Weak Signal Processing Methods Based on Improved HHT and Filtering Techniques for Steel Wire Rope

Abstract

:1. Introduction

2. Experiments

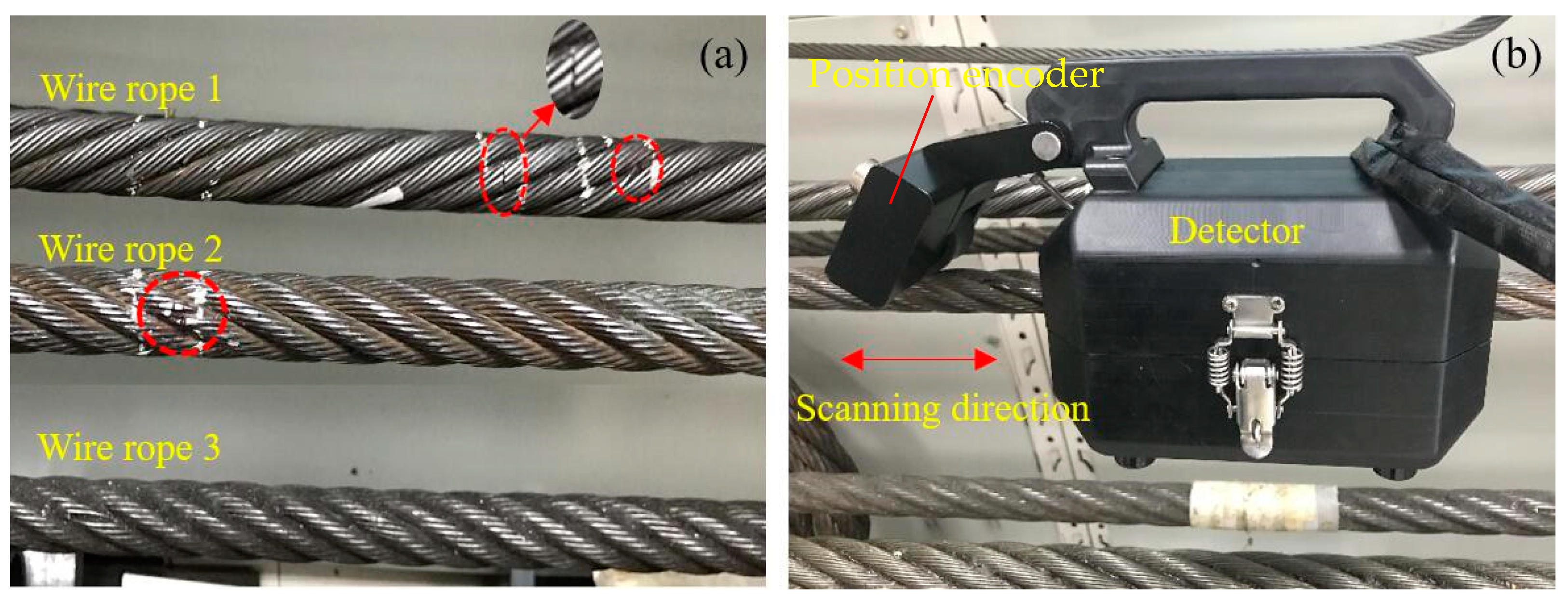

2.1. Experimental Apparatus and Samples

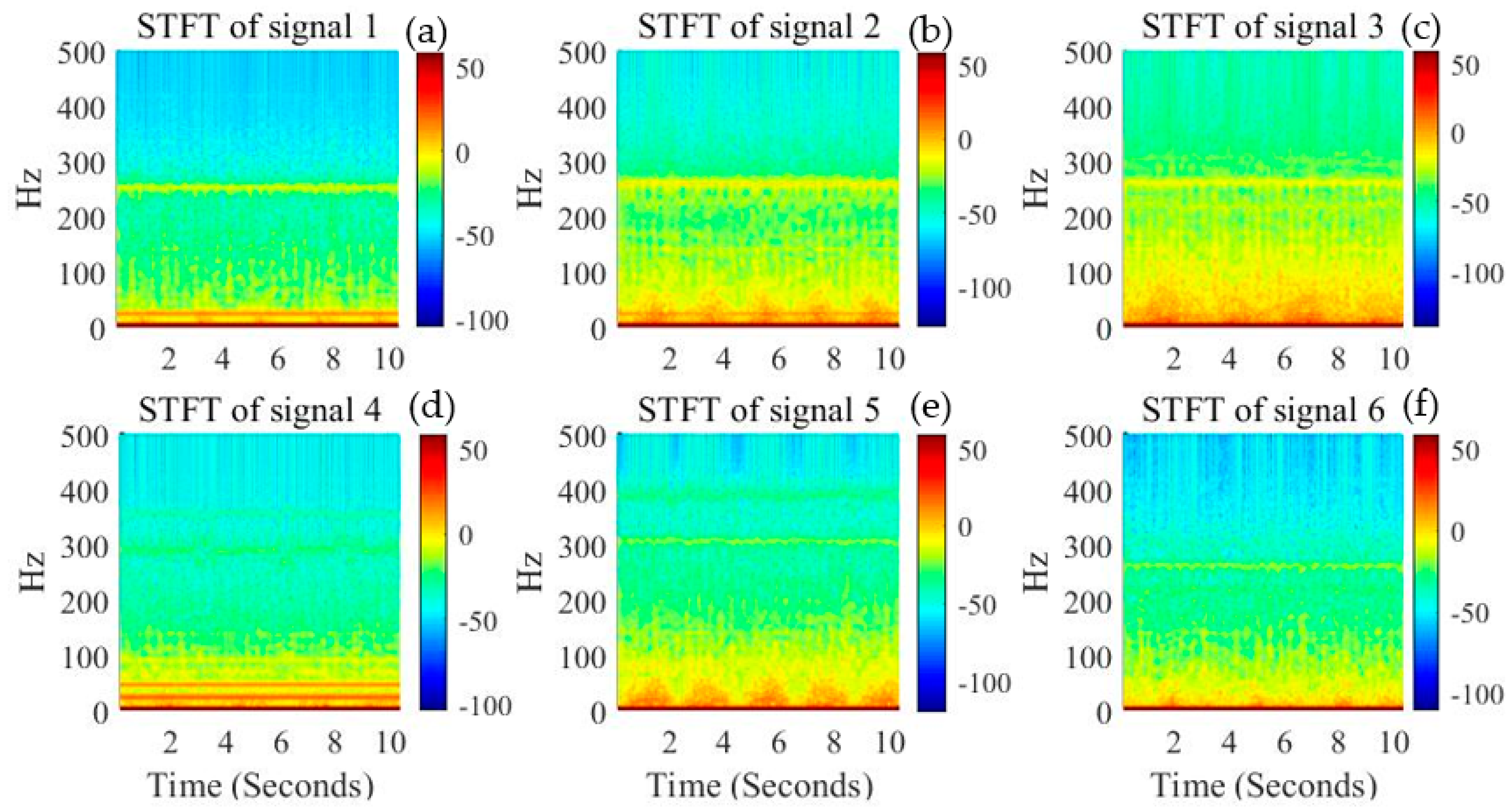

2.2. Time and Frequency Analysis

3. Principles and Methods

3.1. Principle of HHT

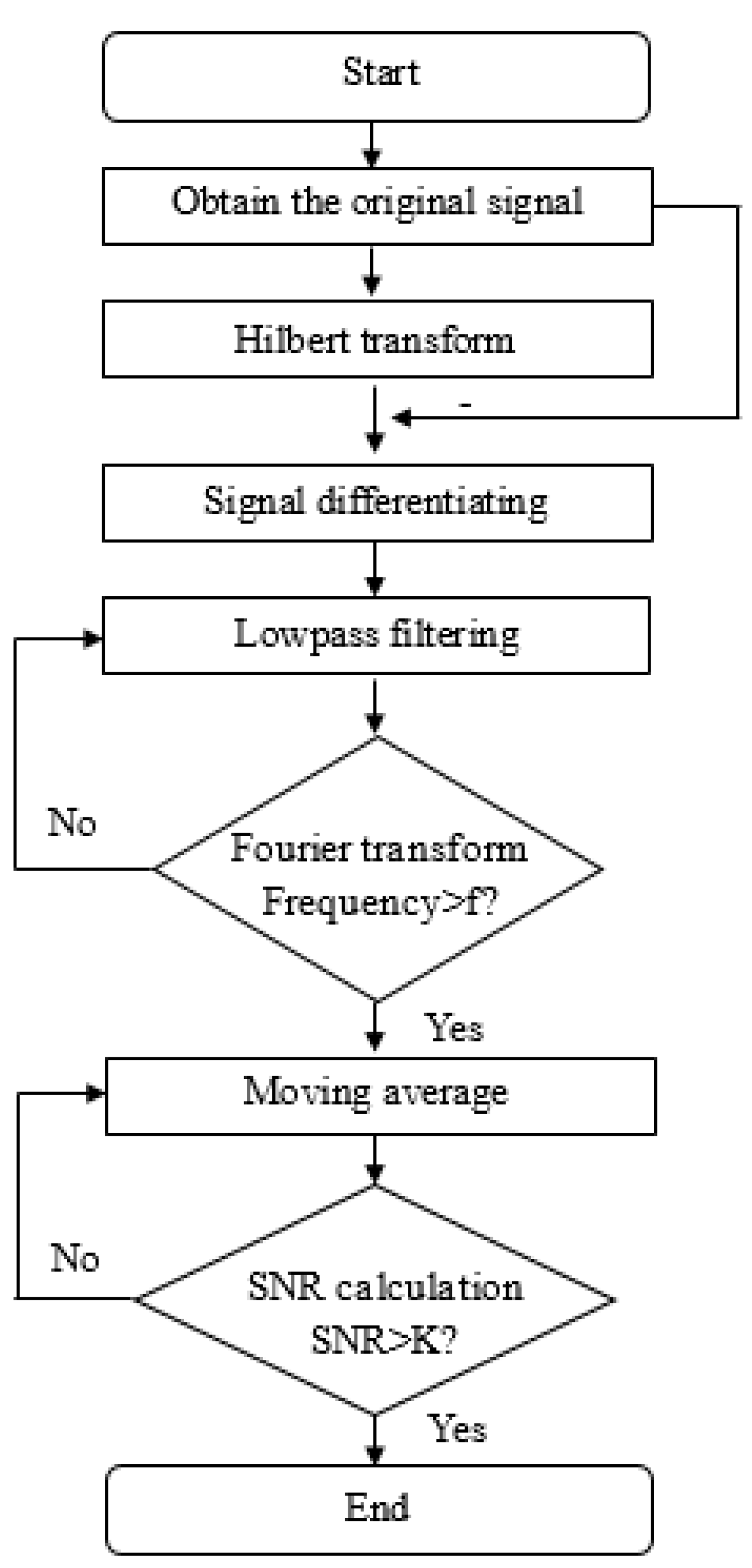

3.2. The Proposed Method

4. Comparison and Results

4.1. Lowpass Filtering and Wavelet Denoising

4.2. Median Filtering and Moving Average Method

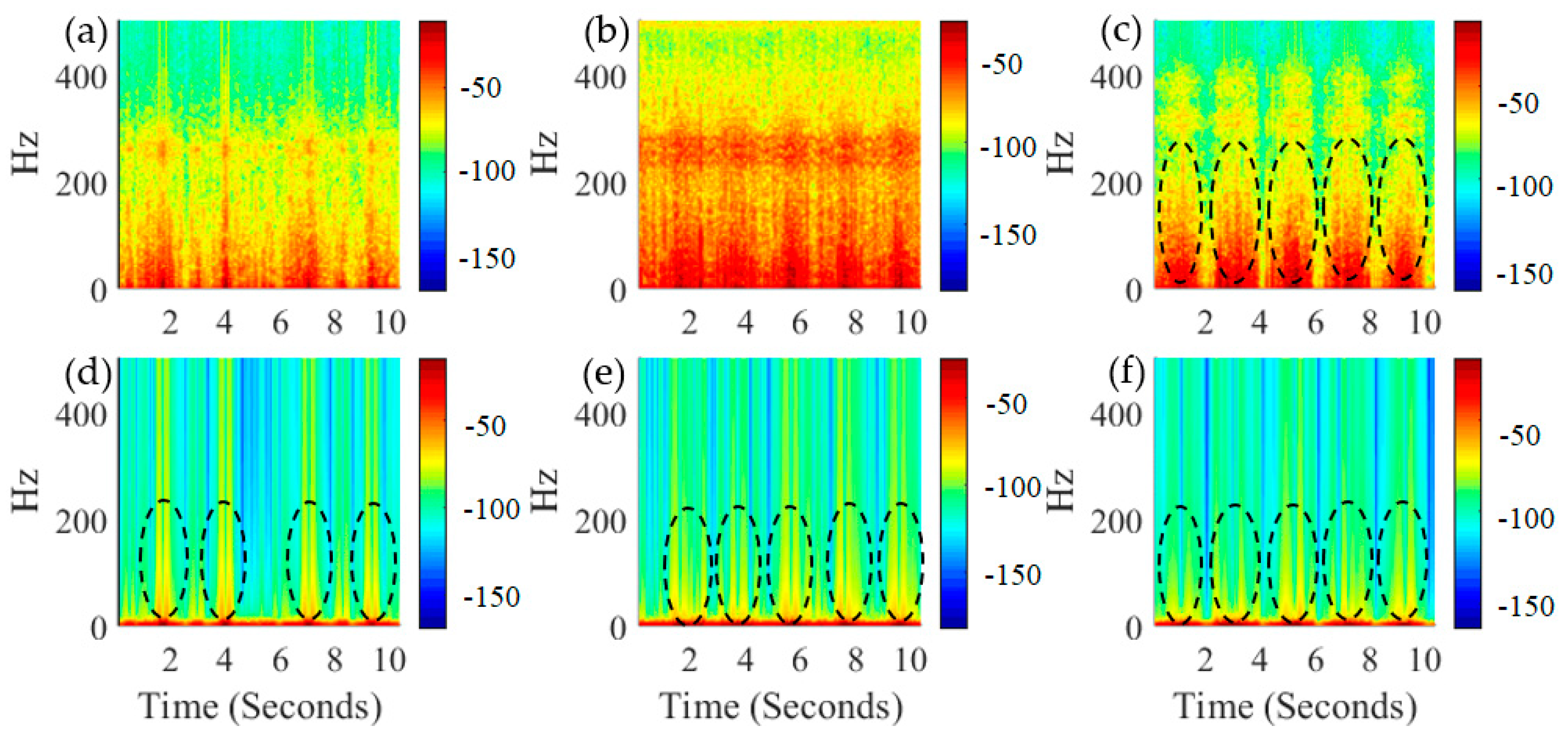

4.3. The New Proposed Method

4.3.1. Hilbert–Huang Transform Combined Lowpass Filter

4.3.2. Influence of Smooth Filtering Methods

4.3.3. Influence of the Span in the Moving Average Method

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Laura, P.A.A.; Rossit, C.A. Theory of Wire Rope. Ocean Eng. 2001, 28, 343–344. [Google Scholar] [CrossRef]

- Danenko, V.F.; Gurevich, L.M.; Kushkina, E.Y.; Gladskikh, E.B. New applications of compacted steel strands and wire rope. Steel Transl. 2016, 46, 757–763. [Google Scholar] [CrossRef]

- Torkar, M.; Arzenšek, B. Failure of crane wire rope. Eng. Fail. Anal. 2002, 9, 227–233. [Google Scholar] [CrossRef]

- Tijani, A.; Meknassi, M.; Chaffoui, H.; El Ghorba, M. Corrosion’s impact on wire rope strand response-Comparison with a theoretical predictive model. Frat. Ed. Integrità Strutt. 2019, 13, 141–148. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Feng, C.; Chen, K.; Wang, D.; Ni, X. Effect of broken wire on bending fatigue characteristics of wire ropes. Int. J. Fatigue 2017, 103, 456–465. [Google Scholar] [CrossRef]

- Weischedel, H.R.; Ramsey, R.P. Electromagnetic Testing, a Reliable Method for the Inspection of Wire Ropes in Service. NDT Int. 1989, 22, 155–161. [Google Scholar]

- Peng, P.-C.; Wang, C.-Y. Use of gamma rays in the inspection of steel wire ropes in suspension bridges. NDT E Int. 2015, 75, 80–86. [Google Scholar] [CrossRef]

- Park, J.; Kim, J.-W.; Park, S. A study on MFL based wire rope damage detection. SPIE 2017, 10168, 427–431. [Google Scholar]

- Ma, X.P.; Su, S.Q.; Wang, W.; Yang, Y.Y.; Yi, S.C.; Zhao, X.R. Damage location and numerical simulation for steel wire under torsion based on magnetic memory method. Int. J. Appl. Electromagn. Mech. 2019, 60, 223–246. [Google Scholar] [CrossRef]

- Liu, X.; Wu, B.; Qin, F.; He, C.; Han, Q. Observation of ultrasonic guided wave propagation behaviours in pre-stressed multi-wire structures. Ultrasonics 2017, 73, 196–205. [Google Scholar] [CrossRef]

- Raišutis, R.; Kažys, R.; Mažeika, L.; Žukauskas, E.; Samaitis, V.; Jankauskas, A. Ultrasonic guided wave-based testing technique for inspection of multi-wire rope structures. NDT E Int. 2014, 62, 40–49. [Google Scholar] [CrossRef]

- Ren, L.; Liu, Z.; Wang, H.; Zhou, J.; Tang, H. Eliminating Shaking Noise for Defect Detection of Steel Wire Ropes Based on Magnetic Flux Leakage Signals. In Proceedings of the 2019 IEEE 4th Advanced Information Technology, Chengdu, China, 20–22 December 2019; Volume 1, pp. 1037–1041. [Google Scholar]

- Kim, J.-W.; Park, S. Magnetic flux leakage–based local damage detection and quantification for steel wire rope non-destructive evaluation. J. Intell. Mater. Syst. Struct. 2018, 29, 3396–3410. [Google Scholar] [CrossRef]

- Jie, T.; Wang, H.Y.; Bilen, S.; Wu, X.L.; Meng, G.Y. Application of a morphological non-sampling wavelet method to the online detection signal processing of coal mine wire rope. Insight 2019, 61, 521–527. [Google Scholar] [CrossRef]

- Zhang, O.; Wei, X. De-noising of Magnetic Flux Leakage Signals Based on Wavelet Filtering Method. Res. Nondestruct. Eval. 2019, 30, 269–286. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, D.; Zhao, F. Improve the signal to noise ratio and installation convenience of the inductive coil for wire rope nondestructive testing. NDT E Int. 2017, 92, 221–227. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Y.; Ma, W.; Xie, F.; Jiang, X.; He, L.; Kang, Y. A New Signal Processing Method Based on Notch Filtering and Wavelet Denoising in Wire Rope Inspection. J. Nondestruct. Eval. 2019, 38, 39. [Google Scholar] [CrossRef]

- Wang, J.; Tan, J.-W.; Zhan, W.-X.; Wang, Q.-S. Signal processing of broken wire damage in steel ropes based on wavelet energy. Qingdao Ligong Daxue Xuebao J. Qingdao Technol. Univ. 2012, 33, 65–69. [Google Scholar]

- Rostami, J.; Tse, P.W.; Yuan, M. Detection of broken wires in elevator wire ropes with ultrasonic guided waves and tone-burst wavelet. Struct. Health Monit. 2020, 19, 481–494. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, S.; Gao, T. Quantitative Detection of Remanence in Broken Wire Rope Based on Adaptive Filtering and Elman Neural Network. J. Fail. Anal. Prev. 2019, 19, 1264–1274. [Google Scholar] [CrossRef]

- Zhang, J.W.; Zheng, P.B.; Tan, X.J. Recognition of Broken Wire Rope Based on Remanence using EEMD and Wavelet Methods. Sensors 2018, 18, 1110. [Google Scholar] [CrossRef] [Green Version]

- Henao, H.; Fatemi, S.M.J.R.; Capolino, G.-A.; Sieg-Zieba, S. Wire Rope Fault Detection in a Hoisting Winch System by Motor Torque and Current Signature Analysis. IEEE Trans. Ind. Electron. 2011, 58, 1727–1736. [Google Scholar] [CrossRef]

- Wacker, E.-S.; Denzler, J. Enhanced anomaly detection in wire ropes by combining structure and appearance. Pattern Recognit. Lett. 2013, 34, 942–953. [Google Scholar] [CrossRef] [Green Version]

- Kaur, D.; Arora, R.; Chhabra, S.; Sharma, S. Characterization of LF and LMA signal of wire rope tester. Int. J. Adv. Res. Comput. Sci. 2017, 8, 1395–1400. [Google Scholar]

- Zhou, Z.; Liu, Z. Fault Diagnosis of Steel Wire Ropes Based on Magnetic Flux Leakage Imaging under Strong Shaking and Strand Noises. IEEE Trans. Ind. Electron. 2020, 68, 2543–2553. [Google Scholar] [CrossRef]

- Čereška, A.; Zavadskas, E.K.; Bucinskas, V.; Podvezko, V.; Sutinys, E. Analysis of Steel Wire Rope Diagnostic Data Applying Multi-Criteria Methods. Appl. Sci. Basel 2018, 8, 260. [Google Scholar] [CrossRef] [Green Version]

- Li, L.-J.; Zhang, X.-G. Discrimination method of wire rope fault signal based on Holzer sensor for multi array weak magnetic detection. Clust. Comput. 2019, 22, 4901–4906. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; Zhu, Z.; Tang, C.; He, Z.; Li, W.; Jiang, F. Health Monitoring for Balancing Tail Ropes of a Hoisting System Using a Convolutional Neural Network. Appl. Sci.-Basel 2018, 8, 1346. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.W.; Park, S.; Ju-Won, K.; Seunghee, P. Magnetic Flux Leakage Sensing and Artificial Neural Network Pattern Recognition-Based Automated Damage Detection and Quantification for Wire Rope Non-Destructive Evaluation. Sensors 2018, 18, 109. [Google Scholar] [CrossRef] [Green Version]

- Pu, H.; Xie, X.; Jia, S.; Liang, G. Research on Detection for Broken Wires in Non-rotating Rope Base on SVM. In Proceedings of the 2010 International Conference on Electrical and Control Engineering, Wuhan, China, 25–27 June 2010; pp. 1664–1667. [Google Scholar]

- Li, J.; Zhang, J. Quantitative Nondestructive Testing of Wire Rope Using Image Super-Resolution Method and AdaBoost Classifier. Shock. Vib. 2019, 2019, 1683494. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Liu, Z.; Zhang, X.; Kang, J.; Zhang, M.; Guo, Y. Surface damage detection for steel wire ropes using deep learning and computer vision techniques. Measurement 2020, 161, 107843. [Google Scholar] [CrossRef]

| Method | LP-WA | Median | Wiener | Proposed Method | |||

|---|---|---|---|---|---|---|---|

| Signal | HHT | LP | MA | ||||

| S1 | 43.7742 | 45.9040 | 32.1887 | 1.8256 | 23.6263 | 80.6473 | |

| S2 | 45.9942 | 45.9440 | 32.1642 | 0.8415 | 24.4783 | 90.3688 | |

| S3 | 40.8502 | 45.6552 | 31.9675 | 1.1997 | 23.9081 | 79.1788 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Sun, Y.; He, L.; Kang, Y. Weak Signal Processing Methods Based on Improved HHT and Filtering Techniques for Steel Wire Rope. Appl. Sci. 2022, 12, 6969. https://doi.org/10.3390/app12146969

Liu S, Sun Y, He L, Kang Y. Weak Signal Processing Methods Based on Improved HHT and Filtering Techniques for Steel Wire Rope. Applied Sciences. 2022; 12(14):6969. https://doi.org/10.3390/app12146969

Chicago/Turabian StyleLiu, Shiwei, Yanhua Sun, Lingsong He, and Yihua Kang. 2022. "Weak Signal Processing Methods Based on Improved HHT and Filtering Techniques for Steel Wire Rope" Applied Sciences 12, no. 14: 6969. https://doi.org/10.3390/app12146969

APA StyleLiu, S., Sun, Y., He, L., & Kang, Y. (2022). Weak Signal Processing Methods Based on Improved HHT and Filtering Techniques for Steel Wire Rope. Applied Sciences, 12(14), 6969. https://doi.org/10.3390/app12146969