Study on the Bending Stiffness of Joints Connecting Porcelain Bushings and Flanges in Ultra-High Voltage Electrical Equipment

Abstract

:1. Introduction

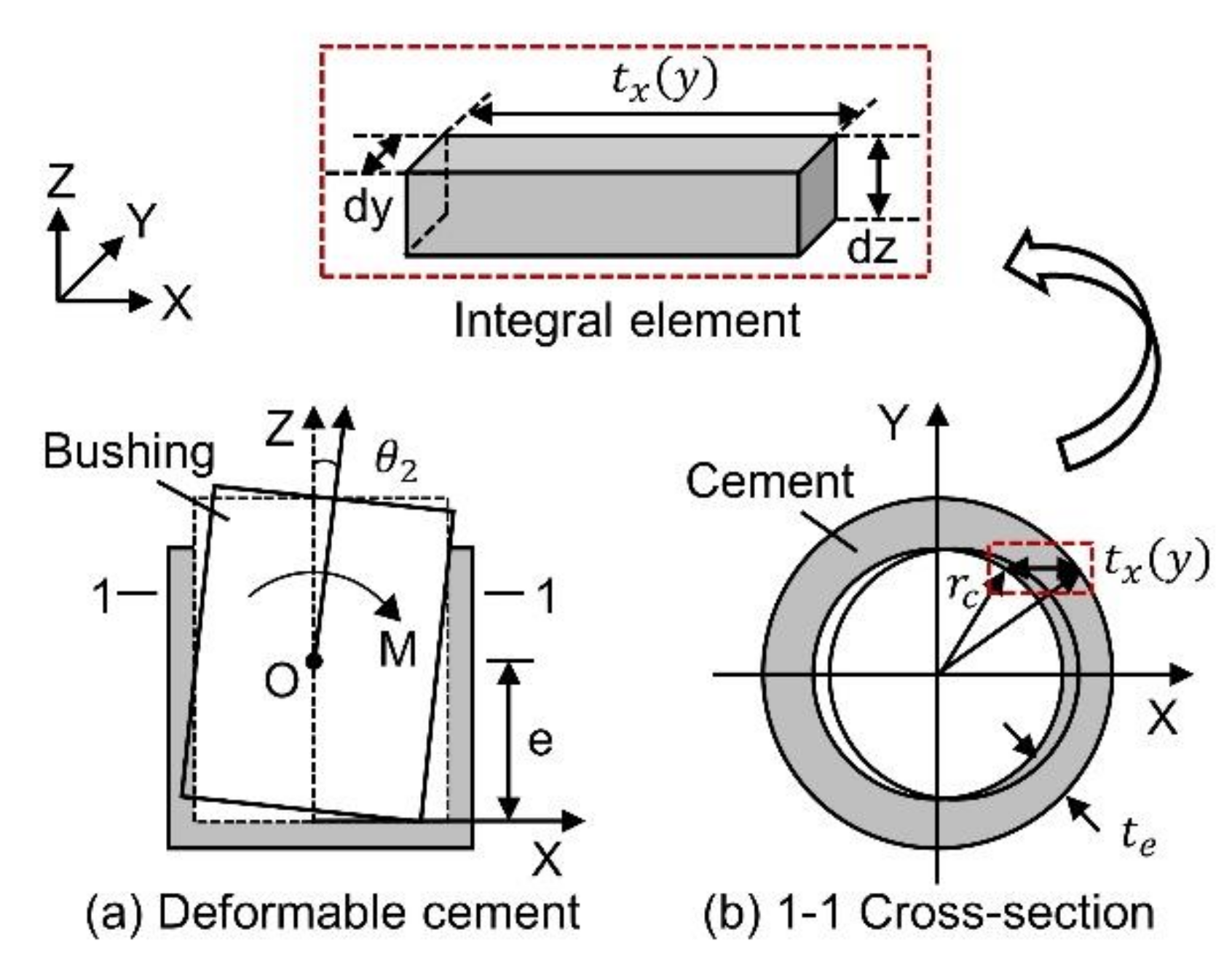

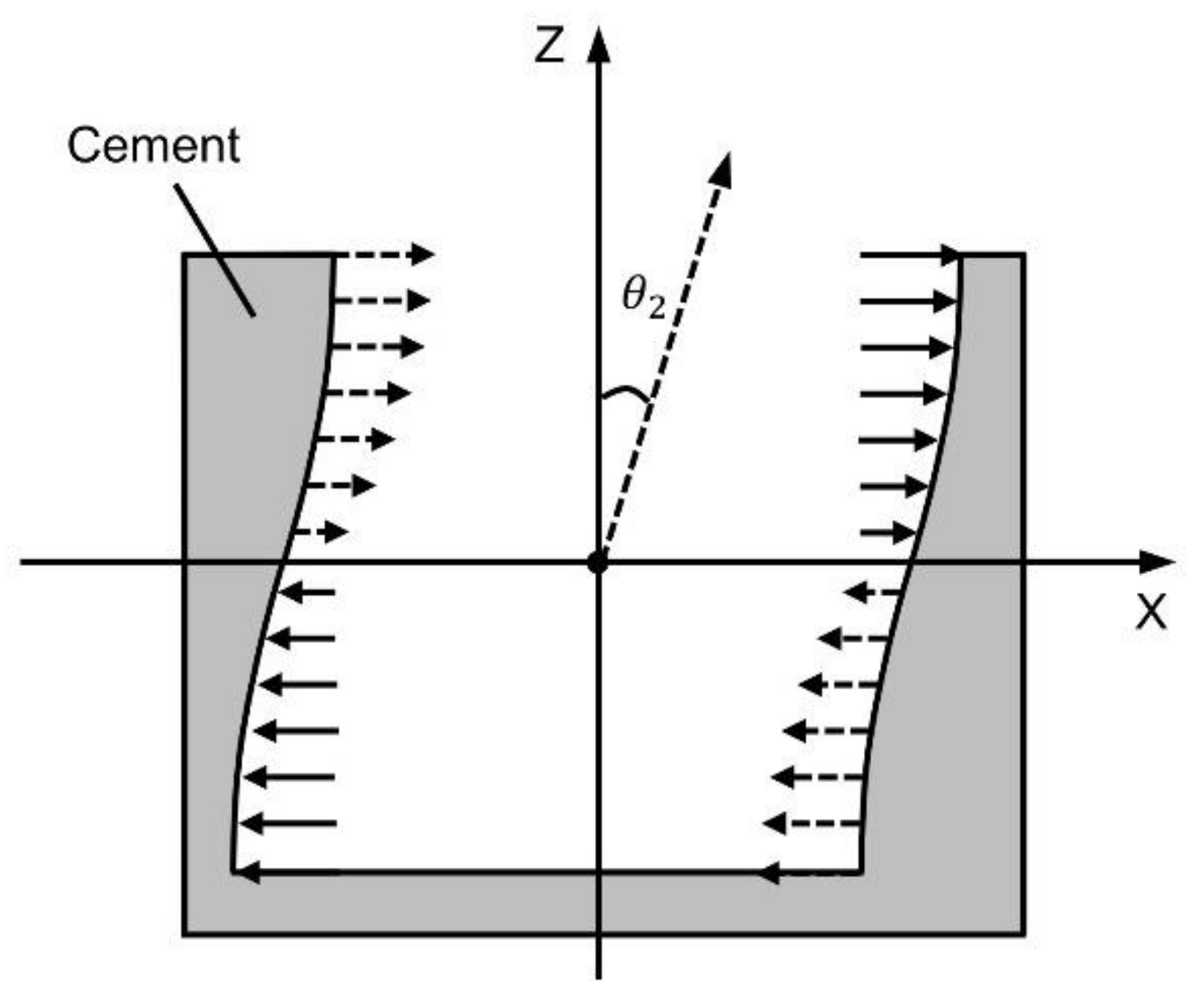

2. Bending Mechanism of the Connection between a Porcelain Bushing and Flange

3. Equivalent Bending Stiffness Model of the Joint Connecting the Porcelain Bushing and Flange

4. Analysis of Bending Stiffness Calculation Coefficients

5. Example Analysis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| a2 | customized parameter, see Equation (17) |

| db | inner diameter of porcelain bushing (m) |

| dc | outer diameter of the porcelain bushing (m) |

| df | inner diameter of a flange (m) |

| Df | ring wall outer diameter of a flange (m) |

| e | Height of the center of rotation (m), see Figure 3 |

| Ec | elastic modulus of porcelain bushing (N/m2) |

| Ef | elastic modulus of flange (N/m2) |

| Eg | elastic modulus of the cement bond (N/m2) |

| hc | height of the cement bond in the flange (m) |

| Ic | cross-sectional moment of inertia of the porcelain bushing (m4) |

| If | upper section moment of inertia of the flange (m4) |

| Kc | bending stiffness of the joint (N∙m/rad) |

| Kc1 | bending stiffness of the porcelain bushing (N∙m/rad) |

| Kc2 | bending stiffness of the cement bond (N∙m/rad) |

| Kc3 | bending stiffness of the flange member ring wall (N∙m/rad) |

| kz | total elastic stiffness coefficient |

| Lc | equivalent length of the porcelain bushing (m) |

| M | sum of the moments of the adhesive side wall compression force (N∙m) |

| rc | radius of the porcelain bushing (m) |

| te | thickness of the cement filling between the flange and the porcelain bushing (m) |

| U1 | bending deformation strain energy of the porcelain bushing (J) |

| U2 | elastic strain energy of the cement bond (J) |

| W | the work performed by the bending moment load (J) |

| W(e) | strain energy of the adhesive side wall compression force (J) |

| 𝛼 | customized parameter, see Equation (23) |

| β | an empirical parameter |

| 𝛾 | customized parameter, see Equation (11) |

| θ | deformation of the flange and porcelain bushing connecting joint (rad) |

| θ1 | porcelain bushing bending deformation (rad) |

| θ2 | cement mortar extrusion deformation (rad) |

| θ3 | flange member ring wall bending deformation (rad) |

| 𝜆 | customized parameter, see Equation (12) |

| μ | elasticity coefficient |

| Π | total potential energy of the porcelain bushing structure after deformation (J) |

References

- Liu, R.; Zhang, M.; Wu, Y. Vulnerability study of electric power grid in different intensity area in Wenchuan earthquake. In Proceedings of the 15th World Conference of Earthquake Engineering (WCEE), Lisboa, Portugal, 24–28 September 2012. [Google Scholar]

- Johnson, F.; Iliev, K. Earthquake effects on SDG&E’s 500/230 kV Imperial Valley Substation. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; pp. 1–2. [Google Scholar]

- Tang, A.K.; Eidinger, J.M. Chile Earthquake of 2010: Lifeline Performance; American Society of Civil Engineers: Reston, VA, USA, 2013. [Google Scholar]

- Liu, R.; Liu, J.; Yan, D.; Ye, F.; Lin, J.; Li, J. Seismic damage investigation and analysis of electric power system in Lushan Ms 7.0 earthquake. J. Nat. Disasters 2013, 22, 83–90. [Google Scholar]

- Liu, Z.; Dai, Z.; Lu, Z. Weibull distribution based seismic vulnerability analysis of porcelain equipment. Power Syst. Technol. 2014, 38, 1076–1081. [Google Scholar]

- Liu, C.; Wang, C.; Long, M.; Zha, C. Study of seismic response and vibration control of High voltage electrical equipment damper based on TMD. Sci. Technol. Eng. 2016, 157, 012027. [Google Scholar] [CrossRef]

- Zareei, S.A.; Hosseini, M.; Ghafory-Ashtiany, M. Evaluation of power substation equipment seismic vulnerability by multivariate fragility analysis: A case study on a 420 kV circuit breaker. Soil Dyn. Earthq. Eng. 2017, 92, 79–94. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, L.; Cheng, Y.; Guo, H.; Lu, Z. On the Nonlinear Seismic Responses of Shock Absorber-Equipped Porcelain Electrical Components. Math. Probl. Eng. 2020, 2020, 9026804. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Han, W. Review on seismic disaster analysis and aseismatic measures of transformer substation. Electr. Power Constr. 2011, 32, 44–50. [Google Scholar]

- Xie, Q.; He, C.; Yang, Z.; Wen, J. Tests and Analyses on Failure Mechanism of 1100 kV UHV Transformer Porcelain Bushing. High Volt. Eng. 2017, 43, 3154–3162. [Google Scholar]

- Zareei, S.A.; Hosseini, M.; Ghafory-Ashtiany, M. Seismic failure probability of a 400 kV power transformer using analytical fragility curves. Eng. Fail. Anal. 2016, 70, 273–289. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Ko, K.-H.; Lee, J.M. Analysis of dynamic characteristics of structural joints using stiffness influence coefficients. KSME Int. J. 2000, 14, 1319–1327. [Google Scholar] [CrossRef]

- Lavassas, I.; Nikolaidis, G.; Zervas, P.; Efthimiou, E.; Doudoumis, I.; Baniotopoulos, C. Analysis and design of the prototype of a steel 1-MW wind turbine tower. Eng. Struct. 2003, 25, 1097–1106. [Google Scholar] [CrossRef]

- Xie, Q.; Hao, J.; Zhang, W.; Ding, Y.-Y.; Li, M.; Lin, S.; Zhang, Y.-M. Comparative study on porcelain insulators design for high-voltage electric equipment at home and abroad. Insul. Surge Arresters 2010, 2, 15–20. [Google Scholar]

- GB 50260-2013; Code for Seismic Design of Electrical Installations. China Planning Press: Beijing, China, 2013.

- JEAG 5003-1980; Seismic Design Guidelines for Electrical Equipment. Standards Press of China: Beijing, China, 1984.

- Cao, M.; Cheng, Y.; Dai, Z.; Lu, Z.; Zhou, F.; Tan, P. Study of seismic performance and damping effects of porcelain column circuit breaker SF6. Eng. J. Wuhan Univ. 2009, 1, 267–272. [Google Scholar]

- Zhu, Z.; Dai, Z.; Lu, Z.; Zhang, X.; Gao, P. Experimental study of the bending rigidity at flange connection of UHV electrical equipment. Electr. Power 2014, 47, 6–11. [Google Scholar]

- Yuhan, S.; Zhicheng, L.; Zhenlin, L. Earthquake simulation shaking table test for 1100 kV UHV bushing. High Volt. Eng. 2017, 43, 4139–4144. [Google Scholar]

- He, C.; Xie, Q.; Zhou, Y. Influence of flange on seismic performance of 1100-kV ultra-high voltage transformer bushing. Earthq. Spectra 2019, 35, 447–469. [Google Scholar] [CrossRef]

- Xue, Y.; Cheng, Y.; Zhu, Z.; Li, S.; Liu, Z.; Guo, H.; Zhang, S. Study on seismic performance of porcelain pillar electrical equipment based on nonlinear dynamic theory. Adv. Civ. Eng. 2021, 2021, 8816322. [Google Scholar] [CrossRef]

- Zhang, X.; Dai, Z.; Zhicheng, L.U.; Cao, M. Coefficient of bending stiffness of interconnected parts between ultra-high voltage porcelain bushings and flanges. Eng. J. Wuhan Univ. 2014, 47, 794–799. [Google Scholar]

- Gao, Z.; Zhu, Q.; Yang, Q.; Cao, M. Study on Bending Stiffness of Interconnected Part Between High Voltage Porcelain Bushing and Flange. Insul. Surge Arresters 2018, 184–189. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, X.; Chen, S. Rayleigh-Ritz method in elastic dynamics. J. Hebei Inst. Technol. 1996, 62–66. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFD9697&filename=HBLG602.018&uniplatform=NZKPT&v=nRFEvR5lgf9x5s968OncmtSvruS1JJFee2xGtiymIbClVnp-stTT1udqFdUKqRFA (accessed on 10 April 2022).

- Zhang, P. Energy Theory in Structural Mechanics; Shanghai Scientific and Technical Publishers: Shanghai, China, 2010. [Google Scholar]

| Specimen | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Outside diameter, dc | 130 | 130 | 140 | 160 | 205 | 245 | 275 | 375 | 500 |

| Inside diameter, db | 80 | 80 | 80 | 105 | 125 | 145 | 175 | 275 | 420 |

| Bushing length | 1265 | 1275 | 1365 | 1385 | 1615 | 1615 | 1875 | 2500 | 2650 |

| Cement height, hc | 60 | 55 | 60 | 65 | 85 | 100 | 110 | 170 | 230 |

| Cement thickness, te | 10 | 9 | 10 | 10 | 10 | 7.5 | 7.5 | 9 | 10 |

| Outside diameter, Df | 192 | 190 | 202 | 224 | 252 | 304 | 348 | 456 | 580 |

| Inside diameter, df | 150 | 148 | 160 | 180 | 225 | 260 | 290 | 393 | 520 |

| Specimen | Experiment (×106 N∙m∙rad−1) | Equation (3) (×106 N∙m∙rad−1) | Elasticity Coefficient, μ |

|---|---|---|---|

| 1 | 2.97 | 3.61 | 0.77 |

| 2 | 2.84 | 3.20 | 0.86 |

| 3 | 3.36 | 4.03 | 0.79 |

| 4 | 4.61 | 5.80 | 0.74 |

| 5 | 9.16 | 14.19 | 0.55 |

| 6 | 20.95 | 31.51 | 0.54 |

| 7 | 27.7 | 50.16 | 0.44 |

| 8 | 57.6 | 146.64 | 0.22 |

| 9 | 133 | 317.03 | 0.19 |

| Specimen | Cement Height, hc (mm) | Elasticity Coefficient, μ |

|---|---|---|

| 1 | 60 | 0.77 |

| 2 | 55 | 0.86 |

| 3 | 60 | 0.79 |

| 4 | 65 | 0.74 |

| 5 | 85 | 0.55 |

| 6 | 100 | 0.54 |

| 7 | 110 | 0.44 |

| 8 | 170 | 0.22 |

| 9 | 230 | 0.19 |

| Specimen | Diameter, dc (mm) | Height, hc (mm) | Experimental Result | Equation (1) β = 6.54 × 107 | Equation (1) β = 5.00 × 107 | Equation (27) |

|---|---|---|---|---|---|---|

| 1 | 130 | 60 | 2.97 | 3.06 (+3.05%) | 2.34 (−21.21%) | 3.02 (+1.83%) |

| 2 | 130 | 55 | 2.84 | 2.86 (+0.62%) | 2.18 (−23.07%) | 2.76 (−2.69%) |

| 3 | 140 | 60 | 3.36 | 3.30 (−1.90%) | 2.52 (−25.0%) | 3.35 (−0.31%) |

| 4 | 160 | 65 | 4.61 | 4.42 (−4.10%) | 3.38 (−26.68%) | 4.61 (+0.03%) |

| 5 | 205 | 85 | 9.16 | 9.69 (+5.75%) | 7.41 (−19.15%) | 9.80 (+6.99%) |

| 6 | 245 | 100 | 20.95 | 21.36 (+1.98%) | 16.33(−22.04%) | 19.85 (−5.26%) |

| 7 | 275 | 110 | 27.70 | 29.02 (+4.75%) | 22.18 (−19.9%) | 27.97 (+0.99%) |

| 8 | 375 | 170 | 57.60 | 78.75(+36.72%) | 60.21 (4.53%) | 56.40 (−2.08%) |

| 9 | 500 | 230 | 133.0 | 172.98(+30.06%) | 132.25(−0.56%) | 134.59(+1.20%) |

| Parameter | Arrester 1 | Arrester 2 |

|---|---|---|

| Outside diameter, dc (mm) | 510 | 600 |

| Inside diameter, db (mm) | 400 | 500 |

| Bushing length (mm) | 2115 | 2350 |

| Cement height, hc (mm) | 200 | 200 |

| Cement clearance, te (mm) | 10 | 20 |

| Outside diameter, Df (mm) | 590 | 700 |

| Parameter | Arrester 1 | Arrester 2 |

|---|---|---|

| Equation (1), β = 6.54 × 107 | 1.33 × 108 | 7.85 × 107 |

| Equation (27) | 1.05 × 108 | 6.80 × 107 |

| Equation (1), β = 5.00 × 107 | 1.02 × 108 | 6.00 × 107 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Zhang, X.; Gao, Z. Study on the Bending Stiffness of Joints Connecting Porcelain Bushings and Flanges in Ultra-High Voltage Electrical Equipment. Appl. Sci. 2022, 12, 5899. https://doi.org/10.3390/app12125899

Zhu Q, Zhang X, Gao Z. Study on the Bending Stiffness of Joints Connecting Porcelain Bushings and Flanges in Ultra-High Voltage Electrical Equipment. Applied Sciences. 2022; 12(12):5899. https://doi.org/10.3390/app12125899

Chicago/Turabian StyleZhu, Quanjun, Xingui Zhang, and Zhengguo Gao. 2022. "Study on the Bending Stiffness of Joints Connecting Porcelain Bushings and Flanges in Ultra-High Voltage Electrical Equipment" Applied Sciences 12, no. 12: 5899. https://doi.org/10.3390/app12125899

APA StyleZhu, Q., Zhang, X., & Gao, Z. (2022). Study on the Bending Stiffness of Joints Connecting Porcelain Bushings and Flanges in Ultra-High Voltage Electrical Equipment. Applied Sciences, 12(12), 5899. https://doi.org/10.3390/app12125899