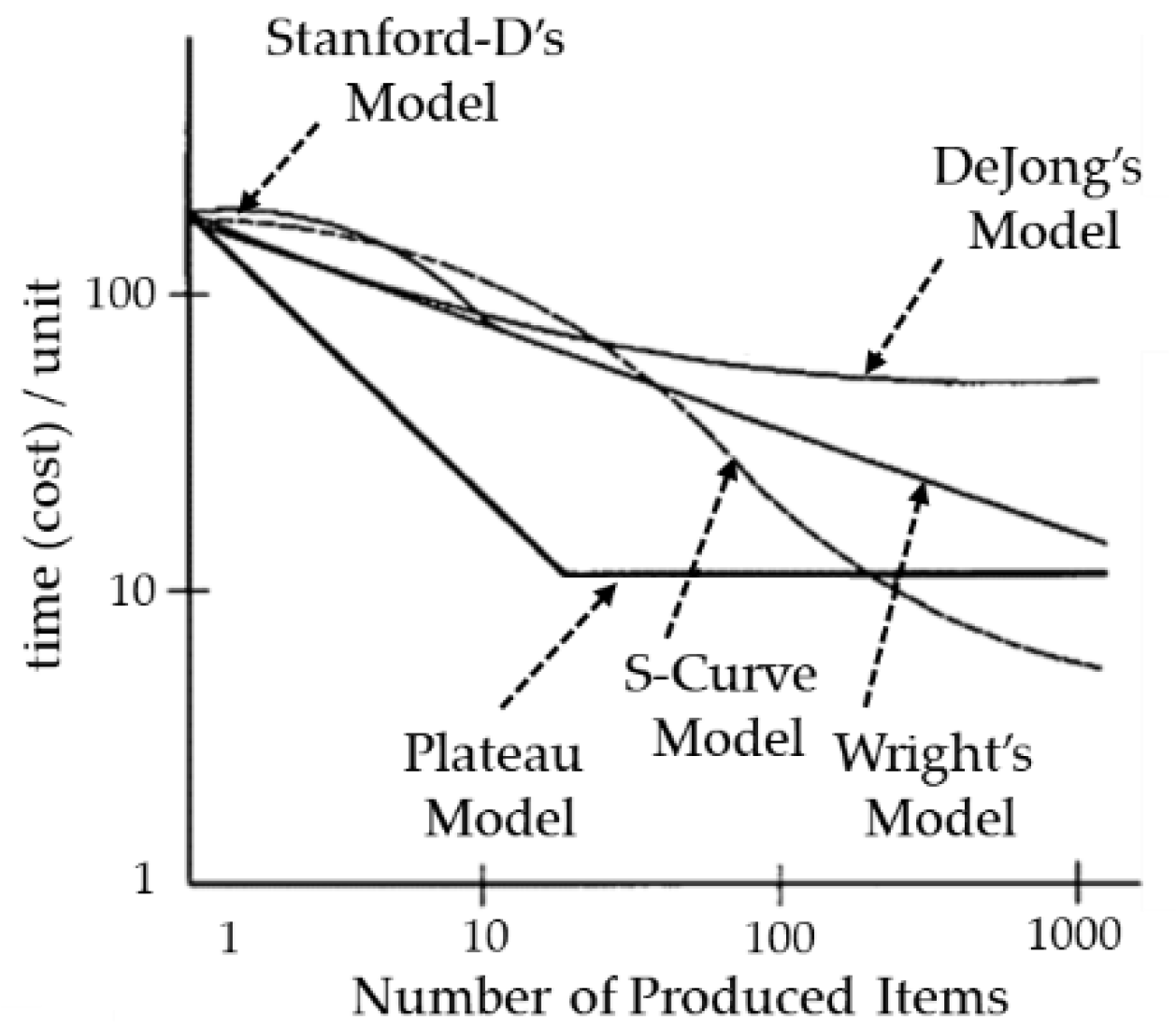

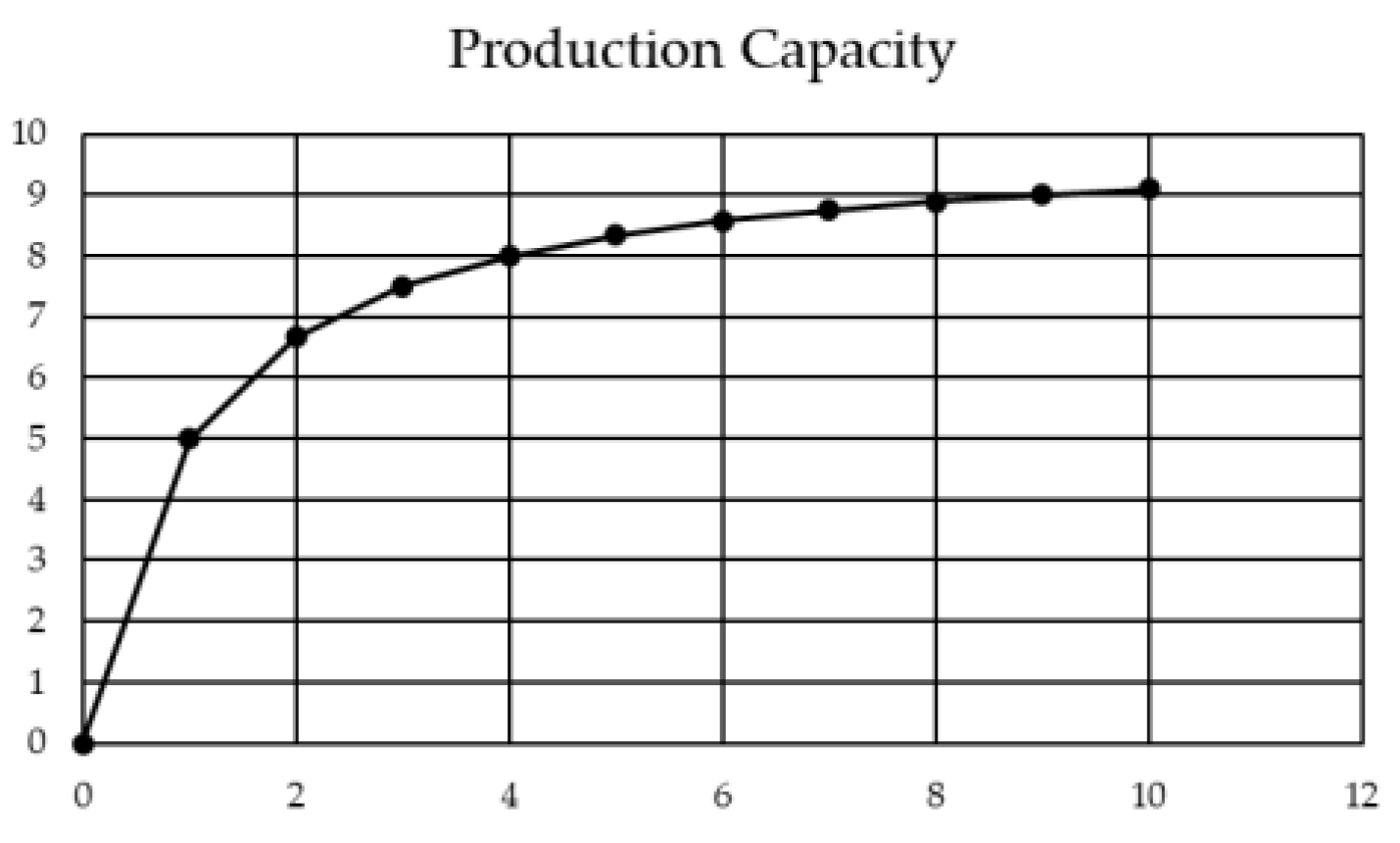

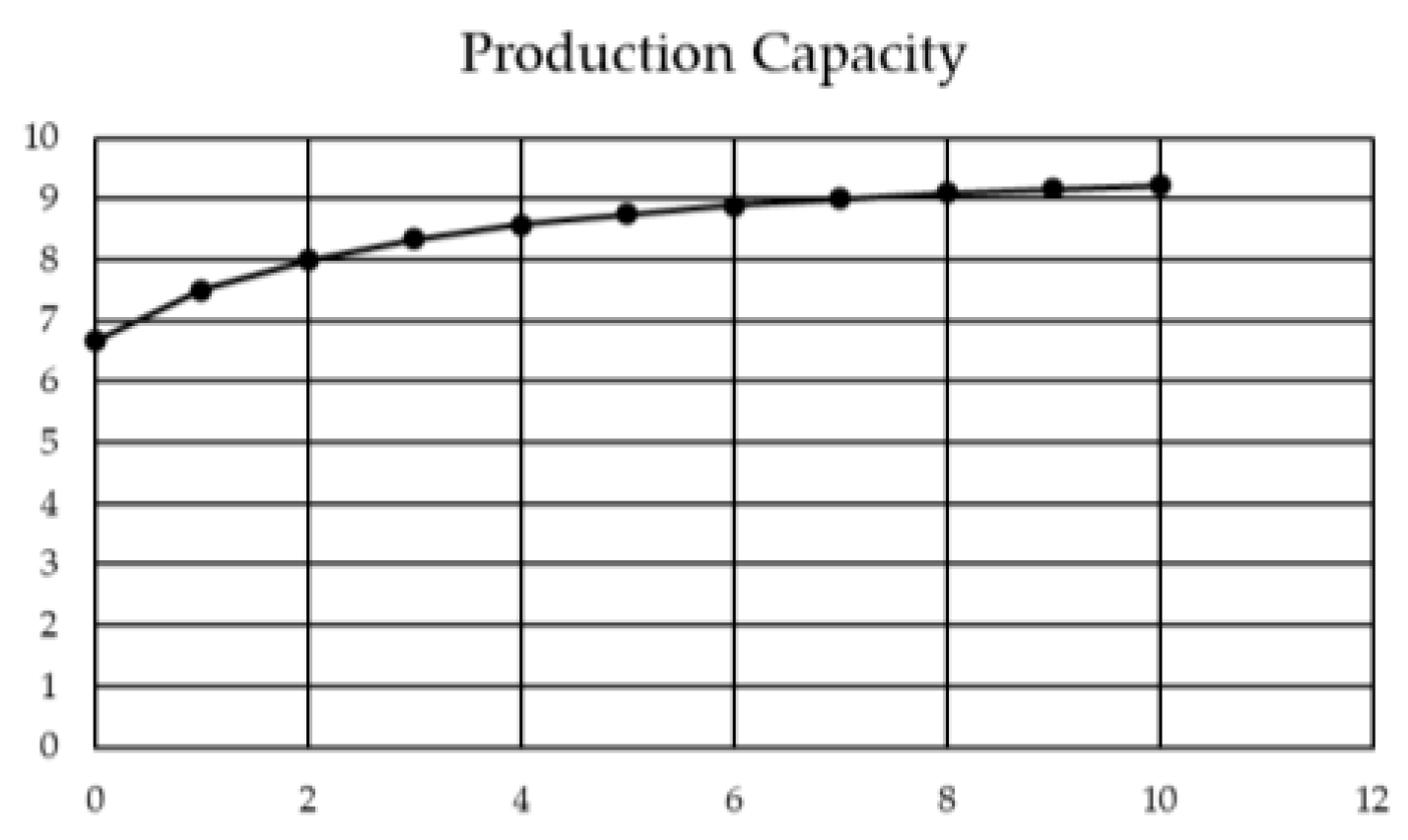

- Plateau Model—In 1957, Conaway & Schultz [13] first described the plateau effect in their learning curve model to account for the reduction in the learning rate. To account for this effect, the authors based their model on Wright’s learning curve [10], modifying it by adding a second process parameter c, which represents the standard time estimated from empirical data (the long-term value of the cycle time), thus generating a plateau on the learning curve on the value of c, via the Equation (2):where the values of A, x, and b are the same as the ones found in Wright’s model [10] (see Figure 3). Another notable example of the plateau geometry model is presented by Yelle in 1979 [14], accounting for the limits a machine presents on the learning curve of an operator, meaning he/she cannot lower the cycle time below the standard operating time of a machine.

- Stanford-B Model—After World War II, the Stanford Research Institute was commissioned by the US Air Force to develop a new cost estimating learning curve for a process with previous similar production, meaning a previous workforce experience. To assess the presented requirement, the Institute developed the Stanford-B model, named after the additional B parameter, corresponding to the previous B number of units of experience, shifting the original log-linear along the time axis [15] (see Figure 3). To achieve this, the new learning curve model was expressed as Equation (3):

- DeJong’s Model—DeJong realized in 1957 [16] that certain operations where machines were involved had a reduced learning effect on the operator, and a fraction of the cycle time came from the standard operation of the machine. He developed a model to assess this effect on burden-heavy operations with the mathematical modelling of Equation (4):where M represents the fraction of the work performed by a machine. When M = 1, meaning a total automated process, the learning effect becomes 0, leaving a constant work rate, and when M = 0 the model simply becomes Wright’s log-linear model [10] (see Figure 3).

- S-Curve Model—Named after the particular shape of the graph of the model [17], it is a combined form of both DeJong’s assessment of the machine involvement in the learning process [16] and Stanford-B’s previous experience effect [15]. Thus, the resulting model is Equation (5):where the parameters keep the same meaning as in the origin model. The result is an S-shaped curve with a more precise but harder-to-estimate model of four parameters (see Figure 3).

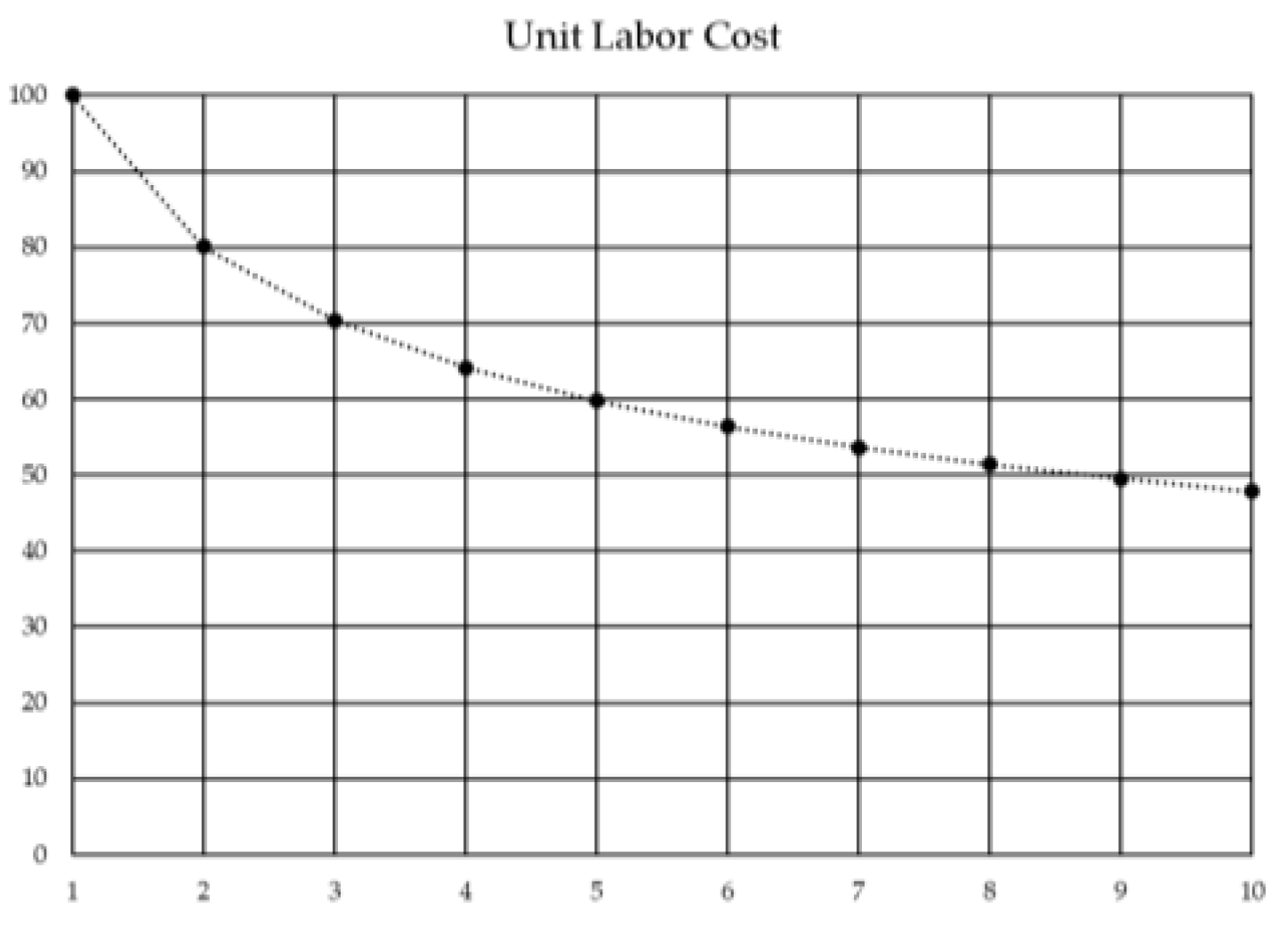

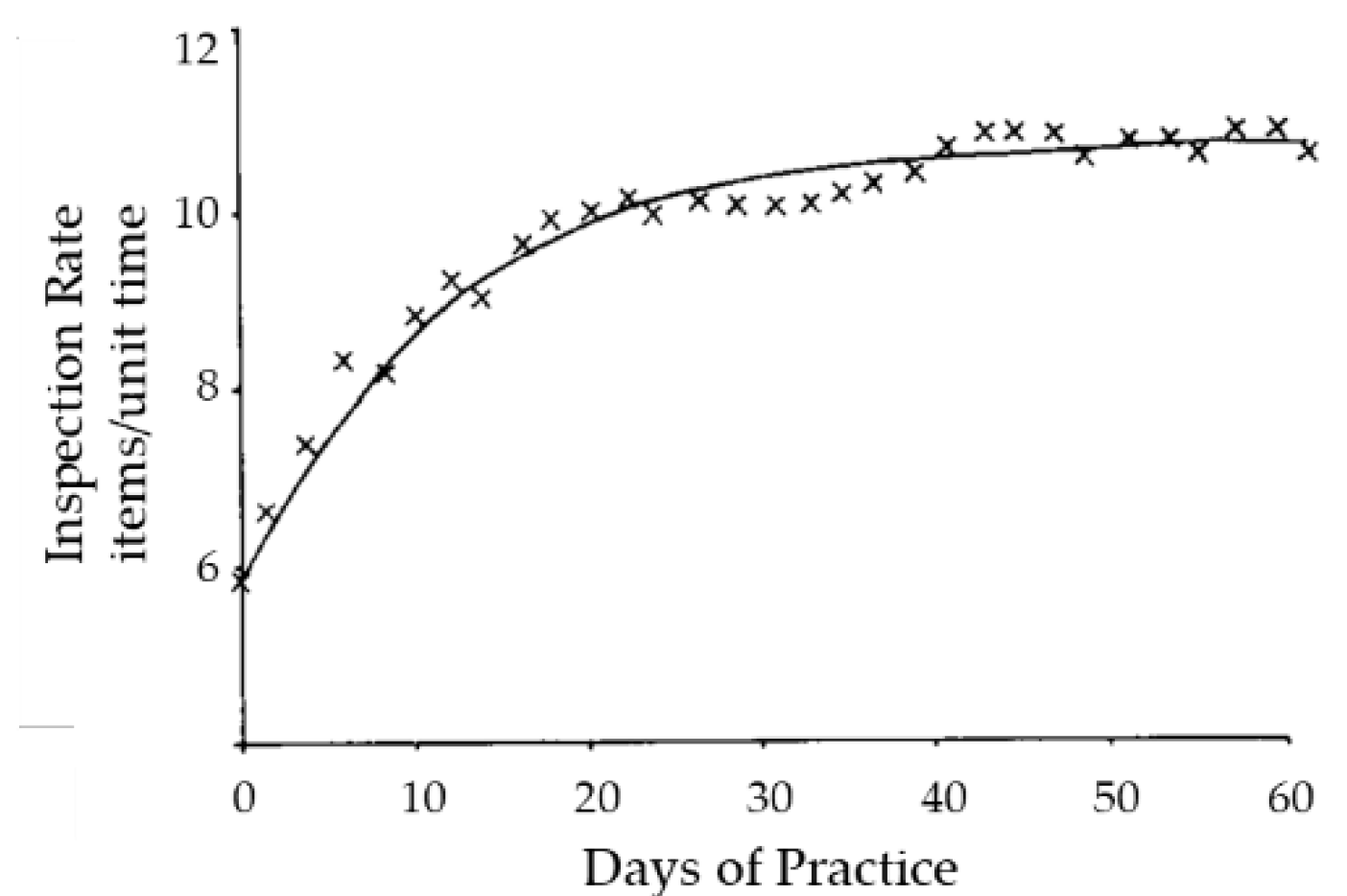

- Levy’s Adapted Function Model—From the adapted function model developed by Levy [18], the author added a parameter λ representing the speed at which the model approaches the maximum estimated throughput (P max). The resulting mathematical Equation (6):where the variables b, x and y keep the same interpretation as in Wright’s model [10], being b the natural logarithm of the learning curve slope divided by the natural logarithm of two, x the current production unit in the lifecycle and y the initial cycle time of the process (see Figure 4).

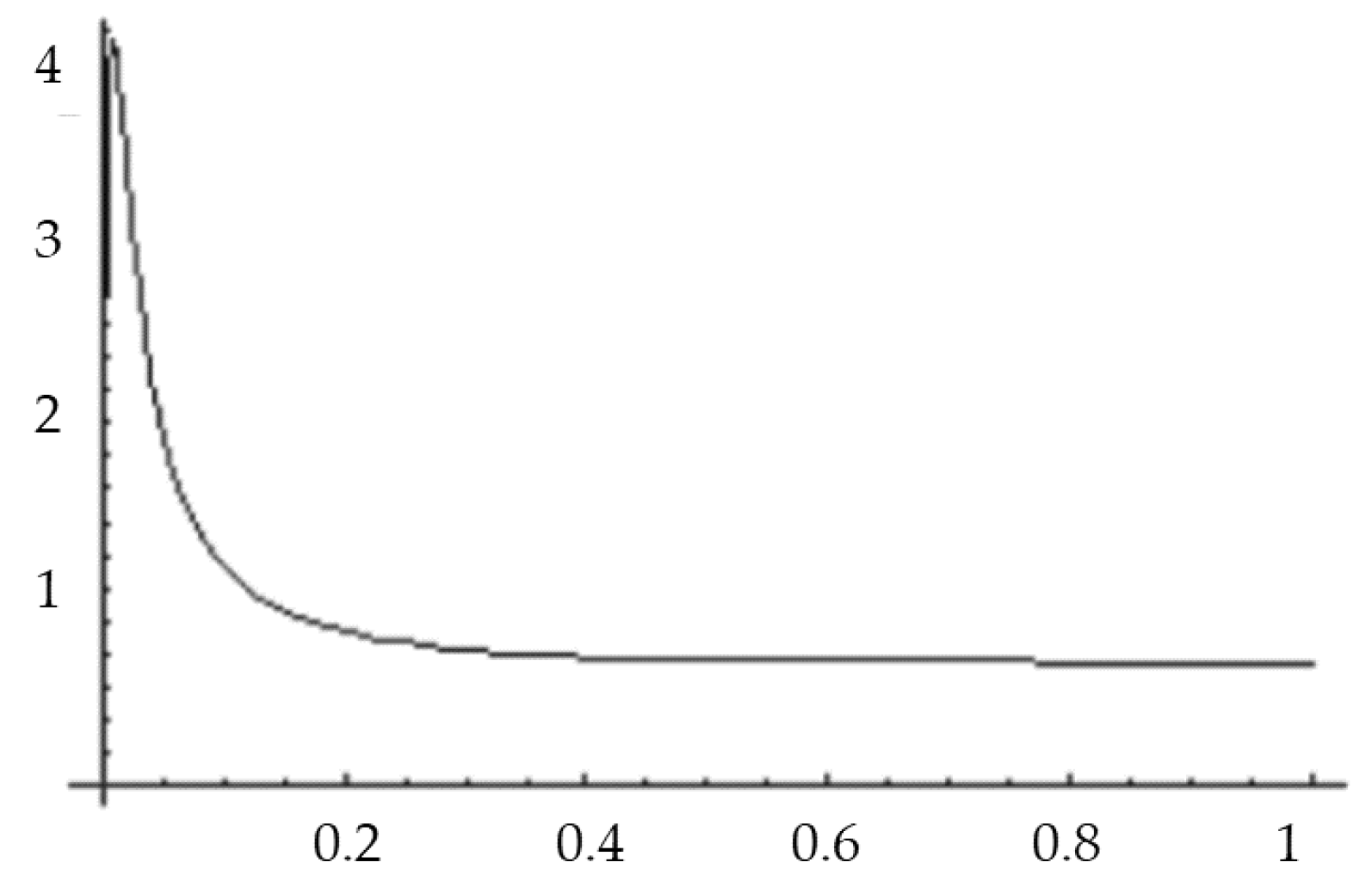

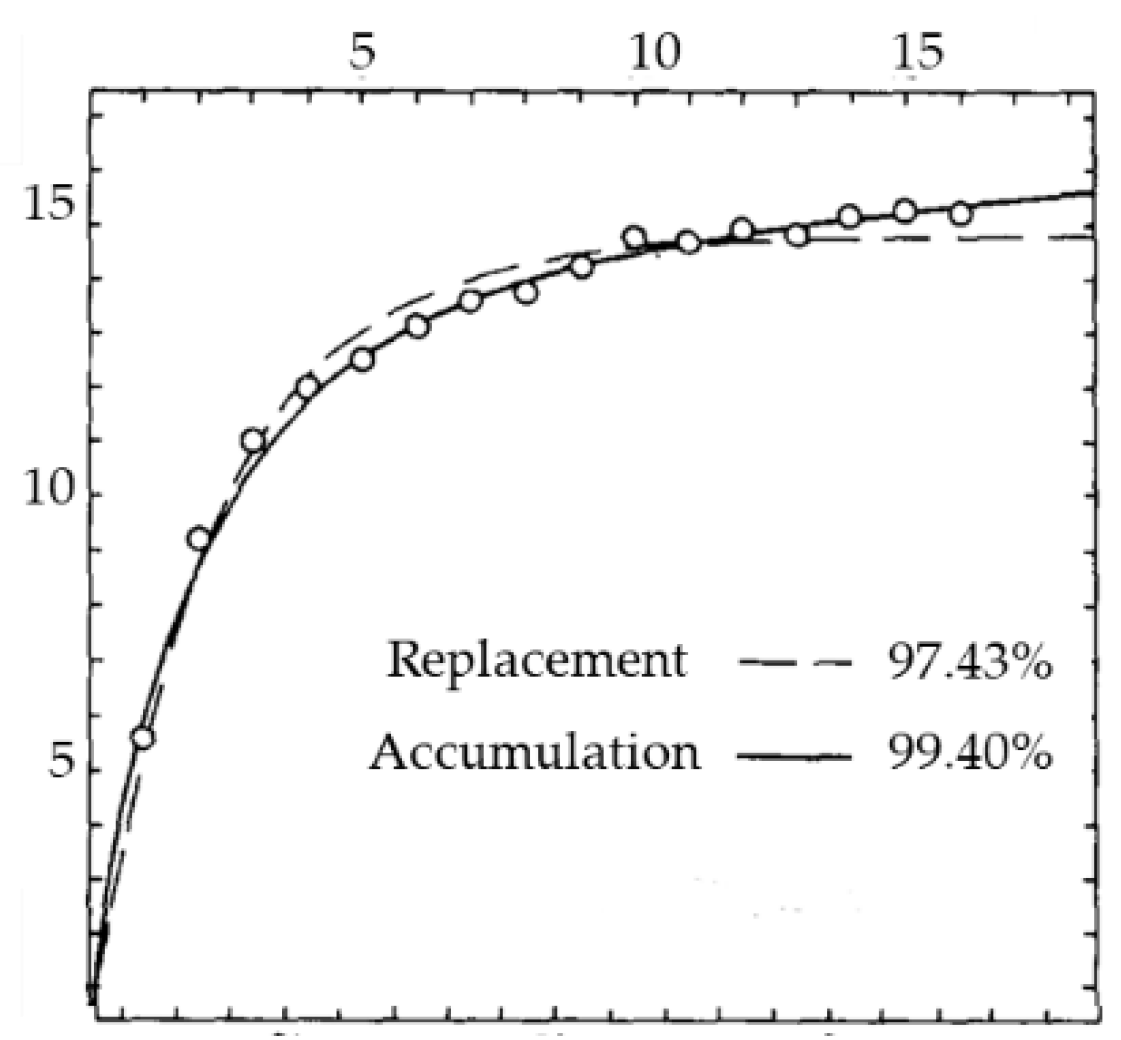

- Two and Three Parameter Models—Both models were proposed by Mazur & Hastie in 1978 [20], the Two Parameter model offers an approximation of the skill development behaviour in the workforce using two new parameters; k which represents the maximum throughput of a worker after the learning curve slope approaching zero, and the parameter r representing the learning rate in time units. The resulting Equation (7) is:After t developing the Two Parameter model, Mazur & Hastie [20] improved the fitting accuracy by adding a third parameter, p which corresponds to the worker’s prior experience, expressed in time units (see Figure 5). The mathematical Equation (8) for this variation is:The authors establish that their Three Parameter model has a good fit with operations where the operator has previous experience but performs poorly with operations that frequently require new and complex tasks (see Figure 6).

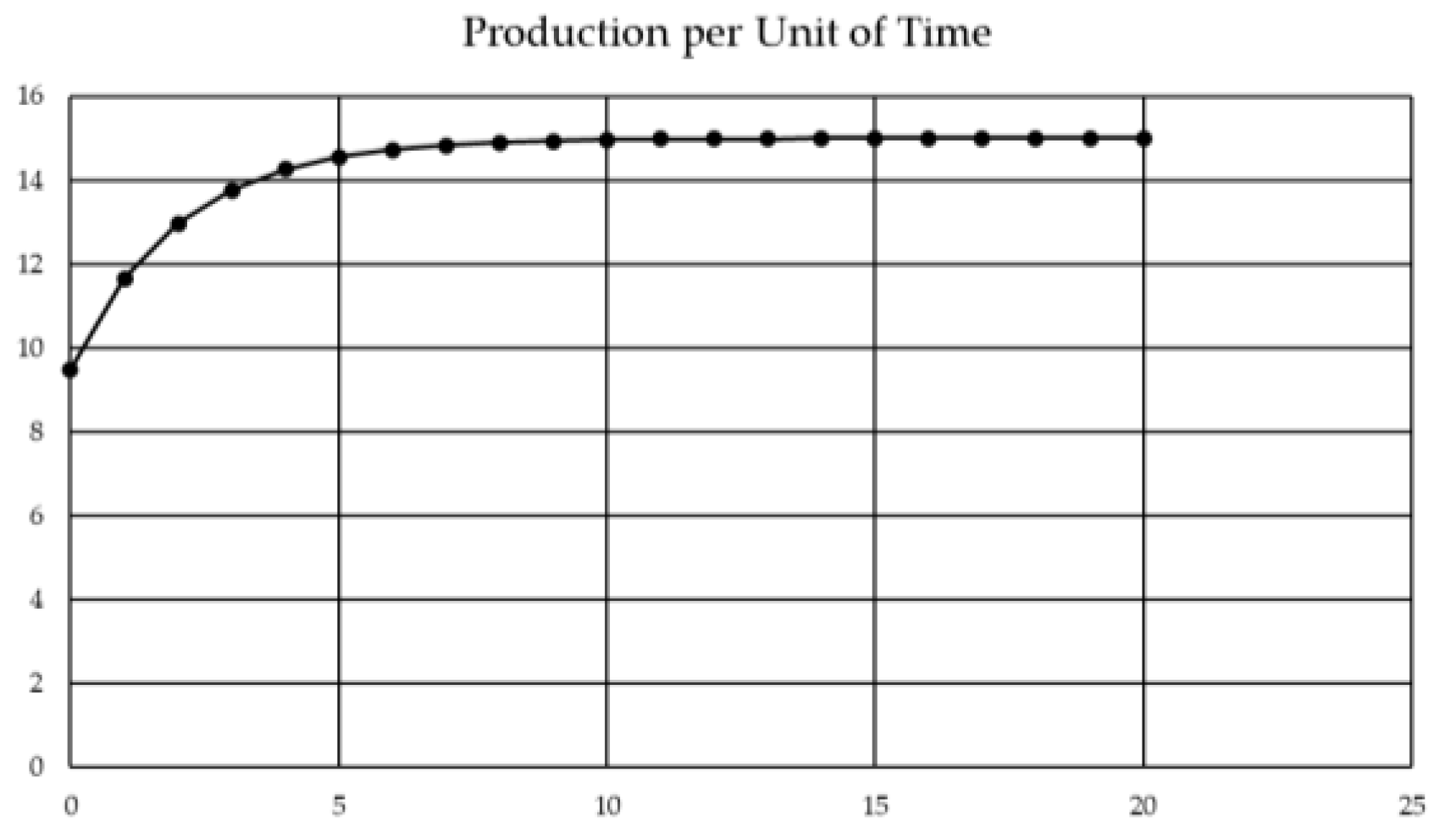

- Constant Time Model—In 1990, Towill [21] validated a similarly structured model to the Two Parameter model. He found that an exponential model with a starting constant value is better suited to estimate the learning curve of processes after the steepest learning curve period, meaning after they have adapted to a new task or job. The model’s mathematical Equation (9) is represented as:where yc represents the worker’s initial performance, yf is the highest achievable performance after learning, x remains the same as previous models (meaning how many units of experience the worker has), and τ is the time constant for a particular curve (see Figure 7).

3. State-of-the-Art Review Methodology

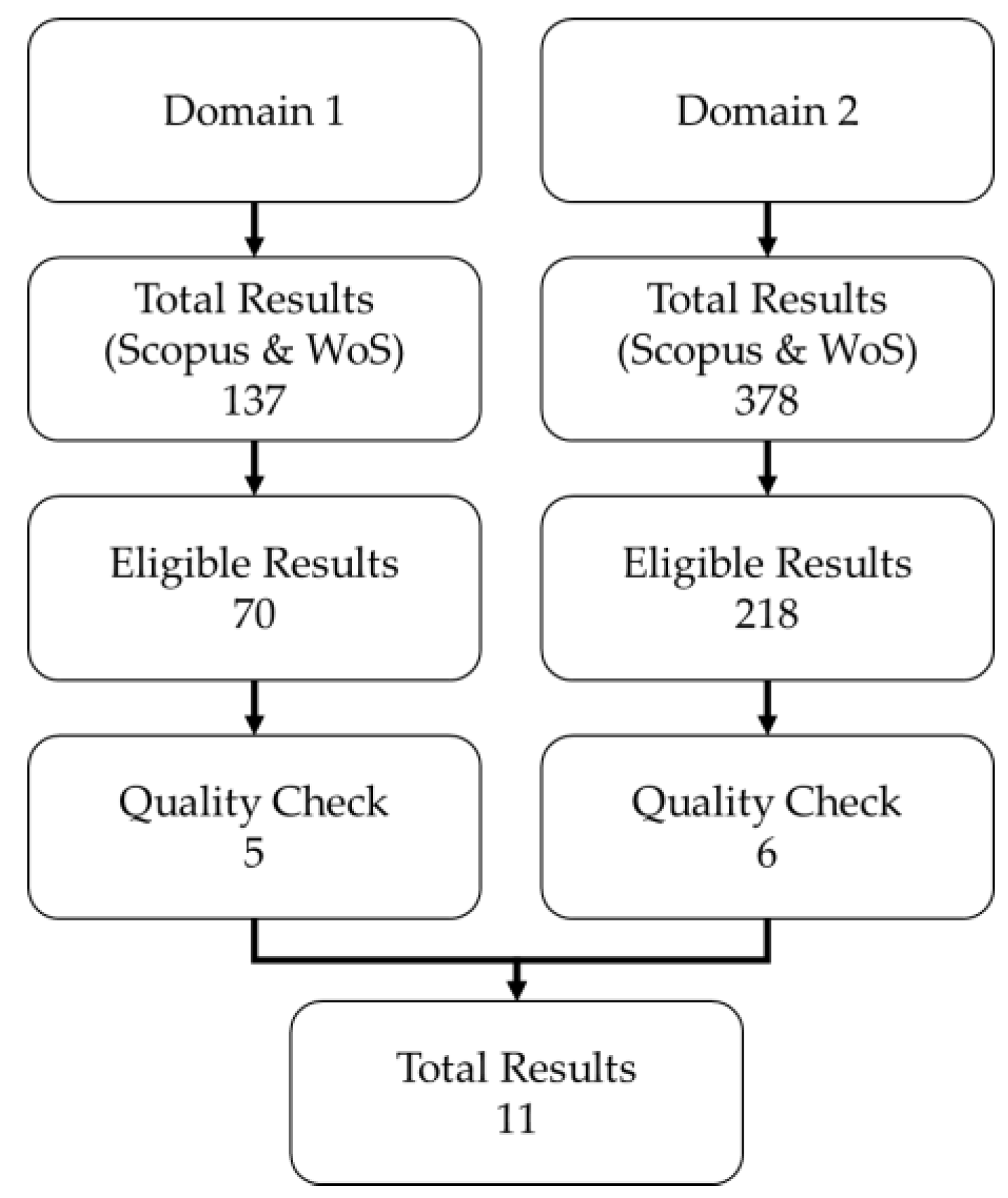

3.1. Search Strategy

3.2. Keywords Selection

3.3. Query Construction and Execution

3.4. Information Sources and Eligibility

- 1.

- Language: English—Due to being the main publishing language for the most important journals and international conference proceedings related to this research.

- 2.

- Time-span: From 2017 to the current writing year (2022) looking to study the research domains state-of-the-art covered by this review.

- 3.

- Article-type: Academic (peer-reviewed) journal articles and international conference papers; these last ones are given that international conference proceedings normally offer the most recent research results.

- 4.

- Full keyword combination hit in an article: Title, keywords, or abstract.

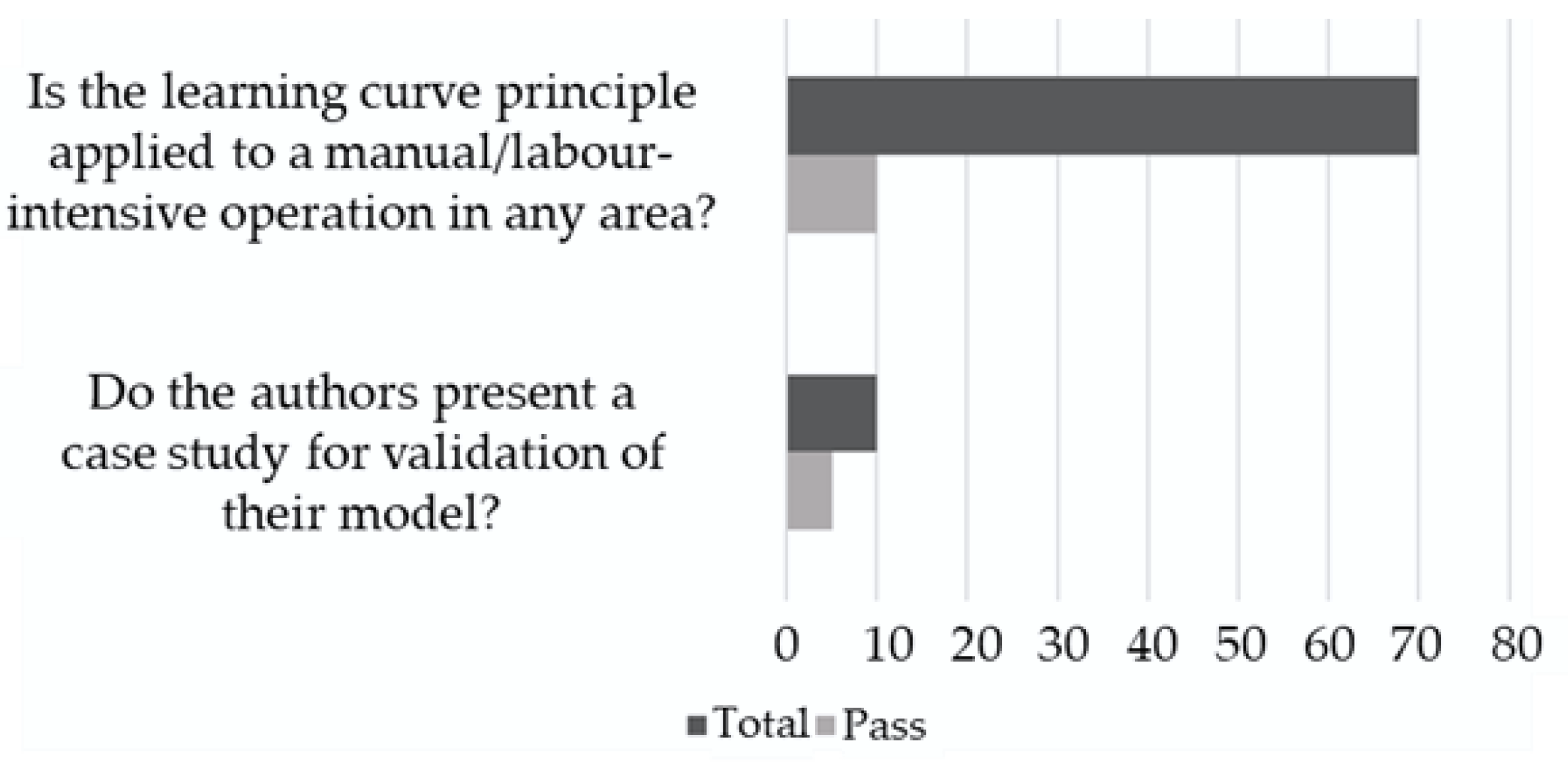

3.5. Quality Check

- Is the learning curve principle applied to a manual/labour-intensive operation in any area?

- Do the authors present a case study to validate their model/research method?

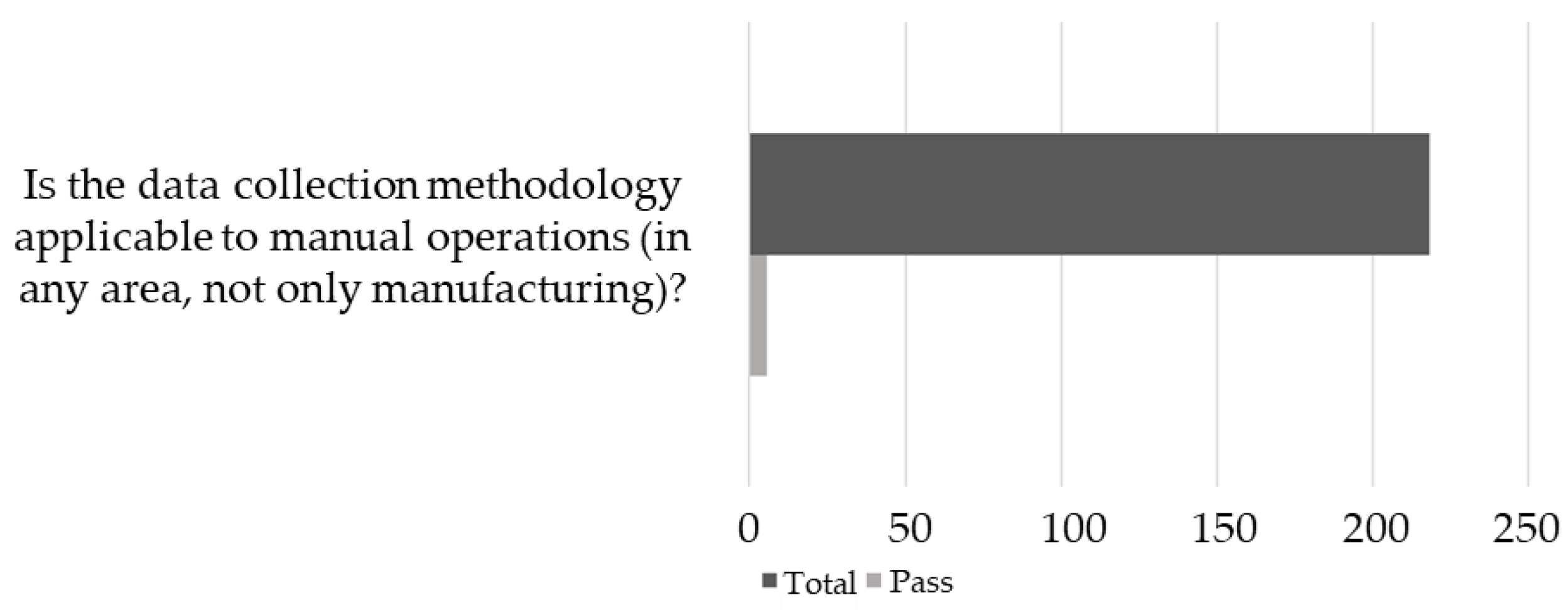

- For Domain 2—Data acquisition and monitoring technologies for human-based assembly operations—The quality criteria were:

- Is the data collection methodology applicable to manual operations (in any area, not only manufacturing)?

4. Results

4.1. Domain 1: Workforce Learning Curves Models and Measurement Methods

4.1.1. Learning Curve Parameter Estimation beyond Traditional Statistics by Tilindis & Kleiza (2017)

4.1.2. Application of Learning Curves in Operations Management Decisions by Tamás & Koltai (2019)

4.1.3. A Machine Learning Approach to Predict Surgical Learning Curves by Gao et al. (2020)

4.1.4. Cost Estimating Using a New Learning Curve Theory for Non-Constant Production Rates by Hogan et al. (2021)

4.1.5. The Human Performance Impact on OEE in the Adoption of New Production Technologies by Di Luozzo et al. (2021)

4.2. Domain 2: Data Acquisition and Monitoring Technologies for Human-Based Assembly Operations

4.2.1. Human Factor Analyzer for Work Measurements of Manual Manufacturing and Assembly Processes by Faccio et al. (2019)

4.2.2. Continuous Measurement of Muscle Fatigue Using Wearable Sensors during Light Manual Operations by Fu et al. (2019)

4.2.3. Exploring the Potential of Operator 4.0 Interface and Monitoring by Peruzzini et al. (2020)

4.2.4. Human Digital Twin for Fitness Management by Barricelli et al. (2020)

4.2.5. A Multi-Sensor Approach for Digital Twins of Manual Assembly and Commissioning by Rebmann et al. (2020)

4.2.6. Parametrization of Manual Work in Automotive Assembly for Wearable Force Sensing by Kerner et al. (2021)

5. Discussion

6. Conclusions and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gölzer, P.; Fritzsche, A. Data-driven Operations Management: Organisational Implications of the Digital Transformation in Industrial Practice. Prod. Plan. Control 2017, 28, 1332–1343. [Google Scholar] [CrossRef]

- Mittal, S.; Kahn, M.; Romero, D.; Wuest, T. Smart Manufacturing: Characteristics, Technologies and Enabling Factors. J. Eng. Manuf. 2019, 233, 1342–1361. [Google Scholar] [CrossRef]

- Wuest, T.; Weimer, D.; Irgens, C.; Thoben, K.-D. Machine Learning in Manufacturing: Advantages, Challenges, and Applications. Prod. Manuf. Res. 2016, 4, 23–45. [Google Scholar] [CrossRef]

- Hogan, D.W. An Analysis of Learning Curve Theory & Diminishing Rates of Learning. Master’s Thesis, Air Force Institute of Technology, Wright-Patterson AFB, OH, USA, 2020; p. 3607. [Google Scholar]

- Ohlig, J.; Hellebrandt, T.; Poetters, P.; Heine, I.; Schmitt, R.H.; Leyendecker, B. Human-centered Performance Management in Manual Assembly. Procedia CIRP 2021, 97, 418–422. [Google Scholar] [CrossRef]

- Andrianakos, G.; Dimitropoulos, N.; Michalos, G.; Makris, S. An Approach for Monitoring the Execution of Human-based Assembly Operations using Machine Learning. Procedia CIRP 2019, 86, 198–203. [Google Scholar] [CrossRef]

- Ebbinghaus, H. Memory: A Contribution to Experimental Psychology; Ruger, H.A.; Bussenius, C.E., Translators; Teachers College Press: New York, NY, USA, 1913. [Google Scholar]

- Yelle, L.E. The Learning Curve: Historical Review and Comprehensive Survey. Decis. Sci. 1979, 10, 302–328. [Google Scholar] [CrossRef]

- Swift, K.G.; Booker, J.D. Manufacturing Process Selection Handbook; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Wright, T.P. Factors Affecting the Cost of Airplanes. J. Aeronaut. Sci. 1936, 3, 122–128. [Google Scholar] [CrossRef]

- Anzanello, M.J.; Fogliatto, F.S. Learning Curve Models and Applications: Literature Review and Research Directions. Int. J. Ind. 2011, 41, 573–583. [Google Scholar] [CrossRef]

- Crawford, J.R. Learning Curve, Ship Curve, Ratios, Related Data; Lockheed Aircraft Corporation: Burbank, CA, USA, 1944. [Google Scholar]

- Conway, R.; Schultz, R. The Manufacturing Progress Function. J. Ind. Eng. 1959, 10, 39–53. [Google Scholar]

- Yelle, L.E. Technological Forecasting: A Learning Curve Approach. Ind. Mark. Manag. 1976, 5, 147–154. [Google Scholar] [CrossRef]

- Baloff, N. Manufacturing Startup: A Model. Dissertation, Stanford University, Redwood City, CA, USA, 1963. [Google Scholar]

- DeJong, J.R. The Effects of Increasing Skill on Cycle Time and Its Consequences for Time Standards. Ergonomics 1957, 1, 51–60. [Google Scholar] [CrossRef]

- Carlson, J.G.H. Cubic Learning Curves—Precision Tool for Labor Estimating. Manuf. Eng. Manag. 1973, 5, 22–25. [Google Scholar]

- Levy, F.K. Adaption in the Production Process. Manag. Sci. 1965, 6, B136–B154. [Google Scholar] [CrossRef]

- Knecht, G.R. Costing, Technological Growth and Generalized Learning Curves. J. Oper. Res. Soc. 1974, 3, 487–491. [Google Scholar] [CrossRef]

- Mazur, J.E.; Hastie, R. Learning as Accumulation: A Reexamination of the Learning Curve. Psychol. Bull. 1978, 6, 1256. [Google Scholar] [CrossRef]

- Towill, D.R. Forecasting Learning Curves. Int. J. Forecast. 1990, 1, 25–38. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Res. Methods Report. 2021, 327, 71. [Google Scholar]

- Tilindis, J.; Kleiza, V. Learning Curve Parameter Estimation beyond Traditional Statistics. Appl. Math. Model. 2017, 45, 768–783. [Google Scholar] [CrossRef]

- Tamás, A.; Koltai, T. Application of Learning Curves in Operations Management Decisions. Period. Polytech. Soc. Manag. Sci. 2019, 1, 81–90. [Google Scholar] [CrossRef]

- Jaber, M.Y.; Bonney, M. The Economic Manufacture/Order Quantity (EMQ/EOQ) and the Learning Curve: Past, Present, and Future. Int. J. Prod. Econ. 1999, 59, 93–102. [Google Scholar] [CrossRef]

- Gao, Y.; Kruger, U.; Intes, X.; Schwaitzberg, S.; De, S. A Machine Learning Approach to Predict Surgical Learning Curves. Surgery 2020, 167, 321–327. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Lee, J.M.; Lee, I.B. A Novel Multivariate Regression Approach based on Kernel Partial Least Squares with Orthogonal Signal Correction. Chemom. Intell. Lab. Syst. 2005, 79, 22–30. [Google Scholar] [CrossRef]

- Hogan, D.; Elshaw, J.; Koschnick, C.; Ritschel, J.; Badiru, A.; Valentine, S. Cost Estimating using a New Learning Curve Theory for Non-Constant Production Rates. Forecasting 2020, 2, 429–451. [Google Scholar] [CrossRef]

- Boone, E.R.; Elshaw, J.J.; Koschnick, C.M.; Ritschel, J.D.; Badiru, A.B. A Learning Curve Model Accounting for the Flattening Effect in Production Cycles. Def. Acquis. Res. J. 2021, 28, 72–97. [Google Scholar]

- Di Luozzo, S.; Pop, G.R.; Schiraldi, M.M. The Human Performance Impact on OEE in the Adoption of New Production Technologies. Appl. Sci. 2021, 11, 8620. [Google Scholar] [CrossRef]

- Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Human Factor Analyser for Work Measurement of Manual Manufacturing and Assembly Processes. Int. J. Adv. Manuf. Technol. 2019, 103, 861–877. [Google Scholar] [CrossRef]

- Jiawei, F.; Ma, L.; Tsao, L.; Zhang, Z. Continuous Measurement of Muscle Fatigue Using Wearable Sensors during Light Manual Operations. In Lecture Notes in Computer Science; Springer International Publishing: New York, NY, USA, 2019; pp. 266–277. [Google Scholar]

- Sundelin, G.; Hagberg, M. Electromyographic Signs of Shoulder Muscle Fatigue in Repetitive Arm Work Paced by the Methods-Time Measurement System. Scand. J. Work. Environ. Health 1992, 18, 262–268. [Google Scholar] [CrossRef]

- Peruzzini, M.; Grandi, F.; Pellicciari, M. Exploring the Potential of Operator 4.0 Interface and Monitoring. Comput. Ind. Eng. 2020, 39, 105600. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Gliozzo, J.; Petrini, A.; Valtolina, S. Human Digital Twin for Fitness Management. IEEE Access 2020, 8, 26637–26664. [Google Scholar] [CrossRef]

- Rebmann, A.; Knoch, S.; Emrich, A.; Fettke, P.; Loos, P. A Multi-Sensor Approach for Digital Twins of Manual Assembly and Commissioning. Procedia Manuf. 2020, 51, 549–556. [Google Scholar] [CrossRef]

- Kerner, S.; Gunasekar, S.; Vedant, R.M.; Krugh, M.; Mears, L. Parametrization of Manual Work in Automotive Assembly for Wearable Force Sensing. J. Manuf. Syst. 2021, 69, 686–700. [Google Scholar] [CrossRef]

- Glock, C.H.; Grosse, E.H.; Jaber, M.Y.; Smunt, T.L. Applications of Learning Curves in Production and Operations Management: A Systematic Literature Review. Comput. Ind. Eng. 2019, 131, 422–441. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

| Cluster | Advantages | Disadvantages |

|---|---|---|

| Traditional Log-Linear Models |

|

|

| Adapted Log-Linear Models |

|

|

| Exponential Models |

|

|

| Hyperbolic Models |

|

|

| Domain | Keywords |

|---|---|

| Learning curves; Human factors; Throughput prediction; Standard times; Productivity |

| Monitoring; Assembly operations; Standard times; Human factors; Prediction; Manufacturing |

| Query Stream | Domain | Results |

|---|---|---|

| (“standard times” AND “learning curve”) OR (“throughput prediction” AND “variability”) OR (“productivity” AND “learning curve” AND “prediction”) OR (“productivity” AND “human factor” AND “prediction”) OR (“productivity” AND “labor intensive” AND “prediction”) | D1 | 137 |

| (“standard times” AND “variability” AND “monitoring”) OR (“monitoring” AND “human factors” AND “prediction”) OR (“labour intensive” AND “monitoring” AND “prediction”) OR (“labour intensive” AND “prediction” AND “variability” AND “manufacturing”) OR (“labor intensive” AND “prediction” AND “variability” AND “manufacturing”) | D2 | 378 |

| Article/Paper | Described Models | Technique | Data Collection Method | Application Area | Contribution | Areas of Opportunity |

|---|---|---|---|---|---|---|

| Section 4.1.1 Tilindis & Kleiza (2017) [23] | Wright’s [10] Crawford’s [12] | Estimation via: Two Point, Invariant Point, Interval, and Two Intervals | Not Specified | Manual Harness Assembly | Achieved the estimation of curve parameters using limited data | Only traditional log-linear models were tested |

| Section 4.1.2 Tamás & Koltai (2019) [24] | Wright’s [10] Crawford’s [12] Plateau [13] Standford-B [15] DeJong’s [16] S-Curve [17] Two & Three Parameter Hyperbolic [20] | None | None | Economic Manufacturing Quantity (EMQ) [24] Break-Even Financial Analysis Balancing of Operations | Multiple application areas are reviewed with a deep comparison between the validation models reviewed by the authors | Applications are not evaluated with Exponential Models |

| Section 4.1.3 Gao et al. (2020) [26] | Wright’s [10] | Machine Learning (Kernel PartialLeast Squares) [26] | VBlaST & FLS Surgery Training Box | Surgery Training | Prediction of learning curves was achieved using the first few points in the proposed Machine Learning Algorithm | Only Wright’s model was tested |

| Section 4.1.4 Hogan et al. (2021) [28] | Boone et al.’s [29] | Data Fit (MAPE Evaluation) | Batch Production Time Reports | Military Plane Assembly | Demonstrated Boone’s model fits better to the presented study case | Only traditional log-linear models were tested |

| Section 4.1.5 Di Luozzo et al. (2021) [30] | Wright’s [10] | OEE Calculation Integration | Maintenance DurationReports | Packaging Semi-Automatic Process Maintenance | Not only learning curve is assessed, but many other human factors in a singl calculation | Learning curve is only considered for maintenance, not for a mainmanual activity |

| Article/Paper | Data Collection Method | Monitored Data | Software | Application | Focus |

|---|---|---|---|---|---|

| Section 4.2.1 Faccio et al. (2019) [31] | Motion Tracking Depth Cameras | Joint Position, Joint Movements, Picking Duration and Frequency, and Travel Distance | Human Factor Analyzer (Proprietary) | Laboratory Production Setting for Picking Operation | Ergonomics, and Workstation Design |

| Section 4.2.2 Fu et al.(2019) [32] | Surface Electromyography Armbands | EMG Muscle Signals | None | Manual Assembly of Electrical Products | Fatigue Management |

| Section 4.2.3 Peruzzini et al. (2020) [34] | Eye Tracking System, Vitals Monitoring Wearable Sensor, Personal Video Camera, and Motion Tracking Cameras | Eye Gaze & Pupil Dilatation, Heart Rate, Breathing Rate, Temperature, Posture Angle, Ergonomic Scores, and Human Positions, Postures and Movements | Human Digital Modelling, and Motion Tracking Digitalization | Manual Assembly of Tractor’s Air Filter | Ergonomics, and Error-Proofing (Quality) |

| Section 4.2.4 Baricelli et al. (2020) [35] | Wristband Tracker | Nutritional Income, Daily User Activity, Duration and Quality of Sleep, and User’s Mood | Mood Tracking App, and Nutritional Tracking App | Fitness | User Feedback Loop for Improvement |

| Section 4.2.5 Rebmann et al. (2020) [36] | Inventory Weight Sensor, and Head Mounted Display Lenses | Material Handling Tracking | Image Based Scenery Classification | Laboratory Assembly Environment | Error-Proofing |

| Section 4.2.6 Kerner et al. (2021) [37] | Proprietary Shear Force Sensor | Manual Shear Force | None | Manual Hose Connections | Manual Operation Parametrization |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peña, C.; Romero, D.; Noguez, J. Workforce Learning Curves for Human-Based Assembly Operations: A State-of-the-Art Review. Appl. Sci. 2022, 12, 9608. https://doi.org/10.3390/app12199608

Peña C, Romero D, Noguez J. Workforce Learning Curves for Human-Based Assembly Operations: A State-of-the-Art Review. Applied Sciences. 2022; 12(19):9608. https://doi.org/10.3390/app12199608

Chicago/Turabian StylePeña, Carlos, David Romero, and Julieta Noguez. 2022. "Workforce Learning Curves for Human-Based Assembly Operations: A State-of-the-Art Review" Applied Sciences 12, no. 19: 9608. https://doi.org/10.3390/app12199608

APA StylePeña, C., Romero, D., & Noguez, J. (2022). Workforce Learning Curves for Human-Based Assembly Operations: A State-of-the-Art Review. Applied Sciences, 12(19), 9608. https://doi.org/10.3390/app12199608