1. Introduction

Since the development of prehistoric hand tools, mankind has tried to improve the functionality of handheld products and tools and their interaction with the users. It has been shown that correctly designed products can provide safety, comfort and increased performance [

1]. Six comfort factors have been identified by previous researchers (functionality, posture and muscles, irritation and pain of hand and fingers, irritation of the hand surface, handle characteristics, aesthetics), which could be grouped into: functionality, physical interaction and appearance [

2]. During physical interaction with handheld products, high complex load cases can occur on the hand due to the hand grasp force and product manipulation, which can lead to discomfort, pain, and even development of musculo-skeletal disorders such as carpal tunnel syndrome, tendonitis, muscle cramping and soreness, etc. [

3,

4,

5].

While the functionality of handheld products and tools has increased rapidly with recent technological development, the physical interaction between the handheld product and the users has mostly been left behind. Hence, several researchers tried to optimize the human tactile perception using various ergonomic and biomechanical principles and methods. Most of the research has been focused on optimizing the size (diameters) of simple cylindrical handles for improving grip force, minimizing muscle exertion, and, thereby, increase safety and comfort [

6,

7,

8,

9,

10,

11,

12,

13,

14]. Due to the complexity of product handle shape determination beyond diameter optimization, researchers developed new methods for optimal shape determination recently [

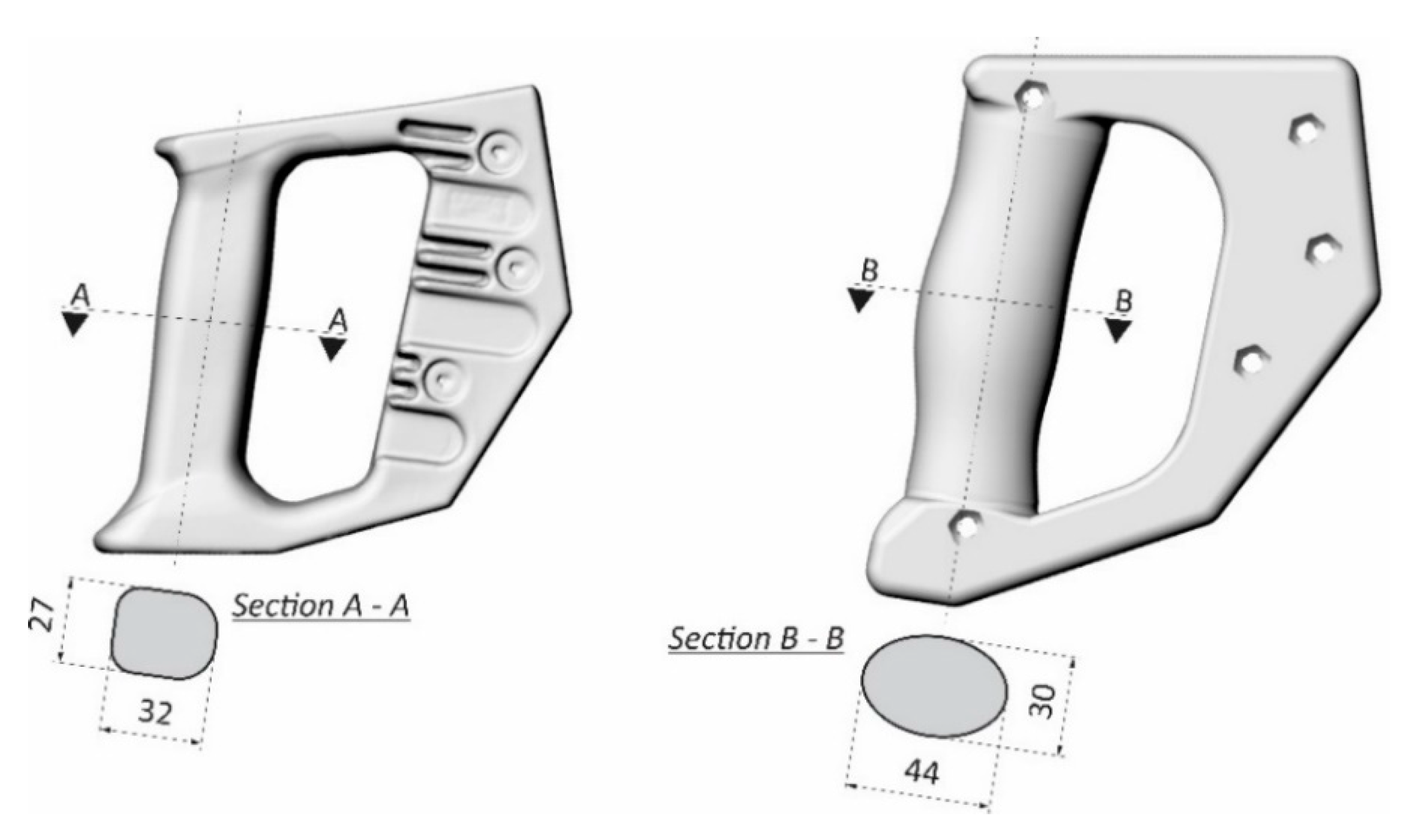

15]. Thereby, a digital human hand model has been developed, which allowed for the determination of the handle shape based on the hand shape in its optimal power grasp posture. Results of subjective comfort rating evaluation have shown that anatomically shaped handles were rated significantly higher compared to cylindrical handles.

Hence, understanding the biomechanical aspect, especially the human tactile perception while grasping a product, is important to optimize the interaction even further. Surface roughness and the influence on the human tactile perception of various materials has been investigated by many authors [

16]. It has been shown that object compliance (deformation) is an important physical determinant for pleasantness, and, hence, subjective comfort [

17]. The biomechanical aspect of tactile perception has also been investigated extensively to improve the tactile perception during robot-assisted surgeries and to improve the grasping capabilities of robots [

18,

19,

20]. Hence, many researchers have investigated various biological tissue mechanical behaviors; however, they did not consider it in the product design process for improved tactile perception. It has been shown that the soft tissue of the human hand (skin, subcutaneous tissue, muscles) is highly deformable, and it shows non-linear mechanical behavior under stress, with a low stiffness region at smaller strains and a rapid increase in stiffness with higher strains [

21]. Researchers have shown that grasping a cylindrical handle results in uneven contact pressure, with peak contact pressure exceeding values, which can induce discomfort, pain and even musculo-skeletal disorders [

22,

23]. Therefore, authors investigated the influence of contact pressure during grasping on the tactile perception and provided values for a pressure discomfort threshold (PDT) and pressure pain threshold (PPT) using measuring equipment and subjective responses [

24,

25,

26]. Results have shown that both thresholds are highly subjective and differ from person to person. A PDT value of 188 kPa has been obtained for the finger area, 200 kPa for the palm and 100 kPa for the thenar area. The PPTs for the finger, palm and thenar area were 496, 494 and 447 kPa, respectively [

27]. The cause of the broad range of values is still not understood well, although it can most likely be attributed to the subjective perception of the load, the difference in biological material behavior and anatomical topological features, and even the time the tissue is under the load [

28].

Hence, most of the authors suggested that product handles should follow the hand’s shape in its optimal grasp posture for increased comfort, safety, and performance [

29]. This ensures even deformation rates of the hand soft tissue, which results in more uniform contact pressure with lower peak values. However, size and shape optimization for a wide target population is impossible, due to the variability of the hand anthropometric values (hand/finger length, hand width, finger circumference, etc.) between users. Accommodation of all users with single sized handles is, thereby, not possible, which results in suboptimal grasping with higher contact pressure on the soft tissue, higher muscle activity, lower stability, lower performance and safety for many users [

12]. Companies usually also do not provide their product with various handle sizes to minimize the effect of hand size and shape variation [

30].

It has been shown that product handle material has an important influence on the tactile perception and, hence, comfort during use. However, most of the authors considered quasi-stiff materials (steel, plastic, wood) and ignored the possibility to improve handle ergonomics further by using deformable materials [

31,

32]. Most of the handheld product handles are currently made of various plastic materials, due to manufacturing reasons [

33]. Products that require high stability are also coated with rubber-like material for increased friction between the product handle and the hand. Plastic and rubber-like materials are magnitudes stiffer compared to the stiffness of soft tissue; hence, almost all deformations during grasping are attributed to the hand’s soft tissue [

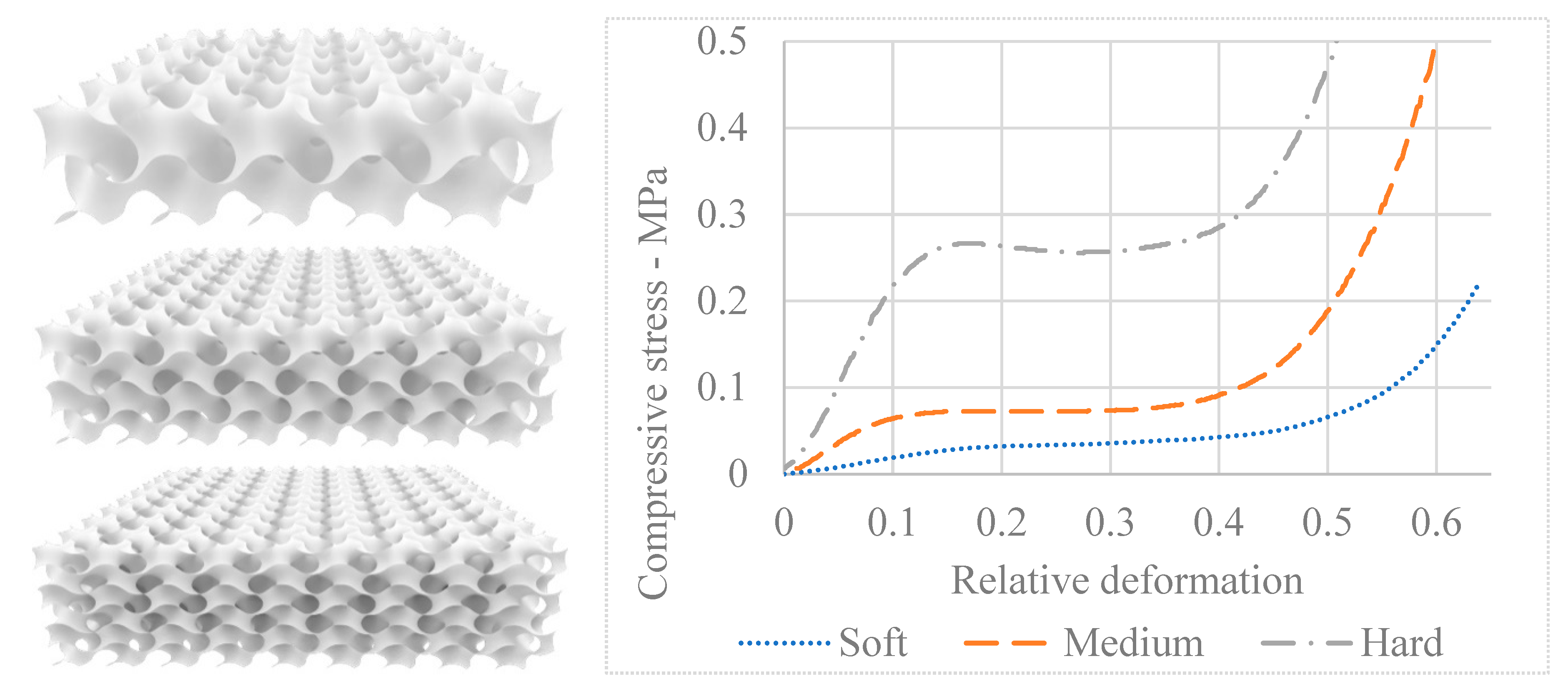

32]. Sub-optimally designed handles and the distinctive non-linear mechanical behavior of rapid stiffening of the soft tissue under compression leads to a sudden rise in contact pressure on the hand’s soft tissue, resulting in uneven contact pressure distribution with high peak values exceeding PDT or even PDT values. Researchers tried to mitigate this problem by using elastomeric foam materials as outer interface handle materials. Results have shown improved tactile perception with increased subjective comfort rating [

34]. This can be attributed to the deformation of the foam interface material during grasping, since the foam interface material provides more uniform contact pressure distribution and lowers the peak contact pressure. However, users also reported the feeling of loss of stability during grasping, which can be explained by excessive foam deformation during grasping. Hence, improved tactile perception can be achieved with deformable material that stays undeformed at lower grasping forces and deforms when the critical contact pressure is reached. The Finite Element Method (FEM) has already been utilized in the past to model and simulate the biomechanical system human hand grasping product handles with various interface materials and to define the material parameters for improved tactile perception [

31,

32]. Three-dimensional printing technology has also been used to develop a methodology for manufacturing the proposed materials obtained in the numerical analysis [

35]. Results have shown the feasibility and repeatability of the methodology and manufacturing process for testing subjective responses.

Due to the lack of investigation and understanding of the influence of material stiffness on the human tactile perception, in this paper, we developed a methodology to manufacture product interface materials with various stiffnesses and to evaluate the tactile perception using a subjective comfort rating questionnaire. The findings can be utilized in the product handle interface material determination for improved tactile perception, comfort, safety, and, hence, product ergonomics.

4. Discussion

It is common practice that manufacturers of handheld products and tools promote the use of rubber or similar materials as outer interface layers on the handles, expecting to improve the tactile perception and lower the risk of musculo-skeletal disorder development. Researchers also investigated foam rubber handles and have shown that they can lower the overall contact pressure and provide more uniform contact pressure distribution; however, a loss of stability has been reported by the users. Authors did not try to optimize the material behavior, and based on the previous results, too soft rubber foam has been utilized that deforms already at lower forces and contact pressures, which led to the feeling of loss of stability of the product in the hands. Hence, exact controllability of the interface material’s behavior and the material parameter determination are therefore needed for the optimal bio-mechanical response of hand–handle systems for improvement of tactile perception. The findings mentioned from the previous research have also been confirmed by our results, which suggest that the mechanical properties and, hence, the behavior of the product handle interface layer, show significant influence on the tactile perception, as outlined in further subsections.

4.1. Subjective Comfort Descriptor Ratings

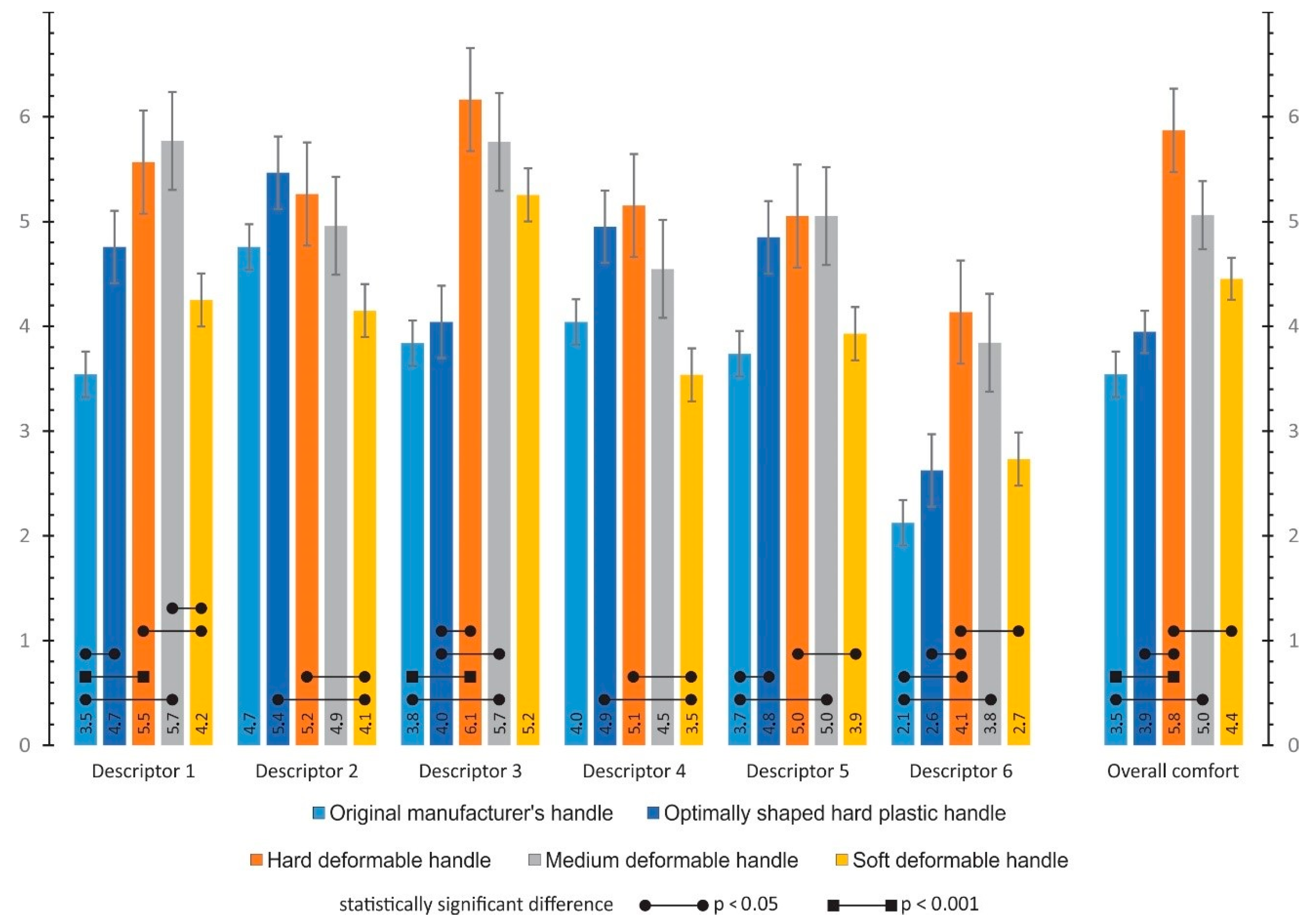

In order to evaluate the influence of the interface material stiffness on the human tactile perception, we firstly discuss the results of the subjective comfort descriptor ratings and compare all the product handles. All significance levels are p < 0.05, unless otherwise stated.

The medium and hard deformable handles were rated the highest, with no statistically significant difference between both handles. However, a statistically significant difference was observed when comparing both aforementioned handles to the soft deformable and the original handle, which were rated significantly lower. The hard deformable handle was statistically significantly different from the original handle at p < 0.001, suggesting a strong difference in the perceived comfort rating predictor. The soft deformable handle was not statistically significantly different from the original handle and the optimally shaped hard plastic handle, which indicates that handle material has an influence on this comfort descriptor. No statistically significant difference was observed between the hard and medium deformable handles when compared to the optimally shaped hard plastic handle, suggesting that the shape of the handle had a major impact on the comfort descriptor, Fits the hand. This had been expected, since this comfort descriptor considers mostly the shape of the handle. Additionally, a statistically significant difference was also observed between the original manufacturer’s handle and the optimally shaped hard plastic handle and both hard and medium deformable handles, which were rated higher, suggesting that the original manufacturer’s handle was not optimized, either in terms of the shape and or in handle material. Based on the results, it is evident that both the shape of the handle, as well as the handle material in the case of deformable material, had an influence on the descriptor, Fits the hand.

The importance of correct material parameter determination of deformable handles can be observed clearly when evaluating the results of the comfort descriptor, Has a good force and torque transmission. The soft deformable handle showed the lowest score with a value of 4.2, and was statistically significantly different to the optimally shaped hard plastic handle and the hard deformable handle. However, it was not statistically significantly different from the medium deformable handle and the original handle. This result suggests that forces and torques cannot be transferred effectively from the hand to the handle, and vice versa when too soft deformable handles are being used, due to the increased deformation of the handle material and the resulting movements and rotations of the handle and, hence, saw, in the hand. By contrast, no other statistically significant differences were observed, indicating that deformable handles can provide the same perceived force and torque transmission as hard plastic handles if the material properties of the deformable material are defined correctly.

The comfort descriptor, Provides a nice feeling during grasping, clearly indicates potential for the improvement of tactile perception based on correct interface material mechanical parameter determination, since both hard and medium deformable handles were rated the highest, with values of 6.1 and 5.7, respectively. The comfort descriptor was rated significantly higher compared to stiff plastic handles and soft deformable handles. The hard deformable handle was statistically significantly different from the original handle at p < 0.001. The results suggest that stiff handles cannot provide the best tactile perception, and, hence, need to be deformable with exact material behavior as not to allow excessive deformation of the handle material during grasping.

The product handle interface material mechanical properties and its tactile perception also have an influence on the descriptor, Can offer a high task performance, since the soft deformable handle was rated the lowest, and was statistically significantly different than the optimally shaped hard plastic handle, as well as the hard deformable handle. No statistically significant difference was observed between the medium deformable handle, as well as the soft deformable handle and the original manufacturer’s handle. Furthermore, the medium deformable handle was not statistically significantly different than any other handle. The results suggest that the negative influence on the perceived task performance becomes apparent when too soft a deformable handle is being used. This can again be explained by the excessive deformation of the deformable handle interface material, which lowers the stability, and, hence, reduces the expected performance.

No statistically significant difference was observed for the comfort descriptor, Needs low hand grip force supply, for stable grip between the stiff plastic handle and the hard and medium deformable handles. This, once again, indicates that a deformable handle interface material with correctly determined material properties can provide the same stability as the stiff plastic handles, despite deforming locally during higher grasping forces for reduction in contact pressure.

The comfort descriptor, Reduces peak pressures on the hand, shows the extensive potential of deformable interface materials and the importance of the correct material properties’ determination for improvement of tactile perception. The hard deformable handle resulted in the highest comfort descriptor value, indicating that the deformable handle material deforms at the appropriate grasping force to provide stability and lower contact pressure simultaneously, due to its controlled deformation. The hard deformable handle was also statistically significantly different from the optimally shaped hard plastic handle, the original manufacturer’s handle, and the soft deformable handle. The medium deformable handle resulted in a similar descriptor value; however, a statistically significant difference could only be observed between the medium deformable handle and the original manufacturer’s handle, suggesting that the handle interface material of the medium handle was already too soft. The soft deformable handle resulted in a comfort descriptor value of 2.7, almost the same value as the optimally shaped plastic handle, and it was not statistically different to the optimally shaped hard plastic handle, medium deformable handle and the original manufacturer’s handle. This result can likely be explained by the fact that users tend to grasp deformable handles that utilize too soft interface materials with higher grasping forces to maintain the desired stability, diminishing the effect of lowering the contact pressure due to the handle interface material deformation. This effect has also been reported in the past by Fellows and Freivalds [

34] when considering soft rubber foam handle interface materials. The results from this comfort descriptor clearly show the importance of the correct handle interface material behavior. The product interface material should deform only at a certain grasping force, and, hence, contact pressure value, and therefore deform only locally to provide more uniform contact pressure and still maintain stability of the handle and product in the hands for improved tactile perception.

4.2. Overall Comfort

The original manufacturer’s handle with the simple handle shape of a rounded square was statistically not significantly different from the optimally shaped hard plastic handle and the soft deformable handle; however, a statistically significant difference was observed between the original manufacturer’s handle and the medium deformable handle and the hard deformable handle (at p < 0.001). Considering the results from the comfort descriptors, the Overall comfort values once more indicate the importance of correct material determination of the deformable handles that need to exhibit appropriate material behavior to deform at certain grasping forces, to lower the contact pressure and provide more uniform distribution while still maintaining the stability of the handle, and, hence, the product in the hands.

Results from the comfort descriptor, Reduces peak pressures, show similar results in terms of relative differences and statistically significant differences between handles to the Overall comfort rating. This indicates clearly that the correct interface material determination in our study has a significantly higher influence on the perceived Overall comfort rating, and, hence, tactile perception than the product handle size and shape.

Both hard handles resulted in lower values of standard deviation when compared to the handles with deformable handles. The higher values of standard deviation of deformable handles indicate that subjects preferred different material stiffness. This can likely be explained by past experiences, expectations and different PDT and PPT values for each subject. This also indicates that it is crucial to include the target population in the handle interface material parameters’ determination and optimization to improve the tactile perception.

The sawing task utilized in this study considered loading cases that occur during the most common manual tasks, such as grasping a handle with pushing, pulling, and twisting. However, the results most likely still cannot be generalized for other tasks and products. Hence, future research should also consider different tasks, which would allow for the analysis of task influence on the perceived comfort rating. The test subjects participating in this study were also instructed to rate the handles relatively; hence, the results from the questionnaire do not necessarily reflect the absolute comfort levels for each handle and product, and, hence, cannot be generalized for every handle shape and task.