Shear-Bond Behaviour of Profiled Composite Slab Incorporated with Self-Compacted Geopolymer Concrete

Abstract

:1. Introduction

Research Significance

2. Material and Methodology

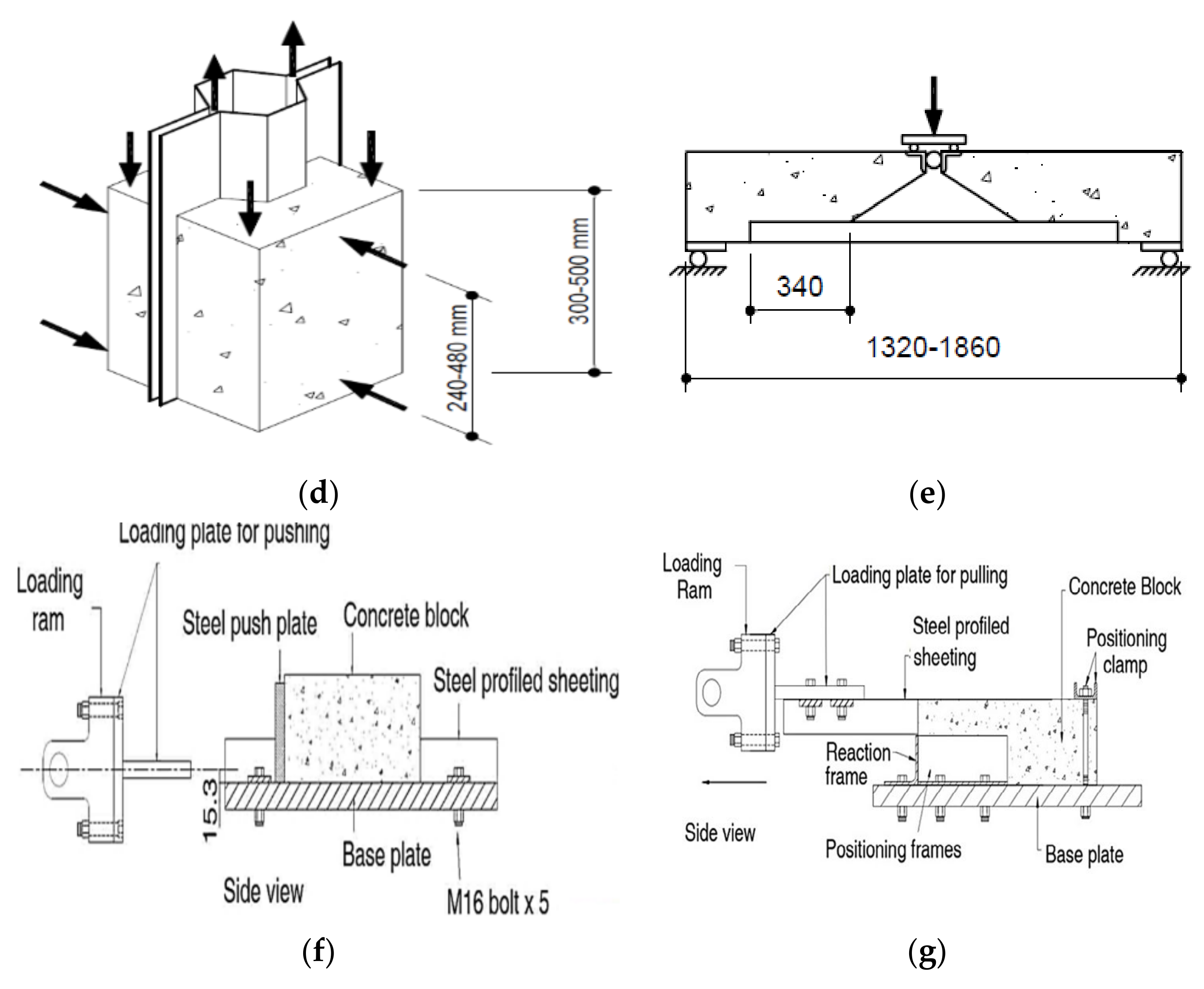

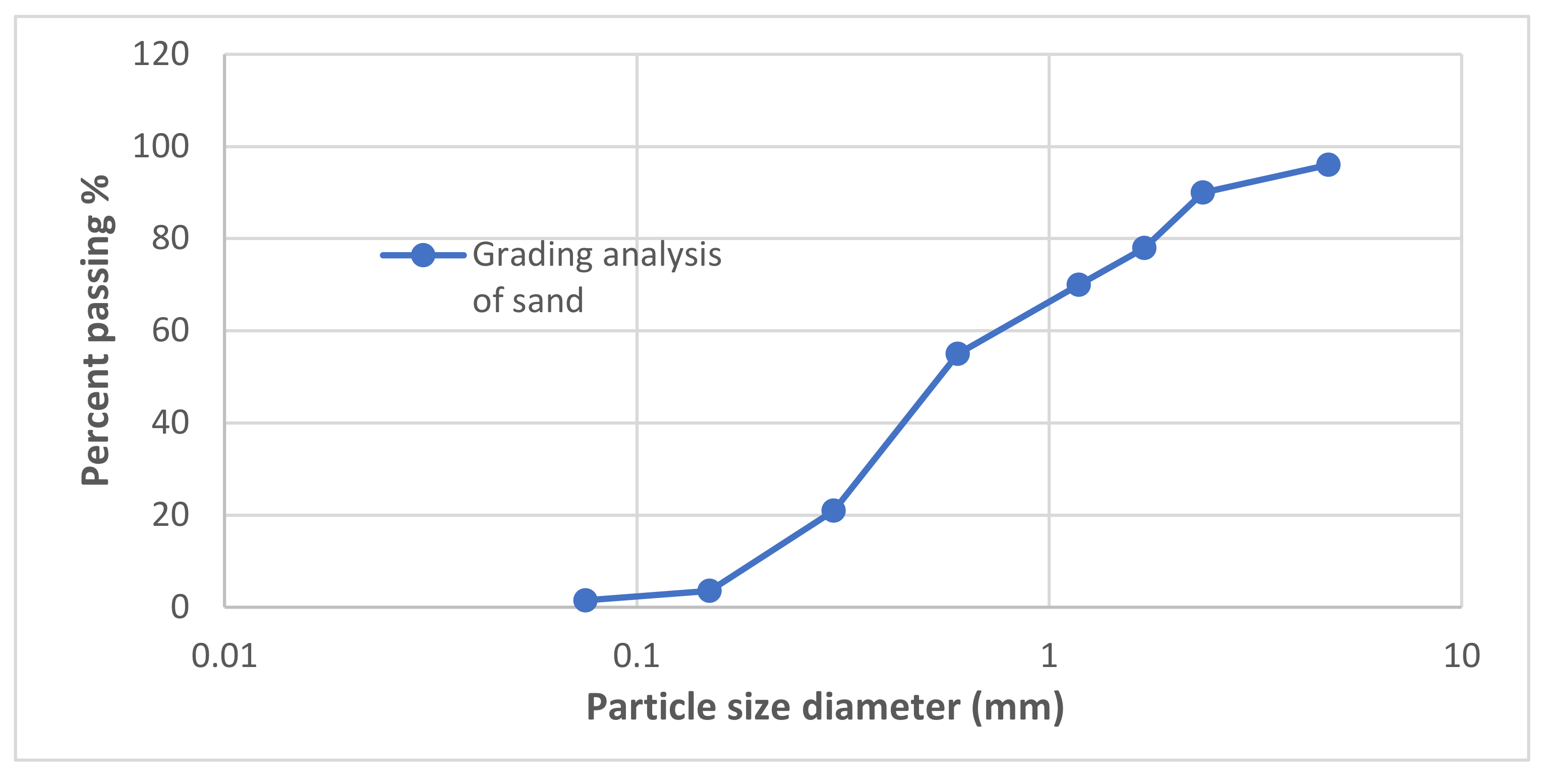

2.1. Material Properties

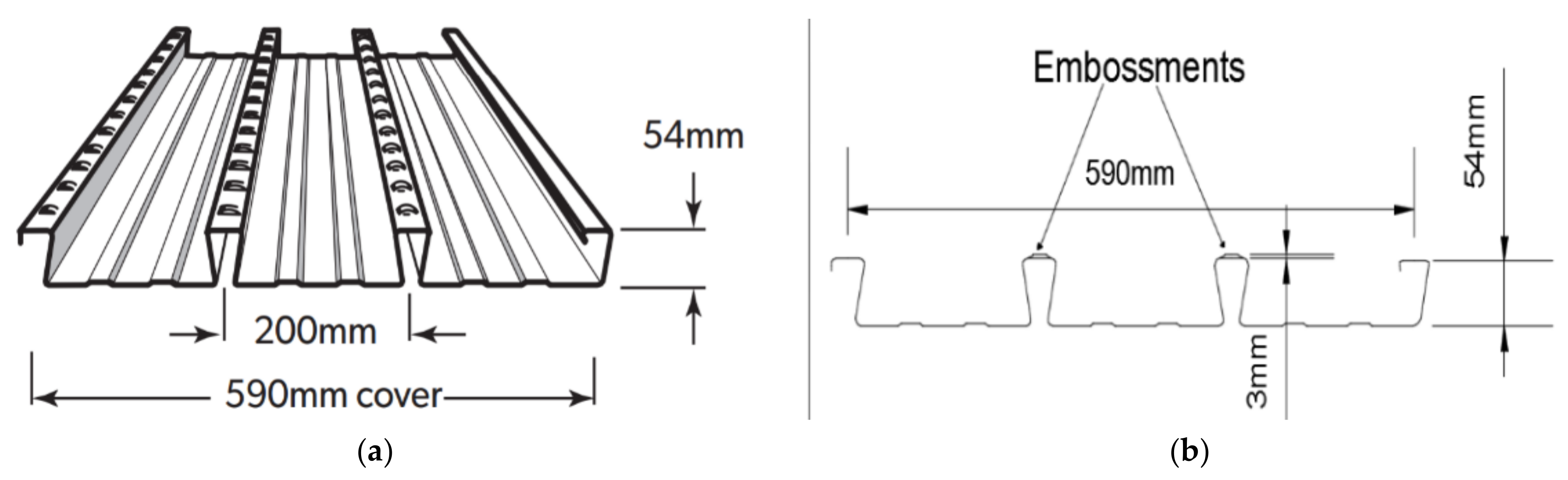

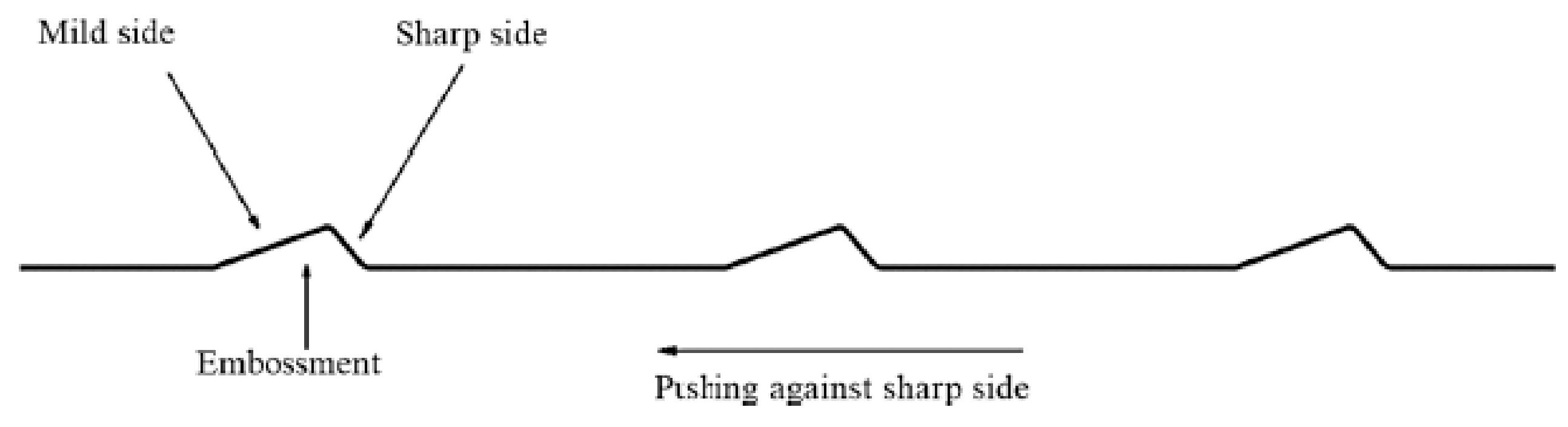

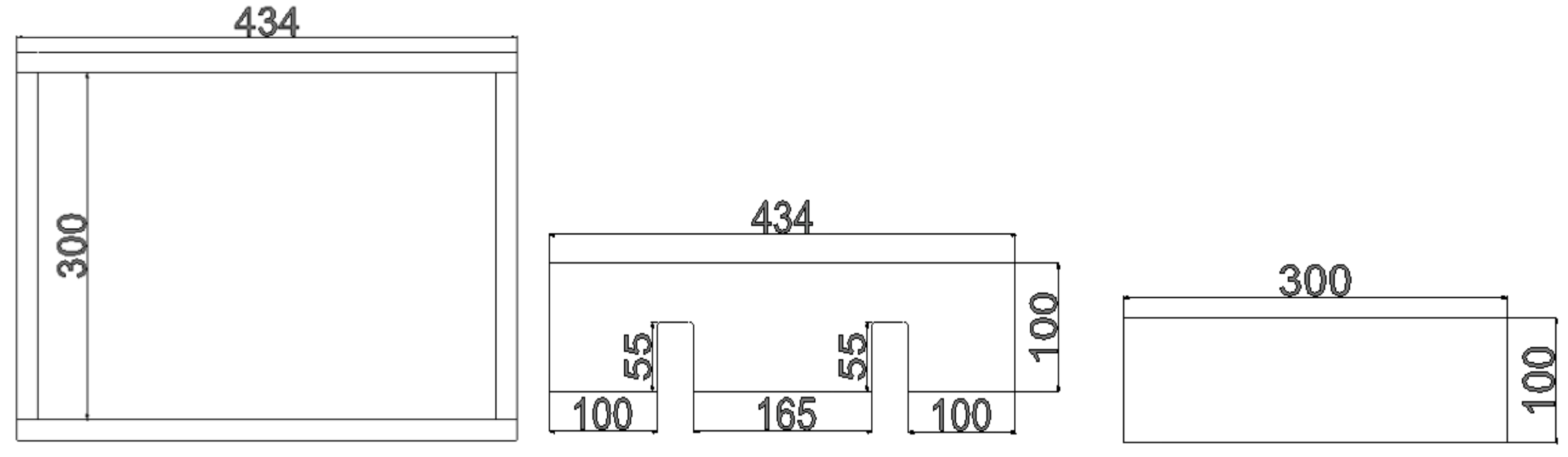

2.2. Specimen Preparation

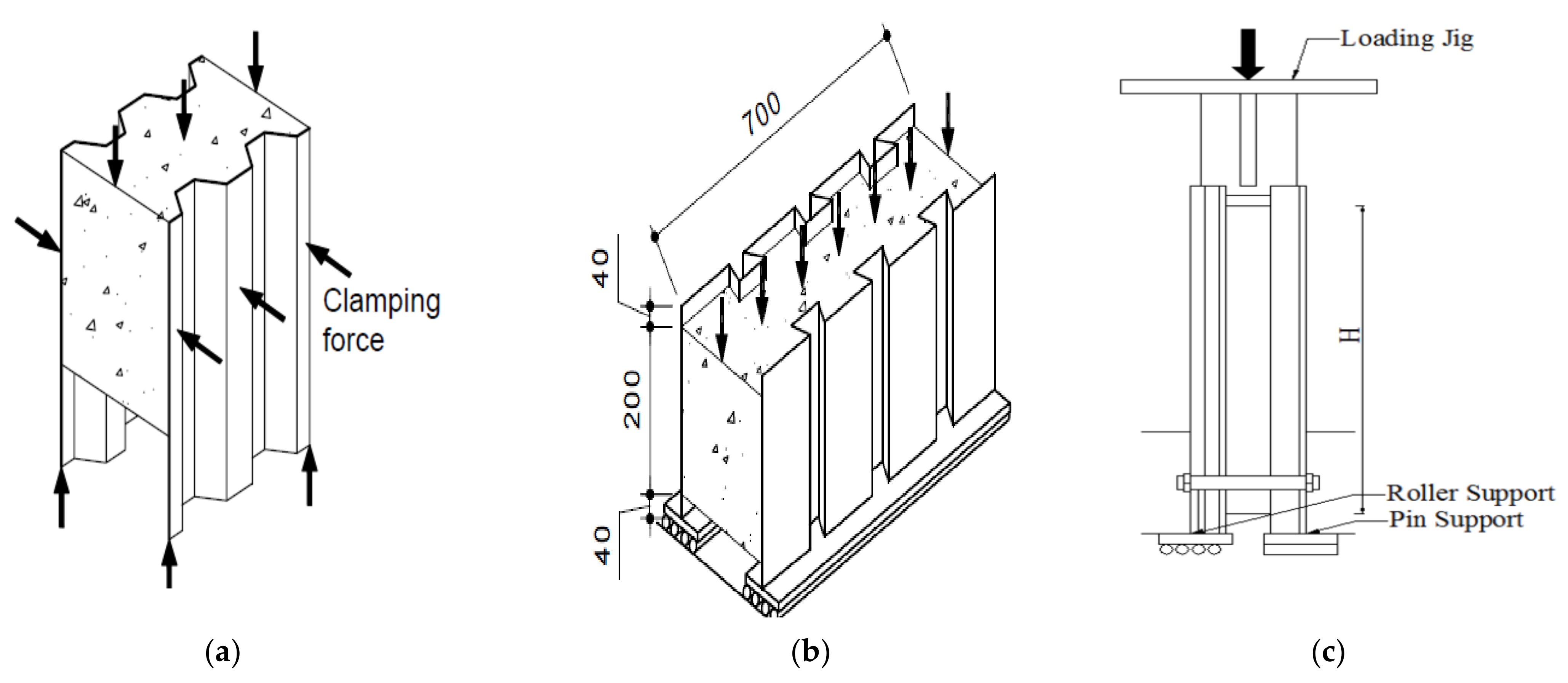

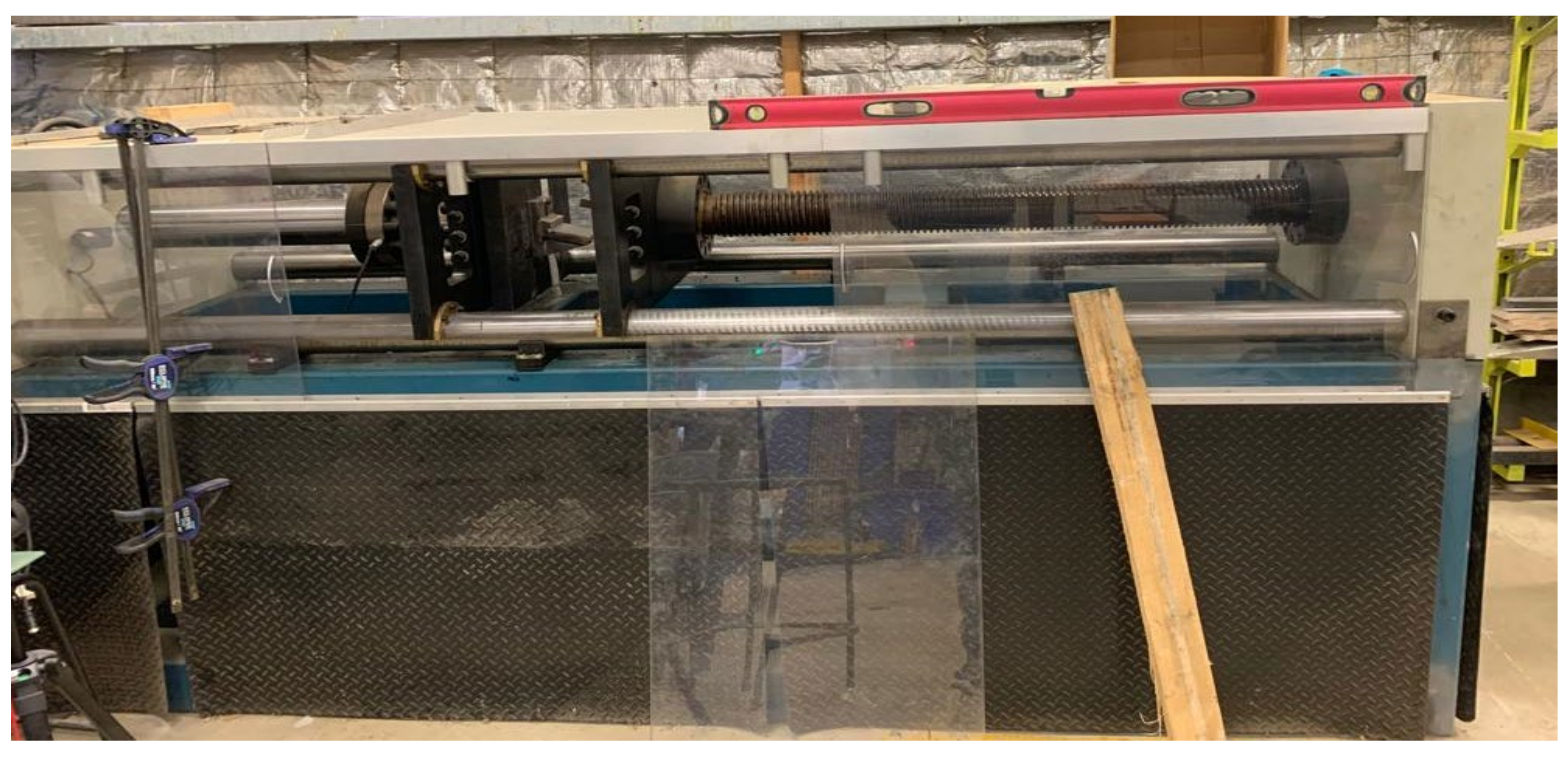

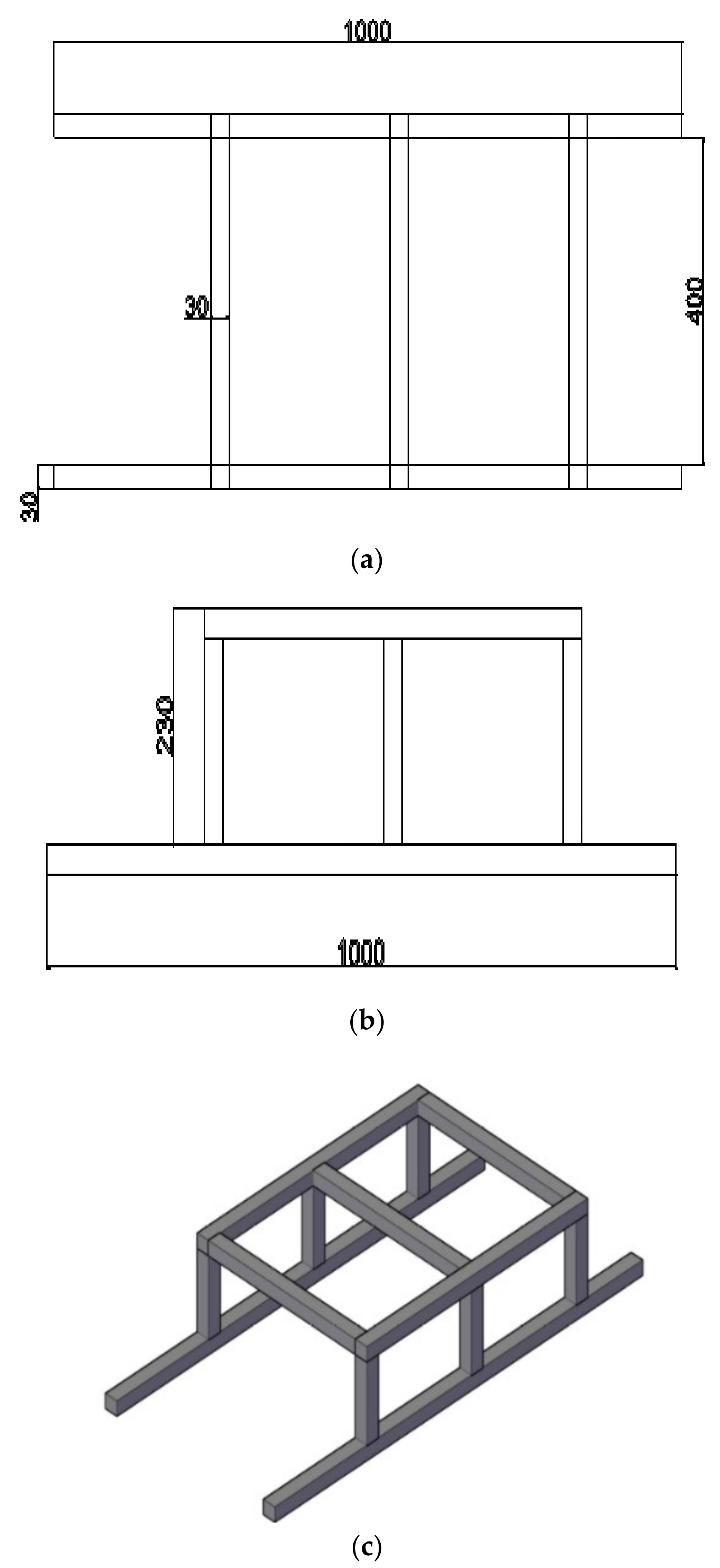

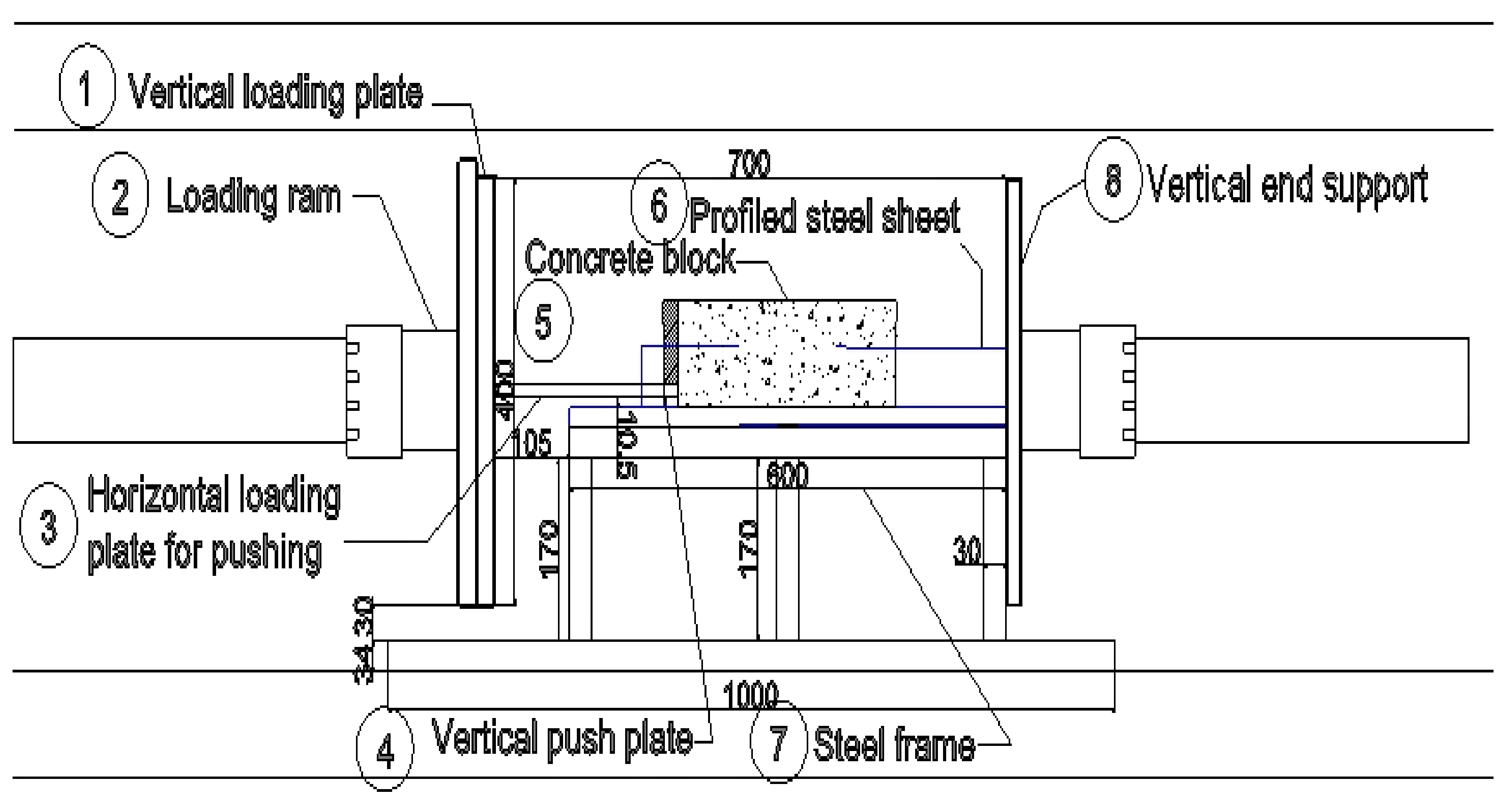

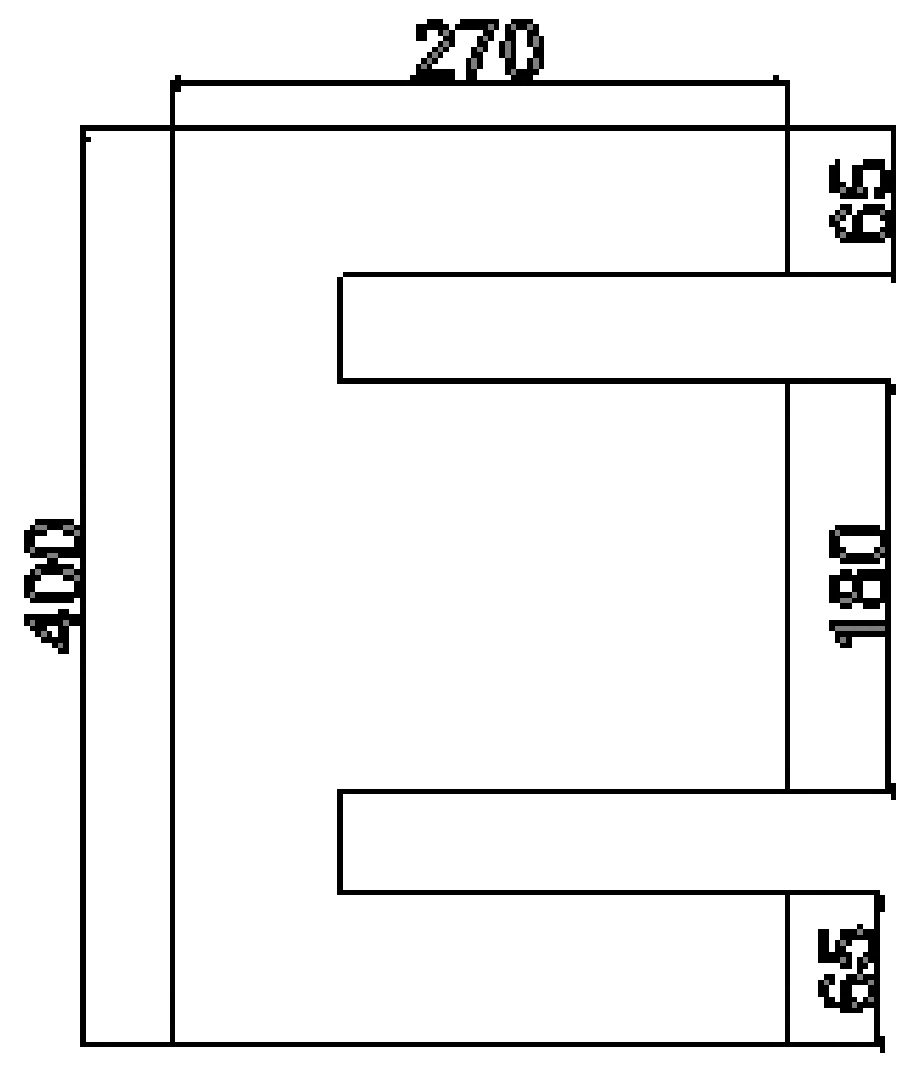

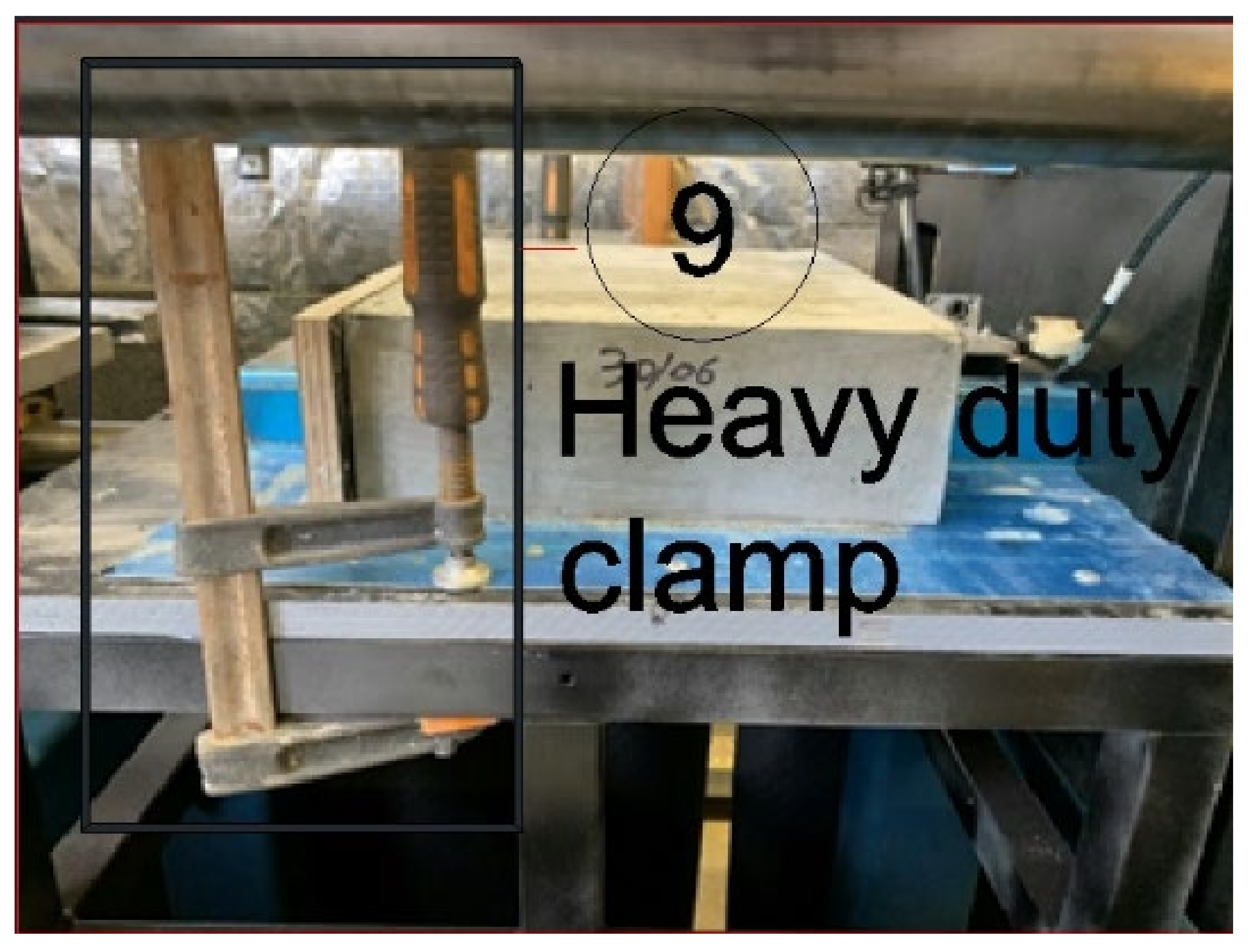

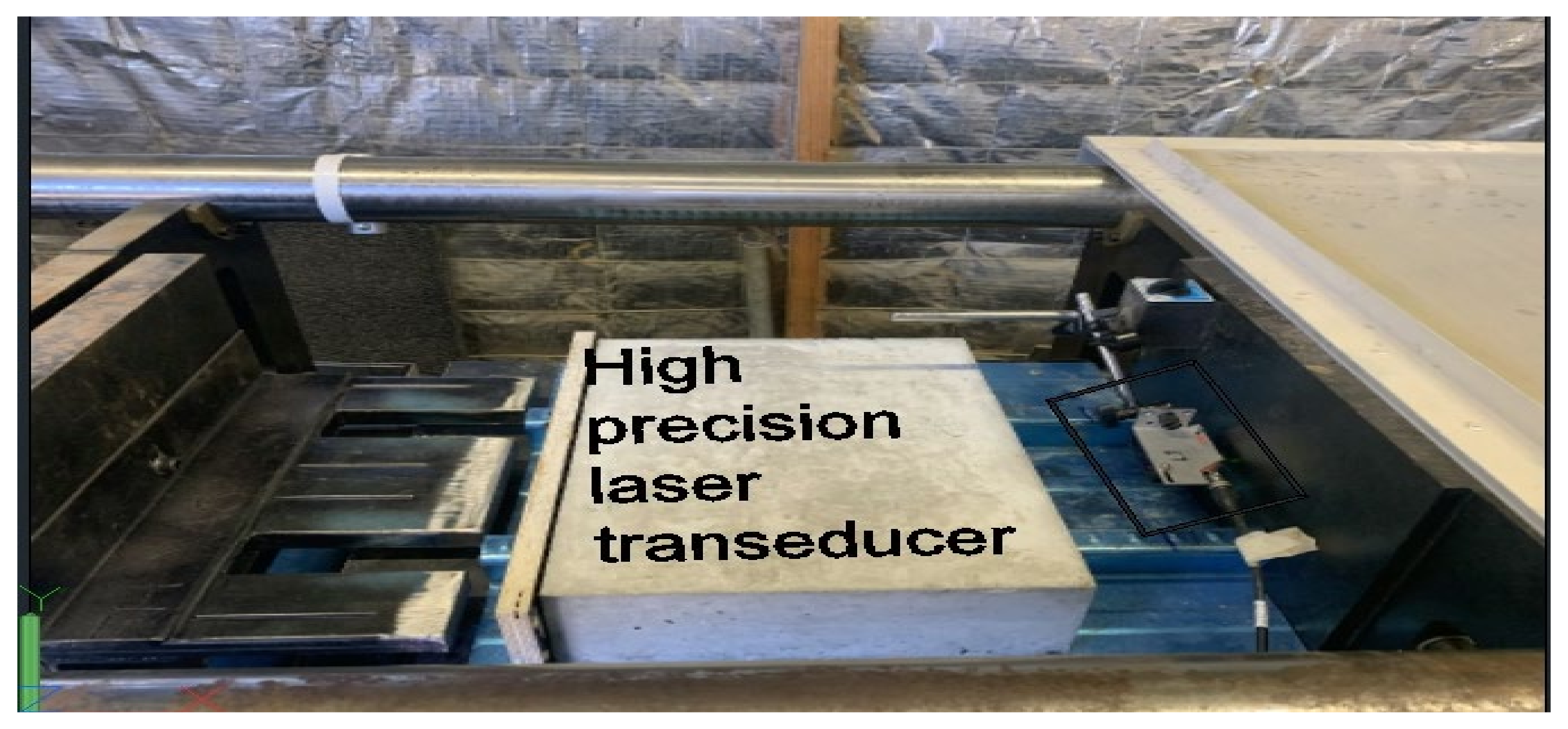

2.3. Test Set-Up and Loading Procedure

3. Test Results and Discussions

3.1. Mechanical Properties

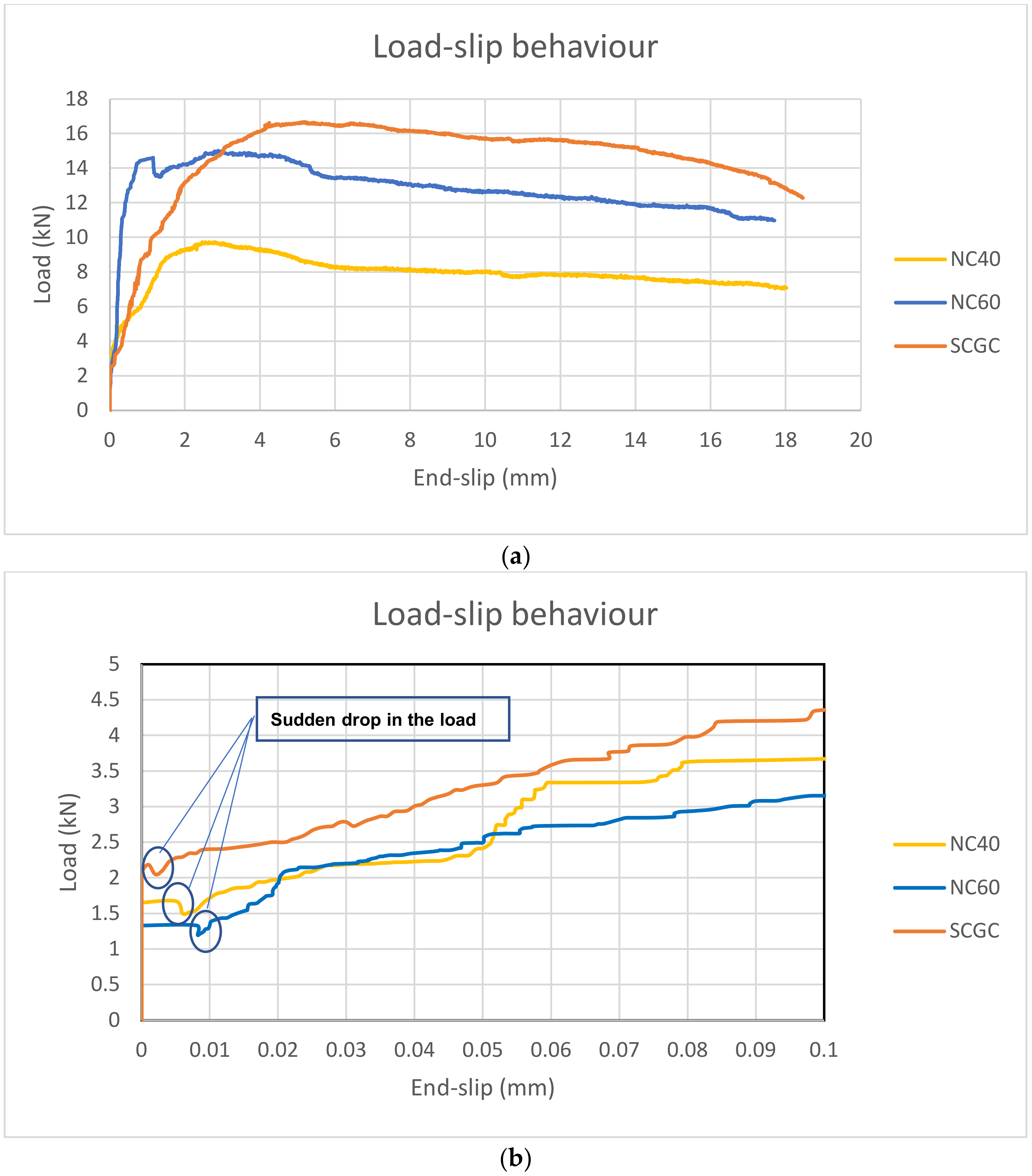

3.2. Bond–Slip Relationship

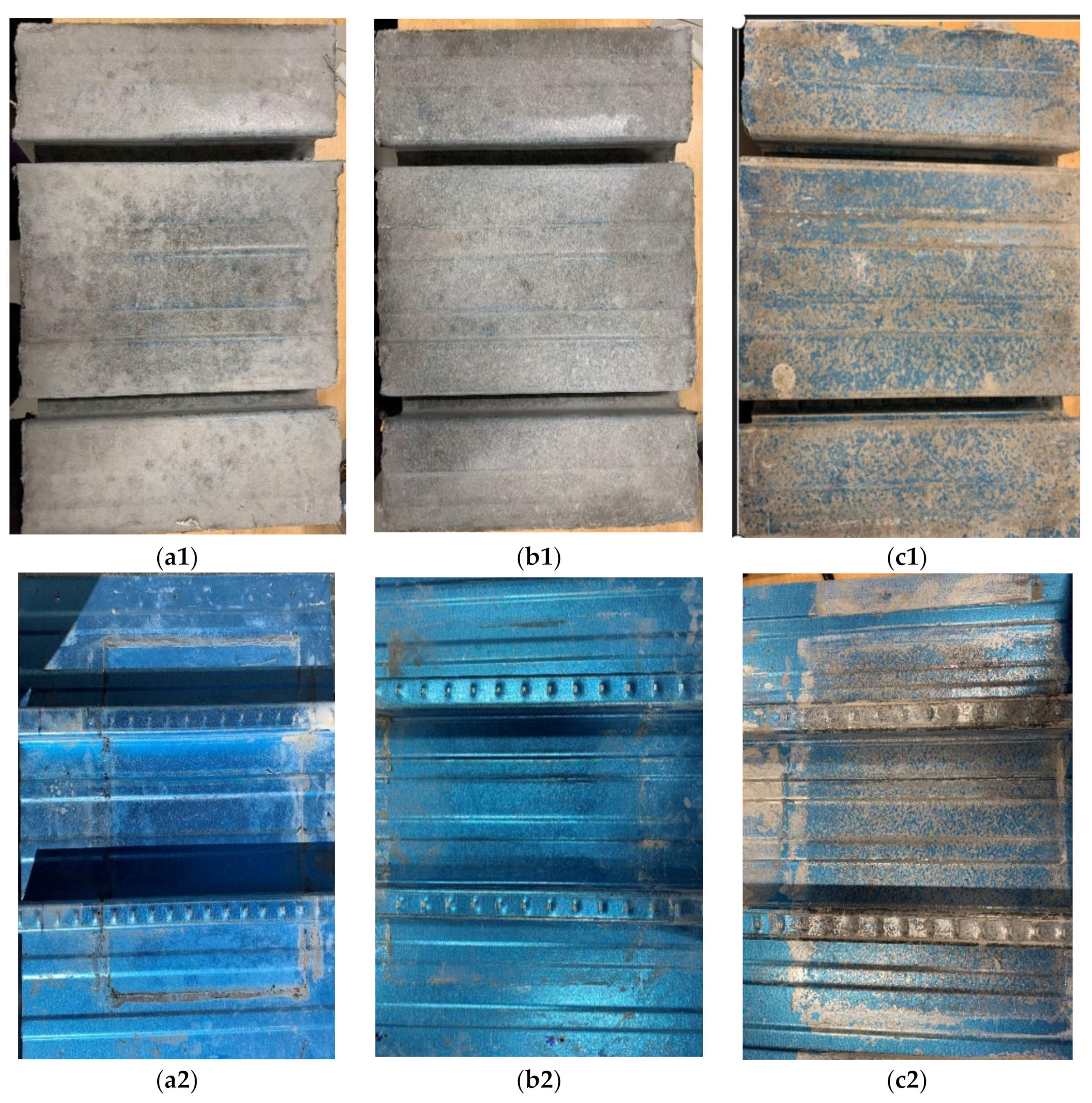

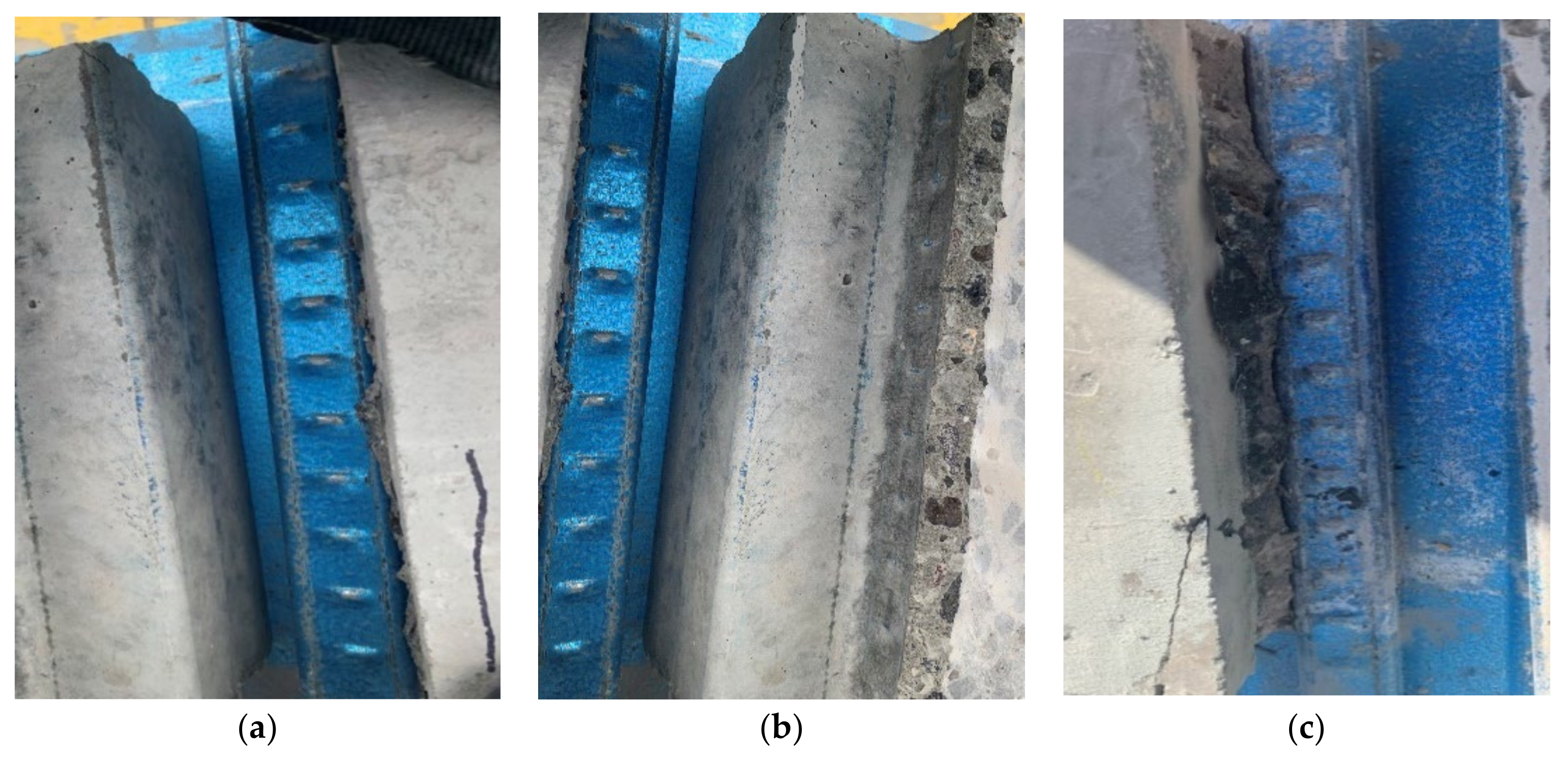

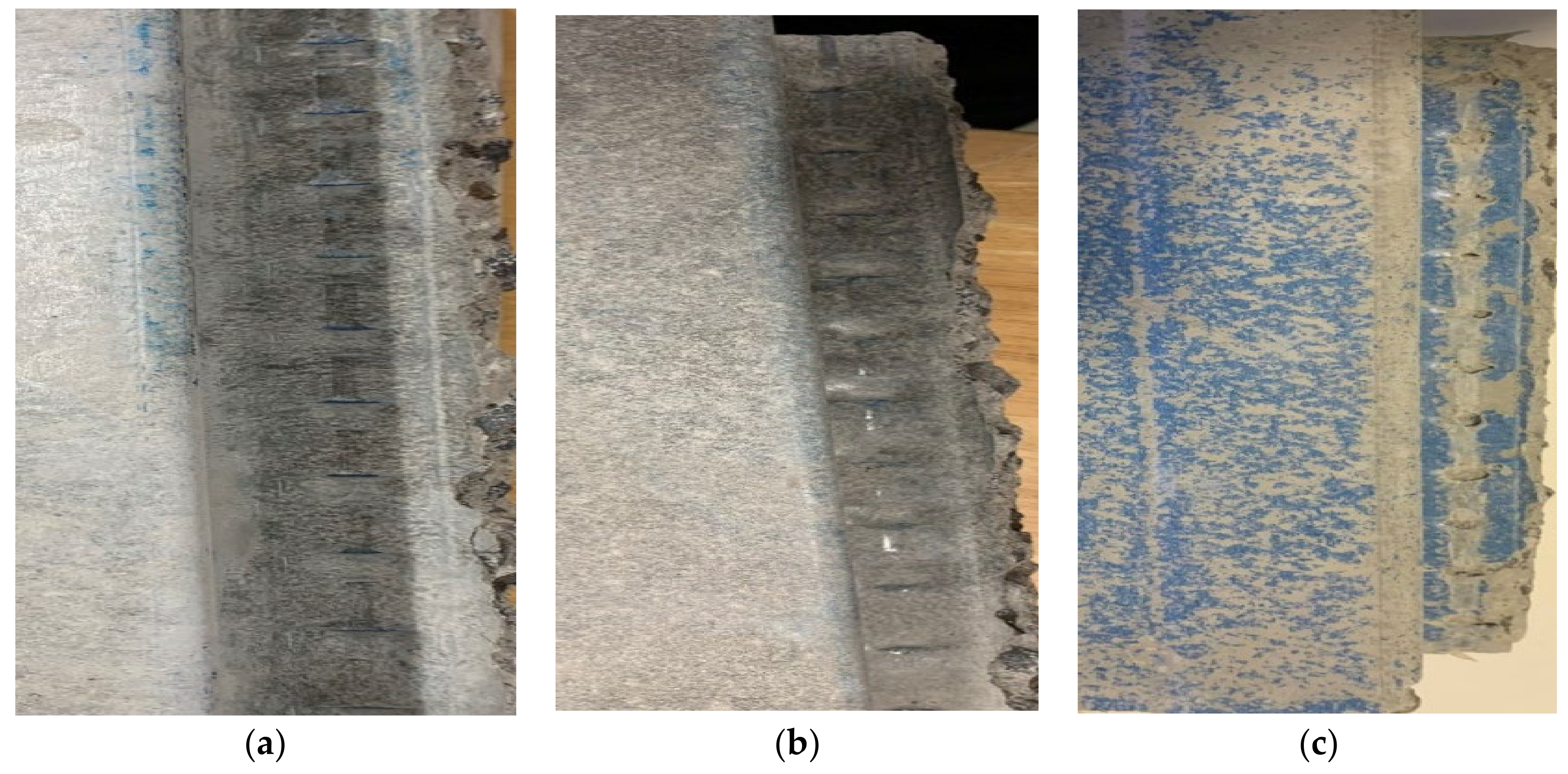

3.3. Visual Observation

4. Conclusions

- SCGC has a better chemical adhesion bond with profiled steel sheets than normal concrete, confirmed by visual observation and the test results. SCGC showed a 131% better chemical adhesion bond than NC40 and 164% better chemical adhesion bond compared to NC60. It can also be concluded that the chemical adhesion bond between concrete and profiled steel sheets is influenced by neither the concrete compressive strength nor the tensile strength, but by the binder distribution at the concrete-profiled steel sheet interface.

- The SCGC composite slab has approximately 71% lower shear connection stiffness than the NC60 composite slab, but 46% higher than the NC40 composite slab.

- The SCGC composite slab developed 66% and 11% higher ultimate strength than NC40 and NC60. In addition, the relevant slip to the maximum load of the SCGC composite slab was higher than that for NC40 and NC60, indicating that the SCGC slab has better resilience than NC40 and NC60.

- The SCGC slab has higher toughness compared to NC40 and NC60, as a result of the low concrete hardness associated with SCGC, which allowed for better mechanical interlock and frictional resistance between the profiled steel sheet and SCGC, compared to NC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vieira, P.S.; Horvath, A. Assessing the end-of-life impacts of buildings. Environ. Sci. Technol. 2008, 42, 4663–4669. [Google Scholar] [CrossRef] [PubMed]

- Lippiatt, B.C. Bees 4.0: Building for Environmental and Economic Sustainability. Technical Manual and User Guide. 2007. Available online: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=860108 (accessed on 8 October 2021).

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Law, D.W.; Adam, A.A.; Molyneaux, T.K.; Patnaikuni, I.; Wardhono, A. Long term durability properties of class F fly ash geopolymer concrete. Mater. Struct. 2015, 48, 721–731. [Google Scholar] [CrossRef]

- Deb, P.S.; Sarker, P.K.; Barbhuiya, S. Sorptivity and acid resistance of ambient-cured geopolymer mortars containing nano-silica. Cem. Concr. Compos. 2016, 72, 235–245. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G. Damage behavior of geopolymer composites exposed to elevated temperatures. Cem. Concr. Compos. 2008, 30, 986–991. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. Factors Influencing the Compressive Strength of Fly Ash-Based Geopolymer Concrete. Civ. Eng. Dimens. 2004, 6, 88–93. [Google Scholar] [CrossRef]

- Ma, C.-K.; Awang, A.Z.; Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical Research and Climate Change as Drivers in the Commercial Adoption of Alkali Activated Materials. Waste Biomass Valorization 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Qazi, S.A.; Kusbiantoro, A.; Shafiq, N. Utilisation of waste material in geopolymeric concrete. Proc. Inst. Civ. Eng.-Constr. Mater. 2011, 164, 315–327. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2017, 130, 22–31. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. A newly developed self-compacting geopolymer concrete under ambient condition. Constr. Build. Mater. 2021, 267, 121822. [Google Scholar] [CrossRef]

- Ariffin, M.A.M.; Bhutta, M.A.R.; Hussin, M.W.; Mohd Tahir, M.; Aziah, N. Sulfuric acid resistance of blended ash geopolymer concrete. Constr. Build. Mater. 2013, 43, 80–86. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Sarker, P.K. Bond strength of reinforcing steel embedded in fly ash-based geopolymer concrete. Mater. Struct. 2011, 44, 1021–1030. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J. Bond strength between blended slag and Class F fly ash geopolymer concrete with steel reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- Zhao, R.; Yuan, Y.; Cheng, Z.; Wen, T.; Li, J.; Li, F.; Ma, Z.J. Freeze-thaw resistance of Class F fly ash-based geopolymer concrete. Constr. Build. Mater. 2019, 222, 474–483. [Google Scholar] [CrossRef]

- Luhar, S.; Nicolaides, D.; Luhar, I. Fire resistance behaviour of geopolymer concrete: An overview. Buildings 2021, 11, 82. [Google Scholar] [CrossRef]

- Fan, Y.; Yin, S.; Wen, Z.; Zhong, J. Activation of fly ash and its effects on cement properties. Cem. Concr. Res. 1999, 29, 467–472. [Google Scholar] [CrossRef]

- Puertas, F.; Martínez-Ramírez, S.; Alonso, S.; Vázquez, T. Alkali-activated fly ash/slag cements: Strength behaviour and hydration products. Cem. Concr. Res. 2000, 30, 1625–1632. [Google Scholar] [CrossRef]

- Somna, K.; Jaturapitakkul, C.; Kajitvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar] [CrossRef]

- Zannerni, G.M.; Fattah, K.P.; Al-Tamimi, A.K. Ambient-cured geopolymer concrete with single alkali activator. Sustain. Mater. Technol. 2020, 23, e00131. [Google Scholar] [CrossRef]

- Ardalan, R.B.; Emamzadeh, Z.N.; Rasekh, H.; Joshaghani, A.; Samali, B. Physical and mechanical properties of polymer modified self-compacting concrete (SCC) using natural and recycled aggregates. J. Sustain. Cem.-Based Mater. 2020, 9, 1–16. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Synthesis of heat and ambient cured one-part geopolymer mixes with different grades of sodium silicate. Ceram. Int. 2015, 41, 5696–5704. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J. Efficiency of Different Superplasticizers and Retarders on Properties of ‘One-Part’ Fly Ash-Slag Blended Geopolymers with Different Activators. Materials 2019, 12, 3410. [Google Scholar] [CrossRef] [PubMed]

- Cifuentes, H.; Medina, F. Experimental study on shear bond behavior of composite slabs according to Eurocode 4. J. Constr. Steel Res. 2013, 82, 99–110. [Google Scholar] [CrossRef]

- Gholamhoseini, A.; Gilbert, R.I.; Bradford, M.A.; Chang, Z.T. Longitudinal shear stress and bond–slip relationships in composite concrete slabs. Eng. Struct. 2014, 69, 37–48. [Google Scholar] [CrossRef]

- Wright, H.D.; Evans, H.R.; Harding, P.W. The use of profiled steel sheeting in floor construction. J. Constr. Steel Res. 1987, 7, 279–295. [Google Scholar] [CrossRef]

- Patrick, M.; Bridge, R.Q. Partial shear connection design of composite slabs. Eng. Struct. 1994, 16, 348–362. [Google Scholar] [CrossRef]

- Porter, M.L.; Ekberg, C.E., Jr. Compendium of ISU Research Conducted on Cold-Formed Steel-Deck-Reinforced Slab Systems; National Academy of Sciences: Washington, DC, USA, 1978. [Google Scholar]

- Oehlers, D.J.; Bradford, M.A. 13-Longitudinal Shear. In Composite Steel and Concrete Structural Members; Oehlers, D.J., Bradford, M.A., Eds.; Pergamon: Oxford, UK, 1995; pp. 326–335. [Google Scholar]

- Marimuthu, V.; Seetharaman, S.; Arul Jayachandran, S.; Chellappan, A.; Bandyopadhyay, T.K.; Dutta, D. Experimental studies on composite deck slabs to determine the shear-bond characteristic (m–k) values of the embossed profiled sheet. J. Constr. Steel Res. 2007, 63, 791–803. [Google Scholar] [CrossRef]

- Mohammed, B.S. Structural behavior and m–k value of composite slab utilizing concrete containing crumb rubber. Constr. Build. Mater. 2010, 24, 1214–1221. [Google Scholar] [CrossRef]

- Youssf, O.; Hassanli, R.; Mills, J.E.; Ma, X.; Zhuge, Y. Cyclic Performance of Steel–Concrete–Steel Sandwich Beams with Rubcrete and LECA Concrete Core. J. Compos. Sci. 2019, 3, 5. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Youssf, O.; Mills, J.E.; Xiao, J.; Singh, A. Structural performance of composite panels made of profiled steel skins and foam rubberised concrete under axial compressive loads. Eng. Struct. 2020, 211, 110448. [Google Scholar] [CrossRef]

- Holmes, N.; Dunne, K.; O’Donnell, J. Longitudinal shear resistance of composite slabs containing crumb rubber in concrete toppings. Constr. Build. Mater. 2014, 55, 365–378. [Google Scholar] [CrossRef]

- Rana, M.M.; Uy, B.; Mirza, O. Experimental and numerical study of the bond–slip relationship for post-tensioned composite slabs. J. Constr. Steel Res. 2015, 114, 362–379. [Google Scholar] [CrossRef]

- Burnet, M.J.; Oehlers, D.J. Rib shear connectors in composite profiled slabs. J. Constr. Steel Res. 2001, 57, 1267–1287. [Google Scholar] [CrossRef]

- Yi, O.; Zhuge, Y.; Ma, X.; Gravina, R.J.; Mills, J.E.; Youssf, O. Push-off and Pull-out Bond Behaviour of CRC Composite Slabs—An Experimental Investigation. Eng. Struct. 2021, 228, 111480. [Google Scholar] [CrossRef]

- Schuster, R.M. Strength and Behavior of Cold-Rolled Steel-Deck-Reinforced Concrete Floor Slabs; Iowa State University: Ames, IA, USA, 1970. [Google Scholar]

- Stark, J.W. Design of composite floors with profiled steel sheet. In Proceedings of the CCFSS International Specialty Conference on Cold-Formed Steel Structures (1971–2018), St. Louis, MO, USA, 1 June 1978. [Google Scholar]

- Jolly, C.K.; Zubair, A.K. The efficiency of shear-bond interlock between profiled steel sheeting and concrete. In Proceedings of the International Conference on Steel and Aluminum Structures Composite Steel Structures, Advances, Design and Construction, Cardiff, UK, 8–10 July 1987. [Google Scholar]

- Daniels, B.J. Shear Bond Pull-Out Tests for Cold-Formed-Steel Composite Slabs: Rapport D’essais; ICOM; École Polytechnique Fédérale de Lausanne Institut de Statique et Structures: Lausanne, Switzerland, 1988. [Google Scholar]

- Patrick, M.; Poh, K. Controlled test for composite slab design parameters. In Proceedings of the IABSE Symposium Brussels, Belgium-Mixed Structures, Including New Materials, Brussels, Belgium, 5–7 September 1990; pp. 227–231. [Google Scholar]

- Veljkovic, M. Behaviour and Resistance of Composite Slabs: Experiments and Finite Element Analysis. Comprehensive Summary. Ph.D. Thesis, Luleå Tekniska Universitet, Luleå, Sweden, 1996. [Google Scholar]

- Veljkovic, M. Behaviour and Design of Shallow Composite Slab. In Composite Construction in Steel and Concrete IV; American Society of Civil Engineers: Reston, VA, USA, 2002; pp. 310–321. [Google Scholar]

- Burnet, M. Analysis of Composite Steel and Concrete Flexural Members that Exhibit Partial Shear Connection. Ph.D. Thesis, University of Adelaide, Adelaide, SA, USA, 1998. [Google Scholar]

- Rana, M.M. The Effects of Bond and Anchorage on the Behaviour and Design of Composite Slabs. Ph.D. Thesis, UNSW Sydney, Sydney, NSW, Australia, 2016. [Google Scholar]

- Abdullah, R. Experimental Evaluation and Analytical Modeling of Shear Bond in Composite Slabs. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2004. [Google Scholar]

- Veljkovic, M. Longitudinal shear capacity of composite slabs. In Proceedings of the Nordic Steel Construction Conference, Malmo, Sweden, 19–21 June 1995; pp. 547–554. [Google Scholar]

- An, L. Load Bearing Capacity and Behaviour of Composite Slabs with Profiled Steel Sheet. Ph.D. Thesis, Chalmers University of Technology, Goteborg, Sweden, 1993. [Google Scholar]

- Holomek, J.; Bajer, M.; Barnat, J.; Schmid, P. Design of composite slabs with prepressed embossments using small-scale tests. Struct. Concr. 2015, 16, 137–148. [Google Scholar] [CrossRef]

- Devika, C.; Deepthi, R. Study of flexural behavior of hybrid fibre reinforced geopolymer concrete beam. Int. J. Sci. Res. 2015, 4, 130–135. [Google Scholar]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the flexural properties of reinforced alkali activated slag concrete. Constr. Build. Mater. 2016, 102, 51–58. [Google Scholar] [CrossRef]

- Visintin, P.; Ali, M.S.M.; Albitar, M.; Lucas, W. Shear behaviour of geopolymer concrete beams without stirrups. Constr. Build. Mater. 2017, 148, 10–21. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Huang, Z.; Chen, W.; Hao, H.; Elchalakani, M. Impact response of fibre reinforced geopolymer concrete beams with BFRP bars and stirrups. Eng. Struct. 2021, 231, 111785. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, W.; Hao, H.; Chen, Z.; Pham, T.M.; Tran, T.T.; Elchalakani, M. Flexural behaviour of ambient cured geopolymer concrete beams reinforced with BFRP bars under static and impact loads. Compos. Struct. 2021, 261, 113282. [Google Scholar] [CrossRef]

- Rahman, M.; Sarker, P. Geopolymer concrete columns under combined axial load and biaxial bending. In Proceedings of the Concrete 2011 Conference, Dresden, Germany, 8–10 June 2011. [Google Scholar]

- Nagan, S.; Karthiyaini, S. A Study on Load Carrying Capacity of Fly Ash Based Polymer Concrete Columns Strengthened Using Double Layer GFRP Wrapping. Adv. Mater. Sci. Eng. 2014, 2014, 312139. [Google Scholar] [CrossRef]

- Elchalakani, M.; Karrech, A.; Dong, M.; Ali, M.S.M.; Yang, B. Experiments and Finite Element Analysis of GFRP Reinforced Geopolymer Concrete Rectangular Columns Subjected to Concentric and Eccentric Axial Loading. Structures 2018, 14, 273–289. [Google Scholar] [CrossRef]

- Hassaine, N.-E. Shear-Bond Performance of Profiled Steel Sheets when Used as Composite Floor Decks. Masters’s Thesis, University College, Cardiff, UK, 1987. [Google Scholar]

- Abdel-Sayed, G.; Temple, M.C.; Madugula, M.K.S. Response of Composite Slabs to Dynamic Loads. Can. J. Civ. Eng. 1974, 1, 62–70. [Google Scholar] [CrossRef]

- Daniels, B.J.; Crisinel, M. Composite slab behavior and strength analysis. Part I: Calculation procedure. J. Struct. Eng. 1993, 119, 16–35. [Google Scholar] [CrossRef]

- Airumyan, E.; Belyaev, V.; Rumyancev, I. Efficient embossment for corrugated steel sheeting. In Proceedings of the IABSE Symposium on Mixed Structures Including New Materials, Brussels, Belgium, 5–7 September 1990; pp. 137–142. [Google Scholar]

- Tremlay, R.; Gignac, P.; Degrange, G.; Rogers, C.A. Variables Affecting the Shear-Bond Resistance of Composite Floor Deck Systems; Missouri University of Science and Technology: Rolla, MO, USA, 2002. [Google Scholar]

- AS/NZS 3582.1:2016; Supplementary Cementitious Materials Fly Ash. Standards Australia: Sydney, Australia, 2016; p. 11. Available online: https://infostore.saiglobal.com/en-us/standards/as-nzs-3582-1-2016-101026_saig_as_as_212259/ (accessed on 9 November 2021).

- General Purpose Cement-Product Data Sheet; Independent Cement: Melbourne, VIC, Australia, 2017; p. 2.

- AS/NZS 2327:2017; Composite Structures-Composite Steel-Concrete Construction in Buildings. Standards Australia: Sydney, Australia, 2017; p. 261. Available online: https://infostore.saiglobal.com/en-us/standards/as-nzs-2327-2017-99192_saig_as_as_208561/ (accessed on 8 January 2021).

- AS 1012.14:2018; Methods of Testing Concrete Method for Securing and Testing Cores from Hardened Concrete for Compressive Strength and Mass Per Unit Volume 11. Standards Australia: Sydney, Australia, 2018. Available online: https://infostore.saiglobal.com/en-us/standards/as-1012-14-2018-99136_saig_as_as_208448/ (accessed on 7 December 2021).

- AS 1012.10-2000; Methods of Testing Concrete Determination of Indirect Tensile Strength of Concrete Cylinders (‘Brazil’ or Splitting Test) (Reconfirmed 2014). Standards Australia: Sydney, Australia, 2014; p. 5. Available online: https://infostore.saiglobal.com/en-us/standards/as-1012-10-2000-129179_saig_as_as_273253/ (accessed on 2 October 2021).

- AS 1012.17-1997; Methods of Testing Concrete Determination of the Static Chord Modulus of Elasticity and Poisson’s Ratio of Concrete Specimens (Reconfirmed 2014). Standards Australia: Sydney, Australia, 1997; p. 13. Available online: https://infostore.saiglobal.com/en-au/standards/as-1012-17-1997-129172_saig_as_as_273232/ (accessed on 12 October 2021).

| Material | Odour | Loss on Ignition (%) | Moisture Content (%) | Relative Density | Melting Point (°C) | pH |

|---|---|---|---|---|---|---|

| Fly ash | No odour | 1 | 0.1 | 2.4 | >1400 | -- |

| Slag | No odour | -- | -- | 3 | >1200 | 12 |

| Micro fly ash | No odour | 0.7 | 0.01 | 2.35 | -- | -- |

| Anhydrous sodium metasilicate | No odour | -- | -- | 2.4 | 1088 | 12.6 |

| Cement | No odour | -- | -- | 3.1 | >1200 | >11 |

| Chemical Composition | Fly Ash (%) | Slag (%) | Sodium Metasilicate Anhydrous (%) | Micro Fly Ash (%) | General Purpose Cement (%) [68] |

|---|---|---|---|---|---|

| SiO2 | 65.75 | 35.19 | 50 | 63.09 | -- |

| CaO | -- | 41.47 | -- | -- | -- |

| Al2O3 | 32.87 | 13.66 | -- | 32.26 | -- |

| MgO | -- | 6.32 | -- | -- | -- |

| K2O | -- | -- | -- | 0.83 | -- |

| MnO | -- | 0.67 | -- | -- | -- |

| SO3 | -- | 2.43 | -- | -- | -- |

| V2O5 | -- | 0.20 | -- | -- | -- |

| TiO2 | 1.38 | 0.73 | -- | 1.67 | -- |

| C4AF | -- | -- | -- | -- | <97 |

| Na2O | -- | -- | 50 | 0.41 | -- |

| CaSO4·2H2O | -- | -- | -- | -- | 2-5 |

| P2O5 | -- | -- | -- | 0.62 | -- |

| FeO | -- | -- | -- | 1.12 | -- |

| Others | -- | -- | -- | -- | 0–7.5 |

| Mix | Targeted Compressive Strength (MPa) | Fly Ash (kg) | Slag (kg) | Micro Fly Ash (kg) | Sodium Metasilicate (kg) | Cement (kg) | Fine Aggregate (kg) | Coarse Aggregate (kg) |

|---|---|---|---|---|---|---|---|---|

| SCGC [13] | 40 | 480 | 360 | 120 | 96 | 0 | 763 | 677 |

| NC40 | 40 | 0 | 0 | 0 | 0 | 400 | 632 | 960 |

| NC60 | 60 | 0 | 0 | 0 | 0 | 552 | 730 | 1080 |

| Property | Thickness (mm) | Mass (kg/m2) | Yield Strength (fy) (Mpa) | Minimum Yield Stress (fu) (MPa) | Coverage (m2/t) | Cross-Sectional Area Ash (mm2/m) | Sheeting Elastic Centroid (mm) |

|---|---|---|---|---|---|---|---|

| Bondek® profiled steel sheet | 1 | 13.79 | 550 | 750 | 72.50 | 1678 | 15.5 |

| Specimen No. | Concrete Type | |

|---|---|---|

| NC40 | NC401 | Normal concrete |

| NC402 | Normal concrete | |

| NC60 | NC601 | Normal concrete |

| NC602 | Normal concrete | |

| SCGC | SCGC1 | Self-compacted geopolymer concrete |

| SCGC2 | Self-compacted geopolymer concrete |

| SCGC | NC40 | NC60 | |

|---|---|---|---|

| Slump (mm) | 680 | 95 | 85 |

| Compressive strength (MPa) | 36.65 | 39.6 | 61.45 |

| Indirect tensile strength (MPa) | 2.53 | 3.4 | 4 |

| Modulus of elasticity (GPa) | 15 | 19 | 32 |

| Specimen | Pk (kN) | m (MPa) | Pu (kN) | Su (mm) | Toughness (J) |

|---|---|---|---|---|---|

| NC40 | 1.66 | 4.32 | 10.26 | 2.70 | 1424 |

| NC60 | 1.33 | 21.50 | 15.30 | 3.35 | 2193 |

| SCGC | 2.18 | 6.25 | 17.03 | 4.64 | 2564 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heweidak, M.; Kafle, B.; Al-Ameri, R. Shear-Bond Behaviour of Profiled Composite Slab Incorporated with Self-Compacted Geopolymer Concrete. Appl. Sci. 2022, 12, 8512. https://doi.org/10.3390/app12178512

Heweidak M, Kafle B, Al-Ameri R. Shear-Bond Behaviour of Profiled Composite Slab Incorporated with Self-Compacted Geopolymer Concrete. Applied Sciences. 2022; 12(17):8512. https://doi.org/10.3390/app12178512

Chicago/Turabian StyleHeweidak, Mohamed, Bidur Kafle, and Riyadh Al-Ameri. 2022. "Shear-Bond Behaviour of Profiled Composite Slab Incorporated with Self-Compacted Geopolymer Concrete" Applied Sciences 12, no. 17: 8512. https://doi.org/10.3390/app12178512

APA StyleHeweidak, M., Kafle, B., & Al-Ameri, R. (2022). Shear-Bond Behaviour of Profiled Composite Slab Incorporated with Self-Compacted Geopolymer Concrete. Applied Sciences, 12(17), 8512. https://doi.org/10.3390/app12178512