Automatic Failure Modes and Effects Analysis of an Electronic Fuel Injection Model

Abstract

:1. Introduction

2. Failure Mode–Failure Effects Trends

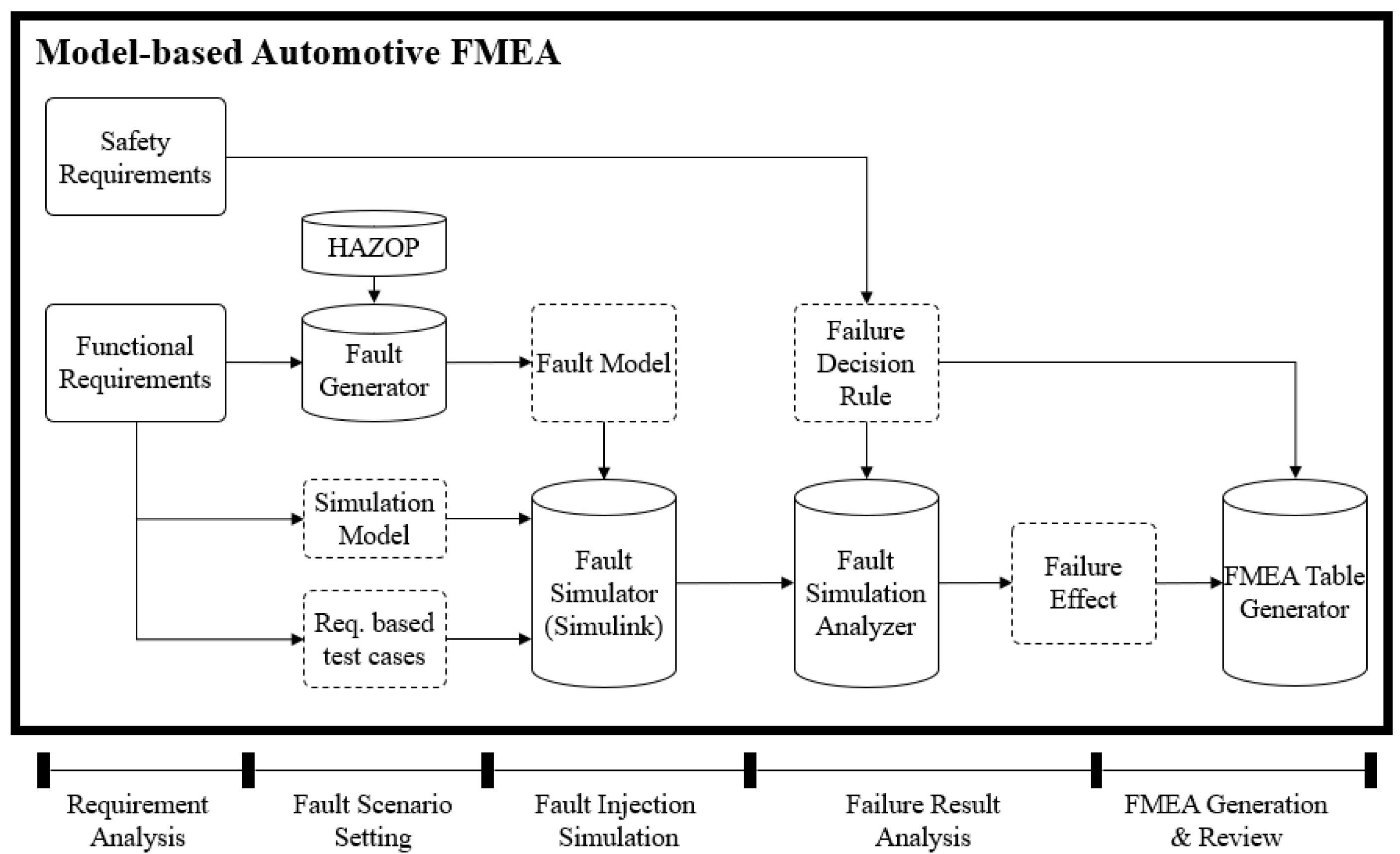

3. Automatic FMEA System

3.1. Automatic FMEA

3.2. The Function of Automatic FMEA

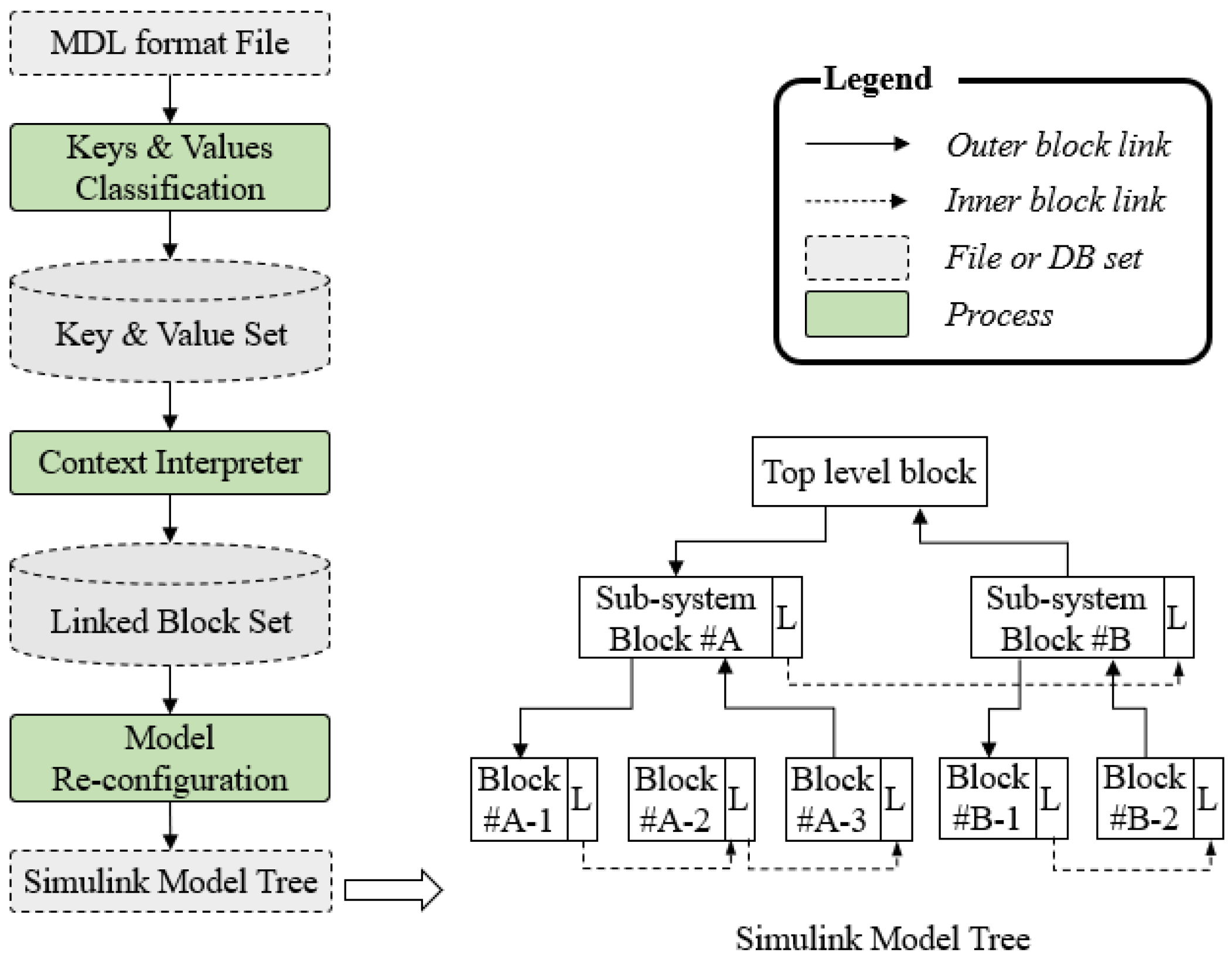

3.2.1. Simulink MDL Parser

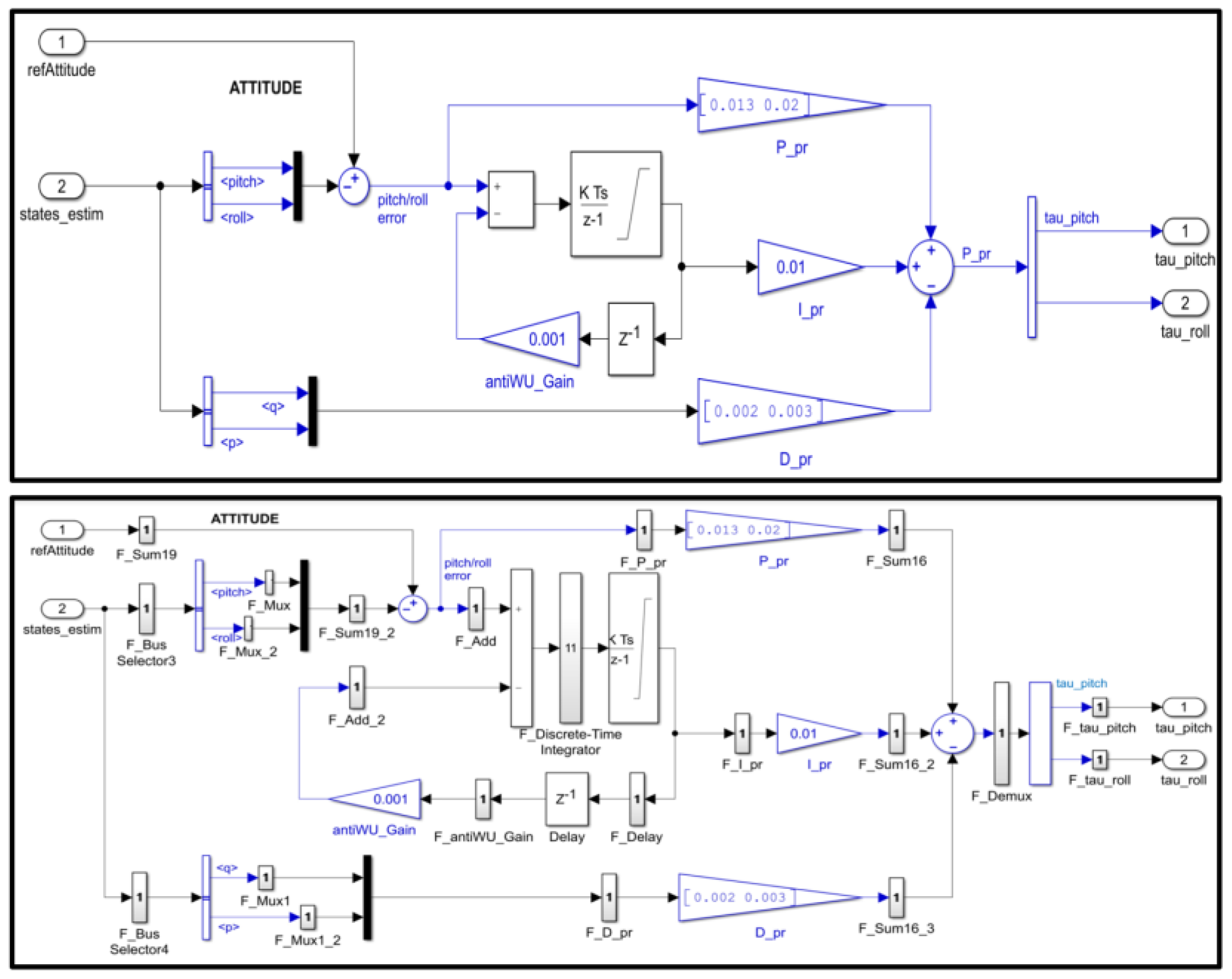

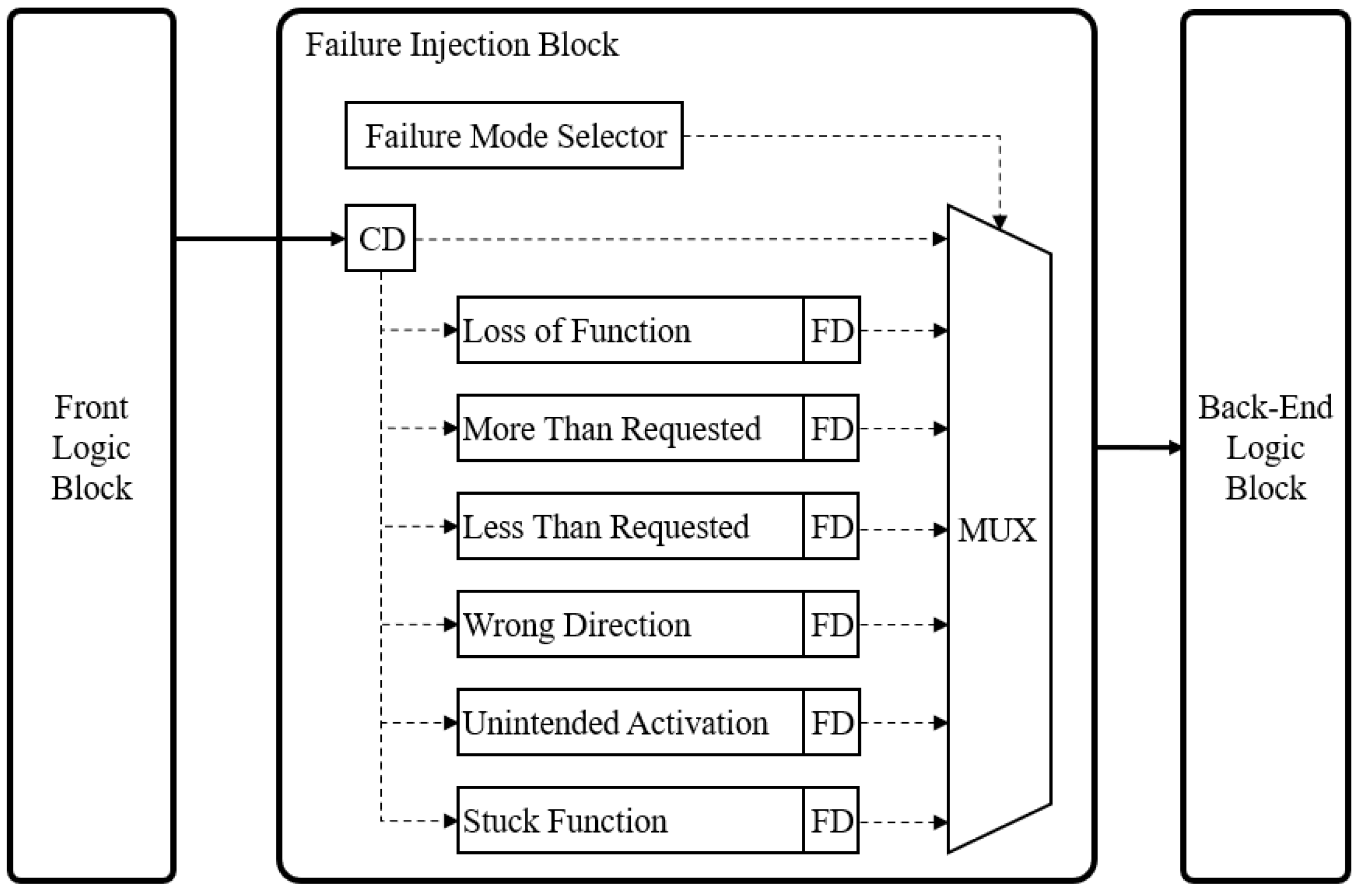

3.2.2. Saboteur-Based Fault Simulation Model Creation

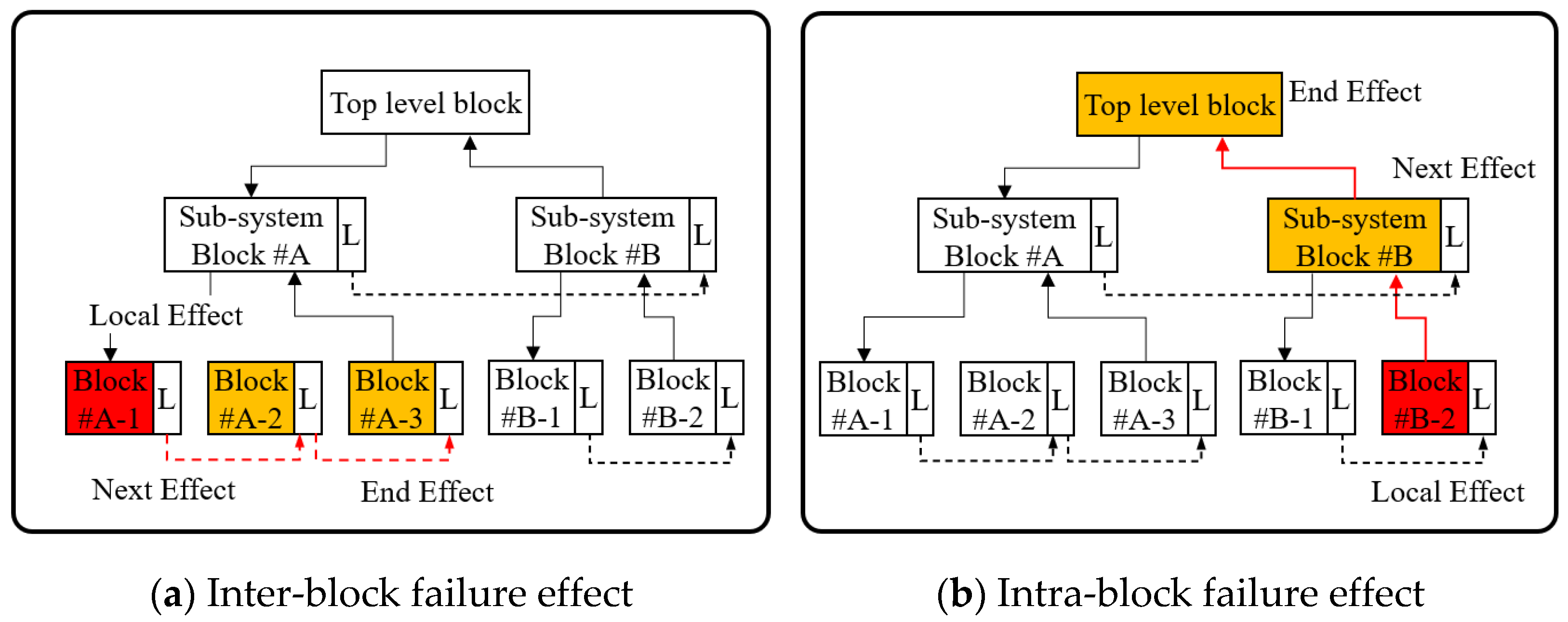

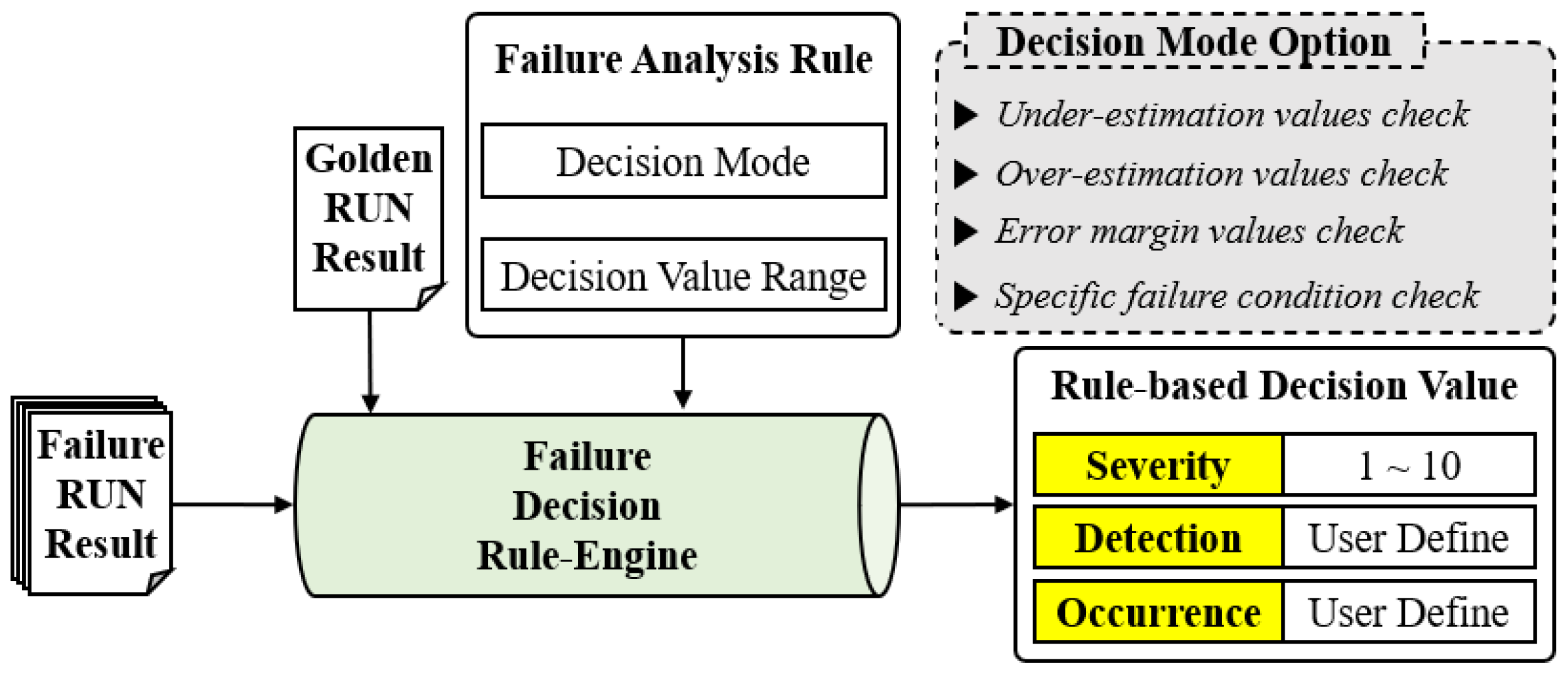

3.2.3. Rule-Based Failure Determination Function

3.2.4. Implementation of Automatic FMEA

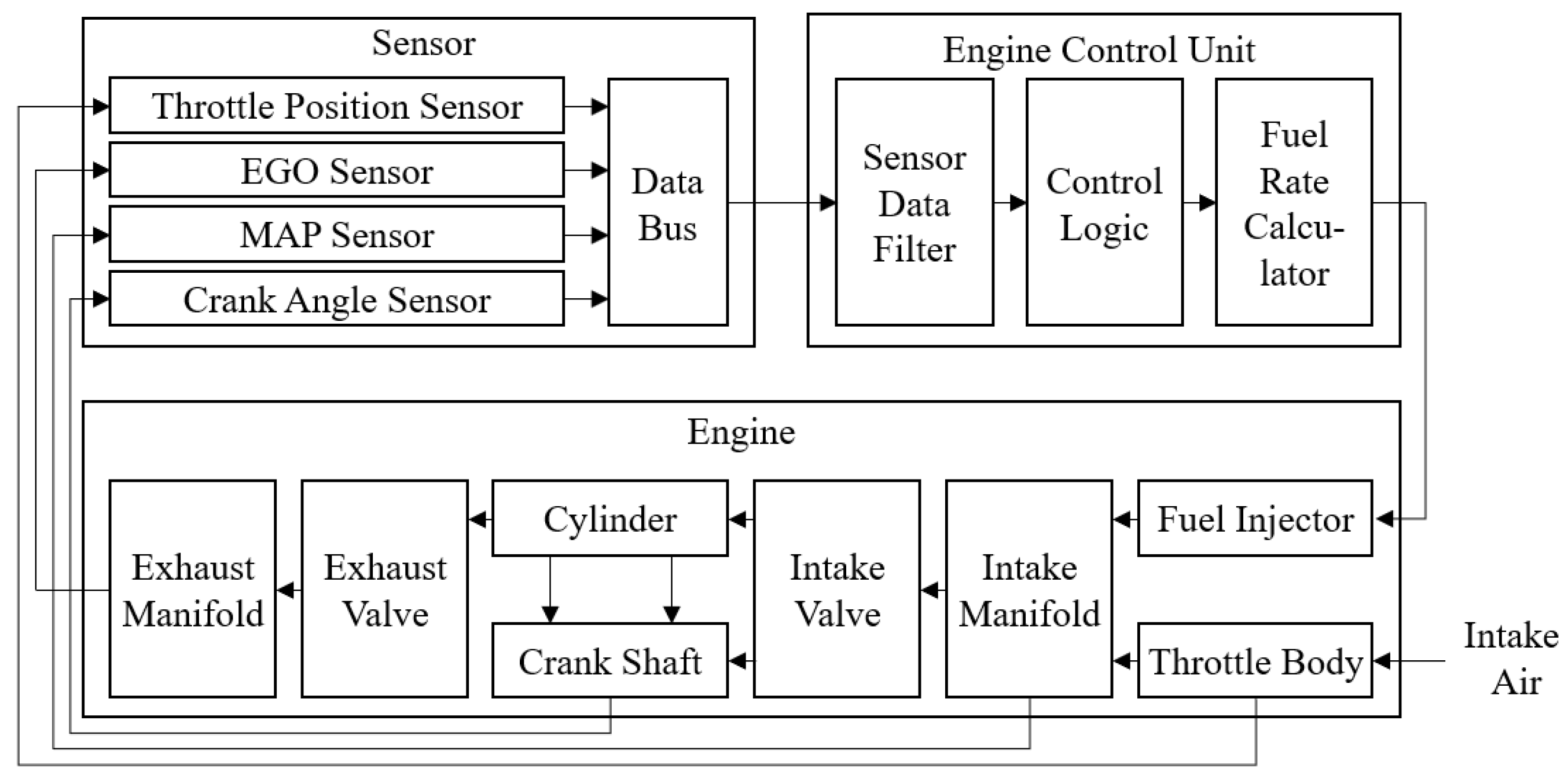

4. Case study: Electronic Fuel Injection System

4.1. Electronic Fuel Injection System

4.1.1. Overview of the Electronic Fuel Injection System

4.1.2. Simulink Design Model of Electronic Fuel Injection System

4.2. Electronic Fuel Injection Analysis Using Automatic FMEA

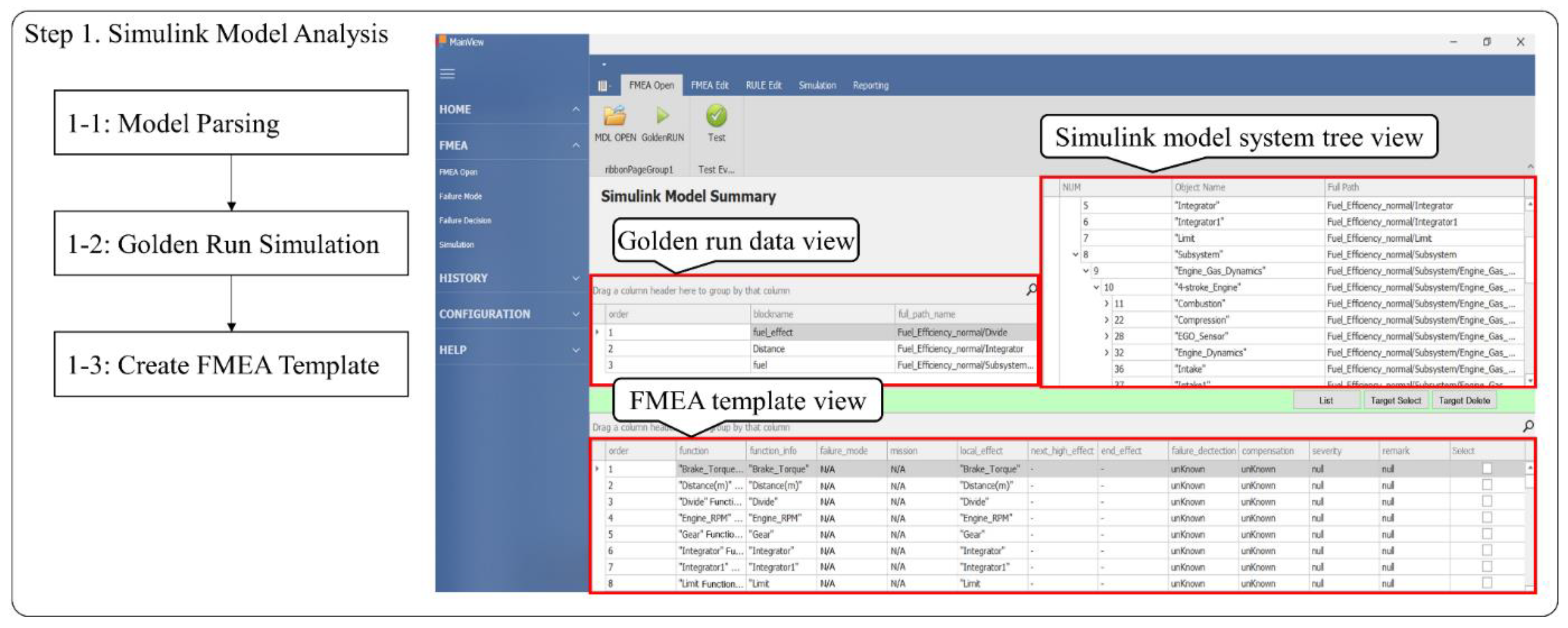

4.2.1. Step 1: Simulink Model Analysis

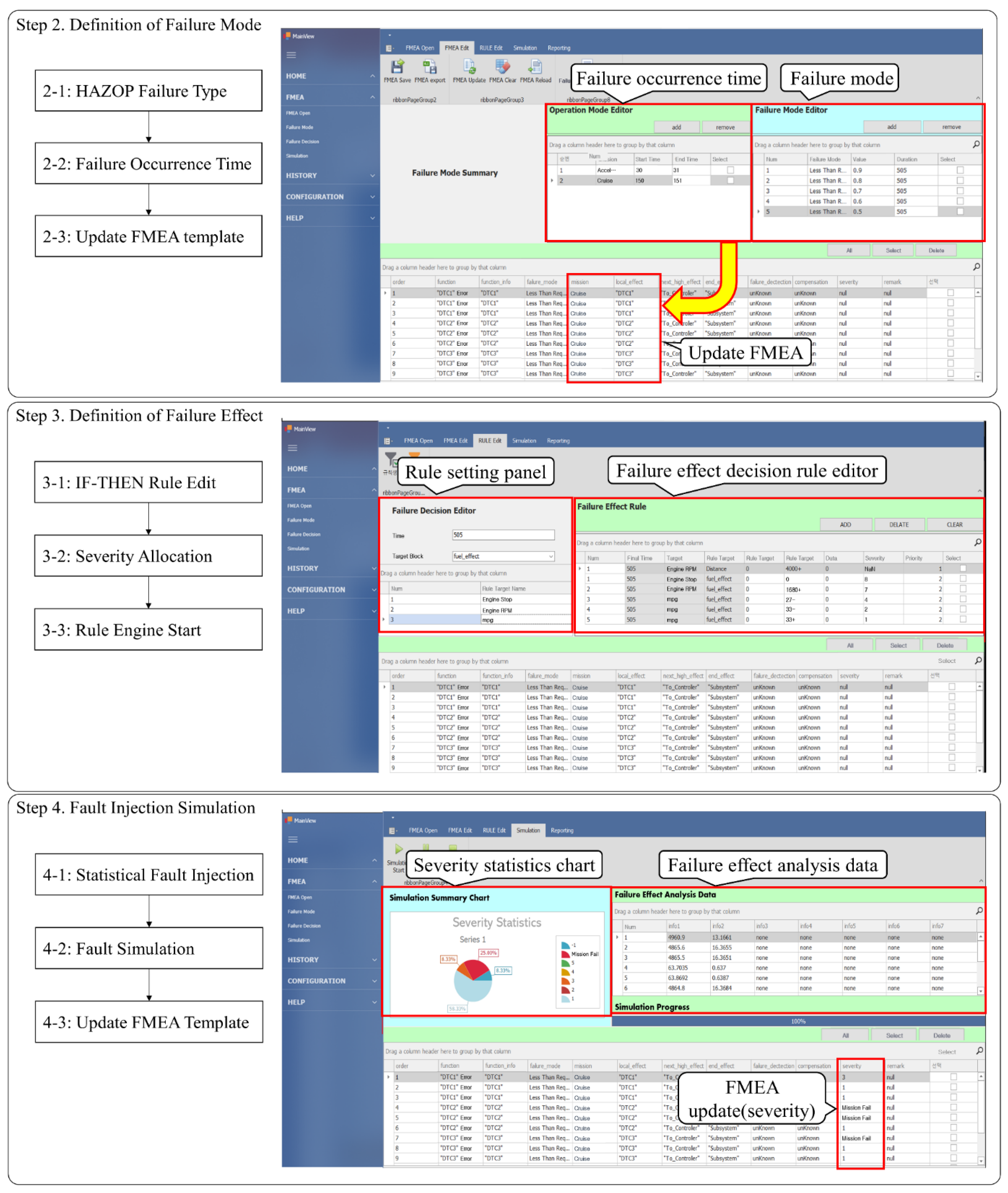

4.2.2. Step 2: Definition of Failure Mode

4.2.3. Step 3: Failure Effect Identification

4.2.4. Step 4: Fault Injection Simulation

4.3. Comparison of Automatic FMEA Tool with Legacy FMEA Tool

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IEC 62425; Railway Application: Communications, Signaling and Processing Systems—Safety Related Electronic System for Signaling. IEC: Geneva, Switzerland, 2005.

- SAE ARP 4761; Guidelines and Methods for Conducting the Safety Assessment Process on Civil Airborne Systems and Equipment. SAE: Sydney, Australia, 1996.

- DO-178C; Software Considerations in Airborne Systems and Equipment Certification. RTCA Inc.: Washington, DC, USA, 2011.

- ISO 26262; Road Vehicles—Function Safety—Part 5: Product Development at the Hardware Level. ISO: Geneva, Switzerland, 2018.

- DO-254; Design Assurance Guidance for Airborne Electronic Hardware. RTCA Inc.: Washington, DC, USA, 2000.

- SAE ARP 4754; Certification Considerations for Highly-Integrated or Complex Aircraft Systems. SAE: Sydney, Australia, 1996.

- Steinke, A.; Kopp, B. RELEX: An Excel-based software tool for sampling split-half reliability coefficients. Methods Psychol. 2020, 2, 100023. [Google Scholar] [CrossRef]

- Eti, M.; Ogaji, S.; Probert, S. Integrating reliability, availability, maintainability and supportability with risk analysis for improved operation of the Afam thermal power-station. Appl. Energy 2007, 84, 202–221. [Google Scholar] [CrossRef]

- Tortorella, M. Reliability, Maintainability, and Supportability: Best Practices for Systems Engineers; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Blanchard, B.S.; Fabrycky, W.J.; Fabrycky, W.J. Systems Engineering and Analysis; Prentice Hall: Hoboken, NJ, USA, 1990; Volume 4. [Google Scholar]

- Cooper, H.C. Capture all critical failure modes into FMEA in half the time with a simple decomposition table (Actual case study savings = $4,206,000). In Proceedings of the 2015 Annual Reliability and Maintainability Symposium (RAMS), Palm Harbor, FL, USA, 26–29 January 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Feng, X.; Qian, Y.; Li, Z.; Wang, L.; Wu, M. Functional Model-Driven FMEA Method and Its System Implementation. In Proceedings of the 2018 12th International Conference on Reliability, Maintainability, and Safety (ICRMS), Shanghai, China, 17–19 October 2018; pp. 345–350. [Google Scholar] [CrossRef]

- Hecht, H.; An, X.; Hecht, M. Computer aided software FMEA for unified modeling language based soft-ware. In Proceedings of the Annual Symposium Reliability and Maintainability, 2004—RAMS, Los Angeles, CA, USA, 26–29 January 2004; pp. 243–248. [Google Scholar]

- Hodkiewicz, M.; Klüwer, J.W.; Woods, C.; Smoker, T.; Low, E. An ontology for reasoning over engineering textual data stored in FMEA spreadsheet tables. Comput. Ind. 2021, 131, 103496. [Google Scholar] [CrossRef]

- Mariani, R.; Boschi, G.; Colucci, F. Using an innovative SoC-level FMEA methodology to design in compliance with IEC61508. In Proceedings of the 2007 Design, Automation & Test in Europe Conference & Exhibition, Nice, France, 16–20 April 2007; pp. 1–6. [Google Scholar]

- Selwyn, T.S.; Kesavan, R. Analysis of Wind Turbine Using Severity and Occurrence at High Uncertain Wind in India. Int. J. Appl. Eng. Res. 2015, 10, 2015. [Google Scholar]

- Kellner, D.W. Software FMEA: A successful application for a complex service oriented architecture system. In Proceedings of the 2017 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, Y.; Wang, L.; Xu, D. Product model-based design process modeling in collaborative design. In Proceedings of the 2010 IEEE International Conference on Industrial Engineering and Engineering Management, Macao, China, 7–10 December 2010; pp. 315–319. [Google Scholar]

- Beshears, R.; Bouma, A. Engaging Supportability Analysis through Model-Based Design. In Proceedings of the 2020 Annual Reliability and Maintainability Symposium (RAMS), Palm Springs, CA, USA, 27–30 January 2020; pp. 1–5. [Google Scholar]

- Kellner, A.; Hehenberger, P.; Weingartner, L.; Friedl, M. Design and use of system models in mechatronic system design. In Proceedings of the 2015 IEEE International Symposium on Systems Engineering (ISSE), Rome, Italy, 28–30 September 2015; pp. 142–149. [Google Scholar]

- Fiorucci, T.; Daveau, J.M.; Di Natale, G.; Roche, P. Automated Dysfunctional Model Extraction for Model Based Safety Assessment of Digital Systems. In Proceedings of the 2021 IEEE 27th International Symposium on On-Line Testing and Robust System Design (IOLTS), Torino, Italy, 28–30 June 2021; pp. 1–6. [Google Scholar]

- Huang, Z.; Hansen, R.; Huang, Z. Toward FMEA and MBSE integration. In Proceedings of the 2018 Annual Reliability and Maintainability Symposium (RAMS), Reno, NV, USA, 22–25 January 2018; pp. 1–7. [Google Scholar]

- Kaukewitsch, C.; Papist, H.; Zeller, M.; Rothfelder, M. Automatic Generation of RAMS Analyses from Model-based Functional Descriptions using UML State Machines. In Proceedings of the 2020 Annual Reliability and Maintainability Symposium (RAMS), Palm Springs, CA, USA, 27–30 January 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Gao, T.; Li, X.-D.; Qu, H.-Y.; Li, C.-F.; Wang, J.-M. Circuit FMEA Method by Fault Simulation Based on Saber. In Proceedings of the 2019 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (QR2MSE), Zhangjiajie, China, 6–9 August 2019; pp. 1039–1045. [Google Scholar] [CrossRef]

- Scippacercola, F.; Pietrantuono, R.; Russo, S.; Esper, A.; Silva, N. Integrating FMEA in a Model-Driven Methodology. In Proceedings of the International Space System Engineering Conference (DASIA), Tallinn, Estonia, 10–12 May 2016; p. 7. [Google Scholar]

- Zhang, J.; Li, G.Q. A Novel Model-Based Method for Automatic Generation of FMEA. Appl. Mech. Mater. 2013, 347, 2605–2609. [Google Scholar] [CrossRef]

- Cui, J.; Ren, Y.; Yang, D.; Zeng, S. Model based FMEA for electronic products. In Proceedings of the 2015 First International Conference on Reliability Systems Engineering (ICRSE), Beijing, China, 21–23 October 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Godina, R.; Silva, B.; Espadinha-Cruz, P. A Dmaic Integrated Fuzzy FMEA Model: A Case Study in the Automotive Industry. Appl. Sci. 2021, 11, 3726. [Google Scholar] [CrossRef]

- Meriem, A.; Abdelaziz, M. A Methodology to do Model-Based Testing using FMEA. In Proceedings of the 2nd International Conference on Networking, Information Systems & Security, Rabat, Morocco, 27–29 March 2019. [Google Scholar] [CrossRef]

- de Magalhães, W.R.; Junior, F.R.L. A Model Based on FMEA and Fuzzy TOPSIS for Risk Prioritization in Industrial Processes. Available online: http://www.scielo.br/j/gp/a/JDrTncwmM3YDrvcZ8X8ztbm/ (accessed on 29 March 2022).

- Chang, T.-W.; Lo, H.-W.; Chen, K.-Y.; Liou, J.J.H. A Novel FMEA Model Based on Rough BWM and Rough TOPSIS-AL for Risk Assessment. Mathematics 2019, 7, 874. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharjee, P.; Dey, V.; Mandal, U. Risk assessment by failure mode and effects analysis (FMEA) using an interval number based logistic regression model. Saf. Sci. 2020, 132, 104967. [Google Scholar] [CrossRef]

- Bonfiglio, V.; Montecchi, L.; Irrera, I.; Rossi, F.; Lollini, P.; Bondavalli, A. Software Faults Emulation at Model-Level: Towards Automated Software FMEA. In Proceedings of the 2015 IEEE International Conference on Dependable Systems and Networks Workshops, Rio de Janeiro, Brazil, 22–25 June 2015; pp. 133–140. [Google Scholar] [CrossRef]

- Hess, A.; Stecki, J.S.; Rudov-Clark, S.D. The Maintenance Aware Design Environment: Development of an Aerospace PHM Software Tool. Proc. PHM08 2008, 16, 1–9. [Google Scholar]

- Rekik, F.; Bannour, B.; Dhouib, S.; Gérard, S. Model-driven consistency verification for service-oriented applications. In Proceedings of the 2015 IEEE 8th International Conference on Service-Oriented Computing and Applications (SOCA), Rome, Italy, 19–21 October 2015; pp. 180–187. [Google Scholar]

- Modeling a Fault-Tolerant Fuel Control System. Available online: https://kr.mathworks.com/help/simulink/slref/modeling-a-fault-tolerant-fuel-control-system.html (accessed on 17 September 2021).

- APIS IQ-Software|FMEA|DRBFM|Functional Safety, APIS Informations Technologien GmbH. Available online: https://www.apis-iq.com/ (accessed on 18 November 2021).

- Tang, T.; Lu, Y.; Zhou, T.T.; Jing, H.L.; Sun, H. FTA and FMEA of braking system based on relex 2009. In Proceedings of the International Conference on Information Systems for Crisis Response and Management (ISCRAM), Harbin, China, 25–27 November 2011; pp. 106–112. [Google Scholar]

- Joshi, A.; Heimdahl, M.P.; Miller, S.P.; Whalen, M.W. Model-Based Safety Analysis; NASA/CR-2006-213953; NASA Langley Research Center: Hanover, VA, USA, 2006. [Google Scholar]

- Failure Modes and Effects Analysis Business Case Cost/Benefit Analysis. Available online: https://elsmar.com/pdf_files/FMEA%20and%20Reliability%20Analysis/Failure%20Modes%20and%20Effects%20Analysis%20Business%20Case%20Cost-Benefit%20Analysis.PDF (accessed on 6 June 2022).

- Belu, N.; Ionescu, L.M.; Misztal, A. Computer Aided Design Solution Based on Genetic Algorithms for FMEA and Control Plan in Automotive Industry. Int. J. Ind. Manuf. Eng. 2015, 9, 2672–2677. [Google Scholar]

- Choi, Y.J.; Choi, G.H.; Chung, G.H. Parsing simulink mdl file and C# data structure for Testing. In Proceedings of the Korean Information Science Society Conference Korean Institute of Information Scientists and Engineers, Jeju-do, Korea, 30 June 2010; pp. 414–418. [Google Scholar]

- Toolbox, S.M. Matlab; Mathworks Inc.: Portola Valley, CA, USA, 1993. [Google Scholar]

- Lee, I.K.; Chun, Y.S.; Kim, C.K.; Kim, D.H.; Kim, Y.G.; Cho, S.H.; Kook, C.H.; Kim, S.C. A study on the sensor of electronic control system. In Proceedings of the Tribology Society Conference, Changwon, Korea, 19–20 June 2008; pp. 9–16. [Google Scholar]

- Lim, S.-Y.; Jang, I.-H.; Lee, Y.-J.; Lee, H.-W.; Im, H.-W. Improvement through failure mode and failure mechanism of piezo sensors used in AVC. In Proceedings of the Korean Reliability Society Conference, Gumi, Korea, 28–29 May 2015; pp. 313–320. [Google Scholar]

- Jan, S.U.; Lee, Y.-D.; Shin, J.; Koo, I. Sensor Fault Classification Based on Support Vector Machine and Statistical Time-Domain Features. IEEE Access 2017, 5, 8682–8690. [Google Scholar] [CrossRef]

- Kim, S.C.; Kim, D.H.; Kang, S.U. Analysis of Voltage, Current and Temperature Signals for Poor Connections at Electrical Connector. J. Korean Soc. Saf. 2014, 29, 12–17. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.W.; Lee, Y.D.; Koo, I.S. Timely Sensor Fault Detection Scheme based on Deep Learning. J. Inst. Internet Broadcasting Commun. 2020, 20, 163–169. [Google Scholar]

- Yang, J.-W.; Lee, Y.-D.; Gu, I. Deep learning and support vector machine-based sensor failure detection techniques. J. Korean Internet Telecommun. Soc. 2018, 18, 185–195. [Google Scholar]

- Fuel Economy Home Page. Gasoline Vehicles: Learn More about the Label. Available online: https://www.fueleconomy.gov/feg/label/learn-more-gasoline-label.shtml (accessed on 12 March 2020).

| Features | Automatic FMEA | HiP-HOPS | MADe | Relex |

|---|---|---|---|---|

| Environment | Simulink | Simulink | MADe FMEA | Spreadsheet SW |

| Failure Assessment | Automatic | Semi-automatic | Automatic | Manual |

| Failure Effects Analysis | Fault injection simulation | Manual simulation | Fault injection simulation | Manual |

| Severity | Rule-based system | FTA | User manual | |

| Occurrence | FTA | MADe-FTA | ||

| Detection | N/A | N/A | ||

| Fault Injection Mechanism | Saboteur | N/A | Mutation | N/A |

| Failure Keyword | Meaning | |

|---|---|---|

| Loss of function (LF) | Functions not activated | |

| Incorrect | More than requested (MTR) | Functions activated in excess of requested quantity |

| Less than requested (LTR) | Functions activated in less than requested quantity | |

| Wrong direction (WD) | Reverse functions activated | |

| Unintended activation of function (UAF) | Functions activated at unintended time | |

| Locked/stuck function (SF) | Function is not updated | |

| Timing | Early | Function activated earlier |

| Late | Functions activated later | |

| No | Sensor Failure Mode | A-FMEA Failure Mode Condition | ||

|---|---|---|---|---|

| Fault Type | Value | Time (s) | ||

| 1 | Drift fault 50% | Less than requested | Vout = VNormal × α, α = 0.5 | 505 |

| 2 | Drift fault 150% | More than requested | Vout = VNormal × β, β = 1.5 | 505 |

| 3 | Hard-over | More than requested | Vout ≥ VMAX, VMAX = 1.0 | 505 |

| 4 | Stuck 0 | Locked/stuck function | Vout = VConst, VConst = 0.0 | 505 |

| Test Scenario | Operation Mode | Vehicle Information | |||

|---|---|---|---|---|---|

| Start Time | End Time | Velocity | Acceleration | Distance | |

| Acceleration Test | 0 | 100 | 30.6 km/h | 0.31 km/s2 | 850 m |

| Cruise Test | 100 | 505 | 32.2 km/h | 0 km/s2 | 4475 m |

| No | Failure Effect | Decision Mode Option | Condition | Severity |

|---|---|---|---|---|

| 1 | Engine stop | Specific failure condition check | RPM == 0 | 8 |

| 2 | Engine hesitation | Error margin values check | (RPM < 1120) & (RPM > 1680) | 7 |

| 3 | Engine hesitation | Error margin values check | (RPM < 1190) & (RPM > 1610) | 6 |

| 4 | Engine hesitation | Error margin values check | (RPM < 1260) & (RPM > 1540) | 5 |

| 5 | Engine hesitation | Error margin values check | (RPM < 1330) & (RPM > 1470) | 4 |

| 6 | Gas mileage low | Underestimation values check | mpg < 20 (FE 1, 2, 3) | 4 |

| 7 | Gas mileage low | Underestimation values check | mpg < 27 (FE 4, 5) | 3 |

| 8 | Gas mileage low | Underestimation values check | mpg < 33 (FE 6, 7) | 2 |

| 9 | Gas mileage low | Overestimation values check | mpg > 33 (FE 8, 9, 10) | 1 |

| Item | Function | Function Info | Failure Mode | Mission | Local Effect | Next High Effect | End Effect | Severity |

|---|---|---|---|---|---|---|---|---|

| Throttle Position Sensor | Data sensing | Throttle position sensing | Drift (505) | Cruise (150–151) | TPS output (6.5 %) | Fuel rate (0 g/s) | Engine RPM (0 rpm) | 8 |

| Sensor | TPS | CPS | EGO | MAP | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Failure Effects | Drift | Hard-Over | Stuck | Drift | Hard-Over | Stuck | Drift | Hard-Over | Stuck | Drift | Hard-Over | Stuck |

| Total tests | 40 | 40 | 2 | 40 | 40 | 2 | 40 | 40 | 2 | 40 | 40 | 2 |

| Masked | 30 | 31 | 0 | 12 | 11 | 0 | 30 | 0 | 0 | 17 | 18 | 0 |

| Engine stop | 6 | 5 | 1 | 14 | 23 | 2 | 10 | 40 | 2 | 15 | 15 | 1 |

| Hesitation | 4 | 4 | 1 | 11 | 2 | 0 | 0 | 0 | 0 | 6 | 6 | 1 |

| Low mileage | 0 | 0 | 0 | 3 | 4 | 0 | 0 | 0 | 0 | 2 | 1 | 0 |

| Total failure | 10 | 9 | 2 | 28 | 29 | 2 | 10 | 40 | 2 | 23 | 22 | 2 |

| (a) Legacy FMEA table | |||||||||||

| Item | Function | Function Info. | Failure Mode | Mission | Effect | S | O | D | RPN | ||

| Local | Next | End | |||||||||

| TPS | Sensor | Throttle position sensing | Signal error | Cruise | TPS signal error | Lack of fuel | Engine hesitation | 6 | 2 | 1 | 12 |

| CPS | Sensor | Crankshaft position sensing | Signalerror | Cruise | CPS signal error | Lack of fuel | Engine stop | 8 | 2 | 1 | 16 |

| EGO | Sensor | Exhaust gas oxygen sensing | Signalerror | Cruise | EGO signal error | Lack of fuel | Low gas mileage | 4 | 2 | 1 | 8 |

| MAP | Sensor | Manifold absolute pressure sensing | Signalerror | Cruise | MAP signal error | Lack of fuel | Engine stop | 8 | 2 | 1 | 16 |

| (b) Automatic FMEA table | |||||||||||

| Item | Function | Function Info. | Failure Mode | Mission | Effect | S | O | D | RPN | ||

| Local | Next | End | |||||||||

| TPS | Sensor | Throttle position sensing | Signal error: Period: permanent Type: drift Signal size: 40% | Acceleration | TPS signal error: Avg. error: 60% Max. error: 60% | Lack of fuel: Avg. error: 19.9% Max. error: 100% | Engine hesitation: Avg. error: 0.48% Max. error: 100% | 7 | 1 | 1 | 7 |

| Signal error: Period: permanent Type: drift Signal size: 40% | Cruise | TPS Signal error: Avg. error: 60% Max. error: 60% | Lack of fuel: Avg. error: 100% Max. error: 100% | Engine stop: Avg. error: 100% Max. error: 100% | 8 | 1 | 1 | 8 | |||

| CPS | Sensor | Crank-shaft position sensing | Signal error: Period: permanent Type: drift Signal size: 140% | Cruise | CPS Signal error: Avg. error: 40% Max. error: 40% | Lack of fuel: Avg. error: 0.4% Max. error: 4.30% | Low gas mileage: Avg. error: 0.8% Max. error: 4.3% | 1 | 2 | 2 | 4 |

| Signal error: Period: permanent Type: drift Signal size: 150% | Cruise | CPS Signal error: Avg. error: 50% Max. error: 50% | Lack of fuel: Avg. error: 1.6% Max. error: 40% | Engine hesitation: Avg. error: 0.8% Max. error: 8.9% | 4 | 2 | 1 | 8 | |||

| Signal error: Period: permanent Type: drift Signal size: 80% | Cruise | CPS Signal error: Avg. error: 20% Max. error: 20% | Lack of fuel: Avg. error: 0.2% Max. error: 66% | Engine hesitation: Avg. error: 0.3% Max. error: 54.8% | 7 | 2 | 1 | 14 | |||

| Signal error: Period: permanent Type: drift Signal size: 70% | Cruise | CPS Signal error: Avg. error: 30% Max. error: 30% | Lack of fuel: Avg. error: 100% Max. error: 100% | Engine stop: Avg. error: 100% Max. error: 100% | 8 | 1 | 1 | 8 | |||

| EGO | Sensor | Exhaust gas oxygen sensing | Signal error: Period: permanent Type: drift Signal size: 60% | Cruise | EGO Signal error: Avg. error: 40% Max. error: 40% | Lack of fuel: Avg. error: 1.9% Max. error: 5.4% | Low gas mileage: Avg. error: 0.1% Max. error: 1.0% | 1 | 2 | 2 | 4 |

| Signal error: Period: permanent Type: drift Signal size: 50% | Cruise | EGO Signal error: Avg. error: 50% Max. error: 50% | Lack of fuel: Avg. error: 100% Max. error: 100% | Engine stop: Avg. error: 100% Max. error: 100% | 8 | 1 | 1 | 8 | |||

| MAP | Sensor | Manifold absolute pressure sensing | Signal error: Period: permanent Type: drift Signal size: 90% | Cruise | MAP Signal error: Avg. error: 10% Max. error: 10% | Lack of fuel: Avg. error: 1.3% Max. error: 11.9% | Low gas mileage: Avg. error: 0.2% Max. error: 2.8% | 1 | 2 | 2 | 4 |

| Signal error: Period: permanent Type: drift Signal size: 70% | Cruise | MAP Signal error: Avg. error: 30% Max. error: 30% | Lack of fuel: Avg. error: 1.9% Max. error: 100% | Engine hesitation: Avg. error: 0.2% Max. error: 100% | 7 | 2 | 1 | 14 | |||

| Signal error: Period: permanent Type: drift Signal size: 60% | Cruise | MAP Signal error: Avg. error: 40% Max. error: 40% | Lack of fuel: Avg. error: 100% Max. error: 100% | Engine stop: Avg. error: 100% Max. error: 100% | 8 | 1 | 1 | 8 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Lee, D.; Na, J. Automatic Failure Modes and Effects Analysis of an Electronic Fuel Injection Model. Appl. Sci. 2022, 12, 6144. https://doi.org/10.3390/app12126144

Lee D, Lee D, Na J. Automatic Failure Modes and Effects Analysis of an Electronic Fuel Injection Model. Applied Sciences. 2022; 12(12):6144. https://doi.org/10.3390/app12126144

Chicago/Turabian StyleLee, Dongwoo, Dongmin Lee, and Jongwhoa Na. 2022. "Automatic Failure Modes and Effects Analysis of an Electronic Fuel Injection Model" Applied Sciences 12, no. 12: 6144. https://doi.org/10.3390/app12126144

APA StyleLee, D., Lee, D., & Na, J. (2022). Automatic Failure Modes and Effects Analysis of an Electronic Fuel Injection Model. Applied Sciences, 12(12), 6144. https://doi.org/10.3390/app12126144