Effect of Optical–Electrical–Thermal Coupling on the Performance of High-Concentration Multijunction Solar Cells

Abstract

:1. Introduction

2. Theoretical Model

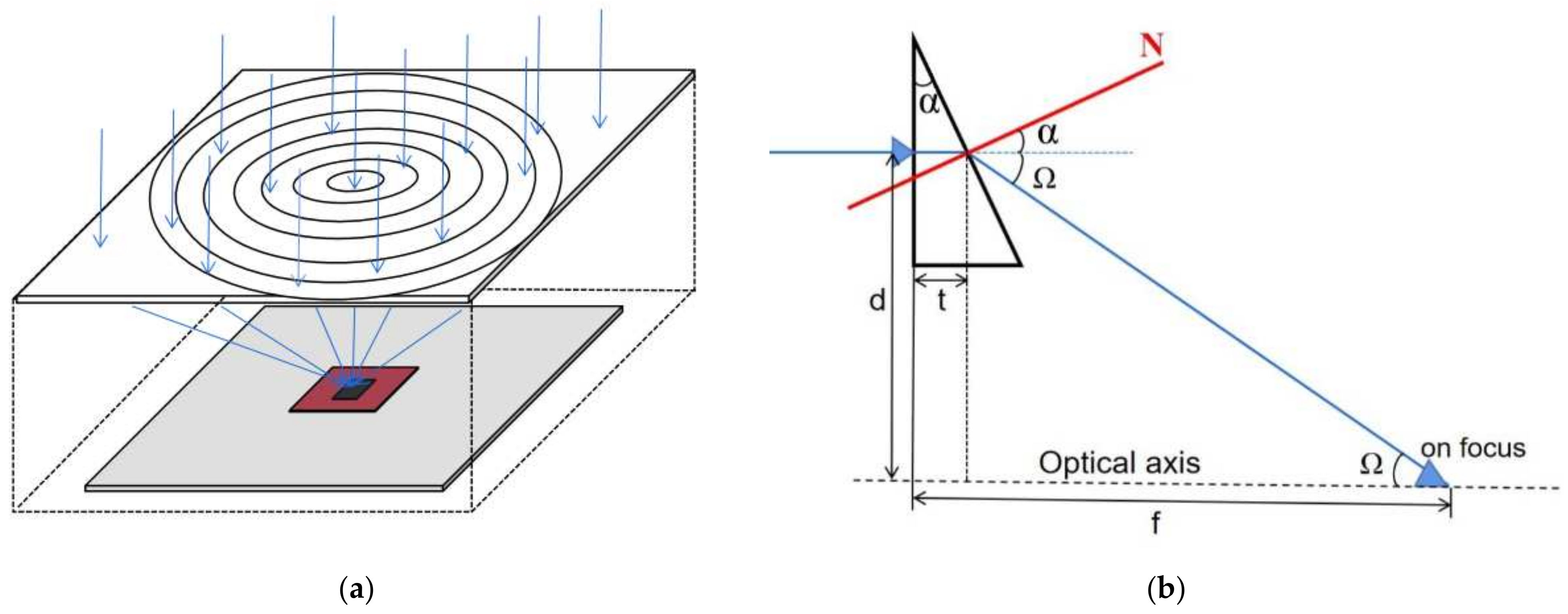

2.1. Optical Model

2.2. Optical–Electrical–Thermal Model of Non-Uniform Concentration

2.3. Heat Transfer Model

3. Calculation Results and Analysis

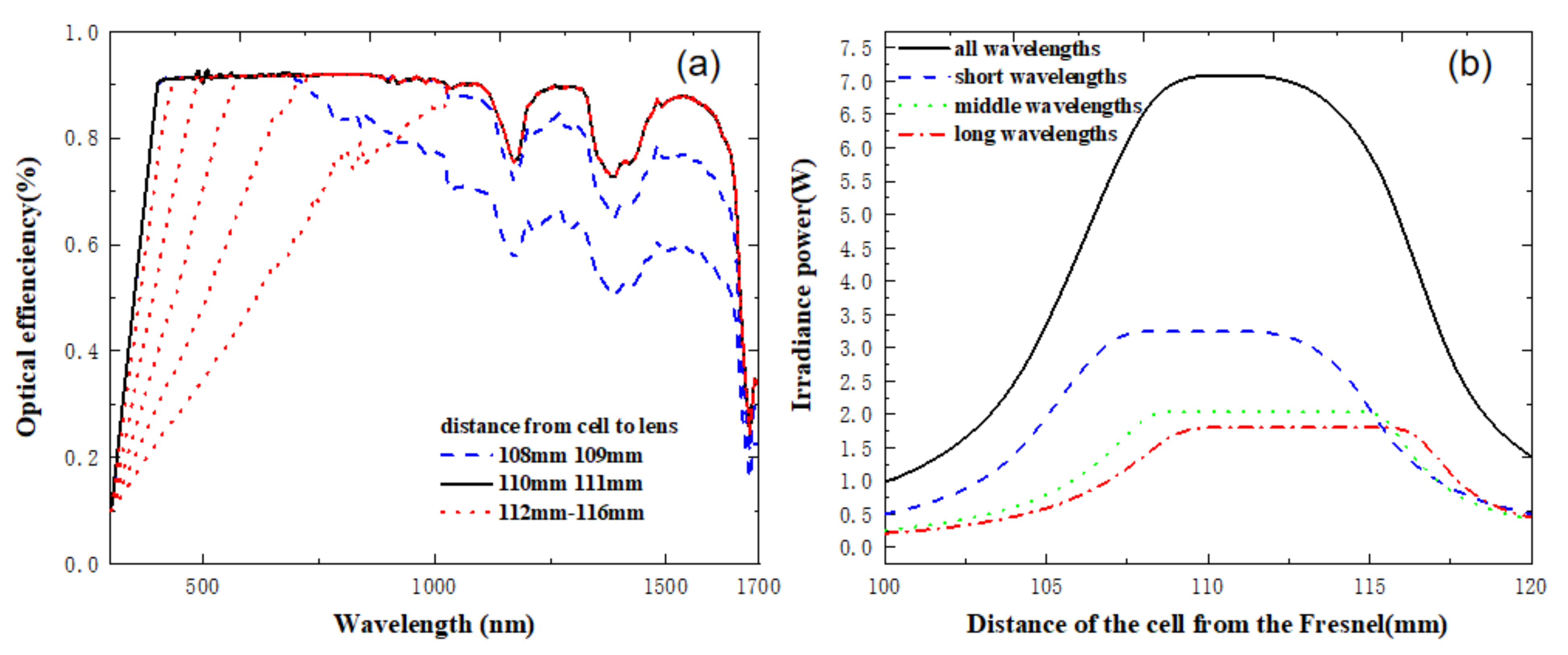

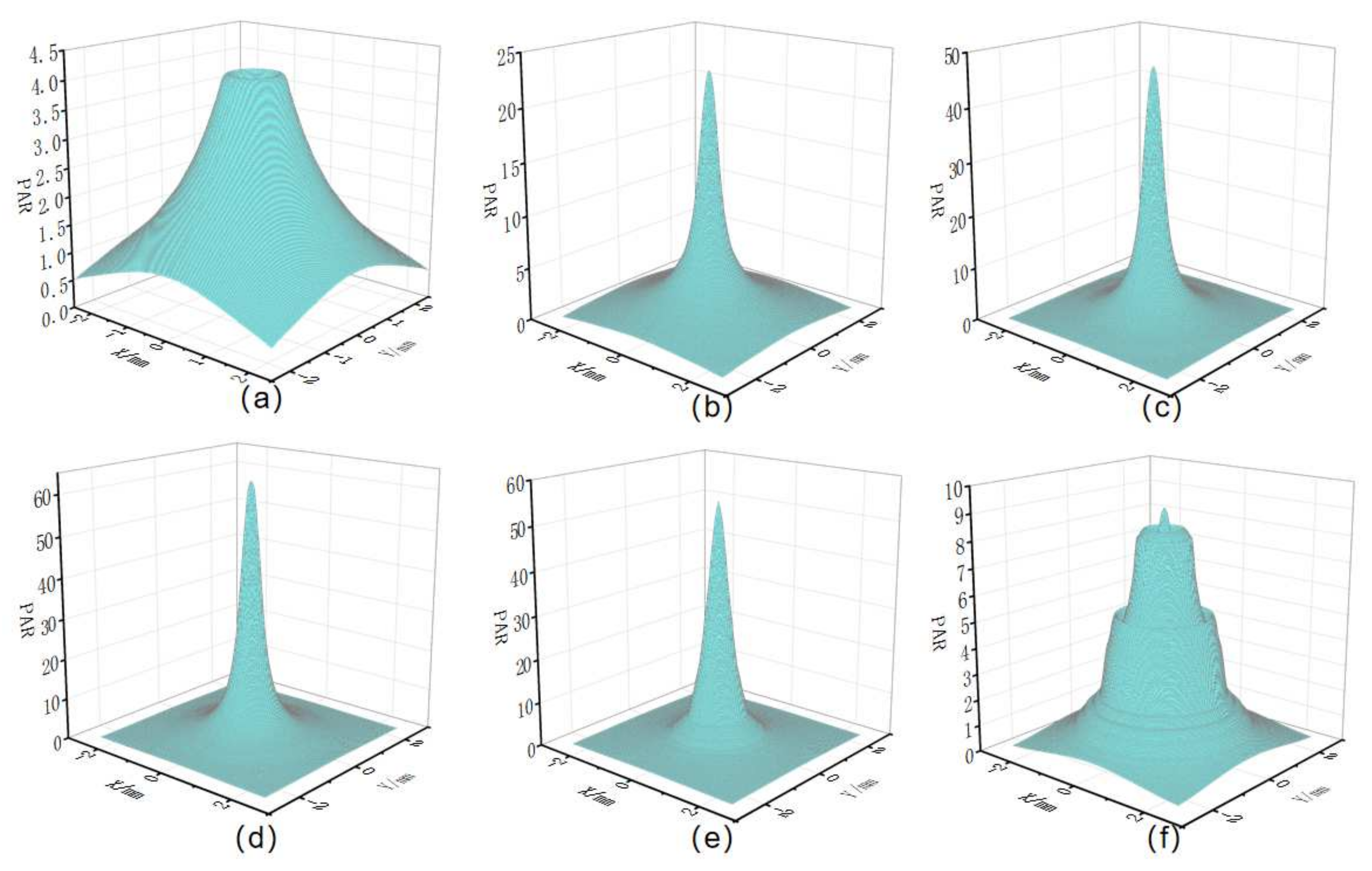

3.1. Concentrated Light Intensity and Spectral Analysis along the Optical Axis

3.2. Analysis of the Cell Temperature along the Optical Axis

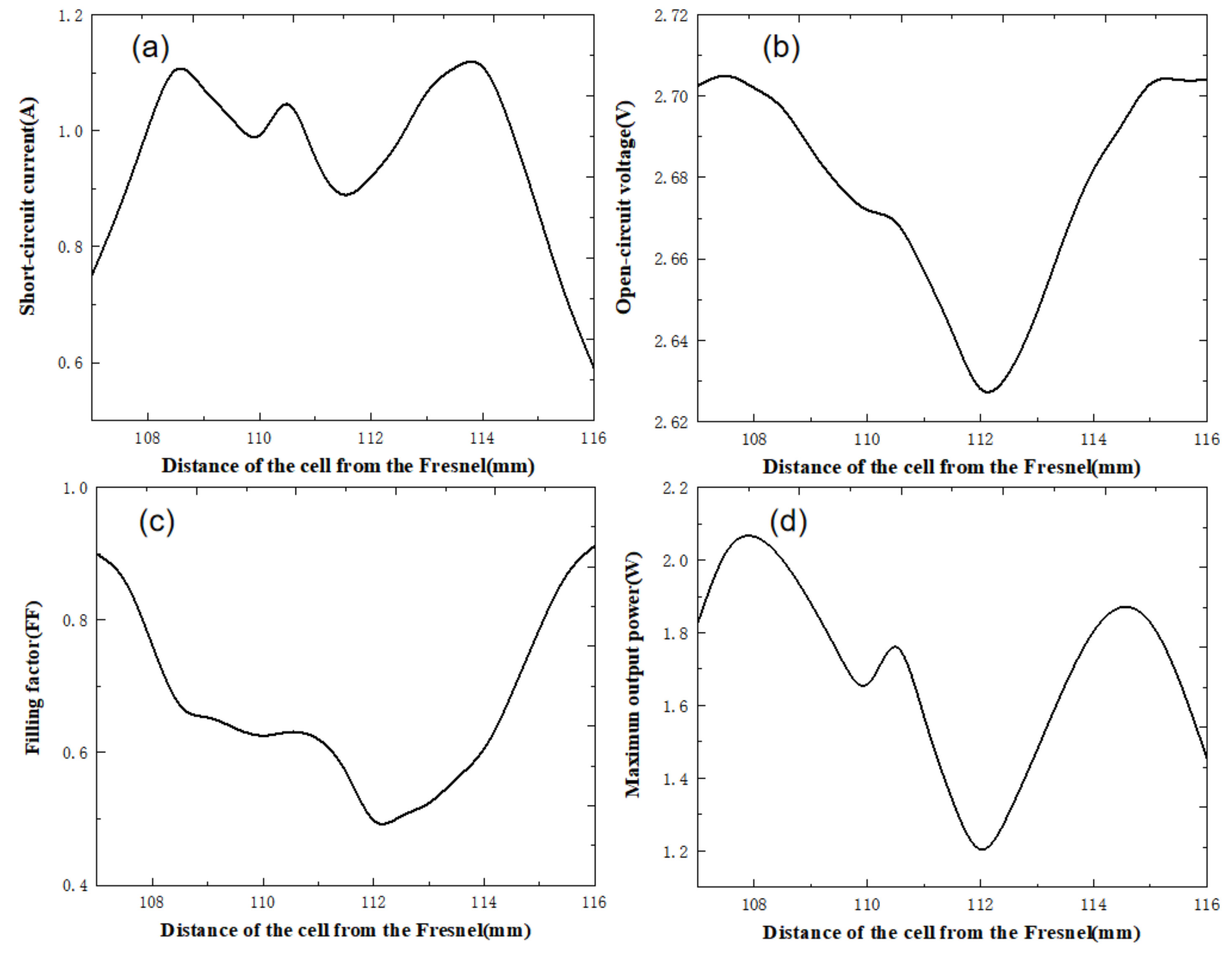

3.3. Analysis of the Optical–Electrical–Thermal Coupling Effect of Output Characteristics

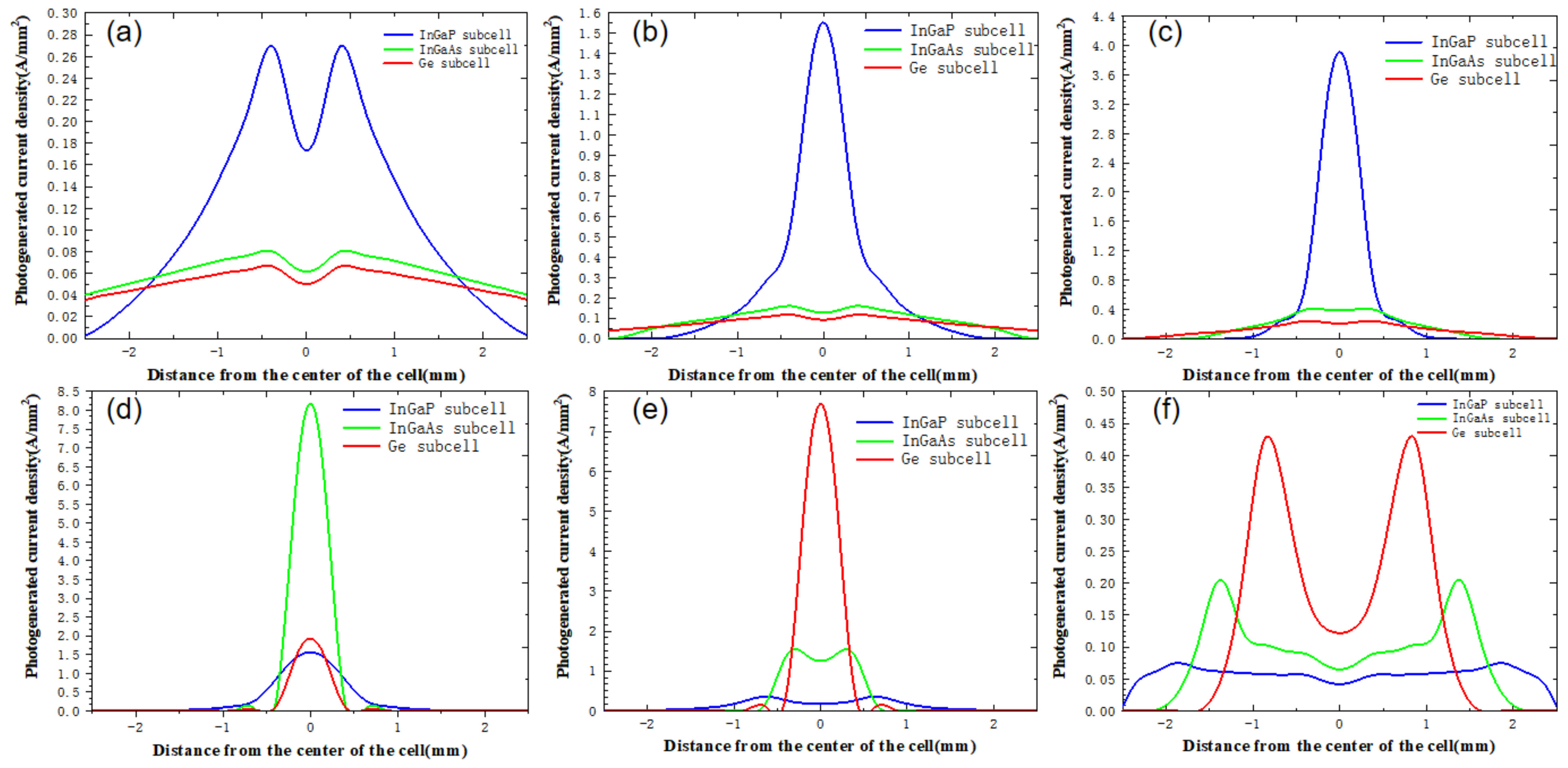

3.3.1. Short-Circuit Current

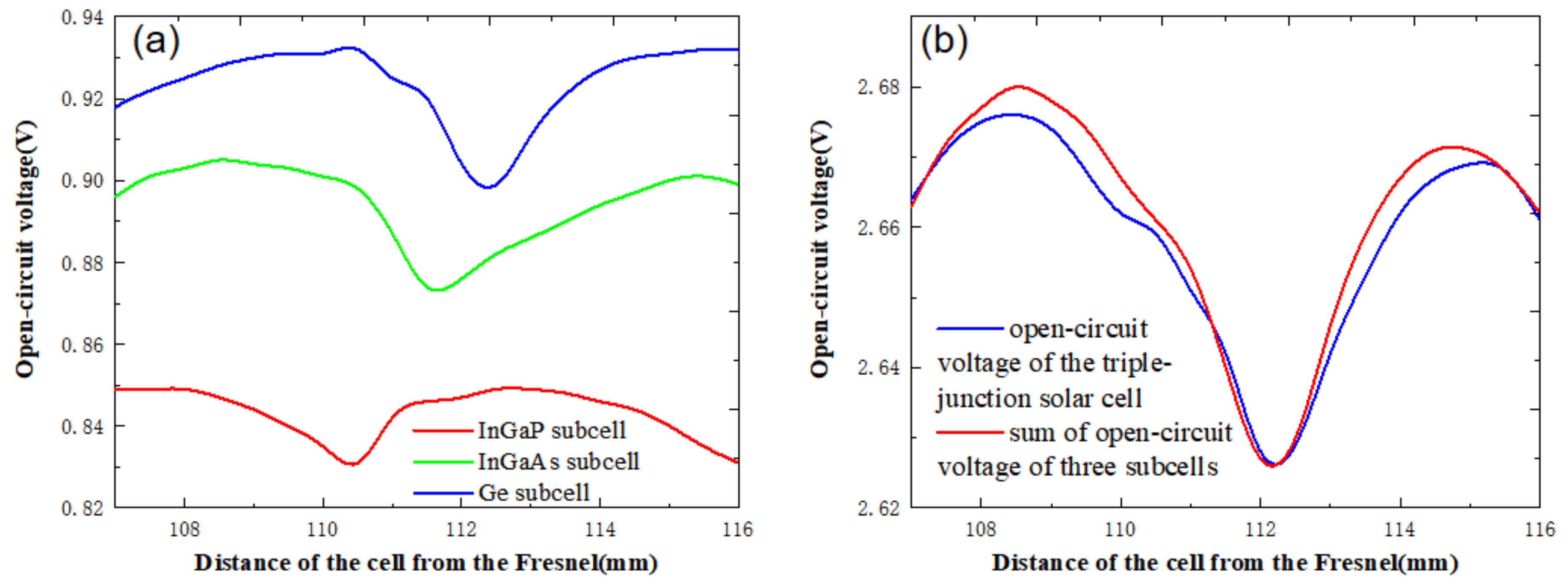

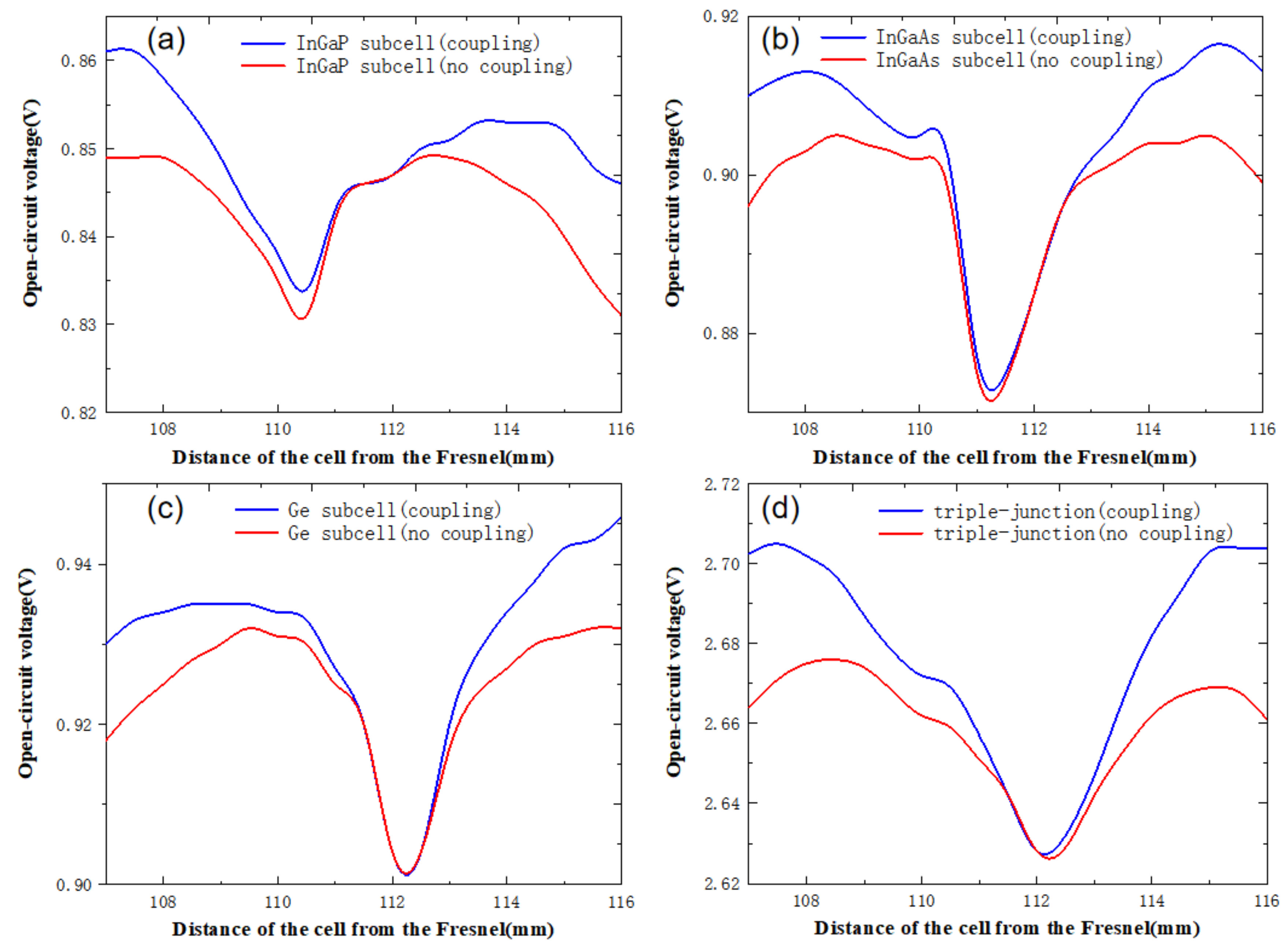

3.3.2. Open-Circuit Voltage

3.3.3. Output Power

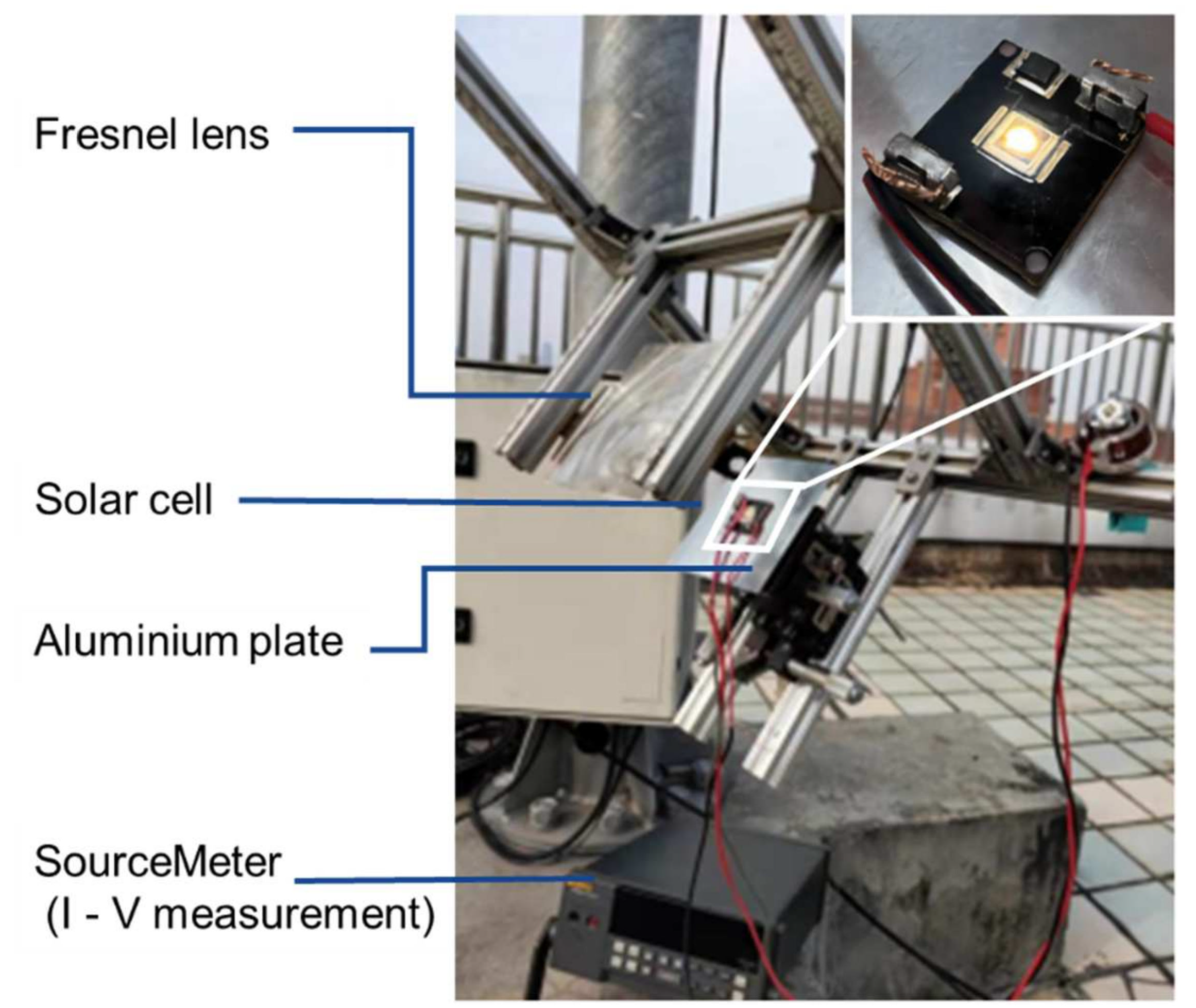

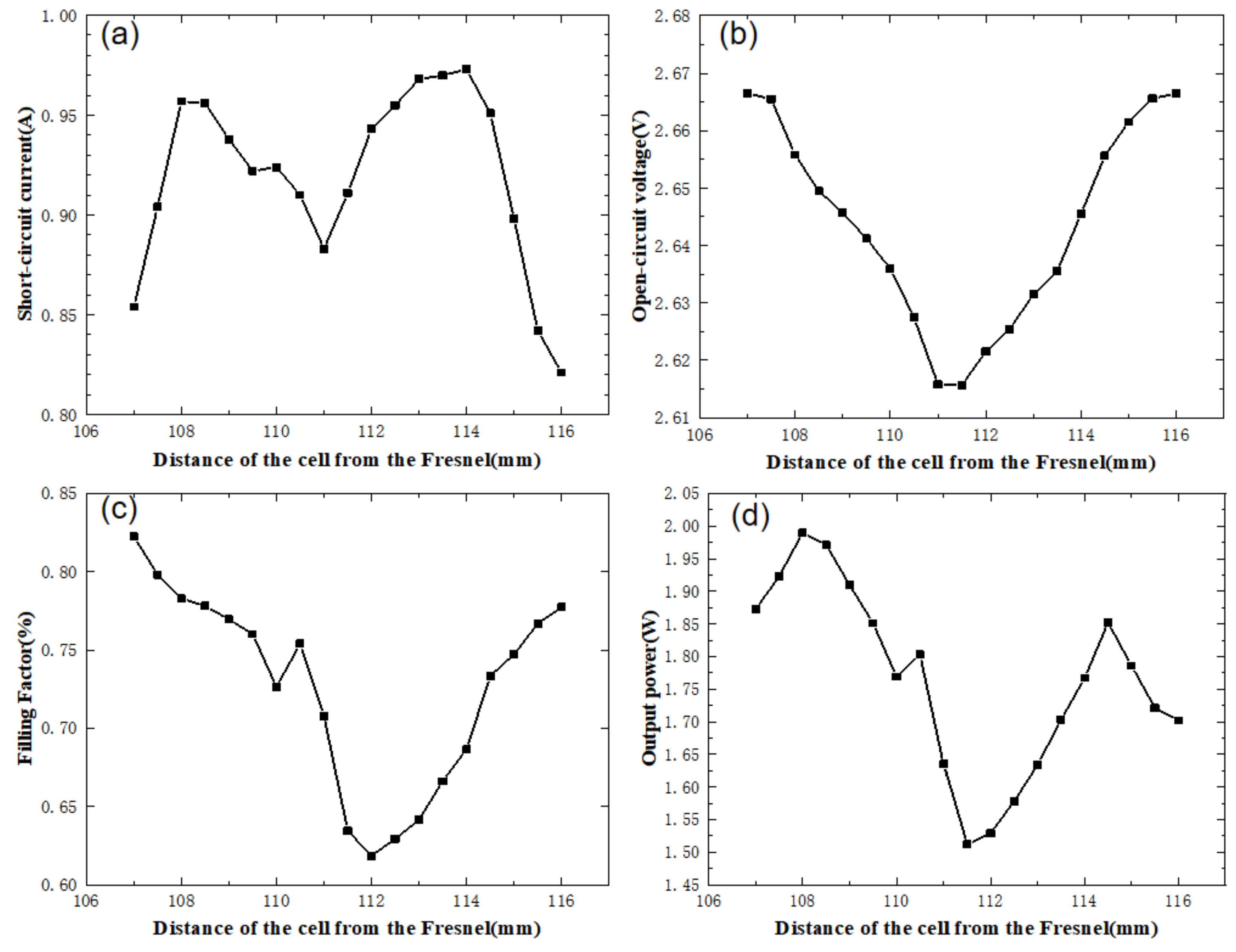

4. Experiment Results

5. Conclusions and Discussion

- Non-uniformity of concentration: The dispersion effect causes the irradiance concentrated, the spectrum distribution, energy and non-uniformity change significantly at different positions along the optical axis. Moreover, the energy proportion of short, medium and long wavelengths on the cell surface does not change synchronously thus causing the spectrum mismatch (including on the focal plane). For a Z value smaller than the focal distance, the loss of medium and long wavelengths mainly exists. For a Z value larger than the focal distance, the loss of short wavelengths mainly occurs. The non-uniformity of short, medium and long bands is the largest at 110.5 mm, 111.4 mm and 112.3 mm, respectively, and the non-uniformity of all wave bands is the largest at 111.8 mm, which is the result of the synthesis of the three bands.

- Output performance of multijunction cells: The non-uniformity of the focusing causes the photoelectric performance of the cell placed near the focal plane to decline the most. The optical–electrical–thermal coupling caused by the temperature rise aggravates the negative impact at the focal plane. Based on the numerical analysis of the coupling model and experiments, it was recommended that optimizing the placement position of the multijunction cell in the direction of the optical axis can effectively alleviate the negative effects of optical–electrical–thermal coupling caused by non-uniformity. In the passive heat dissipation condition of 500 times geometric concentration, compared with the cell placed on the on-focus position, the output power of the solar cell placed 2 mm in front of the focal plane increases by 35% and cell temperature decreases by 15%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shah, A.; Torres, P.; Tscharner, R. Photovoltaic Technology: The Case for Thin-Film Solar Cells. Science 1999, 285, 692–698. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferekides, C.S.; Balasubramanian, U.; Mamazza, R.; Viswanathan, V.; Zhao, H.; Morel, D.L. CdTe thin film solar cells: Device and technology issues. Sol. Energy 2004, 77, 823–830. [Google Scholar] [CrossRef]

- Ciminelli, C.; Dellrolio, F.; Brunetti, G.; Conteduca, D.; Armenise, M.N. Graphene/Silicon Schottky Junction Solar Cells. In Proceedings of the 2018 20th International Conference on Transparent Optical Networks (ICTON), Bucharest, Romania, 1–5 July 2018. [Google Scholar]

- Jin, Y.K.; Lee, J.W.; Jung, H.S.; Shin, H.; Park, N.G. High-Efficiency Perovskite Solar Cells. Chem. Rev. 2020, 120, 7867–7918. [Google Scholar]

- Wang, Z.; Song, Z.; Yan, Y.; Liu, S.; Yang, D. Perovskite—A Perfect Top Cell for Tandem Devices to Break the S–Q Limit. Adv. Sci. 2019, 6, 1801704. [Google Scholar] [CrossRef]

- Liu, M.; Endo, M.; Shimazaki, A.; Wakamiya, A.; Tachibana, Y. Light Intensity Dependence of Performance of Lead Halide Perovskite Solar Cells. J. Photopolym. Sci. Technol. 2017, 30, 577–582. [Google Scholar] [CrossRef] [Green Version]

- Hasan, A.; Sarwar, J.; Shah, A.H. Concentrated photovoltaic: A review of thermal aspects, challenges and opportunities. Renew. Sustain. Energy Rev. 2018, 94, 835–852. [Google Scholar] [CrossRef]

- Cotal, H.; Fetzer, C.; Boisvert, J.; Kinsey, G.; King, R.; Hebert, P.; Yoon, H.; Karam, N. III-V multijunction solar cells for concentrating photovoltaics. Energy Environ. Sci. 2009, 2, 174–192. [Google Scholar] [CrossRef]

- van Riesen, S.; Neubauer, M.; Boos, A.; Rico, M.M.; Gourdel, C.; Wanka, S.; Krause, R.; Guernard, P.; Gombert, A. New Module Design with 4-Junction Solar Cells for High Efficiencies. In Proceedings of the 11th International Conference on Concentrator Photovoltaic Systems (CPV), Aix les Bains, France, 13–15 April 2015. [Google Scholar]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Hao, X. Solar cell efficiency tables (version 59). Prog. Photovolt. 2022, 30, 3–12. [Google Scholar] [CrossRef]

- Geisz, J.F.; Steiner, M.A.; Jain, N.; Schulte, K.L.; France, R.M.; McMahon, W.E.; Perl, E.E.; Friedman, D.J. Building a Six-Junction Inverted Metamorphic Concentrator Solar Cell. IEEE J. Photovolt. 2018, 8, 626–632. [Google Scholar] [CrossRef]

- Baig, H.; Heasman, K.C.; Mallick, T.K. Non-uniform illumination in concentrating solar cells. Renew. Sustain. Energy Rev. 2012, 16, 5890–5909. [Google Scholar] [CrossRef]

- Saura, J.M.; Fernandez, E.F.; Almonacid, F.M.; Chemisana, D. Characterisation and impact of non-uniformity on multi-junction solar cells (MJSC) caused by concentrator optics. AIP Conf. Proc. 2019, 2149, 020004. [Google Scholar]

- Theristis, M.; O’Donovan, T.S. Electrical-thermal analysis of III-V triple-junction solar cells under variable spectra and ambient temperatures. Sol. Energy 2015, 118, 533–546. [Google Scholar] [CrossRef] [Green Version]

- Domenech-Garret, J.-L. Cell behaviour under different non-uniform temperature and radiation combined profiles using a two dimensional finite element model. Sol. Energy 2011, 85, 256–264. [Google Scholar] [CrossRef]

- Li, G.; Xuan, Q.; Pei, G.; Su, Y.; Ji, J. Effect of non-uniform illumination and temperature distribution on concentrating solar cell—A review. Energy 2018, 144, 1119–1136. [Google Scholar] [CrossRef]

- Baumgartner, H.; Oksanen, B.; Karha, P.; Ikonen, E. Optical Characterization of III-V Multijunction Solar Cells for Temperature-Independent Band Gap Features. IEEE J. Photovolt. 2019, 9, 1631–1636. [Google Scholar] [CrossRef]

- Indira, S.S.; Vaithilingam, C.A.; Chong, K.-K.; Saidur, R.; Faizal, M.; Abubakar, S.; Paiman, S. A review on various configurations of hybrid concentrator photovoltaic and thermoelectric generator system. Sol. Energy 2020, 201, 122–148. [Google Scholar] [CrossRef]

- Levina, S.A.; Mintairov, M.A.; Filimonov, E.D.; Shvarts, M.Z. Spectral dependencies of multijunction solar cells in a wide range of temperatures. In Proceedings of the International Conference on PhysicA.SPb, Saint Petersburg, Russia, 22–24 October 2019. [Google Scholar]

- Cuevas, A.; Lopez-Romero, S. The combined effect of non-uniform illumination and series resistance on the open-circuit voltage of solar cells. Sol. Cells 1984, 11, 163–173. [Google Scholar] [CrossRef]

- Mellor, A.; Domenech-Garret, J.L.; Chemisana, D.; Rosell, J.I. A two-dimensional finite element model of front surface current flow in cells under non-uniform, concentrated illumination. Sol. Energy 2009, 83, 1459–1465. [Google Scholar] [CrossRef] [Green Version]

- Bunthof, L.A.A.; Haverkamp, E.J.; van der Woude, D.; Bauhuis, G.J.; Corbeek, W.H.M.; Veelenturf, S.; Vlieg, E.; Schermer, J.J. Influence of laterally split spectral illumination on multi junction CPV solar cell performance. Solar Energy 2018, 170, 86–94. [Google Scholar] [CrossRef]

- Kumar, N.S.; Matty, K.; Rita, E.; Simon, W.; Ortrun, A.; Alex, C.; Roland, W.; Tim, G.; Kumar, M.T. Experimental validation of a heat transfer model for concentrating photovoltaic system. Appl. Therm. Eng. 2012, 33–34, 175–182. [Google Scholar] [CrossRef]

- Lian, R.-H.; Liang, Q.-B.; Shu, B.-F.; Fan, C.; Wu, X.-L.; Guo, Y.; Wang, J.; Yang, Q.-C. Performance and optimization research of triple-junction solar cell along the optical axis direction on the HCPV module. Acta Phys. Sin. 2016, 65. [Google Scholar] [CrossRef]

- Steiner, M.; Boesch, A.; Dilger, A.; Dimroth, F.; Doersam, T.; Muller, M.; Hornung, T.; Siefer, G.; Wiesenfarth, M.; Bett, A.W. FLATCON (R) CPV module with 36.7% efficiency equipped with four-junction solar cells. Prog. Photovolt. 2015, 23, 1323–1329. [Google Scholar] [CrossRef]

- Li, X.; Lin, G.-J.; Liu, H.-H.; Chen, S.-Y.; Liu, G.-Z. Effect of chromatic aberration on performance of concentrated multi-junction solar cells and their optimization. Acta Phys. Sin. 2017, 66. [Google Scholar] [CrossRef]

- Ustun, T.S.; Nakamura, Y.; Hashimoto, J.; Otani, K. Performance analysis of PV panels based on different technologies after two years of outdoor exposure in Fukushima, Japan. Renew. Energy 2019, 136, 159–178. [Google Scholar] [CrossRef]

- Zhang, X.-N. Refractive Index Database, Refractive.INFO. Refractive index of (C5H8O2)n (Poly(methyl methacrylate), PMMA)-Zhang-Tomson. 2020. Available online: https://refractiveindex.info/?shelf=organic&book=poly%28methyl_methacrylate%29&page=Zhang-Tomson (accessed on 10 April 2022).

- Steiner, M.; Siefer, G.; Hornung, T.; Peharz, G.; Bett, A.W. YieldOpt, a model to predict the power output and energy yield for concentrating photovoltaic modules. Prog. Photovolt. 2015, 23, 385–397. [Google Scholar] [CrossRef]

- 3C44A-with 5,5 × 5,55 mm2 Concentrator Triple Junction Solar Cell. 2016. Available online: http://www.azurspace.com/images/products/0004356-00-01_3C44_AzurDesign_5.pdf (accessed on 10 April 2022).

- Lv, H.; Sheng, F.; Dai, J.; Liu, W.; Cheng, C.; Zhang, J. Temperature-dependent model of concentrator photovoltaic modules combining optical elements and III-V multi-junction solar cells. Sol. Energy 2015, 112, 351–360. [Google Scholar] [CrossRef]

- Steiner, M.; Guter, W.; Peharz, G.; Philipps, S.P.; Dimroth, F.; Bett, A.W. A validated SPICE network simulation study on improving tunnel diodes by introducing lateral conduction layers. Prog. Photovolt. 2012, 20, 274–283. [Google Scholar] [CrossRef]

- Lv, H.; Huang, W.; Cheng, C.; Ou, Y.; Liao, J.; Su, Y.; Riffat, S. An improved model to predict thermal runaway in concentrator III-V multi-junction solar cells. Int. J. Low-Carbon Technol. 2018, 13, 432–437. [Google Scholar] [CrossRef]

- Maka, A.O.M.; O’Donovan, T.S. Transient thermal-electrical performance modelling of solar concentrating photovoltaic (CPV) receiver. Sol. Energy 2020, 211, 897–907. [Google Scholar] [CrossRef]

- Espinet, P.; Garcia, I.; Rey-Stolle, I.; Algora, C.; Baudrit, M. Extended description of tunnel junctions for distributed modeling of concentrator multi-junction solar cells. Sol. Energy Mater. Sol. Cells 2011, 95, 2693–2697. [Google Scholar] [CrossRef] [Green Version]

- Araki, K.; Uozumi, H.; Yamaguchi, M.; Ieee, I. A simple-passive cooling structure and its heat analysis for 500 X concentrator PV module. In Proceedings of the Conference Record of the Twenty-Ninth Ieee Photovoltaic Specialists Conference 2002, New Orleans, LA, USA, 19–24 May 2002; pp. 1568–1571. [Google Scholar]

- Maka, A.O.M.; O’Donovan, T.S. A review of thermal load and performance characterisation of a high concentrating photovoltaic (HCPV) solar receiver assembly. Sol. Energy 2020, 206, 35–51. [Google Scholar] [CrossRef]

- Abo-Zahhad, E.M.; Ookawara, S.; Radwan, A.; El-Shazly, A.H.; El-Kady, M.F.; Esmail, M.F.C. Performance, limits, and thermal stress analysis of high concentrator multijunction solar cell under passive cooling conditions. Appl. Therm. Eng. 2020, 164, 114497. [Google Scholar] [CrossRef]

- An, Y.; Sheng, C.; Li, X. Radiative cooling of solar cells: Opto-electro-thermal physics and modeling. Nanoscale 2019, 11, 17073–17083. [Google Scholar] [CrossRef] [PubMed]

- Araki, K.; Yamaguchi, M. Extended distributed model for analysis of non-ideal concentration operation. Sol. Energy Mater. Sol. Cells 2003, 75, 467–473. [Google Scholar] [CrossRef]

- Zhu, L.; Kim, C.; Yoshita, M.; Chen, S.Q.; Sato, S.; Mochizuki, T.; Akiyama, H.; Kanemitsu, Y. Impact of sub-cell internal luminescence yields on energy conversion efficiencies of tandem solar cells: A design principle. Appl. Phys. Lett. 2014, 104, 031118. [Google Scholar] [CrossRef]

- Helmers, H.; Schachtner, M.; Belt, A.W. Influence of temperature and irradiance on triple-junction solar subcells. Sol. Energy Mater. Sol. Cells 2013, 116, 144–152. [Google Scholar] [CrossRef]

- Gopal, R.; Dwivedi, R.; Srivastava, S.K. Effect of nonuniform illumination on the photovoltaic decay characteristic of solar cells. IEEE Trans. Electron Devices 1986, ED-33, 802–809. [Google Scholar] [CrossRef]

- Garcia, I.; Rey-Stolle, I.; Galiana, B.; Algora, C. A 32.6% efficient lattice-matched dual-junction solar cell working at 1000 suns. Appl. Phys. Lett. 2009, 94, 053509. [Google Scholar] [CrossRef]

| Category | Thickness (mm) | Length (mm) | Width (mm) |

|---|---|---|---|

| Cell | 0.19 | 5.5 | 5.5 |

| DBC upper layer | 0.25 | 23 | 25 |

| DBC ceramic layer | 0.32 | 24.5 | 26.5 |

| DBC lower layer | 0.25 | 24 | 26 |

| Aluminum heat spreader | 0.6 | 90 | 90 |

| Maximum PAR | Optical Axis Position of Maximum Par (Z) | |

|---|---|---|

| short wavelengths (300–700 nm) | 55.5 | 110.5 mm |

| middle wavelengths (700–900 nm) | 67.4 | 111.4 mm |

| long wavelengths (900–1700 nm) | 74.8 | 112.3 mm |

| all wavelengths (300–1700 nm) | 64.1 | 111.8 mm |

| Distance of the Cell from the Fresnel (mm) | 108 | 110 | 112 | 114 | 116 |

|---|---|---|---|---|---|

| ) | 56.8 | 62.2 | 63.2 | 58.2 | 51.9 |

| (A) | 0.957 | 0.924 | 0.943 | 0.973 | 0.821 |

| (V) | 2.656 | 2.636 | 2.621 | 2.645 | 2.667 |

| 0.783 | 0.726 | 0.617 | 0.687 | 0.777 | |

| (W) | 1.990 | 1.769 | 1.529 | 1.767 | 1.702 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Q.; Shu, B.; Jiang, J.; Zhang, Y. Effect of Optical–Electrical–Thermal Coupling on the Performance of High-Concentration Multijunction Solar Cells. Appl. Sci. 2022, 12, 5888. https://doi.org/10.3390/app12125888

Shi Q, Shu B, Jiang J, Zhang Y. Effect of Optical–Electrical–Thermal Coupling on the Performance of High-Concentration Multijunction Solar Cells. Applied Sciences. 2022; 12(12):5888. https://doi.org/10.3390/app12125888

Chicago/Turabian StyleShi, Qi, Bifen Shu, Jingxiang Jiang, and Yuqi Zhang. 2022. "Effect of Optical–Electrical–Thermal Coupling on the Performance of High-Concentration Multijunction Solar Cells" Applied Sciences 12, no. 12: 5888. https://doi.org/10.3390/app12125888

APA StyleShi, Q., Shu, B., Jiang, J., & Zhang, Y. (2022). Effect of Optical–Electrical–Thermal Coupling on the Performance of High-Concentration Multijunction Solar Cells. Applied Sciences, 12(12), 5888. https://doi.org/10.3390/app12125888