A Novel Application of New High-Strength Plugging Agent in Baikouquan Oilfield

Abstract

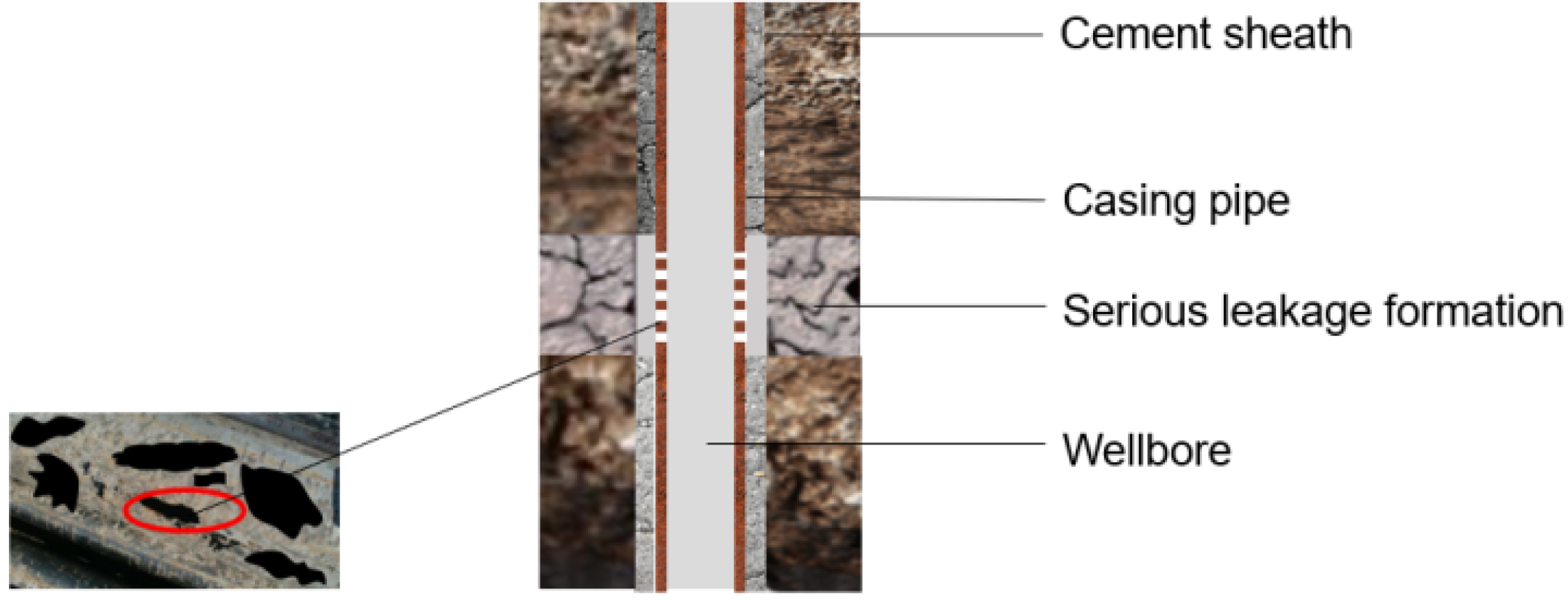

1. Introduction

2. New High-Strength Plugging Agent

3. Performance Evaluation by Laboratory Tests

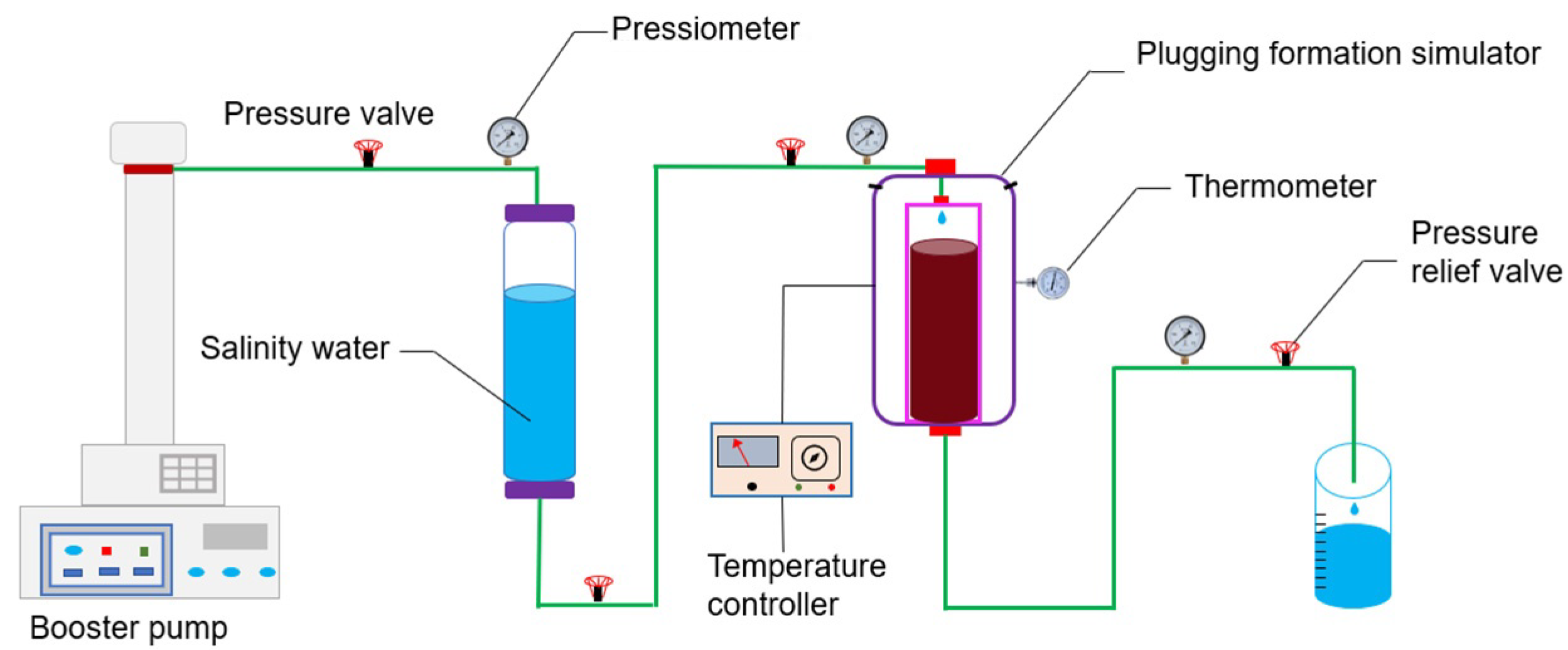

- (1)

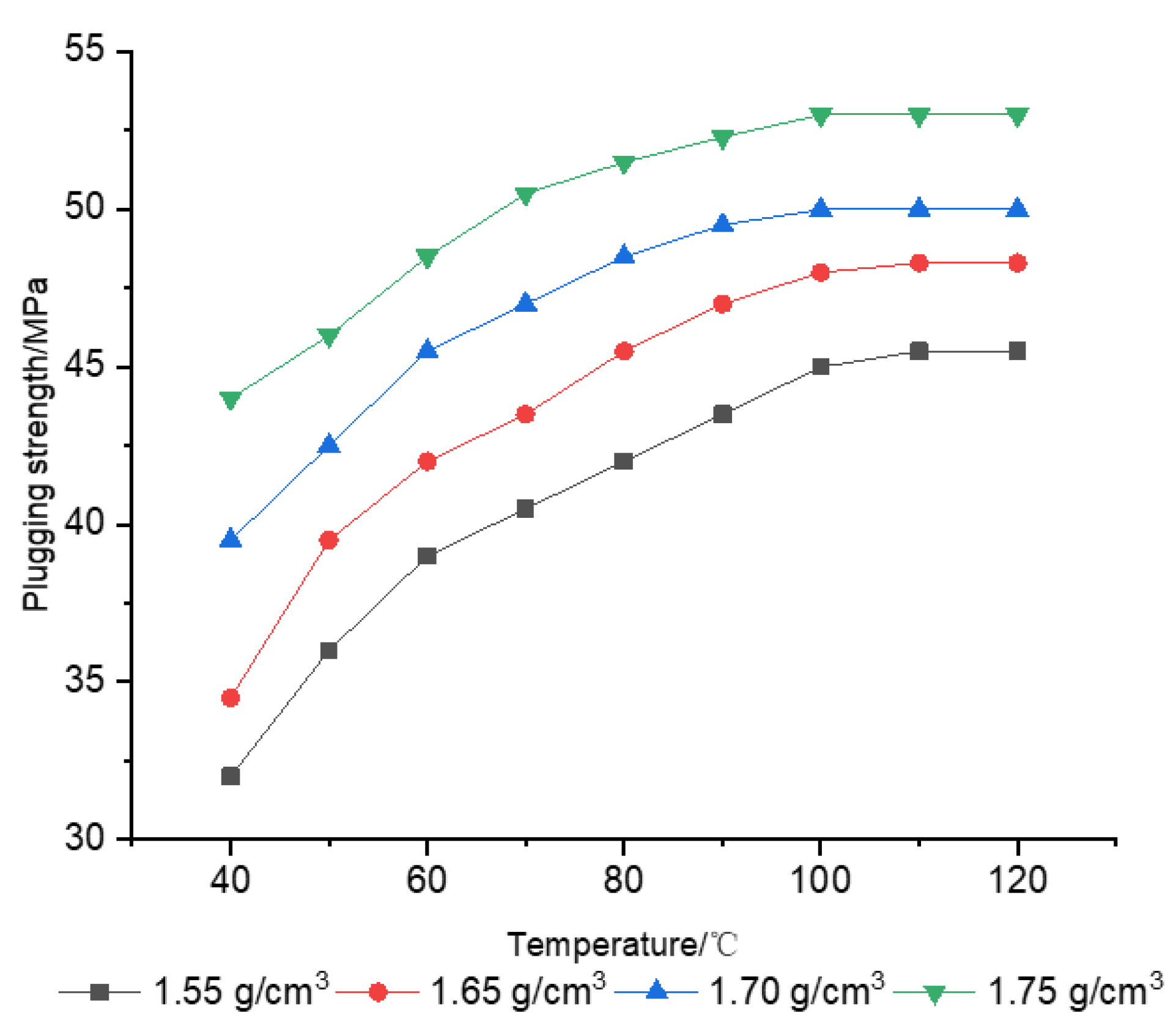

- The electronic balance YP3002 from Shanghai Youke Instrument Co., LTD. was used to weigh the appropriate amount of plugging agent powder, and the plugging agent was stirred evenly by electric mixer D90-A from Qingdao Haitongda Special Instrument Company Ltd. According to different water-cement ratios, the plugging agent slurries with different densities of 1.55 g/cm3, 1.65 g/cm3, 1.70 g/cm3 and 1.75 g/cm3 were prepared, respectively.

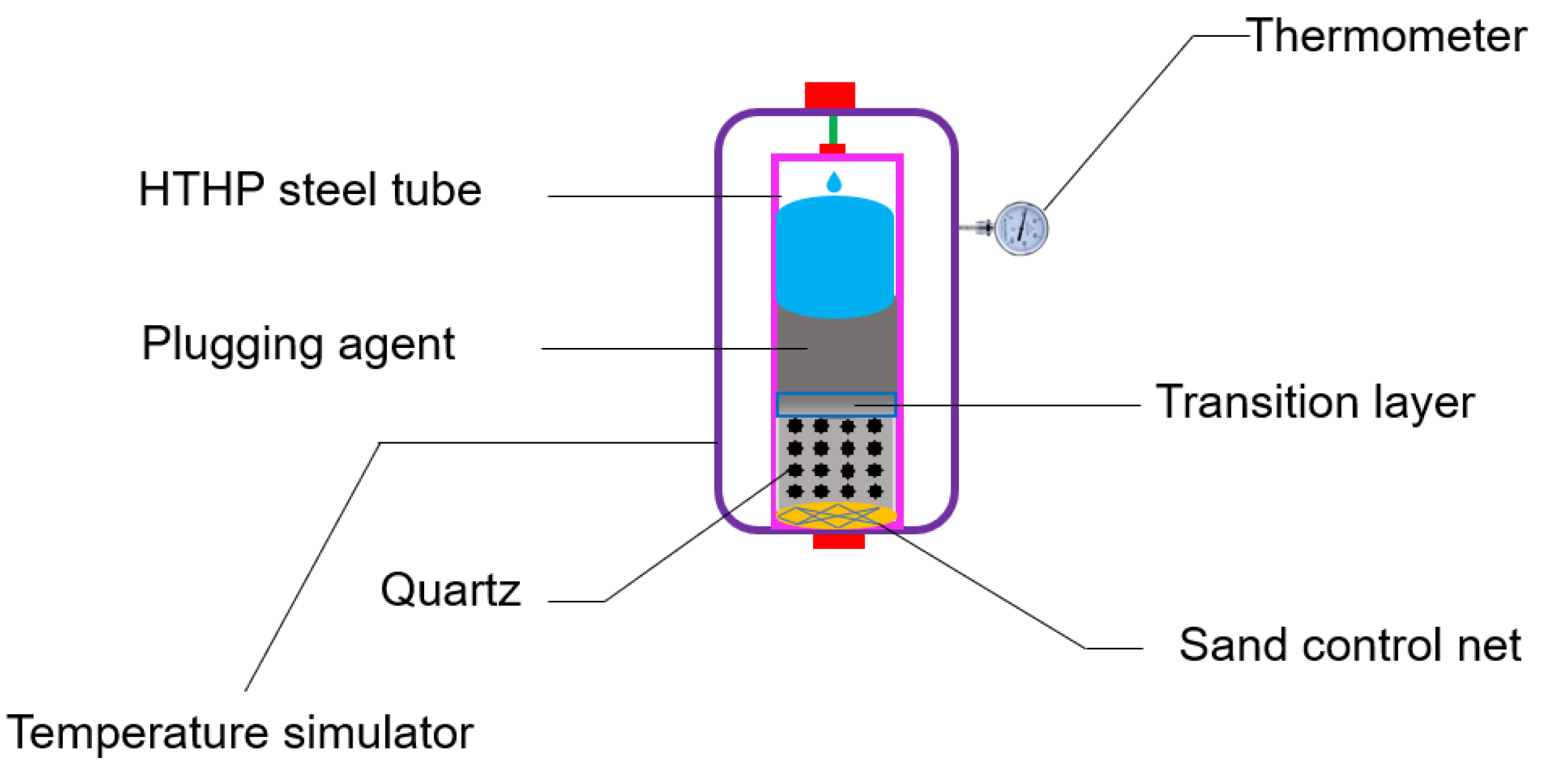

- (2)

- The steel pipe was fixed with a core holder, and a sand control net was placed at the bottom of the steel pipe. Subsequently, on-site formation water with a salinity of 1.5 × 105 mg/L was used to saturate the quartz sand. A certain mesh and particle size of quartz sand were filled into the steel tube uniformly to simulate the Baikouquan Formation with a porosity of 12% [38], and the prepared plugging agent slurry was filled into the steel tube.

- (3)

- The booster pumper and the pressure valve were opened in turn. The pump pressure was adjusted and maintained at a certain pressure to simulate the wellbore conditions at the construction site. At the same time, the temperature simulator was turned on to select different temperatures to simulate the formation environment. The solidified body of plugging agent was maintained under pressure for 48 h under this condition.

- (4)

- The experimental temperatures were selected as 40 °C, 60 °C, 80 °C, 100 °C and 120 °C, respectively. The booster pumper and the pressure valve were opened in turn to adjust the pump pressure. Water with different salinities was passed through the solidified body and the simulated formation under water pressure.

- (5)

- When the first drop of water drops out, the pressure displayed by the pressure meter is the breakthrough pressure, which is also called plugging strength. As water pressure increases, breakthrough phenomena become more obvious. When the pressure suddenly displays zero, this is the maximum pressure, and it is called the breakdown pressure.

- (6)

- In this step, the plugging agent with a density of 1.70 g/cm3 was used. In order to study the effect of time on plugging effect, the plugging strength corresponding to the curing time of 0.5 weeks, 1 week, 5 weeks, 10 weeks, 15 weeks, 20 weeks and 25 weeks was measured under the conditions that the curing temperatures were 80 °C and 100 °C, respectively, referring to the above procedure.

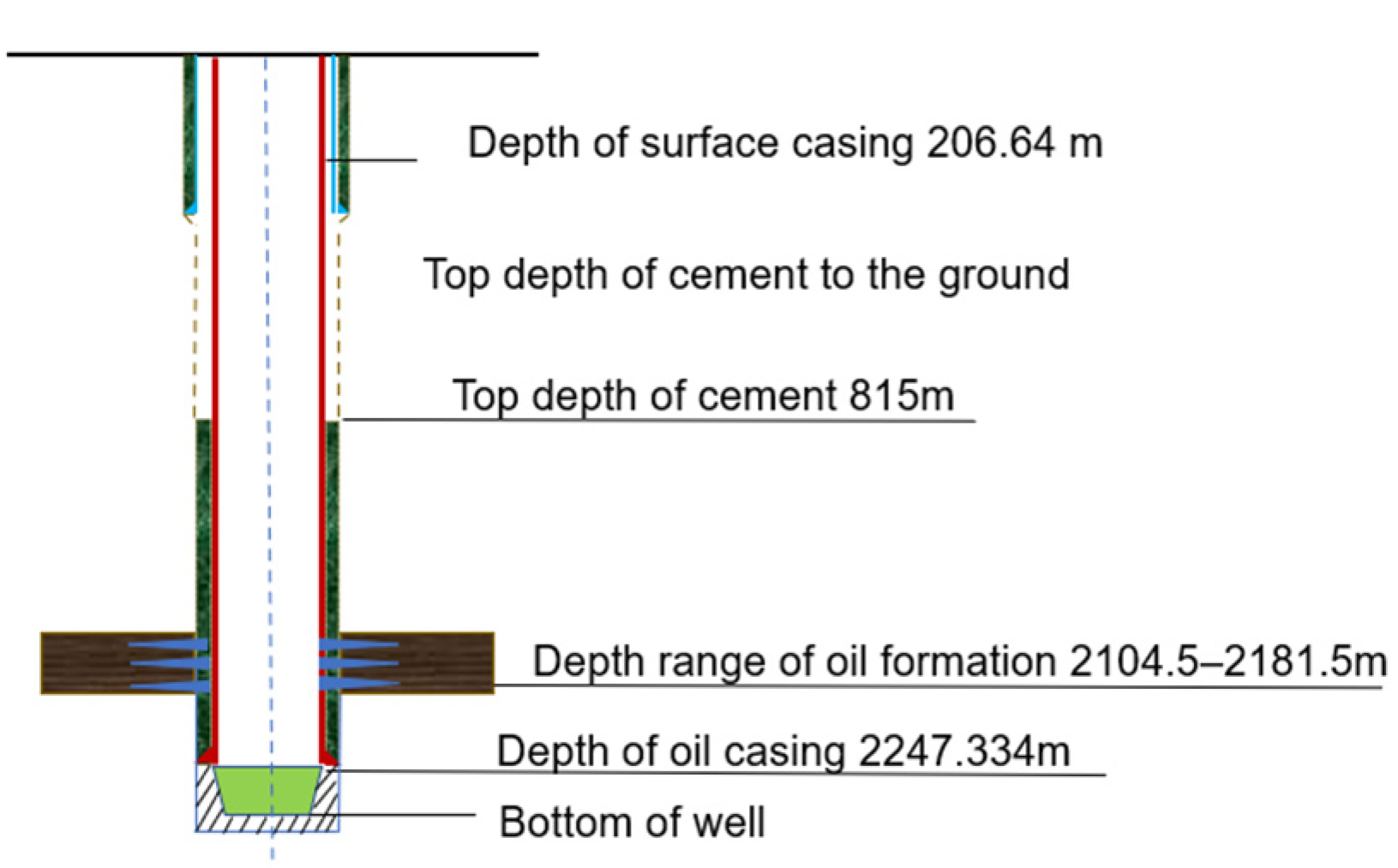

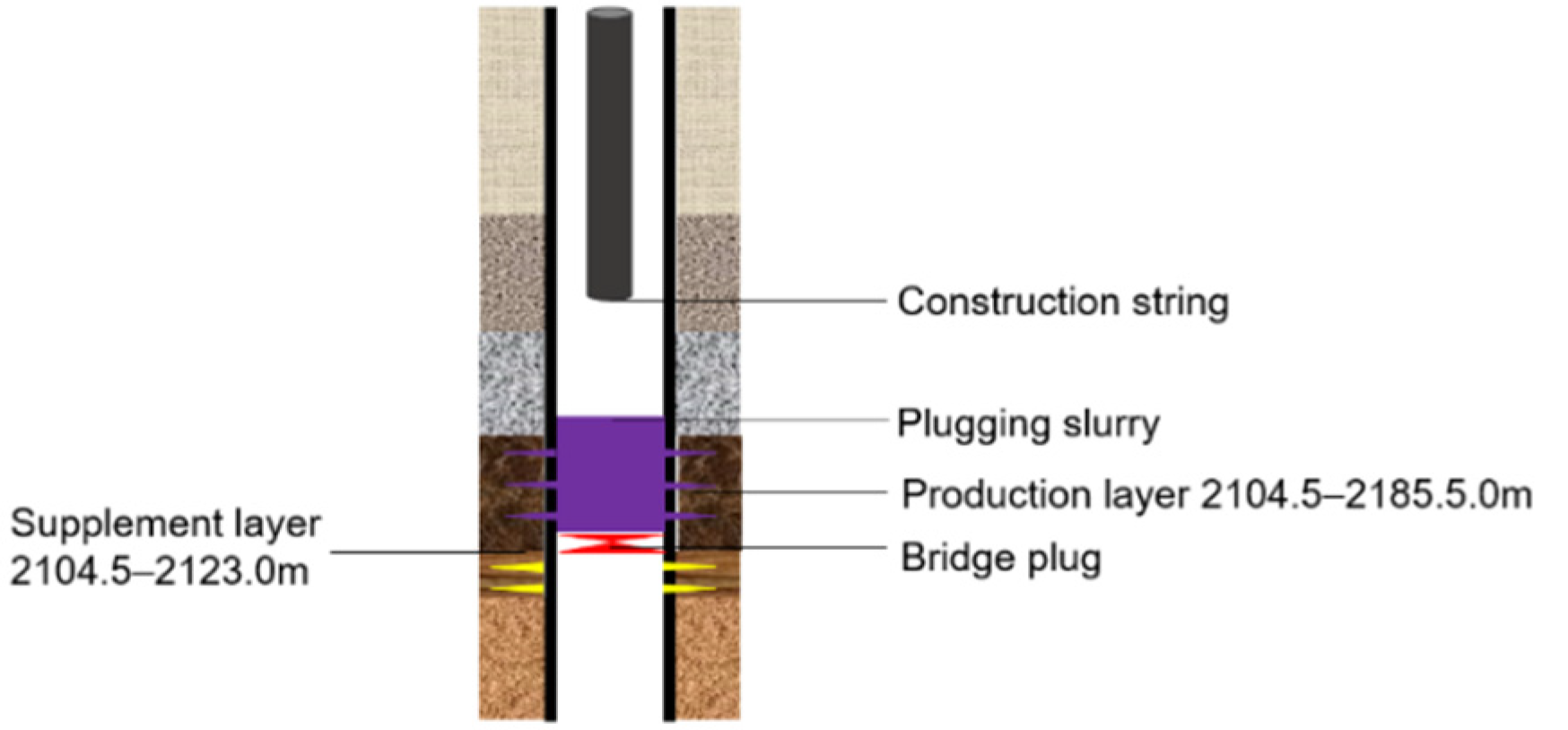

4. Field Application and Effect Analysis

5. Conclusions

- (1)

- The plugging agent is made up of a variety of materials, and its density can be adjusted within the required range to meet the plugging requirements for different formations. In addition, it can quickly form a space network structure so as to effectively reside in the plugging position and also has favorable plugging strength, temperature resistance and salt resistance, with long validity after plugging.

- (2)

- Under the condition of high temperature, the plugging strength can remain stable. Under the laboratory experiment conditions, the maximum plugging strength can reach 53 MPa, meeting the requirements of subsequent boosting pressure water injection and conventional fracturing.

- (3)

- The plugging agent has the property of micro-expansion, and the expansion rate is about 4.3%. The compactness of the solidified body is enhanced by the micro-expansion property of the plugging agent, which improves the bond strength between the solidified body and formation, casing and cement sheath, reducing the risk of late annulus pressure and gas channeling.

- (4)

- The plugging agent has favorable thixotropy, particle suspension ability, and favorable fluidity, so that the particles do not settle down in the slurry, meeting the pumping requirements for the field, which ensures construction safety.

- (5)

- The pressure test value for the plugging agent is large after plugging, which fully meets the requirements for site construction. In addition, this plugging technology can be used in cases where some production wells fail to achieve the expected production after fracturing, or casing leakage and casing faults make the fracturing impossible, requiring a rebuild of the wellbore integrity.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, W.; Xu, Y.; Zhou, Y.; Wang, K. Investigation of Stress Concentration and Casing Strength Degradation Caused by Corrosion Pits. Int. J. Corros. 2016, 2016, 6930234. [Google Scholar] [CrossRef]

- Lin, T.; Zhang, Q.; Lian, Z.; Chang, X.; Zhu, K.; Liu, Y. Evaluation of casing integrity defects considering wear and corrosion—Application to casing design. J. Nat. Gas Sci. Eng. 2016, 29, 440–452. [Google Scholar] [CrossRef]

- Zhu, X.H.; Sun, R.Q.; Tong, H. A new method to predict the remaining life of corrosion casing for steam injection wells. Mater. Corros. 2013, 66, 175–181. [Google Scholar] [CrossRef]

- Tong, Y.; Yang, Y.; Yang, Z.; Wang, H. Causes of tubing corrosion and perforation in a production well. Chem. Enterp. Manag. 2021, 17, 135–138. [Google Scholar]

- Gong, D.; Yu, S.; Yuan, P.; Shuai, Y. Cause analysis of L80 tubing corrosion perforation. Corros. Prot. 2014, 35, 959–963. [Google Scholar]

- Luo, P. Comprehensive water cut status and development direction of water-flooded zone evaluation technology in Bohai oilfield. Chem. Enterp. Manag. 2016, 29, 195. [Google Scholar]

- Ci, J.; He, S.; Li, Z.; Wang, M.; Cui, J.; Jiang, Y. Present Situation of waterflooded zone logging and its developing trend. Nat. Gas Ind. 2005, 25, 44–46. [Google Scholar]

- Gholami, R.; Rasouli, V.; Aadnoy, B.S.; Mohammadnejad, M. Geomechanical and Numerical Studies of Casing Damages in a Reservoir with Solid Production. Rock Mech. Rock Eng. 2016, 49, 1441–1460. [Google Scholar] [CrossRef]

- Yin, F.; Gao, D. Mechanical analysis and design of casing in directional well under in-situ stresses. J. Nat. Gas Sci. Eng. 2014, 20, 285–291. [Google Scholar] [CrossRef]

- Liu, W.; Yu, B.; Deng, J. Analytical method for evaluating stress field in casing-cement-formation system of oil/gas wells. Appl. Math. Mech. 2017, 38, 1273–1294. [Google Scholar] [CrossRef]

- Li, W.; LI, Y.; Zhang, Z.; Fang, P.; Sun, W. The in-situ stress analysis of casing damage wells in the sixth middle district based on kriging interpolation method. Adv. Pet. Explor. Dev. 2016, 11, 45–49. [Google Scholar]

- Wang, T.; Yang, S.; Zhu, W.; Bian, W.; Liu, M.; Lei, Y.; Zhang, Y.; Zhang, J.; Zhao, W.; Chen, L.; et al. Law and countermeasures for the casing damage of oil production wells and water injection wells in tarim oilfield. Pet. Explor. Dev. 2011, 38, 352–361. [Google Scholar]

- Murtaza, M.; Mahmoud, M.; Tariq, Z. Experimental Investigation of a Novel, Efficient, and Sustainable Hybrid Silicate System in Oil and Gas Well Cementing. Energy Fuels 2020, 34, 7388–7396. [Google Scholar] [CrossRef]

- Han, L.; Yin, F.; Yang, S.; Liu, W.; Deng, Y. Coupled seepage-mechanical modeling to evaluate formation deformation and casing failure in waterflooding oilfields. J. Pet. Sci. Eng. 2019, 180, 124–129. [Google Scholar] [CrossRef]

- Lian, Z.; Yu, H.; Lin, T.; Guo, J. A study on casing deformation failure during multi-stage hydraulic fracturing for the stimulated reservoir volume of horizontal shale wells. J. Nat. Gas Sci. Eng. 2015, 23, 538–546. [Google Scholar] [CrossRef]

- Mohammed, A.I.; Oyeneyin, B.; Atchison, B.; Njuguna, J. Casing structural integrity and failure modes in a range of well types—A review. J. Nat. Gas Sci. Eng. 2019, 68, 102898. [Google Scholar] [CrossRef]

- Zakharov, V.; Ismagilov, A.; Antonov, M. Waterproofing of cracks from the side of injection wells in carbonate reservoirs. Xinjiang Pet. Geol. 2013, 34, 108–110. [Google Scholar]

- Wang, Y. Lost circulation law in fractured strata with stress sensitivity. Xinjiang Pet. Geol. 2015, 36, 450–453. [Google Scholar]

- Feng, X.; Kou, M.; Xiong, S.; He, Z.; Xu, K. Discussion on plugging technology of casing leakage. Drill. Prod. Technol. 2018, 41, 127–129. [Google Scholar]

- Cheng, W. Damage of casing and repair process. West-China Explor. Eng. 2015, 27, 71–72. [Google Scholar]

- Dang, D.H.; Gao, F.; He, J.Y.; Jiang, T.; Yao, B.H. Research and Application of Cement Plugging Techniques in Evaporite Bed of Piedmont Tectonic Belt of the Tarim Basin. Adv. Mater. Res. 2013, 807–809, 2634–2638. [Google Scholar] [CrossRef]

- Qin, J.; Zheng, J.; Li, L. Experimental study of the shrinkage behavior of cemented paste backfill. J. Rock Mech. Geotech. Eng. 2021, 13, 545–554. [Google Scholar] [CrossRef]

- Eloget, M.O.; Abuodha, S.O.; Winja, M.M.O. The Effect of Sisal Juice Extract Admixture on Compressive and Flexural Strength of Cement Concrete. Eng. Technol. Appl. Sci. Res. 2021, 11, 7041–7046. [Google Scholar] [CrossRef]

- Fan, X.; Zhao, P.; Zhang, Q.; Zhang, T.; Zhu, K.; Zhou, C. A Polymer Plugging Gel for the Fractured Strata and Its Application. Materials 2018, 11, 856. [Google Scholar] [CrossRef]

- Lai, N.; Chen, Y.; Wang, J.; Wu, C.; Zhang, X. Temporary Plugging Agent System for Thermally Induced Phase Change Fracturing in Shale Gas Reservoirs. Energy Fuels 2022, 36, 6270–6279. [Google Scholar] [CrossRef]

- Zhai, K.; Fan, S.; Fang, J.; Yu, Y.; Xie, H.; Ma, X. Development and evaluation of composite plugging agent of water-absorbent swelling resin. Oilfield Chem. 2021, 38, 196–203. [Google Scholar]

- Yang, Z.; Li, M.; Guo, J.; Zhang, K.; Lin, W.; Bi, H. Recondition injury casing with plugging agent in oil and water injection wells. Oil Drill. Prod. Technol. 2001, 4, 68–71. [Google Scholar]

- Liu, P.; Wei, F.; Zhang, S.; Zhu, X.; Wang, L.; Xiong, C. A bull-heading water control technique of thermo-sensitive temporary plugging agent. Pet. Explor. Dev. 2018, 45, 536–543. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, T.; Yang, Z. Recent progress on preventing and treating lost circulation domestic and overseas. Drill. Fluid Complet. Fluid 2010, 27, 80–84. [Google Scholar]

- Yang, Z.; Yan, P.; Dong, J.; Chen, Y.; Wang, J.; Huang, Q. Study and applications of the high-efficiently plugging agent for thermal production wells. J. Xi’an Shiyou Univ. Nat. Sci. Ed. 2006, 4, 54–57. [Google Scholar]

- Zhang, R.; Hou, B.; Tan, P.; Muhadasi, Y.; Fu, W.; Dong, X.; Chen, M. Hydraulic fracture propagation behavior and diversion characteristic in shale formation by temporary plugging fracturing. J. Pet. Sci. Eng. 2020, 190, 107063. [Google Scholar] [CrossRef]

- Zhai, K.; Yi, H.; Liu, Y.; Geng, Y.; Fan, S.; Zhu, D. Experimental Evaluation of the Shielded Temporary Plugging System Composed of Calcium Carbonate and Acid-Soluble Preformed Particle Gels (ASPPG) for Petroleum Drilling. Energy Fuels 2020, 34, 14023–14033. [Google Scholar] [CrossRef]

- Corredor-Rojas, L.; Hemmati-Sarapardeh, A.; Husein, M.; Dong, M.; Maini Brij, B. Rheological behavior of surface modified Silica nanoparticles dispersed in partially hydrolyzed polyacrylamide and xanthan gum solutions: Experimental measurements, mechanistic understanding, and model development. Energy Fuels 2018, 32, 10628–10638. [Google Scholar] [CrossRef]

- Yazdanpanah, F.; Sokhansanj, S.; Lim, C.J.; Lau, A.; Bi, X. Gas Adsorption Capacity of Wood Pellets. Energy Fuels 2016, 30, 2975–2981. [Google Scholar] [CrossRef]

- Mi, S.; Li, S.; Wu, Q. Rheology and filtration properties of bentonite-water suspensions as influenced by lignocellulosic nanomaterials and water-soluble biopolymer additives. Energy Fuels 2022, 36, 4479–4490. [Google Scholar]

- Wang, D.; Zhang, J.; Li, L.; Yang, B. Synthesis and evaluation of AS fluid loss additive for cement slurry. J. Liaoning Shihua Univ. 2012, 32, 38–42. [Google Scholar]

- Li, L.; Zhao, L.; Wang, Y.; Wu, J.; Meng, G.; Liu, Z.; Zhang, J.; Hu, B.; He, Q.; Guo, X. Novel Dispersant with a Three-Dimensional Reticulated Structure for a Coal–Water Slurry. Energy Fuels 2018, 32, 8310–8317. [Google Scholar] [CrossRef]

- Jia, B.; Xian, C. Permeability measurement of the fracture-matrix system with 3D embedded discrete fracture model. Pet. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Liu, G.; Hu, S.; Xiang, X.; Luo, C.; Guo, B. Development of JHPZ- High temperature and high pressure intelligent expansibility tester. J. Oil Gas Technol. 2000, 22, 107–109. [Google Scholar]

- Lv, K.; Liu, Y.; Qiao, W.; Liu, Y. Study on high strength pre-crosslinked gel plugging agent. Oilfield Chem. 2011, 28, 359–362. [Google Scholar]

- Ba, W.; Wang, Z.; Wang, C. Study on high temperature resistant compound gel plugging agent. Drill. Fluid Complet. Fluid 2021, 38, 728–731. [Google Scholar]

- Chen, S.; Zhao, K.; Chang, D. Synthesis of phenolic resin prepolymer plugging agent with high strength for oil well plugging. China Synth. Resin Plast. 2015, 32, 30–33. [Google Scholar]

- Yan, P.; Zhou, Y.; Yang, Z. Microstructure and sealing mechanism of high-temperature sealant. J. Mater. Sci. Eng. 2006, 24, 811–814. [Google Scholar]

- Yan, P.; Qin, J.; Yang, Z. Microstructure formation and invalidation mechanism of sealant in the simulated environment at the bottom of oil well. J. Chin. Ceram. Soc. 2002, 30, 423–428. [Google Scholar]

- Lu, P.; Meng, X.; Li, W.; Zhang, A. Laboratory study and evaluation of heat resistant and salt resistant chemical plugging agent for casing damaged wells. Nat. Gas Technol. Econ. 2013, 7, 42–45. [Google Scholar]

- Zhang, Z.; Yan, C.; Yan, Z.; Yang, P.; Yang, C.; Guo, B.; Li, M. Research and application of plugging agent for drilling in overflow and leakage coexisting formation. Nat. Gas Technol. Econ. 2019, 13, 40–44, 81–82. [Google Scholar]

- Tian, L.; Chen, Q.; Liu, Y.; Nian, Z. Evaluation and application of high strength expansion plugging agent for treatment of ultradeep casing damage well. Well Test. 2020, 29, 56–61. [Google Scholar]

- Zuo, J.; Ding, Y.; Yu, H. Hydrating expansion compound plugging technology. Drill. Fluid Complet. Fluid 2006, 23, 56–58. [Google Scholar]

- Opravil, T.; Ptáček, P.; Šoukal, F.; Havlica, J.; Brandštetr, J. The synthesis and characterization of an expansive admixture for M-type cements I. The influence of free CaO to the formation of ettringite. J. Therm. Anal. 2013, 111, 517–526. [Google Scholar] [CrossRef]

- Zheng, H.; Wei, Y. A review of ettringite formation and stability and its influence on material properties. Concrete 2001, 6, 44–48. [Google Scholar]

- Han, G.; Li, F.; Xie, T.; Yang, T. Research and application of micro-expansion plugging technology in casing damaged well treatment. Drill. Prod. Technol. 2019, 42, 112–114. [Google Scholar]

- Singh, A.; Singh, B.P.; Chandra, H.; Shyam, R. Analysis of volume expansion data for periclase, lime, corundum and spinel at high temperatures. Bull. Mater. Sci. 2012, 35, 631–637. [Google Scholar] [CrossRef][Green Version]

- Zhang, J.; Duan, X. Properties of sepiolite and its application. China Non-Met. Miner. Ind. 2009, 4, 19–22. [Google Scholar]

- Han, J. Development and application of a low-density compound cement plugging agent. Technol. Superv. Pet. Ind. 2021, 37, 8–11. [Google Scholar]

| Density (g/cm3) | Initial Gel Strength (Pa) | Final Gel Strength (Pa) | Dynamic Shear Force (Pa) | Plastic Viscosity (mPa·s) | Apparent Viscosity (mPa·s) |

|---|---|---|---|---|---|

| 1.45 | 2.7 | 5 | 1.5 | 15 | 16.5 |

| 1.60 | 3 | 6 | 3.5 | 25 | 28.8 |

| 1.70 | 3.5 | 7 | 12 | 43 | 55 |

| Treatment Method | Well No. | Before Construction | After Construction | Comparison | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Liquid Production (t/d) | Oil Production (t/d) | Water Content (t/d) | Liquid Production (t/d) | Oil Production (t/d) | Water Content (t/d) | Liquid Production (t/d) | Oil Production (t/d) | Water Content (t/d) | ||

| Oil layer plugging | 13,324 | 61.7 | 1.9 | 96.9 | 20.7 | 2.6 | 87.4 | −41.0 | 0.7 | −9.5 |

| 1240 | 48.2 | 2.3 | 95.3 | 42 | 10.3 | 75.5 | −6.2 | 8.0 | −19.8 | |

| 1404 | 26.5 | 1.8 | 93.2 | 14.3 | 2.5 | 82.5 | −12.2 | 0.7 | −10.7 | |

| Casingplugging | 1428 | 38.5 | 0.5 | 98.7 | 7.6 | 3.8 | 50 | −30.9 | 3.3 | −48.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Zhang, W.; He, Y.; Kong, S.; Liu, Y.; Han, R. A Novel Application of New High-Strength Plugging Agent in Baikouquan Oilfield. Appl. Sci. 2022, 12, 8150. https://doi.org/10.3390/app12168150

Sun Y, Zhang W, He Y, Kong S, Liu Y, Han R. A Novel Application of New High-Strength Plugging Agent in Baikouquan Oilfield. Applied Sciences. 2022; 12(16):8150. https://doi.org/10.3390/app12168150

Chicago/Turabian StyleSun, Yuanxiu, Weijie Zhang, Yong He, Shaoqi Kong, Yueliang Liu, and Ruifang Han. 2022. "A Novel Application of New High-Strength Plugging Agent in Baikouquan Oilfield" Applied Sciences 12, no. 16: 8150. https://doi.org/10.3390/app12168150

APA StyleSun, Y., Zhang, W., He, Y., Kong, S., Liu, Y., & Han, R. (2022). A Novel Application of New High-Strength Plugging Agent in Baikouquan Oilfield. Applied Sciences, 12(16), 8150. https://doi.org/10.3390/app12168150