Abstract

Beach volleyball is growing in popularity. However, the construction of beach sports courts away from the seashore requires the use of the right quality sand, the desired characteristics of which are defined by FIVB standards. We decided to test sand from 11 volleyball courts in Wrocław, Poland and sand from the Central Sport Centre-Olympic Preparation Centre (CSC-OPC) in Spała, the main training facility for Polish beach volleyball players. Laboratory tests showed that too coarse sand containing admixtures of dark minerals was used for most of the courts in Wrocław. The sand containing the properties most similar to FIVB standards is that at CSC-OPC. Even a small amount of silt found does not guarantee that a sandy surface will be dust-free. Silt can adhere to larger mineral grains and separate from them by mechanical impact or from crushing aggregates. In addition, we surveyed volleyball players. The players unequivocally interpreted the ease of play on finer-grained sands and the reduction of movement dynamics on courts with coarse-grained sand. Nevertheless, these are not the only factors determining their preference for their favourite court. Compliance with FIVB standards, however, guarantees comparable playing conditions.

1. Introduction

Beach volleyball, a sport that has its origins on Hawaiian beaches between 1915 and 1930 [1], is gaining in popularity. Since the 1996 Summer Olympic Games in Atlanta, it has been an Olympic sport under the auspices of the Fédération Internationale de Volleyball (FIVB). Beach volleyball has become an example for the development of other beach sports, including beach soccer, beach handball, and beach tennis, and the concept of two-man outdoor volleyball gave rise to snow volleyball [2]. Unlike indoor volleyball, in the beach version, environmental factors such as wind, rain, and sun influence the way players play and their game strategies. However, the most significant difference remains the difficult ground to move on, affecting the playing technique and fitness requirements for the players [3,4,5].

The sand that covers a beach volleyball court can have different properties, which directly affect the players’ movement dynamics, their jumping ability, and the style and pace of play (Figure 1). Sand conditions will also account for potential knee and ankle injuries, the most common injuries that beach volleyball players suffer [6]. The requirements for sand material are defined by the FIVB [7] standards provided for tournament courts. They specify the range of sand grain sizes and the percentage of each granulometric fraction. This allows for proper drainage properties of the court and avoids the compaction effect of the substrate in case of rainfall. The sand must be free of organic particles that stain the skin and other harmful substances. It is recommended that it be naturally weathered, i.e., it must not come from crushed rocks. It must not contain shells, coral, or other abrasives as potential causes of skin injuries. The absence of any contaminants will also determine its colour, which should be an aesthetically pleasing, non-glaring colour, preferably tan, cream, off-white, beige, blonde, or pale brown. According to the specifications given, the sand should contain sub-angular grains, which increase the softness of the sand and the safety of the players (less abrasiveness than angular grains). The sand at FIVB competitions is subjected to prior approval by the FIVB’s Official Sand Laboratory, Hutcheson Sand and Mixes in Canada. It is taken from different depths of the sand bed, which must not be shallower than 40 cm on the court.

Figure 1.

The growing popularity of beach volleyball means that sand courts are built not only on beaches. The quality of play in this case is determined by the sand used. In the photos are the following players: Maciej Westfal, Natalia Czarnecka, and Piotr Brzóstowicz (photo by M. Kasprzak, published with the permission of the photographed persons).

National volleyball federations generally provide only basic requirements for sand type and quality e.g., [8]. It is important that the sand should not be very coarse and not contain gravel or other dangerous particles. It must also not be too fine so that it does not stick to the players’ skin. It must also not contain clay and silt to avoid a dusting effect. Guidelines in this regard are brought by the practice of companies specialising in the construction of beach courts [9,10]. The presence of silt in sandy material is of particular importance during the construction of indoor courts. Such facilities are increasingly popular in temperate and cold climate countries.

In this paper, we present the results of a study on the quality and playability of sands used for the construction of beach volleyball courts in Wrocław, southwestern Poland. This city is located in a region rich in sand deposits with different origins and properties [11]. Thus, Wrocław’s courts have varied characteristics, as noted by local players. We conducted laboratory testing of sand samples collected from 11 courts, including one located in a sports hall. Additionally, in an anonymous survey, we asked the volleyball players for their opinion on the conditions on each court to confirm their observations on the impact of sand quality on playing conditions. However, due to the conditions described in the following sections, we consider the survey only as a supplementary element. We assumed that fine-grained sand would promote dynamic play and coarse-grained sand would reduce that dynamic play. We were also interested in the presence of silt and characteristics of the larger grains, which are important from the point of view of the quality of the material used to build the courts. We compared the results with a sample taken from a court at the Central Sport Centre—Olympic Preparation Centre (CSC–OPC) in Spała, the main training facility for Polish beach volleyball players.

2. Properties and Differentiation of Sand

Sand is a loose sedimentary rock composed of mineral grains ranging from 0.063 to 2 mm in diameter [12]. The mineral composition of sand depends on the rock that has provided the source of the sandy material by weathering and erosion [13]. Sand is most commonly composed of quartz, which is the major component of granitic rocks. It is a very stable mineral, resistant to chemical weathering, and does not react with other substances regardless of environmental conditions. This property, combined with its high hardness (7 on the Mohs scale), means that quartz can be transported for a long time and over long distances in an aquatic or aeolian environment without changing its physical and chemical structure. In addition to quartz, feldspar grains are most common and are also abundant in magmatic rocks. Feldspars are less hard than quartz (6 on the Mohs scale) and much more sensitive to chemical weathering, making them easy to break down and transform into other minerals. Other common admixtures in the sand are mica and heavy minerals. The admixture content depends mainly on the distance from the source of the material. The resistance of quartz makes sands that are older and moved longer distances more quartz-like, homogeneous, and sorted. This makes quartz sands a more valuable material than limestone, volcanic or polymineral sands.

Depending on the environment in which the mineral sediment was transported, quartz grains acquire different shapes and surface textures [14,15,16]. New grains formed by weathering or erosion of the bedrock have very irregular shapes, and fresh fracture surfaces are visible (Figure 2A). Grains transported by wind have a shape most similar to a sphere and a rough (matt) surface, which is the result of multiple collisions of grains in the saltation process (Figure 2B). Grains that have undergone fluvial transport are characterised by an elongated shape and a shiny surface (Figure 2C). Particularly elongated are marine (beach) grains, which align their longer axis perpendicular to sea waves. Multiple redeposition of sand can also lead to the development of various transitional forms, such as completely matted (nontransparent) grains with a shiny surface. As a principle, grains become more regular in shape as the transport and processing process is lengthened.

Figure 2.

Examples of grains developed under different environmental conditions.

The physical properties of sand, apart from mineral composition and grain texture, are mainly affected by the size of mineral grains. According to the Wentworth scale [17] sand is divided into very fine (0.063–0.125 mm), fine (0.125–0.250 mm), medium (0.25–0.5 mm), coarse (0.5–1 mm), and very coarse (1–2 mm). This classification can be considered universal and is commonly used in environmental studies. However, in geotechnical investigations, classes with slightly different ranges are often used which are derived from accepted standards, such as ISO 14688-1 [18], which distinguishes fine sand (>0.063 to ≤0.20 mm), medium sand (>0.20 to ≤0.63 mm) and coarse sand (>0.63 to ≤2.0 mm). Since many national standards are used in addition to ISO standards worldwide, in this article we will identify grain size based on the Wentworth scale [17].

Very coarse, coarse, and medium sand have very high water and air permeability due to the loose grain arrangement and large voids between grains. Fine sand and very fine sand gradually increase the water holding capacity and cohesiveness of the sediment. The key factor is the contribution of silt and clay, which strongly affect the water absorption and water storage capacity by compacting the sediment. Therefore, sand containing more than 90% sandy fraction is considered loose sand [19]. The permeability of sand is also affected by its sorting. More well-sorted sands, due to the larger distances between grains, are more easily permeable than poorly sorted sediments [20]. Sediment grain size also affects the aerodynamic properties of sand. Grains less than 0.1 mm in diameter are undergoing suspension, whilst larger grains are transported in saltation or as bedload, as they are too heavy to hover in the air for long periods [21].

Due to its commonness, durability, and mechanical and chemical properties, sand is one of the most widely used mineral resources. It is used in construction (a component of concrete and cement [22] and a material for embankments and roads), metallurgy (a component of moulding masses), the chemical industry (a stabilizer and a source of silicon), the production of glass and ceramics, as well as a material for filtering water used for municipal purposes. Also important is the use of sand in sports and recreation as a surface for playing fields. For this reason, individual sports federations define their requirements for sand as a substrate during play. The FIVB has set standards for both granulometric composition (Table 1) and sand properties, as listed in the introduction.

Table 1.

FIVB sand specifications.

3. Materials and Methods

The study was conducted on sand samples collected in March and April 2022 from 10 outdoor beach volleyball courts located in Wrocław and one beach sports hall in the city (Figure 3). The 12th comparative sample was taken from the beach sports hall in CSC–OPC in Spała (Central Poland). Samples with a weight of about 500 g were taken from a depth of approximately 20 cm outwards from the posts supporting the net, where the sediment should be least disturbed during the games. The samples were dried at 60 °C for 48 h to evaporate the water whilst preserving the organic material present in the samples. The samples were then divided into two portions (200 g) and dry sieved (10 min) on two sets of sieves conforming to ISO 3310 [23]. The first set (for granulometric analyses) consisted of sieves at an interval of ½ phi with a mesh diameter of 0.032 mm (5.5 phi)—2 mm (−1 phi). The second set, consistent with FIVB standards [7], was composed of sieves with mesh diameters: 0.05, 0.15, 0.25, 0.5, 1.0, 2.0, and 3.35 mm. Statistical parameters of the grain size distribution (median grain diameter, mean grain diameter, sorting, skewness, kurtosis, and grain size distribution) were calculated using formulas developed by Folk and Ward [24] and implemented into GRADISTAT 9.1 software (Kenneth Pye Associates Ltd., Wokingham, UK) [25]. The permeability of each sample was determined from the grain size using the USBR formula [26] implemented into HydrogeoSieveXL 2.3.6 software (University of Kansas, Lawrence, KS, USA) [27]. Additionally, pH, the content of CaCO3, Fe (atomic absorption spectrometry; AAS) and organic matter (Tyurin method) were measured for each sample. Detailed analyses of samples were performed on 100–150 grains of coarse sand (0.71–1 mm) under an optical microscope with 20× magnification. The roundness of quartz grains was determined according to Krumbein’s chart [28]. The texture of quartz grains was described based on Cailleux’s classification [14]. Mineralogical analysis was performed to determine the content of quartz, feldspars, amphiboles and micas in the sand composition. Images of the samples were taken using a DLT-Cam Pro 8 camera.

Figure 3.

Study area. Locations of beach volleyball courts examined for sand characteristics are marked: 1—Skowroni Park (Weigla St.); 2—KS AZS Wratislavia (Na Grobli St.); 3—Wrocław University of Science and Technology, PWR (Wybrzeże Stanisława Wyspiańskiego); 4—Wrocław University of Health and Sport Sciences, AWF (Adama Mickiewicza St.); 5—‘Morskie Oko’ swimming facility (Fryderyka Chopina St.); 6—GEM Sports Complex (Mianowskiego St.); 7—Millennium Park (Sukielicka St.); 8—LGW Arena court (Prosta St.); 9—‘Glinianki’ swimming facility (Kosmonautów St.); 10—Primary School No. 95 (Stanisława Iwaszkiewicza St.); 11—K69 hall (Kozanowska St.). Map based on BDOT10K database made available by the Central Office of Geodesy and Cartography, Poland (geoportal.gov.pl, public domain).

We supplemented the laboratory analysis with a survey that asked beach volleyball players about the quality of play on specific courts and their preferred volleyball courts. We began the survey in 2019. At that time, the number of beach volleyball courts in Wrocław changed. The assumption was that we only asked about generally accessible courts so that those who were surveyed would have the opportunity to use them. The survey was posted on two Facebook profiles used for communication by amateur and professional players.

4. Results

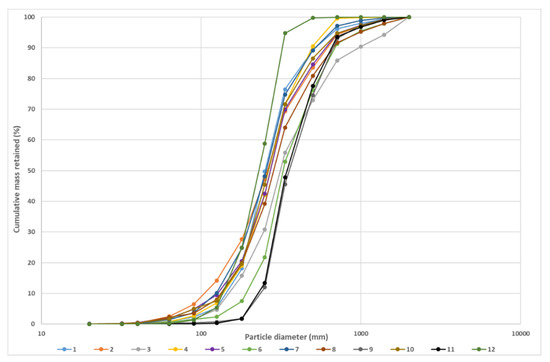

The results of granulometric analyses performed according to the Wentworth scale are presented in Table 2 and Figure 4, with their statistical parameters calculated according to the method of Folk and Ward [24] presented in Table 3. All the studied samples are mainly composed of sand, and the average grain diameter corresponds to either medium sand (9/12 courts) or coarse sand (3/12).

Table 2.

Percentage of granulometric fractions in collected samples according to Wentworth’s classification [17].

Figure 4.

Cumulative grain size distribution of samples on a logarithmic scale. Numbering according to sites in Figure 3.

Table 3.

Statistical parameters of the grain size distribution of collected samples according to Folk and Ward [24].

The silt fraction usually does not exceed 0.2% of the sample, reaching a maximum contribution of 0.5% of the sample (no. 5). Some samples are enriched in gravels (up to 5.7%), with single grains of this size found in all samples. In 9 of the 12 courts, the contribution of gravel by weight did not exceed 1% (Table 2).

The sorting of the samples ranges from poorly (1/12) through moderately (8/12) to moderately-well sorted (3/12), and the most homogeneous was the sample from the CSC-OPC court (no. 12). Half of the samples are characterised by symmetrical grain size distribution, which means that they contain equal amounts of sand of all fractions, and 5/12 courts are characterised by a skewed grain size distribution in the direction of coarse grains. The distinctive sample is the one from the CSC-OPC court, which is skewed towards the fine grains and has a platykurtic distribution. The platykurtic distribution is defined as the flattest, but in this case, this parameter is strongly influenced by the lack of silt and gravel in the sample. Furthermore, it is the best sorted of all the samples. The kurtosis of the remaining samples is either meso- (4/12) or leptokurtic (7/12) when the majority of grains are close to the sample mean grain size.

The consistency of the grain size results with FIVB standards for beach volleyball courts is shown in Table 4. None of the courts surveyed comply with FIVB standards, with very fine sand (9/12 samples) and fine gravel (12/12 samples) being the most frequently violated norms. In the case of very fine sand, the excesses are significant, reaching more than 7%, often referring to the scale of deficiency in the medium and coarse sand class, which according to the standards should dominate the weight content of the sample (80–92%). Gravel is present in all courts, but in half of the samples, its content does not exceed 1%, which for sieved samples of 200 g means the presence of one/two grains of given sizes. The sensitivity of sieve analysis to gravel can be seen in the comparison of two consecutive measurement series (Table 2 and Table 4, respectively), where in extreme cases the difference in gravel content is 2%. In the second half of the samples, gravel is common and represents even more than 5% of the sample weight value. Clay and silt do not represent more than 0.31% of the samples by weight and exceed the standard by no more than 0.16%. The CSC-OPC court (no. 12), at the AWF (no. 4), and in Skowroni Park (no. 1) are the most similar to FIVB standards considering grain size distribution. The variation in granulometric composition and sorting of the samples is reflected in the permeability of the substrate of individual courts, which varies from 5.2 to 20.3 m/d (Table 5).

Table 4.

Conformity of samples with FIVB grain size standards [7]. Green—standard complied; orange—standard exceeded by no more than 0.1%; red—standard exceeded by more than 0.1%. The 0.1% error is marked because an error of this magnitude can come from grains stopping within the mesh of the sieve.

Table 5.

Chemical properties and permeability of samples.

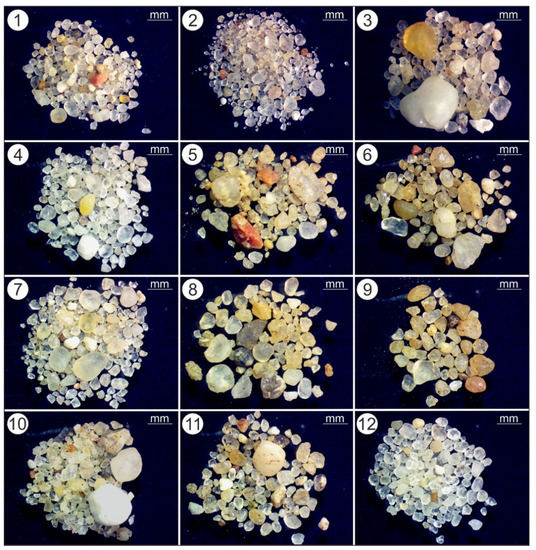

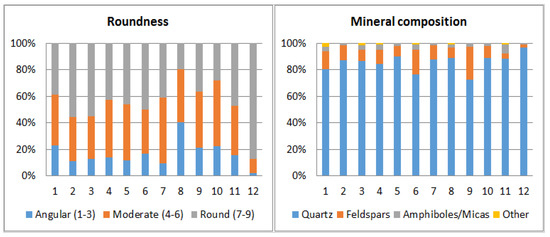

All the studied samples consist mainly of quartz grains (Figure 5 and Figure 6). The texture of the grains surface does not clearly indicate the source of the sand, as the majority of the grains can be found to be slightly aeolised grains subjected to an earlier fluvial transport. Most samples probably originate from sand pits located on higher fluvioglacial terraces and fluvioglacial outwash plains. The roundness of quartz grains varies both within and between samples (Figure 6). The content of angular grains ranges from 2 to 40% (mean 17%), moderate grains range from 11 to 49% (mean 38%), and rounded grains range from 20 to 88% (mean 46%). The dominant mineral component is quartz (average 86%) with feldspar admixture (average 11%; Figure 6). Amphiboles, micas and other minerals comprise no more than 8% of the mineral composition of the sample with an average contribution of 4%. The monomineralic (97% quartz) sample from CSC-OPC (no. 12) stands out as being composed mainly of highly rounded grains (88% grains). Microscopic analysis (Figure 6) also indicated the possibility of silt coating the mineral grains. It is visible in sample no. 9, which at the same time is not characterized by an increased content of silt, CaCO3, Fe, or organic material content (Table 2 and Table 5).

Figure 5.

Microscopic images of sand samples taken from beach volleyball courts located in Wrocław (1–11, numbered according to Figure 3) and in the CSC-OPC in Spała (12).

Figure 6.

Roundness and mineral composition of samples collected in Wrocław (1–11, numbered according to Figure 3) and in the Central Sports Centre—Olympic Preparation Centre in Spała (12).

The pH of the samples ranges from acidic (5.14) to alkaline (8.65) and is related to the presence of calcium carbonate in the samples (Table 5). CaCO3 is present in half of the samples and its maximum content is 3.32% of the weight. The heightened concentration of CaCO3 in samples no. 1, 8, and 10 does not relate to the content of feldspars in those samples (Figure 5). The content of iron in the samples is low, ranging from 0.02–0.17% of the weight. The samples are also poor in organic matter, even on courts located in city parks (no. 1, and 7). The organic matter content ranges from 0.005 to 0.027%.

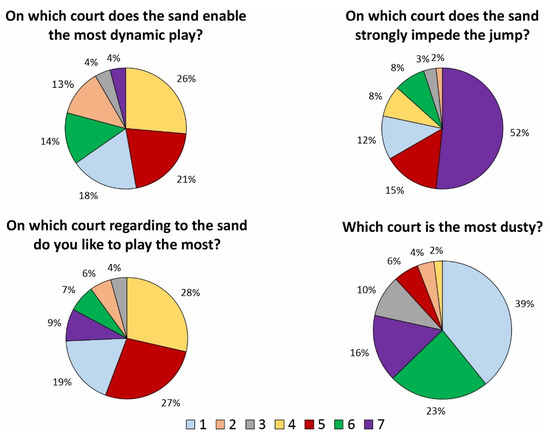

We received 49 valid responses from respondents. Due to the low sample size, responses are not statistically significant and may not be representative. The game quality surveys conducted showed variation in the characteristics of the individual courts (Figure 7). The relation between courts allowing dynamic play and high satisfaction from the game is well visible. Such conditions are characterised by the courts with grain sizes close to FIVB standards (AWF and Skowroni Park), but the court at the ‘Morskie Oko’ complex is also similarly perceived, which does not meet FIVB standards in 5 of the 7 granulometric fractions (Table 4). A similar situation occurs at the LGW Arena court, which, despite good sand parameters, was not chosen as a favourite. The court at ‘Glinianki’ (31 votes), which is characterized by an extremely low content of fine sand (<2%), is considered the most difficult to jump. Additionally, on this court the total content of grains <250 µm is only 2.07% (Table 2), which may result in very low cohesiveness of the sand making it difficult to jump up the court surface. At the same time, the high proportion of gravel (PWr, LGW Arena), according to the respondents, does not negatively affect the possibility of jumping. Volleyball players considered the Skowroni Park, LGW, and ‘Glinianki’ courts as the dustiest. These responses do not correlate with the amount of silt (0.14%, 0.21%, and 0.11%, respectively) or very fine sand (3.30%, 5.42%, and 0.42%, respectively) in these samples. A potential source of dust in these samples could be CaCO3, Fe, or organic particles, but these were not common in the samples (Table 5) despite their drying at 60°, which favours the preservation of organic matter.

Figure 7.

Results of the survey conducted among beach volleyball players playing in Wrocław. 1—Skowroni Park, 2—KS AZS Wratislavia, 3—Wrocław University of Science and Technology, 4—Wrocław University of Health and Sport Sciences, 5—‘Morskie Oko’ swimming facility, 6—LGW Arena, 7—‘Glinianki’ swimming facility.

5. Discussion

Our research allowed us to identify the quality of sand used for the construction of courts in Wrocław and the specialised training facility in CSC-OPC in relation to the requirements of FIVB [7]. The sand from the court in Spała (CSC-OPC, sample no. 12) is the most compliant with the standards, while in Wrocław the best sand parameters are the AWF courts (no. 4) and Skowroni Park (no. 1). Sand from the hall in Spała is the best sorted, and most homogeneous in terms of minerals, and quartz grains are well rounded. Thanks to the uniform mineral composition, the colour of the sand is bright, and the lack of admixtures with different properties causes the skin of players to remain clean after the game. Nevertheless, even this court does not completely meet FIVB standards, containing too much fine sand. Among the examined courts in Wrocław, the opposite trend can be seen. They usually contain too much coarse sand, which is shown by the clearest example of the court at the PWR campus (no. 3). Another problem is the insufficient roundness of the quartz grains, which has been pointed out by FIVB because of the effect of grain shape on skin abrasion [7]. Round grains account for more than 50% in only four samples, and in three samples their content is less than 30%. In the extreme case of the LGW Arena court (no. 8), angular grains make up 40% of the total, which can adversely affect players’ health. Surveys indicate that this court is one of the least liked by players, possibly due to the unfavourable properties of the sand used.

We found gravel grains in several of the sand samples analysed. This is very unfavourable from the point of view of comfort and at times safety of the game. The presence of gravel strongly influences the looseness of the substrate, its porosity and permeability. Courts with good substrate sorting and an average grain diameter < 400 µm have more than twice lower permeability than sites where the substrate shows a skewness towards coarse fractions of sand. The ‘Glinianki’ court (no. 9), which does not meet standards for coarse sand and gravel and has the highest permeability of all courts (over 20 m/d) is indicated by players as being the most difficult to jump out of during play, significantly leading to low satisfaction of the game.

The microscopic analysis allowed us to determine the mineral composition of sand, which is responsible for its colour. Admixtures of feldspars and amphiboles make it take on a darker, less desirable colour. This condition is influenced by the origin of the sand used in Wrocław, which comes from mines exploiting fluvial or fluvioglacial sediments. At the same time, dune sands are not used, which because of their good sorting, monominerality, and grain size distribution in the range of 70–250 µm [21] should be an ideal material for the construction of beach volleyball courts. Practice indicates that sand with the highest possible quartz content will be the best material for the construction of courts.

Our analyses did not indicate that the sand samples contain large amounts of clay and silt. The amount was generally less than 0.1% of the weight of the sample. This is in contrast to our observations that moving players on courts nos.1 and 11 causes a particularly large amount of silt to be stirred up. In this case, three alternative scenarios can be assumed: (1) even a minor percentage of silt content is sufficient to produce an adverse dusting effect, (2) the quartz grains are coated with silt that separates from them by mechanical stress, and (3) the mineral composition of the sand causes the grains to disintegrate during games. Scenarios 1 and 2 seem most likely, with the first not explaining why some courts were not listed as silty in the survey, despite containing this fraction in the granulometric composition. The source of the dust is not the organic material in the sand, the content of which is extremely low in all tested samples. Secondary minerals formed on the surface of the quartz grains can be responsible for the dustiness. The observed silt particles may be aggregates of iron hydroxides formed on the surface of the quartz grains [29], but detailed chemical analyses showed only small concentrations of iron (maximum 0.17%) on the surface of the courts. Considering all these results, the cause of the dustiness in the different courts remains unsolved.

The high silt content is an extremely negative factor. The silt stirred up during the game settles in the surroundings of the courts, dirtying all other surfaces. It also threatens the health of the players, penetrating their lungs and irritating their eyes. Sand with too high silt content cannot be used in indoor facilities. A commonly used method to remove silt is to wash the sand. It is recommended that during the production of sand for court construction it should be washed at least twice. The effect will depend not only on the quality of the material but also on the technological process used. In practice, it is almost impossible to get rid of the silt completely, which is confirmed by examples of beach sports halls known to the authors in Poland, Czechia, or Germany. Their interiors are covered with silt.

Our fairly obvious hypothesis regarding the effect of sand quality on beach volleyball play was confirmed by the respondents’ perception of the courts, although it was much easier for the players to indicate a court with coarse sand impeding play (no. 9) than to unanimously single out a court favouring dynamic play. Nevertheless, the answers confirm that the most dynamic games are played on courts dominated by the sand of finer fractions. The choice of the favourite sand court was a more complex matter. The largest number of players chose the court with the best possible sand in Wrocław (no. 4), although a slightly lower number of people pointed to the court with poor quality sand located at the city swimming pool. It cannot be ruled out that this choice was determined by considerations other than the type of sand itself, such as habit (the longest existing courts) or the possibility of using the swimming pool.

It should be stated that maintaining FIVB standards [7] is particularly important to ensure similar training and match conditions at tournaments held in different regions of the world. Nevertheless, we do not make an unequivocal judgement as to whether jumping sand (fine-grained) or impeding sand (coarse-grained) is better for the game. After all, it depends on the players’ preferences and habits. Coarse-grained sand can also be used at certain stages of training to improve players’ physical motor characteristics and shape players’ playing technique [3,4,5], requiring more varied forms of attack in the face of a hindered jump.

There is no clear research linking the quality of the sandy surface and the number and type of injuries to players. Bahr and Reeser [6] report that apart from the shoulder, lower back and fingers injuries, which are less dependent on the characteristics of the surface, the most common injuries in beach volleyball are knee (30% of injuries) and ankle (17%) injuries. The soft ground and lack of collisions with other players make the rate of severe injuries in beach volleyball much lower than in most other team sports [30], for example, the number of ankle sprains in beach volleyball is half that of indoor play [6]. Jumping and landing on soft sand is less demanding on the tendons, reducing the risk of, among other things, patellar tendinopathy [31]. It can only be conservatively assumed that courts with coarser sand are safer for the health of players than courts with fine sand, especially during days with rainfall when the sand tends to become compacted.

Our results and comparison of sand in different courts lead to the conclusion that FIVB standards [7] are well established, although difficult to comply with in areas located far from sea beaches. The quality of the sand used in the construction of Wrocław’s courts is not the best. This is a result of both the characteristics of the sand deposits themselves, the methods of its production, and economic factors in the construction of the courts. Also, the grain size fractions of sand established by FIVB are difficult to study. The division of grains does not correspond to the logarithmic phi scale used in Europe to establish standards and methods of laboratory testing.

6. Conclusions

Based on our research we can determine the quality of sand used for the construction of volleyball courts in Wrocław and at the Central Sport Centre—Olympic Preparation Centre in Spała, and additionally its compliance with FIVB standards [7]. At the same time, these tests make it possible to arrive at some more general conclusions helpful in choosing the right sand material for beach sports, which are listed below.

- Even a small amount of silt detected by sieve analysis does not guarantee that a sandy court will be free of dusting phenomena. Silt can be adhered to larger mineral grains and separated from them by mechanical action or come from crushing aggregates of secondary minerals.

- Sand used for the construction of volleyball courts should be monomineralic, rounded, and well-sorted. Even a small presence of coarse sand and gravel has a very negative effect on playing satisfaction. Sands that are poorly sorted and contain a high amount of dark minerals are chosen for beach court construction mainly for economic reasons but do not guarantee adequate properties according to FIVB recommendations.

- Players have different preferences for sand granulometric characteristics that result in different game dynamics. Nevertheless, maintaining FIVB standards guarantees comparable playing conditions, and these standards should be aimed at by acquiring sand that meets these requirements.

- In Poland, the court sand of the Central Sport Centre—Olympic Preparation Centre in Spała exceeds the quality of the sand used for the construction of courts in Wrocław and is the closest to FIVB standards. It can be an example for the construction of other courts.

Author Contributions

Conceptualization, M.K.; methodology, M.K. and M.Ł.; laboratory analysis, M.Ł.; writing—original draft preparation, M.K. and M.Ł.; writing—review and editing, M.K.; visualization, M.K. and M.Ł. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by a budget subsidy at the Institute of Geography and Regional Development, University of Wrocław, Poland and used the laboratory equipment of the institute’s soil science laboratory.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank colleagues Andrzej Melon for providing sand samples from the CSC–OPC in Spała, Poland, and Jerzy Raczyk for his help in laboratory analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Couvillon, A. Sands of Time: The History of Beach Volleyball; Information Guides: Hermosa Beach, CA, USA, 2002; Volume 1, 264p. [Google Scholar]

- FIVB. Official Snow Volleyball Rules 2021–2024. Available online: https://www.cev.eu/media/yj3d41v5/fivb-snowvolleyball_rules2021_2024-en.pdf (accessed on 10 May 2022).

- Koch, C.; Tilp, M. Beach volleyball techniques and tactics: A comparison of male and female playing characteristics. Kinesiology 2009, 41, 52–59. [Google Scholar]

- Schläppi-Lienhard, O.; Hossner, E.-J. Decision making in beach volleyball defense: Crucial factors derived from interviews with top-level experts. Psychol. Sport Exerc. 2015, 16, 60–73. [Google Scholar] [CrossRef]

- Giatsis, G.; Pérez-Turpin, J.A.; Hatzimanouil, D. Analysis of time characteristics, jump patterns and technical-tactical skills of beach volley men’s final in Rio Olympics 2016. J. Hum. Sport Exerc. 2020, 15, S1013–S1019. [Google Scholar]

- Bahr, R.; Reeser, J.C. Injuries among World-Class Professional Beach Volleyball Players: The Fédération Internationale de Volleyball Beach Volleyball Injury Study. Am. J. Sports Med. 2003, 31, 119–125. [Google Scholar] [CrossRef] [PubMed]

- FIVB. 2019, Beach Volleyball Handbook. Available online: https://www.fivb.com/-/media/2020/fivb%20corporate/beach%20volley/tools%20page/2019_handbook_clean_n.pdf?la=en&hash=992E031B62B8BDB49BF6286BF3E3B3AE (accessed on 10 May 2022).

- Polish Volleyball. Official Beach Volleyball Rules 2017–2020. Approved by the 35th FIVB Congress 2016. Available online: https://www.pzps.pl/pl/siatkowka-plazowa/przepisy-i-wytyczne/przepisy/697-przepisy-gry-w-siatkowke-plazowa (accessed on 10 May 2022). (In Polish).

- Volleyball Canada. How to Build a Beach Court. Available online: https://www.volleyballalberta.ca/sites/default/files/sites/Beach/General_Info/Facilities/BEACH-TECH-HowtoBuildaBeachCourt.pdf (accessed on 10 May 2022).

- Volleyball England, SportPark, Loughborough University. Development of Beach Volleyball Courts. Available online: https://www.volleyballengland.org/docs/Development%20of%20beach%20courts_.pdf (accessed on 10 May 2022).

- Szamałek, K.; Szuflicki, M.; Malon, A.; Tymiński, M. (Eds.) Mineral Resources of Poland; Polish Geological Institute—National Research Institute: Warsaw, Poland, 2017; 153p. [Google Scholar]

- Nichols, G. Sedimentology and Stratigraphy, 2nd ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2009. [Google Scholar]

- Siever, R. Sand, 2nd ed.; W. H. Freeman & Co.: New York, NY, USA, 1988. [Google Scholar]

- Cailleux, A. Les actions éoliennes périglaciaires en Europe. Mém. Soc. Géol. Fr. 1942, 41, 1–176. [Google Scholar]

- Mycielska-Dowgiałło, E.; Woronko, B. The degree of aeolization of Quaternary deposits in Poland as a tool for stratigraphic interpretation. Sediment. Geol. 2004, 168, 149–163. [Google Scholar] [CrossRef]

- Kim, Y.; Yun, T.S. How to classify sand types: A deep learning approach. Eng. Geol. 2021, 288, 106142. [Google Scholar] [CrossRef]

- Wenworth, C.K. A Scale of Grade and Class Terms for Clastic Sediments. J. Geol. 1922, 30, 377–392. [Google Scholar]

- ISO 14688-1: 2017; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 1: Identification and Description. International Organization for Standardization: Geneva, Switzerland, 2017.

- Folk, R.L. The distinction between grain size and mineral composition in sedimentary-rock nomenclature. J. Geol. 1954, 62, 344–359. [Google Scholar] [CrossRef]

- Beard, D.C.; Weyl, P.K. Influence of Texture on Porosity and Permeability of Unconsolidated Sand. AAPG Bull. 1973, 57, 349–369. [Google Scholar]

- Pye, K.; Tsoar, H. Aeolian Sand and Sand Dunes; Unwin Hyman: London, UK, 1990. [Google Scholar]

- Belhadj, B.; Bederina, M.; Khadra, B.; Quéneudec, M. Effect of the type of sand on the fracture and mechanical properties of sand concrete. Adv. Concr. Constr. 2014, 2, 13–27. [Google Scholar] [CrossRef] [Green Version]

- ISO 3310-2; Test Sieves—Technical Requirements and Testing—Part 2: Test Sieves of Perforated Metal Plate. International Organization for Standardization: Geneva, Switzerland, 2010.

- Folk, R.L.; Ward, W.C. Brazos river bar: A study of significance of grain size parameters. J. Sediment. Petrol. 1957, 27, 3–26. [Google Scholar] [CrossRef]

- Blott, S.J.; Pye, K. GRADISTAT: A grain size distribution and statistics package for the analysis of unconsolidated sediments. Earth Surf. Processes Landf. 2001, 26, 1237–1248. [Google Scholar] [CrossRef]

- Kasenov, M. Determination of Hydraulic Conductivity from Grain Size Analysis; Water Resources Publication: Highlands Ranch, CO, USA, 2002. [Google Scholar]

- Devlin, J.F. HydrogeoSieveXL: An Excel-based tool to estimate hydraulic conductivity from grain size analysis. Hydrogeol. J. 2015, 23, 837–844. [Google Scholar] [CrossRef]

- Krumbein, W.C. Measurement and geological significance of shape and roundness of sedimentary particles. J. Sediment. Res. 1941, 11, 64–72. [Google Scholar] [CrossRef]

- Regelink, I.C.; Stoof, C.R.; Rousseva, S.; Weng, L.; Lair, G.J.; Kram, P.; Nikolaidis, N.P.; Kercheva, M.; Banwart, S.; Comans, R.N.J. Linkages between aggregate formation, porosity and soil chemical properties. Geoderma 2015, 247–248, 24–37. [Google Scholar] [CrossRef]

- Reeser, J.C.; Verhagen, E.; Briner, W.W.; Askeland, T.I.; Bahr, R. Strategies for the prevention of volleyball related injuries. Br. J. Sports Med. 2006, 40, 594–600. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferretti, A.; Puddu, G.; Mariani, P.P.; Neri, M. Jumper’s knee: An epidemiological study of volleyball players. Physician Sportsmed. 1984, 12, 97–106. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).