First-Principles Investigation of the Shear Properties and Sliding Characteristics of c-ZrO2(001)/α-Al2O3(

Abstract

1. Introduction

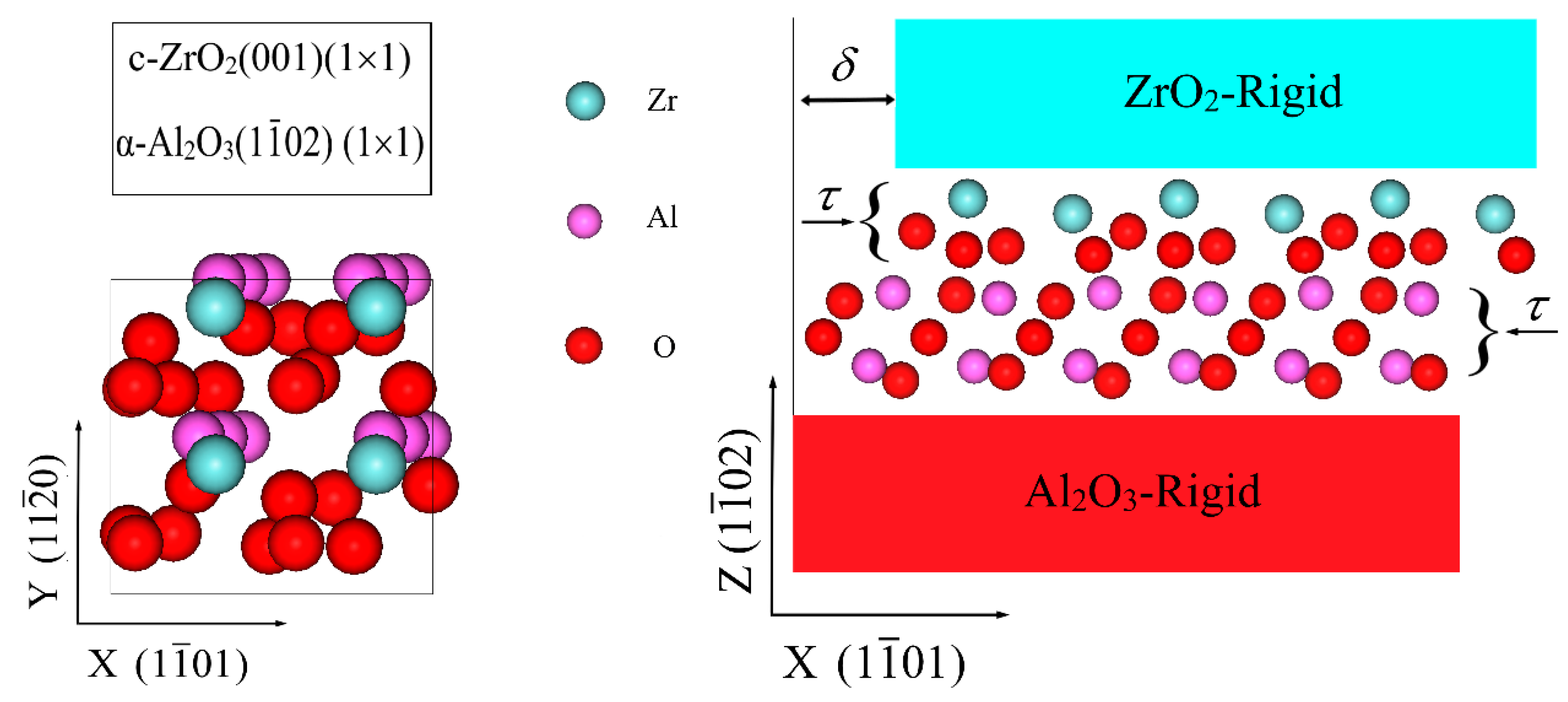

2. Methodology

3. Results and Discussion

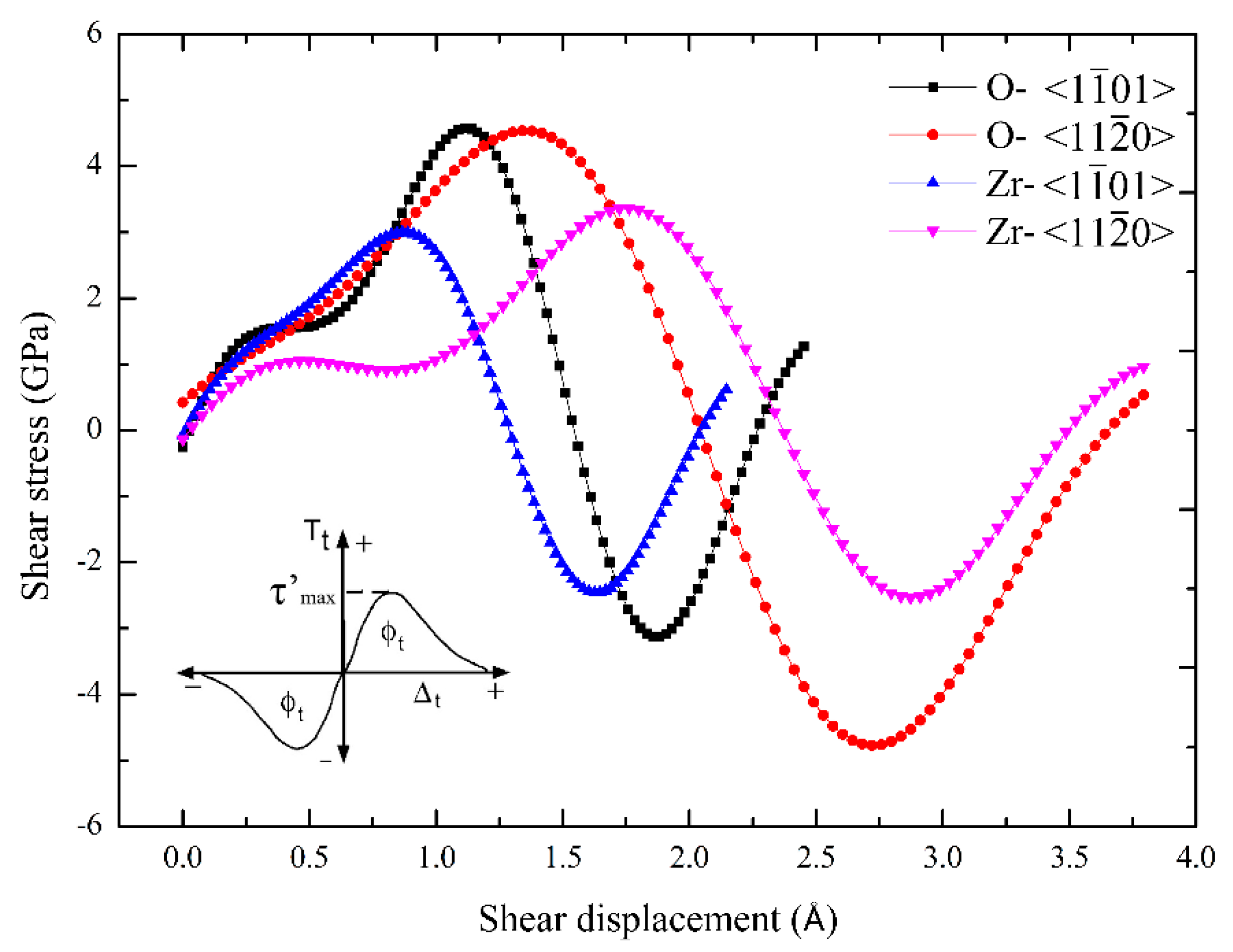

3.1. Shear Strength Parameters

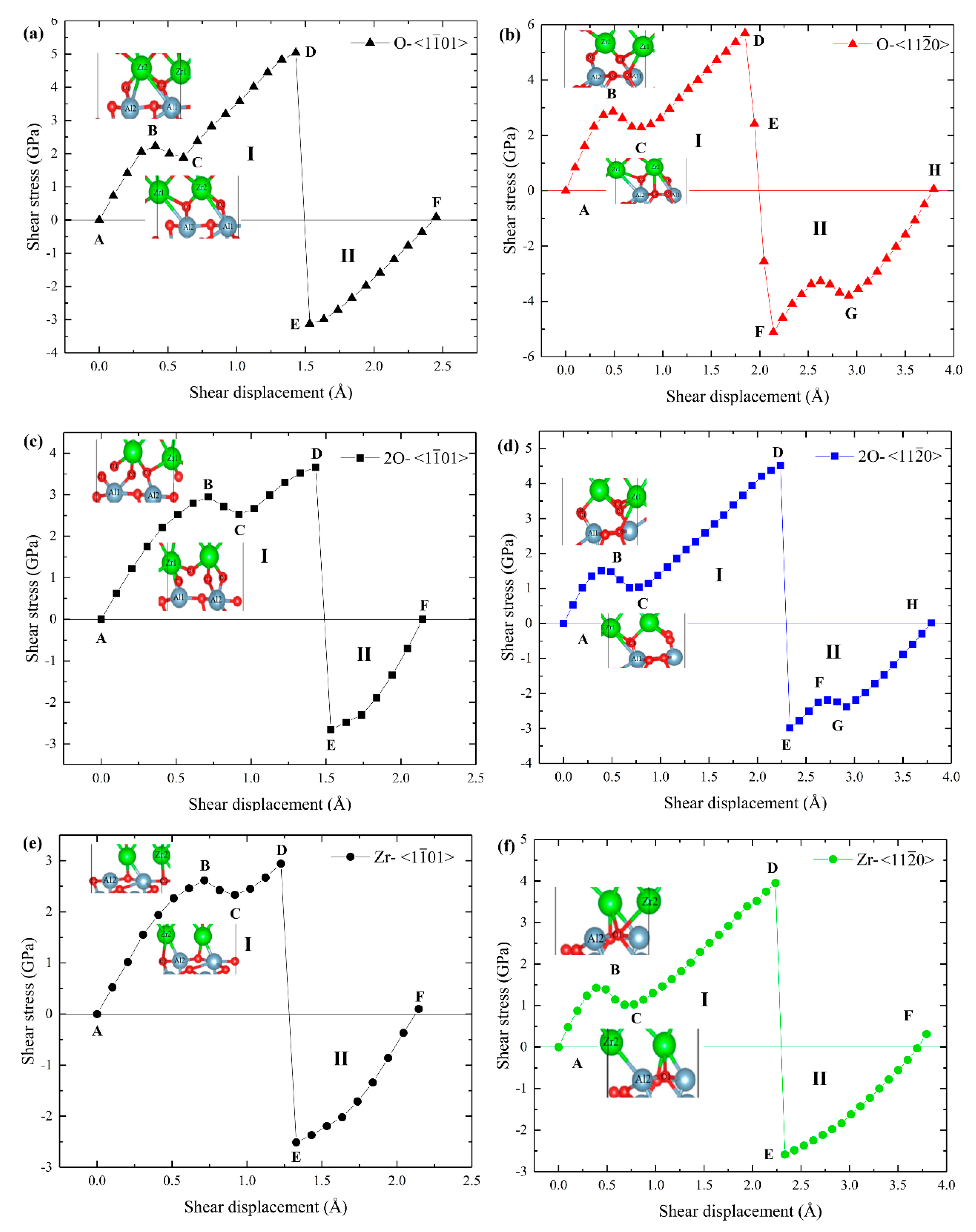

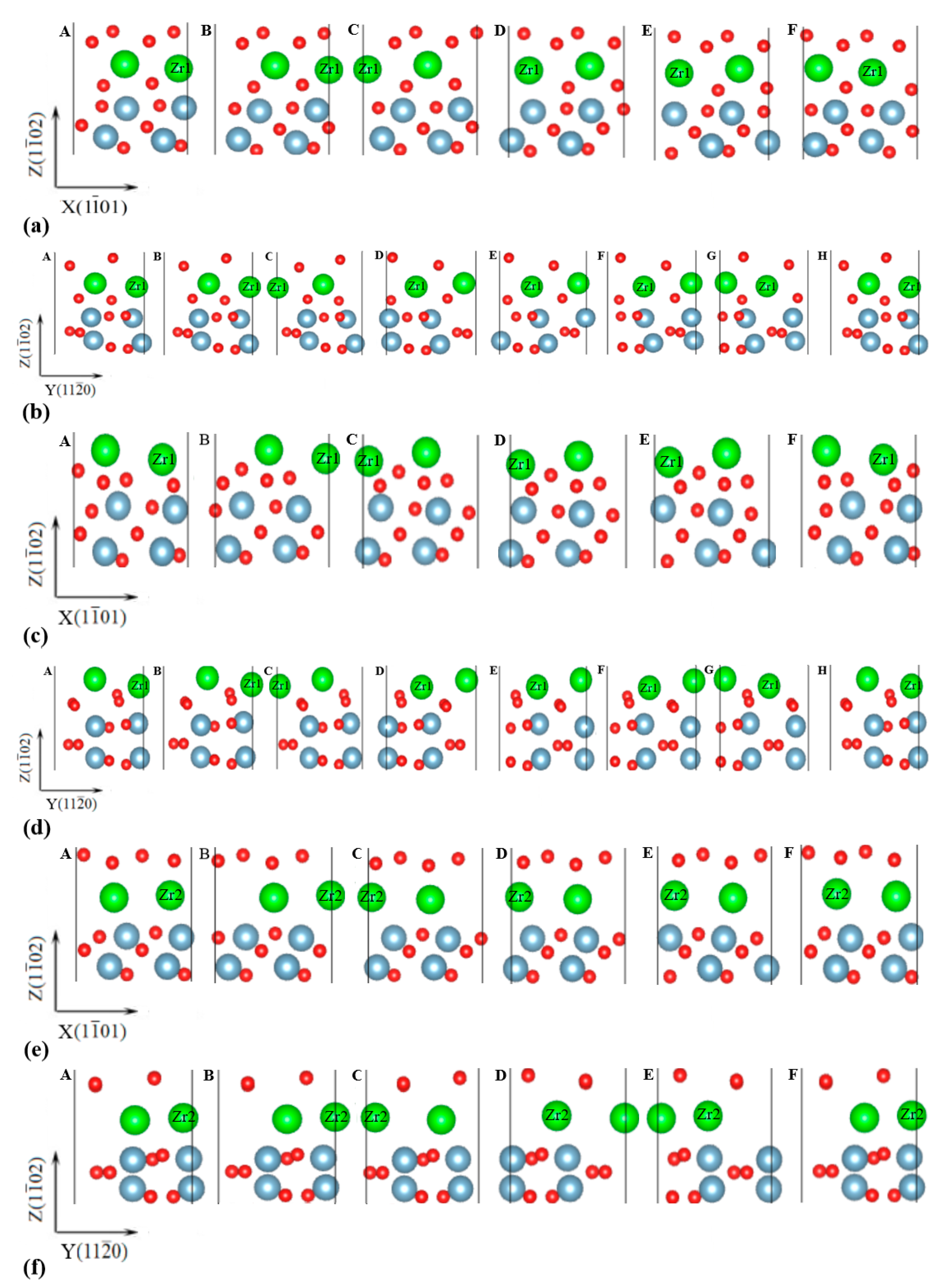

3.2. Failure Mechanism

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Evans, A.; Hutchinson, J. The mechanics of coating delamination in thermal gradients. Surf. Coat. Technol. 2007, 201, 7905–7916. [Google Scholar] [CrossRef]

- Cheng, B.; Yang, N.; Zhang, Q.; Zhang, M.; Zhang, Y.-M.; Chen, L.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Sintering induced the failure behavior of dense vertically crack and lamellar structured TBCs with equivalent thermal insulation performance. Ceram. Int. 2017, 43, 15459–15465. [Google Scholar] [CrossRef]

- Venkadesan, G.; Muthusamy, J. Experimental investigation of Al2O3/8YSZ and CeO2/8YSZ plasma sprayed thermal barrier coating on diesel engine. Ceram. Int. 2019, 45, 3166–3176. [Google Scholar] [CrossRef]

- Chen, L.; Gao, L.-L.; Yang, G.-J. Imaging Slit Pores Under Delaminated Splats by White Light Interference. J. Therm. Spray Technol. 2018, 27, 319–335. [Google Scholar] [CrossRef]

- Bolelli, G.; Righi, M.G.; Mughal, M.Z.; Moscatelli, R.; Ligabue, O.; Antolotti, N.; Sebastiani, M.; Lusvarghi, L.; Bemporad, E. Damage progression in thermal barrier coating systems during thermal cycling: A nano-mechanical assessment. Mater. Des. 2019, 166, 107615. [Google Scholar] [CrossRef]

- Fattahi, M.; Nezafat, N.B.; Ţălu, Ş; Solaymani, S.; Ghoranneviss, M.; Elahi, S.M.; Shafiekhani, A.; Rezaee, S. Topographic characterization of zirconia-based ceramics by atomic force microscopy: A case study on different laser irradiations. J. Alloy Compd. 2020, 831, 154763. [Google Scholar] [CrossRef]

- Boissonnet, G.; Chalk, C.; Nicholls, J.; Bonnet, G.; Pedraza, F. Phase stability and thermal insulation of YSZ and erbia-yttria co-doped zirconia EB-PVD thermal barrier coating systems. Surf. Coat. Technol. 2020, 389, 125566. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Jonnalagadda, K.P.; Eriksson, R.; Yuan, K.; Li, X.-H.; Ji, X.; Yu, Y.; Peng, R.L. A study of damage evolution in high purity nano TBCs during thermal cycling: A fracture mechanics based modelling approach. J. Eur. Ceram. Soc. 2017, 37, 2889–2899. [Google Scholar] [CrossRef]

- Yang, J.; Wang, L.; Li, D.; Zhong, X.; Zhao, H.; Tao, S. Stress Analysis and Failure Mechanisms of Plasma-Sprayed Thermal Barrier Coatings. J. Therm. Spray Technol. 2017, 26, 890–901. [Google Scholar] [CrossRef]

- Jamali, H.; Loghman-Estarki, M.R.; Razavi, R.S.; Mozafarinia, R.; Edris, H.; Bakhshi, S. Comparison of thermal shock behavior of nano-7YSZ, 15YSZ and 5.5 SYSZ thermal barrier coatings produced by APS method. Ceramics 2016, 60, 210–219. [Google Scholar] [CrossRef][Green Version]

- Loghman-Estarki, M.; Razavi, R.S.; Jamali, H. Thermal stability and sintering behavior of plasma sprayed nanostructured 7YSZ, 15YSZ and 5.5SYSZ coatings at elevated temperatures. Ceram. Int. 2016, 42, 14374–14383. [Google Scholar] [CrossRef]

- Zeng, J.; Sun, J.; Zhang, H.; Yang, X.; Qiu, F.; Zhou, P.; Niu, W.; Dong, S.; Zhou, X.; Cao, X. Lanthanum magnesium hexaluminate thermal barrier coatings with pre-implanted vertical microcracks: Thermal cycling lifetime and CMAS corrosion behaviour. Ceram. Int. 2018, 44, 11472–11485. [Google Scholar] [CrossRef]

- Bal, E.; Karabaş, M.; Taptik, I.Y. The effect of CMAS interaction on thermal cycle lifetime of YSZ based thermal barrier coatings. Mater. Res. Express 2018, 5, 065201. [Google Scholar] [CrossRef]

- Cocks, A.; Fleck, N. Constrained sintering of an air-plasma-sprayed thermal barrier coating. Acta Mater. 2010, 58, 4233–4244. [Google Scholar] [CrossRef]

- Cocks, A.; Fleck, N.; Lampenscherf, S. A brick model for asperity sintering and creep of APS TBCs. J. Mech. Phys. Solids 2014, 63, 412–431. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Withers, P.J.; Markocsan, N.; Xiao, P. Determination of local residual stress in an air plasma spray thermal barrier coating (APS-TBC) by microscale ring coring using a picosecond laser. Scr. Mater. 2019, 167, 126–130. [Google Scholar] [CrossRef]

- Li, C.; Zhang, X.; Chen, Y.; Carr, J.; Jacques, S.; Behnsen, J.; di Michiel, M.; Xiao, P.; Cernik, R. Understanding the residual stress distribution through the thickness of atmosphere plasma sprayed (APS) thermal barrier coatings (TBCs) by high energy synchrotron XRD; digital image correlation (DIC) and image based modelling. Acta Mater. 2017, 132, 1–12. [Google Scholar] [CrossRef]

- Guan, P.; Ai, Y.; Fei, C.; Yao, Y. Thermal Fatigue Life Prediction of Thermal Barrier Coat on Nozzle Guide Vane via Master–Slave Model. Appl. Sci. 2019, 9, 4357. [Google Scholar] [CrossRef]

- Dong, H.; Yang, G.; Li, C.-X.; Luo, X.-T.; Li, C.-J. Effect of TGO Thickness on Thermal Cyclic Lifetime and Failure Mode of Plasma-Sprayed TBCs. J. Am. Ceram. Soc. 2014, 97, 1226–1232. [Google Scholar] [CrossRef]

- Finnis, M. The theory of metal - ceramic interfaces. J. Phys. Condens. Matter 1996, 8, 5811–5836. [Google Scholar] [CrossRef]

- Guo, X.; Shang, F. Shear strength and sliding behavior of Ni/Al2O3 interfaces: A first-principle study. J. Mater. Res. 2012, 27, 1237–1244. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, Y.; Jung, Y.-G.; Li, L.; Knapp, J.; Zhang, J. Ideal tensile strength and shear strength of ZrO2(111)/Ni(111) ceramic-metal Interface: A first principle study. Mater. Des. 2016, 112, 254–262. [Google Scholar] [CrossRef]

- Soler, J.M.; Artacho, E.; Gale, J.D.; García, A.; Junquera, J.; Ordejón, P.; Sánchez-Portal, D. The SIESTA method for ab initio order-N materials simulation. J. Phys. Condens. Matter 2002, 14, 2745–2779. [Google Scholar] [CrossRef]

- Bao, Z.Y.; Shang, F.L. First-principles investigation of the tensile strength and fracture property of c-ZrO2(001)/α-Al2O3() interfaces. Mater. Sci. Eng. B. 2022, submitted.

- Christensen, A.; Carter, E.A. First-principles characterization of a heteroceramic interface: ZrO2(001) deposited on an α − Al2O3() substrate. Phys. Rev. B 2000, 62, 16968–16983. [Google Scholar] [CrossRef]

- Eichler, A.; Kresse, G. First-principles calculations for the surface termination of pure and yttria-doped zirconia surfaces. Phys. Rev. B 2004, 69, 045402. [Google Scholar] [CrossRef]

- Duan, W.; Karki, B.B.; Wentzcovitch, R.M. High-pressure elasticity of alumina studied by first principles. Am. Miner. 1999, 84, 1961–1966. [Google Scholar] [CrossRef]

- Xu, Q.; Salles, N.; Chevalier, J.; Amodeo, J. Atomistic simulation and interatomic potential comparison in α-Al2O3: Lattice, surface and extended-defects properties. Model. Simul. Mater. Sci. Eng. 2022, 30, 035008. [Google Scholar] [CrossRef]

- Cousland, G.; Cui, X.; Smith, A.; Stampfl, A.; Stampfl, C. Mechanical properties of zirconia, doped and undoped yttria-stabilized cubic zirconia from first-principles. J. Phys. Chem. Solids 2018, 122, 51–71. [Google Scholar] [CrossRef]

- Liu, H.; Inokoshi, M.; Nozaki, K.; Shimizubata, M.; Nakai, H.; Too, T.D.C.; Minakuchi, S. Influence of high-speed sintering protocols on translucency, mechanical properties, microstructure, crystallography, and low-temperature degradation of highly translucent zirconia. Dent. Mater. 2022, 38, 451–468. [Google Scholar] [CrossRef] [PubMed]

- Rice, J.R. Dislocation nucleation from a crack tip: An analysis based on the Peierls concept. J. Mech. Phys. Solids 1992, 40, 239–271. [Google Scholar] [CrossRef]

- Farkas, D. Atomistic theory and computer simulation of grain boundary structure and diffusion. J. Phys. Condens. Matter 2000, 12, R497–R516. [Google Scholar] [CrossRef]

- Urata, S.; Hirobe, S.; Oguni, K.; Li, S. Atomistic to continuum simulations of fracture and damage evolutions in oxide glass and glass-ceramic materials: A critical review. J. Non Cryst. Solids X 2022, 15, 100102. [Google Scholar] [CrossRef]

- Wang, R.; Liu, Y.; Mao, J.; Liu, Z.; Hu, D. Cyclic cohesive zone model damage parameter acquisition for fatigue crack growth considering crack closure effect. Int. J. Fatigue 2022, 163, 107021. [Google Scholar] [CrossRef]

- Needleman, A. A Continuum Model for Void Nucleation by Inclusion Debonding. J. Appl. Mech. 1987, 54, 525–531. [Google Scholar] [CrossRef]

- Xu, X.-P.; Needleman, A. Void nucleation by inclusion debonding in a crystal matrix. Model. Simul. Mater. Sci. Eng. 1993, 1, 111–132. [Google Scholar] [CrossRef]

- Umeno, Y.; Kitamura, T. Ab initio simulation on ideal shear strength of silicon. Mater. Sci. Eng. B 2002, 88, 79–84. [Google Scholar] [CrossRef]

| Models | σmax (GPa) | Wsep (mJ/m2) | Shear Direction | τmax (GPa) | γus (mJ/m2) |

|---|---|---|---|---|---|

| O- | 9.012 | 1208 | <> | 5.04 | 399 |

| <> | 5.69 | 612 | |||

| 2O- | 7.452 | 829 | <> | 3.66 | 349 |

| <> | 4.52 | 494 | |||

| Zr- | 6.893 | 715 | <> | 2.94 | 245 |

| <> | 3.95 | 437 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, Z.; Shang, F.

First-Principles Investigation of the Shear Properties and Sliding Characteristics of c-ZrO2(001)/α-Al2O3(

Bao Z, Shang F.

First-Principles Investigation of the Shear Properties and Sliding Characteristics of c-ZrO2(001)/α-Al2O3(

Bao, Zeying, and Fulin Shang.

2022. "First-Principles Investigation of the Shear Properties and Sliding Characteristics of c-ZrO2(001)/α-Al2O3(

Bao, Z., & Shang, F.

(2022). First-Principles Investigation of the Shear Properties and Sliding Characteristics of c-ZrO2(001)/α-Al2O3(