Layer Orientation Effect on Fracture Mode and Acoustic Emission Characteristics of Continental Shale

Abstract

:1. Introduction

2. Experimental Setup and Method

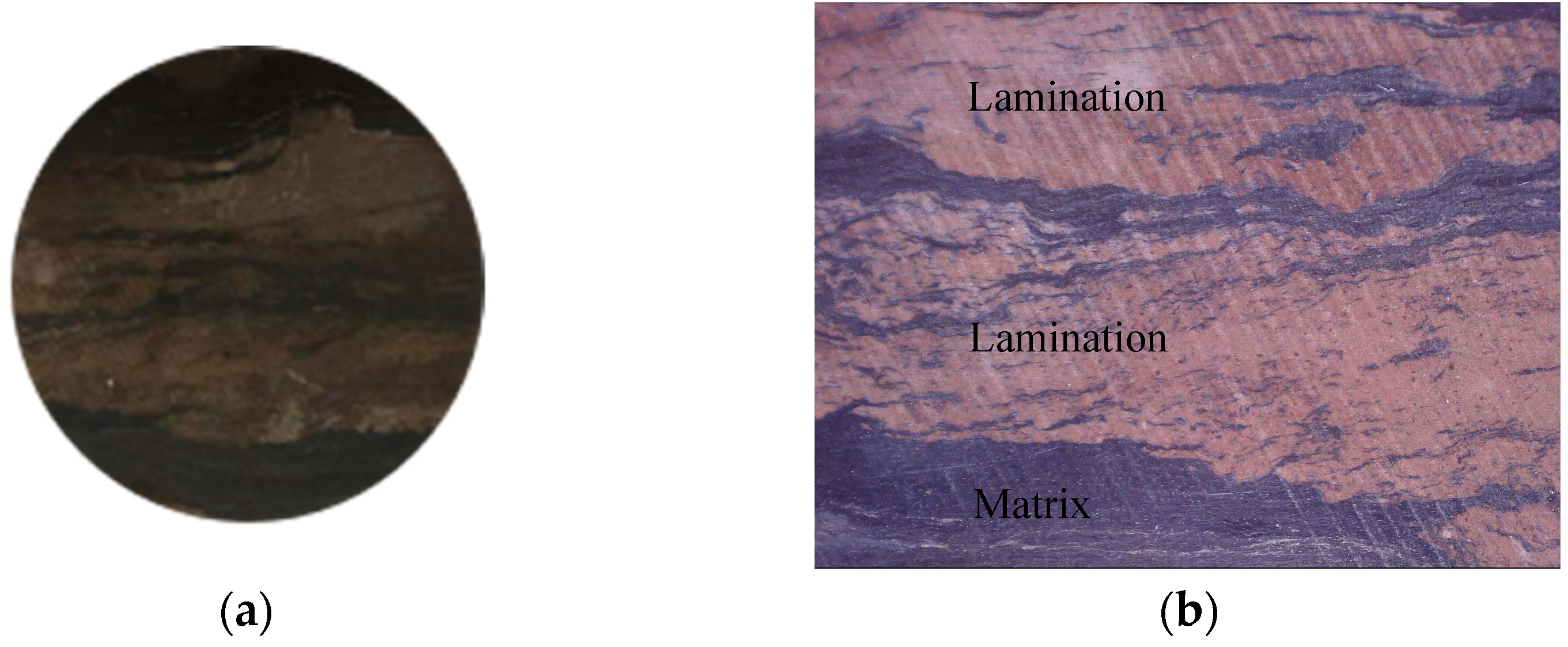

2.1. Sample Preparation

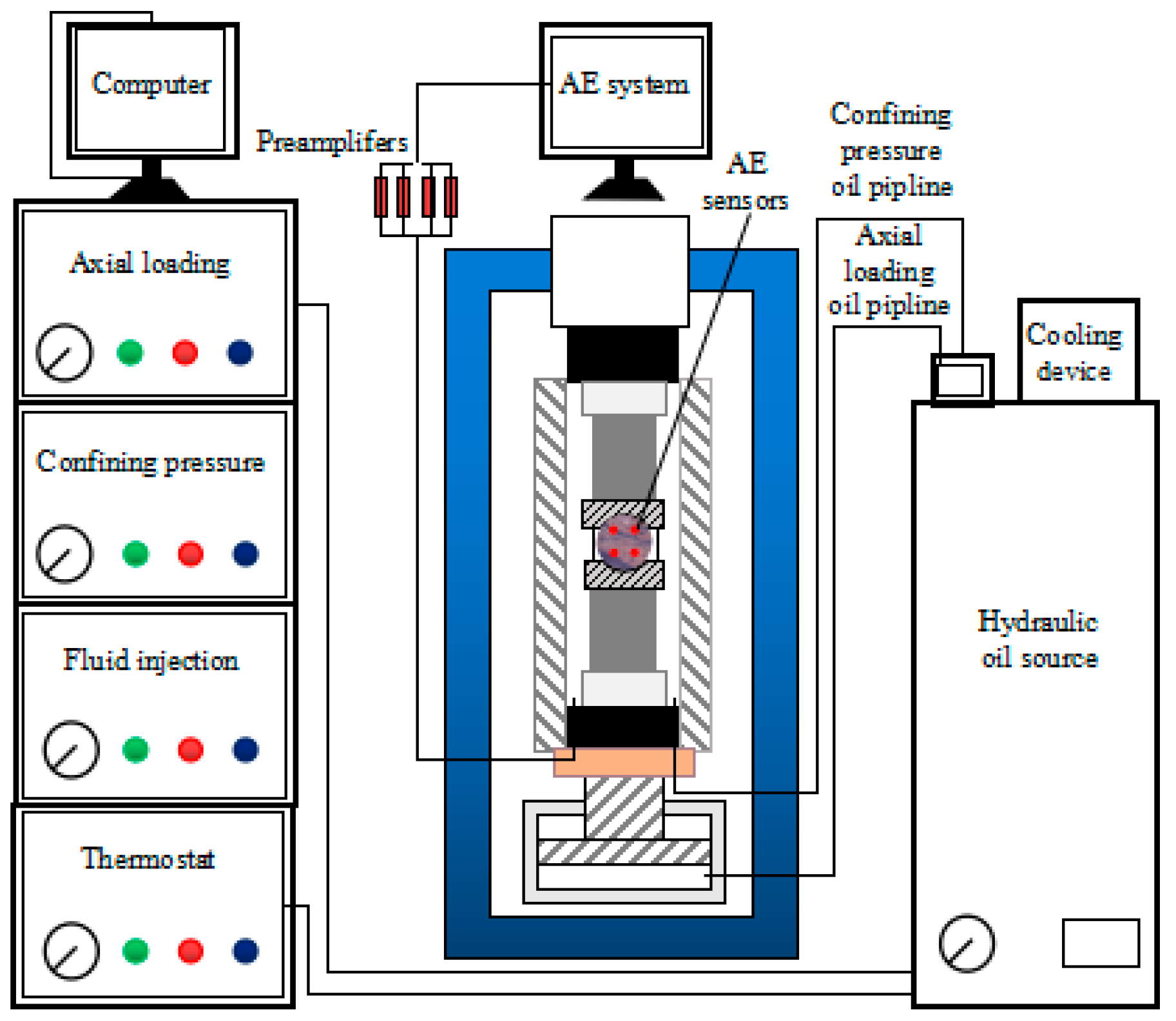

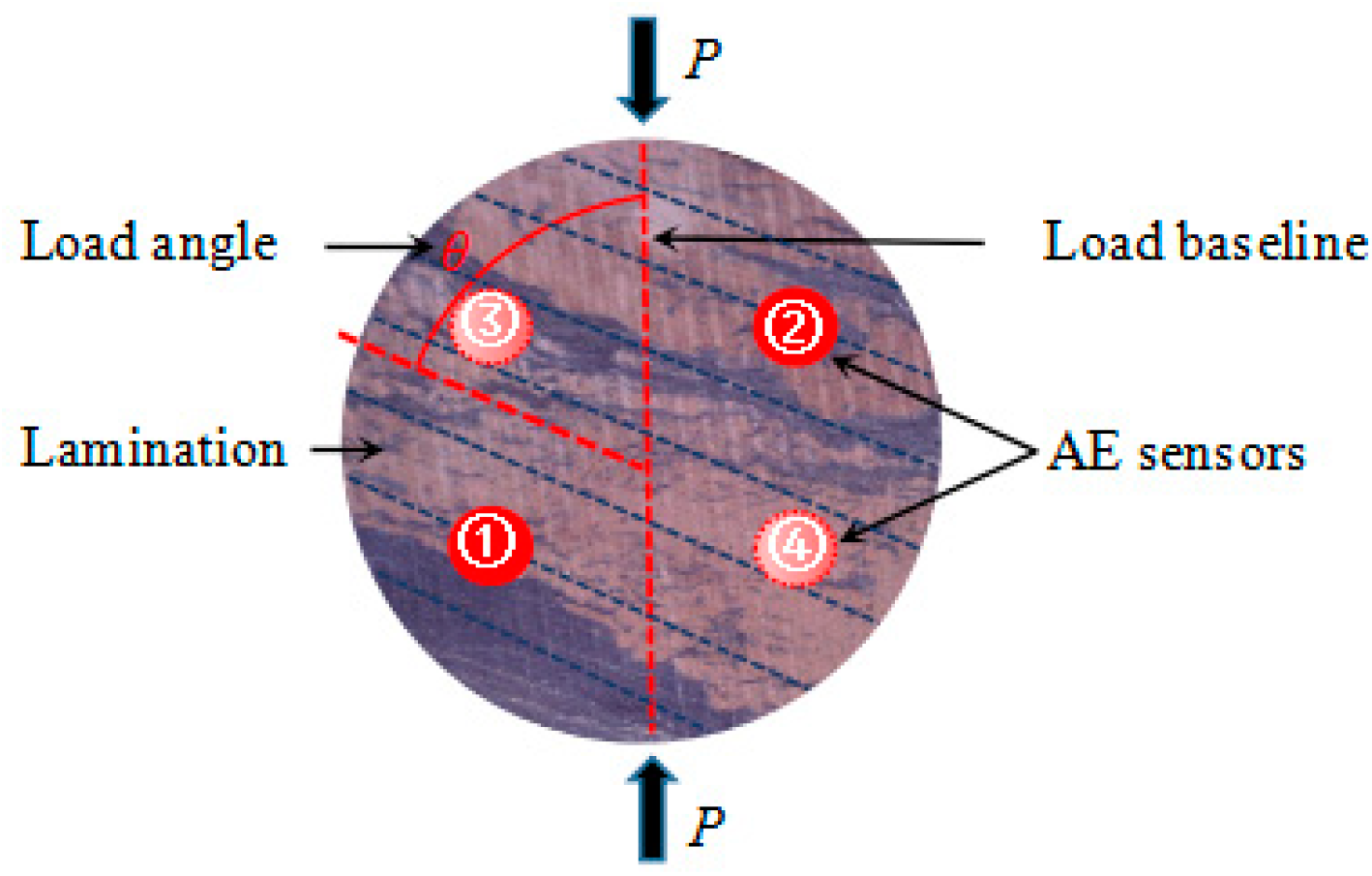

2.2. Setup and Method

3. Experimental Results

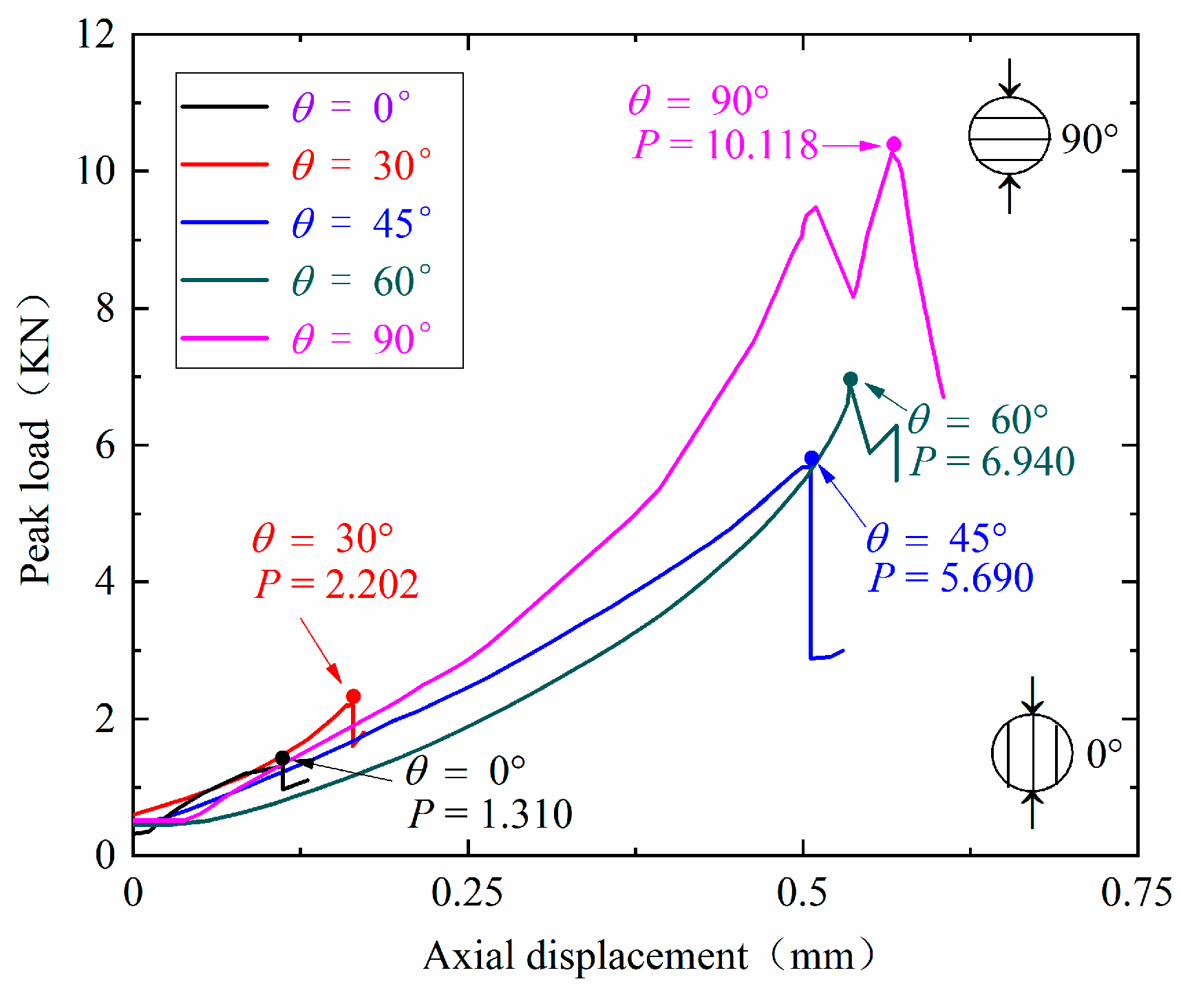

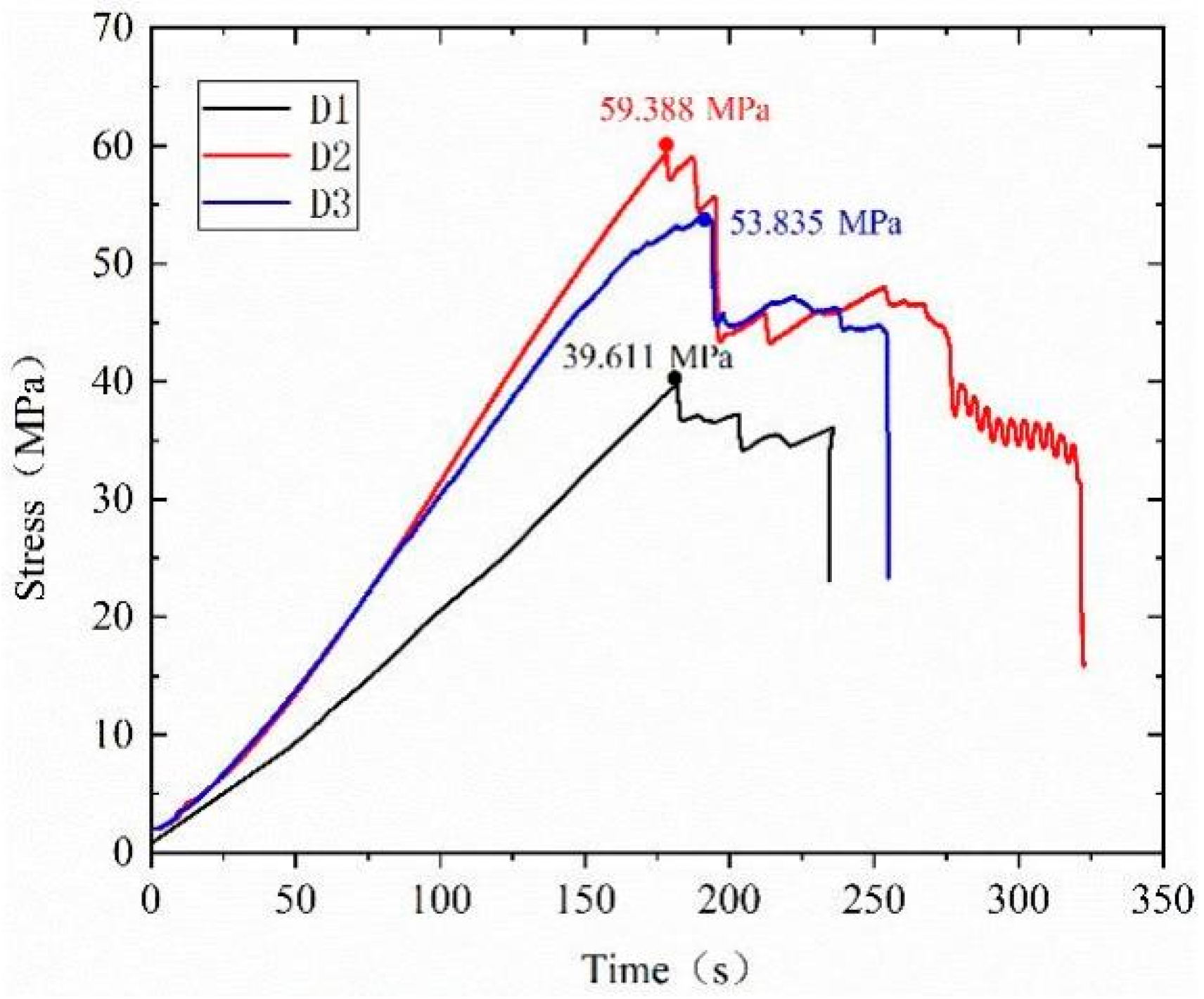

3.1. Mechanical Response Characteristics of Continental Shale with Different Layer Orientations

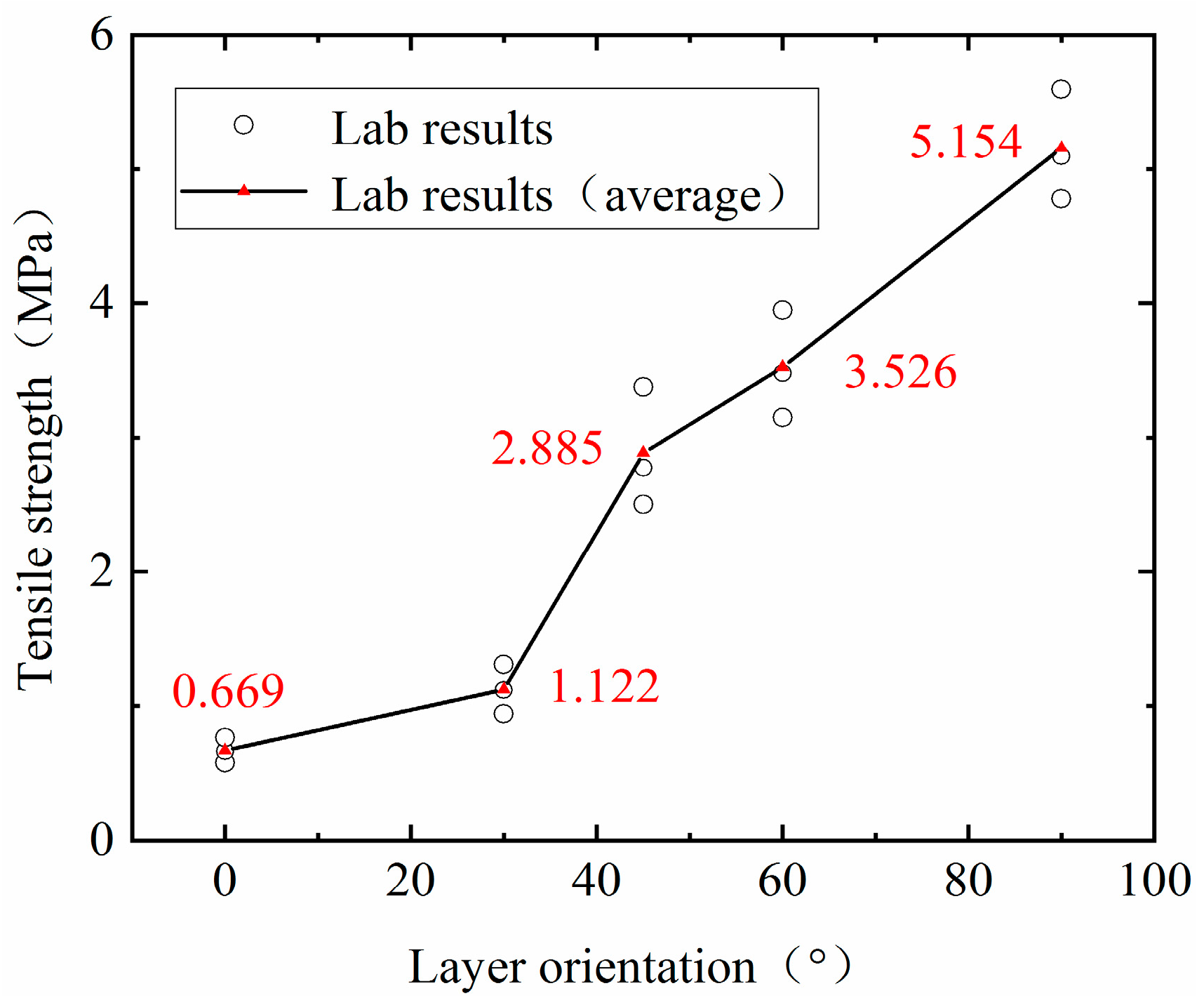

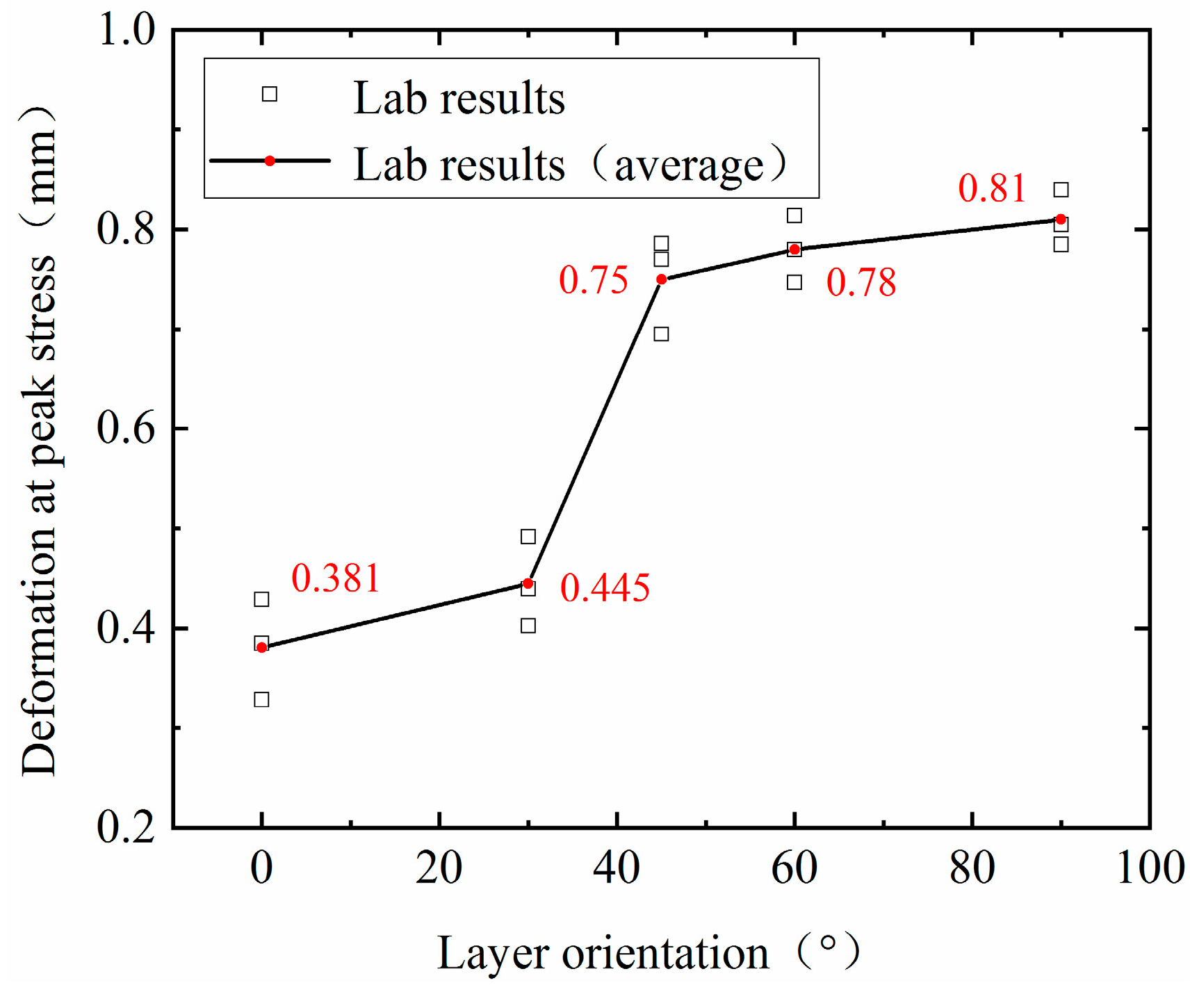

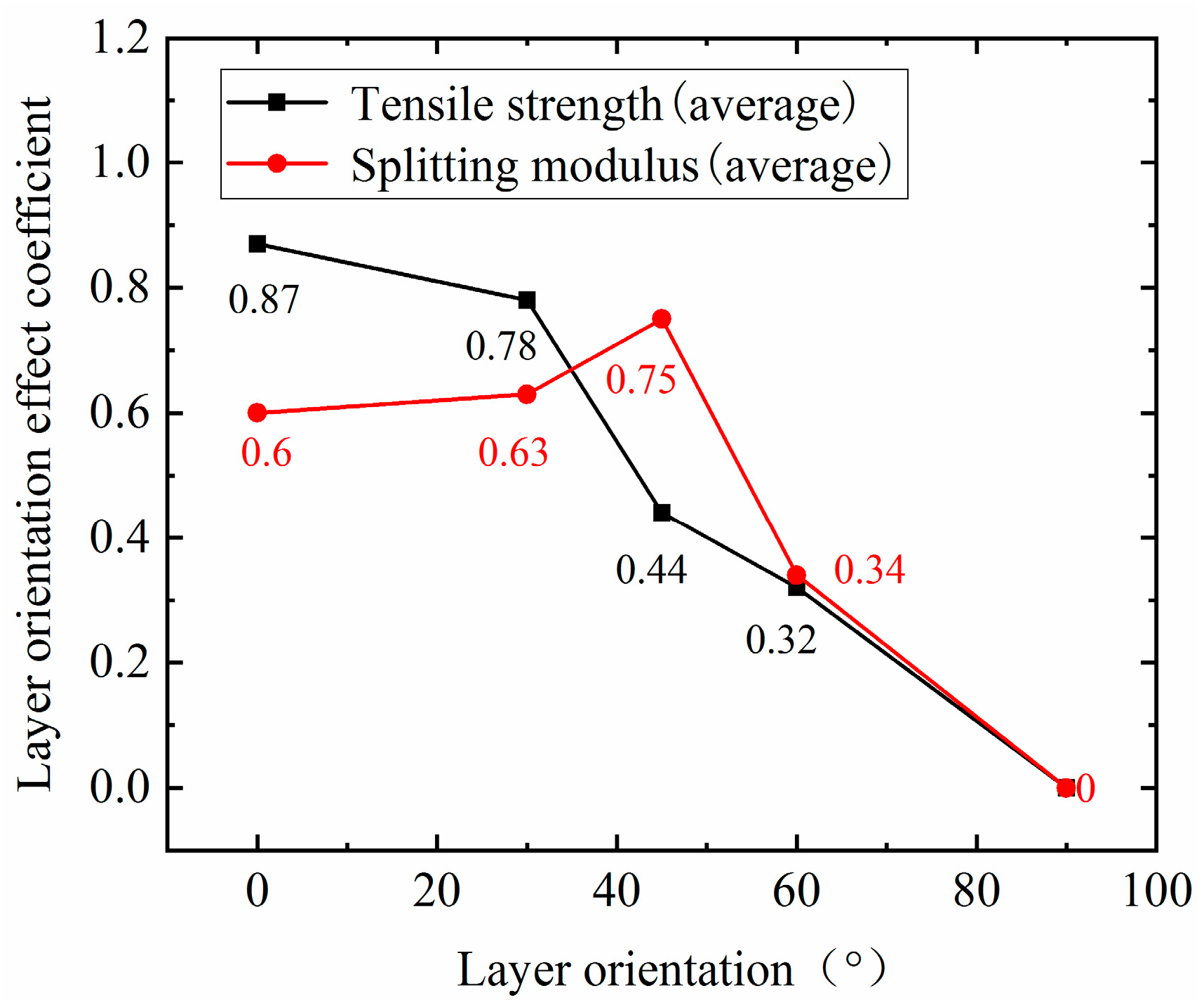

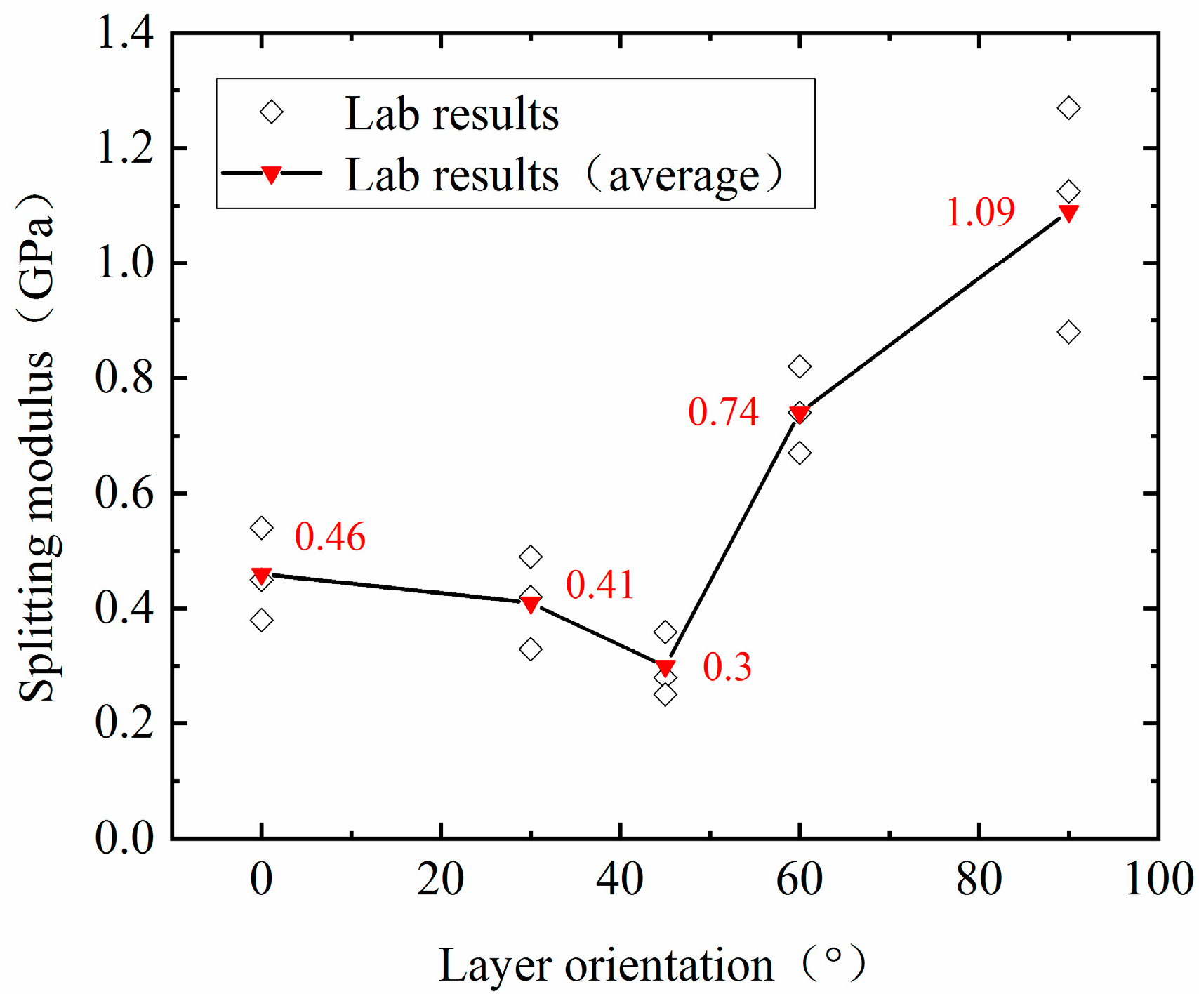

3.2. Influence of Layer Orientation Effect on Mechanical Parameters

3.3. Influence of Layer Orientation Effect on Crack Growth and Fracture Mode

3.3.1. Morphological Characterization of Crack

3.3.2. Influence of Layer Orientation Effect on Fracture Mode

4. Discussions

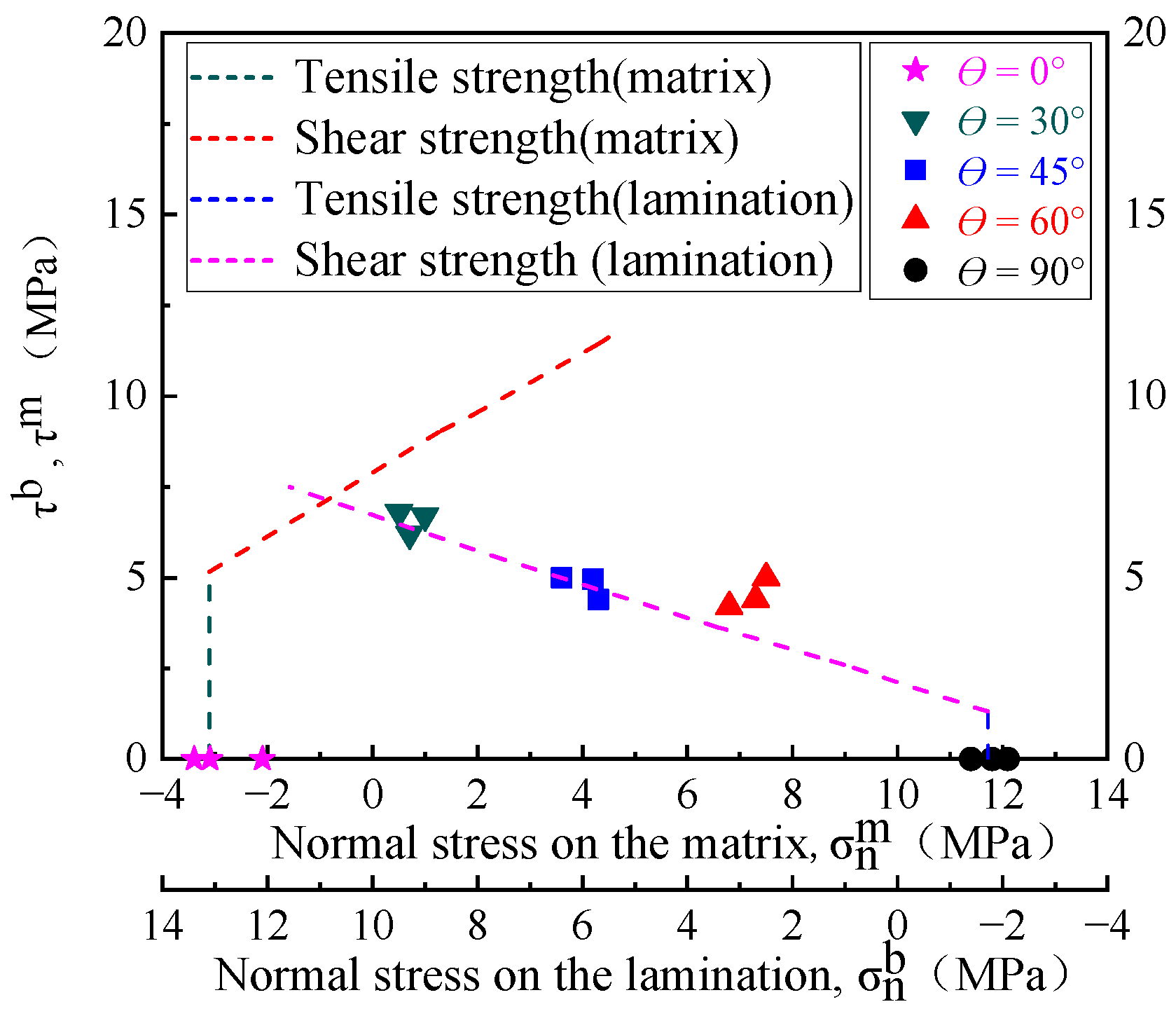

4.1. Mechanical Analysis of Fracture Mode

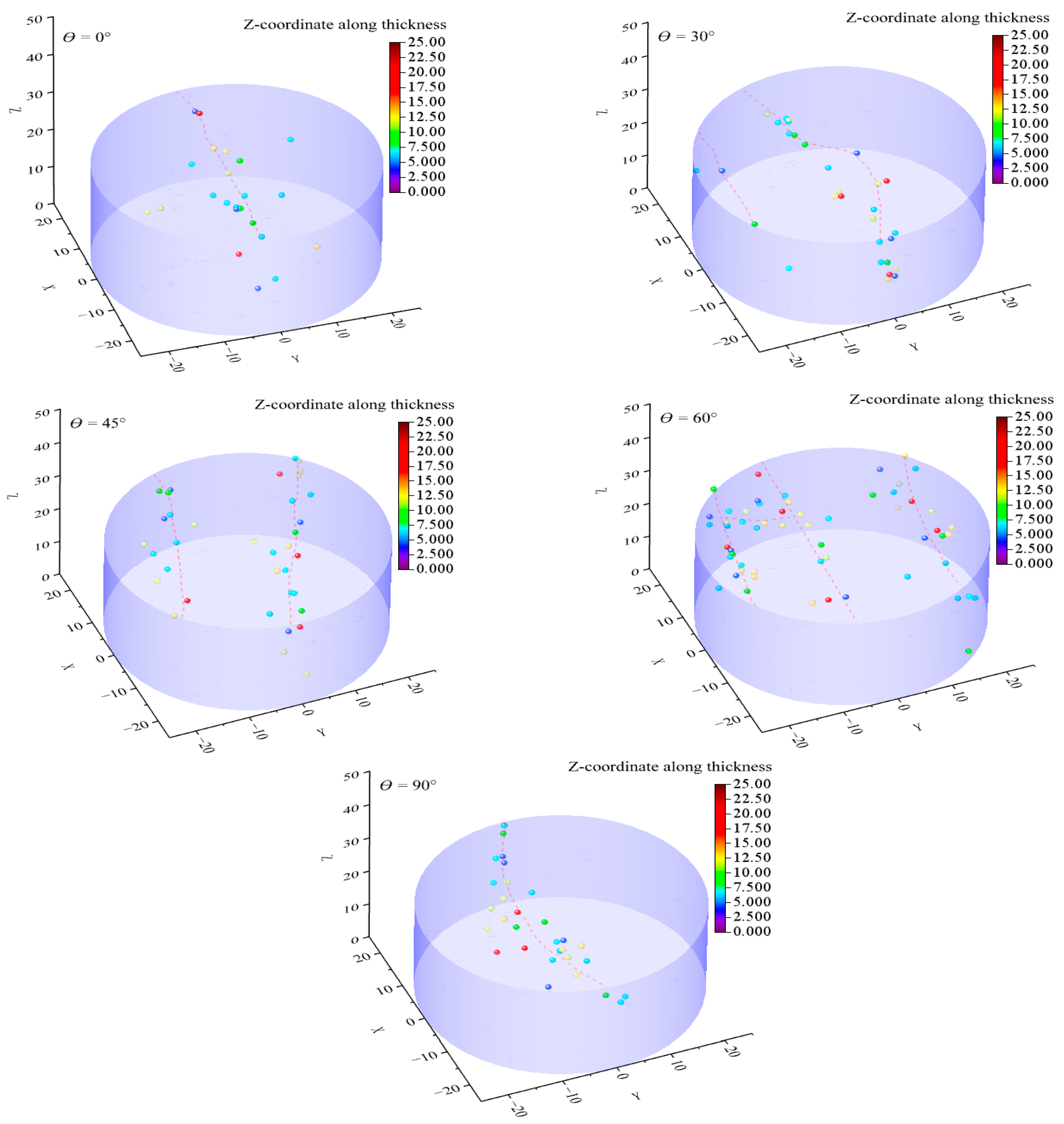

4.2. AE Evolution Process and Spatial Distribution Characteristics

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, P.; Li, X.; Li, S.; Yang, W.; Wu, Y.; Li, G. Quantitative analysis of anisotropy effect on hydrofracturing efficiency and process in shale using X-ray computed tomography and acoustic emission. Rock Mech. Rock Eng. 2021, 54, 5715–5730. [Google Scholar] [CrossRef]

- He, J.M.; Afolagboye, L.O. Influence of layer orientation and interlayer bonding force on the mechanical behavior of shale under Brazilian test conditions. Acta Mech. Sin. 2018, 34, 349–358. [Google Scholar] [CrossRef]

- Wang, J.; Xie, L.; Xie, H.; Ren, L.; He, B.; Li, C.; Yang, Z.; Gao, C. Effect of layer orientation on acoustic emission characteristics of anisotropic shale in Brazilian tests. J. Nat. Gas Sci. Eng. 2016, 36, 1120–1129. [Google Scholar] [CrossRef]

- Hou, P.; Gao, F.; Yang, Y.G.; Zhang, Z.; Gao, Y.N.; Zhang, X.X.; Zhang, J. Effect of bedding plane direction on acoustic emission characteristics of shale in Brazilian tests. Rock Soil Mech. 2016, 37, 1604–1612. [Google Scholar] [CrossRef]

- Noori, M.; Khanlari, G.; Sarfarazii, V.; Rafiei, B.; Nejati, H.R.; Schubert, W. Experimental test and numerical simulation of the effect of brittleness on the microfracturing of sandstone. Bull. Eng. Geol. Environ. 2022, 81, 309. [Google Scholar] [CrossRef]

- Wang, L.; Guo, Y.; Yang, C.; Xiao, J.; Lu, C.; Song, Y. Mechanical characterization of continental shale in Sichuan Basin of China and its potential impact on reservoir stimulation. J. Nat. Gas Sci. Eng. 2020, 79, 103346. [Google Scholar] [CrossRef]

- Huang, B.X.; Li, L.H.; Tan, Y.F.; Hu, R.; Li, X. Investigating the Meso-Mechanical anisotropy and fracture surface roughness of continental shale. J. Geophys. Res. Solid Earth 2020, 125, e2019JB017828. [Google Scholar] [CrossRef]

- Noori, M.; Khanlari, G.; Rafiei, B. Estimation of Brittleness Indexes from Petrographic Characteristics of Different Sandstone Types (Cenozoic and Mesozoic Sandstones), Markazi Province, Iran. Rock Mech. Rock Eng. 2022, 55, 1955–1995. [Google Scholar] [CrossRef]

- Wang, X.L. Experimental Study on Bedding Structure Effect of Soft Rock. Ph.D. Thesis, China University of Mining and Technology (Beijing), Beijing, China, 2013. [Google Scholar]

- Tavallalia, A.; Vervoort, A. Effect of layer orientation on the failure of layered sandstone under Brazilian test conditions. Int. J. Rock Mech. Min. Sci. 2010, 47, 313–322. [Google Scholar] [CrossRef]

- Heng, S.; Yang, C.H.; Guo, Y.T. Influence of bedding planes on hydraulic fracture propagation in shale formations. Chin. J. Rock Mech. Eng. 2015, 34, 228–237. [Google Scholar] [CrossRef]

- Claesson, J.; Bohloli, B. Brazilian test: Stress field and tensile strength of anisotropic rocks using an analytical solution. Int. J. Rock Mech. Min. Sci. 2002, 39, 991–1004. [Google Scholar] [CrossRef]

- Zhao, Z.H. Characteristics of Fracture Propagation Caused by Supercritical Carbon Dioxide and Hydraulic Fracturing in Shale. Ph.D. Thesis, Institute of Geology and Geophysics, Chinese Academy of Sciences, Beijing, China, 2018. [Google Scholar]

| No. | Layer Orientation (°) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 30 | 45 | 60 | 90 | ||||||

| P (KN) | Φ × H (mm) | P (KN) | Φ × H (mm) | P (KN) | Φ × H (mm) | P (KN) | Φ × H (mm) | P (KN) | Φ × H (mm) | |

| 1 | 1.126 | 49.66 × 24.95 | 1.837 | 49.94 × 24.89 | 4.964 | 50.02 × 25.22 | 6.208 | 49.96 × 25.09 | 9.345 | 49.73 × 25.02 |

| 2 | 1.300 | 49.86 × 24.97 | 2.195 | 50.01 × 24.98 | 5.483 | 50.08 × 25.09 | 6.873 | 50.10 × 25.07 | 10.028 | 50.05 × 25.03 |

| 3 | 1.504 | 49.94 × 25.02 | 2.574 | 49.98 × 25.03 | 6.623 | 49.98 × 24.95 | 7.739 | 49.96 × 24.95 | 10.981 | 49.97 × 24.98 |

| Mean | 1.310 | 49.82 × 24.98 | 2.202 | 49.98 × 24.97 | 5.690 | 50.03 × 25.09 | 6.940 | 50.01 × 25.04 | 10.118 | 49.92 × 25.01 |

| SD | 0.154 | 0.118 × 0.029 | 0.301 | 0.029 × 0.058 | 0.693 | 0.041 × 0.110 | 0.627 | 0.066 × 0.062 | 0.671 | 0.136 × 0.022 |

| Mechanical Response Characteristics | Feature Point | Feature Point Threshold/KN | ||

|---|---|---|---|---|

| 0° ≤ θ ≤ 30° | 30° ≤ θ ≤ 60° | 60° ≤ θ ≤ 90° | ||

| Compaction stage | Compaction closure point | ≤1.00 | 1.00–3.75 | 3.75–5.24 |

| Elastic stage | Crack cracking point | ≤1.80 | 1.80–6.05 | 6.05–8.93 |

| Failure stage | Strength failure point | 1.310–2.202 | 2.202–6.940 | 6.940–10.118 |

| Layer Orientation θ (°) | σt (MPa) | Layer Orientation Effect Coefficient | Average Splitting Modulus (GPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | Mean | SD | Largest Deviation (%) | Average Tensile Strength | Average Splitting Modulus | ||

| 0 | 0.578 | 0.664 | 0.766 | 0.669 | 0.077 | 14.5 | 0.87 | 0.60 | 0.45 |

| 30 | 0.940 | 1.117 | 1.309 | 1.122 | 0.151 | 16.7 | 0.78 | 0.63 | 0.42 |

| 45 | 2.503 | 2.775 | 3.378 | 2.885 | 0.366 | 17.1 | 0.44 | 0.75 | 0.28 |

| 60 | 3.150 | 3.480 | 3.949 | 3.526 | 0.328 | 12.0 | 0.32 | 0.34 | 0.74 |

| 90 | 4.777 | 5.091 | 5.595 | 5.154 | 0.337 | 8.6 | 0.00 | 0.00 | 1.125 |

| No. | Layer Orientation θ (°) | ||||

|---|---|---|---|---|---|

| 0° | 30° | 45° | 60° | 90° | |

| 1 |  |  |  |  |  |

| 2 |  |  |  |  |  |

| 3 |  |  |  |  |  |

| Layer Orientation θ (°) | Typical Fracture Morphology | Characteristics of Secondary Cracks | Fracture Mode |

|---|---|---|---|

| 0 |  | 1. The secondary crack connects to the single main crack. 2. Secondary cracks propagate along the lamination direction. | Straight through-center fracture mode. |

| 30 |  | Invisible to the naked eye. | Straight and crescent-shaped deviating-center compound fracture mode. |

| 45 |  | 1. The secondary crack connects to the single main crack. 2. The secondary cracks deviate from the lamination direction and propagate vertically. | Straight, crescent-shaped and folded-shape deviating-center compound mode. |

| 60 |  | 1. Secondary cracks connect adjacent double main cracks. 2. Secondary cracks propagate along the lamination direction. | Straight and crescent-shaped, through-center, and deviating-center compound mode. |

| 90 |  | Invisible to the naked eye. | 1. Crescent-shaped deviating-center mode. 2. Fold-shaped through-center or deviating-center through-layer fracture mode (with primary crack). |

| E (GPa) | Matrix | Lamina | |||||

|---|---|---|---|---|---|---|---|

| φ (°) | c (Mpa) | φ (°) | c (Mpa) | ||||

| 31.3 | 15.8 | 0.2 | 8.7 | 35.94 | 16.88 | 27.02 | 5.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Gao, Q.; Li, X. Layer Orientation Effect on Fracture Mode and Acoustic Emission Characteristics of Continental Shale. Appl. Sci. 2022, 12, 8683. https://doi.org/10.3390/app12178683

Wang X, Gao Q, Li X. Layer Orientation Effect on Fracture Mode and Acoustic Emission Characteristics of Continental Shale. Applied Sciences. 2022; 12(17):8683. https://doi.org/10.3390/app12178683

Chicago/Turabian StyleWang, Xinyao, Quanchen Gao, and Xiao Li. 2022. "Layer Orientation Effect on Fracture Mode and Acoustic Emission Characteristics of Continental Shale" Applied Sciences 12, no. 17: 8683. https://doi.org/10.3390/app12178683

APA StyleWang, X., Gao, Q., & Li, X. (2022). Layer Orientation Effect on Fracture Mode and Acoustic Emission Characteristics of Continental Shale. Applied Sciences, 12(17), 8683. https://doi.org/10.3390/app12178683