A Hybrid Neural Network Model for Predicting Bottomhole Pressure in Managed Pressure Drilling

Abstract

:Featured Application

Abstract

1. Introduction

- The ANN models have significantly improved the accuracy and efficiency of BHP compared with traditional calculation modeling, overcome the limitations of empirical and mechanistic models, and even replaced the function of downhole sensors.

- These models scarcely considered the temporal properties of datasets and variation mechanism of BHP.

2. Theory Background

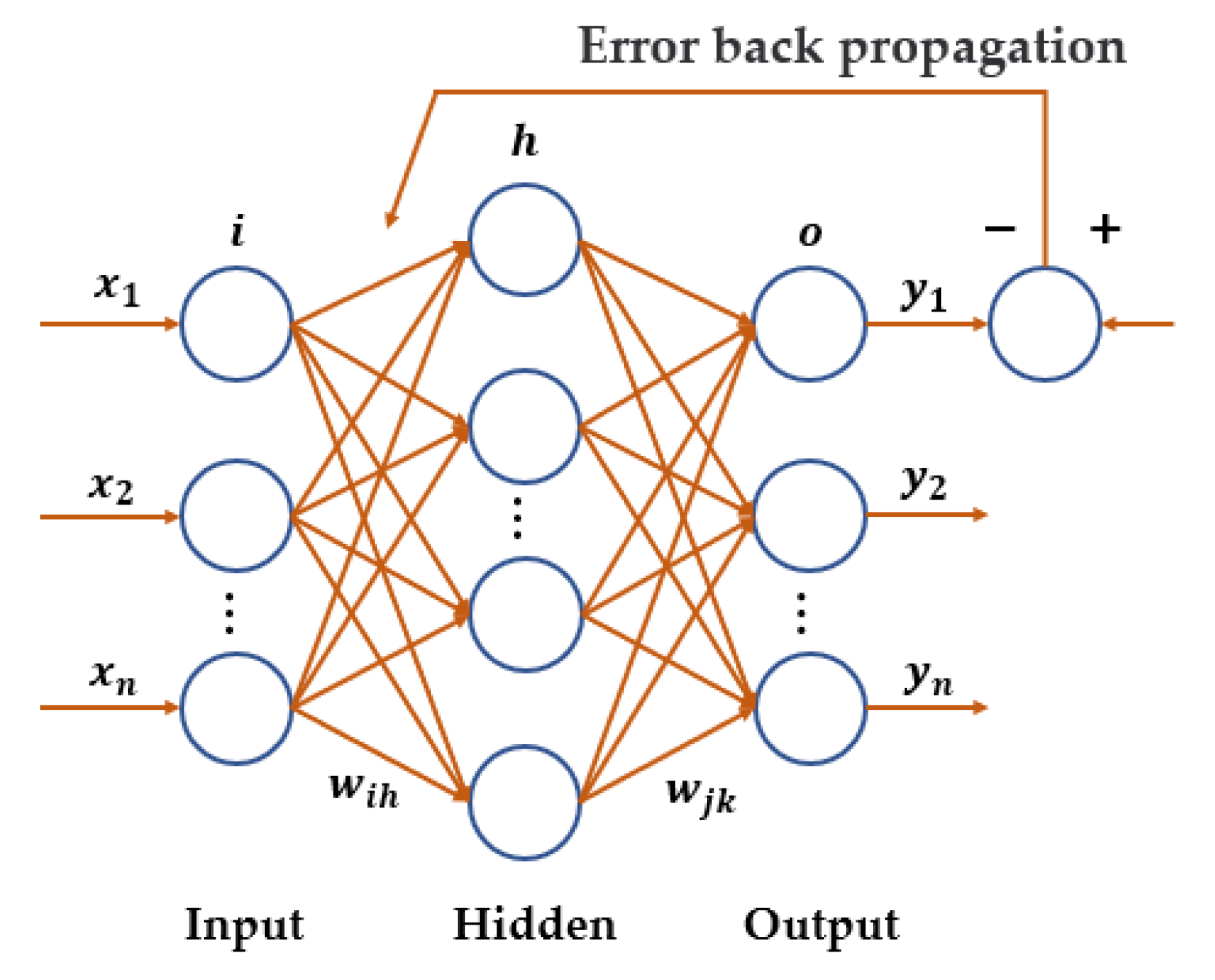

2.1. BP Neural Network

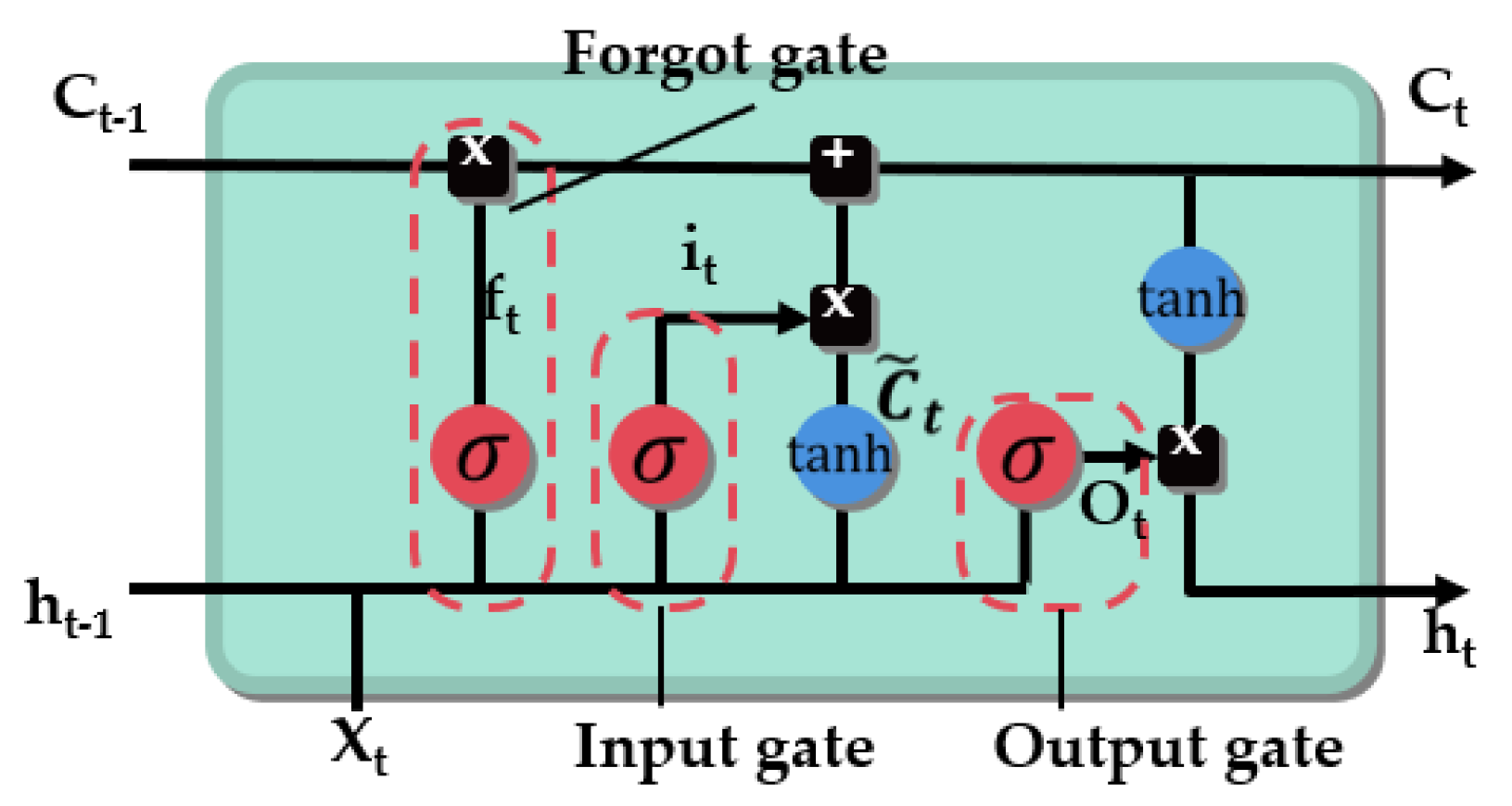

2.2. LSTM Neural Network

2.3. 1DCNN

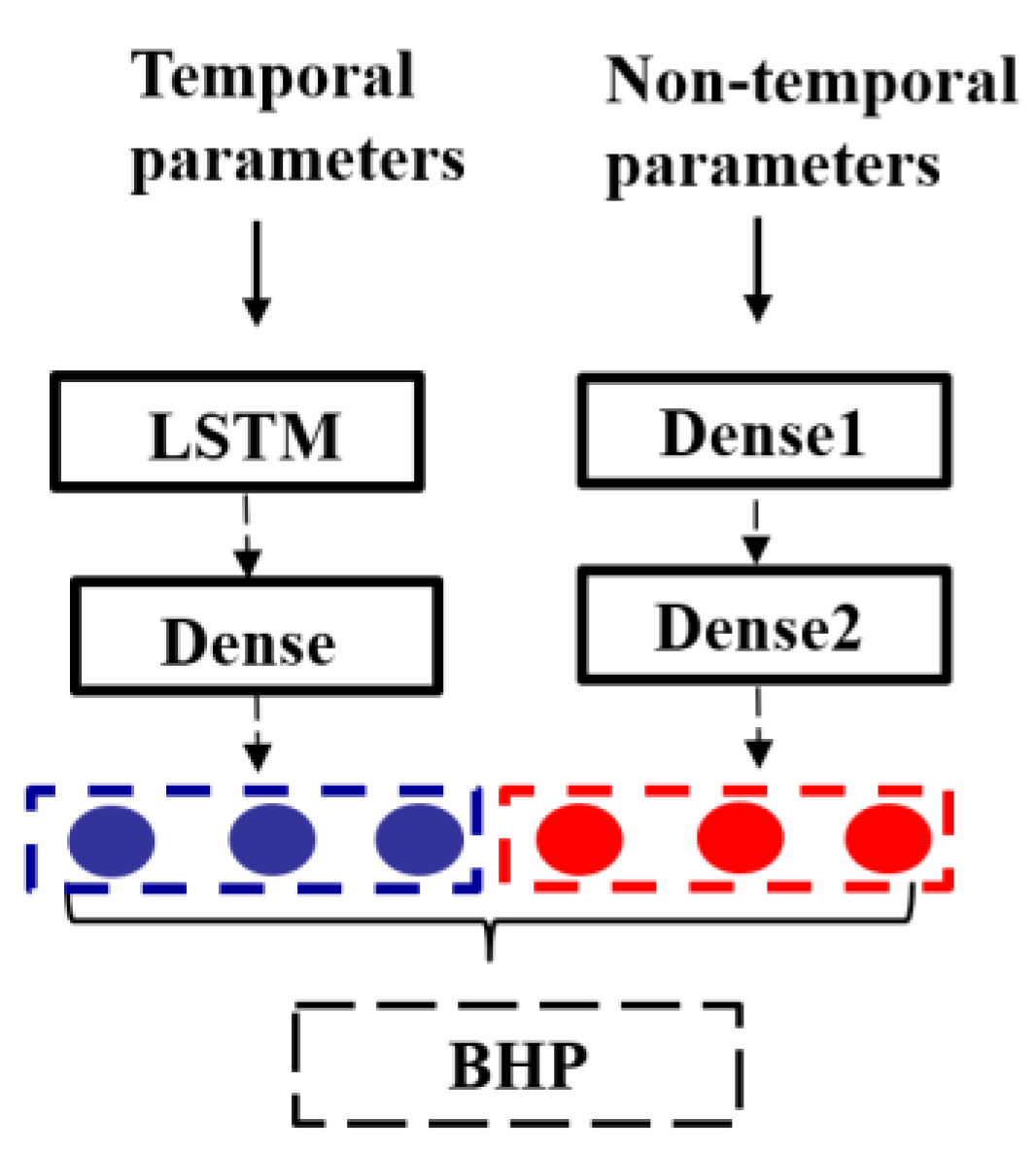

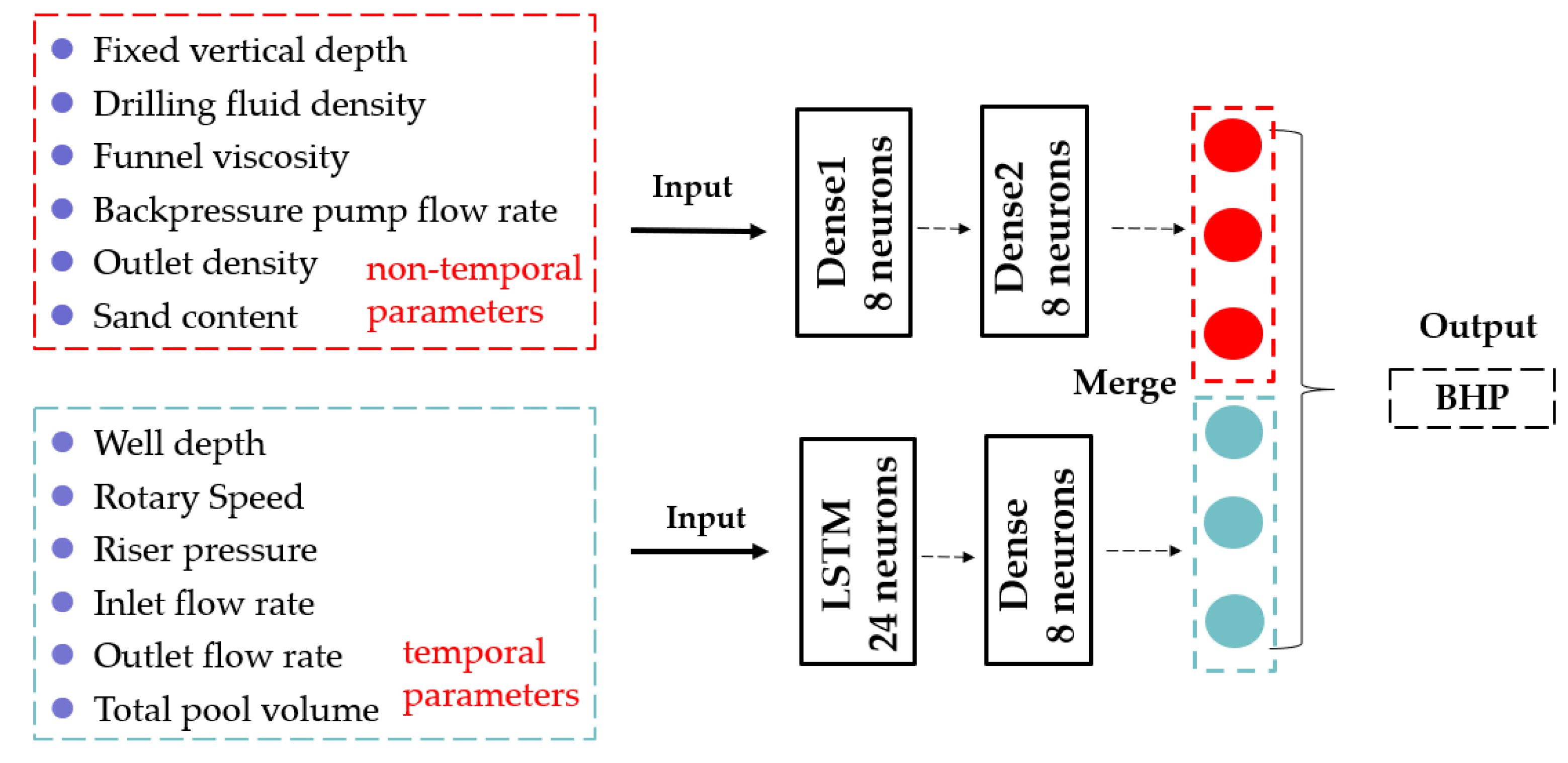

2.4. Parallel Network of BP and LSTM

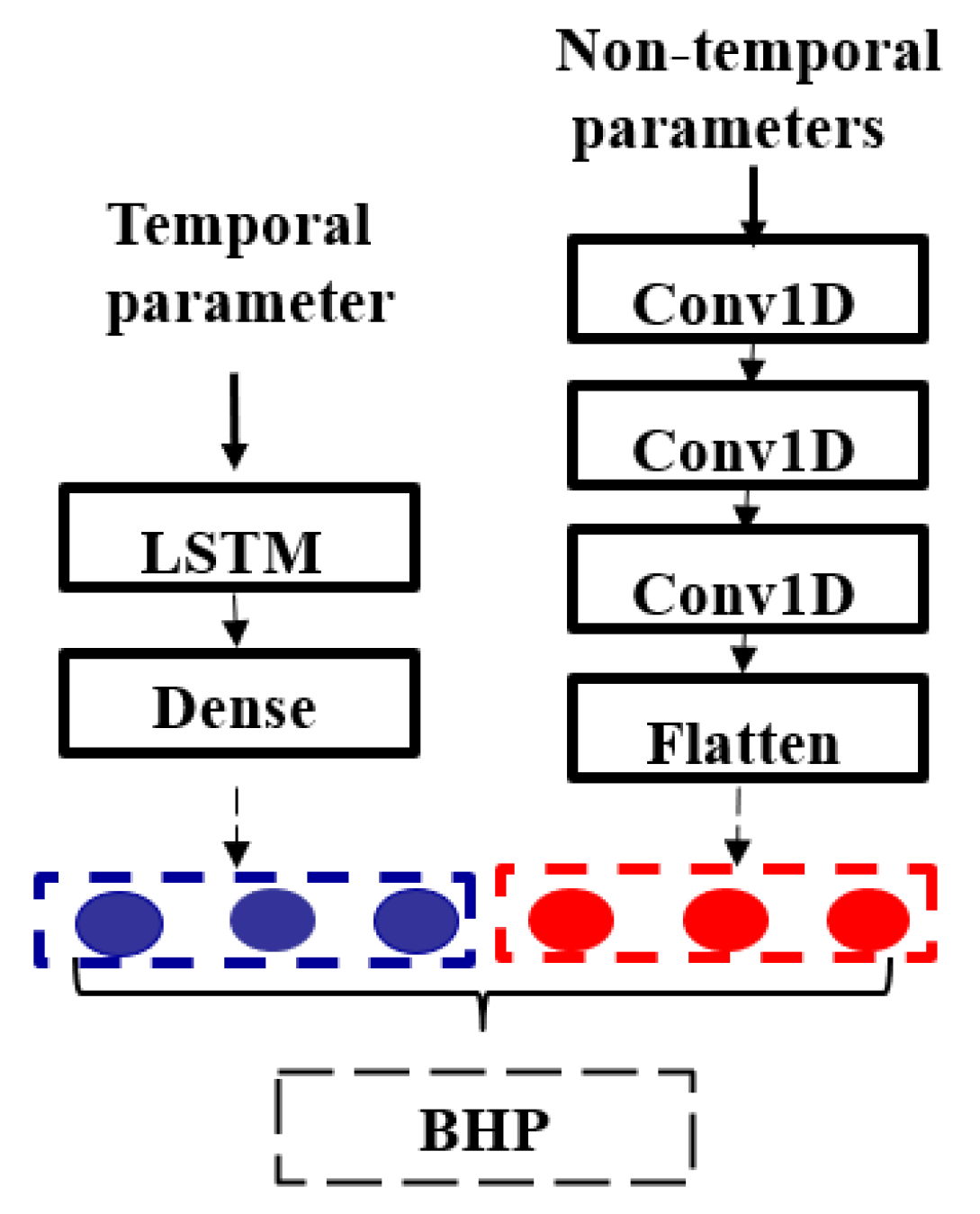

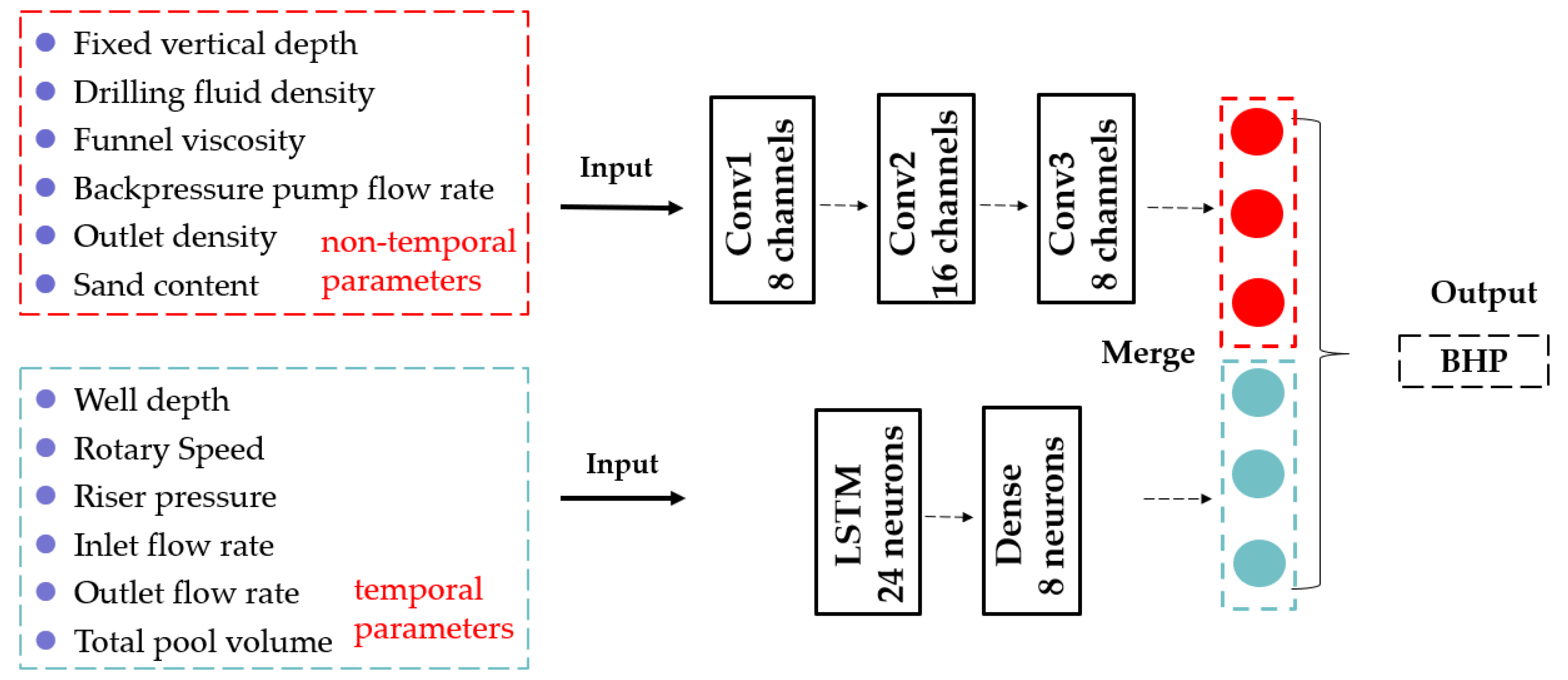

2.5. Parallel Network of 1DCNN and LSTM

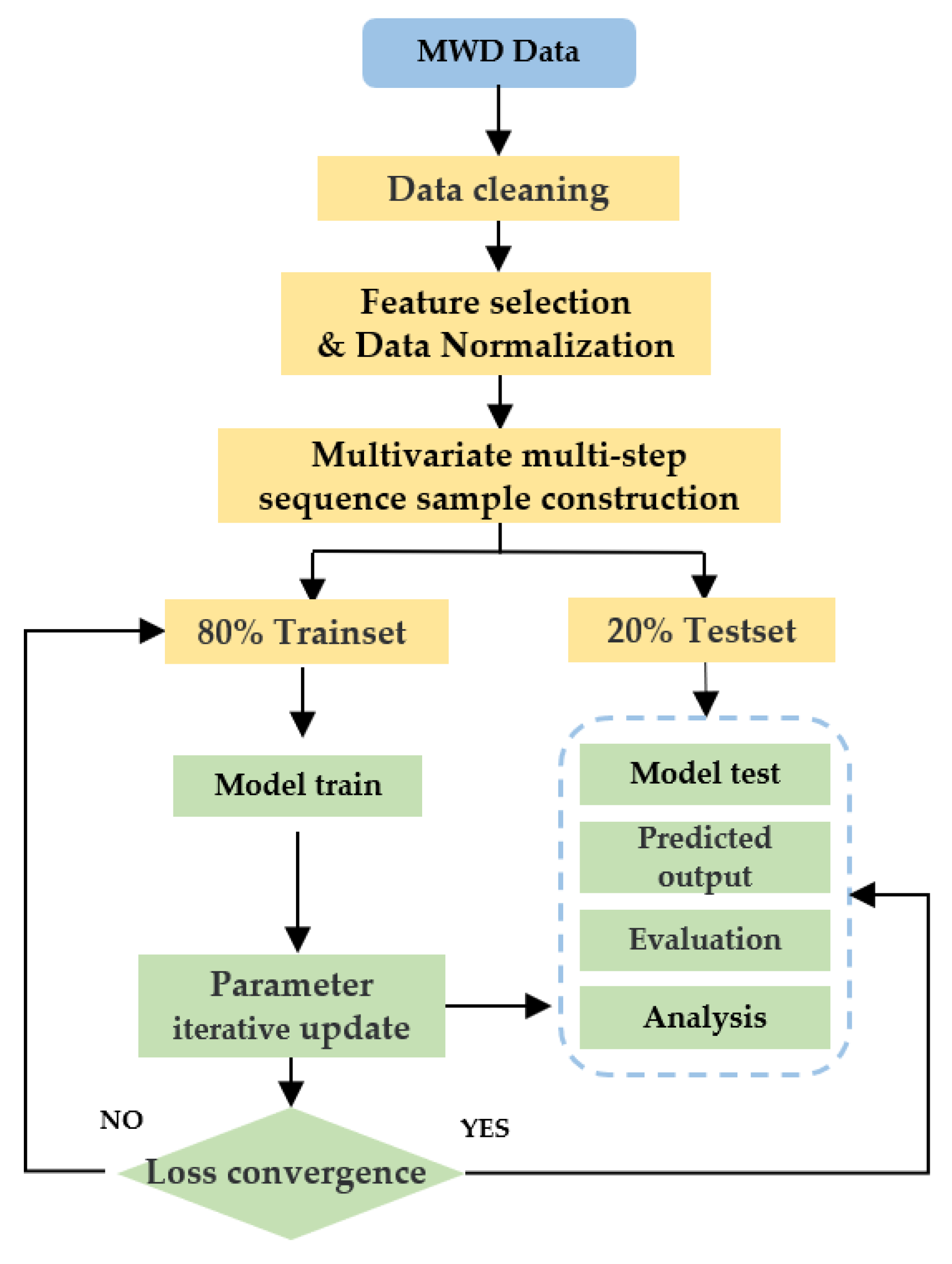

3. Dataset and Methodology

3.1. Data Pre-Processing

3.1.1. Data Description

3.1.2. Feature Selection and Data Normalization

3.1.3. Multivariate Multi-Step Sequence Sample Construction

3.2. Evaluation Indicators Selection

3.3. Model Establishment

3.3.1. Single Intelligence Models

3.3.2. Hybrid Parallel Intelligence Models

4. Results and Discussion

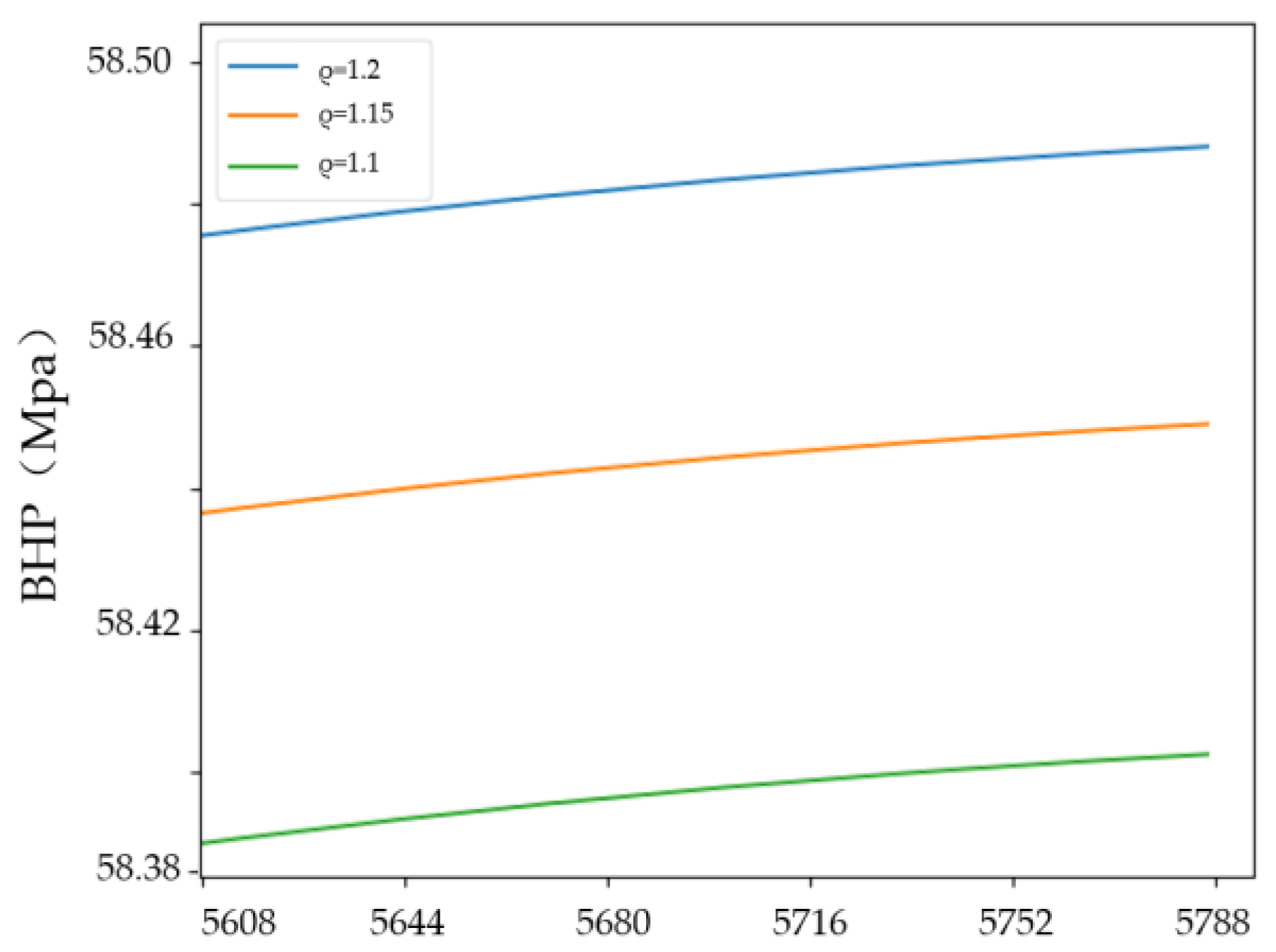

5. Trend Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sami, N.A.; Ibrahim, D.S. Forecasting multiphase flowing bottom-hole pressure of vertical oil wells using three machine learning techniques. Pet. Res. 2021, 6, 417–422. [Google Scholar] [CrossRef]

- Aziz, K.; Govier, G.W. Pressure Drop In Wells Producing Oil And Gas. J. Can. Pet. Technol. 1972, 11, 30940. [Google Scholar] [CrossRef]

- Chokshi, R.N.; Schmidt, Z.; Doty, D.R. Experimental Study and the Development of a Mechanistic Model for Two-Phase Flow Through Vertical Tubing. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 22–24 May 1996. [Google Scholar]

- Ansari, A.M.; Sylvester, N.D.; Sarica, C.; Shoham, O.; Brill, J.P. A Comprehensive Mechanistic Model for Upward Two-Phase Flow in Wellbores. SPE Prod. Facil. 1994, 9, 143–151. [Google Scholar] [CrossRef] [Green Version]

- Duns, H., Jr.; Ros, N.C.J. Vertical flow of gas and liquid mixtures in wells. In Proceedings of the 6th World Petroleum Congress, Frankfurt am Main, Germany, 19–26 June 1963. [Google Scholar]

- Gomez, L.E.; Shoham, O.; Schmidt, Z.; Chokshi, R.N.; Northug, T. Unified Mechanistic Model for Steady-State Two-Phase Flow: Horizontal to Vertical Upward Flow. SPE J. 2000, 5, 339–350. [Google Scholar] [CrossRef]

- Hagedorn, A.R.; Brown, K.E. Experimental Study of Pressure Gradients Occurring During Continuous Two-Phase Flow in Small-Diameter Vertical Conduits. J. Pet. Technol. 1965, 17, 475–484. [Google Scholar] [CrossRef]

- Orkiszewski, J. Predicting Two-Phase Pressure Drops in Vertical Pipe. J. Pet. Technol. 1967, 19, 829–838. [Google Scholar] [CrossRef]

- Ternyik, J., IV; Bilgesu, H.I.; Mohaghegh, S.; Rose, D.M. Virtual Measurement in Pipes: Part 1-Flowing Bottom Hole Pressure Under Multi-Phase Flow and Inclined Wellbore Conditions. In Proceedings of the SPE Eastern Regional Meeting, Morgantown, West Virginia, 17–21 September 1995. [Google Scholar]

- Mohammadpoor, M.; Shahbazi, K.; Torabi, F.; Qazvini, A. A New Methodology for Prediction of Bottomhole Flowing Pressure in Vertical Multiphase Flow in Iranian Oil Fields Using Artificial Neural Networks (ANNs). In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Lima, Peru, 1–3 December 2010. [Google Scholar]

- Jahanandish, I.; Salimifard, B.; Jalalifar, H. Predicting bottomhole pressure in vertical multiphase flowing wells using artificial neural networks. J. Pet. Sci. Eng. 2011, 75, 336–342. [Google Scholar] [CrossRef]

- Chen, W.; Di, Q.; Ye, F.; Zhang, J.; Wang, W. Flowing bottomhole pressure prediction for gas wells based on support vector machine and random samples selection. Int. J. Hydrogen Energy 2017, 42, 18333–18342. [Google Scholar] [CrossRef]

- Spesivtsev, P.; Sinkov, K.; Sofronov, I.; Zimina, A.; Umnov, A.; Yarullin, R.; Vetrov, D. Predictive model for bottomhole pressure based on machine learning. J. Pet. Sci. Eng. 2018, 166, 825–841. [Google Scholar] [CrossRef]

- Mask, G.; Wu, X.; Ling, K. An improved model for gas-liquid flow pattern prediction based on machine learning. J. Pet. Sci. Eng. 2019, 183, 106370. [Google Scholar] [CrossRef]

- Okoro, E.E.; Obomanu, T.; Sanni, S.E.; Olatunji, D.I.; Igbinedion, P. Application of artificial intelligence in predicting the dynamics of bottom hole pressure for under-balanced drilling: Extra tree compared with feed forward neural network model. Petroleum 2021, 8, 227–236. [Google Scholar] [CrossRef]

- Tariq, Z.; Mahmoud, M.; Abdulraheem, A. Real-time prognosis of flowing bottom-hole pressure in a vertical well for a multiphase flow using computational intelligence techniques. J. Pet. Explor. Prod. Technol. 2019, 10, 1411–1428. [Google Scholar] [CrossRef] [Green Version]

- Nait Amar, M.; Zeraibi, N.; Redouane, K. Bottom hole pressure estimation using hybridization neural networks and grey wolves optimization. Petroleum 2018, 4, 419–429. [Google Scholar] [CrossRef]

- Irani, R.; Nasimi, R. Application of artificial bee colony-based neural network in bottom hole pressure prediction in underbalanced drilling. J. Pet. Sci. Eng. 2011, 78, 6–12. [Google Scholar] [CrossRef]

- Ashena, R.; Moghadasi, J. Bottom hole pressure estimation using evolved neural networks by real coded ant colony optimization and genetic algorithm. J. Pet. Sci. Eng. 2011, 77, 375–385. [Google Scholar] [CrossRef]

- Barati-Harooni, A.; Najafi-Marghmaleki, A.; Tatar, A.; Arabloo, M.; Phung, L.T.K.; Lee, M.; Bahadori, A. Prediction of frictional pressure loss for multiphase flow in inclined annuli during Underbalanced Drilling operations. Nat. Gas Ind. B 2016, 3, 275–282. [Google Scholar] [CrossRef]

- Liang, H.; Wei, Q.; Lu, D.; Li, Z. Application of GA-BP neural network algorithm in killing well control system. Neural Comput. Appl. 2021, 33, 949–960. [Google Scholar] [CrossRef]

- Fruhwirth, R.K.; Thonhauser, G.; Mathis, W. Hybrid Simulation Using Neural Networks To Predict Drilling Hydraulics in Real Time. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006. [Google Scholar]

- Elzenary, M.; Elkatatny, S.; Abdelgawad, K.Z.; Abdulraheem, A.; Mahmoud, M.; Al-Shehri, D. New Technology to Evaluate Equivalent Circulating Density While Drilling Using Artificial Intelligence. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018. [Google Scholar]

- Al Shehri, F.H.; Gryzlov, A.; Al Tayyar, T.; Arsalan, M. Utilizing Machine Learning Methods to Estimate Flowing Bottom-Hole Pressure in Unconventional Gas Condensate Tight Sand Fractured Wells in Saudi Arabia. In Proceedings of the SPE Russian Petroleum Technology Conference, Virtual, 26–29 October 2020. [Google Scholar]

- Li, X.; Miskimins, J.L.; Hoffman, B.T. A Combined Bottom-hole Pressure Calculation Procedure Using Multiphase Correlations and Artificial Neural Network Models. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. [Google Scholar]

- Gola, G.; Nybø, R.; Sui, D.; Roverso, D. Improving Management and Control of Drilling Operations with Artificial Intelligence. In Proceedings of the SPE Intelligent Energy International, Utrecht, The Netherlands, 27–29 March 2012. [Google Scholar]

- Wiśniowski, R.; Skrzypaszek, K.; Małachowski, T. Selection of a Suitable Rheological Model for Drilling Fluid Using Applied Numerical Methods. Energies 2020, 13, 3192. [Google Scholar] [CrossRef]

- Sheu, B.J.; Choi, J. Back-Propagation Neural Networks. In Neural Information Processing and VLSI; Springer: Boston, MA, USA, 1995; pp. 277–296. [Google Scholar] [CrossRef]

- Gers, F.A.; Schmidhuber, J.; Cummins, F. Learning to Forget: Continual Prediction with LSTM. Neural Comput. 2000, 12, 2451–2471. [Google Scholar] [CrossRef] [PubMed]

| Evaluation Standard | Value | Evaluation Standard | Value |

|---|---|---|---|

| Count | 60,000 | 25% (Mpa) | 58.26 |

| Mean (Mpa) | 58.61 | 50% (Mpa) | 58.70 |

| Std (Mpa) | 0.40 | 75% (Mpa) | 58.70 |

| Min (Mpa) | 57.37 | Max (Mpa) | 59.58 |

| Input Parameters | Output Parameter | |

|---|---|---|

| Temporal parameters | Well depth, Rotary speed, Riser pressure, Inlet flow rate, Outlet flow rate, Total pool volume | BHP |

| Non-temporal parameters | Fixed vertical depth, Drilling fluid density, Funnel viscosity, Back-pressure pump flow rate, Outlet density, Sand content | |

| Var6(t−1) | var7(t−1) | var8(t−1) | var9(t−1) | … | var13(t−1) |

|---|---|---|---|---|---|

| 0.00038 | 0.957212 | 0.849603 | 0.009718 | … | 0.799 |

| 0.00042 | 0.957229 | 0.879854 | 0.018351 | … | 0.799 |

| 0.00046 | 0.957242 | 0.867551 | 0.016718 | … | 0.799 |

| 0.00050 | 0.957263 | 0.855436 | 0.026837 | … | 0.799 |

| 0.00058 | 0.95728 | 0.881510 | 0.020017 | … | 0.799 |

| Parameter | BP | LSTM | 1DCNN |

|---|---|---|---|

| Model parameter | 3249 | 3953 | 3769 |

| Time steps | / | 10 | 10 |

| Batch size | 600 | 600 | 600 |

| Learning rate | 0.001 | 0.001 | 0.001 |

| Optimizer | Adam | Adam | Adam |

| Activation function | Relu | Relu | Relu |

| Hidden layer neurons/ Channels | Dense1: 8; Dense2: 8 | LSTM: 24; Dense: 8 | Conv1: 8; Conv2: 16; Conv3: 8 |

| Evaluation Indicator | BP | LSTM | 1DCNN | BP-LSTM | CNN-LSTM |

|---|---|---|---|---|---|

| Run time (s) | 30.042 | 39.034 | 160.711 | 45.089 | 200.640 |

| MAPE (%) | 0.156 | 0.148 | 0.270 | 0.040 | 0.031 |

| MAE | 0.092 | 0.087 | 0.158 | 0.023 | 0.018 |

| RMSE | 0.117 | 0.106 | 0.255 | 0.049 | 0.047 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Song, X.; Zhang, R.; Li, G.; Han, L.; Hu, X.; Li, D.; Yang, D.; Qin, F. A Hybrid Neural Network Model for Predicting Bottomhole Pressure in Managed Pressure Drilling. Appl. Sci. 2022, 12, 6728. https://doi.org/10.3390/app12136728

Zhu Z, Song X, Zhang R, Li G, Han L, Hu X, Li D, Yang D, Qin F. A Hybrid Neural Network Model for Predicting Bottomhole Pressure in Managed Pressure Drilling. Applied Sciences. 2022; 12(13):6728. https://doi.org/10.3390/app12136728

Chicago/Turabian StyleZhu, Zhaopeng, Xianzhi Song, Rui Zhang, Gensheng Li, Liang Han, Xiaoli Hu, Dayu Li, Donghan Yang, and Furong Qin. 2022. "A Hybrid Neural Network Model for Predicting Bottomhole Pressure in Managed Pressure Drilling" Applied Sciences 12, no. 13: 6728. https://doi.org/10.3390/app12136728

APA StyleZhu, Z., Song, X., Zhang, R., Li, G., Han, L., Hu, X., Li, D., Yang, D., & Qin, F. (2022). A Hybrid Neural Network Model for Predicting Bottomhole Pressure in Managed Pressure Drilling. Applied Sciences, 12(13), 6728. https://doi.org/10.3390/app12136728