Crushing Analysis and Optimization of Adjacent Variable Thickness Hexagonal Tubes

Abstract

1. Introduction

2. Materials and Methods

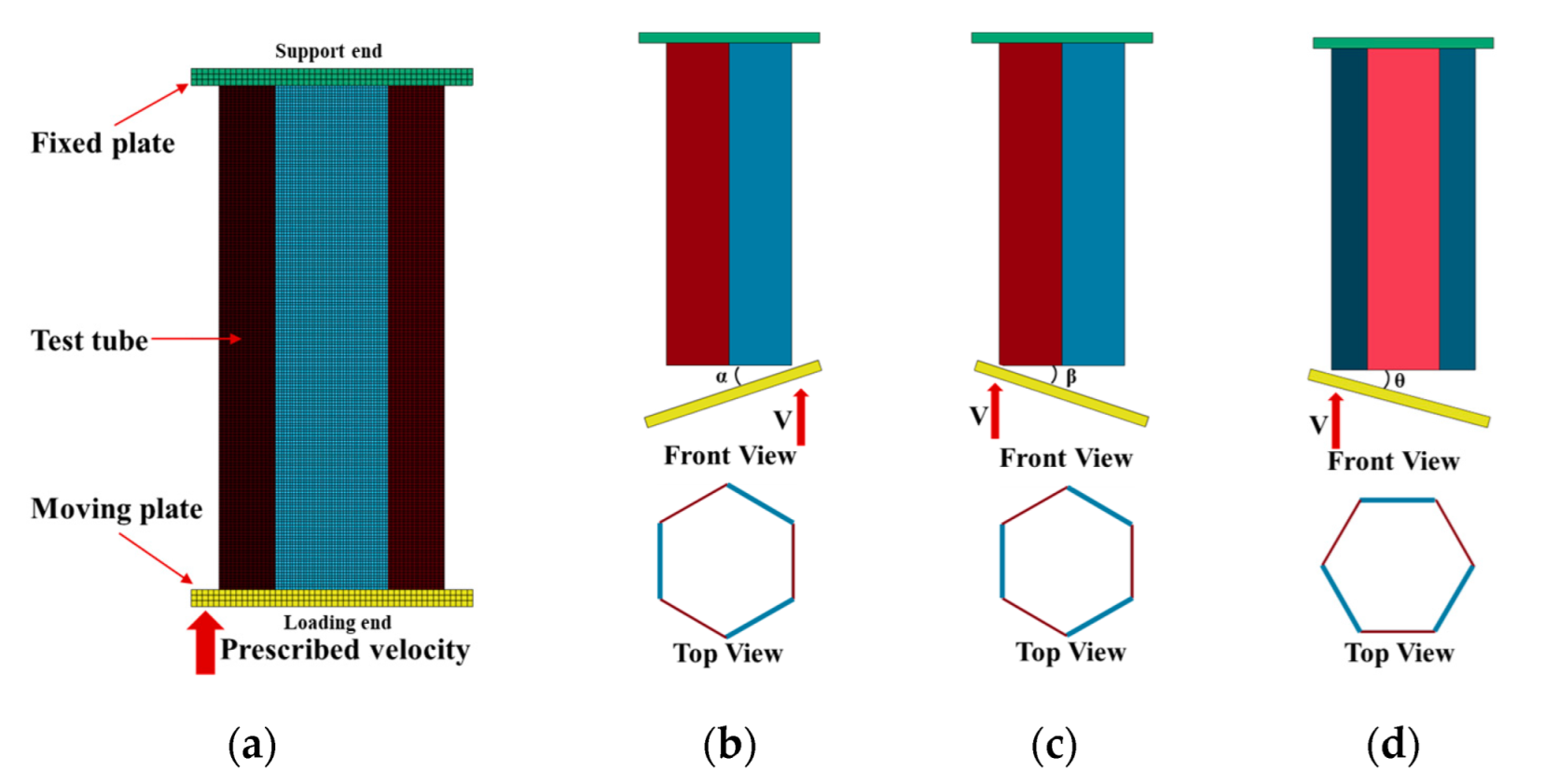

2.1. Description of Models

2.2. Crashworthiness Indices

2.3. Finite Element Modelling

2.4. Experimental Setup

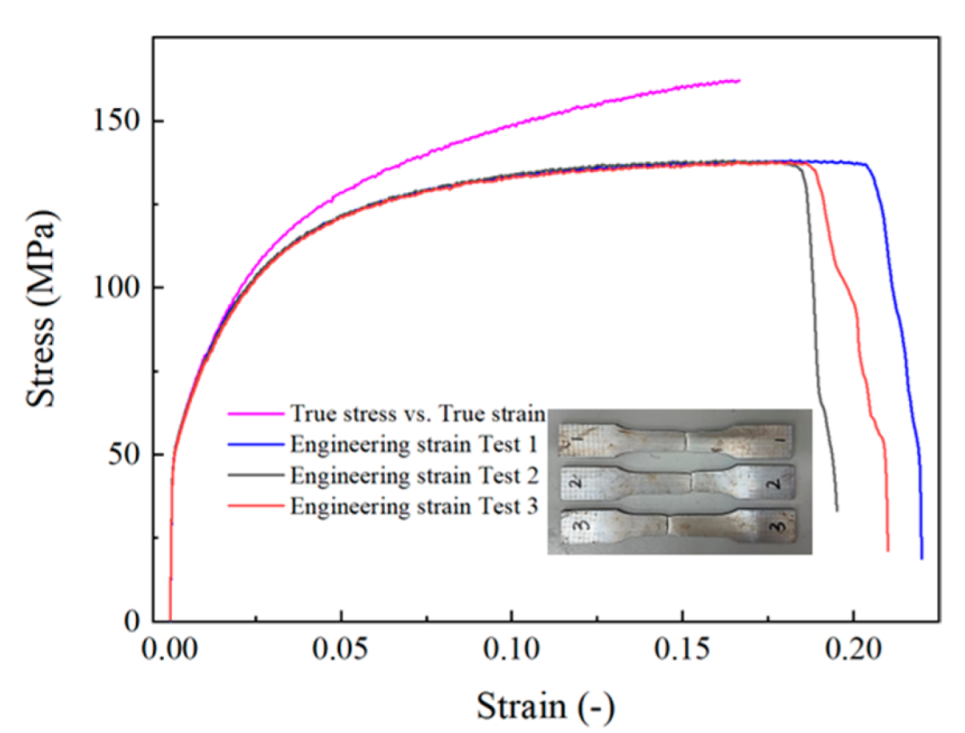

2.4.1. Material Properties

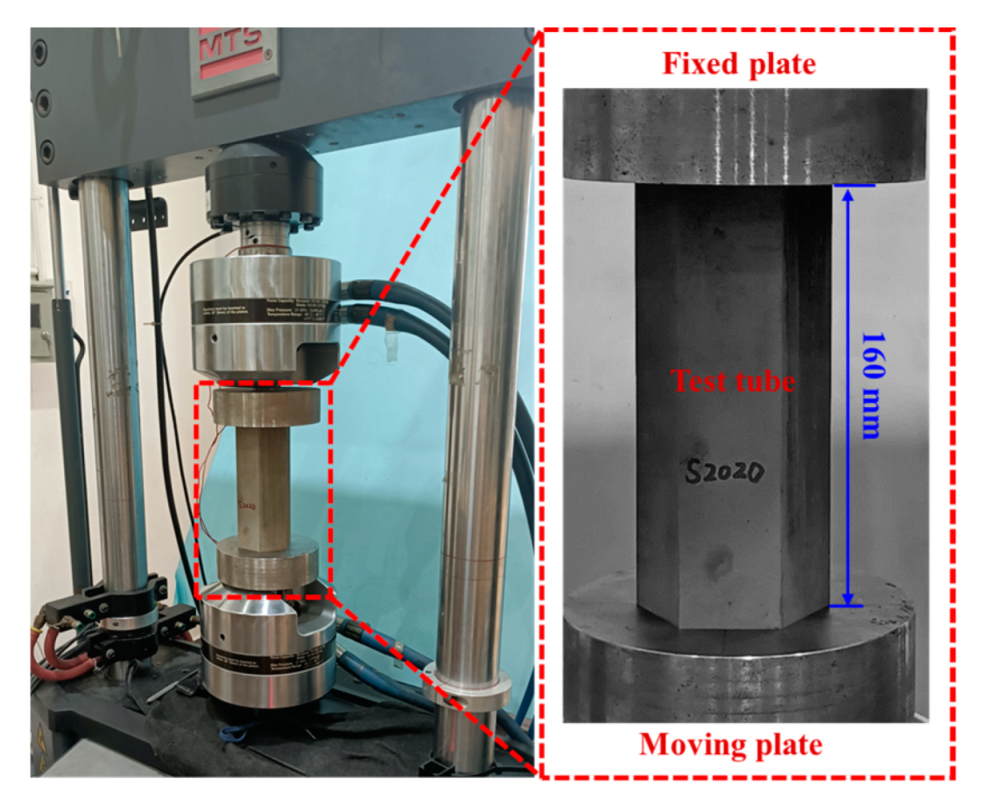

2.4.2. Quasi-Static Axial Compressive Tests

2.5. Optimization Definition and Method

2.6. Surrogate Models and the Design of Experiments (DOE)

3. Results and Discussion

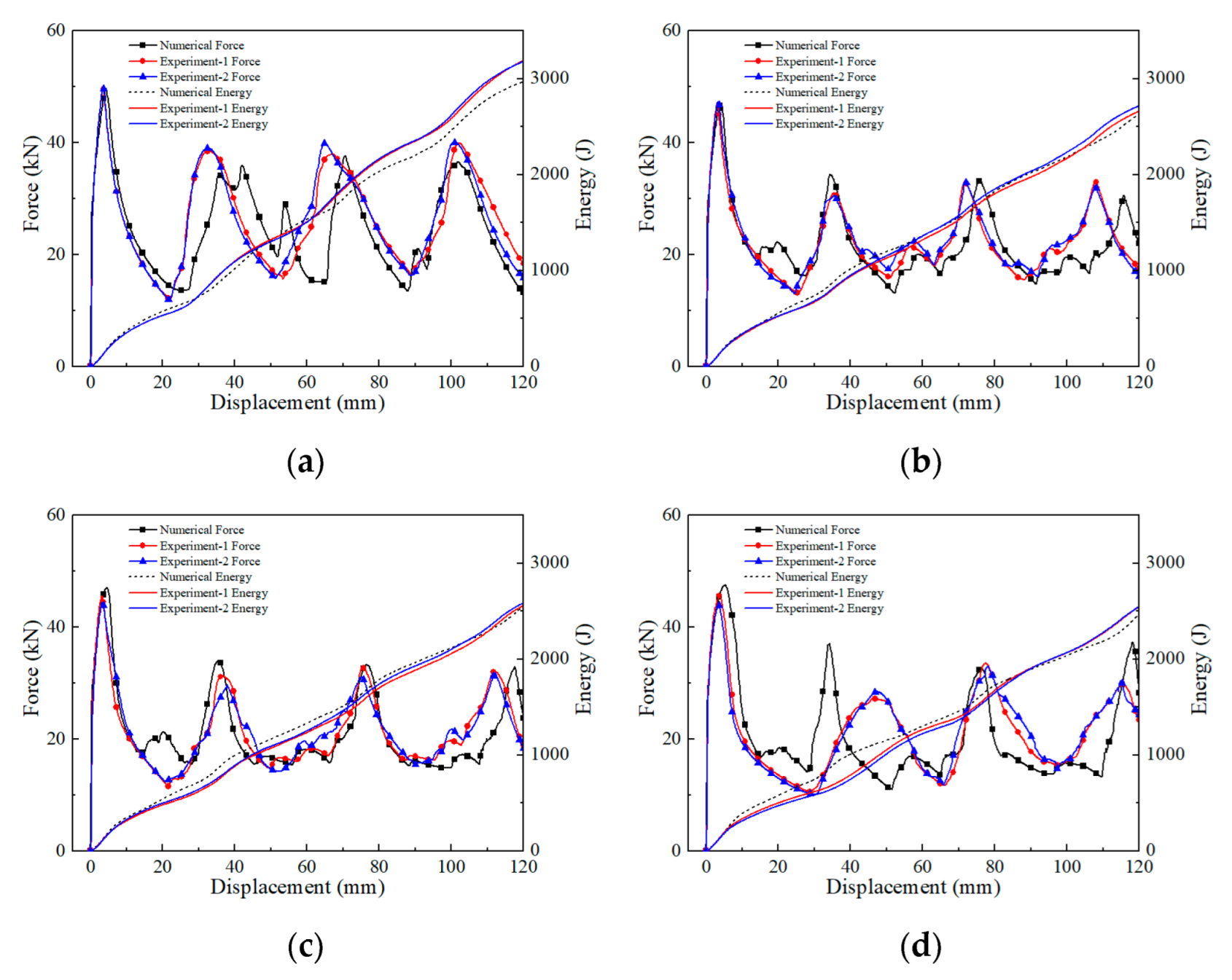

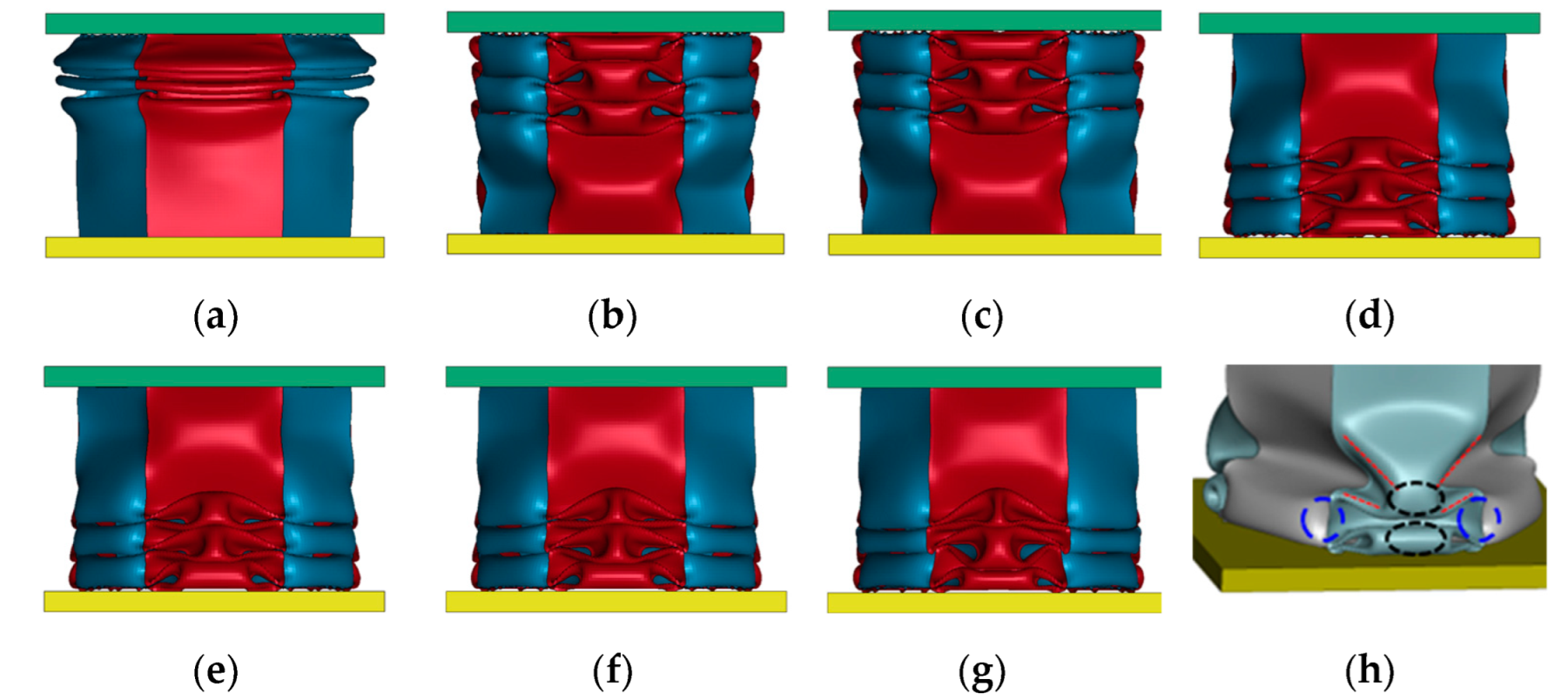

3.1. FE Model Validation

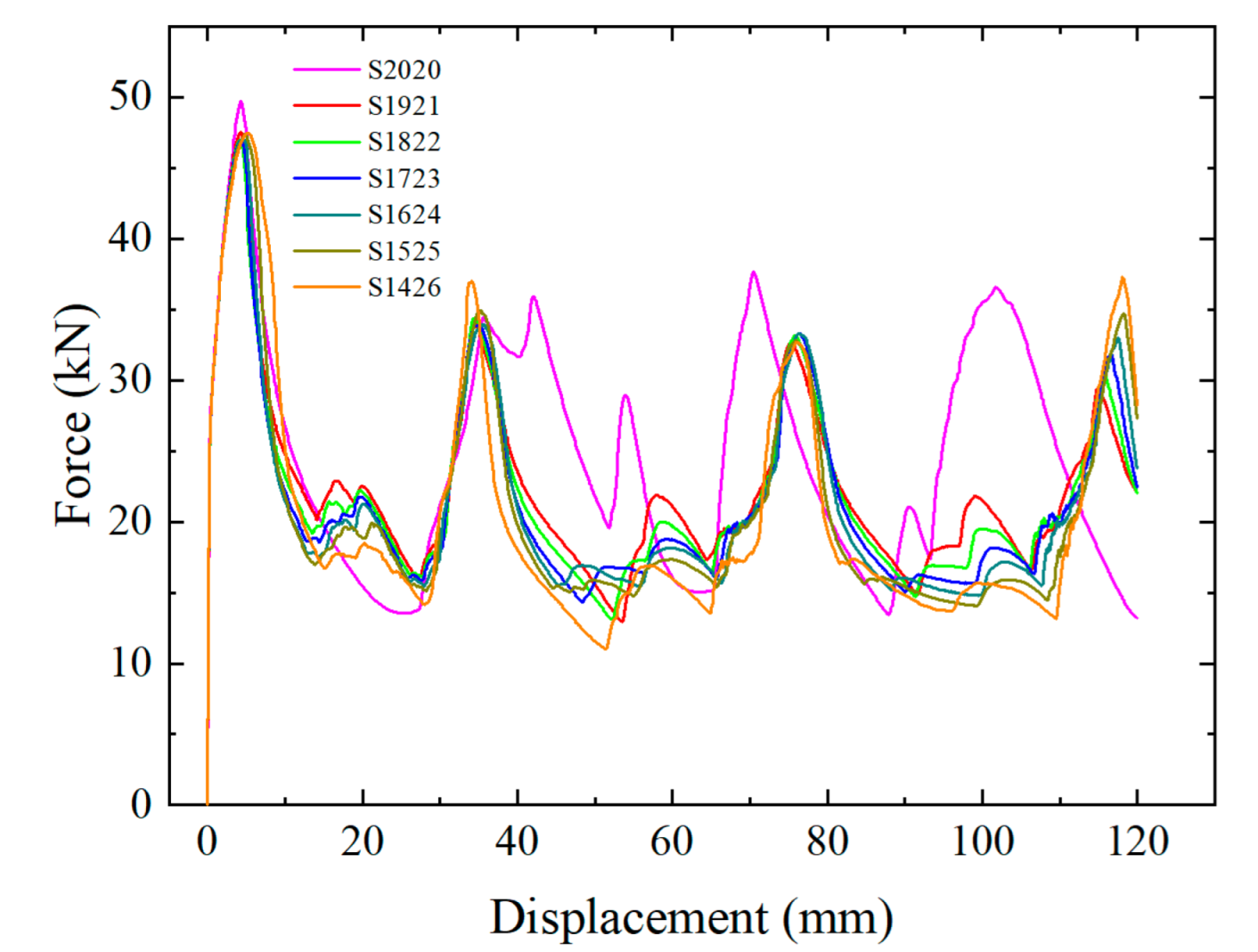

3.2. Crushing Performance Analysis under Axial Loading

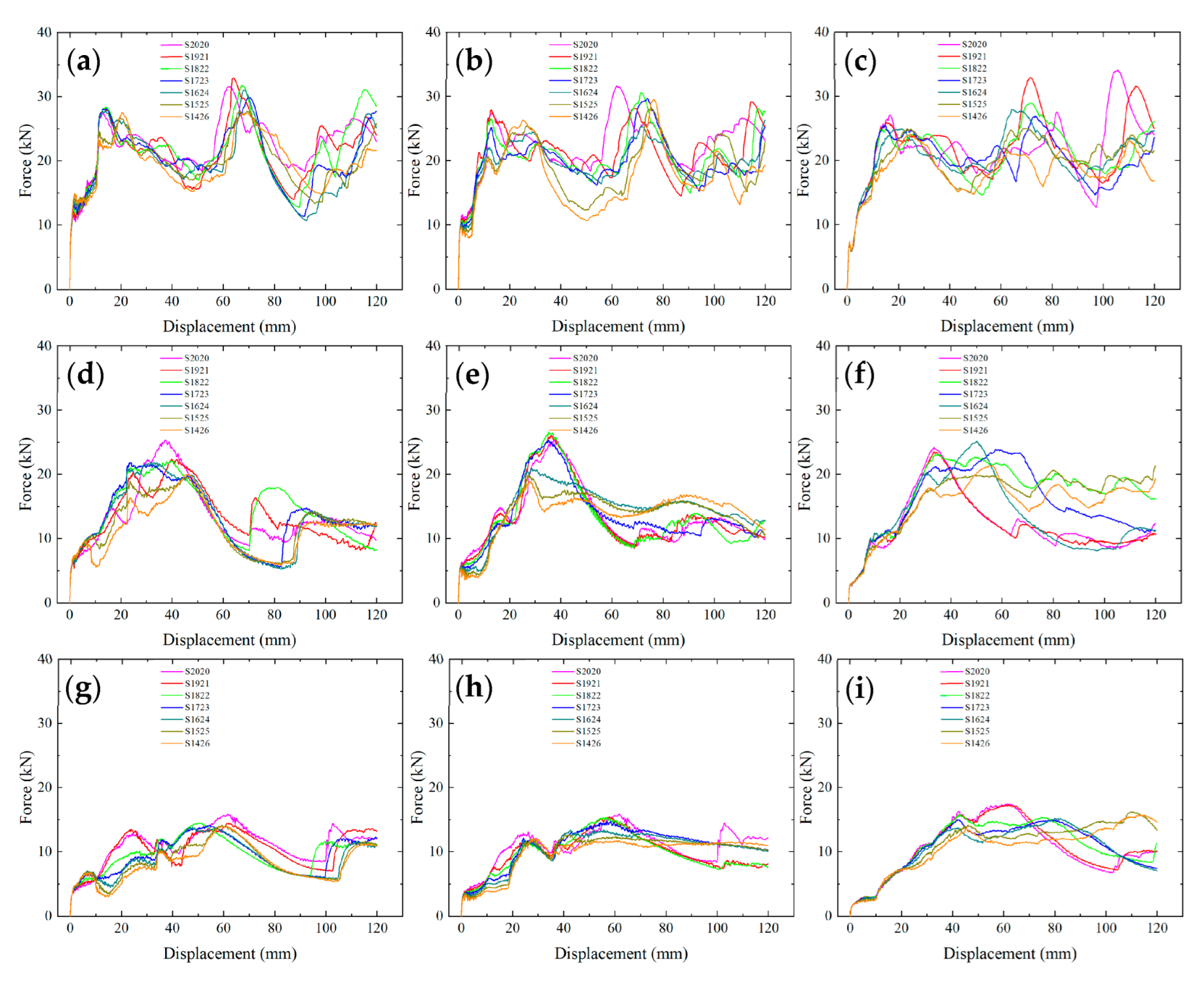

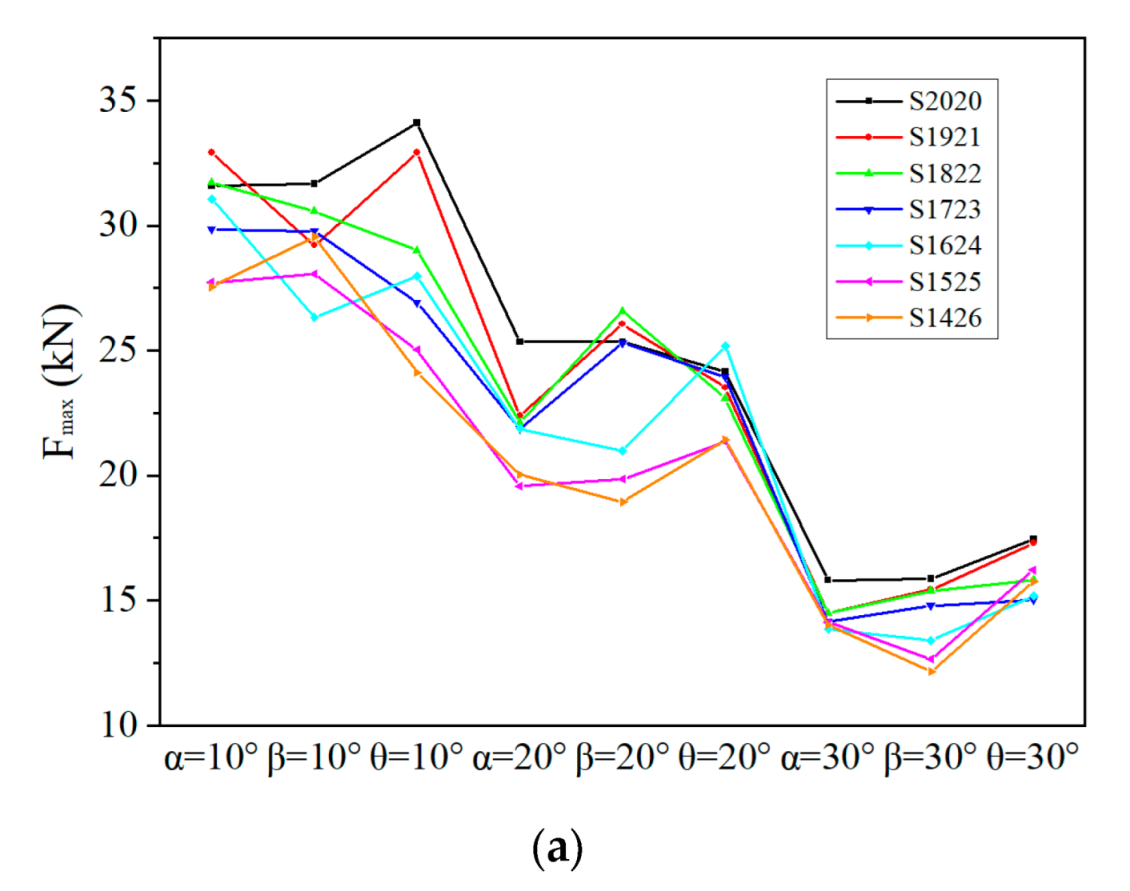

3.3. Crushing Performance Analysis under Oblique Loading

3.4. Optimization Results and Discussion

4. Conclusions

- The manufactured AVTHTs could exhibit a progressive deformation mode with generating folds under axial loading, whether in experiments or simulations;

- AVTHTs under several types of loading angles (0°, 10°, 20°, and 30°) and patterns exhibited different deformation modes, as well as force-displacement characteristics and crashworthiness indices. The changing of plate thickness configuration could change the crushing performance of AVTHTs under axial and oblique loadings;

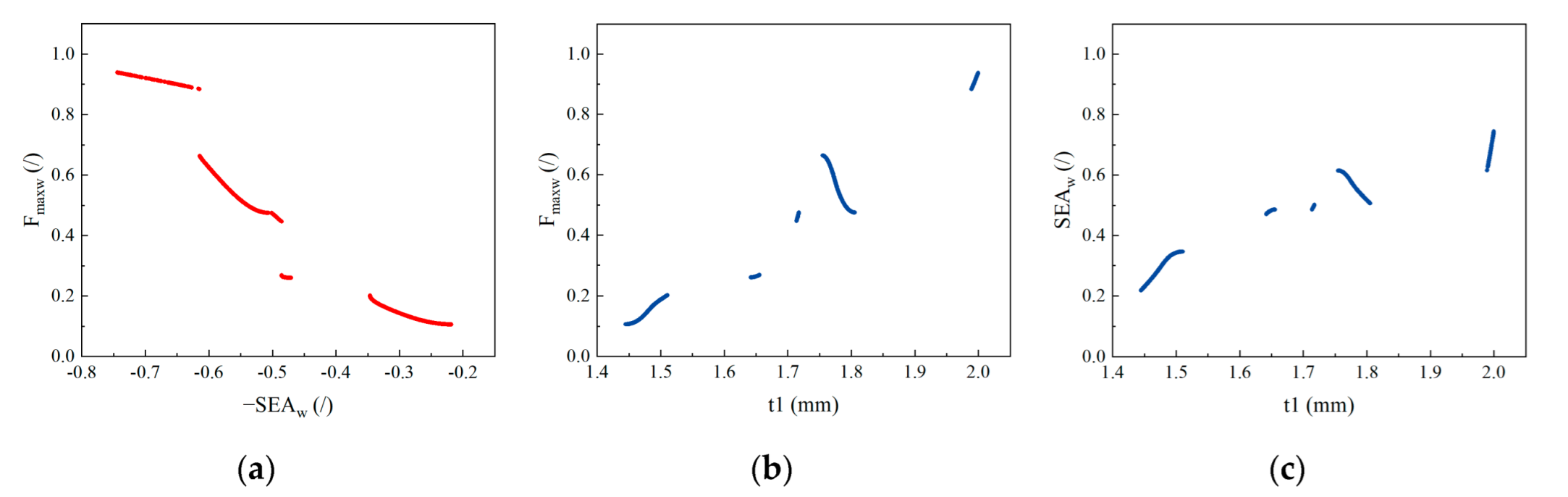

- The results of optimization determined the thickness of the design domains and indicated that a certain thickness range should be avoided, such as the ranges of and . In the pareto results, increasing t1 would not always increase the Fmaxw and SEAw. For example, when , increasing t1 would lead to decline of Fmaxw and SEAw.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, S.; Liang, X.; Zhou, H. Design and analysis of a composite energy-absorbing structure for use on railway vehicles. Proc. Inst. Mech. Eng. Part F—J. Rail Rapid Transit 2015, 230, 825–839. [Google Scholar] [CrossRef]

- Yao, S.; Li, Z.; Yan, J.; Xu, P.; Peng, Y. Analysis and parameters optimization of an expanding energy-absorbing structure for a rail vehicle coupler. Thin-Walled Struct. 2018, 125, 129–139. [Google Scholar] [CrossRef]

- Xu, P.; Yang, C.; Peng, Y.; Yao, S.; Zhang, D.; Li, B. Crash performance and multi-objective optimization of a gradual ener-gy-absorbing structure for subway vehicles. Int. J. Mech. Sci. 2016, 107, 1–12. [Google Scholar] [CrossRef]

- Lin, Y.; Min, J.; Li, Y.; Lin, J. A thin-walled structure with tailored properties for axial crushing. Int. J. Mech. Sci. 2019, 157–158, 119–135. [Google Scholar] [CrossRef]

- Xie, S.; Zhou, H. Analysis and optimisation of parameters influencing the out-of-plane energy absorption of an aluminium honeycomb. Thin-Walled Struct. 2015, 89, 169–177. [Google Scholar] [CrossRef]

- Yang, C.; Xu, P.; Yao, S.; Xie, S.; Li, Q.; Peng, Y. Optimization of honeycomb strength assignment for a composite ener-gy-absorbing structure. Thin-Walled Struct. 2018, 127, 741–755. [Google Scholar] [CrossRef]

- Ali, M.; Ohioma, E.; Kraft, F.; Alam, K. Theoretical, numerical, and experimental study of dynamic axial crushing of thin walled pentagon and cross-shape tubes. Thin-Walled Struct. 2015, 94, 253–272. [Google Scholar] [CrossRef]

- Altin, M.; Kılınçkaya, Ü.; Acar, E.; Guler, M. Investigation of combined effects of cross section, taper angle and cell structure on crashworthiness of multi-cell thin-walled tubes. Int. J. Crashworth. 2017, 24, 121–136. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H. Experimental and numerical investigation on crush resistance of polygonal columns and angle elements. Thin-Walled Struct. 2012, 57, 25–36. [Google Scholar] [CrossRef]

- Chen, D.-H.; Masuda, K. Crushing Behavior of Thin-Walled Hexagonal Tubes with Partition Plates. ISRN Mech. Eng. 2011, 2011, 503973. [Google Scholar] [CrossRef][Green Version]

- Li, W.; Luo, Y.; Li, M.; Sun, F.; Fan, H. A more weight-efficient hierarchical hexagonal multi-cell tubular absorber. Int. J. Mech. Sci. 2018, 140, 241–249. [Google Scholar] [CrossRef]

- Qiu, N.; Gao, Y.; Fang, J.; Feng, Z.; Sun, G.; Li, Q. Theoretical prediction and optimization of multi-cell hexagonal tubes under axial crashing. Thin-Walled Struct. 2016, 102, 111–121. [Google Scholar] [CrossRef]

- Zou, X.; Gao, G.-J.; Dong, H.-P.; Li, J.; Zhou, X.-S.; Chen, W.; Guan, W.-Y. Crushing analysis and multi-objective optimization of bitubular hexagonal columns with ribs. J. Cent. South Univ. 2017, 24, 1164–1173. [Google Scholar] [CrossRef]

- Xu, K.; Xu, P.; Yang, C.; Wang, T.; Li, B.; Che, Q.; Yao, S.; Huang, Q. Crashworthiness optimisation for the rectangular tubes with axisymmetric and uniform thicknesses under offset loading. Struct. Multidiscip. Optim. 2020, 62, 957–977. [Google Scholar] [CrossRef]

- Xu, P.; Wang, D.; Yao, S.; Xu, K.; Zhao, H.; Wang, S.; Guo, W.; Li, B. Multi-objective uncertain optimization with an ellipsoid-based model of a centrally symmetrical square tube with diaphragms for subways. Struct. Multidiscip. Optim. 2021, 64, 2789–2804. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H. Crush resistance of square tubes with various thickness configurations. Int. J. Mech. Sci. 2016, 107, 58–68. [Google Scholar] [CrossRef]

- Ahmad, Z.; Thambiratnam, D.; Tan, A. Dynamic energy absorption characteristics of foam-filled conical tubes under oblique impact loading. Int. J. Impact Eng. 2010, 37, 475–488. [Google Scholar] [CrossRef]

- Alkhatib, S.E.; Tarlochan, F.; Hashem, A.; Sassi, S. Collapse behavior of thin-walled corrugated tapered tubes under oblique impact. Thin-Walled Struct. 2018, 122, 510–528. [Google Scholar] [CrossRef]

- Azarakhsh, S.; Ghamarian, A. Collapse behavior of thin-walled conical tube clamped at both ends subjected to axial and oblique loads. Thin-Walled Struct. 2017, 112, 1–11. [Google Scholar] [CrossRef]

- Chen, Y.; Bai, Z.; Zhang, L.; Wang, Y.; Sun, G.; Cao, L. Crashworthiness analysis of octagonal multi-cell tube with functionally graded thickness under multiple loading angles. Thin-Walled Struct. 2017, 110, 133–139. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, G.; Xu, X.; Li, G.; Li, Q. Multiobjective crashworthiness optimization of hollow and conical tubes for multiple load cases. Thin-Walled Struct. 2014, 82, 331–342. [Google Scholar] [CrossRef]

- Li, Z.; Ma, W.; Xu, P.; Yao, S. Crashworthiness of multi-cell circumferentially corrugated square tubes with cosine and triangular configurations. Int. J. Mech. Sci. 2019, 165, 105205. [Google Scholar] [CrossRef]

- Yao, S.; Tian, Y.; Li, Z.; Yang, F.; Xu, P. Crushing characteristic of polygonal tubes with hierarchical triangular cells. Thin-Walled Struct. 2020, 157, 107031. [Google Scholar] [CrossRef]

- Li, Z.; Yao, S.; Ma, W.; Xu, P.; Che, Q. Energy-absorption characteristics of a circumferentially corrugated square tube with a cosine profile. Thin-Walled Struct. 2019, 135, 385–399. [Google Scholar] [CrossRef]

- Feng, Z.; Xie, S.; Ma, W.; Jing, K.; Wang, H. Multi-tube energy-absorbing structures with different matching patterns of heights and diaphragm spacings. Alex. Eng. J. 2022, 61, 11111–11127. [Google Scholar] [CrossRef]

- Yao, S.; Li, Z.; Ma, W.; Xu, P. Crashworthiness analysis of a straight-tapered shrink tube. Int. J. Mech. Sci. 2019, 157–158, 512–527. [Google Scholar] [CrossRef]

- Xing, J.; Xu, P.; Yao, S.; Zhao, H.; Zhao, Z.; Wang, Z. Study on the layout strategy of diaphragms to enhance the energy absorption of thin-walled square tubes. Structures 2021, 29, 294–304. [Google Scholar] [CrossRef]

- Li, Z.; Ma, W.; Yao, S.; Xu, P. Crashworthiness performance of corrugation- reinforced multicell tubular structures. Int. J. Mech. Sci. 2020, 190, 106038. [Google Scholar] [CrossRef]

- Nia, A.A.; Parsapour, M. Comparative analysis of energy absorption capacity of simple and multi-cell thin-walled tubes with triangular, square, hexagonal and octagonal sections. Thin-Walled Struct. 2014, 74, 155–165. [Google Scholar] [CrossRef]

- Fan, Z.; Lu, G.; Liu, K. Quasi-static axial compression of thin-walled tubes with different cross-sectional shapes. Eng. Struct. 2013, 55, 80–89. [Google Scholar] [CrossRef]

- Li, W.; Zhang, B.; Fan, H. Crushing Behaviors of Fractal Hexagonal Tubular Structures: Experiments and Plastic Analysis. Acta Mech. Solida Sin. 2019, 32, 713–724. [Google Scholar] [CrossRef]

- Ying, L.; Dai, M.; Zhang, S.; Ma, H.; Hu, P. Multiobjective crashworthiness optimization of thin-walled structures with func-tionally graded strength under oblique impact loading. Thin-Walled Struct. 2017, 117, 165–177. [Google Scholar] [CrossRef]

- Yang, S.; Qi, C. Multiobjective optimization for empty and foam-filled square columns under oblique impact loading. Int. J. Impact Eng. 2013, 54, 177–191. [Google Scholar] [CrossRef]

- Djamaluddin, F.; Abdullah, S.; Ariffin, A.; Nopiah, Z. Optimization of foam-filled double circular tubes under axial and oblique impact loading conditions. Thin-Walled Struct. 2015, 87, 1–11. [Google Scholar] [CrossRef]

- Xu, P.; Xing, J.; Yao, S.; Yang, C.; Chen, K.; Li, B. Energy distribution analysis and multi-objective optimization of a gradual energy-absorbing structure for subway vehicles. Thin-Walled Struct. 2017, 115, 255–263. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, Z.; Cheng, A.; Li, G. Design optimisation of composite bumper beam with variable cross-sections for automotive vehicle. Int. J. Crashworth. 2016, 22, 365–376. [Google Scholar] [CrossRef]

- Zhang, Y.; Ge, P.; Lu, M.; Lai, X. Crashworthiness study for multi-cell composite filling structures. Int. J. Crashworth. 2017, 23, 32–46. [Google Scholar] [CrossRef]

- Shan, S.; Wang, G.G. Metamodeling for High Dimensional Simulation-Based Design Problems. J. Mech. Des. 2010, 132, 051009. [Google Scholar] [CrossRef]

- Xie, S.; Li, H.; Yang, C.; Yao, S. Crashworthiness optimisation of a composite energy-absorbing structure for subway vehicles based on hybrid particle swarm optimisation. Struct. Multidiscip. Optim. 2018, 58, 2291–2308. [Google Scholar] [CrossRef]

- Xie, S.; Li, H.; Yang, W.; Wang, N. Crashworthiness optimisation of a composite energy-absorbing structure for railway vehicles. Struct. Multidiscip. Optim. 2017, 57, 1793–1807. [Google Scholar] [CrossRef]

- Yamashita, M.; Hattori, T.; Nishimura, N.; Tange, Y. Quasi-Static and Dynamic Axial Crushing of Various Polygonal Tubes. Key Eng. Mater. 2007, 340–341, 1399–1404. [Google Scholar] [CrossRef]

- Li, G.; Zhang, Z.; Sun, G.; Xu, F.; Huang, X. Crushing analysis and multiobjective optimization for functionally graded foam-filled tubes under multiple load cases. Int. J. Mech. Sci. 2014, 89, 439–452. [Google Scholar] [CrossRef]

- Li, G.; Zhang, Z.; Sun, G.; Huang, X.; Li, Q. Comparison of functionally-graded structures under multiple loading angles. Thin-Walled Struct. 2015, 94, 334–347. [Google Scholar] [CrossRef]

| Properties | Values | Standard Deviation | Coefficient of Variation |

|---|---|---|---|

| Young’s modulus E (GPa) | 69.07/69.54/70.76 | 0.712 | 1.021% |

| Yield stress σy (MPa) | 53.78/54.45/53.77 | 0.318 | 0.589% |

| Peak Stress (MPa) | 138.07/138.19/137.80 | 0.163 | 0.118% |

| Properties | Values |

|---|---|

| Density ρ (kg/m3) | 2700 |

| Young’s modulus E (GPa) | 69.79 |

| Yield stress σy (MPa) | 54.00 |

| Ultimate stress σu (MPa) | 163.46 |

| Poisson’s ratio υ | 0.3 |

| Types | t1 |

|---|---|

| Sampling design points | 1.4 1.45 1.5 1.55 1.6 1.65 1.7 1.75 1.8 1.85 1.9 1.95 2 |

| Validation points | 1.42 1.69 1.74 1.87 |

| Tubes | Fmax (kN) | SEA (kJ/kg) | CFE (/) | |

|---|---|---|---|---|

| S2020 | Simulation results | 49.727 | 12.686 | 0.497 |

| Experiment-1 results | 49.709 | 13.628 | 0.535 | |

| Experiment-2 results | 49.589 | 13.593 | 0.534 | |

| Average experimental value | 49.649 | 13.610 | 0.535 | |

| Standard deviation | 0.060 | 0.018 | 0.000 | |

| Coefficient of variation | 0.121% | 0.129% | 0.066% | |

| Average error | 0.157% | −6.793% | −7.041% | |

| S1822 | Simulation results | 46.998 | 11.227 | 0.466 |

| Experiment-1 results | 47.138 | 11.378 | 0.471 | |

| Experiment-2 results | 47.343 | 11.616 | 0.478 | |

| Average experimental value | 47.240 | 11.497 | 0.475 | |

| Standard deviation | 0.102 | 0.119 | 0.004 | |

| Coefficient of variation | 0.216% | 1.035% | 0.764% | |

| Average error | −0.513% | −2.349% | −1.817% | |

| S1624 | Simulation results | 47.086 | 10.884 | 0.451 |

| Experiment-1 results | 45.603 | 10.931 | 0.467 | |

| Experiment-2 results | 44.342 | 11.056 | 0.486 | |

| Average experimental value | 44.972 | 10.993 | 0.476 | |

| Standard deviation | 0.631 | 0.062 | 0.009 | |

| Coefficient of variation | 1.402% | 0.567% | 1.992% | |

| Average error | 4.700% | −0.994% | −5.349% | |

| S1426 | Simulation results | 47.448 | 10.523 | 0.432 |

| Experiment-1 results | 45.607 | 10.878 | 0.465 | |

| Experiment-2 results | 43.967 | 10.899 | 0.483 | |

| Average experimental value | 44.787 | 10.889 | 0.474 | |

| Standard deviation | 0.820 | 0.011 | 0.009 | |

| Coefficient of variation | 1.831% | 0.097% | 1.918% | |

| Average error | 5.942% | −3.357% | −8.879% |

| Tubes | Fmax (kN) | SEA (kJ/kg) | CFE (/) |

|---|---|---|---|

| S2020 | 49.727 | 12.686 | 0.497 |

| S1921 | 47.539 | 11.473 | 0.466 |

| S1822 | 46.998 | 11.227 | 0.466 |

| S1723 | 47.003 | 11.009 | 0.452 |

| S1624 | 47.086 | 10.884 | 0.451 |

| S1525 | 47.363 | 10.649 | 0.434 |

| S1426 | 47.448 | 10.523 | 0.432 |

| Indices | Fmaxw | −SEAw |

|---|---|---|

| R2 | 0.9904 | 0.9926 |

| RAAE | 0.08564 | 0.0675 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, K.; Xu, P.; Xing, J.; Yao, S.; Huang, Q. Crushing Analysis and Optimization of Adjacent Variable Thickness Hexagonal Tubes. Appl. Sci. 2022, 12, 7348. https://doi.org/10.3390/app12147348

Xu K, Xu P, Xing J, Yao S, Huang Q. Crushing Analysis and Optimization of Adjacent Variable Thickness Hexagonal Tubes. Applied Sciences. 2022; 12(14):7348. https://doi.org/10.3390/app12147348

Chicago/Turabian StyleXu, Kai, Ping Xu, Jie Xing, Shuguang Yao, and Qi Huang. 2022. "Crushing Analysis and Optimization of Adjacent Variable Thickness Hexagonal Tubes" Applied Sciences 12, no. 14: 7348. https://doi.org/10.3390/app12147348

APA StyleXu, K., Xu, P., Xing, J., Yao, S., & Huang, Q. (2022). Crushing Analysis and Optimization of Adjacent Variable Thickness Hexagonal Tubes. Applied Sciences, 12(14), 7348. https://doi.org/10.3390/app12147348