Performance Evaluation of Lateritic Subgrade Soil Treated with Lime and Coir Fibre-Activated Carbon

Abstract

1. Introduction

2. Laboratory Investigations

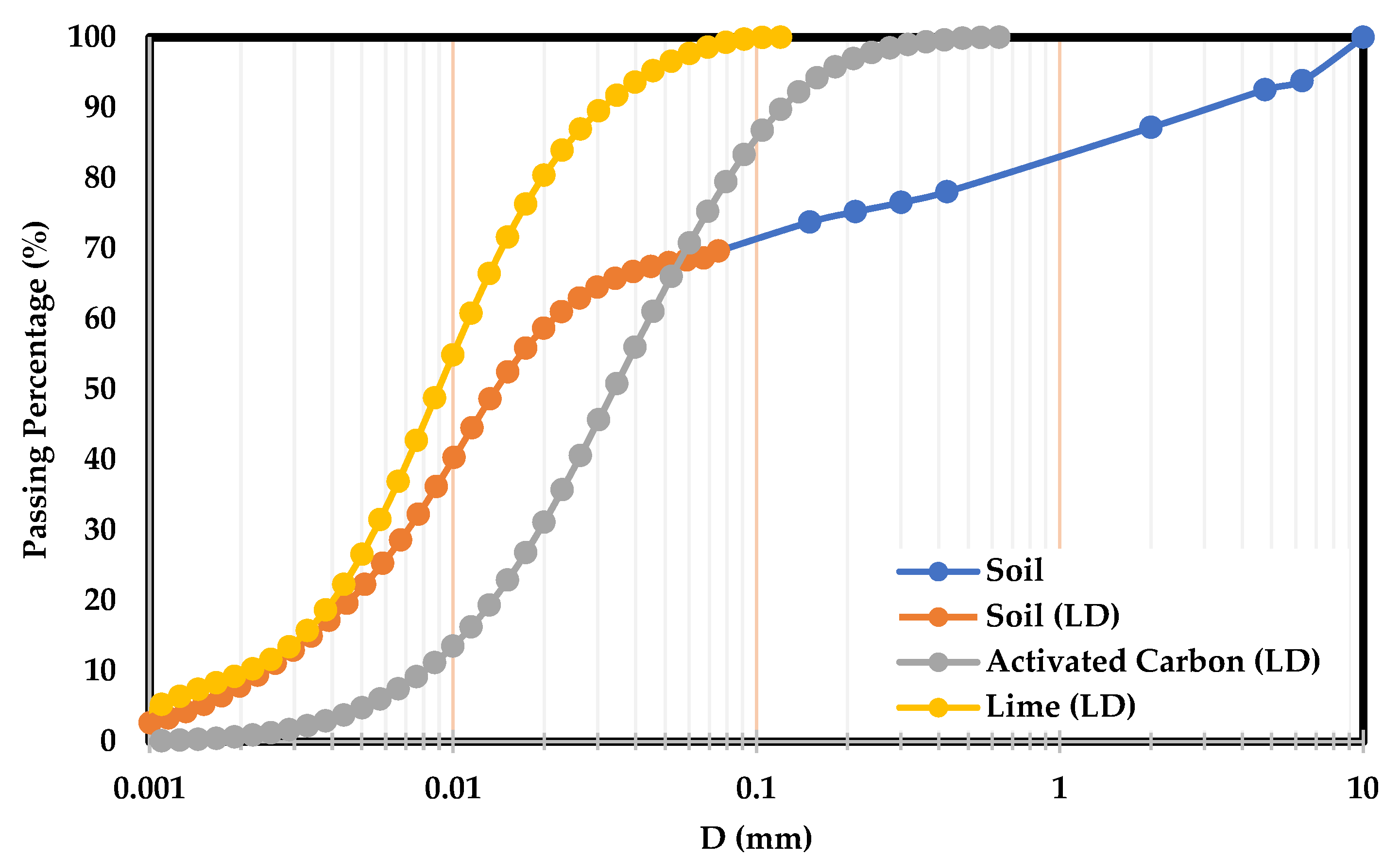

2.1. Materials

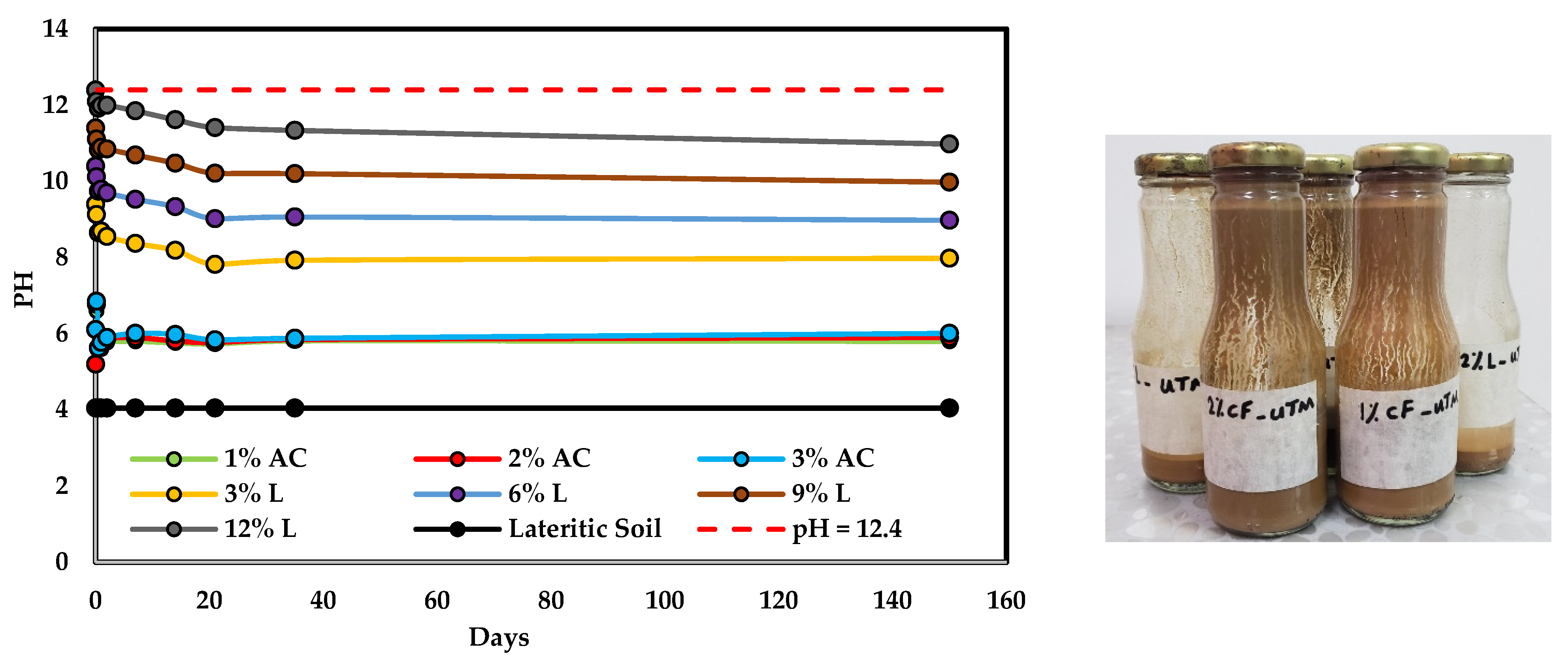

2.2. pH Test

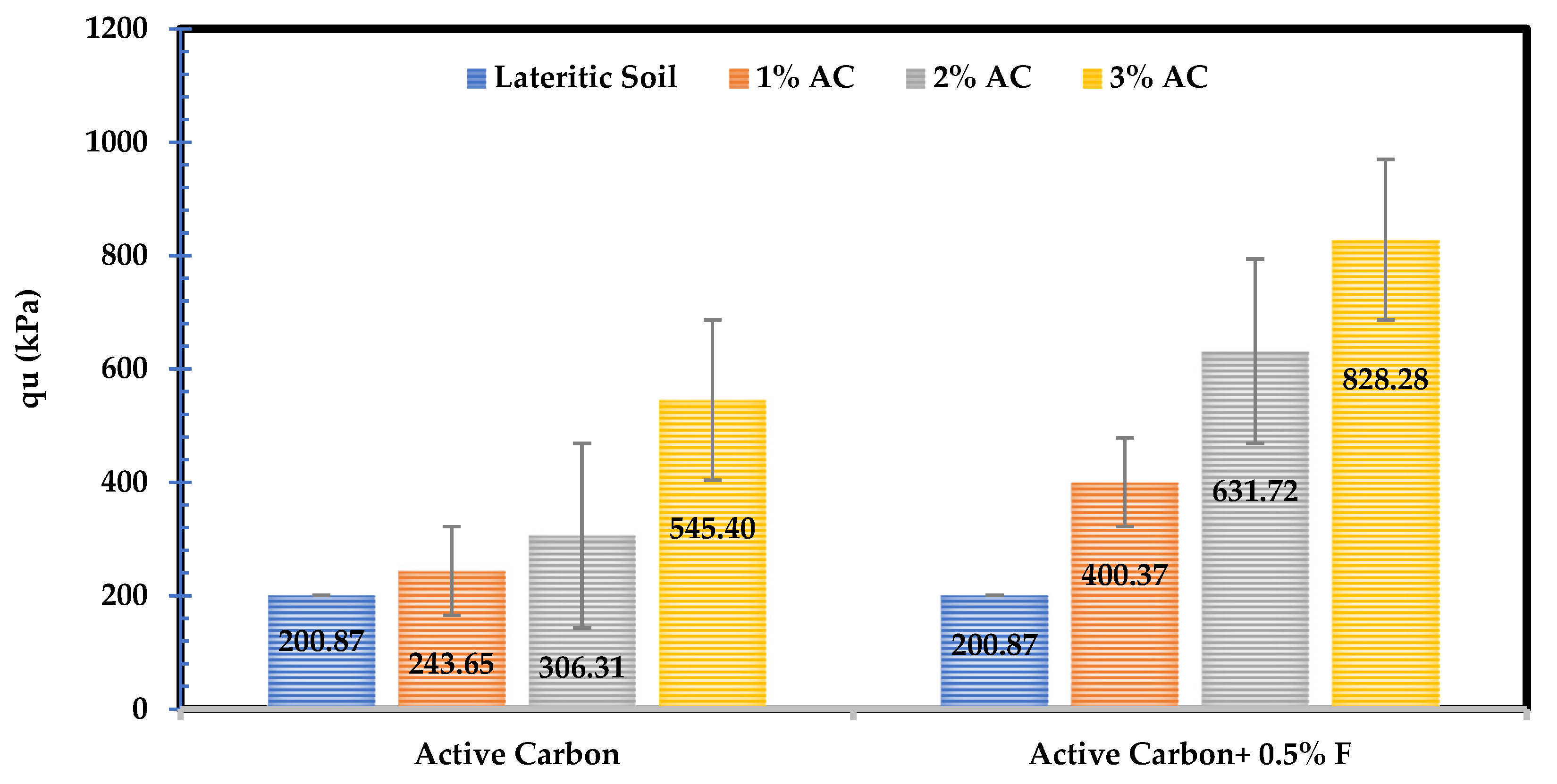

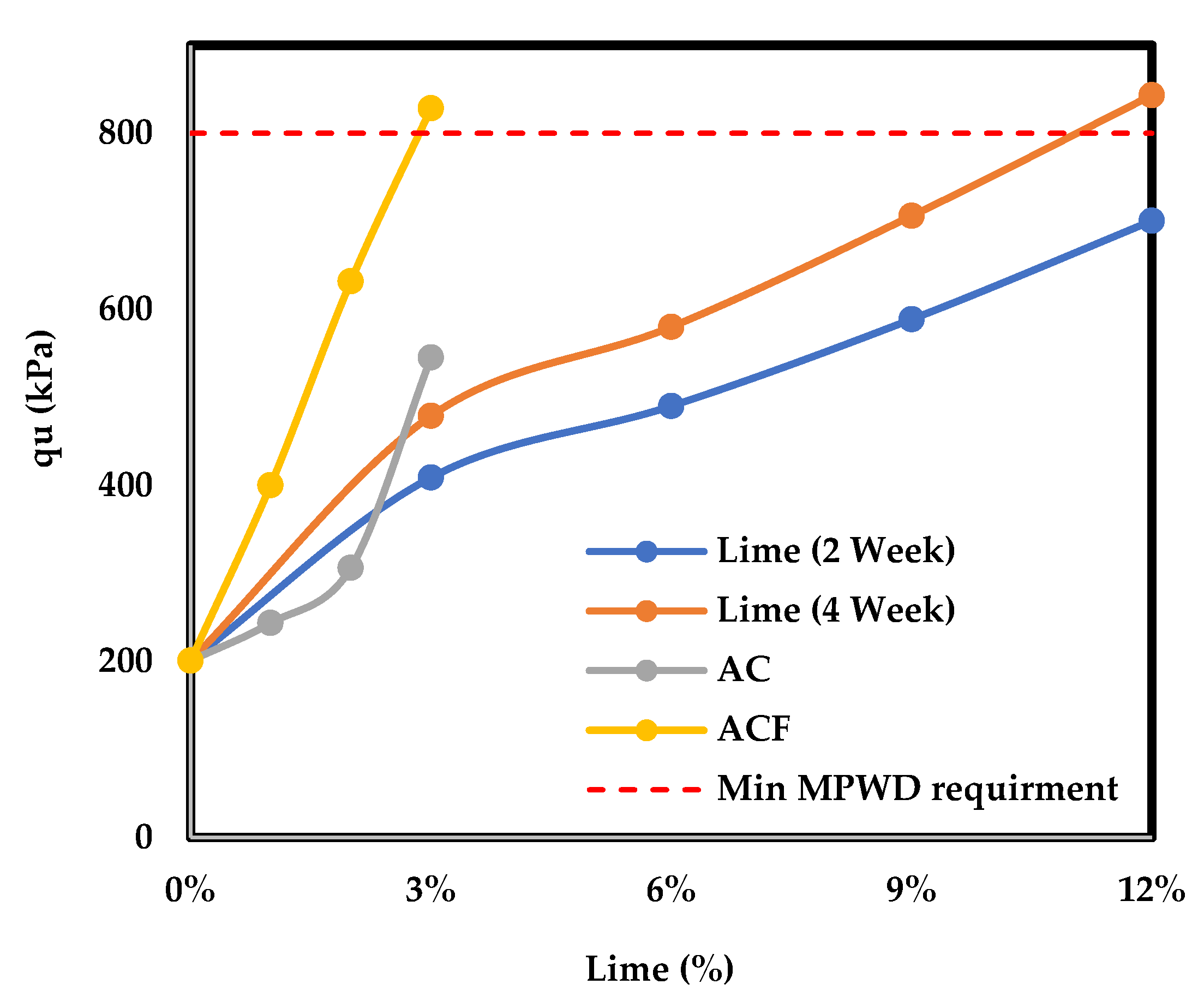

2.3. Unconfined Compressive Strength Test

2.4. One-Dimensional Consolidation Test

2.5. Microstructural Analysis

2.6. Surface Area Analysis (BET)

3. Test Results and Discussion

3.1. pH

3.2. Unconfined Compression Strength

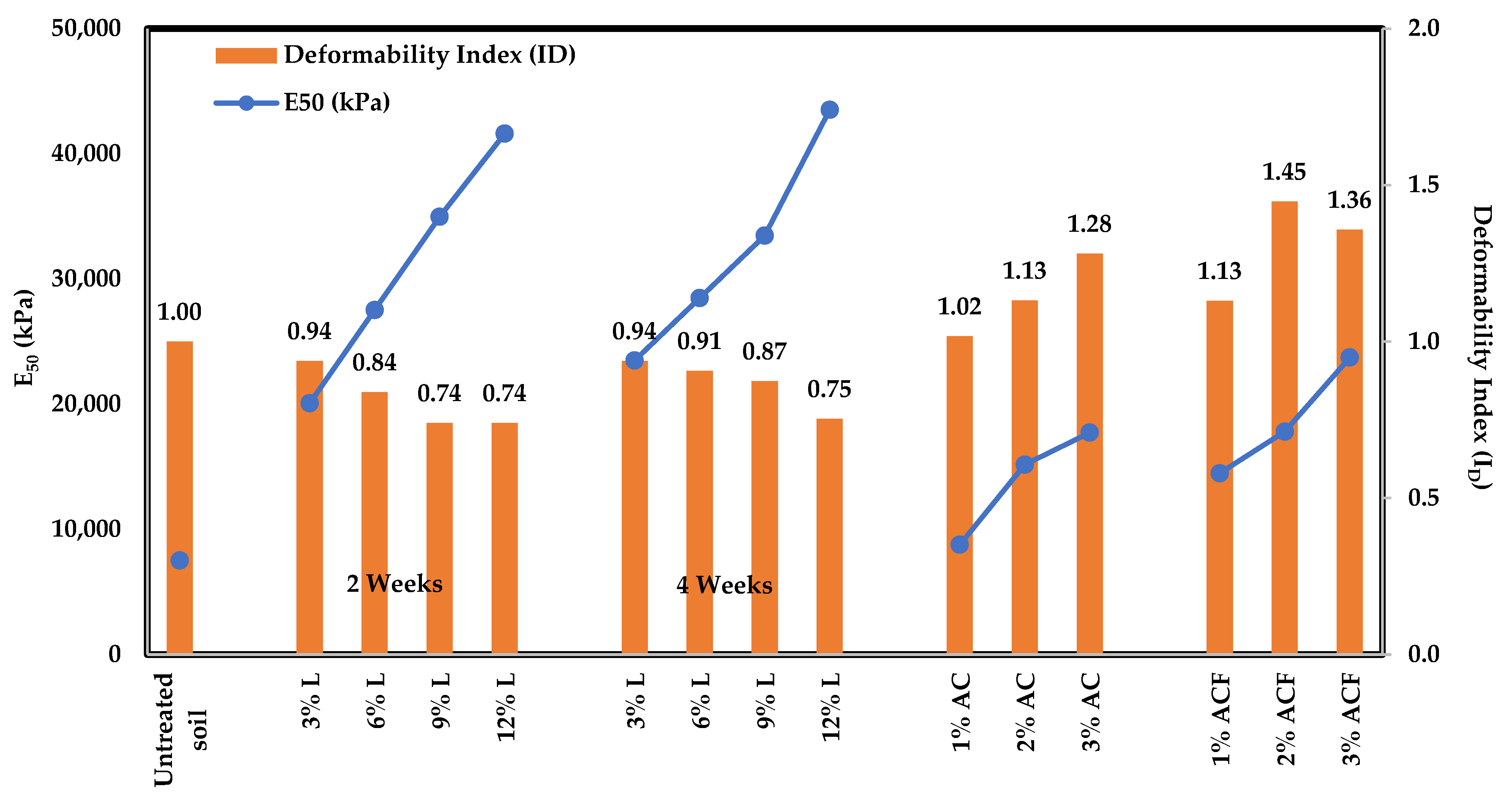

3.3. Deformability Index (ID) and Elastic Modulus (E50)

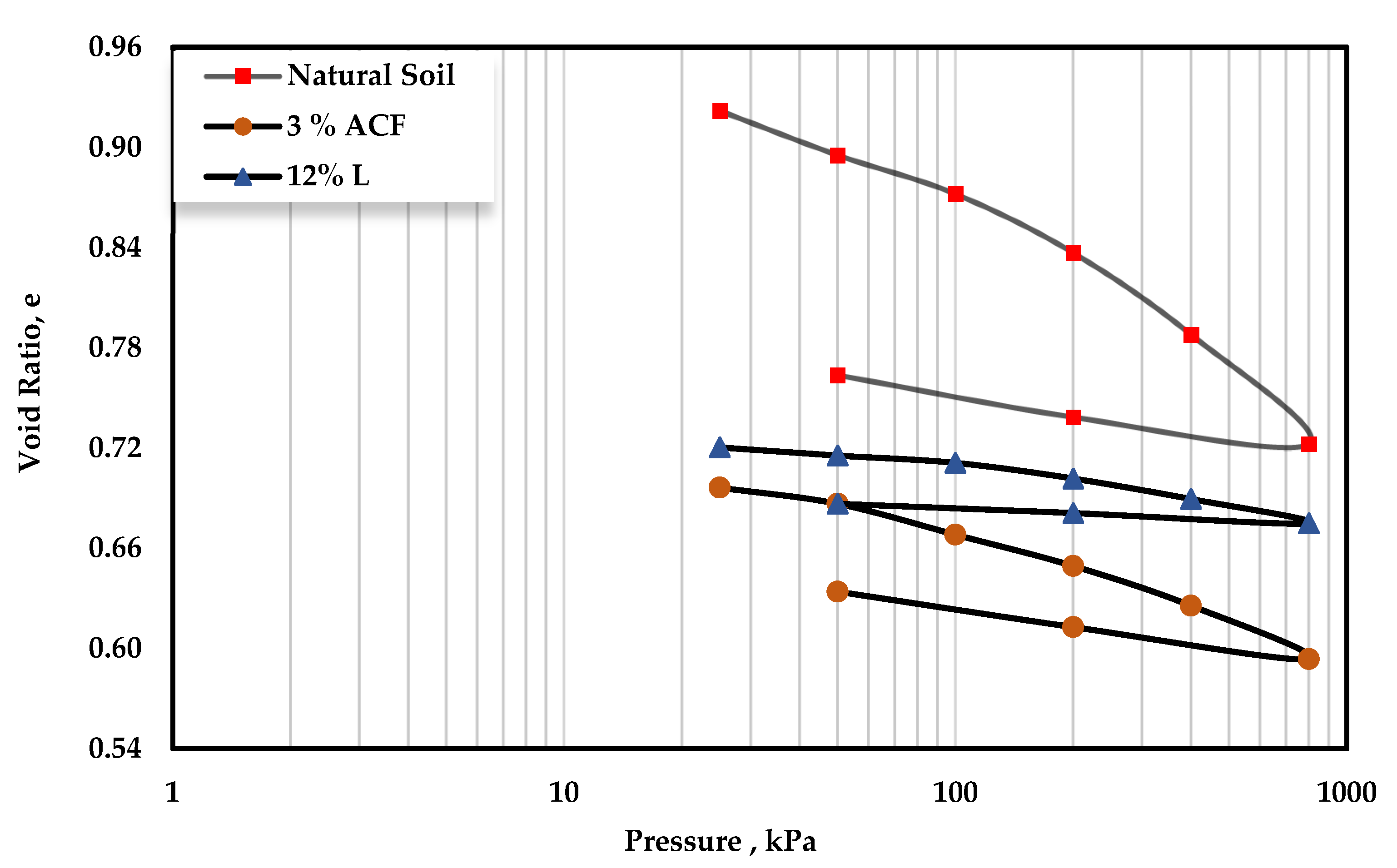

3.4. One-Dimensional Consolidation

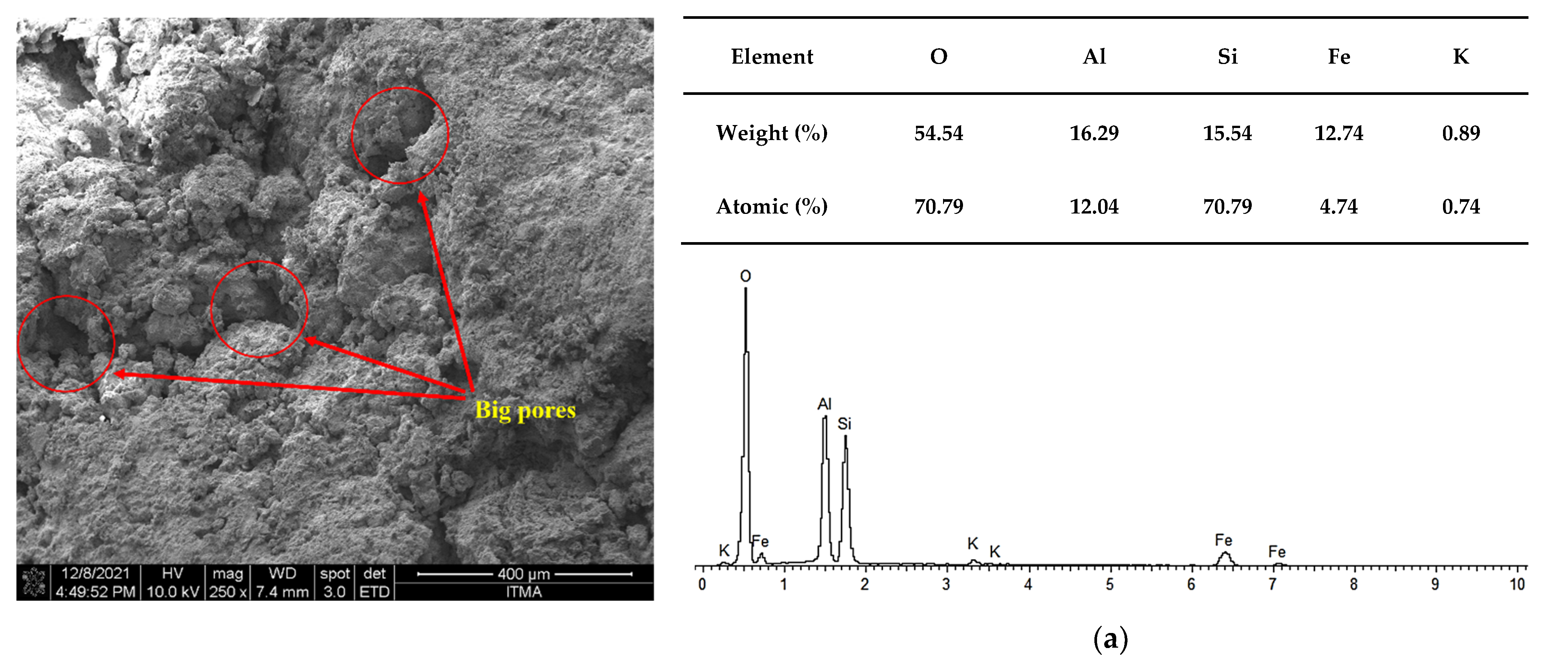

3.5. Microstructural Analysis

3.6. Surface Area Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roshan, M.J.; Rashid, A.S.A.; Wahab, N.A.; Hezmi, M.A.; Jusoh, S.N.; Azmi, M. Stability of Railway Embankment in Saturated and Unsaturated Conditions. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1153, 012007. [Google Scholar] [CrossRef]

- Roshan, M.J.; Rashid, A.S.A.; Abdul Wahab, N.; Tamassoki, S.; Jusoh, S.N.; Hezmi, M.A.; Nik Daud, N.N.; Mohd Apandi, N.; Azmi, M. Improved Methods to Prevent Railway Embankment Failure and Subgrade Degradation: A Review. Transp. Geotech. 2022, 37, 100834. [Google Scholar] [CrossRef]

- Ta’negonbadi, B.; Noorzad, R. Physical and Geotechnical Long-Term Properties of Lignosulfonate-Stabilized Clay: An Experimental Investigation. Transp. Geotech. 2018, 17, 41–50. [Google Scholar] [CrossRef]

- Pooni, J.; Robert, D.; Giustozzi, F.; Setunge, S.; Xie, Y.M.; Xia, J. Novel Use of Calcium Sulfoaluminate (CSA) Cement for Treating Problematic Soils. Constr. Build. Mater. 2020, 260, 120433. [Google Scholar] [CrossRef]

- Wahab, N.A.; Rashid, A.S.A.; Roshan, M.J.; Rizal, N.H.A.; Yunus, N.Z.M.; Hezmi, M.A.; Tadza, M.Y.M. Effects of Cement on the Compaction Properties of Lateritic Soil. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1153, 012015. [Google Scholar] [CrossRef]

- Billong, N.; Melo, U.C.; Louvet, F.; Njopwouo, D. Properties of Compressed Lateritic Soil Stabilized with a Burnt Clay–Lime Binder: Effect of Mixture Components. Constr. Build. Mater. 2009, 23, 2457–2460. [Google Scholar] [CrossRef]

- Su, L.; Zhou, L.; Zhang, X.; Ling, X. Experimental and Numerical Modeling on Liquefaction Resistance of Geotextile Reinforced Sand. Soil Dyn. Earthq. Eng. 2022, 159, 107345. [Google Scholar] [CrossRef]

- Tamassoki, S.; Moayed, R.Z.; Ashkani, M.; Rahimi, H. Scale Effect on the Shear Strength of Two-Layer Soil Reinforced by Geogrid. Malays. J. Civ. Eng. 2018, 30, 113–127. [Google Scholar] [CrossRef][Green Version]

- Chen, R.P.; Wang, Y.W.; Ye, X.W.; Bian, X.C.; Dong, X.P. Tensile Force of Geogrids Embedded in Pile-Supported Reinforced Embankment: A Full-Scale Experimental Study. Geotext. Geomembr. 2016, 44, 157–169. [Google Scholar] [CrossRef]

- Mypati, V.N.K.; Saride, S. Feasibility of Alkali-Activated Low-Calcium Fly Ash as a Binder for Deep Soil Mixing. J. Mater. Civ. Eng. 2022, 34, 04021410. [Google Scholar] [CrossRef]

- Ahmad, A.S.; Black, J.A.; Kueh, A.B.H.; Md Noor, N. Behaviour of Weak Soils Reinforced with Soil Cement Columns Formed by the Deep Mixing Method: Rigid and Flexible Footings. Measurement 2015, 68, 262–279. [Google Scholar] [CrossRef]

- Muhammed, J.J.; Jayawickrama, P.W.; Teferra, A.; Özer, M.A. Settlement of a Railway Embankment on PVD-Improved Karakore Soft Alluvial Soil. Eng. Sci. Technol. Int. J. 2020, 23, 1015–1027. [Google Scholar] [CrossRef]

- Arivalagan, J.; Indraratna, B.; Rujikiatkamjorn, C.; Warwick, A. Effectiveness of a Geocomposite-PVD System in Preventing Subgrade Instability and Fluidisation under Cyclic Loading. Geotext. Geomembr. 2022, 50, 607–617. [Google Scholar] [CrossRef]

- Petry, T.M.; Little, D.N. Review of Stabilization of Clays and Expansive Soils in Pavements and Lightly Loaded Structures—History, Practice, and Future. J. Mater. Civ. Eng. 2002, 14, 447–460. [Google Scholar] [CrossRef]

- Behnood, A. Soil and Clay Stabilization with Calcium- and Non-Calcium-Based Additives: A State-of-the-Art Review of Challenges, Approaches and Techniques. Transp. Geotech. 2018, 17, 14–32. [Google Scholar] [CrossRef]

- Rosone, M.; Ferrari, A.; Celauro, C. On the Hydro-Mechanical Behaviour of a Lime-Treated Embankment during Wetting and Drying Cycles. Geomech. Energy Environ. 2018, 14, 48–60. [Google Scholar] [CrossRef]

- Osinubi, K.J.; Ijmdiya, T.S.; Nmadu, I. Lime Stabilization of Black Cotton Soil Using Bagasse Ash as Admixture in Advanced Materials Research; Trans Tech Publications: Schwyz, Switzerland, 2009; Volume 62–64, pp. 3–10. [Google Scholar]

- Hamidi, A.; Hooresfand, M. Effect of Fiber Reinforcement on Triaxial Shear Behavior of Cement Treated Sand. Geotext. Geomembr. 2013, 36, 1–9. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A Simple Review of Soil Reinforcement by Using Natural and Synthetic Fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, D. Behavior of Cement-Stabilized Fiber-Reinforced Pond Ash, Rice Husk Ash-Soil Mixtures. Geotext. Geomembr. 2016, 44, 466–474. [Google Scholar] [CrossRef]

- Jamsawang, P.; Voottipruex, P.; Horpibulsuk, S. Flexural Strength Characteristics of Compacted Cement-Polypropylene Fiber Sand. J. Mater. Civ. Eng. 2015, 27, 04014243. [Google Scholar] [CrossRef]

- Narani, S.S.; Abbaspour, M.; Mir Mohammad Hosseini, S.M.; Moghadas Nejad, F. Long-Term Dynamic Behavior of a Sandy Subgrade Reinforced by Waste Tire Textile Fibers (WTTFs). Transp. Geotech. 2020, 24, 100375. [Google Scholar] [CrossRef]

- Ranjan, G.; Vasan, R.M.; Charan, H.D. Behaviour of Plastic-Fibre-Reinforced Sand. Geotext. Geomembr. 1994, 13, 555–565. [Google Scholar] [CrossRef]

- Ramkrishnan, R.; Sruthy, M.R.; Sharma, A.; Karthik, V. Effect of Random Inclusion of Sisal Fibres on Strength Behavior and Slope Stability of Fine Grained Soils. Mater. Today Proc. 2018, 5, 25313–25322. [Google Scholar] [CrossRef]

- Kravchenko, E.; Liu, J.; Krainiukov, A.; Chang, D. Dynamic Behavior of Clay Modified with Polypropylene Fiber under Freeze-Thaw Cycles. Transp. Geotech. 2019, 21, 100282. [Google Scholar] [CrossRef]

- Praveen, G.V.; Kurre, P. Influence of Coir Fiber Reinforcement on Shear Strength Parameters of Cement Modified Marginal Soil Mixed with Fly Ash. Mater. Today Proc. 2020, 39, 504–507. [Google Scholar] [CrossRef]

- Boz, A.; Sezer, A.; Özdemir, T.; Hızal, G.E.; Azdeniz Dolmacı, Ö. Mechanical Properties of Lime-Treated Clay Reinforced with Different Types of Randomly Distributed Fibers. Arab. J. Geosci. 2018, 11, 122. [Google Scholar] [CrossRef]

- Kafodya, I.; Okonta, F. Effects of Natural Fiber Inclusions and Pre-Compression on the Strength Properties of Lime-Fly Ash Stabilised Soil. Constr. Build. Mater. 2018, 170, 737–746. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Syamsir, A.; Huat, B.B.K. Three Point Bending Flexural Strength of Cement Treated Tropical Marine Soil Reinforced by Lime Treated Natural Fiber. Measurement 2017, 111, 158–166. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, P.; Li, X.; Lin, H.; Liu, Y.; Yuan, H. Behavior of Fiber-Reinforced and Lime-Stabilized Clayey Soil in Triaxial Tests. Appl. Sci. 2019, 9, 900. [Google Scholar] [CrossRef]

- Jairaj, C.; Prathap Kumar, M.T.; Ramesh, H.N. Effect of Addition of Lime on Coir Fiber Admixed BC Soil. Innov. Infrastruct. Solut. 2020, 5, 49. [Google Scholar] [CrossRef]

- Lenoir, T.; Preteseille, M.; Ricordel, S. Contribution of the Fiber Reinforcement on the Fatigue Behavior of Two Cement-Modified Soils. Int. J. Fatigue 2016, 93, 71–81. [Google Scholar] [CrossRef]

- Ghadakpour, M.; Choobbasti, A.J.; Kutanaei, S.S. Investigation of the Kenaf Fiber Hybrid Length on the Properties of the Cement-Treated Sandy Soil. Transp. Geotech. 2020, 22, 100301. [Google Scholar] [CrossRef]

- Sarkar, J.K.; Wang, Q. Different Pyrolysis Process Conditions of South Asian Waste Coconut Shell and Characterization of Gas, Bio-Char, and Bio-Oil. Energies 2020, 13, 1970. [Google Scholar] [CrossRef]

- Siengchum, T.; Isenberg, M.; Chuang, S.S.C. Fast Pyrolysis of Coconut Biomass—An FTIR Study. Fuel 2013, 105, 559–565. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent Developments in Chemical Modification and Characterization of Natural Fiber-Reinforced Composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, And Biocomposites; Mohanty, A.K., Misra, M., Drzal, L.T., Eds.; CRC Press: Boca Raton, FL, USA, 2005; ISBN 9780849317415. [Google Scholar]

- Tamassoki, S.; Norsyahariati, N.; Daud, N.; Jakarni, F.M.; Kusin, F.M.; Safuan, A.; Rashid, A.; Roshan, M.J. Compressive and Shear Strengths of Coir Fibre Reinforced Activated Carbon Stabilised Lateritic Soil. Sustainability 2022, 14, 9100. [Google Scholar] [CrossRef]

- Al-Soudany, K.; Al-Gharbawi, A.; Al-Noori, M. Improvement of Clayey Soil Characteristics by Using Activated Carbon. In MATEC Web of Conferences, Proceedings of the 3rd International Conference on Buildings, Construction and Environmental Engineering, BCEE3-2017, Sharm El Shiekh, Egypt, 23–25 October 2017; EDP Sciences: Paris, France, 2018; Volume 162, p. 1009. [Google Scholar]

- Anirudhan, T.S.; Sreekumari, S.S.; Bringle, C.D. Removal of Phenols from Water and Petroleum Industry Refinery Effluents by Activated Carbon Obtained from Coconut Coir Pith. Adsorption 2009, 15, 439–451. [Google Scholar] [CrossRef]

- Furuya, E.G.; Chang, H.T.; Miura, Y.; Noll, K.E. A Fundamental Analysis of the Isotherm for the Adsorption of Phenolic Compounds on Activated Carbon. Sep. Purif. Technol. 1997, 11, 69–78. [Google Scholar] [CrossRef]

- Lee, C.S.; Ong, Y.L.; Aroua, M.K.; Daud, W.M.A.W. Impregnation of Palm Shell-Based Activated Carbon with Sterically Hindered Amines for CO2 Adsorption. Chem. Eng. J. 2013, 219, 558–564. [Google Scholar] [CrossRef]

- El-Shafey, E.I.; Ali, S.N.F.; Al-Busafi, S.; Al-Lawati, H.A.J. Preparation and Characterization of Surface Functionalized Activated Carbons from Date Palm Leaflets and Application for Methylene Blue Removal. J. Environ. Chem. Eng. 2016, 4, 2713–2724. [Google Scholar] [CrossRef]

- AASHTO M 145-1991 R2004 Classification of Soils & Soil-Aggregate Mixtures for Highway Construction Purposes FEISMO.COM Web Standards-Based Platform. Available online: https://feismo.com/doc-viewer (accessed on 10 August 2022).

- Mengue, E.; Mroueh, H.; Lancelot, L.; Eko, R.M. Mechanical Improvement of a Fine-Grained Lateritic Soil Treated with Cement for Use in Road Construction. J. Mater. Civ. Eng. 2017, 29, 4017206. [Google Scholar] [CrossRef]

- Wanogho, S.; Gettinby, G.; Caddy, B. Particle-Size Distribution Analysis of Soils Using Laser Diffraction. Forensic Sci. Int. 1987, 33, 117–128. [Google Scholar] [CrossRef]

- Ullah, R.; Abdullah, R.A.; Kassim, A.; Yunus, N.Z.M.; Ullah, A.; Junaid, M.; Roshan, M.J. Effectiveness of Laser Diffraction Method for Particle Size Evaluation of Residual Soil. Indian Geotech. J. 2022, 2022, 1–11. [Google Scholar] [CrossRef]

- Chada, N.; Romanos, J.; Hilton, R.; Suppes, G.; Burress, J.; Pfeifer, P. Activated Carbon Monoliths for Methane Storage. In Proceedings of the APS March Meeting 2012, Boston, MA, USA, 27 February–2 March 2012; Volume 57, pp. W12–W33. [Google Scholar]

- British Standards Institution. British Standard Methods of Test for Soils for Civil Engineering Purposes; British Standards Institution: Milton Keynes, UK, 1990; ISBN 9780580176920. [Google Scholar]

- Dhar, S.; Hussain, M. The Strength Behaviour of Lime-Stabilised Plastic Fibre-Reinforced Clayey Soil. Road Mater. Pavement Des. 2019, 20, 1757–1778. [Google Scholar] [CrossRef]

- Salimi, M.; Ghorbani, A. Mechanical and Compressibility Characteristics of a Soft Clay Stabilized by Slag-Based Mixtures and Geopolymers. Appl. Clay Sci. 2020, 184, 105390. [Google Scholar] [CrossRef]

- Eisazadeh, A.; Kassim, K.A.; Nur, H. Morphology and BET Surface Area of Phosphoric Acid Stabilized Tropical Soils. Eng. Geol. 2013, 154, 36–41. [Google Scholar] [CrossRef]

- Cristelo, N.; Fernández-Jiménez, A.; Vieira, C.; Miranda, T.; Palomo, Á. Stabilisation of Construction and Demolition Waste with a High Fines Content Using Alkali Activated Fly Ash. Constr. Build. Mater. 2018, 170, 26–39. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior; John Wiley & Sons: Hoboken, NY, USA, 2005; Volume 3. [Google Scholar]

- Rauch, A.F.; Katz, L.E.; Liljestrand, H.M. An Analysis of the Mechanisms and Efficacy of Three Liquid Chemical Soil Stabilizers; Center for Transportation Research, the University of Texas at Austin: Austin, TX, USA, 2003. [Google Scholar]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Al-Jabban, W.; Laue, J.; Knutsson, S.; Al-Ansari, N. A Comparative Evaluation of Cement and By-Product Petrit T in Soil Stabilization. Appl. Sci. 2019, 9, 5238. [Google Scholar] [CrossRef]

- Al-Mukhtar, M.; Lasledj, A.; Alcover, J.-F. Behaviour and Mineralogy Changes in Lime-Treated Expansive Soil at 50 °C. Appl. Clay Sci. 2010, 50, 199–203. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Q. The Behaviour of Organic Matter in the Process of Soft Soil Stabilization Using Cement. Bull. Eng. Geol. Environ. 2006, 65, 445–448. [Google Scholar] [CrossRef]

- Jairaj, C.; Prathap Kumar, M.T.; Raghunandan, M.E. Compaction Characteristics and Strength of BC Soil Reinforced with Untreated and Treated Coir Fibers. Innov. Infrastruct. Solut. 2018, 3, 21. [Google Scholar] [CrossRef]

- Crane, R.E.; Cassidy, D.P.; Srivastava, V.J. Activated Carbon Preconditioning to Reduce Contaminant Leaching in Cement-Based Stabilization of Soils. J. Environ. Eng. 2014, 140, 04014032. [Google Scholar] [CrossRef]

- Chaple, P.M.; Dhatrak, A.I. Performance of Coir Fiber Reinforced Clayey Soil. Int. J. Eng. Sci. 2013, 2, 54–64. [Google Scholar]

- Bhurtel, A.; Eisazadeh, A. Strength and Durability of Bottom Ash and Lime Stabilized Bangkok Clay. KSCE J. Civ. Eng. 2020, 24, 404–411. [Google Scholar] [CrossRef]

- Sobhan, K. Improving the Tensile Strength and Toughness of a Soil-Cement-Fly Ash Pavement Subgrade with Recycled HDPE Strips. In Proceedings of the GeoCongress 2008: Geosustainability and Geohazard Mitigation, New Orleans, LA, USA, 9–12 March 2008; pp. 1065–1072. [Google Scholar]

- Anggraini, V.; Asadi, A.; Huat, B.B.K.; Nahazanan, H. Effects of Coir Fibers on Tensile and Compressive Strength of Lime Treated Soft Soil. Measurement 2015, 59, 372–381. [Google Scholar] [CrossRef]

- Park, S.-S. Unconfined Compressive Strength and Ductility of Fiber-Reinforced Cemented Sand. Constr. Build. Mater. 2011, 25, 1134–1138. [Google Scholar] [CrossRef]

- Saberian, M.; Jahandari, S.; Li, J.; Zivari, F. Effect of Curing, Capillary Action, and Groundwater Level Increment on Geotechnical Properties of Lime Concrete: Experimental and Prediction Studies. J. Rock Mech. Geotech. Eng. 2017, 9, 638–647. [Google Scholar] [CrossRef]

- Ateş, A. Mechanical Properties of Sandy Soils Reinforced with Cement and Randomly Distributed Glass Fibers (GRC). Compos. Part B Eng. 2016, 96, 295–304. [Google Scholar] [CrossRef]

- Abdi, M.R.; Ghalandarzadeh, A.; Chafi, L.S. An Investigation into the Effects of Lime on Compressive and Shear Strength Characteristics of Fiber-Reinforced Clays. J. Rock Mech. Geotech. Eng. 2021, 13, 885–898. [Google Scholar] [CrossRef]

- Rashid, A.S.A.; Kalatehjari, R.; Noor, N.M.; Yaacob, H.; Moayedi, H.; Sing, L.K. Relationship between Liquidity Index and Stabilized Strength of Local Subgrade Materials in a Tropical Area. Measurement 2014, 55, 231–237. [Google Scholar] [CrossRef]

- Locat, J.; Tremblay, H.; Leroueil, S. Mechanical and Hydraulic Behaviour of a Soft Inorganic Clay Treated with Lime. Can. Geotech. J. 1996, 33, 654–669. [Google Scholar] [CrossRef]

- Makki-Szymkiewicz, L.; Hibouche, A.; Taibi, S.; Herrier, G.; Lesueur, D.; Fleureau, J.M. Evolution of the Properties of Lime-Treated Silty Soil in a Small Experimental Embankment. Eng. Geol. 2015, 191, 8–22. [Google Scholar] [CrossRef]

- Dillon, E.C., Jr.; Wilton, J.H.; Barlow, J.C.; Watson, W.A. Large Surface Area Activated Charcoal and the Inhibition of Aspirin Absorption. Ann. Emerg. Med. 1989, 18, 547–552. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Al-Saidi, A.A.; Jaber, M.M. Consolidation Properties of Compacted Soft Soil Stabilized with Lime-Silica Fume Mix. Int. J. Sci. Eng. Res. 2014, 21, 756. [Google Scholar]

- Mengue, E.; Mroueh, H.; Lancelot, L.; Medjo Eko, R. Physicochemical and Consolidation Properties of Compacted Lateritic Soil Treated with Cement. Soils Found. 2017, 57, 60–79. [Google Scholar] [CrossRef]

- Akula, P.; Hariharan, N.; Little, D.N.; Lesueur, D.; Herrier, G. Evaluating the Long-Term Durability of Lime Treatment in Hydraulic Structures: Case Study on the Friant-Kern Canal. Transp. Res. Rec. 2020, 2674, 431–443. [Google Scholar] [CrossRef]

- Shen, S.L.; Wang, Z.F.; Horpibulsuk, S.; Kim, Y.H. Jet Grouting with a Newly Developed Technology: The Twin-Jet Method. Eng. Geol. 2013, 152, 87–95. [Google Scholar] [CrossRef]

- Lav, A.H.; Lav, M.A. Microstructural Development of Stabilized Fly Ash as Pavement Base Material. J. Mater. Civ. Eng. 2000, 12, 157–163. [Google Scholar] [CrossRef]

- Wahab, N.A.; Roshan, M.J.; Rashid, A.S.A.; Hezmi, M.A.; Jusoh, S.N.; Nik Norsyahariati, N.D.; Tamassoki, S. Strength and Durability of Cement-Treated Lateritic Soil. Sustainability 2021, 13, 6430. [Google Scholar] [CrossRef]

- Athanasopoulou, A. The Role of Curing Period on the Engineering Characteristics of a Cement-Stabilized Soil. Rom. J. Transp. Infrastruct. 2016, 5, 38–52. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R. Upscaling Effects of Soil Improvement by Microbially Induced Calcite Precipitation by Surface Percolation. Geomicrobiol. J. 2014, 31, 396–406. [Google Scholar] [CrossRef]

- Choi, S.G.; Chang, I.; Lee, M.; Lee, J.H.; Han, J.T.; Kwon, T.H. Review on Geotechnical Engineering Properties of Sands Treated by Microbially Induced Calcium Carbonate Precipitation (MICP) and Biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

| Test | Soil | Stabilising Admixture | Fibre Reinforcing | Days Curing | Ref. |

|---|---|---|---|---|---|

| UCS and DST | SC (Marginal soil) | Cement and Fly Ash | randomly distributing 2% coir fibre | 3 | [26] |

| USC | Clay (A kaolin type) | Lime | 0.75% basalt | 90 | [27] |

| UCS | CL | Lime and fly ash | 0.5% sisal fibre | 7 | [28] |

| TPB, TST | marine clay soil | Lime and cement | 1% coconut fibre | 28 | [29] |

| UUT | Hefei clayey soil | Lime | 0.4 wheat straw | 28 | [30] |

| UCS | CH | Lime | 0.5% coir fibre | 7 | [31] |

| TPB, cyclic loadings, | A-2-6 A-7-5 | Cement | 0.15% hemp fibre | 7 | [32] |

| UCS, STS, | SP | Cement | Kenaf fibre | 28 | [33] |

| Composition | (%) by Weight | ||

|---|---|---|---|

| Soil | Activated Carbon | Lime | |

| Fe2O3 | 57.57% | 11.27 | - |

| SiO2 | 20.85% | - | - |

| Al2O3 | 19.507 | - | - |

| K2O | 1.72% | 17.68 | 0.30 |

| MnO | 0.15% | 2.57 | - |

| Cr2O3 | 0.14% | - | - |

| As2O3 | 0.05% | - | - |

| CaO | - | 39.77 | 98.85 |

| P2O5 | - | 16.62 | - |

| SO3 | - | 7.83 | 0.80 |

| ZnO | - | 3.47 | - |

| CuO | - | 0.62 | - |

| SrO | - | 0.18 | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamassoki, S.; Nik Daud, N.N.; Jakarni, F.M.; Mohd Kusin, F.; Rashid, A.S.A.; Roshan, M.J. Performance Evaluation of Lateritic Subgrade Soil Treated with Lime and Coir Fibre-Activated Carbon. Appl. Sci. 2022, 12, 8279. https://doi.org/10.3390/app12168279

Tamassoki S, Nik Daud NN, Jakarni FM, Mohd Kusin F, Rashid ASA, Roshan MJ. Performance Evaluation of Lateritic Subgrade Soil Treated with Lime and Coir Fibre-Activated Carbon. Applied Sciences. 2022; 12(16):8279. https://doi.org/10.3390/app12168279

Chicago/Turabian StyleTamassoki, Sakina, Nik Norsyahariati Nik Daud, Fauzan Mohd Jakarni, Faradiella Mohd Kusin, Ahmad Safuan A. Rashid, and Mohammad Jawed Roshan. 2022. "Performance Evaluation of Lateritic Subgrade Soil Treated with Lime and Coir Fibre-Activated Carbon" Applied Sciences 12, no. 16: 8279. https://doi.org/10.3390/app12168279

APA StyleTamassoki, S., Nik Daud, N. N., Jakarni, F. M., Mohd Kusin, F., Rashid, A. S. A., & Roshan, M. J. (2022). Performance Evaluation of Lateritic Subgrade Soil Treated with Lime and Coir Fibre-Activated Carbon. Applied Sciences, 12(16), 8279. https://doi.org/10.3390/app12168279