Synthesis of an Aluminum Alloy Metal Matrix Composite Using Powder Metallurgy: Role of Sintering Parameters

Abstract

:1. Introduction

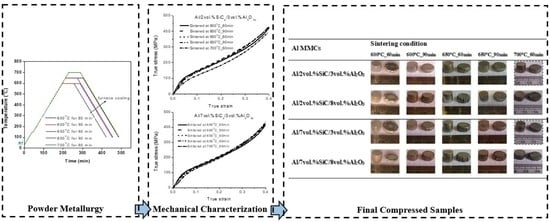

2. Experimental Approach

3. Results and Discussion

4. Conclusions

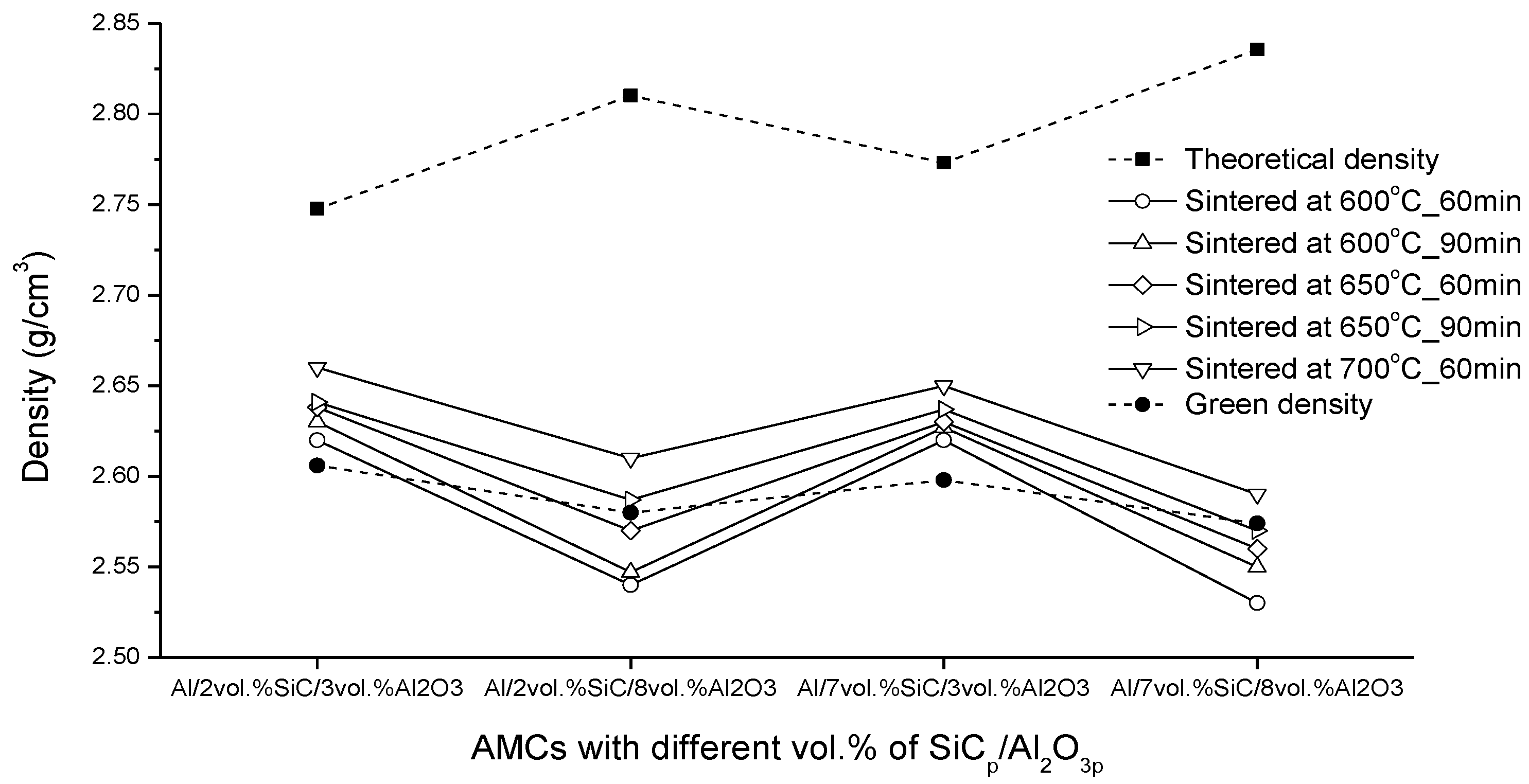

- The addition of particulate reinforcements such as SiC and alumina to an aluminum matrix improved the compressive true strength. An excess in the addition of reinforcements (beyond 7 vol.% of SiC and 3 vol.% of Al2O3) caused poor sinterability for the chosen sintering condition.

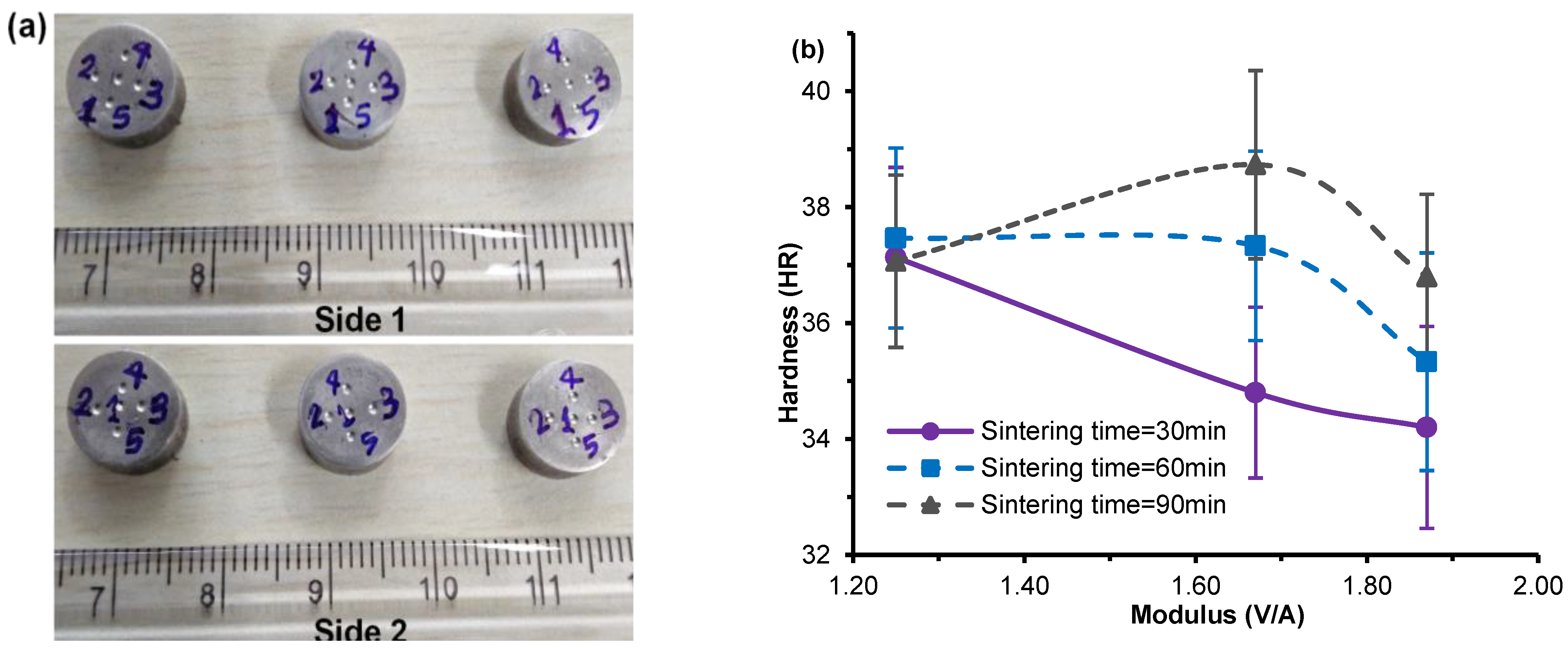

- An increase in the sintering time contributed less to the compressive strength of the composite material (Al/SiC/Al2O3 MMCs). However, a higher densification was evident for the sintered density, hardness and metallographic analysis when the sintering time was increased from 30 min to 90 min for the Al/7 vol.% SiC composite.

- The sintering condition of 700 °C for 60 min was suitable for the aluminum metal matrix composites (Al MMCs) to achieve a higher density and improved mechanical properties for the hybrid composites: (a) Al/2 vol.% SiC/3 vol.% Al2O3 and (b) Al/7 vol.% SiC/3 vol.% Al2O3.

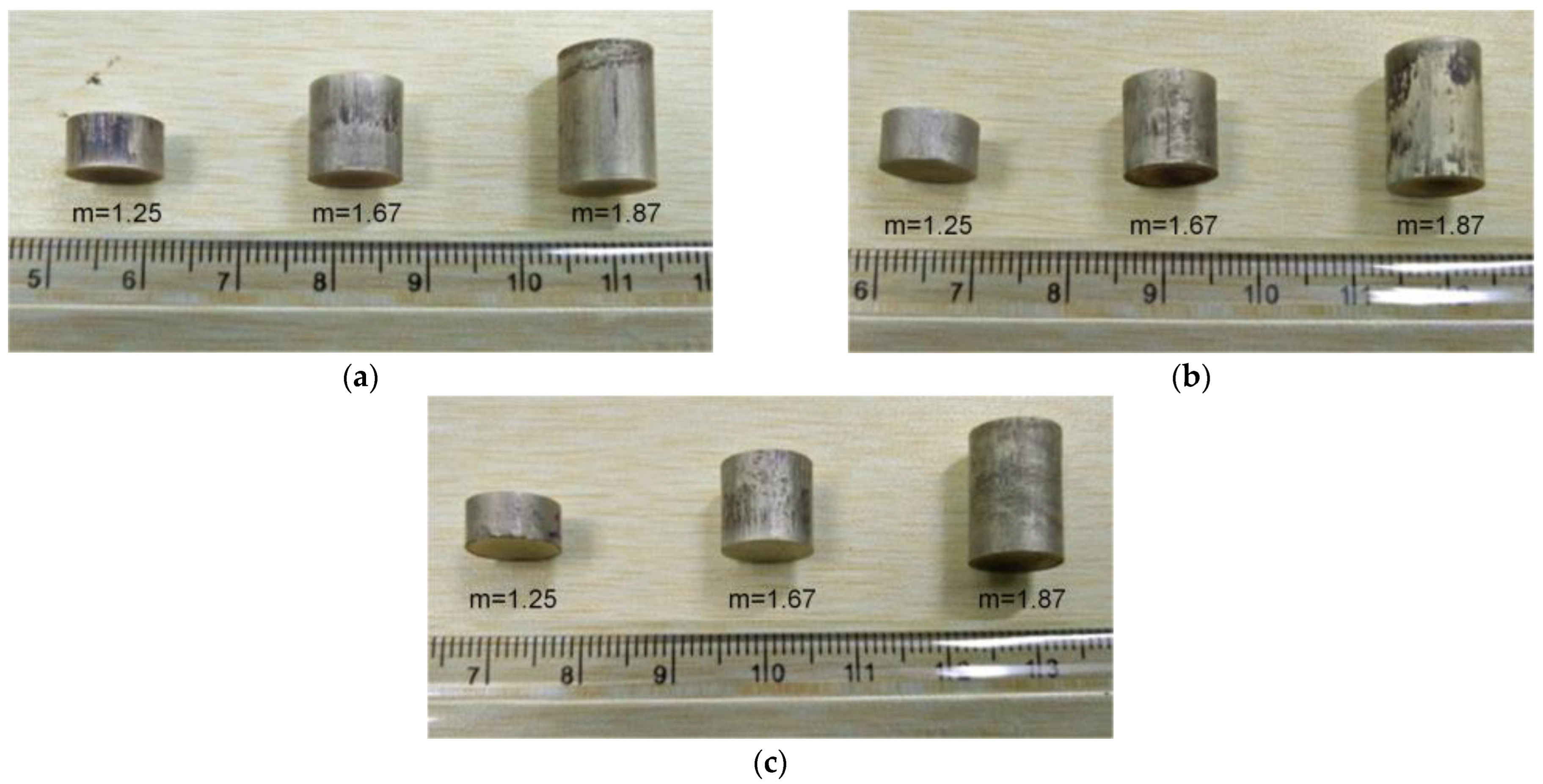

- A marginal variation in the sintered properties was seen when varying the part modulus. Further, the parts with the 1.67 modulus produced the best combination of sintered properties. Interfacial bonding between the reinforcing SiC particles and the aluminum metal matrix was not observably influenced by changing the part modulus, but was significantly altered by the sintering parameters (sintering temperature and sintering time).

- At 650 °C and below, the matrix phase and the reinforcement phase did not uniformly transfer the compressive load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kok, M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Process. Technol. 2005, 161, 381–387. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Şap, S.; Giasin, K.; Pimenov, D.Y. Tribological aspects, optimization and analysis of Cu-B-CrC composites fabricated by powder metallurgy. Materials 2021, 14, 4217. [Google Scholar] [CrossRef] [PubMed]

- Chintada, S.; Dora, S.P.; Kare, D.; Pujari, S.R. Powder metallurgy versus casting: Damping behavior of pure aluminum. J. Mater. Eng. Perform. 2022. [Google Scholar] [CrossRef]

- Kumar, D.R.; Loganathan, C.; Narayanasamy, R. Effect of glass in aluminium matrix on workability and strain hardening behavior of powder metallurgy composite. Mater. Des. 2011, 32, 2413–2422. [Google Scholar] [CrossRef]

- Gräbner, M.; Wiche, H.; Treutler, K.; Wesling, V. Micromagnetic properties of powder metallurgically produced Al composites as a fundamental study for additive manufacturing. Appl. Sci. 2022, 12, 6695. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Ebrahimifard, R.; Baghchesara, M.A. Investigation of microstructure and mechanical properties of nano MgO reinforced Al composites manufactured by stir casting and powder metallurgy methods: A comparative study. Compos. Part B 2014, 56, 217–221. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, G. Casting defects and properties of cast A356 aluminum alloy reinforced with SiCp particles. Compos. Sci. Technol. 1993, 47, 51–56. [Google Scholar] [CrossRef]

- Hull, D.; Clyne, T.W. An Introduction to Composite Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1996. [Google Scholar]

- Şap, S.; Uzun, M.; Usca, Ü.A.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Investigation on microstructure, mechanical, and tribological performance of Cu base hybrid composite materials. J. Mater. Res. Technol. 2021, 15, 6990–7003. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Şap, S.; Uzun, M.; Giasin, K.; Pimenov, D.Y. Evaluation of mechanical and tribological aspect of self-lubricating Cu-6Gr composites reinforced with SiC–WC hybrid particles. Nanomaterials 2022, 12, 2154. [Google Scholar] [CrossRef]

- Şap, S.; Turgut, A.; Uzun, M. Investigation of microstructure and mechanical properties of Cu/Ti–B–SiCp hybrid composites. Ceram. Int. 2021, 47, 29919–29929. [Google Scholar] [CrossRef]

- Milan, M.T.; Bowen, P. Tensile and fracture toughness properties of SiCp reinforced Al alloys: Effects of particle size, particle volume fraction, and matrix strength. J. Mater. Eng. Perform. 2004, 13, 775–783. [Google Scholar] [CrossRef]

- Umasankar, V.; Anthony, M.X.; Karthikeyan, S. Experimental evaluation of the influence of processing parameters on the mechanical properties of SiC particle reinforced AA6061 aluminium alloy matrix composite by powder processing. J. Alloy. Compd. 2014, 582, 380–386. [Google Scholar] [CrossRef]

- Ghit, C.; Popescu, I.N. Experimental research and compaction behavior modelling of aluminum-based composites reinforced with silicon carbide particles. Comput. Mater. Sci. 2012, 64, 136–140. [Google Scholar] [CrossRef]

- Diler, E.A.; Ipek, R. An experimental and statistical study of interaction effects of matrix particle size, reinforcement particle size and volume fraction on the flexural strength of Al–SiCp composites by P/M using central composite design. Mater. Sci. Eng. A 2012, 548, 43–55. [Google Scholar] [CrossRef]

- Ballantine, J.A.; Conner, J.J.; Handrock, J.L. Fundamentals of Metal Fatigue Analysis, 1st ed.; Prentice Hall: Hoboken, NJ, USA, 1990. [Google Scholar]

- George, T.; Rajkumar, R.; Richard, F. Proceeding of Powder Metallurgy Aluminium & Light Alloys for Automotive Applications Conference; Jandeska, W.F., Jr., Chernenk, R.A., Eds.; MPIF: Princeton, NJ, USA, 1998; pp. 35–42. [Google Scholar]

- Nayak, K.C.; Date, P.P. Development of constitutive relationship for thermo-mechanical processing of Al-SiC composite eliminating deformation heating. J. Mater. Eng. Perform. 2019, 29, 5323–5343. [Google Scholar] [CrossRef]

- Rosso, M. Ceramic and metal matrix composites: Routes and properties. J. Mater. Process. Technol. 2006, 175, 364–375. [Google Scholar] [CrossRef]

- Tan, Z.; Chen, Z.; Fan, G.; Ji, G.; Zhang, J.; Xu, R.; Shan, A.; Li, Z.; Zhang, D. Effect of particle size on the thermal and mechanical properties of aluminum composites reinforced with SiC and diamond. Mater. Des. 2016, 90, 845–851. [Google Scholar] [CrossRef]

- Zeng, X.; Liu, W.; Xu, B.; Shu, G.; Li, Q. Microstructure and mechanical properties of Al–SiC nanocomposites synthesized by surface-modified aluminium powder. Metals 2018, 8, 253. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Laoui, T.; Haseeb, A.S.M.A.; Celis, J.P.; Froyen, L. Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: A comparative study. J. Mater. Processing Technol. 2003, 142, 738–743. [Google Scholar] [CrossRef]

- Tosun, G.; Kurt, M. The porosity, microstructure and hardness of Al-Mg composites reinforced with micro particle SiC/Al2O3 produced using powder metallurgy. Compos. Part B. 2019, 174, 106965. [Google Scholar] [CrossRef]

- Tekmen, C.; Ozdemir, I.; Cocen, U.; Onel, K. The mechanical response of Al-Si-Mg/SiC composite: Influence of porosity. Mater. Sci. Eng. A 2003, 360, 365–371. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Q.; Yang, S.; Chen, Z.; Liu, Q.; Jiang, Z. Microstructural evolution of hybrid aluminum matrix composites reinforced with SiC nanoparticles and graphene/graphite prepared by powder metallurgy. Prog. Nat. Sci. Mater. Int. 2020, 30, 192–199. [Google Scholar] [CrossRef]

- Blanco, I. Synthesis, characterization and application of hybrid composites. Appl. Sci. 2020, 10, 5456. [Google Scholar] [CrossRef]

- Biswal, S.R.; Sahoo, S. Fabrication of WS2 dispersed al-based hybrid composites processed by powder metallurgy: Effect of compaction pressure and sintering temperature. J. Inorg. Organomet. Polym. Mater. 2020, 30, 2971–2978. [Google Scholar] [CrossRef]

- Daha, M.A.; Nassef, B.G.; Nassef, M.G.A. Mechanical and tribological characterization of a novel hybrid aluminum/Al2O3/RGO composite synthesized using powder metallurgy. J. Mater. Eng. Perform. 2021, 30, 2473–2481. [Google Scholar] [CrossRef]

- Manohar, G.; Maity, S.R.; Pandey, K.M. Microstructural and mechanical properties of microwave sintered AA7075/graphite/SiC hybrid composite fabricated by powder metallurgy techniques. Silicon 2022, 14, 5179–5189. [Google Scholar] [CrossRef]

- Proietti, A.; Gallo, N.; Bellisario, D.; Quadrini, F.; Santo, L. Damping behavior of hybrid composite structures by aeronautical technologies. Appl. Sci. 2022, 12, 7932. [Google Scholar] [CrossRef]

- Salman, K.D.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Microstructural analysis and mechanical properties of a hybrid Al/Fe2O3/Ag nano-composite. Appl. Sci. 2022, 12, 4730. [Google Scholar] [CrossRef]

- Yoshimura, H.N.; Goncalves, M.; Goldenstein, H. The effects of SiCp clusters and porosity on the mechanical properties of PM Al matrix composite. Key Eng. Mater. 1997, 127–131, 985–992. [Google Scholar]

| Material | Mean Particle Size (µm) # | Young’s Modulus (GPa) * | Tensile Strength (MPa) * | Coefficient of Thermal Expansion (10−6 K−1) * | Density (g/cm3) * |

|---|---|---|---|---|---|

| Al2O3p | 1.27 | 360–400 | 250–300 | 8.5 | 3.95 |

| SiCp | 8.13 | 400–440 | 310 | 4.8 | 3.2 |

| Al | 46.16 | 70 | 200 | 22.2 × 10−4 | 2.7 |

| Material | Composites | Volume Fraction (%) | Weight for 10 g of Aluminum |

|---|---|---|---|

| Al MMCs (Al/SiC/Al2O3) | Al/2–SiC/3–Al2O3 | 2 and 7 vol.% of SiC | 0.375 SiC + 0.692 Al2O3 |

| Al/2–SiC/8–Al2O3 | 0.396 SiC + 1.950 Al2O3 | ||

| Al/7–SiC/3–Al2O3 | 3 and 8 vol.% of Al3 | 1.387 SiC + 0.731 Al2O3 | |

| Al/7–SiC/8–Al2O3 | 1.468 SiC + 2.065 Al2O3 |

| Al MMCs | Sintering Condition | ||||

|---|---|---|---|---|---|

| 600 °C/60 min | 600 °C/90 min | 650 °C/60 min | 650 °C/90 min | 700 °C/60 min | |

| Al/2 vol.% SiC/3 vol.% Al2O3 |  |  |  |  |  |

| Al/2 vol.% SiC/8 vol.% Al2O3 |  |  |  |  |  |

| Al/7 vol.% SiC/3 vol.% Al2O3 |  |  |  |  |  |

| Al/7 vol.% SiC/8 vol.% Al2O3 |  |  |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nayak, K.C.; Rane, K.K.; Date, P.P.; Srivatsan, T.S. Synthesis of an Aluminum Alloy Metal Matrix Composite Using Powder Metallurgy: Role of Sintering Parameters. Appl. Sci. 2022, 12, 8843. https://doi.org/10.3390/app12178843

Nayak KC, Rane KK, Date PP, Srivatsan TS. Synthesis of an Aluminum Alloy Metal Matrix Composite Using Powder Metallurgy: Role of Sintering Parameters. Applied Sciences. 2022; 12(17):8843. https://doi.org/10.3390/app12178843

Chicago/Turabian StyleNayak, Kanhu C., Kedarnath K. Rane, Prashant P. Date, and T. S. Srivatsan. 2022. "Synthesis of an Aluminum Alloy Metal Matrix Composite Using Powder Metallurgy: Role of Sintering Parameters" Applied Sciences 12, no. 17: 8843. https://doi.org/10.3390/app12178843

APA StyleNayak, K. C., Rane, K. K., Date, P. P., & Srivatsan, T. S. (2022). Synthesis of an Aluminum Alloy Metal Matrix Composite Using Powder Metallurgy: Role of Sintering Parameters. Applied Sciences, 12(17), 8843. https://doi.org/10.3390/app12178843

_Yang.png)