Construction and Application of Enterprise Knowledge Base for Product Innovation Design

Abstract

1. Introduction

2. Related Research

2.1. Mechanical Product Design Knowledge Base

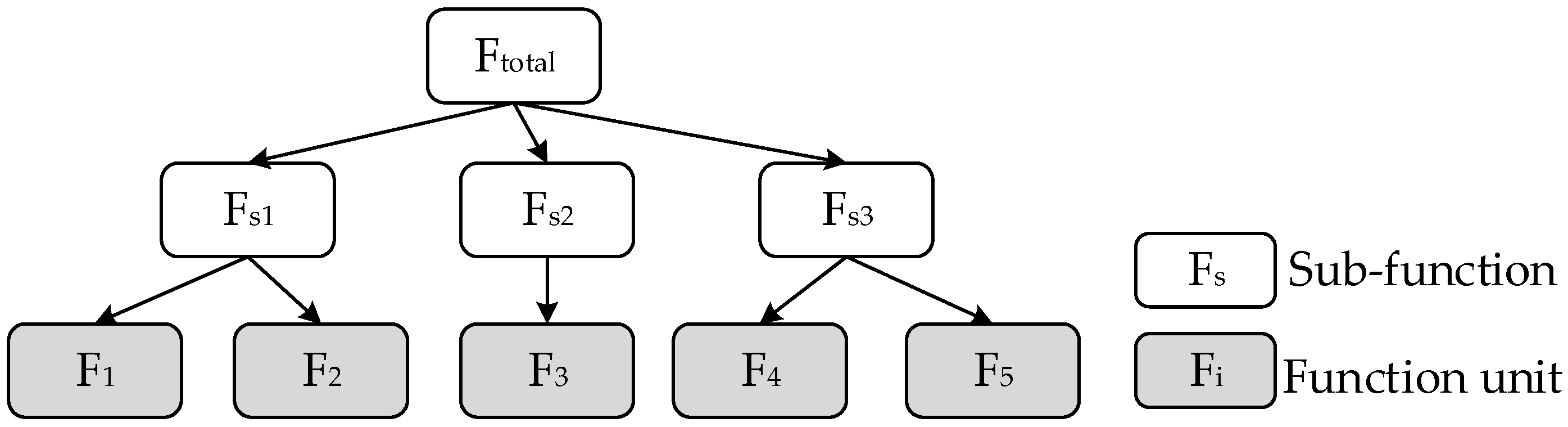

2.2. Functional Tree Research

3. Proposed Method

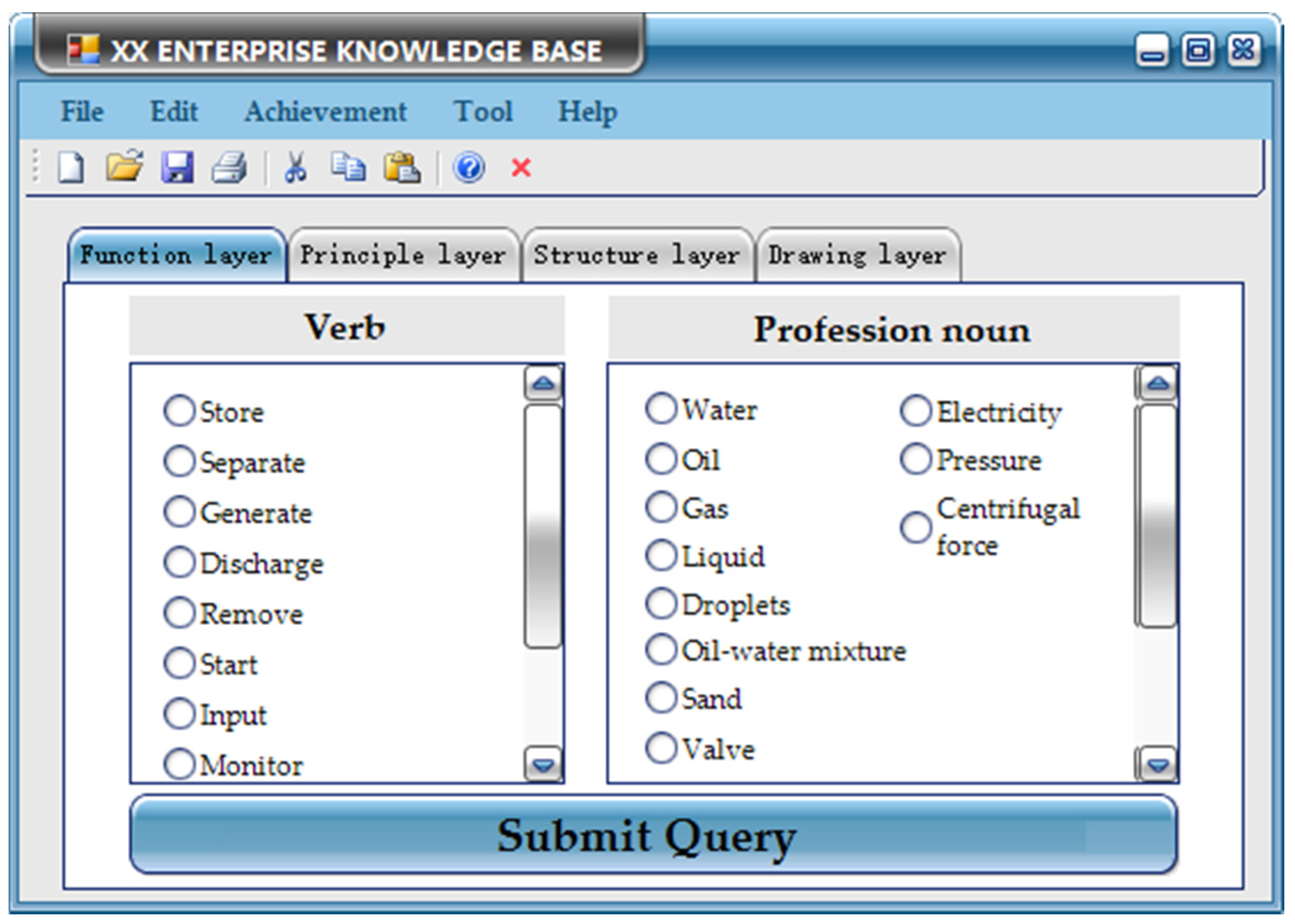

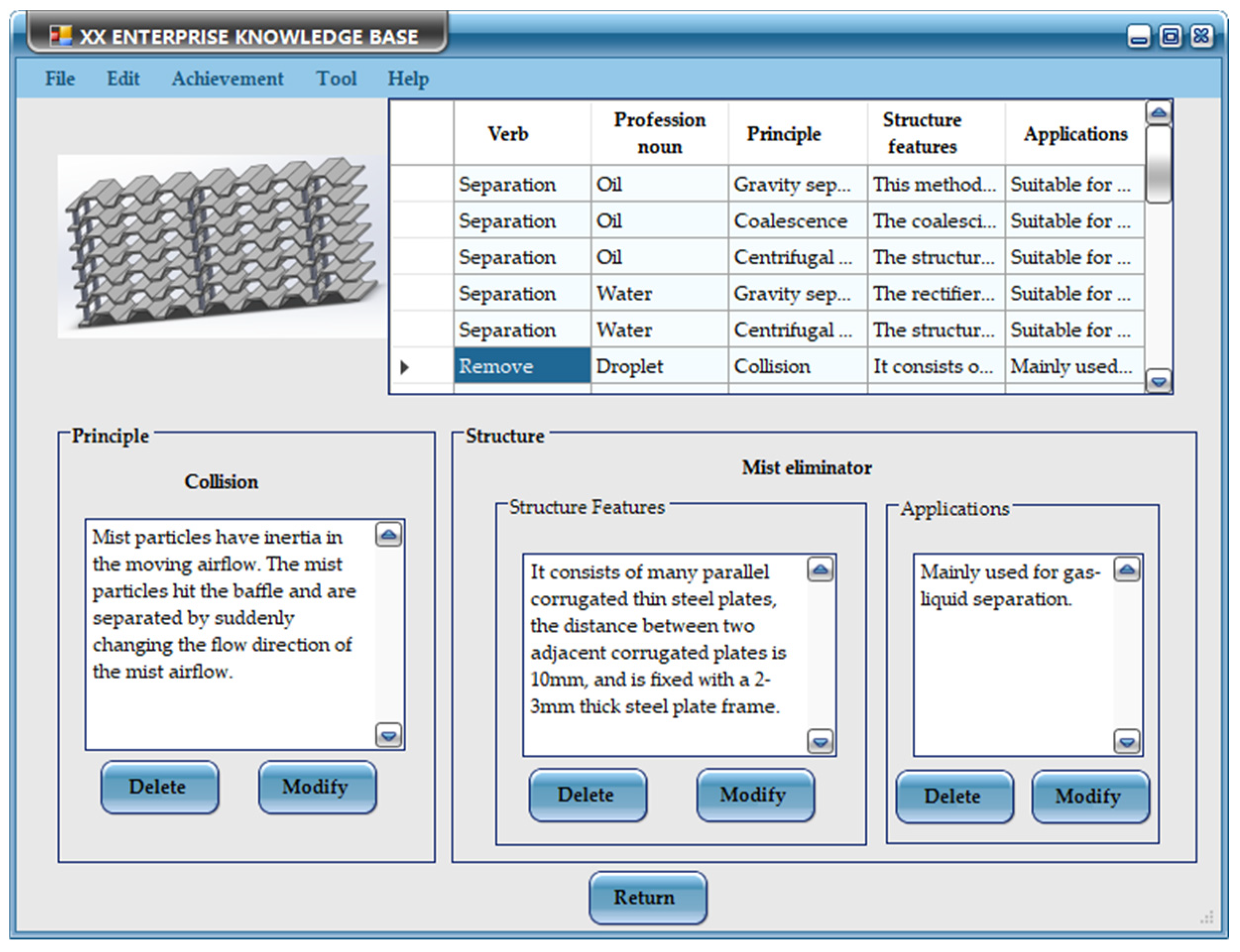

3.1. Construction of EKB Based on FBP

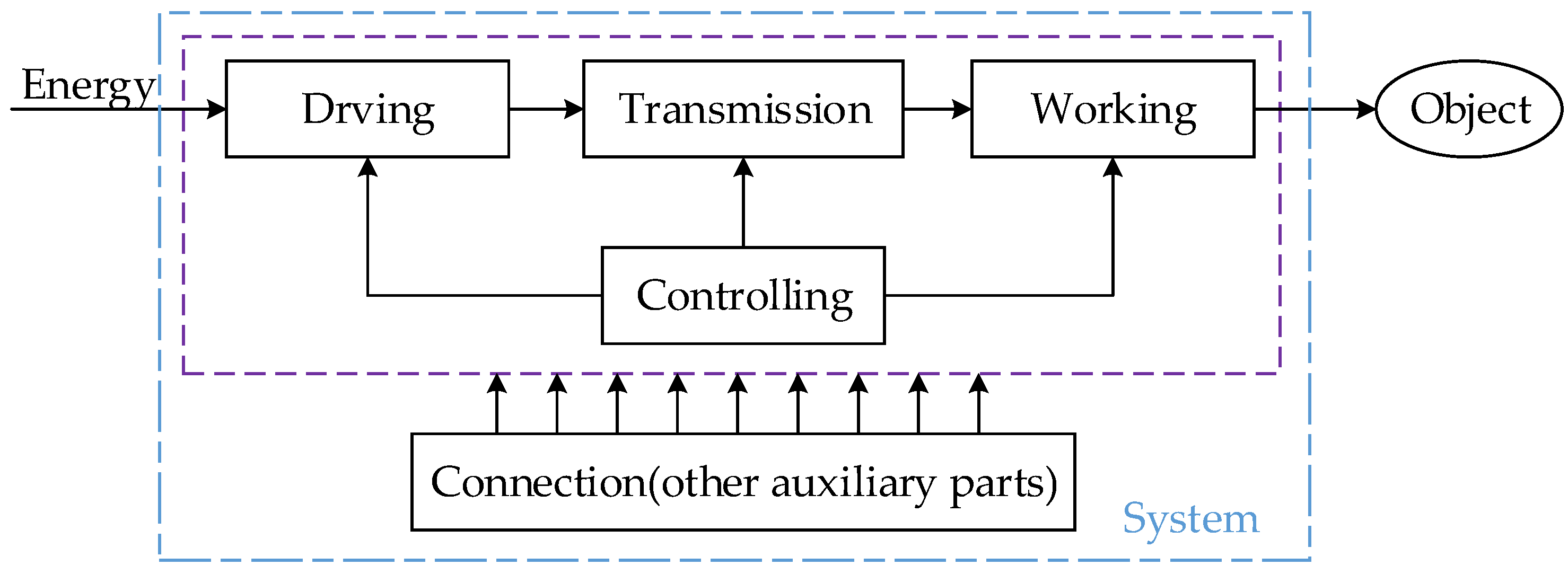

3.1.1. The Concept of FBP

3.1.2. Technical Unit

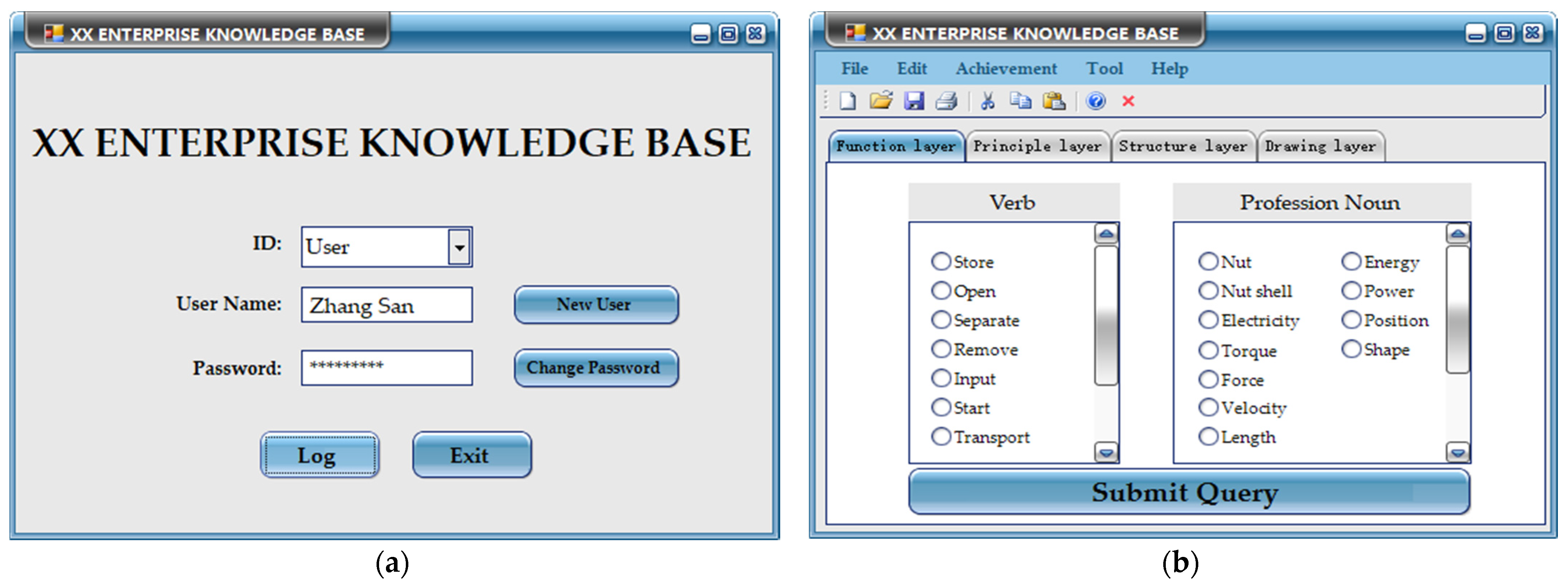

3.1.3. The Construction Process of EKB Based on FBP

- If Fi and Tj have a one-to-one relationship, then

- 2.

- If Fi and Tj have a one-to-many relationship, then

3.2. Product Innovation Design Process Based on EKB

4. Case Study

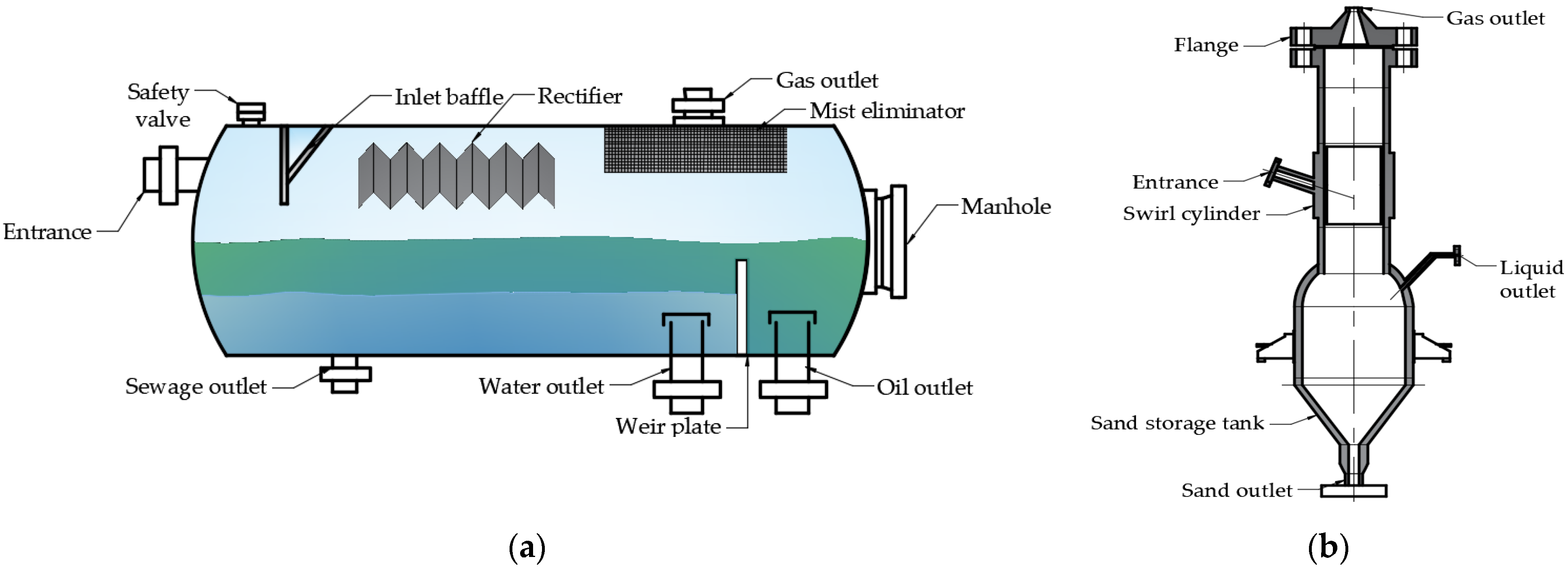

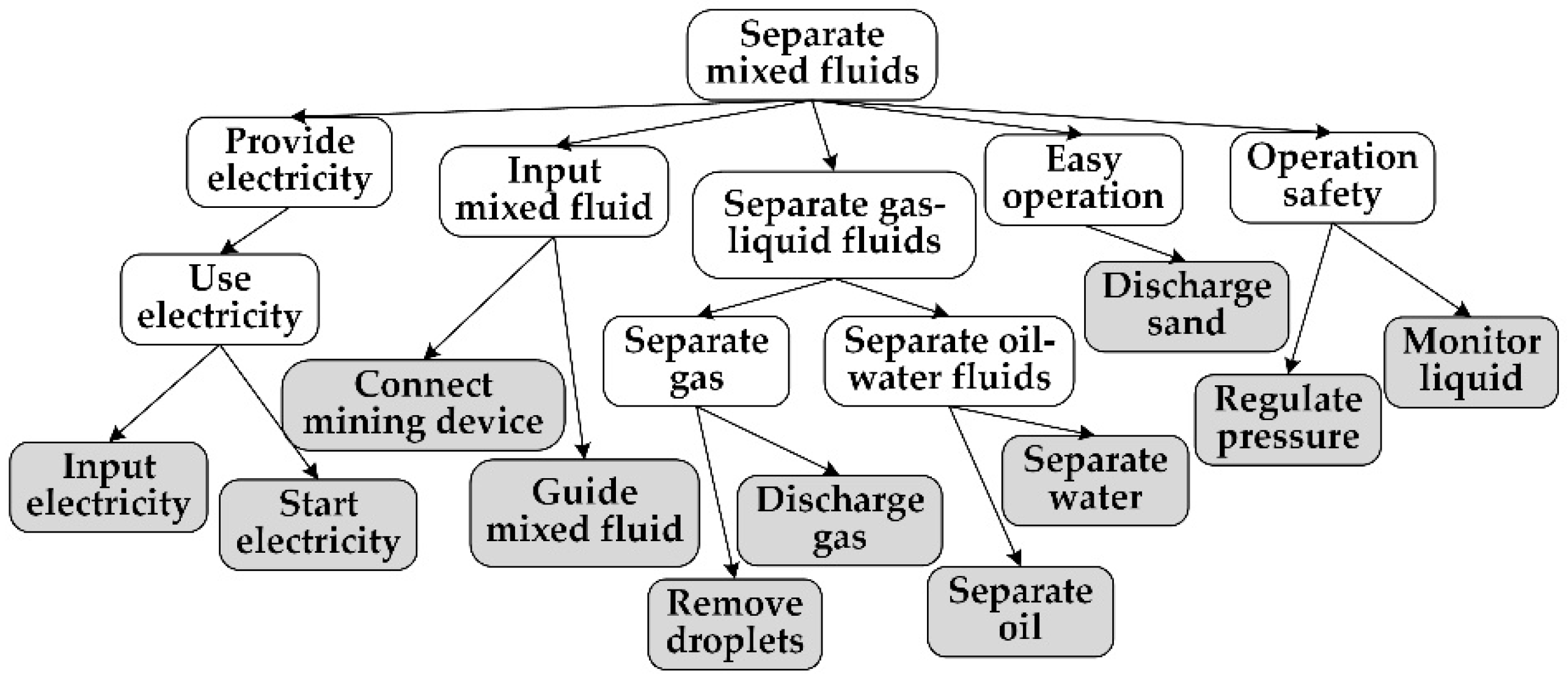

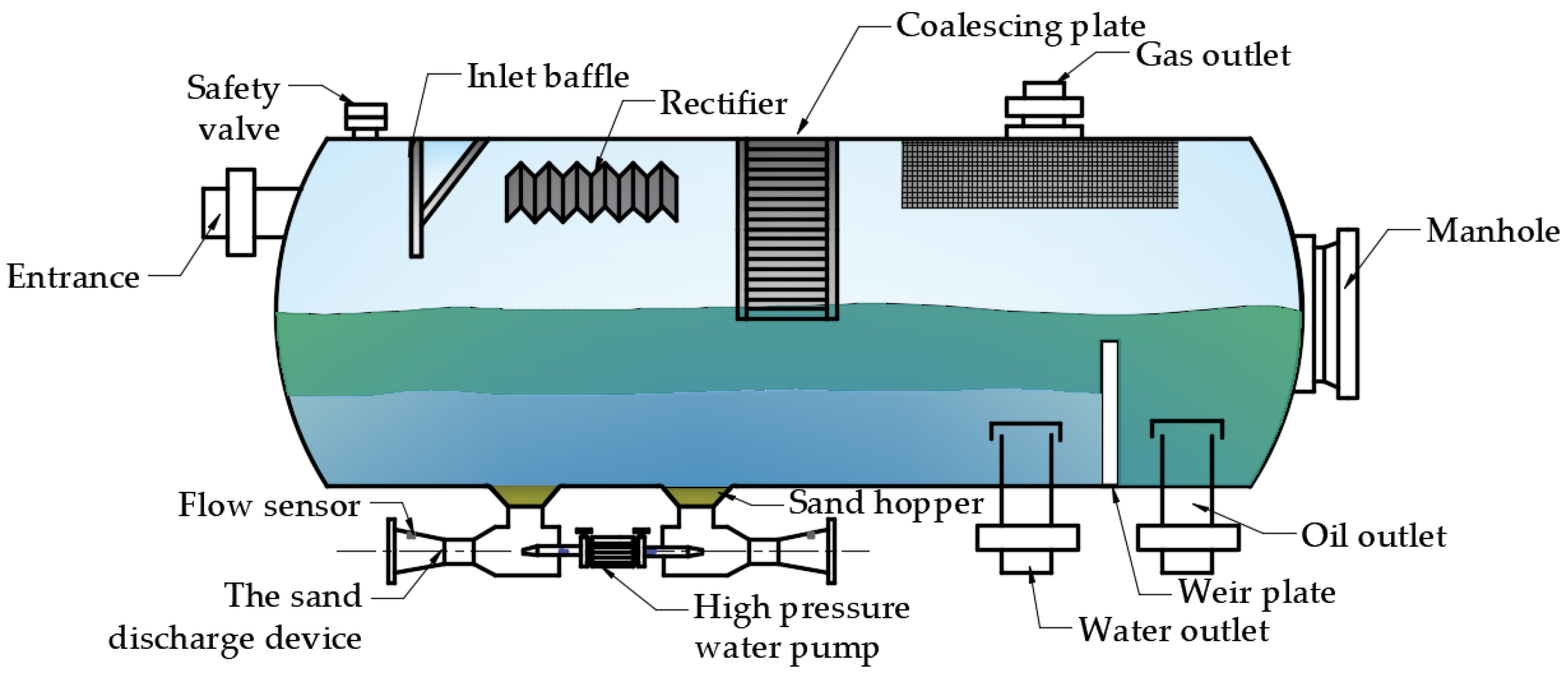

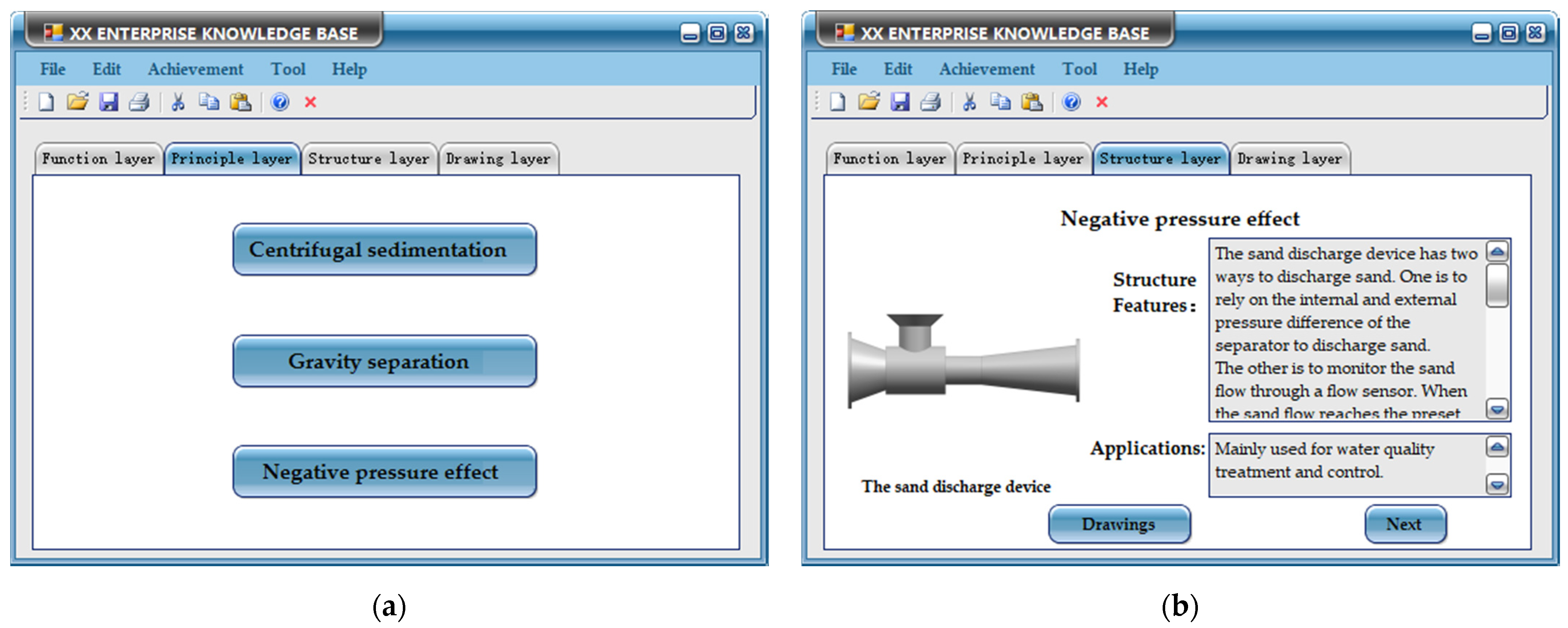

4.1. The Construction Process of EKB Based on FBP

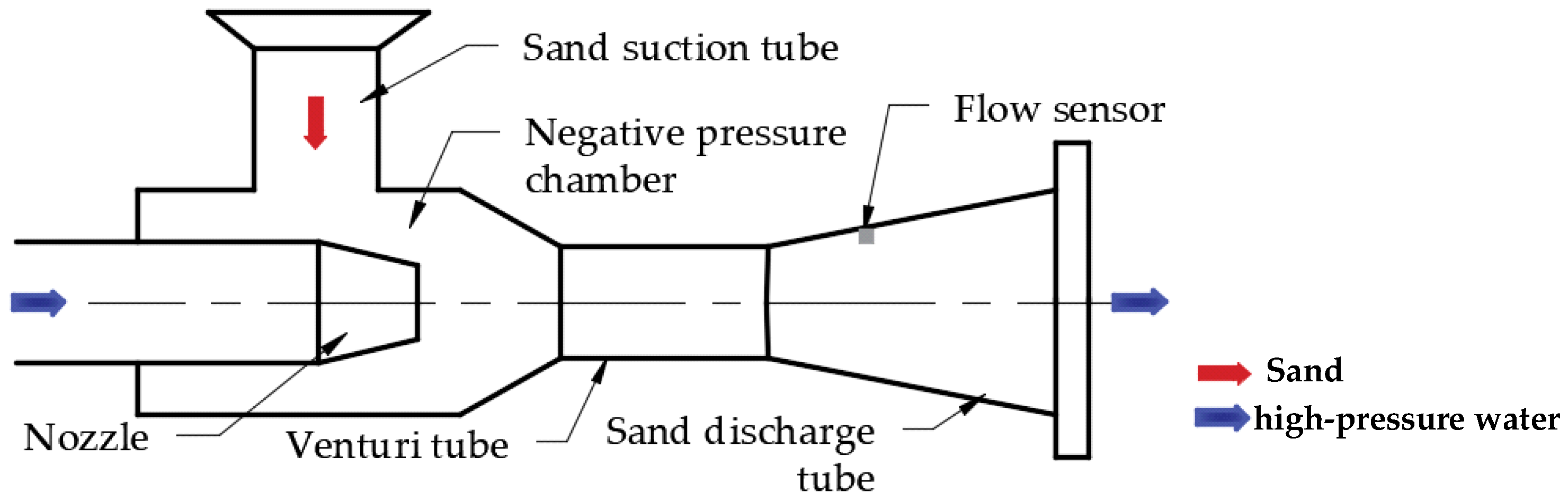

4.2. Product Innovation Design Process Based on EKB

5. Discussions

5.1. Implications

- (1)

- The construction of an EKB is a prerequisite for knowledge reuse in an enterprise. The construction process of existing knowledge bases does not consider the classification and storage of knowledge from the perspective of product innovation; they cannot provide innovative knowledge for product innovation design. Although these knowledge bases have accumulated a lot of knowledge for enterprises, they have not been reused in the innovative design process. Some CAIS can provide innovative knowledge for the product design process, such as the Goldfire innovator, Ideation Workbench. However, they can only provide technical solutions outside the enterprise and cannot effectively manage previous design achievements. From the perspective of the functional design of product innovation, this paper proposes an EKB that efficiently integrates existing design knowledge to inspire the product innovation design of an enterprise. The EKB stores product information in the form of K = {Fi Ti (P, S) Di}, which can maximize the reuse of previous achievements and provide rich, innovative knowledge to help engineers generate innovative ideas in the product design process. The EKB improves upon the limitations of a traditional knowledge base for product innovation design.

- (2)

- The construction process of an EKB proposed in this paper uses the concept of FBP. Because the functional basis proposed by Stone cannot be well adapted to current enterprise product design activities, this paper proposes a method of building functional trees based on FBP. In addition, the FBP is used as the retrieval path of the EKB to search related principles and structures. Compared with the retrieval method based on keywords or codes in the traditional knowledge base, the new retrieval method is easy to operate for engineers and enables them to find knowledge quickly. The organized retrieval process is beneficial to the product innovation design process of an enterprise.

- (3)

- EKB is one of the important tools in product innovation design. The process based on the EKB presented in this paper provides an operational method for product development for enterprises. The proposed method can effectively utilize the knowledge and technology in the EKB to improve the development of innovation, reduce the difficulty and risk of product development, and encourage enterprises to produce innovative designs. This will attract more enterprises to participate in innovation activities, produce innovative products, reshape the existing market environment, and even accelerate the development of the entire industry.

5.2. Limitations and Suggestions for Further Research

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Verganti, R.; Vendraminelli, L.; Iansiti, M. Innovation and design in the age of artificial intelligence. J. Prod. Innov. Manage. 2020, 37, 212–227. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, X.; Lyles, M. Effects of absorptive capacity, trust and information systems on product innovation. Int. J. Oper. Prod. Manage. 2018, 38, 493–512. [Google Scholar] [CrossRef]

- Shao, X.; Zhou, Y. Strategic significance and technical route of “NC Generation” mechanical product innovation project. Chin. Mech. Eng. 2012, 23, 1. [Google Scholar]

- Zhou, J. Digitalization and intelligentization of manufacturing industry. Adv. Manuf. 2013, 1, 1–7. [Google Scholar] [CrossRef]

- Hsu, W.; Woon, I.M.Y. Current research in the conceptual design of mechanical products. Comput.-Aided Des. 1998, 30, 377–389. [Google Scholar] [CrossRef]

- Corso, M.; Martini, A.; Paolucci, E. Knowledge management in product innovation: An interpretative review. Int. J. Manag. Rev. 2001, 3, 341–352. [Google Scholar] [CrossRef]

- Un, C.A.; Cuervo-Cazurra, A.; Asakawa, K. R&D collaborations and product innovation. J. Prod. Innov. Manage. 2010, 27, 673–689. [Google Scholar]

- Bohm, M.R.; Stone, R.B. Product design support: Exploring a design repository system. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–20 November 2004. [Google Scholar]

- Zhang, D.; Hu, D.; Xu, Y. A Framework for Ontology-Based Product Design Knowledge Management. In Proceedings of the 2010 Seventh International Conference on Fuzzy Systems and Knowledge Discovery, Yantai, China, 10–12 August 2010. [Google Scholar]

- Naykhanova, L.V.; Naykhanova, I.V. Conceptual Model of Knowledge Base System. In Proceedings of the International Conference Information Technologies in Business and Industry, Tomsk, Russia, 17–20 January 2018. [Google Scholar]

- Gilmore, J.F. Knowledge base systems in computer aided technology. In Proceedings of the 23rd IEEE Conference on Decision and Control, Las Vegas, NV, USA, 12–14 December 1984. [Google Scholar]

- Zhongyi, M.; Sanshan, Z.; Younus, M. Research on knowledge-based system for typical aircraft composite component design. Proc. Eng. 2011, 15, 1431–1435. [Google Scholar] [CrossRef][Green Version]

- Philpotts, M. An introduction to the concepts, benefits and terminology of product data management. Ind. Manage. Data Syst. 1996, 96, 11–17. [Google Scholar] [CrossRef]

- Panetto, H.; Dassisti, M.; Tursi, A. ONTO-PDM: Product-driven ONTOlogy for Product Data Management interoperability within manufacturing process environment. Adv. Eng. Inform. 2012, 26, 334–348. [Google Scholar] [CrossRef]

- Stark, J. Product Lifecycle Management (PLM); Springer: Cham, Switzerland, 2016; pp. 37–45. [Google Scholar]

- Weber, C.; Werner, H.; Deubel, T. A different view on Product Data Management/Product Life-Cycle Management and its future potentials. J. Eng. Des. 2003, 14, 447–464. [Google Scholar] [CrossRef]

- Gero, D.P. A knowledge representation schema for design. AI Mag. 1990, 11, 26–36. [Google Scholar]

- Hubka, V. Principles of Engineering Design; Redwood Burn Ltd.: Trowbrige, UK, 2015. [Google Scholar]

- Gero, J.S.; Kannengiesser, U. The situated function–behaviour–structure framework. Des. Stud. 2004, 25, 373–391. [Google Scholar] [CrossRef]

- Brodie, M.; Mylopoulos, J. On Knowledge Base Management Systems: Integrating Artificial Intelligence and Database Technologies; Springer-Verlag: New York, NY, USA, 1986. [Google Scholar]

- Davydenko, I.T. Ontology-Based Knowledge Base Design; Belarussian State Universityof Informatics and Radioelectronics: Minska, Belarus, 2017. [Google Scholar]

- Tsang, Y.P.; Wu, C.H.; Lin, K.Y. Unlocking the power of big data analytics in new product development: An intelligent product design framework in the furniture industry. J. Manuf. Syst. 2022, 62, 777–791. [Google Scholar] [CrossRef]

- He, D.J.; Song, X.; Wang, Q. Method for complex product collaborative design based on cloud service. CIMS. 2011, 17, 533–539. [Google Scholar]

- Ye, Y.; Hu, T.; Zhang, C. Design and development of a CNC machining process knowledge base using cloud technology. Int. J. Adv. Manuf. Technol. 2018, 94, 3413–3425. [Google Scholar] [CrossRef]

- Luo, X.C.; Huang, N. Constructing a constraint net during the modeling stage of aircraft product design. In Proceedings of the 2005 IEEE International Technology Management Conference, Munich, Germany, 20–22 June 2005. [Google Scholar]

- Jayakiran, R.E.; Sridhar, C.N.V.; Pandu, R.V. Research and Development of Knowledge Based Intelligent Design System for Bearings Library Construction Using SolidWorks API; Springer International Publishing: Cham, Switzerland, 2016; pp. 311–319. [Google Scholar]

- Dong, X.; Zhang, W.; Yang, K. Research on intelligent design method and application of cable route for offshore platform. Shipbuild. China 2021, 42, 213–230. [Google Scholar]

- Wang, T.C.; Hu, X.X.; Zhong, S.S. Research on extension knowledge base system for scheme design of mechanical product. Math. Model. Eng. Probl. 2016, 3, 141–145. [Google Scholar] [CrossRef]

- Zhang, J.Y.; An, L.L.; Li, W. Research and development of knowledge base system for process design of composite-structure. Aeronaut. Manuf. Technol. 2015, 18, 60–63. [Google Scholar]

- Mesihovic, S.; Malmqvist, J.; Pikosz, P. Product data management system-based support for engineering project management. J. Eng. Des. 2004, 15, 389–403. [Google Scholar] [CrossRef]

- Peltonen, H. Concepts and an Implementation for Product Data Management; Finnish Academy of Technology: Helsinki, Finland, 2000; pp. 1–188. [Google Scholar]

- Ahmed, Z. Proposing semantic-oriented agent and knowledge base product data management. Inf. Manag. Comput. Secur. 2009, 17, 360–371. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Y. Research and application of heterogeneous PDM System integration technology based on Web Service technology. Digit. Technol. Appl. 2020, 38, 148–151. [Google Scholar]

- Ostroukh, A.V.; Gusenitsa, D.O.; Golubkova, V.B. Integration of PDM and ERP systems within a unified information space of an enterprise. IOSR-JCE 2014, 16, 31–33. [Google Scholar] [CrossRef]

- Liu, D.T.; Xu, X.W. A review of web-based product data management systems. Comput. Ind. 2001, 44, 251–262. [Google Scholar]

- Gao, J.X.; Aziz, H.; Maropoulos, P.G. Application of product data management technologies for enterprise integration. Int. J. Comput. Integr. Manuf. 2003, 16, 491–500. [Google Scholar] [CrossRef]

- Kropsu-Vehkapera, H.; Haapasalo, H.; Harkonen, J. Product data management practices in high-tech companies. Ind. Manag. Data Syst. 2009, 109, 758–774. [Google Scholar] [CrossRef]

- Otto, B. Managing the business benefits of product data management: The case of Festo. J. Enterp. Inf. Manag. 2012, 25, 272–297. [Google Scholar] [CrossRef]

- Matsokis, A.; Kiritsis, D. An ontology-based approach for Product Lifecycle Management. Comput. Ind. 2010, 61, 787–797. [Google Scholar] [CrossRef]

- Sudarsan, R.; Fenves, S.J.; Sriram, R.D. A product information modeling framework for product lifecycle management. Comput.-Aided Des. 2005, 37, 1399–1411. [Google Scholar] [CrossRef]

- Srinivasan, V. An integration framework for product lifecycle management. Comput. Aided Des. 2011, 43, 464–478. [Google Scholar] [CrossRef]

- Wiesner, S.; Freitag, M.; Westphal, I. Interactions between service and product lifecycle management. Proc. CIRP 2015, 30, 36–41. [Google Scholar] [CrossRef]

- Paavel, M.; Karjust, K.; Majak, J. Development of a product lifecycle management model based on the fuzzy analytic hierarchy process. Proc. Estonian Acad. Sci. 2017, 66, 279–286. [Google Scholar] [CrossRef]

- Makino, K.; Sawaguchi, M.; Miyata, N. Research on functional analysis useful for utilizing TRIZ. Proc. Eng. 2015, 131, 1021–1030. [Google Scholar] [CrossRef][Green Version]

- Timothy, W.; Simpson. Product Platform and Product Family Design: Methods and Applications; Springer Science & Business Media: New York, NY, USA, 2006. [Google Scholar]

- Atilola, O.; Tomko, M.; Linsey, J.S. The effects of representation on idea generation and design fixation: A study comparing sketches and function trees. Des. Stud. 2016, 42, 110–136. [Google Scholar] [CrossRef]

- Dong, Y.; Tan, R.; Zhang, P. Product redesign using functional backtrack with digital twin. Adv. Eng. Inform. 2021, 49, 101361. [Google Scholar] [CrossRef]

- Liu, H.; Huo, Z.; Cao, G. A Sustainable Model of Function Decomposition Based on Effect; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–6. [Google Scholar]

- Cascini, G.; Rotini, F.; Russo, D. Functional modeling for TRIZ-based evolutionary analyses. In Proceedings of the International Conference on Engineering Design, Stanford University, Stanford, CA, USA, 24–27 August 2009. [Google Scholar]

- Sun, J.; Tan, R. Method for forecasting DI based on TRIZ technology system evolution theory. Int. J. Technol. Manage. 2012, 9, 1250010. [Google Scholar] [CrossRef]

- Shupe, J.A.; Mistree, F.; Sobieszanski-Sobieski, J. Compromise: An effective approach for the hierarchical design of structural systems. Comput. Struct. 1987, 26, 1027–1037. [Google Scholar] [CrossRef]

- Suh, N.P. Axiomatic design theory for systems. Res. Eng. Des. 1998, 10, 189–209. [Google Scholar] [CrossRef]

- Guo, J.; Peng, Q.; Zhang, L. Estimation of product success potential using product value. Int. J. Prod. Res. 2021, 59, 5609–5625. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, R. Radical Concept Generation Inspired by Cross-Domain Knowledge. Appl. Sci. 2022, 12, 4929. [Google Scholar] [CrossRef]

- Collins, J.A.; Hagan, B.T.; Bratt, H.M. The failure-experience matrix—A useful design tool. J. Eng. Ind. 1976, 98, 1074–1079. [Google Scholar] [CrossRef]

- Beitz, W.; Pahl, G.; Grote, K. Engineering design: A systematic approach. MRS Bull. 1996, 21, 71. [Google Scholar]

- Hundal, M.S. A systematic method for developing function structures, solutions and concept variants. Mech. Mach. Theory. 1990, 25, 243–256. [Google Scholar] [CrossRef]

- Lind, M. Modeling goals and functions of complex industrial plants. Appl. Artif. Intell. 1994, 8, 259–283. [Google Scholar] [CrossRef]

- Altshuller, G.S. Creativity as an Exact Science: The Theory of the Solution of Inventive Problems; Gordon and Breach Science Publishers: Philadelphia, PA, USA, 1984. [Google Scholar]

- Stone, R.B.; Wood, K.L. Development of a Functional Basis for Design. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Las Vegas, NV, USA, 12–16 September 1999. [Google Scholar]

- Stone, R.B.; Wood, K.L.; Crawford, R.H. A heuristic method for identifying modules for product architectures. Des. Stud. 2000, 21, 5–31. [Google Scholar] [CrossRef]

- Stone, R.B.; Wood, K.L.; Crawford, R.H. Using quantitative functional models to develop product architectures. Des. Stud. 2000, 21, 239–260. [Google Scholar] [CrossRef]

- Hirtz, J.; Stone, R.B.; McAdams, D.A. A functional basis for engineering design: Reconciling and evolving previous efforts. Res. Eng. Des. 2002, 13, 65–82. [Google Scholar] [CrossRef]

- Stroble, J.K.; Watkins, S.E.; Stone, R.B. Modeling the Cellular Level of Natural Sensing with the Functional Basis For The Design of Biomimetic Sensor Technology. In Proceedings of the 2008 IEEE Region 5 Conference, Kansas City, MO, USA, 17–20 April 2008. [Google Scholar]

- Yoon, J.; Park, H.; Seo, W. Technology opportunity discovery (TOD) from existing technologies and products: A function-based TOD framework. Technol. Forecast. Soc. Chang. 2015, 100, 153–167. [Google Scholar] [CrossRef]

- Cheong, H.; Li, W.; Cheung, A. Automated extraction of function knowledge from text. J. Mech. Des. 2017, 139, 111407. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Xiong, Y. A new function-based patent knowledge retrieval tool for conceptual design of innovative products. Comput. Ind. 2020, 115, 103154. [Google Scholar] [CrossRef]

- Szykman, S.; Racz, J.W.; Sriram, R.D. The representation of function in computer-based design. In Proceedings of the ASME 1999 Design Engineering Technical Conference, Las Vegas, NV, USA, 12–16 September 1999. [Google Scholar]

- Szykman, S.; Sriram, R.; Smith, S. Proceedings of the NIST Design Repository Workshop; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1996. [Google Scholar]

- Tan, R. Eliminating technical obstacles in innovation pipelines using CAIs. Comput.Ind. 2011, 62, 414–422. [Google Scholar]

- Tan, R.; Ma, J.; Liu, F. UXDs-driven conceptual design process model for contradiction solving using CAIs. Comput. Ind. 2009, 60, 584–591. [Google Scholar] [CrossRef]

- Fey, V.; Rivin, E. Innovation on Demand: New Product Development using TRIZ; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Yuan, F.; Wang, T.; Nie, H. Function and principle innovative design of mechanical products based on TRIZ/FA. Front. Mech. Eng. 2006, 1, 350–355. [Google Scholar] [CrossRef]

- Cheng, S.; Mi, J.; Zhao, R. Patent product innovation re-design based on function analysis. Recent Pat. Mech. Eng. 2016, 9, 71–78. [Google Scholar] [CrossRef]

- Cao, G.Z.; Tan, R.H.; Sun, J.G. Process and realization of functional design based on extended-effect Model. J. Mech. Eng. 2009, 45, 157–167. [Google Scholar] [CrossRef]

- Cao, G.Z.; Tan, R.H.; Sun, J.G. The Principle and Application of Functional Design, 1st ed.; Higher Education Press: Beijing, China, 2016; pp. 1–296. [Google Scholar]

- Litvin, S. New TRIZ-based tool—function-oriented search (FOS). In Proceedings of the TRIZ Future Conference, Florence, Italy, 3–5 November 2004. [Google Scholar]

- Montecchi, T.; Russo, D. FBOS: Function/behaviour–oriented search. Proc. Eng. 2015, 131, 140–149. [Google Scholar] [CrossRef]

- Patsnap. Available online: https://analytics.zhihuiya.com (accessed on 3 March 2022).

- Baghapour, M.A.; Shooshtarian, M.R. Extending a consensus-based fuzzy ordered weighting average (FOWA) model in new water quality indices. Iran. J. Health Saf. Environ. 2017, 4, 824–834. [Google Scholar]

- Golfam, P.; Ashofteh, P.S.; Loáiciga, H.A. Evaluation of the VIKOR and FOWA multi-criteria decision making methods for climate-change adaptation of agricultural water supply. Water Resour. Manag. 2019, 33, 2867–2884. [Google Scholar] [CrossRef]

- Li, M.; Ming, X.; Zheng, M. A framework of product innovative design process based on TRIZ and Patent Circumvention. J. Eng. Des. 2013, 24, 830–848. [Google Scholar] [CrossRef]

- Li, H.; Yuan, J.F.; Tan, R.H. Design around bundle patent portfolio based on technological evolution. Chin. J. Mech. Eng. 2019, 32, 1–16. [Google Scholar] [CrossRef]

- Ramírez-Rios, L.Y.; Camargo-Wilson, C.; Olguín-Tiznado, J.E.; López-Barreras, J.A.; Inzunza-González, E.; García-Alcaraz, J.L. Design of a modular plantar orthosis system through the application of TRIZ methodology tools. Appl. Sci. 2021, 11, 2051. [Google Scholar] [CrossRef]

- Li, M.; Ming, X.; He, L.; Zheng, M.; Xu, Z. A TRIZ-based trimming method for patent design around. Comput. Aided Des. 2015, 62, 20–30. [Google Scholar] [CrossRef]

- Feng, L.; Niu, Y.; Wang, J. Development of morphology analysis-based technology roadmap considering layer expansion paths: Application of TRIZ and text mining. Appl. Sci. 2020, 10, 8498. [Google Scholar] [CrossRef]

- Boavida, R.; Navas, H.; Godina, R. A combined use of TRIZ methodology and eco-compass tool as a sustainable innovation model. Appl. Sci. 2020, 10, 3535. [Google Scholar] [CrossRef]

- Dong, T.Y. Research on Gas-Liquid Separation Device and Control System of Subsea Separator. Master’s Thesis, M-Harbin Engineering University, Heilongjiang, China, 2018. [Google Scholar]

| Concepts | Explanation |

|---|---|

| Product Function | Input/output relationship of the total product task in the form of “verb + noun”. |

| Sub-function | Input/output relationship of product sub-tasks in the form of “verb + noun”. |

| Function | Operation of a component or product in the form of “verb”. |

| Flow | Energy, materials, and signals as recipients of functional operations. |

| Functional Basis | Function sets and flow sets. |

| Function | Technology | |

|---|---|---|

| Transmit torque | P | |

| ||

| S1 (interference fit) | S2 (clamping connection) | |

|  | |

| Value | Meaning |

|---|---|

| 0.9 | The former is more important than the latter. |

| 0.7 | The former is important compared to the latter. |

| 0.5 | Both are equally important. |

| 0.3 | The latter is important compared to the former. |

| 0.1 | The latter is more important than the former. |

| 0.8, 0.6, 0.4, 0.2 | Median of adjacent meanings. |

| No. | Patent Number | Patent Name | Explanation |

|---|---|---|---|

| 1 | CN113374010B | River silt and mud cleaner for water conservancy projects | The brush and water work together to remove the sludge. |

| 2 | CN101291746B | Mud Shaker | Solids are removed from the sieve by shaking. |

| 3 | CN111438003A | A centrifuge for the preparation of disinfecting bath liquid | Using high-pressure water to remove residual slag. |

| 4 | CN211690504U | A lake bottom sludge suction device | The mud is sucked in by the negative pressure generated by the vacuuming device and discharged by the pressurizing device. |

| 5 | CN213111146U | A magnetic suction conveyor | Magnetic solids are moved by magnetic traction. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Tan, R.; Peng, Q.; Shao, P.; Dong, Y.; Wang, K. Construction and Application of Enterprise Knowledge Base for Product Innovation Design. Appl. Sci. 2022, 12, 6358. https://doi.org/10.3390/app12136358

Zhang L, Tan R, Peng Q, Shao P, Dong Y, Wang K. Construction and Application of Enterprise Knowledge Base for Product Innovation Design. Applied Sciences. 2022; 12(13):6358. https://doi.org/10.3390/app12136358

Chicago/Turabian StyleZhang, Lulu, Runhua Tan, Qingjin Peng, Peng Shao, Yafan Dong, and Kang Wang. 2022. "Construction and Application of Enterprise Knowledge Base for Product Innovation Design" Applied Sciences 12, no. 13: 6358. https://doi.org/10.3390/app12136358

APA StyleZhang, L., Tan, R., Peng, Q., Shao, P., Dong, Y., & Wang, K. (2022). Construction and Application of Enterprise Knowledge Base for Product Innovation Design. Applied Sciences, 12(13), 6358. https://doi.org/10.3390/app12136358