Mineral Identification Based on Deep Learning Using Image Luminance Equalization

Abstract

:1. Introduction

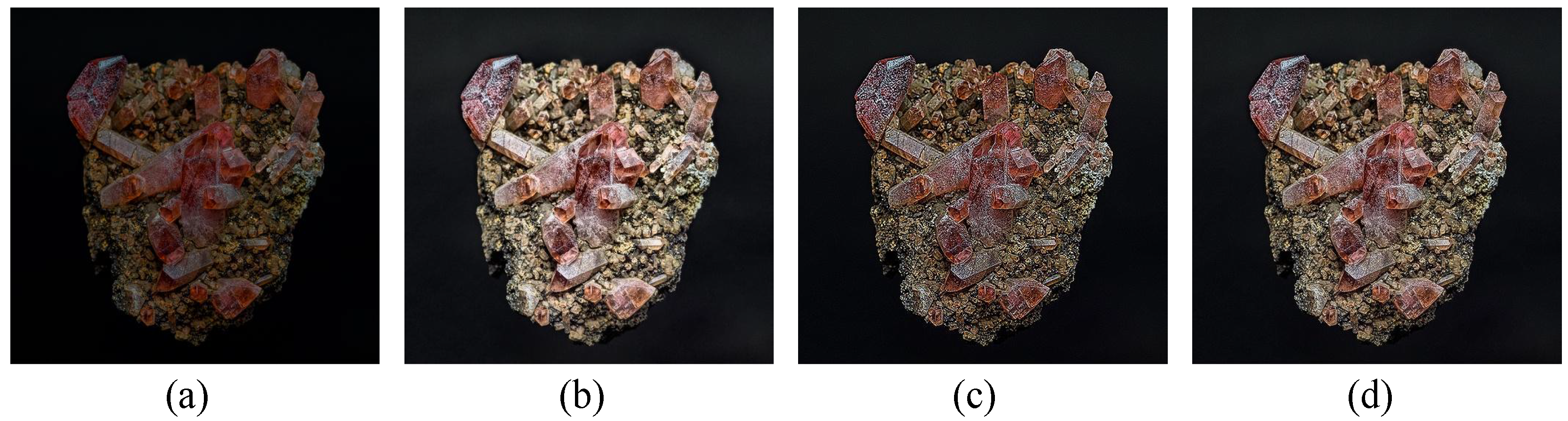

- We first propose a novel image enhancement algorithm, one which combines histogram equalization (HE) and the Laplace algorithm. In subsequent experiments, the algorithm shows powerful results.

- We achieved the an efficient identification of 50 minerals, which is a significant expansion of the number of mineral species identified compared to the existing works.

- Experiments show that our method achieves 95.6% accuracy in mineral identification, surpassing existing mineral identification methods.

2. The Proposed Method

2.1. Histogram Equalization

2.2. Laplace Operator Image Enhancement

2.3. A New Algorithm Based on HELaplace

| Algorithm 1 HELaplace |

|

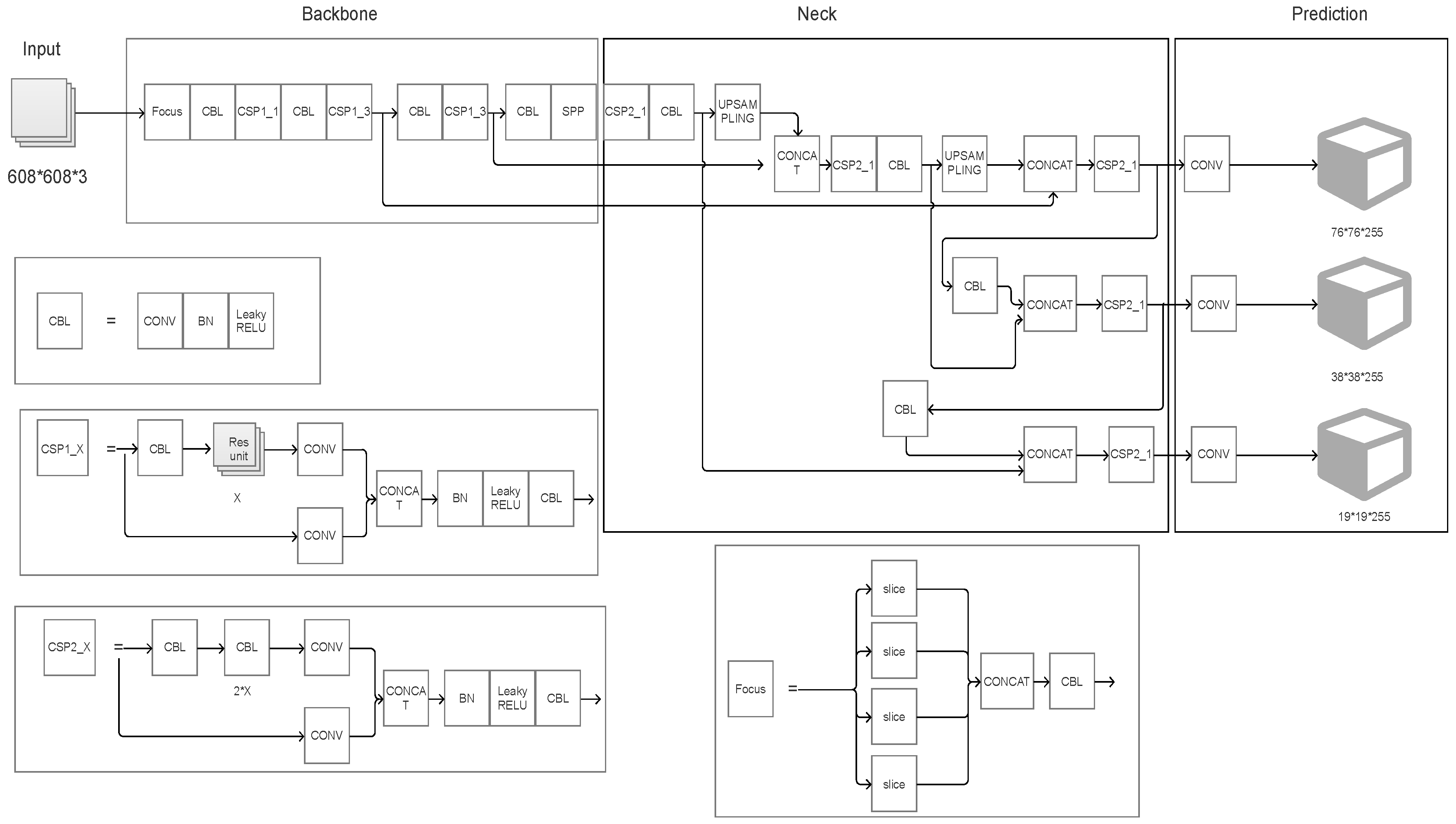

3. Architecture of the Neural Network

3.1. Description of Our Model

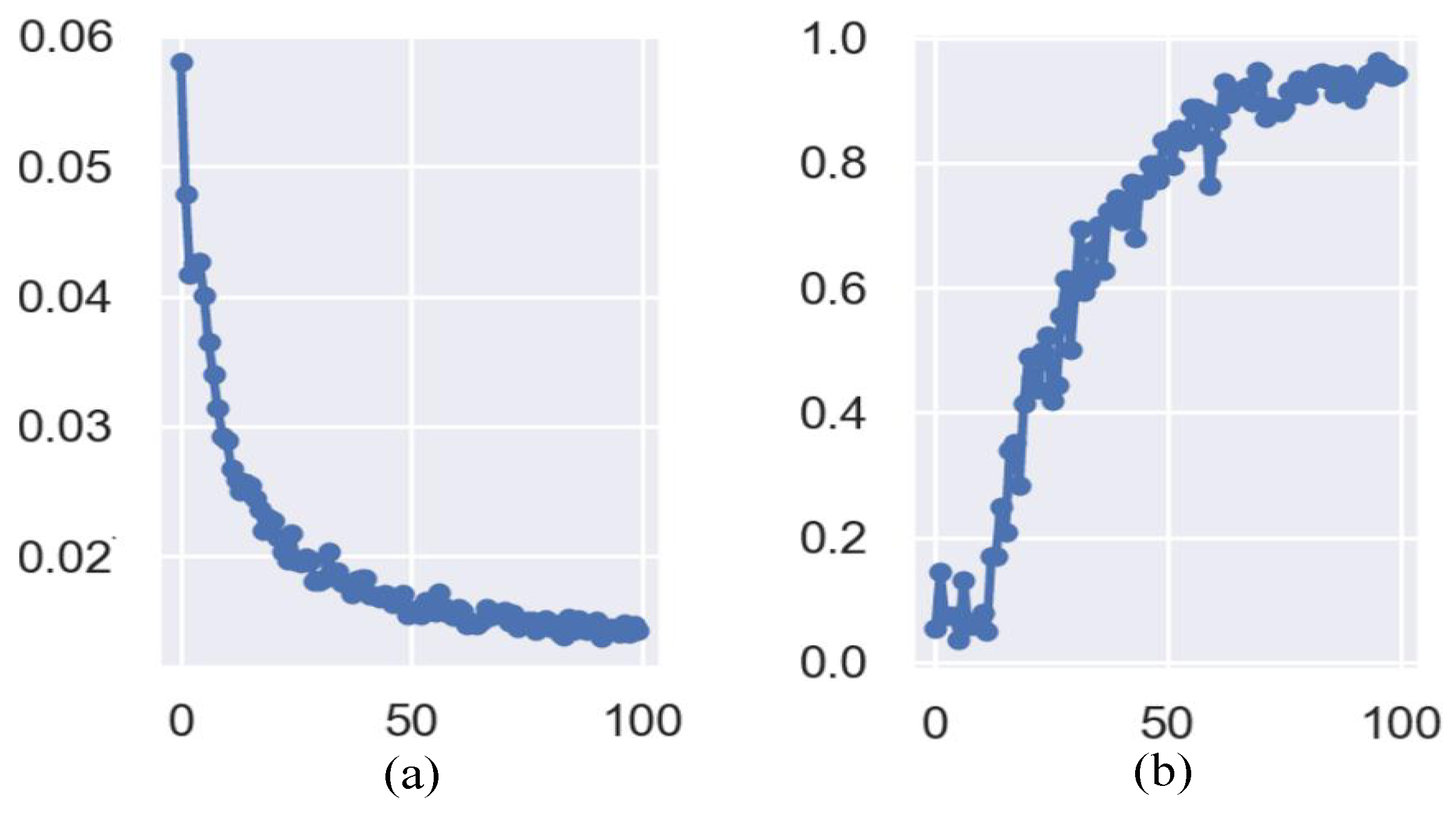

3.2. Model Training

4. Test Result and Discussion

4.1. Data

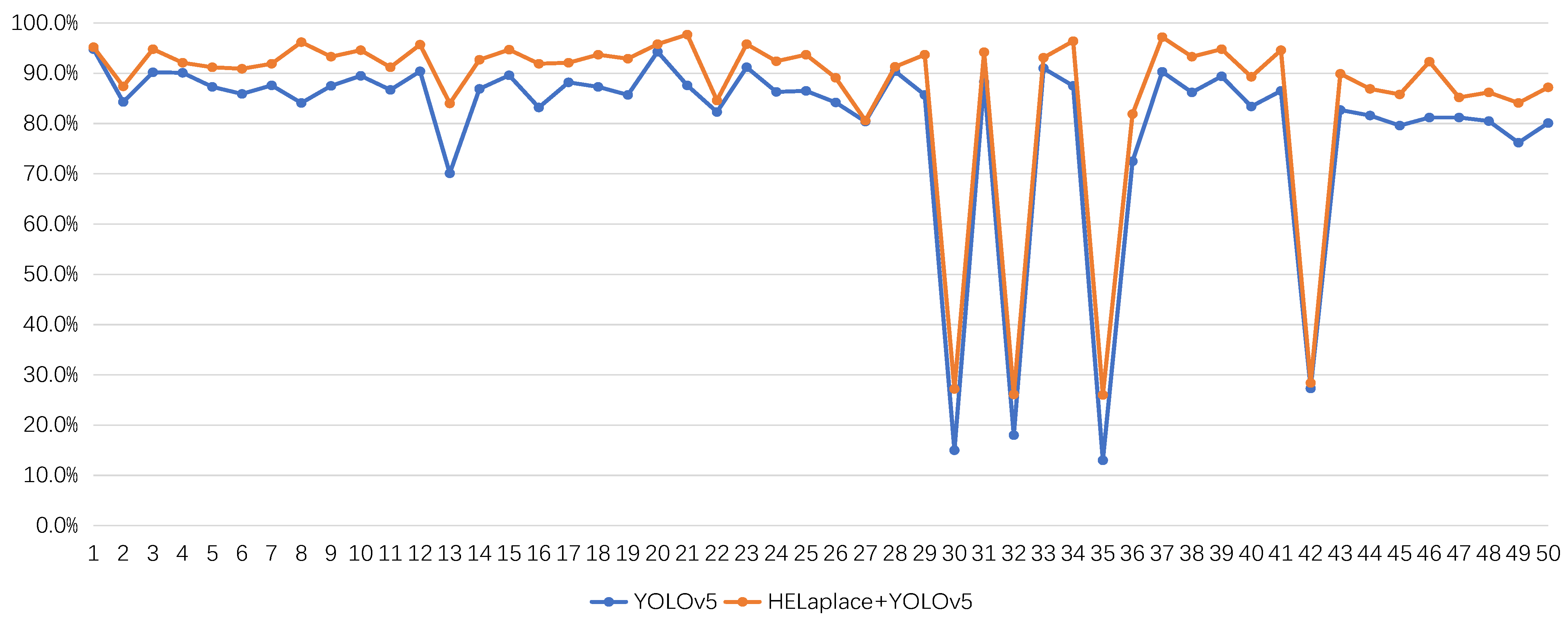

4.2. Test Result

4.3. Comparison with Other Methods

4.4. Objective Evaluation Indicators

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Y.; Yang, K.; Xiu, L. Identification of hydrocarbon and clay minerals based on near-infrared spectroscopy and its geological significance. Geol. Bull. China 2017, 36, 1884–1891. [Google Scholar]

- Wang, R.-S.; Yang, S.-M.; Yan, B.K. A review of mineral spectral identification methods and models with imaging spectrometer. Remote Sens. Land Resour. 2007, 19, 1–9. [Google Scholar]

- Porwal, A.; Carranza, E.; Hale, M. Artificial neural networks for mineral-potential mapping: A case study from Aravalli Province, Western India. Nat. Resour. Res. 2003, 12, 155–171. [Google Scholar] [CrossRef]

- Li, S.; Chen, J.; Liu, C.; Wang, Y. Mineral prospectivity prediction via convolutional neural networks based on geological big data. J. Earth Sci. 2021, 32, 327–347. [Google Scholar] [CrossRef]

- Lou, W.; Zhang, D.; Bayless, C.R. Review of Mineral Recognition and Its Future. Appl. Geochem. 2020, 122, 104727. [Google Scholar] [CrossRef]

- Ruisanchez, I.; Potokar, P.; Zupan, J.; Smolej, V. Classification of Energy Dispersion X-ray Spectra of Mineralogical Samples by Artificial Neural Networks. J. Chem. Inf. Model. 1996, 36, 214–220. [Google Scholar] [CrossRef]

- Tsuji, T.; Yamaguchi, H.; Ishii, T.; Matsuoka, T. Mineral classification from quantitative X-ray maps using neural network: Application to volcanic rocks. Island Arc 2010, 19, 105–119. [Google Scholar] [CrossRef]

- El Haddad, J.; de Lima Filho, E.S.; Vanier, F.; Harhira, A.; Padioleau, C.; Sabsabi, M.; Wilkie, G.; Blouin, A. Multiphase mineral identification and quantification by laser-induced breakdown spectroscopy. Miner. Eng. 2019, 134, 281–290. [Google Scholar] [CrossRef]

- Liu, J.; Osadchy, M.; Ashton, L.; Foster, M.; Solomon, C.J.; Gibson, S.J. Deep convolutional neural networks for raman spectrum recognition: A unified solution. Analyst 2017, 142, 4067–4074. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Zhou, Z.; Lin, H.; Liu, X.; Chen, D.; Zhu, J.; Wu, J. The mineral intelligence identification method based on deep learning algorithms. Earth Sci. Front. 2020, 27, 39–47. [Google Scholar]

- Álvarez Iglesias, J.C.; Santos, R.B.M.; Paciornik, S. Deep learning discrimination of quartz and resin in optical microscopy images of minerals. Miner. Eng. 2019, 138, 79–85. [Google Scholar] [CrossRef]

- Maitre, J.; Bouchard, K.; Bédard, L.P. Mineral grains recognition using computer vision and machine learning. Comput. Geosci. 2019, 130, 84–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Han, S.; Ren, Q.; Shi, J. Intelligent Identification for Rock-Mineral Microscopic Images Using Ensemble Machine Learning Algorithms. Sensors 2019, 19, 3914. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.; Zhou, Y. Artificial intelligence identification of ore minerals under microscope based on deep learning algorithm. Acta Petrol. Sin. 2018, 34, 3244–3252. [Google Scholar]

- Izadi, H.; Sadri, J.; Mehran, N.A. Intelligent mineral identification using clustering and artificial neural networks techniques. In Proceedings of the Conference on Pattern Recognition and Image Analysis, Birjand, Iran, 6–8 March 2013; pp. 1–5. [Google Scholar]

- Zeng, X.; Xiao, Y.; Ji, X.; Wang, G. Mineral Identification Based On Deep Learning That Combines Image And Mohs Hardness. Minerals 2021, 11, 506. [Google Scholar] [CrossRef]

- Peng, W.; Bai, L.; Shang, S.; Tang, X.; Zhang, Z. Common mineral intelligent recognition based on improved InceptionV3. Geol. Bull. China 2019, 38, 2059–2066. [Google Scholar]

- Ramil, A.; López, A.; Pozo-Antonio, J.; Rivas, T. A computer vision system for identification of granite-forming minerals based on RGB data and artificial neural networks. Measurement 2018, 117, 90–95. [Google Scholar] [CrossRef]

- Li, Z.; Jia, Z.; Yang, J.; Kasabov, N. A method to improve the accuracy of SAR image change detection by using an image enhancement method. ISPRS J. Photogramm. Remote Sens. 2020, 163, 137–151. [Google Scholar] [CrossRef]

- Xiao, Y.; Jiang, A.; Ye, J.; Wang, M.W. Making of Night Vision: Object Detection Under Low-Illumination. IEEE Access 2020, 8, 123075–123086. [Google Scholar] [CrossRef]

- Xiong, J.; Zou, X.; Wang, H.; Peng, H.; Zhu, M.; Lin, G. Recognition of ripe litchi in different illumination conditions based on Retinex image enhancement. Trans. Chin. Soc. Agric. Eng. 2013, 29, 170–178. [Google Scholar]

- Tan, M.; Pang, R.; Le, Q.V. Efficientdet: Scalable and efficient object detection. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 13–19 June 2020; pp. 10781–10790. [Google Scholar]

- Bochkovskiy, A.; Wang, C.Y.; Liao, H.Y.M. Yolov4: Optimal speed and accuracy of object detection. arXiv 2020, arXiv:2004.10934. [Google Scholar]

- Xu, Q.; Zhu, Z.; Ge, H.; Zhang, Z.; Zang, X. Effective Face Detector Based on YOLOv5 and Superresolution Reconstruction. Comput. Math. Methods Med. 2021, 2021, 7748350. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Li, Y.; Li, Y.; Li, M.; Xu, X. YOLO-FIRI: Improved YOLOv5 for Infrared Image Object Detection. IEEE Access 2021, 9, 141861–141875. [Google Scholar] [CrossRef]

- Pizer, M.S.; Amburn, P.E.; Austin, D.J.; Cromartie, R.; Geselowitz, A.; Greer, T.; Romeny, T.H.B.; Zimmerman, B.J. Adaptive histogram equalization and its variations. Comput. Vis. Graph. Image Process. 1987, 39, 355–368. [Google Scholar] [CrossRef]

- Jebadass, J.R.; Balasubramaniam, P. Low contrast enhancement technique for color images using interval-valued intuitionistic fuzzy sets with contrast limited adaptive histogram equalization. Soft Comput. 2022, 26, 4949–4960. [Google Scholar] [CrossRef]

- Van Vliet, L.J.; Young, I.T.; Beckers, G.L. A nonlinear laplace operator as edge detector in noisy images. Comput. Vis. Graph. Image Process. 1989, 45, 167–195. [Google Scholar] [CrossRef] [Green Version]

- Szedo, G. Color-Space Converter: RGB to YCrCb; Xilinx Corp.: San Jose, CA, USA, 2006. [Google Scholar]

- Reza, A.M. Realization of the contrast limited adaptive histogram equalization (CLAHE) for real-time image enhancement. J. VLSI Signal Process. Syst. Signal Image Video Technol. 2004, 38, 35–44. [Google Scholar] [CrossRef]

- Wang, C.Y.; Liao, H.Y.M.; Wu, Y.H.; Chen, P.Y.; Hsieh, J.W.; Yeh, I.H. CSPNet: A New Backbone that can Enhance Learning Capability of CNN. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops, Long Beach, CA, USA, 16–17 June 2019. [Google Scholar]

- Rezatofighi, H.; Tsoi, N.; Gwak, J.; Sadeghian, A.; Reid, I.; Savarese, S. Generalized intersection over union: A metric and a loss for bounding box regression. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Long Beach, CA, USA, 16–17 June 2019; pp. 658–666. [Google Scholar]

- A Mineral Database. Available online: https://www.mindat.org/ (accessed on 7 June 2022).

- Martini, M.; Francus, P.; Trotta, D.S.L.; Despres, P. Identification of Common Minerals Using Stoichiometric Calibration Method for Dual-Energy CT. Geochem. Geophys. Geosyst. 2021, 22, e2021GC009885. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, M.; Zhu, L.; He, Y.; Sun, G. Raman mineral recognition method based on all-optical diffraction deep neural network. Infrared Laser Eng. 2020, 49, 20200221-1–20200221-8. [Google Scholar]

- Mittal, A.; Soundararajan, R.; Bovik, A.C. Making a “completely blind” image quality analyzer. IEEE Signal Process. Lett. 2012, 20, 209–212. [Google Scholar] [CrossRef]

- Wang, S.; Zheng, J.; Hu, H.M.; Li, B. Naturalness preserved enhancement algorithm for non-uniform illumination images. IEEE Trans. Image Process. 2013, 22, 3538–3548. [Google Scholar] [CrossRef] [PubMed]

| Methods | Studies | Characteristics |

|---|---|---|

| Instrument Observation | [1] | Wide range of applications. |

| [2] | Spectrometer with very high pixels. | |

| Chemical Composition Analysis | [6] | Fast data acquisition. |

| [7] | High accuracy of chemical element identification. | |

| [8] | Low sample loss. | |

| Spectral Analysis | [9] | Reliable and has international datasets. |

| Micro-optical Picture Analysis | [10] | High accuracy rate. |

| [11] | Effectively differentiate between quartz and resin. | |

| [12] | Effective mineral grain identification. | |

| [13] | Good results for rock minerals. | |

| [14] | High accuracy of sulfide mineral identification. | |

| [15] | Good performance in petrographic thin sections. | |

| Traditional Image Analysis | [16] | Combined with mineral hardness. |

| [17] | High accuracy of malachite and blue copper mineral identification. | |

| [18] | Be able to distinguish the formation minerals of different granite types. |

| Parameters | Configuration |

|---|---|

| Pre-training weight | YOLOV5S.PT |

| Epochs | 100 |

| Sample size | 183,380 |

| Conf-thres | 0.05 |

| Iou-thres | 0.45 |

| Img-size | 640 |

| Batch-size | 10 |

| #No. | Mineral | Number of Samples | #No. | Mineral | Number of Samples |

|---|---|---|---|---|---|

| 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 | Adularia Aegirine Agate Albite Almandine Amber Anglesite Azurite Beryl Biotite Boracite Cassiterite Chalcopyrite Cinnabar Copper Demantoid Diopside Elbaite Epidote Fluorite Galena Goethite Gold Gypsum Halite | 738 909 3636 1882 2124 294 1981 8320 9836 1437 240 3321 3296 1618 5504 785 1649 5683 3915 28,147 6661 4063 4796 2439 821 | 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 | Hematite Magnetite Malachite Marcasite Moissanite Niccolite Nitratine Opal Orpiment Ozocerite Pyrite Quartz Rhodochrosite Ruby Sapphire Schorl Selenium Sphalerite Stibnite Sulphur Topaz Torbernite Turquoise Whewellite Wulfenite |

6086 2615 7919 1748 10 245 10 3283 754 23 13,042 46,398 4510 872 1056 2200 106 6412 2548 1843 3926 1170 988 94 8104 |

| Total | 220,057 | ||||

| Method | Accuracy |

|---|---|

|

YOLOv5 HE + YOLOv5 Laplace + YOLOv5 HELaplace + YOLOv5 | 85.31% 87.14% 86.82% 95.63% |

| Studies | Accuracy (%) | Number of Identified Minerals | Image Type |

|---|---|---|---|

| [10] | 89 | 5 | Microscopic |

| [11] | 95 | 2 | Microscopic |

| [12] | 90 | 9 | Microscopic |

| [13] | 90.9 | 4 | Microscopic |

| [14] | 90 | 4 | Microscopic |

| [15] | 95.4 | 23 | Microscopic |

| [34] | \ | 23 | CT |

| [35] | 94.2 | 5 | Raman spectra |

| [16] | 90.6 | 36 | Photo and hardness |

| [17] | 86 | 16 | Photo |

| [18] | 90 | 7 | Photo |

| Our method | 95.6 | 50 | Photo |

| Index | HE | Laplace | HELaplace |

|---|---|---|---|

| LOE | 222.6444 | 156.2836 | 150.7435 |

| NIQE | 25.3780 | 41.7903 | 25.2050 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Gao, Q.; Luo, H.; Long, T. Mineral Identification Based on Deep Learning Using Image Luminance Equalization. Appl. Sci. 2022, 12, 7055. https://doi.org/10.3390/app12147055

Zhang J, Gao Q, Luo H, Long T. Mineral Identification Based on Deep Learning Using Image Luminance Equalization. Applied Sciences. 2022; 12(14):7055. https://doi.org/10.3390/app12147055

Chicago/Turabian StyleZhang, Junyu, Qi Gao, Hailin Luo, and Teng Long. 2022. "Mineral Identification Based on Deep Learning Using Image Luminance Equalization" Applied Sciences 12, no. 14: 7055. https://doi.org/10.3390/app12147055

APA StyleZhang, J., Gao, Q., Luo, H., & Long, T. (2022). Mineral Identification Based on Deep Learning Using Image Luminance Equalization. Applied Sciences, 12(14), 7055. https://doi.org/10.3390/app12147055