Abstract

An alternate renewable energy source, through a piezoelectric vibration energy harvester with a bluff splitter body, could lead to higher efficiency in energy harvesting, through vortex-induced vibration at a near-resonance condition at 20 m/s high wind speed. However, wind energy is not as popular as solar energy, as the main renewable energy source in Malaysia, due to the relatively low wind speed available in the country. The INVELOX machine, introduced in 2014, was one of the most recent systems used to harvest wind power by accelerating wind speed. This omni-directional wind funnel could capture wind from all directions and tunnel it through a convergent-divergent nozzle, where the coupled bluff splitter body and piezoelectric vibration energy harvester (PVEH) are located at its venturi throat, which could lead to an increase in wind speed to fulfil the task of VIV energy harvesting. The proposed modified design is found to achieve 2.7 times the wind speed amplification at the venturi, which outperformed previously proposed designs. To achieve the optimum wind speed of 20 m/s for the coupled bluff splitter body and the PVEH plate, a free-stream wind speed of 7.4 m/s is recommended. The integration of the PVEH plate and the wind funnel is expected to harvest maximum voltage output at 20.99 V or 4.96 V, with a maximum power output of 0.82mW at 20 m/s.

1. Introduction

In 2019, petroleum and natural gas remained as the primary energy sources of consumption in Malaysia, at 37% and 36%, respectively. The country’s coal consumption is at about 21% of total consumption, whereas renewable energy is only consumed at 6%. In 2020, renewable energy accounted for 15.2% of the total electricity capacity in Peninsular Malaysia and Sabah, which is an increase of 6.6% compared to 4.3% in 2019. The renewable energy capacity is targeted to achieve 31% by 2025 and 40% by 2035. Therefore, it shows the promising potential of renewable energy sources in Malaysia’s power-generation plan [1,2].

However, wind energy is not as popular as solar energy as the main renewable energy source in Malaysia, because of the relatively low wind speed, and, thus, it is not suitable for the establishment of large-scale wind-energy farms. Wind-energy plants should be selected wisely based on the wind-power potential at the site [3]. It is noted that Malaysia’s mean annual wind speed is recorded at around 1.8 m/s, with the highest wind speed recorded at 5.4 m/s [4]. It is noted that towns on the east coast of Peninsular Malaysia, such as Mersing, Kota Bharu, and Kuala Terengganu, experience stronger wind [5]. Previous work by Mudathir Funsho Akorede et al. showed that the wind turbine sites at Mersing recorded the highest wind-capacity factor, of 4.39% [6].

In recent decades, vibration energy harvesting (VEH) received greater attention due to its potential for the renewable- and sustainable-energy supply. Inspired by vortex-induced vibration energy harvesting development as a new source of renewable energy, as proposed by the authors earlier, a T-shaped-design vibration energy harvester was proposed to enhance the vortex-induced VEH performance. It was recommended that the proposed VEH model is only suitable to be installed at high-speed flow locations, such as pipelines or exhaust fans, to generate VIV and maximum power output consistently [7].

This research proposes the design of an omni-directional wind funnel, which is installed together with the coupled bluff splitter body and PVEH plate, to fulfil the energy harvesting objective, especially in Malaysia, which has a relatively low mean wind speed. One of the most recent systems used to harvest wind power by accelerating wind speed is the INVELOX machine, introduced in 2014 by Allaei and Andreopoulos [8]. They achieved the goal of INVELOX, as they have achieved a maximum speed ratio (SR) of 1.8 at the venturi throat.

In recent years, many works have reported on the study of the INVELOX design, to further enhance its performance through some modifications and configuration changes. Anbarsooz et al. studied the effects of several geometrical parameters affecting the aerodynamic performance of the INVELOX. It was found that the area contraction at the venturi, the inlet area, inlet height, and funnel height have a considerable effect on the SR. Meanwhile, the wind speed has negligible effect on the SR [9]. In 2019, Anbarsooz et al. then proposed a few possible curtain designs to reduce or fully eliminate this escaping air. It is noted that the best design can lead to a 25% increase in the average wind speed inside the venturi and achieve a maximum SR of 1.95 [10]. Gohar et al. proposed to reduce the diameter of the venturi throat, and the wind speed at the venturi section was increased with an SR of 2.3 [11]. Meanwhile, Sotoudeh et al. revealed that by increasing the assemble height, i.e., a two-storey INVELOX, it was found to be effective to reach higher performance than the conventional design, with an SR of 1.90 [12]. The effect of geometric changes in the nozzle–diffuser section was further investigated by Hosseini et al. Some geometrical changes were applied, including changes in the nozzle length, diffuser length, and diffuser-opening angle, and by replacing the conical nozzle with an ideal one and adding an exit flange. However, the best SR obtained was 1.67 in this study [13]. In Ding’s study, the flow-field characteristics of increased speed in INVELOX system under different wind directions were studied. It was found that after considering the atmospheric boundary layer (ABL) wind profile, the SR of the system decreased. The best SR obtained in this proposed design was 1.9 [14]. A study conducted by Nardecchia et al. proposed several possible configurations for the INVELOX system. It was found that the lower cone and elbow sections and the presence of the duct with a constant section after the elbow had led to unsatisfactory results. In addition, the introduction of a constant section after the venturi section decreased system performance. Meanwhile, optimal performance could be obtained by changing the convergent–divergent diameter. From this study, the best SR obtained was 1.74, which was slightly lower than the first design [15].

Based on the reported previous work on the effects of the INVELOX design parameters, there is room to further improve its performance. In this research, a new omni-directional wind funnel is proposed by considering a few design parameters, such as the length of each guide vane, the number of guide vanes, the elbow diameter, the ratio of the diameter of the intake to the venturi (aiming to effectively direct the winds from multiple directions and amplify to an optimum wind speed range), and the channel to the coupled bluff splitter body and PVEH plate. It is expected to generate maximum energy output if an optimum vortex frequency is produced to match with the resonant frequency of the PVEH plate.

2. Methodology

2.1. New Omni-Directional Wind-Funnel Design

The first INVELOX omni-directional wind funnel was introduced by Allaei and Andreopoulos [8] to harvest wind power by accelerating wind speed at the venturi throat. This system works based on capturing wind from all directions and tunnelling it through the convergent–divergent nozzle, where the wind turbine is located at its throat, leading to an increase in wind speed. The detailed dimension and geometry of the first INVELOX were introduced in 2014.

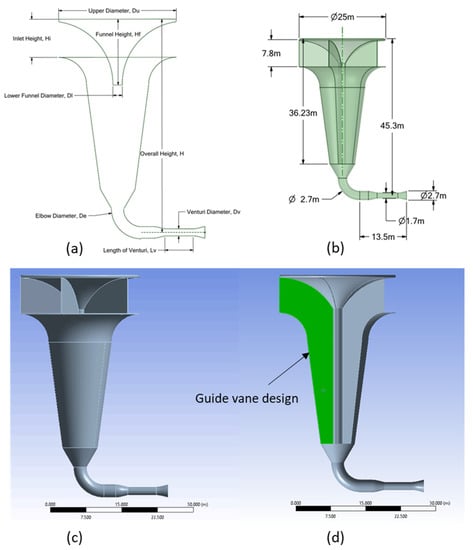

In this research, a few design parameters are considered, such as the length of each guide vane, number of guide vanes, the elbow diameter, and the ratio of diameter of intake to venturi. Figure 1 includes details of the changes, dimensions, length of guide vane, number of guide vanes, elbow diameter, and the ratio of diameter of intake to venturi to increase the inlet air, reduce the escaping air, avoid the formation of re-circulation zone, increase the pressure drop in the passage, and direct more air to the venturi throat.

Figure 1.

(a) Schematic drawing of the omni-directional wind funnel; (b) detailed dimension and geometry of the omni-directional wind funnel; (c) 3D model of the omni-directional wind funnel with the configuration of five fins at 72° each; (d) cross section of the 3D model.

The most prominent changes as compared with the conventional INVELOX are summarized in Table 1.

Table 1.

Comparison of changes in dimension and design between conventional INVELOX and newly proposed omni-directional wind funnel.

The overall wind funnel height was doubled to reduce the amount of air entering the INVELOX and the amount of air escaping from the opposite side of the INVELOX, and thus, increase the pressure drop of the air passage inside.

Instead of increasing the diameter of the lower funnel like previous research, the lower funnel diameter is fixed at 2 m and extended to the bottom of the funnel at the circular diameter of 7.8 m, giving a narrowing effect on the escaping air path, while the extended length of the guide vane also helps to guide the air towards the venturi throat section and, thus, prevent the early escape of the inlet air flow at the opposite end, directing sufficient speed of the air flow to enter the venturi throat and creating a low-pressure region at the venturi. Meanwhile, the extended length of lower-funnel diameter and guide vane could also prevent the formation of recirculation zone in the passage, which is undesirable and would reduce the amount of air to the venturi throat.

In addition, the reduction in the size of the venturi throat and elbow diameter by 8.6% and 11.4%, respectively, as compared with the conventional INVELOX, has created the contraction effect at the venturi throat and, thus, increased the trapped air speed to satisfy the law of mass conversion. This could also increase the overall pressure drop of the wind funnel.

Finally, the upper diameter is also doubled, while the inlet height is increased by 28%, as compared with the conventional INVELOX, to increase the amount of the inlet air to overcome the pressure drop effect, which limits the amount of air entering the wind funnel. The configuration of five fins at 72° each, compared with the four fins in the conventional configuration, aims to collect and direct the winds from all directions more efficiently. Figure 1b shows the best design.

2.2. Numerical Model

2.2.1. Governing Equations

The mathematical model used in this study is based on the three-dimensional Reynolds-averaged Navier–Stokes (RANS) equations for the turbulent flow of incompressible Newtonian fluid with constant thermophysical properties. The differential form of these equations in the Cartesian coordinate system of an inertial reference frame at steady-state condition can be written as follows [16]:

where is the averaged component of the velocity vector, is the density of air, is the viscosity of air, is the gravitational body force, is the static pressure, and is the Reynolds stress terms, which will be modelled by an appropriate turbulence model.

2.2.2. Turbulence Model

The turbulence model used in this study is a k--based shear-stress transport (SST) turbulence model. The k- model consists of two transport equations of the turbulence kinetic energy (k) and turbulence frequency ( which are linked to the turbulence viscosity to determine the energy of the turbulence and the specific dissipation rate to predict the turbulence scale, and its properties are as follows [16]:

where is turbulence viscosity given as , is the production rate of turbulence, and are the buoyancy production terms in k-equation and -equation, respectively, and , and .

The k--based SST model accounts for the transport of the turbulent shear stress and gives highly accurate predictions of the onset and the amount of flow separation under adverse pressure gradients. The k--based SST turbulence model combines the advantages displayed by both k-ε and k-ω turbulence models. The k-ω turbulence model is used when solving the inner parts of the boundary layer, making the model directly usable all the way down to the wall through viscous sub-layer. A k-ε turbulence is switched when the flow behaves like a free stream away from the boundary layer. Therefore, by using k--based SST turbulence model, low Reynolds number turbulence flow can be calculated without any wall functions and prevent over-prediction of inlet free-stream turbulence properties [17].

2.2.3. Solution Procedure

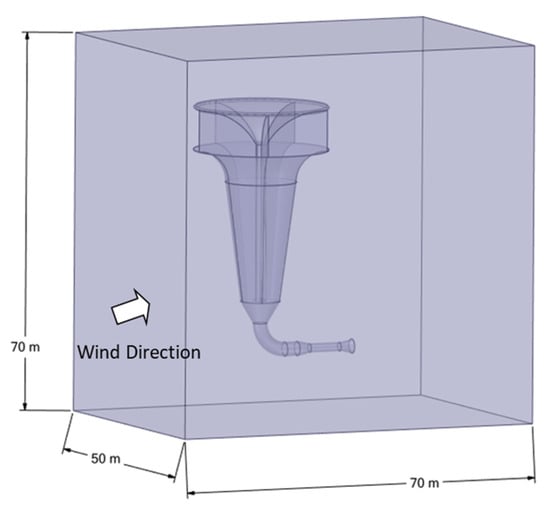

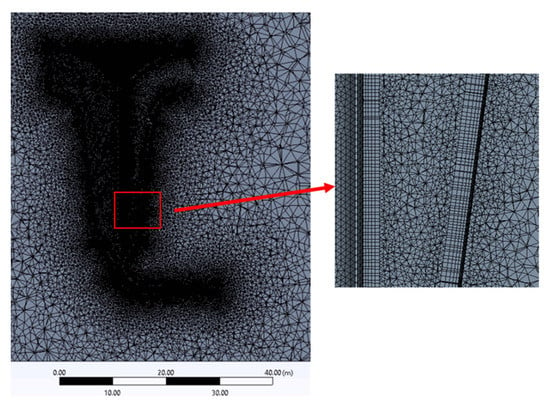

Figure 2 shows a typical flow domain used in the computations. The computational domain used in the ANSYS computations had a size of 70 m length, 50 m width, and 70 m height. The wall function is adopted for the airflow through the system. The air density is considered to be 1.225 kg/m3, and the dynamic viscosity is considered to be 1.81 × 10–5 kg/(m·s). The mesh is decreased in size, until the difference in the results is within 2%. As shown in Figure 3, the flow domain was discretized with a mesh of tetrahedral elements. In total, 2,153,969 nodes and 9,553,863 elements were used for the simulation in ANSYS CFX. Higher mesh resolution was used near the wall regions with inflation layer applied. The boundary condition is chosen as the following: wall-surface body condition is stationary wall, wall roughness is 0.5, and turbulence intensity is 5%. The convergence criterion is achieved when the variation in the speed between successive iterations is 0.1%. A constant input speed field, representing the free-stream wind, was assigned to the entire frontal plane of the flow domain. The magnitude of the speed was set at 6 m/s. The exit plane was assigned as pressure-outlet boundary condition. The reference pressure was assumed to be the atmospheric pressure throughout the domain.

Figure 2.

Dimensions of computational domain.

Figure 3.

Meshing of the omni-directional wind funnel.

3. Results and Discussions

3.1. Performance of New Omni-Directional Wind-Funnel Design

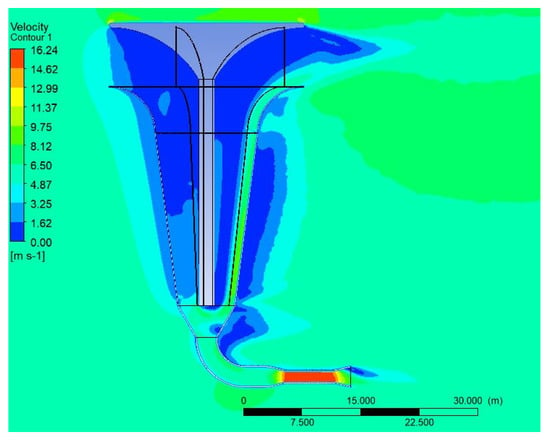

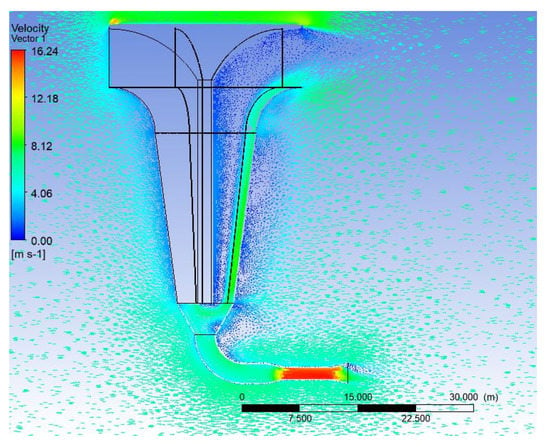

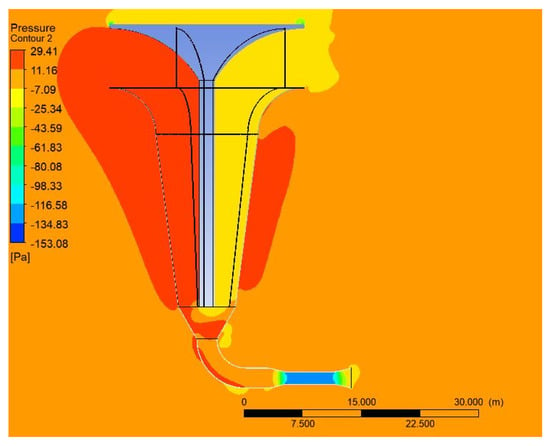

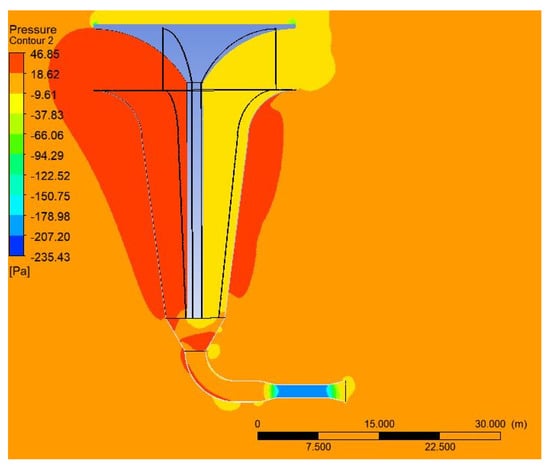

Figure 4 shows that the maximum speed of 16.24 m/s is achieved with a free-stream wind speed of 6 m/s, which leads to a 2.71-times wind-speed amplification at the venturi throat. The velocity vector and pressure distribution, as in Figure 5 and Figure 6, also show how the importance of the length of the guide vane in the current study, preventing the early escape of the inlet air flow at the opposite end and directing sufficient speed of the airflow to enter the venturi throat, create a low-pressure region at the venturi.

Figure 4.

Velocity contour of the omni-directional wind funnel.

Figure 5.

Velocity vector of the omni-directional wind funnel.

Figure 6.

Pressure distribution of the omni-directional wind funnel.

Table 2 shows the comparison with previous research of the performance of the proposed omni-directional wind funnel in terms of its speed ratio (SR). It is noted that the speed ratio (SR) obtained by the proposed omni-directional wind funnel design in this study outperforms the conventional design of INVELOX as well as other designs from previous research working on the performance enhancement of INVELOX.

Table 2.

Comparison with previous research of the performance of the proposed omni-directional wind funnel in terms of its speed ratio (SR).

Different free-stream wind speeds were tested to study their effect on the speed ratio (SR) and to understand the suitability and performance of the proposed omni-directional wind funnel in Malaysia’s low wind-speed condition. The speed ratio (SR) of the proposed omni-directional wind funnel is found to be consistent and steadily increase, i.e., 2.47–2.78 over the increase in free-stream wind speeds, i.e., 1–10 m/s, as shown in Table 3. It is noted that at the maximum wind speed in Malaysia of 5.4 m/s, it is expected to achieve output wind speed at the venturi throat of the wind funnel at 14.45 m/s.

Table 3.

Performance summary of the proposed omni-directional wind funnel in terms of its speed ratio (SR) under different inlet wind speeds.

3.2. Performance of Vibration Energy Harvester Located at Its Venturi Throat of New Omni-Directional Wind-Funnel Design

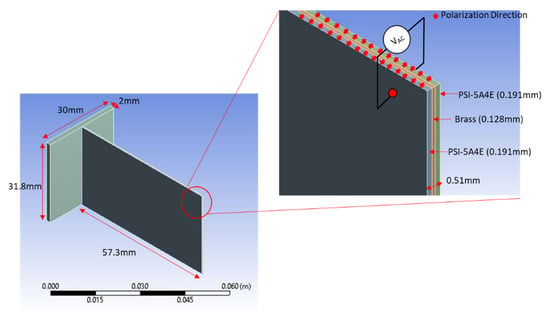

Figure 7 shows a PVEH plate with dimensions 57.3 mm × 31.8 mm × 0.51 mm fixed at a rectangular bluff splitter body (2 mm × 31.8 mm × 30 mm). The first three fundamental resonant frequencies, i.e., first bending mode, twisting mode, and second bending mode under Direct Piezoelectric Effect (DPE), when it was excited by an electrodynamic shaker, were recorded at 81 Hz, 299 Hz and 478 Hz, respectively, by amplitude-fluctuation electronic speckle pattern interferometry (AF-ESPI).

Figure 7.

Dimensions and construction of bluff splitter body and PVEH plate.

To study the electromechanical coupling piezoelectric materials voltage and power output in ANSYS, the conversion of the material properties of PZT or piezoelectric ceramic-based material is required. Based on the relation of Equations (5)–(7), the compliance matrix, permittivity at constant stress, and piezoelectric-strain matrix in mechanical, electrical, and electromechanical coupling disciplines, respectively, which are usually provided by PZT manufacturers, are converted to stiffness matrix, permittivity at constant strain, and piezoelectric stress matrix, as required by ANSYS. The full material properties are tabulated in Table 4.

where

Table 4.

Material properties of PVEH plate model.

[cE] = compliance matrix at constant electric field;

[sE] = stiffness matrix at constant electric field;

[d] = piezoelectric matrix relating strain/electric field;

[e] = piezoelectric matrix relating stress/electric field;

[εT] = dielectric matrix evaluated at constant stress;

[εS] = dielectric matrix evaluated at constant strain.

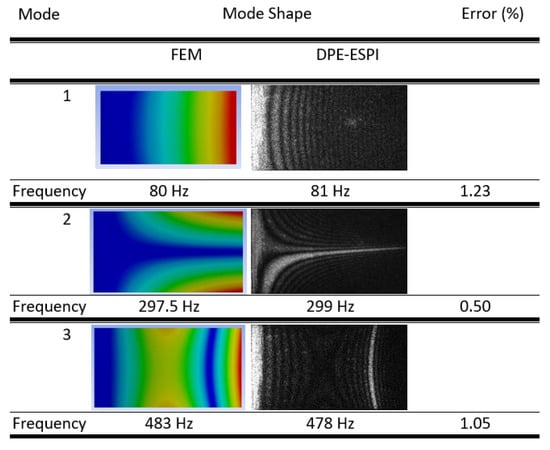

Computational modal analysis was performed on the coupled bluff splitter body and the electromechanical coupled PVEH plate. It was then by the experimental results obtained from Electronic Speckle Pattern Interferometry (ESPI). As shown in Figure 8, the Finite Element Method (FEM) computational modal analysis results show good agreement with the experimental results obtained, giving a small percentage difference ranging from 0.50% to 1.23% between the computational modal analysis and the experiment, hence, the FE model is considered experimentally validated in terms of the structural aspect.

Figure 8.

Resonant frequency and corresponding mode shape of PVEH plate under cantilevered boundary condition.

FSI simulation required the setup in the CFX module and mechanical APDL module for computational fluid and structural dynamic analyses, respectively.

The standard Reynolds stress model in ANSYS CFX is based on the -equation. The CFX-Solver solves the following equations for the transport of the Reynolds stresses [16].

where = pressure-strain correlation, is the exact production rate of turbulence, is the buoyancy production term, is the Kronecker Delta function, and = 0.22 is the Reynolds stress model constant.

One of the most important terms in Reynolds stress models is the pressure–strain correlation, since it acts to drive turbulence towards an isotropic state by redistributing the Reynolds stresses. The Speziale–Sarkar–Gatski (SSG) Reynolds stress model was developed by Speziale, Sarkar, and Gatski and uses a quadratic relation for the pressure–strain correlation. The SSG model is an approach towards the normal Reynolds stress model, which makes it more accurate for homogeneous turbulence and, subsequently, it simulates most flows, especially swirling flows, more accurately.

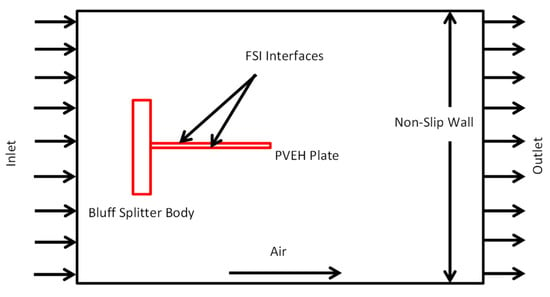

The material properties, as tabulated in Table 3, were used. The boundary of the bluff splitter body model was fixed. The surfaces of the PVEH plate model were set as fluid-structure interfaces, which allow the data exchange of fluid and structure models. FSI simulation results were used to simulate the electrical performance in terms of open-circuit voltage and short-circuit optimal power output under the electromechanical-coupling condition.

The CFD module setup is shown in Figure 9 for input wind speeds of 5 m/s, 7.4 m/s 10 m/s, 15 m/s, 20 m/s, 25 m/s, and 30 m/s at the inlet, when the outlet is set with the reference pressure of 1 atm. In this study, the SSG Reynolds stress turbulence model was applied. The total time steps set for the simulation were 600 or 0.3 s, with the time step at 5 × 10−4 s used. For each time step, a maximum of 5 iterations were used for the CFD solver and a maximum of 10 iterations were used for the FSI coupling solution, respectively.

Figure 9.

The 3D fluid domain simulation setup of coupled model of bluff splitter body and PVEH plate.

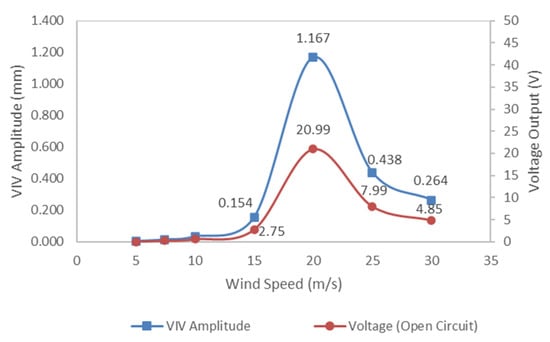

As shown in Figure 10, a bell-curve trend of vibration amplitude against wind speed is observed, in which the amplitude increases when the wind speed increases, until it reaches the peak maximum amplitude at 20 m/s wind speed, before it starts the downward trend. It could be related to the structural resonance phenomenon, in which a higher vibration amplitude is produced when the vortex frequency is close to or coincides with the resonant frequency of the model.

Figure 10.

Vibration amplitude and voltage output of the PVEH plate under different wind speeds.

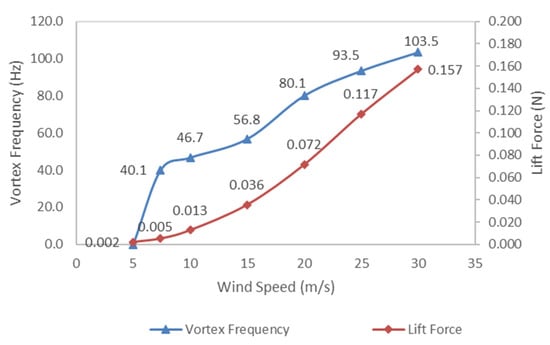

Meanwhile, Figure 11 shows that the vortex frequency increases proportionally with wind-speed magnitude. When the vortex frequency lies near or coincides with the PVEH plate’s resonant frequency, it causes structural resonance lock-in and leads to a high vortex-induced vibration amplitude of the PVEH plate.

Figure 11.

Vortex frequency and lift force created under different wind speeds.

A vortex frequency of 80.1 Hz created at 20 m/s coincides with the model’s resonant frequency of 80 Hz, and, thus, resonance happens and produces the highest VIV amplitude of 1.167 mm and a voltage output of 20.99 V. At wind speeds below 20 m/s, it is noted that the VIV amplitudes produced are low, as the vortex frequencies created are not close to the model’s resonant frequency. It is also noted that at higher wind speeds, i.e., 25 m/s and 30 m/s, which create the vortex frequencies of 93.5 Hz and 103.5 Hz, respectively, are also far away from the resonant frequency of the model, and, thus, the resonant mode contributes less to the overall vibration. Due to this, the PVEH plate is vibrating at a relatively lower VIV amplitude, i.e., 0.438 mm and 0.264 mm, as well as an open circuit voltage output, i.e., 7.99 V and 4.85 V, respectively, at these two wind speeds, despite having a higher fluctuating lift force.

Figure 11 shows that when wind speed increases, the fluctuating lift force acting on the surface of the PVEH plate also increases. It is noted that higher flow speed could induce lower pressure surrounding the region of vortex and produce higher force, which acts on the opposite of the plate’s surface. The vortex is unstable by nature and, when it achieves steady condition, it usually produces a periodical fluctuating lift force with a certain frequency. It is noted that a larger wind speed creates a higher vortex frequency because the alternating lift force is created at higher rate and acts on the PVEH plate. Figure 11 shows that higher wind speeds of 25 m/s and 30 m/s produce a larger lift force, acting on the surface of the PVEH plate. However, the vibration amplitude produced is lower compared with the vibration amplitude produced at an input wind speed of 20 m/s, because there is a mismatch between the vortex frequency created and the resonant frequency of the model. In summary, vortex-induced vibration amplitude is affected more by the vortex frequency than the fluctuating lift force.

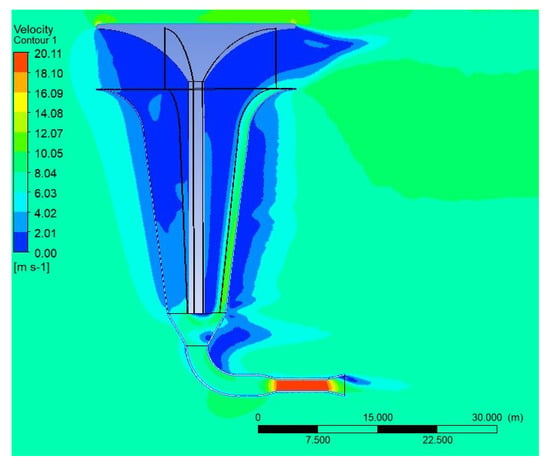

To achieve the optimum wind speed of 20 m/s at the venturi throat of the proposed omni-directional wind-funnel design, it is recommended to have the free-stream wind speed of 7.4 m/s collected at the inlet of the wind funnel. The speed ratio (SR) remains at 2.71 in this case. The velocity profile and pressure distribution results are shown in Figure 12 and Figure 13.

Figure 12.

Velocity profile of the omni-directional wind funnel with free-stream wind speed of 7.4 m/s.

Figure 13.

Pressure distribution of the omni-directional wind funnel with free-stream wind speed of 7.4 m/s.

If the coupled bluff splitter body and PVEH plate are placed directly at a low free-stream wind speed of 7.4 m/s, it is noted from the electromechanical coupling FSI simulation that the maximum VIV amplitude at the tip of the PVEH plate achieves only 0.012 mm, and the generated voltage output is also insignificant, i.e., 0.22 V. Meanwhile, if the coupled bluff splitter body and PVEH plate are placed at the venturi throat of the proposed wind funnel, it is observed that the same low free-stream wind speed of 7.4 m/s could amplify the wind speed at the venturi throat to 20 m/s, and this is expected to produce the maximum VIV amplitude at the tip of the PVEH plate at 1.167 mm, which is equivalent to the open-circuit voltage output of 20.99 V at 80 Hz.

The electromechanical coupling FSI simulation was repeated with a load-resistance condition. The value of the load resistance showed some effect on the vibrational characteristics of the PVEH, including the vibration amplitude and the resonant frequency [18]. The first resonant frequency has dropped to 76.79 Hz at adjusted optimal load resistance . At 20 m/s wind speed, the vortex frequency of 76.79 Hz is created, and, thus, the maximum power output under this optimal load resistance is generated. It is noted that the VIV amplitude is recorded at 0.351 mm, and the maximum power output at wind speed of 20 m/s is 0.82 mW, with a voltage output of 4.96 V.

It is noted that the 7.4 m/s wind speed is still considered high in Malaysia. By considering the wind condition in Malaysia, i.e., a maximum wind speed at 5.4 m/s, the coupled bluff splitter body and PVEH plate may need to be re-designed or fine-tuned to lower down its natural frequency, by either adding tip mass or adjusting the length of the PVEH plate, so it matches the vortex frequency created at the venturi throat at 14.45 m/s. Based on another electromechanical coupling FSI simulation conducted, when the natural frequency of the coupled bluff splitter body and PVEH plate is lowered down to 56.73 Hz, by adding a tip mass of 1.25 g, it matches with the vortex frequency created at 56.71 Hz and, thus, produces the maximum VIV amplitude at the tip of the PVEH plate at 0.645 mm, equivalent to an open-circuit voltage output of 11.42 V. This shows a significant improvement of 323% by achieving resonance condition at 56.71 Hz through VIV, as compared with the original design of the coupled bluff splitter body and PVEH plate without a tip mass, which can only achieve approximately 0.15 mm of tip displacement and an open-circuit voltage output of 2.7 V, if it is placed under a 14.5 m/s wind speed, as shown in Figure 10.

In summary, the maximum power output of the PVEH does not appear at the maximum vibrational displacement, as recorded during the open-circuit condition. The optimal load resistance value is computed based on the assumption that the vibration amplitude is independent of the externally connected load resistor. However, it is worth mentioning that under the electromechanical coupling FSI analysis, the load resistance value changes the fundamental resonant frequency and vibration amplitude, and this subsequently changes the optimal load resistance computation. Maximum power output could be obtained with the adjusted or through the impedance analysis.

4. Conclusions

An alternate renewable energy source through a vortex-induced vibration energy harvester coupled with a bluff splitter body could lead to higher energy conversion efficiency, by achieving near resonance condition through vortex-induced vibration. This study, inspired by the INVELOX design, integrates a newly designed omni-directional wind funnel and a coupled bluff splitter body and PVEH plate, in which the wind funnel is modified in terms of the length of each guide vane, the number of guide vanes, the elbow diameter, and the ratio of the diameter of the intake to venturi is effectively capturing wind from all directions, tunnelling it through the convergent–divergent nozzle to increase the wind speed at its venturi throat, where the coupled bluff splitter body and PVEH plate are located, with the aim to fulfil the task of VIV energy harvesting by achieving near resonance condition at 80 Hz at 20 m/s wind speed, with a vortex frequency of 80.13 Hz. It is found that the proposed design could achieve 2.71-times wind-speed amplification at the venturi throat. It is noted that the speed ratio (SR) obtained by the proposed omni-directional wind funnel design in this study outperforms the conventional design of INVELOX, as well as other designs from previous research working on the performance enhancement of INVELOX. To achieve the optimum wind speed of 20 m/s for the coupled bluff splitter body and PVEH plate at the venturi throat of the proposed omni-directional wind-funnel design, it is recommended to have a low free-stream wind speed of 7.4 m/s collected at the inlet of the wind funnel. The integration of the PVEH plate and the wind funnel is expected to harvest greater voltage output (i.e., 9440% enhancement) at 20.99 V or with a maximum power output of 0.82 mW.

Author Contributions

Z.C.O. and K.K.K., initiated the study and were involved in the design and numerical simulations. Y.-H.H. was involved in the experimental set-up and conducted the experiments. All authors were involved in the analysis of simulation and experimental results and writing and revising the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by SATU Joint Research University Grant (ST020-2020), Ministry of Science and Technology, Republic of China (Taiwan) Research Grant (MOST 107-2221-E-002-192-MY3) and private funding by SD Advance Engineering Sdn Bhd (PV032-2018).

Acknowledgments

The authors wish to acknowledge the financial support and advice given by a SATU Joint Research University Grant (ST020-2020), Ministry of Science and Technology, Republic of China (Taiwan) Research Grant (MOST 107-2221-E-002-192-MY3), private funding by SD Advance Engineering Sdn Bhd (PV032-2018), the Advanced Shock and Vibration Research (ASVR) Group of Universiti Malaya, and other project collaborators.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Energy Commission, Energy Malaysia: Towards A World Class Energy Sector. Available online: https://www.st.gov.my/en/general/add_counter/851/download/read_count (accessed on 26 July 2022).

- Energy Commission, Annual Report 2020. Available online: https://www.st.gov.my/en/general/add_counter/848/download/read_count (accessed on 26 July 2022).

- Oh, T.H.; Pang, S.Y.; Chua, S.C. Energy policy and alternative energy in Malaysia: Issues and challenges for sustainable growth. Renew. Sustain. Energy Rev. 2010, 14, 1241–1252. [Google Scholar] [CrossRef]

- Irwanto, M.; Gomesh, N.; Mamat, M.; Yusoff, Y. Assessment of wind power generation potential in Perlis, Malaysia. Renew. Sustain. Energy Rev. 2014, 38, 296–308. [Google Scholar] [CrossRef]

- Siti, M.R.; Norizah, M.; Syafrudin, M. The Evaluation of Wind Energy Potential in Peninsular Malaysia. Int. J. Chem. Environ. Eng. 2011, 2, 284–291. [Google Scholar]

- Akorede, M.F.; Mohd Rashid, M.I.; Sulaiman, M.H.; Mohamed, N.B.; Ab Ghani, S.B. Appraising the viability of wind energy conversion system in the Peninsular Malaysia. Energy Convers. Manag. 2013, 76, 801–810. [Google Scholar] [CrossRef]

- Chin, W.K.; Ong, Z.C.; Kong, K.K.; Khoo, S.Y.; Huang, Y.-H.; Chong, W.T. Enhancement of Energy Harvesting Performance by a Coupled Bluff Splitter Body and PVEH Plate through Vortex Induced Vibration near Resonance. Appl. Sci. 2017, 7, 921. [Google Scholar] [CrossRef]

- Allaei, D.; Andreopoulos, Y. INVELOX: Description of a new concept in wind power and its performance evaluation. Energy 2014, 69, 336–344. [Google Scholar] [CrossRef]

- Anbarsooz, M.; Hesam, M.S.; Moetakef-Imani, B. Numerical study on the geometrical parameters affecting the aerodynamic performance of Invelox. IET Renew. Power Gener. 2017, 11, 791–798. [Google Scholar] [CrossRef]

- Anbarsooz, M.; Amiri, M.; Rashidi, I. A novel curtain design to enhance the aerodynamic performance of Invelox: A steady-RANS numerical simulation. Energy 2019, 168, 207–221. [Google Scholar] [CrossRef]

- Gohar, G.A.; Manzoor, T.; Ahmad, A.; Hameed, Z.; Saleem, F.; Ahmad, I.; Sattar, A.; Arshad, A. Design and comparative analysis of an INVELOX wind power generation system for multiple wind turbines through computational fluid dynamics. Adv. Mech. Eng. 2019, 11, 1687814019831475. [Google Scholar] [CrossRef]

- Sotoudeh, F.; Kamali, R.; Mousavi, S.M. Field tests and numerical modeling of INVELOX wind turbine application in low wind speed region. Energy 2019, 181, 745–759. [Google Scholar] [CrossRef]

- Hosseini, S.R.; Ganji, D.D. A novel design of nozzle-diffuser to enhance performance of INVELOX wind turbine. Energy 2020, 198, 117082. [Google Scholar] [CrossRef]

- Ding, L. Study of Invelox Wind Turbine Considering Atmospheric Boundary Layer: Based on Numerical Simulation. J. Phys. Conf. Ser. 2020, 1600, 012063. [Google Scholar] [CrossRef]

- Nardecchia, F.; Groppi, D.; Astiaso Garcia, D.; Bisegna, F.; de Santoli, L. A new concept for a mini ducted wind turbine system. Renew. Energy 2021, 175, 610–624. [Google Scholar] [CrossRef]

- ANSYS. ANSYS CFX-Solver Theory Guide, ANSYS Manual; Release 14.0; ANSYS, Inc.: Canonsburg, PE, USA, 2011. [Google Scholar]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Zhu, M.; Worthington, E.; Njuguna, J. Analyses of power output of piezoelectric energy-harvesting devices directly connected to a load resistor using a coupled piezoelectric-circuit finite element method. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 1309–1317. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).