1. Introduction

The increase in the cost of natural gas in Ukraine, and in the Poltava region in particular, has forced owners of private farm households to search for alternative sources of space heating in recent years. Solid biofuel plays a significant role in the energy supply of industrialized countries. In the United States, their share is about 4%; in Denmark–6%; in Canada–7%; in Austria–14%; and in Sweden–16% of the total consumption of primary energy resources [

1,

2]. In Ukraine, the problem of environmental safety steadily grows every year, and non-waste technologies are in demand. Particularly, there is the problem of the utilization of branches of fruit trees and ornamental shrubs cut on the territory of private farm households. Depending on the age of the trees, the type of rootstock, variety, breed, planting scheme, and type of pruning, 0.25 to 0.65 tons of wood is cut annually from one hectare of compacted orchards from caring for the crowns of fruit trees. The complexity of the operations to prune, collect, and utilize the branches is about 220 people-hours/ha per year. If the pruning of the branches in private household is usually performed manually, the sub-sequent disposal of them is reduced to the formation of piles with subsequent combustion. Therefore, shredded tree branches constitute a crisis-resistant, ever-renewable sustainable fuel material.

The efficiency of processing branches into energy products can only be achieved by integrating upgraded chopping machines into the process line. In the work of Karwandy J. [

3], the production process is described along with the technical means for the production of wood pellets in Saskatchewan. However, industrial production significantly differs from the production of wood pellets in private households. Campbell K. [

4] offers technical and economic assessment of the requests from farmers and entrepreneurs who are interested in the production and sale of agricultural fuel pellets from biomass. The given technology is quite interesting, but according to the authors, there is not enough agricultural biomass to produce fuel pellets under the conditions of a homestead plot in the Poltava region. The innovative design of Warguła Ł. [

5] provides a continuous operation of the wood chipper. The author proposes to use wood chips as a biomass (in biogas plants, composting plants, waste incineration plants), and large pieces as firewood in central heaters of single-family houses. This technology of wood chips and firewood can be adapted to the conditions of private households in Ukraine, but the design of wood chippers requires improvement. In order to find more suitable combinations of production parameters (technological and structural) for different types of input materials (hard round wood, soft round wood, and branches), Krajnc M. [

6] conducted a number of experiments on wood chip production using a drum chopper. The topic of the presented research of Krajnc M. is the most recent and has the prospect of further development with the application of a disc chopper. However, the research carried out by Wegener J. [

7] shows that the angle of cutting of the wood has a significant impact on the power requirement during the chopping process.

Scientists have almost never been engaged in the justification of the main parameters of disc cutting systems of a tree branch chopping machine and the determination of the optimal design and technological parameters to be adjusted, although these parameters determine the overall efficiency of the designed tree branch choppers, including domestic small-sized ones.

The aim of this work is to improve the non-waste technology for the utilization of tree branches and to justify the energy-saving mode of the operation of mechanical means for their chopping in order to produce fuel material for private farm households.

The main objectives of this work are as follows: to justify the technology of non-waste utilization of tree branches; to choose the optimal design parameters for the developed chopper, which is used in the technological process of chopping the tree branches; and to analyze the effect of the cutting angle of tree branches and the size of knife protrusions on the power consumption of the electric motor of the household chopper.

According to the authors’ own observations, the technology of the utilization of tree branches requires the implementation of approaches to prevent their spontaneous burning and uncontrolled accumulation on the territory of plots of private farm households. The lack of financial and organizational capabilities encourages the owners of personal household plots to solve the problems of the utilization of tree branches and plant residues via their incineration or uncontrolled accumulation on the territory of homestead plots. Protecting the population from negative environmental consequences from the incineration of the tree branches and plant residues, the development of innovative utilization technologies is required. According to the authors, the technology of chopped branches for fuel (firewood) should be considered as a promising solution of the problem of non-waste utilization. The plant residues (cut weeds, leaves, grass) should be utilized according to the technology of composting and the production of organic fertilizers from them [

8].

Therefore, the authors of the article offered the technology of non-waste utilization of tree branches under the conditions of a private farm household. This technology includes the layout and organization of the mobile complex of equipment for the utilization of branches by chopping the pruned trees and shrubs. The developed technology of non-waste utilization of tree branches solves the problems of smoke in the city caused by their uncontrolled incineration or littering of the territory of rural communities due to their uncontrolled accumulation. Chopped wood residues are sold as a fuel. Leaves and plant residues are used for composting.

The review of the known technologies of tree branches utilization and the analysis of the existing research on shredding of tree branches, vines, and other stem materials make it possible to conclude that there is not enough data to substantiate the design and the technological scheme of the device for shredding branches on the personal homestead plot or its parameters and operation modes. Due to this, there is a need to conduct research on the process of shredding branches of trees and develop the working bodies of the device, namely, the substantiation of rational parameters and modes of operation of a mechanical device for shredding the branches of trees.

The analysis of the constructions of mechanical means for chopping tree branches showed that there are three types of cutting systems, which is one of the most important components of the chopper.

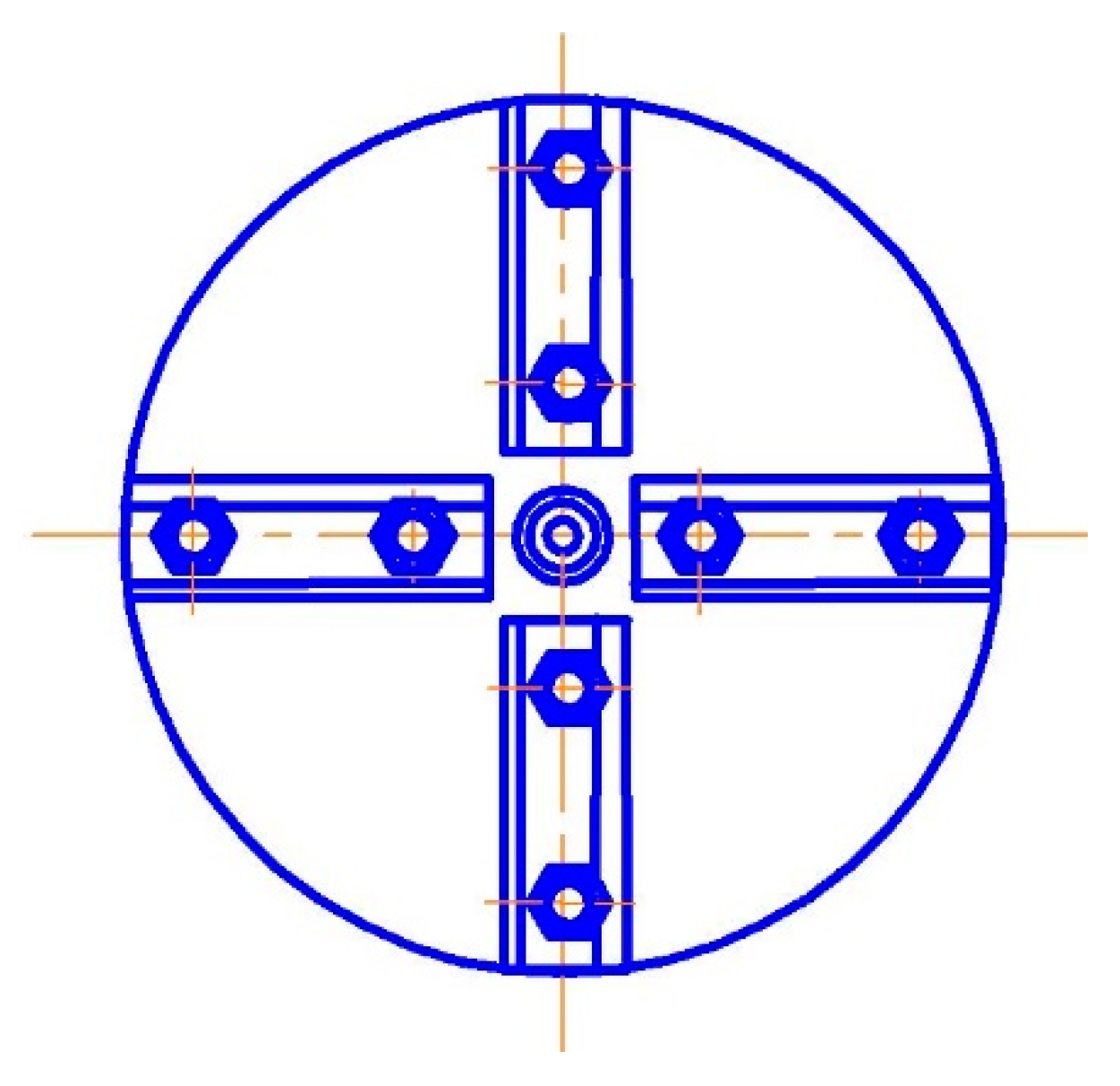

A disc cutting system is equipped with hardened steel blades that chop the branches with a diameter of up to 4 cm while rotating [

9], see

Figure 1.

A screw cutting system possesses a screw cutting mechanism that chops the branches with a diameter up to 5 cm, see

Figure 2.

The body of the branch chopper is usually made demountable to make it easier to access the blade system, which requires periodic maintenance and sharpening. The cutting system can be easily disassembled at home.

A chopping system with a cutting drum is installed in more expensive models of choppers. They chop branches up to 6 cm in diameter and work almost silently, see

Figure 3.

The blade of the disc cutting system mounted on the disc knife is fixed with two screws. If necessary, the disc knife can be removed and sharpened. This should be conducted periodically or in case of the deterioration in the chopper’s operation after the formation of chips on the knives, which negatively affects the cutting quality. The delivery tray of the chopper is designed to load the material that needs to be chopped. Some models of choppers are made with an inclined receiving chamber in order to load the material more easily. The chopped material is discharged through the outlet. Some choppers are equipped with a container for chopped material: Wolf-Garden SDL2500 EVO; Sadko GS 2800; AL-KO LH 2800 Easy Crush.

Wheels are needed for the easy transportation of the chopper around the plot. Branch choppers can have either an electric or gasoline engine. Electric ones have an engine power of 1.6 to 3 kW and can chop branches with a diameter of no more than 5 cm.

The distinctive features of the electric choppers are: low noise during operation; relatively low price; easy maintenance; and powerful motors.

The advantages of this class of choppers include: compact design; light weight; cost-effectiveness; and no need to refuel with gasoline. However, the mentioned class of choppers also has disadvantages: the need to connect it to the power grid using long power cables; the limited diameter of loading branches that is up to 3 cm; and low productivity. This line includes branch choppers with disc cutting systems, see

Figure 4.

The middle class of choppers is equipped with engines with a power of 2 to 2.5 kW. The knife system is a steel roller with a spiral cutting mechanism. Its weight is greater than the weight of choppers in the amateur class. It is within 30 kg. These choppers cope well with the chopping of the grass and branches. They are used in both small and large gardens with mature trees. All choppers of this class are equipped with a self-pulling function and chop the branches up to 3.5 cm in diameter. All models are equipped with special wheels for easy movement. The middle class includes the branch chopper of the manufacturer AL-KO, the model LH 2810 Easy Crush, see

Figure 5. The advantages of this class of choppers include: compact design; cost-effectiveness; increased productivity; and there is no need to fill it up with gasoline.

However, the above-mentioned class of choppers also has disadvantages: the plastic body of the machine; the need to connect to the power grid using long power cables; and the limited diameter of loaded branches up to 4 cm [

10].

The professional class of branch choppers is presented by our own development. It is a model of a small mobile biomass shredder equipped with a Weima WM168F gasoline engine with a power of 6.5 hp, a working volume of 196.00 cubic cm, and fuel consumption only 395 g/h of gasoline A-92, see

Figure 6 [

11]. The productivity of this wood chipper is a maximum of 2.0 cubic meters of the finished product per hour of work.

The wood chipper cuts branches, vines, and other wood wastes into the technological chips of 5.50 mm in size. The maximum diameter of branches is 60 mm, depending on the tree species and the humidity. The finished wood chips are fed through the outlet nozzle under pressure. The wood chipper is equipped with wheels for easy mobility around the territory. Its main application is in large households and large orchards with mature trees. They can also be used by public utilities that have to carry out tree trimming work in the city to clean up the effects of hurricanes [

12].

The advantages of the design are the mobility and the use of its own engine. The main difference in this wood chipper is the principle of its operation. The working body is a disc, on which three knives are located for the entire length of the disc. The disc rotates at a speed of about 2500 rpm. It creates the necessary air pressure in order to feed the wood chips through the discharge nozzle. The disadvantages include the high cost of the chopper, and the diameter of the material to be loaded into the delivery tray must not exceed 60 mm [

13].

Therefore, after analyzing the design features of three machines of different classes, we can conclude the following: the design of a branch chopper under the conditions of a private farm household should combine a disc-knife working body and should be supplied with an electric motor with a power of 2 to 3 kW.

2. Materials and Methods

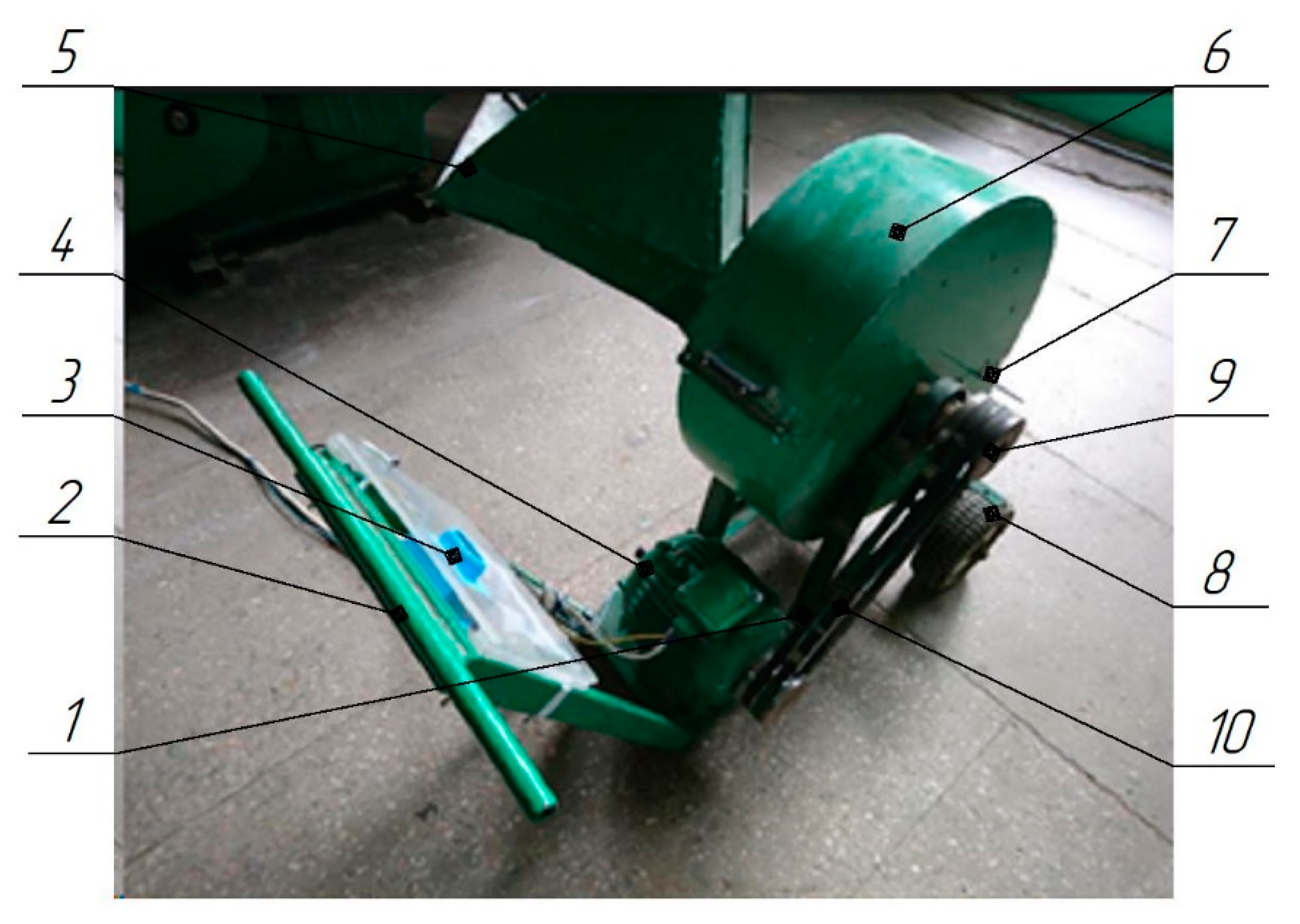

The scientists of the Technologies and Mechanical Means of Agricultural Production Department at Engineering and Technology Faculty of the Poltava State Agrarian University designed and patented the small-sized chopper of wood branches (see

Figure 7 [

14,

15,

16]). They took into account all advantages and eliminated the disadvantages of the analyzed structures of the mentioned mechanical means.

From the analysis of theoretical studies, it was established that the important factors effecting the process of chopping the tree branches, namely, the size of the chopped material, are the cutting angle

of tree branches and the size of the knife protrusion

, see

Figure 8 [

17].

The pilot model shown in

Figure 7 was used to determine the electric power consumption by the machine motor in the process of chopping tree branches. The main construction of the pilot model is a wood chipper (patent № 125965), the basic design of which corresponds to disc choppers used on the homestead plots of households. The clamp meter UNI-T UTM 1200A was used to determine the electric power consumption of the electric motor (power of 2.2 kW) during the chopping process. The calculations were performed using the following formula:

where

—the electric power consumption (the specific energy demand) for tree branch chopping, kW;

—the average electric power consumption for tree branch chopping, kW;

—the average electric power consumption for idle stroke, kW;

—the duration of chopping one sample, s.

The experiment planned nine tests conducted in triplicate. The statistical analysis of the results was performed using the Statistica 14.0 (StatSoft, Tulsa, OK, USA) software package [

18].

The analysis of theoretical studies revealed the cutting angle of tree branches and the size of the knife protrusion to be important factors effecting the process of chopping branches, namely, the size of the chopped material, see

Figure 8 [

17].

Since the design of the chopper loading tray (position 5,

Figure 7) provides a fixed attachment to the frame, the authors changed the cutting angle three times (15 degrees, 30 degrees, 45 degrees) by installing a special guiding corner insert (adjusted to the size of the three cutting angles) in the loading tray. The control of the cutting angle was carried out with the help of the angle gauge of nonius type 2UN-127 GOST 5378-88, as shown in

Figure 8b. The size of the knives’ protrusion over the surface of the disc was changed three times (0.010 m, 0.0125 m, 0.015 m). The values were checked with the caliper SHTS-125 0.1 GOST 16689.

Maintaining the purity of the experiment while feeding the samples with branch shanks of different diameters into the shredder proved to be a real problem for the authors. To provide the same conditions, branch samples were combined in piles for each experiment so that the average branch diameter of the selected wood samples differed within 10%. The maximum diameter did not exceed 35 mm, with a total cross-sectional square of samples in the pile ranging from 57 to 67 cm2. This ensured that the chopper filling was constant; hence, the same conditions for all branch chopping experiments were maintained. In addition, all branches were separated from the trunk before chopping.

3. Results

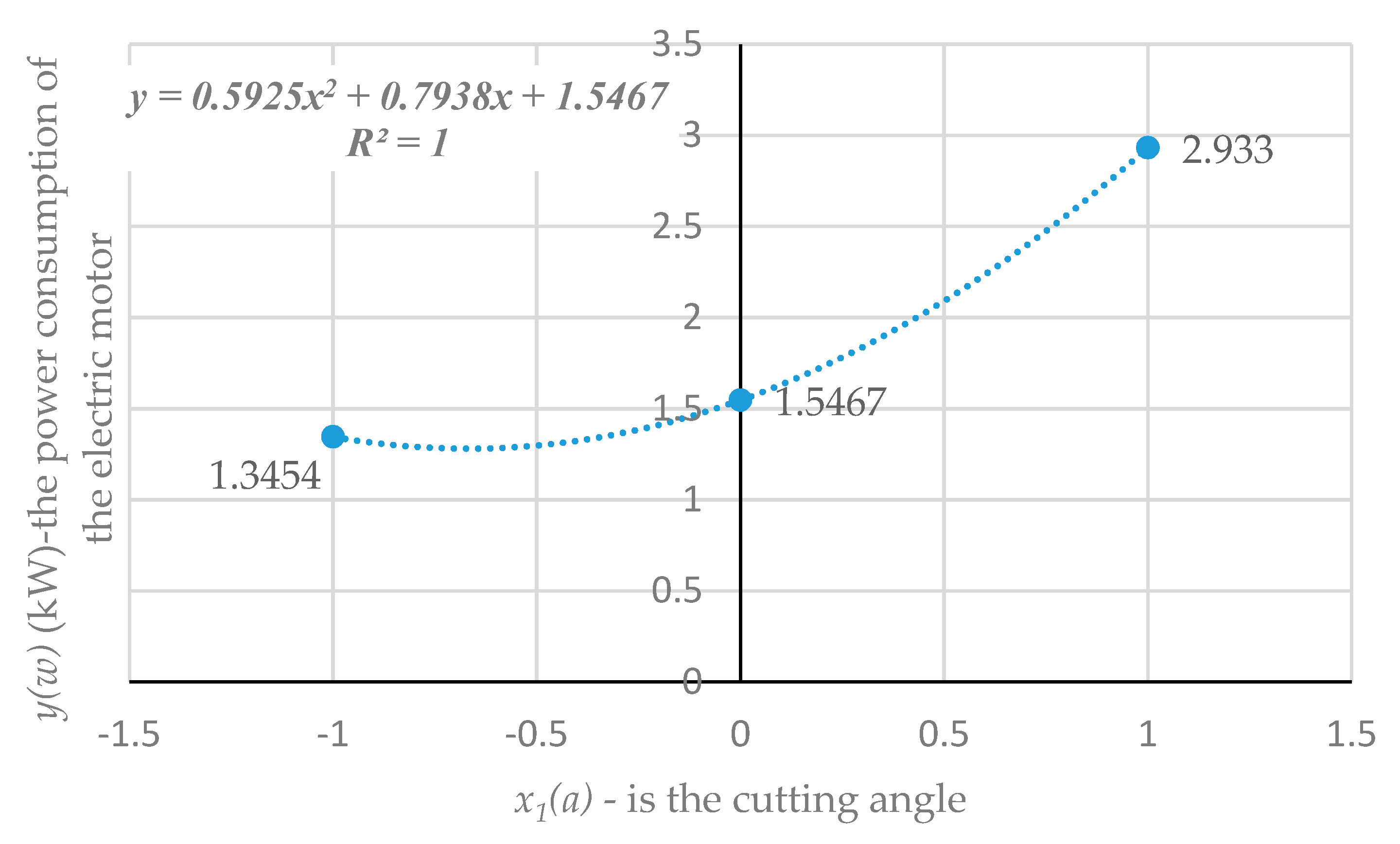

As a result of the research, the regression equation was obtained to find out the values of optimal parameters (cutting angle of tree branches during feeding and distance of knife protrusion from the disc plane) and their effect on the power consumption of the chopper motor (see

Table 1).

To determine the power consumption of small-sized branch choppers, the equation in encoded form will be as follows:

where

is the parameter of the cutting angle (the angle of feeding the branches to the loading tray) in encoded form,

;

is the parameter of the size of the knife protrusion in encoded form,

.

The obtained equations were studied using the Statistica 14.0 software package [

18]. A graphical interpretation and regression levels of the dependence of the power consumption of the branch chopper on the cutting angle and the value of the knife protrusion are shown in

Figure 9 and

Figure 10, respectively.

Figure 9 shows that the cutting angle (parameter

) has a significant impact on the power consumption by the electric motor of the small-sized branch chopper. As the cutting angle increases, the power consumption of the chopping process increases. As the knife protrusion (parameter h) on the chopper disc increases, the power consumption also increases (

Figure 10).

Taking into account the methodology of experimental investigations and the obtained test results, it should be noted that the humidity of the tree branches affects the change in the energy parameters of the machine during the chopping of tree branches. Studies on the chopping of tree branches into fuel material were carried out using the branches of different humidity in the range from 100% (freshly cut wood) to 12% (dry wood) [

19].

After switching from coded parameter notations to natural ones, we obtained:

where

is the cutting angle (the angle of feeding the branches to the loading tray),

, and

is the knife protrusion value,

.

The obtained equations were studied using the Mathcad software package.

As a result of working out the schedules, we found out that at and , the power consumption of the electric motor of a small-sized tree branch chopper will be optimal, and it will be equal to .

The performed multi-factor complex technical and economic assessment of the existing foreign means for chopping tree branches using the distance to target method made it possible to determine the technical and economic substantiation of the application of a single-stage, small-sized chopper with a vertical rotor rotation axis, the working bodies of which are fixed knives.

4. Discussion

The research results will help the population in using tree branches, shrubs, and other plant residues as fuel sources. They will allow the owners of household plots planning and organizing both periodic and seasonal free events and provide unscheduled paid services ordered by the residents or organizations. In addition, they will allow organizing the sale of the excess of chopped branches for household needs, whether for space heating or cooking. An additional area to expand the possibilities of the application the small-sized mobile chopper is the organization of compost production from plant residues and its implementation for household needs, the improvement of tree and shrubs plantations in the village, and the possibility to transfer the equipment for a paid rent.

The residents of the united territorial communities and the owners of mansions or households and homesteads cannot solve the problem of the utilization of plant residues and branches on their own because of the high cost of the equipment and composting technologies. Therefore, the authorities of the united territorial communities and municipal enterprises should be involved in the implementation of this project in order to concentrate capabilities and resources in the fight against the environmental problems caused by the unauthorized, spontaneous incineration of plant residues by the population. In addition, for additional motivation in the implementation of the proposed technology of the non-waste utilization of tree branches, it is proposed to organize the sale of surplus processing products, as well as the organization of additional paid services for the use of the developed small-sized tree branch choppers.

Taking into account the pronounced seasonality of problems with smoke in the air, the authors of the article propose to organize free services for the residents of communities during the period when trees are actively shedding leaves, namely, October to November, as well as during the period of pruning garden trees and shrubs in late February and March. During other periods, the services can be provided upon request on a paid basis. It is also proposed to organize a place for the reception, storage, and composting of plant residues, both from public utilities and from the population of rural communities.

The quality of the operation of most mechanical means directly depends on the setting of optimal modes for their operation. Based on the analysis of the existing mechanical means for the energy-saving technology of chopping tree branches under the conditions of private farm households, the minimum power consumption by an electric motor is chosen as the optimization parameter. To conduct experimental investigation on determining the energy-saving mode of operation of the chopper and to determine its impact on power consumption during the chopping process is one of the promising directions to solve this problem.

To implement the latest technologies for energy-saving chopping of tree branches, a new generation of mechanical means is being developed and tested. It differs from the traditional ones in special constructional elements and the possibility of minimizing the power consumption in the process of chopping tree branches due to the settings of structural parameters [

20].

Scientific studies have proven that the adjustments in the size of the knife protrusion in the design of the chopper makes it possible to cut tree branches of different thicknesses into particles of the same size along the length without increasing power consumption. The optimal setting of the cutting angle (the angle of inclination of the loading tray) allows for reductions in labor costs, since the branch raw materials during the loading of the chopper into the delivery tray leads to the violation of the cutting balance position, combined with the self-tightening effect of branches. All of the mentioned improvements in the developed chopper increase its reliability in operation and cost-effectiveness, which is especially important in the conditions of private farm households.

According to the obtained data, machines with a driving power of 5 kW and above can be attributed to the mechanical means for chopping tree branches of low power produced by the Ukrainian industry. The analysis of the conducted research showed that it was necessary to offer a chopping machine with a drive power of up to 5 kW (optimal ratio of price and quality) for private households.

The most promising mechanical means for the chopping of branches are considered to be choppers with motor power supply from 220 V mains. The corresponding advantages of such choppers are that they are most optimally adapted to the conditions of private farm households and that they are small-sized, mobile, and affordable.