Propagation Characteristics of Rotation Waves in Transversely Isotropic Granular Media Considering Microstructure Effect

Abstract

:1. Introduction

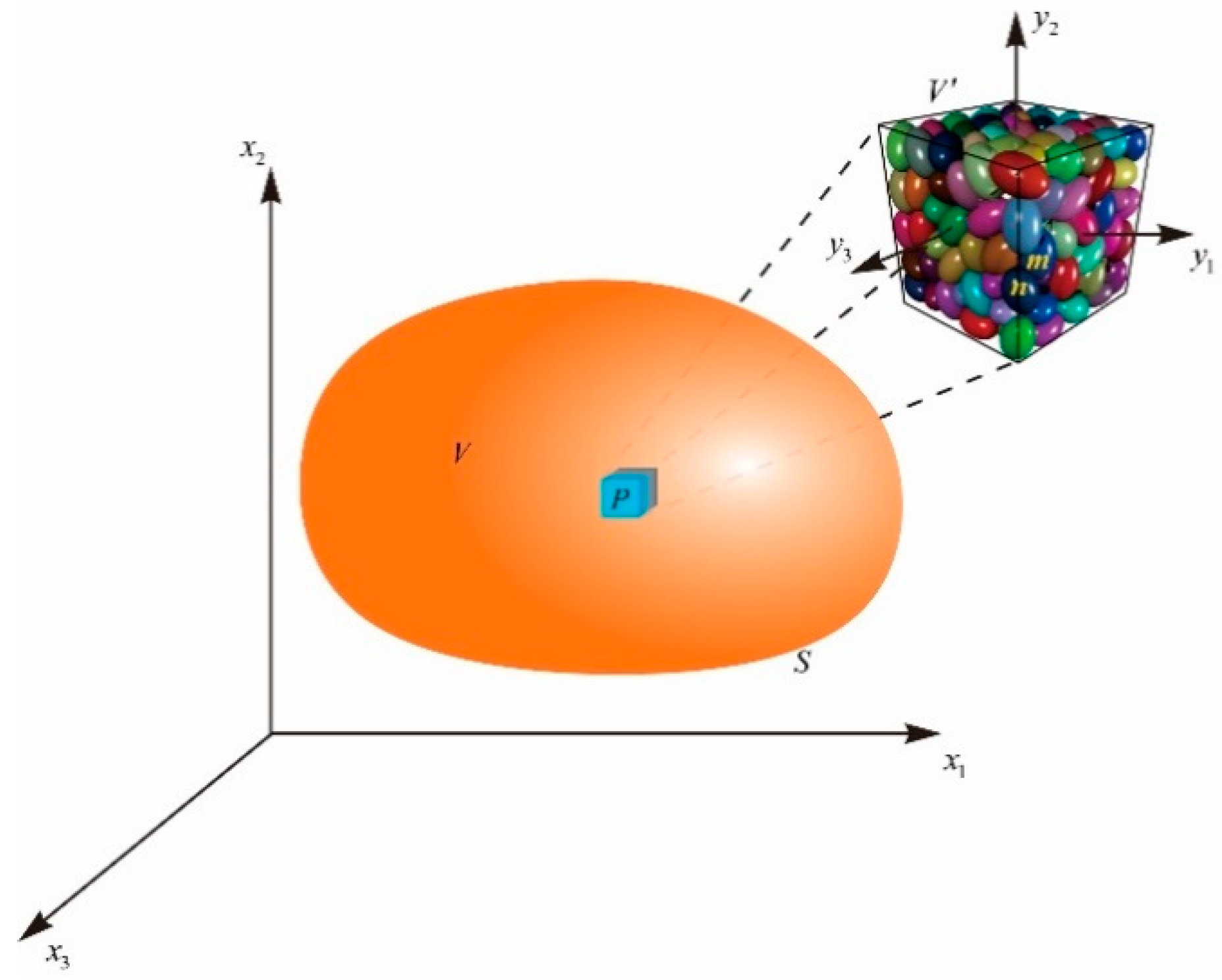

2. The Microstructure Model Considering Nonaffine Deformations

2.1. Macroscale and Microscale Deformations

2.2. Governing Equations and Boundary Conditions

2.3. Local and Global Constitutive Relations

3. Propagation of Particle Rotation Waves

3.1. Wave Equations

3.2. Dispersion Relations

4. Results and Analysis

4.1. Dispersion Characteristics of Particle Rotation Waves

4.2. Frequency Bandgaps of Particle Rotation Waves

5. Conclusions

- The present model can predict 12 particle rotation waves, including 3 rotation longitudinal waves, 6 rotation transverse waves, and 3 rotation in-plane shear waves in the transversely isotropic granular media. These waves can reflect eight kinds of dispersion relations.

- The effect of the change in fabric on the dispersion relation of particle rotation waves can be mainly attributed to the effect of equivalent stiffness on frequency. With the increase in a, the frequencies of rotation longitudinal and transverse waves increase, except for the lower-frequency LO wave, while all rotation in-plane shear waves decrease.

- The present model can predict the presence of bandgaps between particle rotation waves. With the increase in stiffness ratio from 0 to 1, the bandwidths of RLB1 and RTB1 gradually increase, while that of other bandgaps decrease to 0.

- The degree of anisotropy has significant effect on the width of frequency bandgap of longitudinal waves, while has little effect on the width of frequency bandgap of transverse and in-plane shear waves. With the increase in a, the locations of bandgaps between transverse waves gradually increase, while the location of the bandgap between in-plane shear waves decreases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Symbols | Meanings |

| Strain tensor | |

| Curvature tensor | |

| Macroscale displacement vector | |

| Macroscale rotation vector | |

| Particle translation vector | |

| Particle rotation vector | |

| Micro-strain tensor | |

| Micro-curvature tensor | |

| 3 | The gradient of micro-strain |

| 3 | The gradient of micro-curvature |

| Macroscale density | |

| Microscale (particle) density | |

| The volume of unit cell | |

| Second order moment of inertia | |

| Second order polar moments of inertia | |

| Relative Cauchy stress tensor | |

| Relative couple stress tensor | |

| Double body force tensor | |

| Double surface traction tensor | |

| Double body moment tensor | |

| Double surface moment tensor | |

| Contact linear stiffness tensor | |

| Contact rotation stiffness tensor | |

| Second order identity tensor | |

| Kronecker tensor | |

| The probability density function of contact distribution | |

| Anisotropy parameter | |

| , 𝔼4, 𝕄4 | 4th order constitutive tensors |

| , | 6th order constitutive tensors |

| Wave number | |

| V | The volume of material point |

| S | The surface of material point |

| , | Relative deformation tensors |

| , 𝔻3 | Higher-order relative deformation tensors |

| Relative displacement at contact | |

| Relative rotation at contact | |

| Branch vector | |

| Internal length tensor | |

| Kinetic energy | |

| Deformation energy | |

| The work done by external forces | |

| Cauchy stress tensor | |

| Couple stress tensor | |

| Unit outwards-pointing normal vector of the boundary surface S | |

| Fourth order polar moments of inertia | |

| 𝕋3,𝕍3 | Higher-order stress tensors |

| Volume (body) force vector | |

| Surface traction vector | |

| Volume (body) moment vector | |

| Surface moment vector | |

| Contact force | |

| Contact moment | |

| Contact normal vector | |

| The total number of contacts | |

| Deviatoric tensor of contact distribution | |

| The number of contacts per volume | |

| The amplitude of rotation vector | |

| The amplitude of micro-curvature tensor | |

| Angular frequency |

Appendix A

Appendix B

Appendix C

References

- Bai, B.; Zhou, R.; Cai, G.; Hu, W.; Yang, G. Coupled thermo-hydro-mechanical mechanism in view of the soil particle rearrangement of granular thermodynamics. Comput. Geotech. 2021, 137, 104272. [Google Scholar] [CrossRef]

- Venier, C.M.; Márquez Damián, S.; Bertone, S.E.; Puccini, G.D.; Risso, J.M.; Nigro, N.M. Discrete and Continuum Approaches for Modeling Solids Motion Inside a Rotating Drum at Different Regimes. Appl. Sci. 2021, 11, 10090. [Google Scholar] [CrossRef]

- El-Husseiny, A. Improved Packing Model for Functionally Graded Sand-Fines Mixtures—Incorporation of Fines Cohesive Packing Behavior. Appl. Sci. 2020, 10, 562. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Chang, C.S. Relationship between element-level and contact-level parameters of micromechanical and upscaled plasticity models for granular soils. Acta Geotech. 2020, 15, 1779–1798. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, L.; Zhou, J. Numerical Investigation of Mineral Grain Shape Effects on Strength and Fracture Behaviors of Rock Material. Appl. Sci. 2019, 9, 2855. [Google Scholar] [CrossRef] [Green Version]

- Ahn, J.; Jung, J. Effects of Fine Particles on Thermal Conductivity of Mixed Silica Sands. Appl. Sci. 2017, 7, 650. [Google Scholar] [CrossRef]

- Cheng, H.; Luding, S.; Saitoh, K.; Magnanimo, V. Elastic wave propagation in dry granular media: Effects of probing characteristics and stress history. Int. J. Solids Struct. 2020, 187, 85–99. [Google Scholar] [CrossRef] [Green Version]

- Mital, U.; Kawamoto, R.; Andrade, J.E. Effect of fabric on shear wave velocity in granular soils. Acta Geotech. 2019, 15, 1189–1203. [Google Scholar] [CrossRef]

- Di Bella, A.; Gliozzi, A.S.; Scalerandi, M.; Tortello, M. Analysis of Elastic Nonlinearity Using Continuous Waves: Validation and Applications. Appl. Sci. 2019, 9, 5332. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhang, D.; Wu, S.; Yu, P. DEM Investigation on the Evolution of Fabric under True Triaxial Conditions in Granular Materials. Int. J. Geomech. 2020, 20, 04020110. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Yu, P. Upscaling critical state considering the distribution of meso-structures in granular materials. Int. J. Numer. Anal. Methods Geomech. 2021, 45, 1624–1646. [Google Scholar] [CrossRef]

- Wu, M.; Wang, J. Estimating Contact Force Chains Using Artificial Neural Network. Appl. Sci. 2021, 11, 6278. [Google Scholar] [CrossRef]

- Li, X.S.; Dafalias, Y.F. Anisotropic Critical State Theory: Role of Fabric. J. Eng. Mech. 2012, 138, 263–275. [Google Scholar] [CrossRef]

- Hobiny, A.; Alzahrani, F.; Abbas, I.; Marin, M. The Effect of Fractional Time Derivative of Bioheat Model in Skin Tissue Induced to Laser Irradiation. Symmetry 2020, 12, 602. [Google Scholar] [CrossRef]

- Marin, M.; Othman, M.I.A.; Abbas, I.A. An extension of the domain of influence theorem for generalized thermoelasticity of anisotropic material with voids. J. Comput. Theor. Nanosci. 2015, 12, 1594–1598. [Google Scholar] [CrossRef]

- Chang, C.S.; Hicher, P.Y. An elasto-plastic model for granular materials with microstructural consideration. Int. J. Solids Struct. 2005, 42, 4258–4277. [Google Scholar] [CrossRef] [Green Version]

- Tong, L.H.; Ding, H.B.; Yan, J.; Xu, W.C.; Lei, Z. Strain gradient nonlocal Biot poromechanics. Int. J. Eng. Sci. 2020, 156, 103372. [Google Scholar] [CrossRef]

- Chang, C.S.; Gao, J. Second-gradient constitutive theory for granular material with random packing structure. Int. J. Solids Struct. 1995, 32, 2279–2293. [Google Scholar] [CrossRef]

- Suiker, A.S.J.; De Borst, R.; Chang, C.S. Micro-mechanical modelling of granular material. Part 1: Derivation of a second-gradient micro-polar constitutive theory. Acta Mech. 2001, 149, 161–180. [Google Scholar] [CrossRef]

- Chang, C.S.; Gao, J. Kinematic and static hypotheses for constitutive modelling of granulates considering particle rotation. Acta Mech. 1996, 115, 213–229. [Google Scholar] [CrossRef]

- Chang, C.S.; Gao, J.; Zhong, X. High-gradient modeling for Love wave propagation in geological materials. J. Eng. Mech. 1998, 124, 1354–1359. [Google Scholar] [CrossRef]

- Chang, C.S.; Gao, J. Wave propagation in granular rod using high-gradient theory. J. Eng. Mech. 1997, 123, 52–59. [Google Scholar] [CrossRef]

- Suiker, A.S.J.; De Borst, R.; Chang, C.S. Micro-mechanical modelling of granular material. Part 2: Plane wave propagation in infinite media. Acta Mech. 2001, 149, 181–200. [Google Scholar] [CrossRef]

- Tong, L.; Yu, Y.; Hu, W.; Shi, Y.; Xu, C. On wave propagation characteristics in fluid saturated porous materials by a nonlocal Biot theory. J. Sound Vib. 2016, 379, 106–118. [Google Scholar] [CrossRef]

- Poorsolhjouy, P.; Misra, A. Granular micromechanics based continuum model for grain rotations and grain rotation waves. J. Mech. Phys. Solids 2019, 129, 244–260. [Google Scholar] [CrossRef]

- Misra, A.; Poorsolhjouy, P. Granular micromechanics based micromorphic model predicts frequency band gaps. Contin. Mech. Thermodyn. 2016, 28, 215–234. [Google Scholar] [CrossRef]

- Nejadsadeghi, N.; Placidi, L.; Romeo, M.; Misra, A. Frequency band gaps in dielectric granular metamaterials modulated by electric field. Mech. Res. Commun. 2019, 95, 96–103. [Google Scholar] [CrossRef]

- Mindlin, R.D. Microstructure in linear elasticity. Arch. Ration. Mech. Anal. 1964, 16, 51–78. [Google Scholar] [CrossRef]

- Eringen, A.C. Mechanics of micromorphic continua. In Mechanics of Generalized Continua, Proceedings of the IUTAM-Symposium on the Generalized Cosserat Continuum and the Continuum Theory of Dislocations with Applications, Freudenstadt, Germany; Stuttgart, Germany, 28 August–2 September 1967; Kröner, E., Ed.; Springer: Berlin/Heidelberg, Germany, 1968; pp. 18–35. [Google Scholar]

- Xiu, C.; Chu, X.; Wang, J.; Wu, W.; Duan, Q. A micromechanics-based micromorphic model for granular materials and prediction on dispersion behaviors. Granul. Matter 2020, 22, 74. [Google Scholar] [CrossRef]

- Xiu, C.; Chu, X. A micromorphic elastoplastic model and finite element simulation on failure behaviors of granular materials. Int. J. Numer. Anal. Methods Geomech. 2019, 44, 484–515. [Google Scholar] [CrossRef]

- Rosi, G.; Auffray, N. Anisotropic and dispersive wave propagation within strain-gradient framework. Wave Motion 2016, 63, 120–134. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Cao, W.; Xue, L.; Zhang, J.M. An anisotropic plasticity model incorporating fabric evolution for monotonic and cyclic behavior of sand. Acta Geotech. 2021, 16, 43–65. [Google Scholar] [CrossRef]

- Kaviani-Hamedani, F.; Fakharian, K.; Lashkari, A. Bidirectional shear wave velocity measurements to track fabric anisotropy evolution of a crushed silica sand during shearing. J. Geotech. Geoenviron. Eng. 2021, 147, 04021104. [Google Scholar] [CrossRef]

- Yang, Z.; Liao, D.; Xu, T. A hypoplastic model for granular soils incorporating anisotropic critical state theory. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 723–748. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| /m | 5 | ||

| 5 | |||

| 1570 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; Liu, Y.; Shi, M.; Chen, Z. Propagation Characteristics of Rotation Waves in Transversely Isotropic Granular Media Considering Microstructure Effect. Appl. Sci. 2022, 12, 6129. https://doi.org/10.3390/app12126129

Yu P, Liu Y, Shi M, Chen Z. Propagation Characteristics of Rotation Waves in Transversely Isotropic Granular Media Considering Microstructure Effect. Applied Sciences. 2022; 12(12):6129. https://doi.org/10.3390/app12126129

Chicago/Turabian StyleYu, Pengqiang, Yang Liu, Muke Shi, and Zixuan Chen. 2022. "Propagation Characteristics of Rotation Waves in Transversely Isotropic Granular Media Considering Microstructure Effect" Applied Sciences 12, no. 12: 6129. https://doi.org/10.3390/app12126129

APA StyleYu, P., Liu, Y., Shi, M., & Chen, Z. (2022). Propagation Characteristics of Rotation Waves in Transversely Isotropic Granular Media Considering Microstructure Effect. Applied Sciences, 12(12), 6129. https://doi.org/10.3390/app12126129