Fused Deposition Modeling with Induced Vibrations: A Study on the Mechanical Characteristics of Printed Parts

Abstract

:1. Introduction

2. Background

2.1. Fused Deposition Modeling (FDM)

2.2. Open Source 3D Printers

2.3. Effects of Induced Vibration on Printed Parts

2.4. Objective of the Study

2.5. Previous Work

3. Materials and Methods

3.1. Printer and Print Settings

3.2. Vibration Setup

3.3. Pen Attachment

3.4. Measurement of Position

3.5. Tensile Testing

4. Results and Discussion

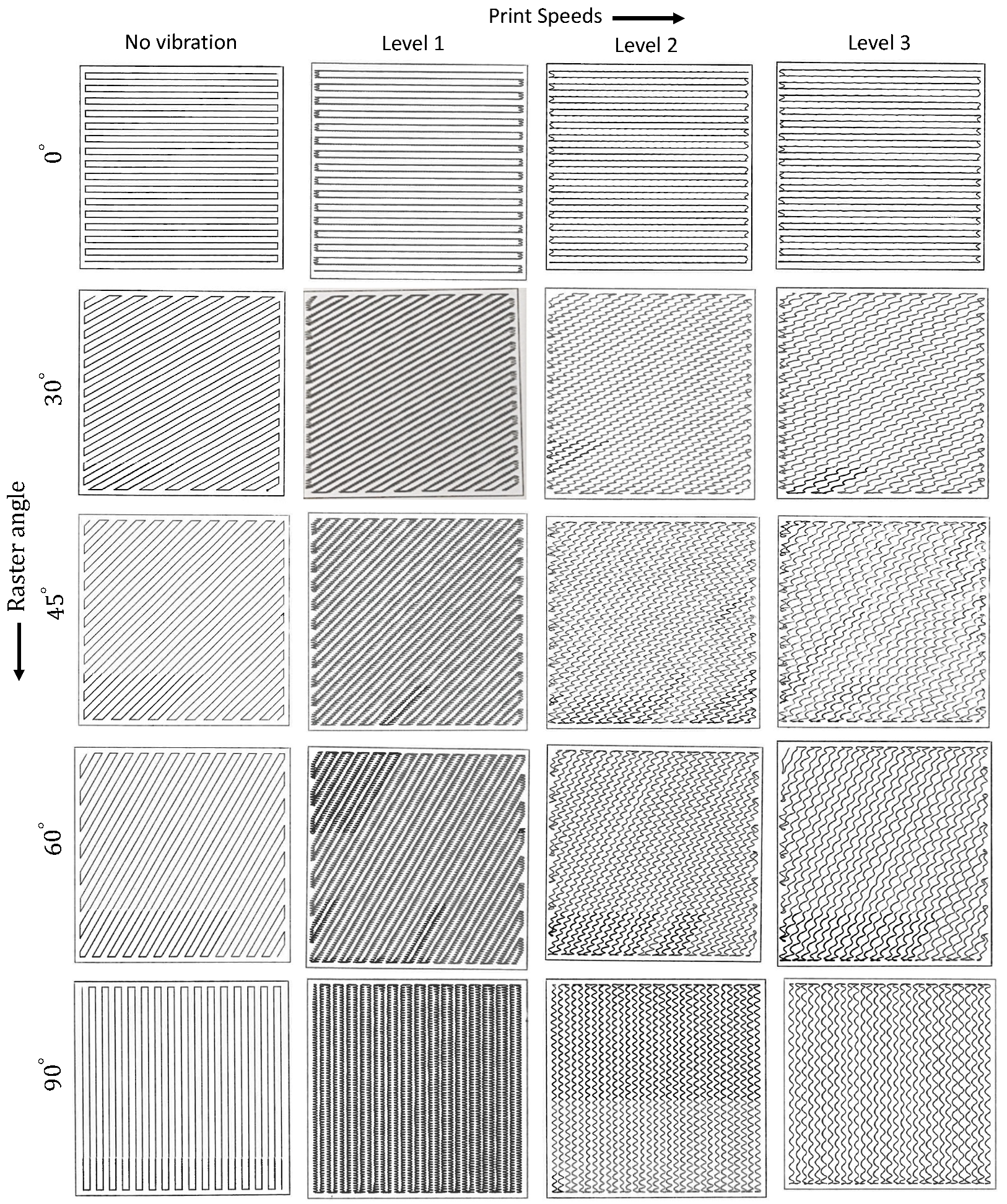

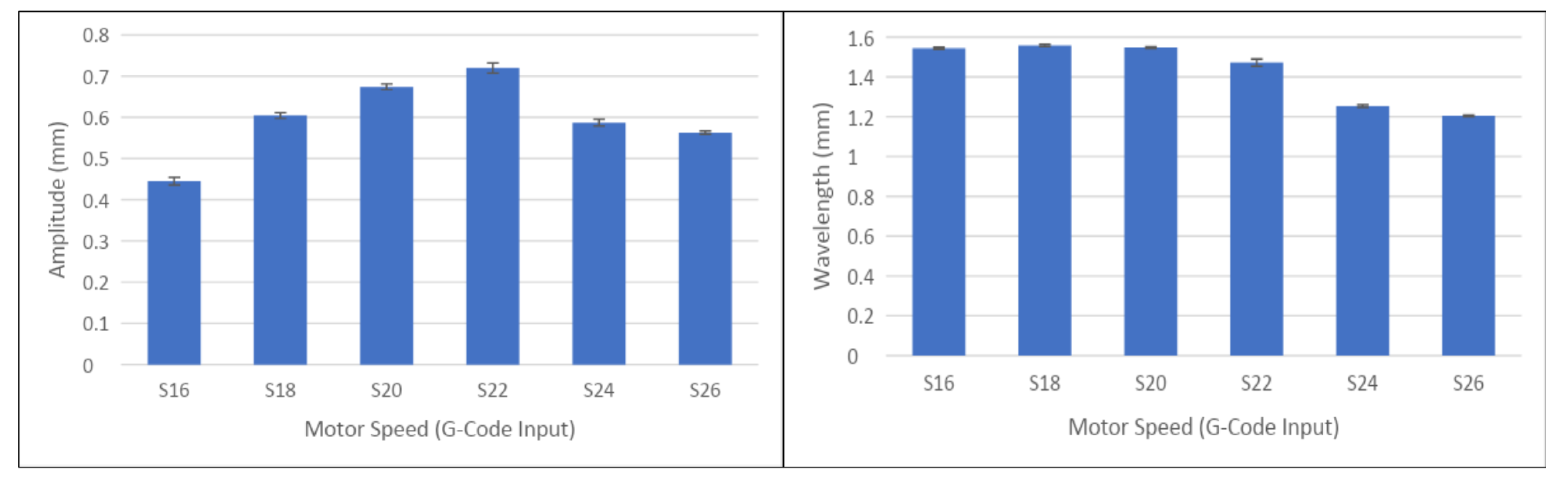

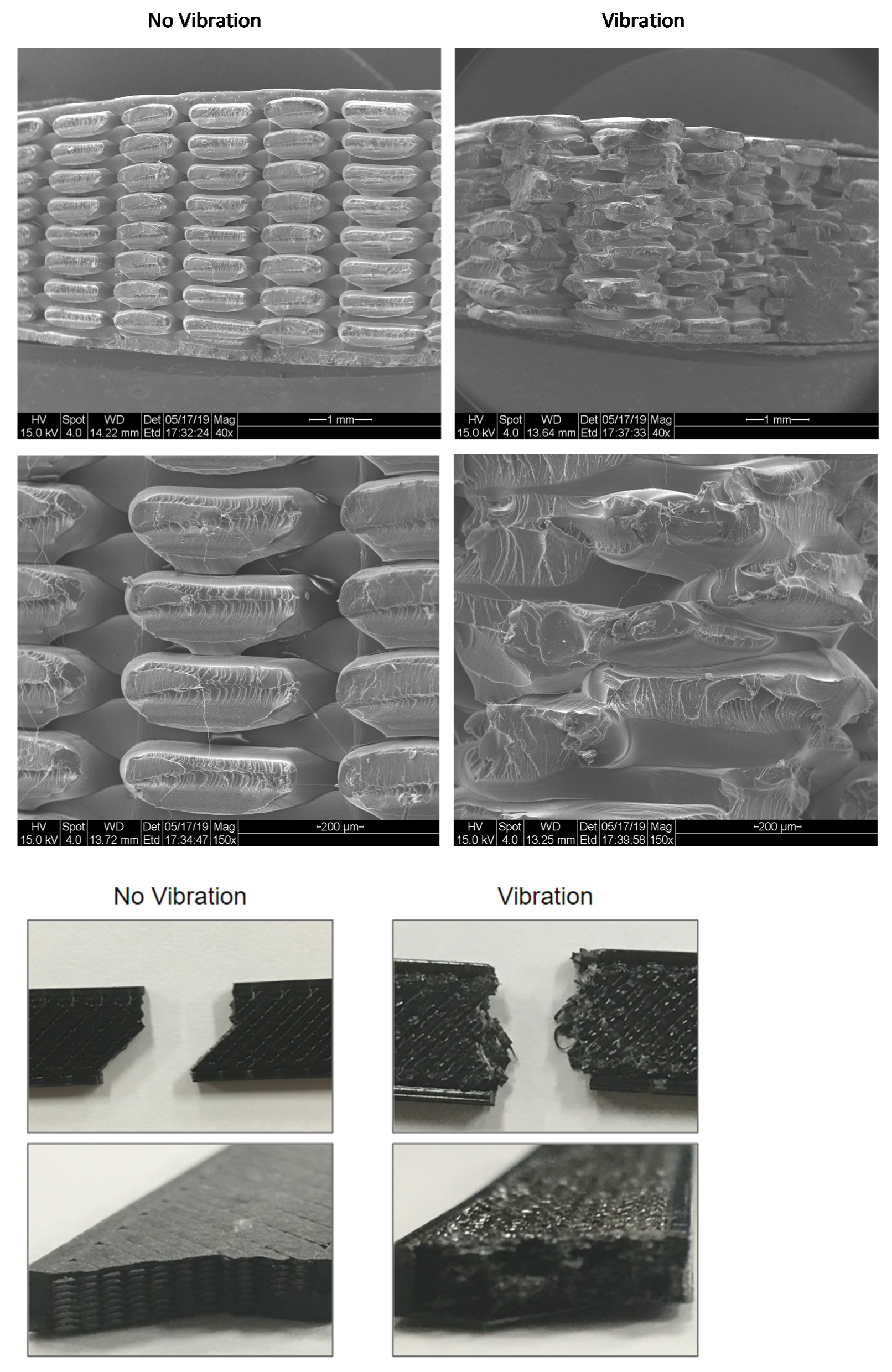

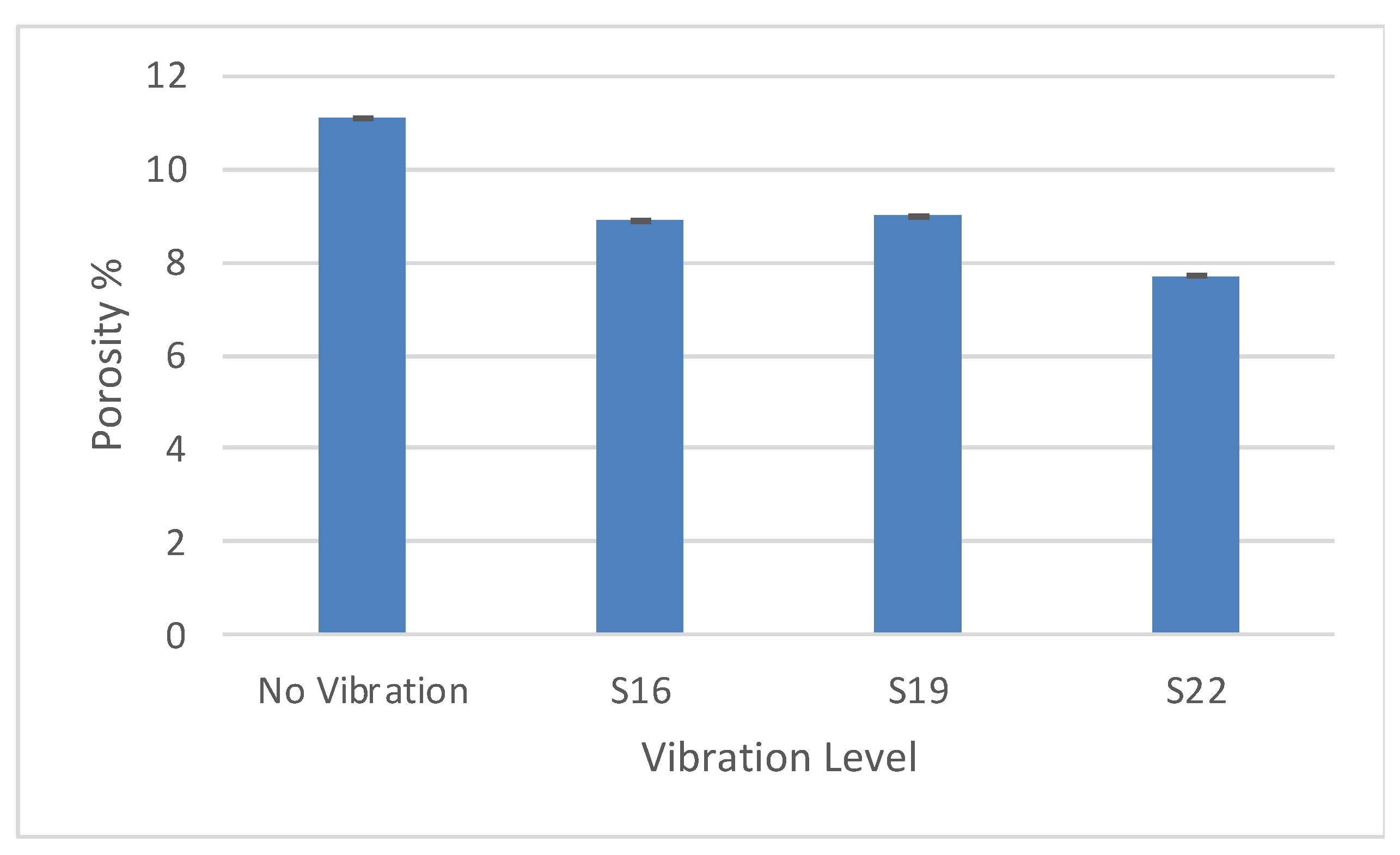

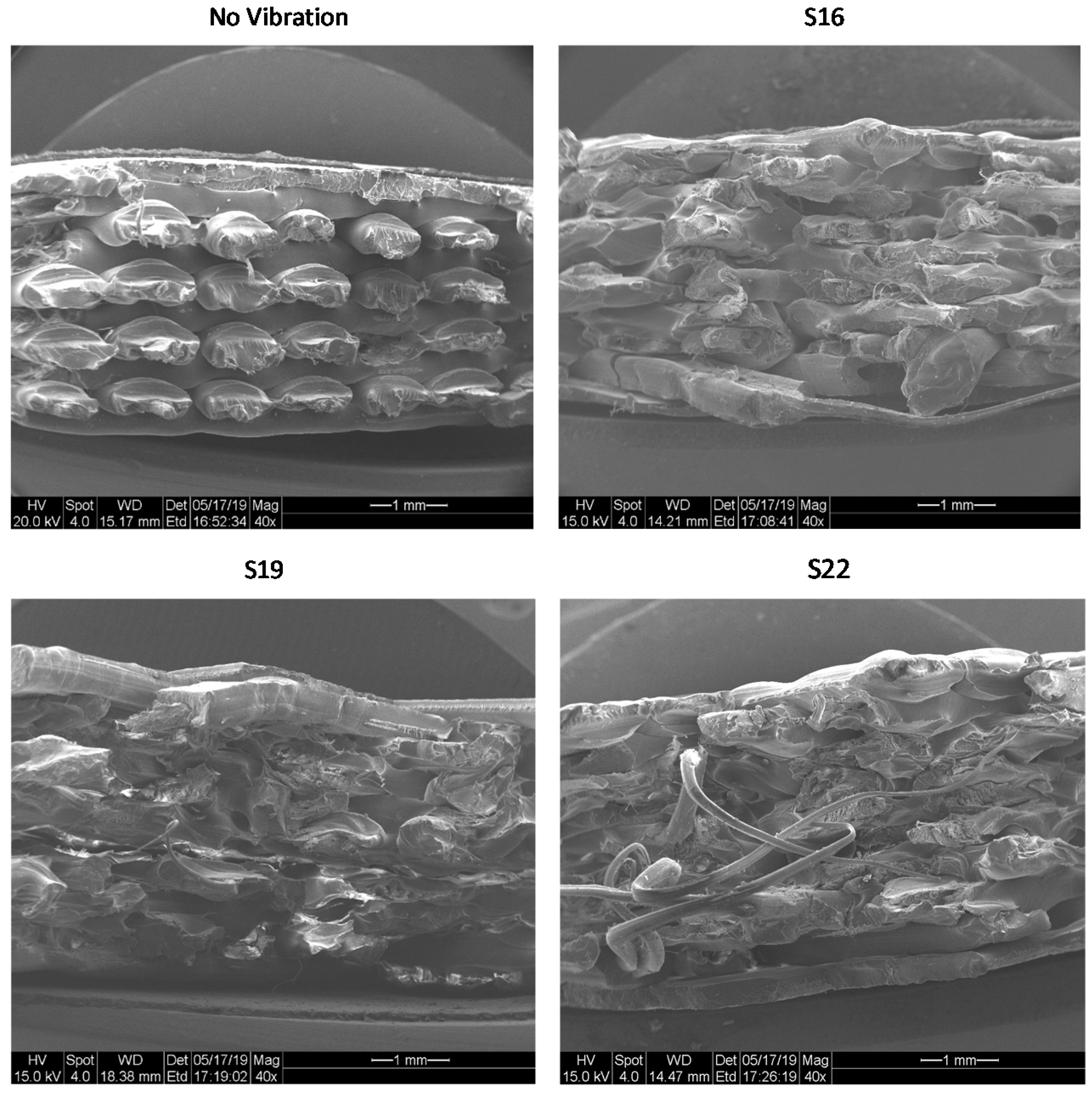

4.1. Material Distribution with Induced Vibrations

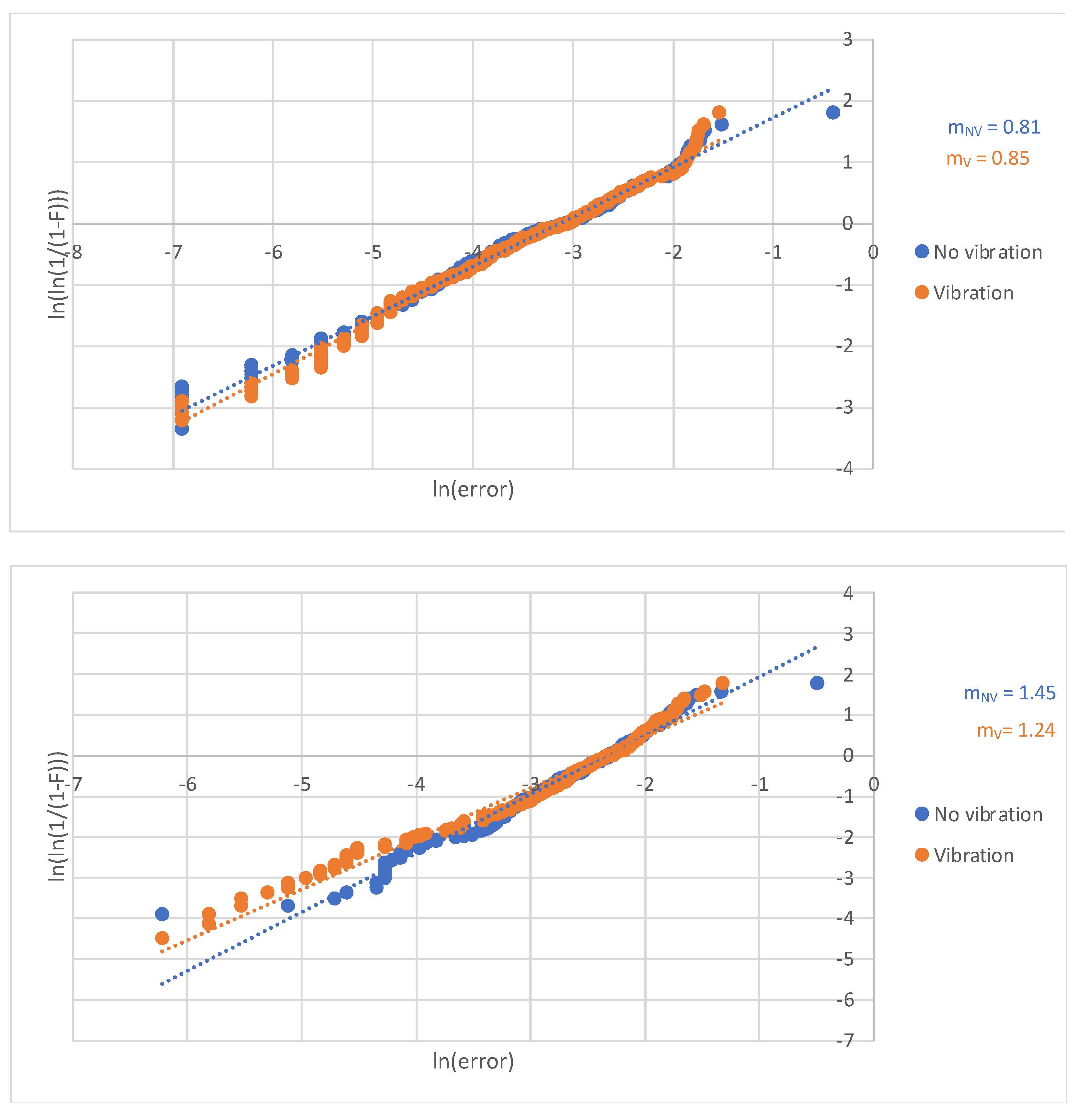

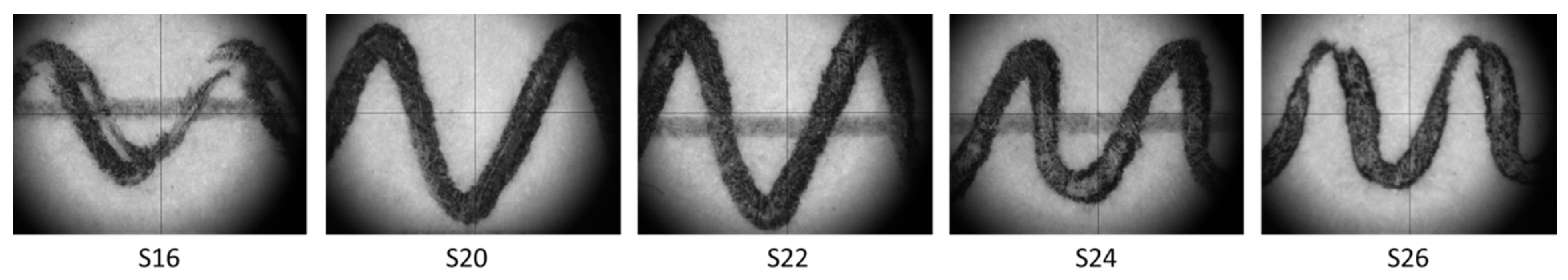

4.2. Positional Accuracy with and without Vibrations

4.3. Determination of the Optimum Characteristics

4.4. Material Properties

5. Conclusions

6. Limitations of the Study

7. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mueller, B. Additive Manufacturing Technologies—Rapid Prototyping to Direct Digital Manufacturing. Assem. Autom. 2012, 32. [Google Scholar] [CrossRef]

- Petrovic, V.; Gonzalez, J.V.H.; Ferrando, O.J.; Gordillo, J.D.; Puchades, J.R.B.; Griñan, L.P. Additive layered manufacturing: Sectors of industrial application shown through case studies. Int. J. Prod. Res. 2010, 49, 1061–1079. [Google Scholar] [CrossRef]

- Upcraft, S.; Fletcher, R. The Rapid Prototyping Technologies. Assem. Autom. 2003, 23, 318–330. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Adams, S. Half Million 3d Printers Sold in 2017—On Track for 100m Sold in 2030. 2018. Available online: https://3dprintingindustry.com/news/half-million-3d-printers-sold-2017-track-100m-sold-2030-131642/ (accessed on 5 May 2018).

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. Reprap–the Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Pearce, J.M. Building Research Equipment with Free, Open-Source Hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef]

- Pearce, J.M. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs; Newnes; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Pearce, J.M.; Blair, C.M.; Laciak, K.J.; Andrews, R.; Nosrat, A.; Zelenika-Zovko, I. 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development. J. Sustain. Dev. 2010, 3, 17. [Google Scholar] [CrossRef]

- Turner, B.; Strong, R.; Gold, S. A Review of Melt Extrusion Additive Manufacturing Processes: I. Process Design and Modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Neff, C.; Trapuzzano, M.; Crane, N.B. Impact of vapor polishing on surface quality and mechanical properties of extruded ABS. Rapid Prototyp. J. 2018, 24, 501–508. [Google Scholar] [CrossRef]

- Singh, R.; Singh, S.; Singh, I.P. Effect of Hot Vapor Smoothing Process on Surface Hardness of Fused Deposition Modeling Parts. 3D Print. Addit. Manuf. 2016, 3, 128–133. [Google Scholar] [CrossRef]

- Espalin, D.; Medina, F.; Arcaute, K.; Zinniel, B.; Hoppe, T.; Wicker, R. Effects of Vapor Smoothing on Abs Part Dimensions. In Proceedings of the Proceedings from Rapid 2009 Conference & Exposition, Schaumburg, IL, USA, 26–27 May 2009. [Google Scholar]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. Fdm Process Parameters Influence over the Mechanical Properties of Polymer Specimens: A Review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Chacón, J.; Caminero, M.Á.; García-Plaza, E.; Núñez, P.J. Additive Manufacturing of Pla Structures Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties and Their Optimal Selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.; Mahapatra, S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Eiliat, H.; Urbanic, J. Determining the relationships between the build orientation, process parameters and voids in additive manufacturing material extrusion processes. Int. J. Adv. Manuf. Technol. 2018, 100, 683–705. [Google Scholar] [CrossRef]

- Ravi, P.; Shiakolas, P.S.; Thorat, A.D. Analyzing the Effects of Temperature, Nozzle-Bed Distance, and Their Interactions on the Width of Fused Deposition Modeled Struts Using Statistical Techniques toward Precision Scaffold Fabrication. J. Manuf. Sci. Eng. 2017, 139, 071007. [Google Scholar] [CrossRef]

- Eiliat, H.; Urbanic, J. Visualizing, Analyzing, and Managing Voids in the Material Extrusion Process. Int. J. Adv. Manuf. Technol. 2018, 96, 4095–4109. [Google Scholar] [CrossRef]

- Jin, Y.-A.; He, Y.; Xue, G.-H.; Fu, J.-Z. A parallel-based path generation method for fused deposition modeling. Int. J. Adv. Manuf. Technol. 2015, 77, 927–937. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V. Measurements of the Mechanical Response of Unidirectional 3d-Printed Pla. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Bond and part strength in fused deposition modeling. Rapid Prototyp. J. 2017, 23, 414–422. [Google Scholar] [CrossRef]

- Hossain, M.S.; Espalin, D.; Ramos, J.; Perez, M.; Wicker, R. Improved Mechanical Properties of Fused Deposition Modeling-Manufactured Parts Through Build Parameter Modifications. J. Manuf. Sci. Eng. 2014, 136, 061002. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L. Accuracy Prediction in Fused Deposition Modeling. Int. J. Adv. Manuf. Technol. 2014, 73, 913–928. [Google Scholar] [CrossRef]

- Santana, L.; Ahrens, C.H.; da Costa Sabino Netto, A.; Bonin, C. Evaluating the deposition quality of parts produced by an open-source 3D printer. Rapid Prototyp. J. 2017, 23, 796–803. [Google Scholar] [CrossRef]

- Melenka, G.; Schofield, J.S.; Dawson, M.; Carey, J. Evaluation of dimensional accuracy and material properties of the MakerBot 3D desktop printer. Rapid Prototyp. J. 2015, 21, 618–627. [Google Scholar] [CrossRef]

- Roberson, D.; Espalin, D.; Wicker, R. 3D printer selection: A decision-making evaluation and ranking model. Virtual Phys. Prototyp. 2013, 8, 201–212. [Google Scholar] [CrossRef]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental Optimization of Fused Deposition Modelling Processing Parameters: A Design-for-Manufacturing Approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Sealy, M.P.; Madireddy, G.; Williams, R.E.; Rao, P.; Toursangsaraki, M. Hybrid Processes in Additive Manufacturing. J. Manuf. Sci. Eng. 2018, 140, 060801. [Google Scholar] [CrossRef]

- Wu, W.; Jiang, J.; Jiang, H.; Liu, W.; Li, G.; Wang, B.; Tang, M.; Zhao, J. Improving Bending and Dynamic Mechanics Performance of 3d Printing through Ultrasonic Strengthening. Mater. Lett. 2018, 220, 317–320. [Google Scholar] [CrossRef]

- Keleş, Ö.; Anderson, E.H.; Huynh, J. Mechanical reliability of short carbon fiber reinforced ABS produced via vibration assisted fused deposition modeling. Rapid Prototyp. J. 2018, 24, 1572–1578. [Google Scholar] [CrossRef]

- Dei Rossi, J.; Keleş, Ö.; Viswanathan, V. Fused Deposition Modeling with Added Vibrations: A Parametric Study on the Accuracy of the Printed Parts. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition (IMECE 2019), Salt Lake City, UT, USA, 11–14 November 2019. [Google Scholar]

- Instron. Instron 5960 Series Universal Testing Systems. 2019. Available online: https://www.instron.us/products/testing-systems/universal-testing-systems/electromechanical/5900-series/5960-dual-column (accessed on 23 September 2019).

| Raster Angle | Extrusion Multiplier | Extrusion Width | Layer Height | Perimeter Layers | Fill Percentage | Bed Temperature | Nozzle Diameter |

|---|---|---|---|---|---|---|---|

| −45°/45° | 0.90 | 1.2 mm | 0.2 mm | 1 | 100% | 55 °C | 1 mm |

| Area of Print Bed | Vibration Level | Print Head Speed | Extruder Temperature |

|---|---|---|---|

| Upper Left | Off | 2400 mm/min | 195 °C |

| Lower Right | On | 3600 mm/min | 205 °C |

| Print Speed (mm/min) | No Vibration | With Vibration (S16) | |

|---|---|---|---|

| Number of samples | 2400 | 5 | 11 |

| 3600 | 22 | 27 | |

| Average tensile strength (Mpa) | 2400 | 35.5 | 37.7 |

| 3600 | 33.5 | 36.5 | |

| Average strain at failure (%) | 2400 | 1.8 | 2.0 |

| 3600 | 1.8 | 2.1 | |

| Average elastic modulus | 2400 | 2933.8 | 2969.8 |

| 3600 | 2799.0 | 2862.3 | |

| Average fracture strength (Mpa) | 2400 | 31.5 | 33.7 |

| 3600 | 28.4 | 33.5 | |

| Average strain at fracture (%) | 2400 | 3.2 | 2.7 |

| 3600 | 3.3 | 2.8 | |

| Extrusion temperature = 200 °C | |||

| Tensile Strength (MPa) | Strain at Tensile Strength (%) | Elastic Modulus (MPa) | Fracture Strength (MPa) | Strain at Fracture Strength (%) | |

|---|---|---|---|---|---|

| No Vibration | 34.5 | 1.8 | 2859 | 28.7 | 3.2 |

| Vibration | 37.1 | 2.0 | 2914 | 33.3 | 2.7 |

| Tensile Strength (MPa) | Strain at Tensile Strength (%) | Elastic Modulus (MPa) | Fracture Strength (MPa) | Strain at Fracture Strength (%) | |

|---|---|---|---|---|---|

| No Vibration | 26.8 | 2.09 | 2427 | 19.3 | 3.5 |

| S16 | 29.2 | 2.00 | 2545 | 21.0 | 3.2 |

| S19 | 29.1 | 2.0 | 2548 | 21.3 | 3.2 |

| S22 | 29.6 | 1.97 | 2590 | 24.4 | 3.0 |

| Thickness (mm) | Width (mm) | S.E. Thickness (mm) | S.E. Width (mm) | |

|---|---|---|---|---|

| No Vibration | 3.582 | 13.130 | 0.010 | 0.012 |

| S16 | 3.576 | 13.140 | 0.002 | 0.003 |

| S19 | 3.590 | 13.139 | 0.003 | 0.004 |

| S22 | 3.590 | 13.156 | 0.004 | 0.003 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dei Rossi, J.; Keles, O.; Viswanathan, V. Fused Deposition Modeling with Induced Vibrations: A Study on the Mechanical Characteristics of Printed Parts. Appl. Sci. 2022, 12, 9327. https://doi.org/10.3390/app12189327

Dei Rossi J, Keles O, Viswanathan V. Fused Deposition Modeling with Induced Vibrations: A Study on the Mechanical Characteristics of Printed Parts. Applied Sciences. 2022; 12(18):9327. https://doi.org/10.3390/app12189327

Chicago/Turabian StyleDei Rossi, Joseph, Ozgur Keles, and Vimal Viswanathan. 2022. "Fused Deposition Modeling with Induced Vibrations: A Study on the Mechanical Characteristics of Printed Parts" Applied Sciences 12, no. 18: 9327. https://doi.org/10.3390/app12189327

APA StyleDei Rossi, J., Keles, O., & Viswanathan, V. (2022). Fused Deposition Modeling with Induced Vibrations: A Study on the Mechanical Characteristics of Printed Parts. Applied Sciences, 12(18), 9327. https://doi.org/10.3390/app12189327