Structural, Magnetic, and Magnetocaloric Studies of Ball-Milled Fe100−xTx (T = Ni and Mn) Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

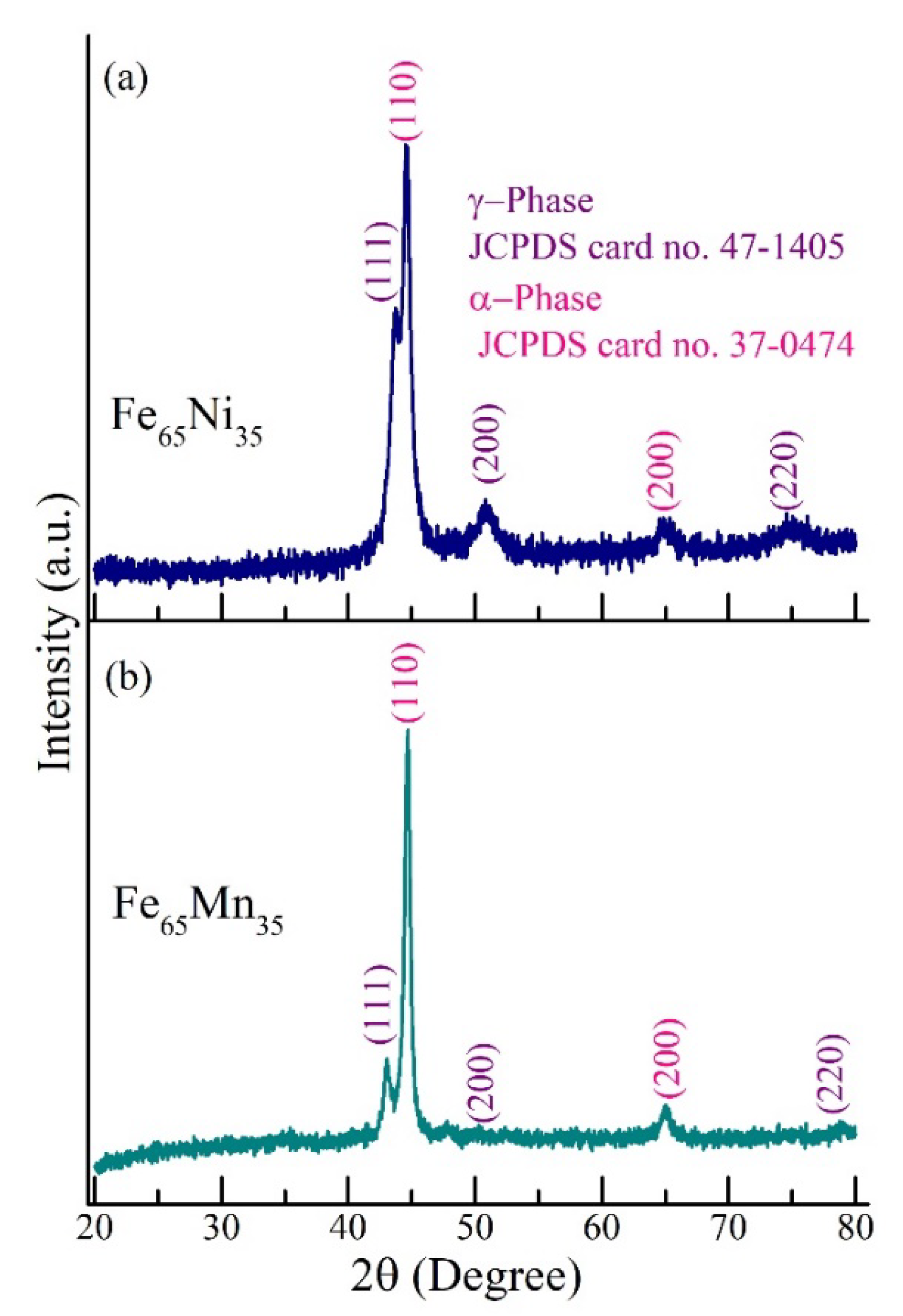

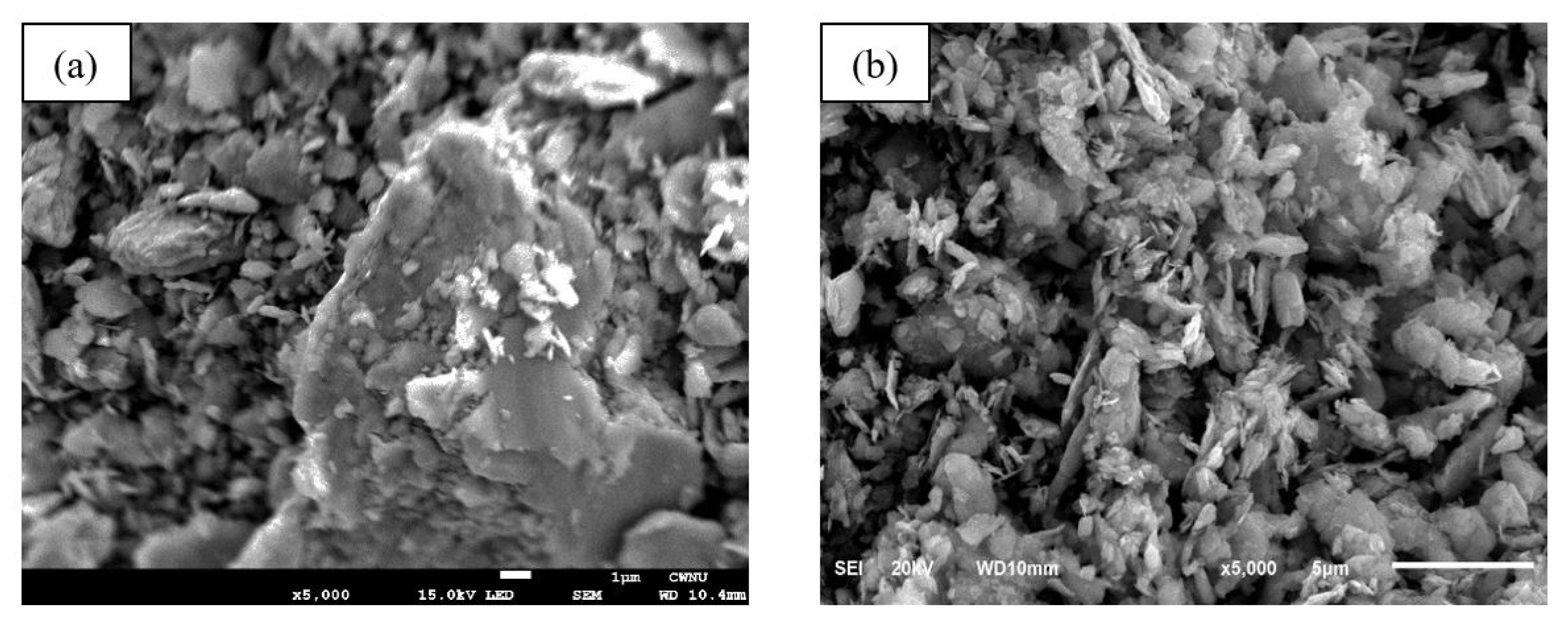

3.1. Structural and Morphological Properties of Fe65Ni35 and Fe65Mn35 Alloys

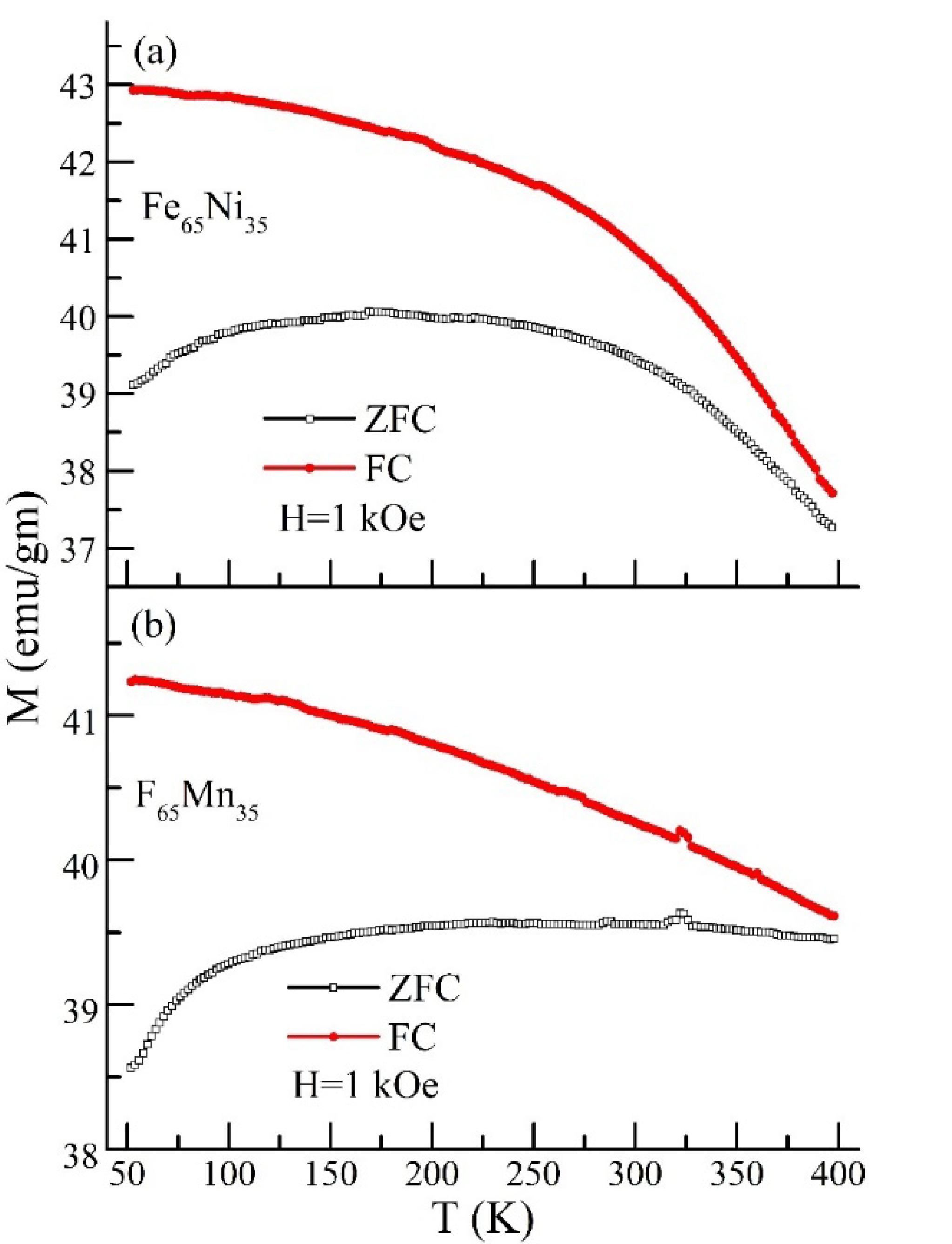

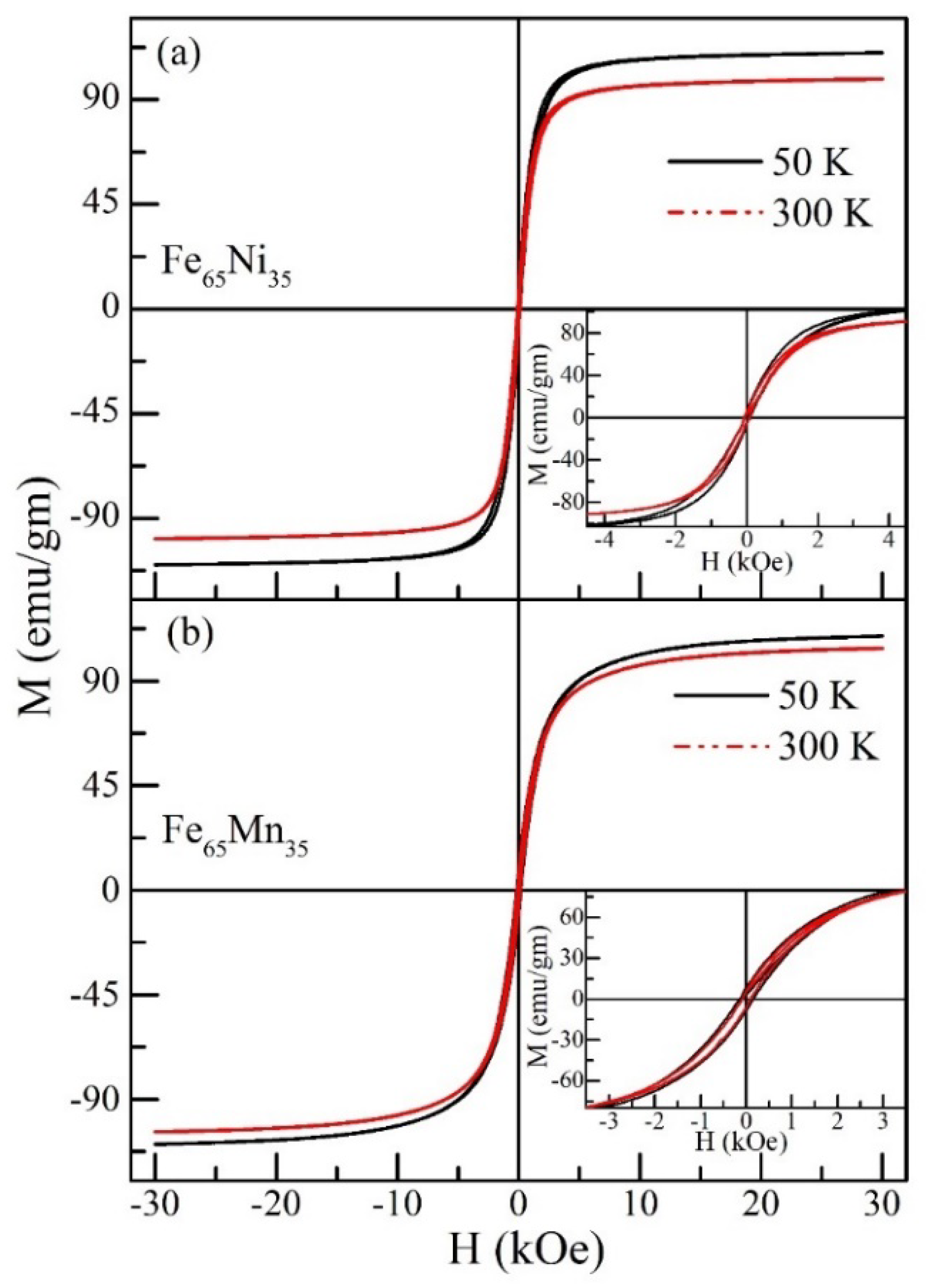

3.2. Magnetic Properties of Fe65Ni35 and Fe65Mn35 Alloys

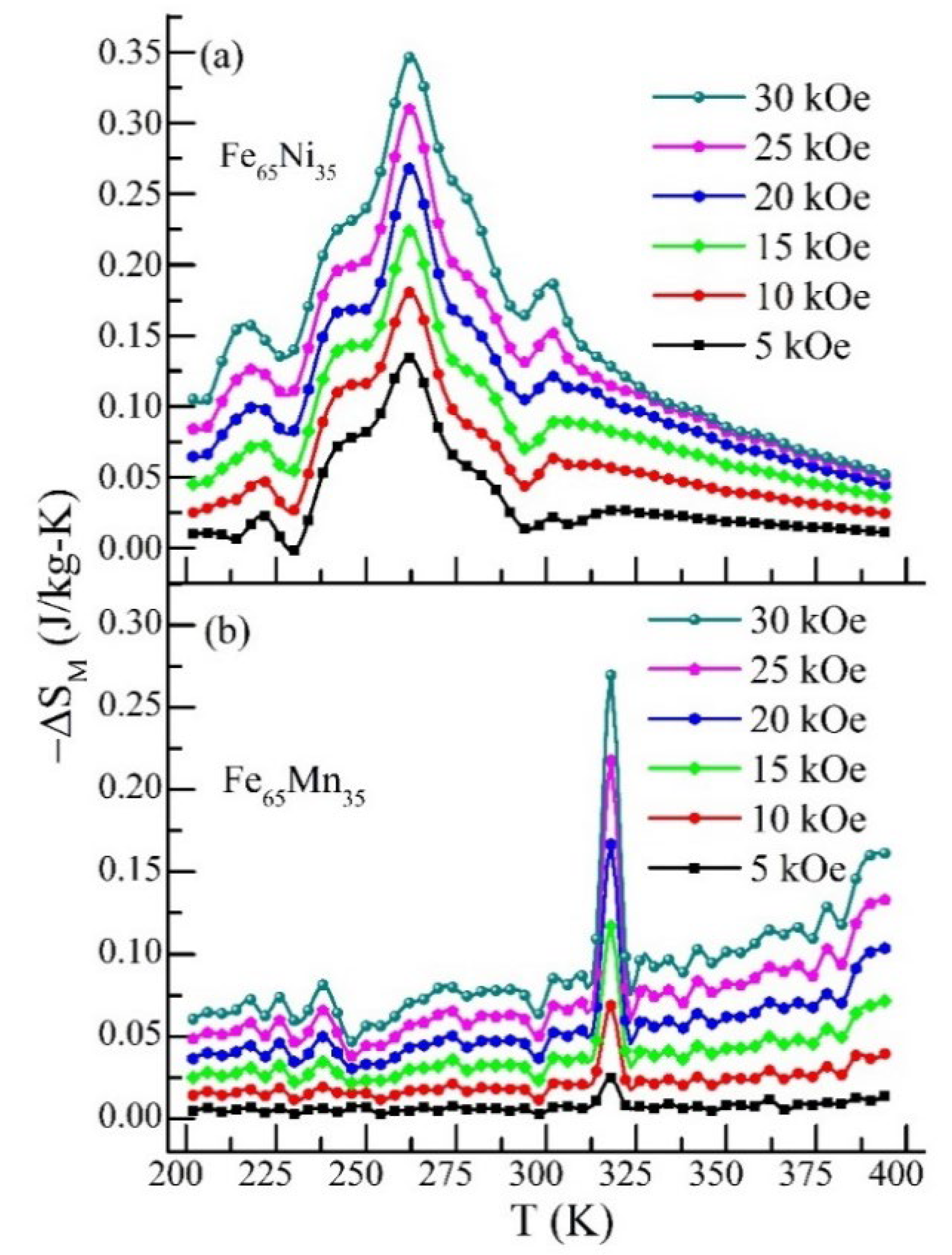

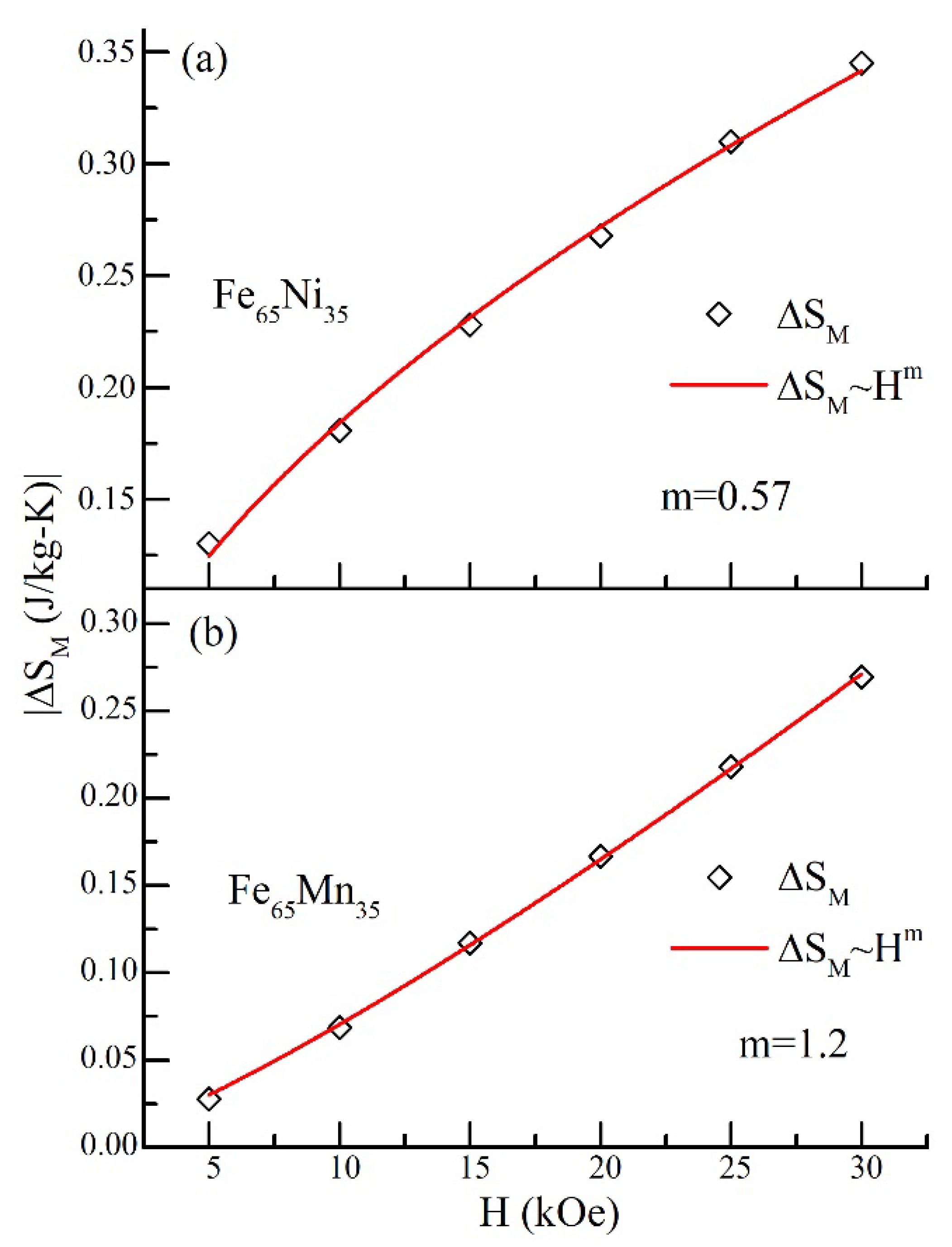

3.3. Magnetocaloric Properties of Fe65Ni35 and Fe65Mn35

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tishin, A.M.; Spichkin, Y.I. The Magnetocaloric Effect and its Applications; Institute of Physics Publishing: Bristol, UK, 2003. [Google Scholar]

- Pecharsky, V.K.; Gschneidner, K.A., Jr. Magnetocaloric effect and magnetic refrigeration. J. Magn. Magn. Mater. 1999, 200, 44–56. [Google Scholar] [CrossRef]

- Bruck, E. Developments in magnetocaloric refrigeration. J. Phys. D Appl. Phys. 2005, 38, R381. [Google Scholar] [CrossRef]

- Gschneider, K.A., Jr.; Pecharsky, V.K.; Tsokol., A.O. Recent developments in magnetocaloric materials. Rep. Prog. Phys. 2005, 68, 1479. [Google Scholar]

- Moya, X.; Kar-Narayan, V.; Mathur, N.D. Caloric materials near ferroic phase transitions. Nat. Mater. 2014, 13, 439. [Google Scholar] [CrossRef] [PubMed]

- Li, L.-W. Review of magnetic properties and magnetocaloric effect in the intermetallic compounds of rare earth with low boiling point metals. Chin. Phys. B 2016, 25, 037502. [Google Scholar] [CrossRef]

- Lyubina, J. Magnetocaloric materials for energy efficient cooling. J. Phys. D Appl. Phys. 2017, 50, 053002. [Google Scholar] [CrossRef]

- Sharma, M.K.; Mukherjee, K. Evidence of large magnetic cooling power and double glass transition in Tb5Pd2. J. Magn. Magn. Mater. 2018, 466, 317–322. [Google Scholar] [CrossRef]

- Sharma, K.; Yadav, K.; Mukherjee, K. Complex magnetic behaviour and evidence of superspin glass state in the binary intermetallic compound Er5Pd2. J. Phys. Condens. Matter 2018, 30, 215803. [Google Scholar] [CrossRef]

- Biswas, A.; Chandra, S.; Samanta, T.; Phan, M.H.; Das, I.; Srikanth, H. The universal behavior of inverse magnetocaloric effect in antiferromagnetic materials. J. Appl. Phys. 2013, 113, 17A902. [Google Scholar] [CrossRef]

- Sharma, M.K.; Mukherjee, K. Magnetic and universal magnetocaloric behavior of rare-earth substituted DyFe0.5Cr0.5O3. J. Magn. Magn. Mater. 2017, 444, 178–183. [Google Scholar] [CrossRef]

- Sharma, M.K.; Kaur, G.; Mukherjee, K. Nature of glassy magnetic state in magnetocaloric materials Dy5Pd2-xNix (x = 0 and 1) and universal scaling analysis of R5Pd2 (R = Tb, Dy and Er). J. Alloys Compd. 2019, 782, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Xuexi Zhang, X.; Zhang, H.; Qian, M.; Geng, L. Enhanced magnetocaloric efect in Ni-Mn-Sn-Co alloys with two successive magnetostructural transformations. Sci. Rep. 2018, 8, 8235. [Google Scholar] [CrossRef]

- Sarkar, S.K.; Sarita; Babu, P.; Biswas, A.; Siruguri, V.; Krishnan, M. Giant magnetocaloric effect from reverse martensitic transformation in Ni-Mn-Ga-Cu ferromagnetic shape memory alloys. J. Alloys Compd. 2016, 670, 281–288. [Google Scholar] [CrossRef]

- Deng, J.Q.; Zhuang, Y.H.; Li, J.Q.; Zhou, K.W. Magnetic phase transition and magnetocaloric effect in (Gd1−xTbx)5Si1.72Ge2.28 compounds. J. Alloys Compd. 2007, 428, 28–33. [Google Scholar] [CrossRef]

- Quetz, A.; Koshkid’Ko, Y.S.; Titov, I.; Rodionov, I.; Pandey, S.; Aryal, A.; Ibarra-Gaytan, P.J.; Prudnikov, V.; Granovsky, A.; Dubenko, I.; et al. Giant reversible inverse magnetocaloric effect in Ni50Mn35In15 Heusler alloys. J. Alloys Compd. 2016, 683, 139–142. [Google Scholar] [CrossRef]

- Dan, N.H.; Duc, N.H.; Yen, N.H.; Thanh, P.T.; Bau, L.V.; An, N.M.; Anh, D.T.K.; Bang, N.A.; Mai, N.T.; Anh, P.K.; et al. Magnetic properties and magnetocaloric effect in Ni-Mn-Sn alloys. J. Magn. Magn. Mater. 2015, 374, 372–375. [Google Scholar] [CrossRef]

- Umetsu, R.Y.; Kusakari, Y.; Kanomata, T.; Suga, K.; Sawai, Y.; Kindo, K.; Oikawa, K.; Kainuma, R.; Ishida, K. Metamagnetic behaviour under high magnetic fields in Ni50Mn50−xInx (x=14.0 and 15.6) shape memory alloys. J. Phys. D Appl. Phys. 2009, 42, 075003. [Google Scholar] [CrossRef]

- Chaudhary, V.; Chen, X.; Ramanujan, R.V. Iron and manganese based magnetocaloric materials for near room temperature thermal management. Prog. Mater. Sci. 2019, 100, 64–98. [Google Scholar] [CrossRef]

- Chaudhary, V.; Ramanujan, R.V. Magnetic and structural properties of high relative cooling power (Fe70Ni30)92Mn8 magnetocaloric nanoparticles. J. Phys. D Appl. Phys. 2015, 48, 305003. [Google Scholar] [CrossRef]

- Chaudhary, V.; Ramanujan, R.V. High Relative Cooling Power in a Multiphase Magnetocaloric FeNiB Alloy. IEEE Magn. Lett. 2015, 6, 6700104. [Google Scholar] [CrossRef]

- Ucar, H.; Craven, M.; Laughlin, D.E.; McHenry, M.E. Effect of Mo addition on structure and magnetocaloric effect in γ-FeNi nanocrystals. J. Electron. Mater. 2014, 43, 137–141. [Google Scholar] [CrossRef]

- Ucar, H.; Ipus, J.J.; Laughlin, D.E.; McHenry, M.E. Tuning the Curie temperature in gamma-FeNi nanoparticles for magnetocaloric applications by controlling the oxidation kinetics. J. Appl. Phys. 2013, 113, 17A918–921. [Google Scholar] [CrossRef]

- Chaudhary, V.; Ramanujan, R.V. Magnetocaloric Properties of Fe-Ni-Cr Nanoparticles for Active Cooling. Sci. Rep. 2016, 6, 35156. [Google Scholar] [CrossRef]

- Sarlar, K.; Tekgul, A.; Küçük, N.; Etemoğlu, A.B. Structural and magnetocaloric properties of FeNi high entropy alloys. Phys. Scr. 2021, 96, 125847. [Google Scholar] [CrossRef]

- Kurlyandskaya, G.V.; Bhagat, S.M.; Bagazeev, A.V.; Medvedev, A.I.; Ballesteros, A.; Beketov, I.V.; Safronov, A.P. Structure, magnetic and microwave properties of FeNi invar nanoparticles obtained by electrical explosion of wire in different preparation conditions. J. Phys. Chem. Solids 2016, 98, 255–262. [Google Scholar] [CrossRef]

- Paduani, C.; Krause, J.C. Local magnetic properties of γ-Fe-Mn alloys. Phys. Rev. B 1998, 58, 175–179. [Google Scholar] [CrossRef]

- Kumari, K.; Kumar, A.; Shin, M.; Kumar, S.; Huh, S.H.; Koo, B.H. Investigating the magnetocrystalline anisotropy and the exchange bias through interface efects of nanocrystalline FeCo. J. Korean Phys. Soc. 2021, 79, 1180–1189. [Google Scholar] [CrossRef]

- Kumari, K.; Kumar, A.; Koo., B.H. Investigating the origin of exchange bias efect in ferromagnetic FeNi nanoparticles prepared via controlled synthesis. Appl. Nanosci. 2021. [Google Scholar] [CrossRef]

- Ghisari, K.; Oh, J.T.; Javapour, S. The effect of heat treatment on the structure and magnetic properties of mechanically alloyed Fe—45%Ni nanostructured powders. J. Alloys Compd. 2011, 509, 1020–1024. [Google Scholar] [CrossRef]

- Guo, D.Q.; Chan, K.C.; Xia, L.; Yu, P. Magneto-caloric effect of FexZryB100−x−y metallic ribbons for room temperature magnetic refrigeration. J. Magn. Magn. Mater. 2017, 423, 379–385. [Google Scholar] [CrossRef]

- Maury, F.; Lucassont, A.; Lucasson, P.; Loreaux, Y.; Moserg, P. Interstitial mobility in FeNi, FeCo, and FeMn dilute alloys. J. Phys. F Met. Phys. 1986, 16, 523–541. [Google Scholar] [CrossRef]

- Vas’kovskiy, V.O.; Lepalovskij, V.N.; Gor’kovenko, A.N.; Kulesh, N.A.; Savin, P.A.; Svalov, A.V.; Stepanova, E.A.; Shchegoleva, N.N.; Yuvchenko, A.A. Fe20Ni80/Fe50Mn50 Film Magnetoresistive Medium. Tech. Phys. 2015, 60, 116–122. [Google Scholar] [CrossRef]

- Gor’kovenko, A.N.; Lepalovskij, V.N.; Savin, P.A.; Vas’kovskiy, V.O. Effect of Technological Conditions on the Magnetic and Magnetoresistive Properties of Fe20Ni80/Fe50Mn50 Films. Bull. Russ. Acad. Sci. Phys. 2014, 78, 925–926. [Google Scholar] [CrossRef]

- Bhardwaj, V.; Zhou, Q.; Zhang, F.; Han, W.; Du, Y.; Hua, K.; Wang, H. Effect of Al addition on the microstructure, mechanical and wear properties of TiZrNbHf refractory high entropy alloys. Tribol. Int. 2021, 160, 107031. [Google Scholar] [CrossRef]

- Hong, L.B.; Fultz, B. Two-phase coexistence in Fe–Ni alloys synthesized by ball milling. J. Appl. Phys. 1996, 79, 3946–3955. [Google Scholar] [CrossRef]

- Sharma, V.; Repaka, D.V.M.; Chaudhary, V.; Ramanujan, R.V. Enhanced magnetocaloric properties and critical behavior of (Fe0.72Cr0.28)3 Al alloys for near room temperature cooling. J. Phys. D Appl. Phys. 2017, 50, 145001. [Google Scholar] [CrossRef]

- Bla´zquez, J.S.; Ipus, J.J.; Moreno-Ramirez, L.M.; Alvarez-Gomez, J.M.; Sanchez-Jimenez, D.; Lozano-Perez, S.; Franco, V.; Conde, A. Ball milling as a way to produce magnetic and magnetocaloric materials: A review. J. Mater. Sci. 2017, 52, 11834–11850. [Google Scholar] [CrossRef]

- Kuhrt, C.; Schultz, L. Phase formation and martensitic transformation in mechanically alloyed nanocrystalline Fe-Ni. J. Appl. Phys. 1993, 73, 1975. [Google Scholar] [CrossRef]

- Huang, E.; Bassett, W.A.; Weathers, M.S. Phase Diagram and Elastic Properties of Fe 30% Ni alloy by synchrotron radiation. J. Geophys. Res. 1992, 97, 4497–4502. [Google Scholar] [CrossRef]

- Endoh, Y.; Ishikawa, Y. Antiferromagnetism of γ iron manganese alloy. J. Phys. Soc. Jpn. 1971, 30, 1614–1627. [Google Scholar] [CrossRef]

- Kumar, A.; Kumari, K.; Sharma, M.K.; Vij, A.; Kumar, S.; Huh, S.H.; Koo, B.H. Chemically inducing room temperature spin-crossover in double layered magnetic refrigerants Pr1.4+xSr1.6-xMn2O7 (0.0 ≤ x ≤ 0.5). J. Mater. Sci. Technol. 2022, 124, 232–242. [Google Scholar] [CrossRef]

- Swartzendruber, L.J.; Itkin, V.P.; Alcock, C.B. The Fe-Ni (Iron-Nickel) system. J. Phase Equilibria Diffus. 1991, 12, 288–312. [Google Scholar] [CrossRef]

- Miettinen, J.; Lilova, K.; Vassilev, G. Thermodynamic Description of Ternary Fe-B-X Systems. Part 3: Fe-B-Mn. Arch. Metall. Mater. 2014, 59, 2. [Google Scholar] [CrossRef]

- Miettinen, J.; Lilova, K.; Vassilev, G. Thermodynamic description of ternary Fe-B-X systems. Part 2: Fe-B-Ni. Arch. Metall. Mater. 2014, 59, 2. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Sommer, F.; Mittemeijer, E.J. Reevaluation of the Fe-Mn Phase Diagram. J. Phase Equilibria Diffus. 2004, 25, 346–354. [Google Scholar] [CrossRef]

- Földeàki, M.; Chahine, R.; Bose, T.K. Magnetic measurements: A powerful tool in magnetic refrigerator design. J. Appl. Phys. 1995, 77, 3528. [Google Scholar] [CrossRef]

- Sharma, M.K.; Singh, K.; Mukherjee, K. Exchange bias in a mixed metal oxide based magnetocaloric compound YFe0.5Cr0.5O3. J. Magn. Magn. Mater. 2016, 414, 116–121. [Google Scholar] [CrossRef]

- M’NASSRI, R. Magnetocaloric effect and its implementation in critical behaviour study of La0.67Ca0.33Mn0.9Fe0.1O3. Bull. Mater. Sci. 2016, 39, 551–557. [Google Scholar] [CrossRef]

- Franco, V.; Blazquez, J.S.; Conde, A. Field dependence of the magnetocaloric effect in materials with a second order phase transition: A master curve for the magnetic entropy change. Appl. Phys. Lett. 2006, 89, 222512. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, M.K.; Kumar, A.; Kumari, K.; Park, S.-j.; Yadav, N.; Huh, S.-H.; Koo, B.-H. Structural, Magnetic, and Magnetocaloric Studies of Ball-Milled Fe100−xTx (T = Ni and Mn) Alloy. Appl. Sci. 2022, 12, 9098. https://doi.org/10.3390/app12189098

Sharma MK, Kumar A, Kumari K, Park S-j, Yadav N, Huh S-H, Koo B-H. Structural, Magnetic, and Magnetocaloric Studies of Ball-Milled Fe100−xTx (T = Ni and Mn) Alloy. Applied Sciences. 2022; 12(18):9098. https://doi.org/10.3390/app12189098

Chicago/Turabian StyleSharma, Mohit K., Akshay Kumar, Kavita Kumari, Su-jeong Park, Naveen Yadav, Seok-Hwan Huh, and Bon-Heun Koo. 2022. "Structural, Magnetic, and Magnetocaloric Studies of Ball-Milled Fe100−xTx (T = Ni and Mn) Alloy" Applied Sciences 12, no. 18: 9098. https://doi.org/10.3390/app12189098

APA StyleSharma, M. K., Kumar, A., Kumari, K., Park, S.-j., Yadav, N., Huh, S.-H., & Koo, B.-H. (2022). Structural, Magnetic, and Magnetocaloric Studies of Ball-Milled Fe100−xTx (T = Ni and Mn) Alloy. Applied Sciences, 12(18), 9098. https://doi.org/10.3390/app12189098