Analysis of Contact Stress Distribution between Rolling Element and Variable Diameter Raceway of Cageless Bearing

Abstract

1. Introduction

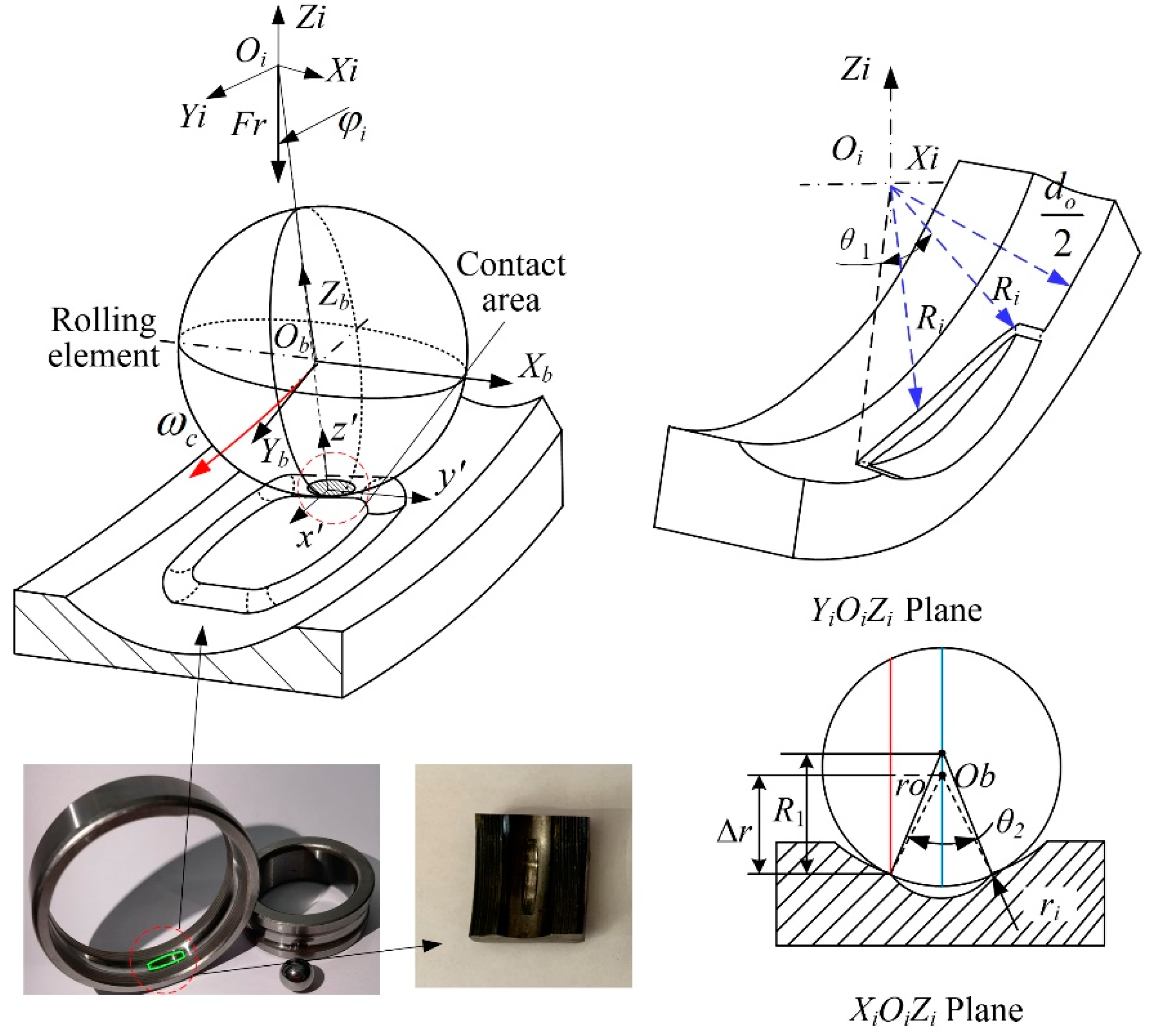

2. Motion and Contact State of the Rolling Element

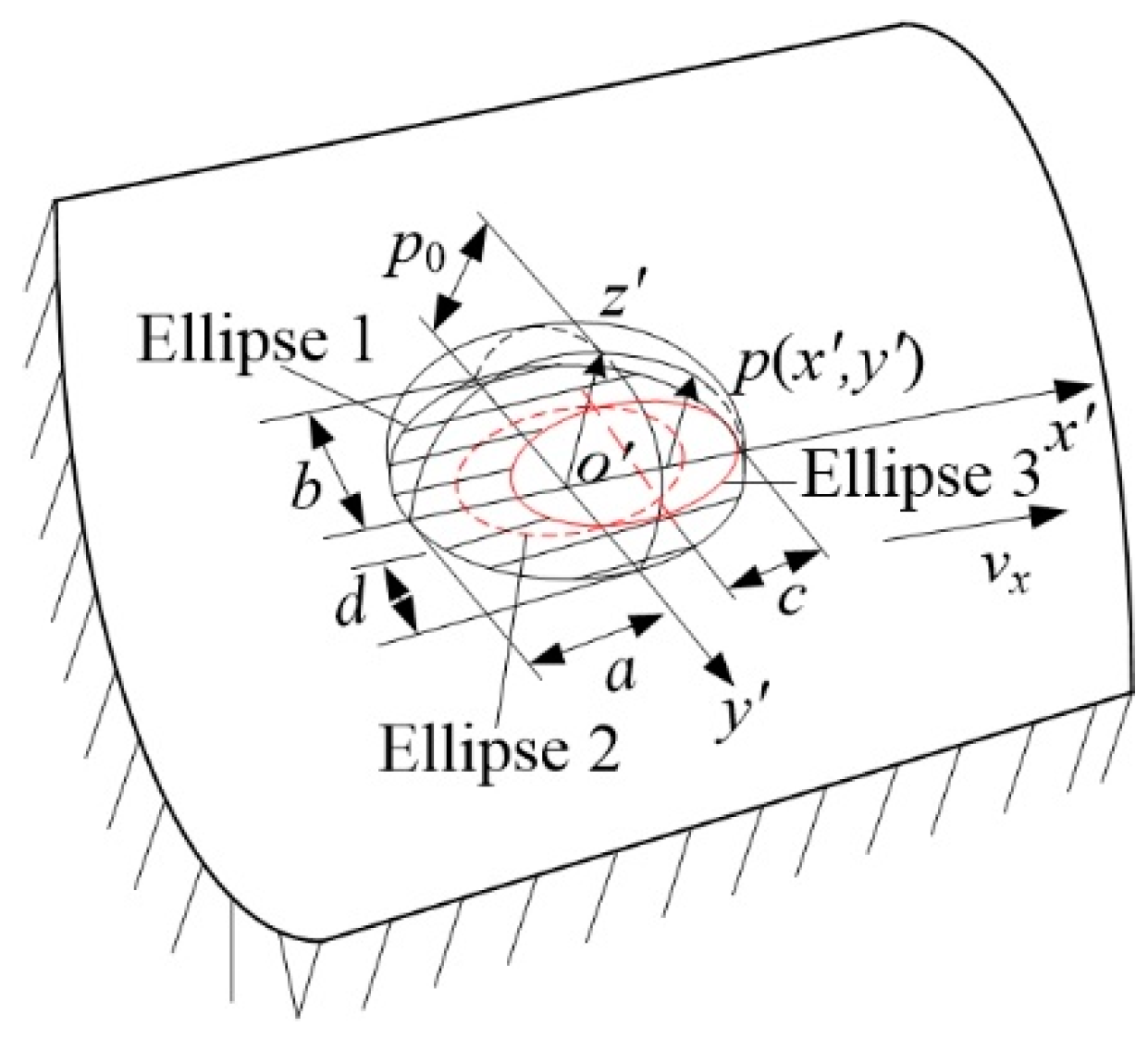

3. Analysis of Contact Stress Distribution between Rolling Element and Variable Diameter Raceway

4. Numerical Analysis of the Contact Characteristics

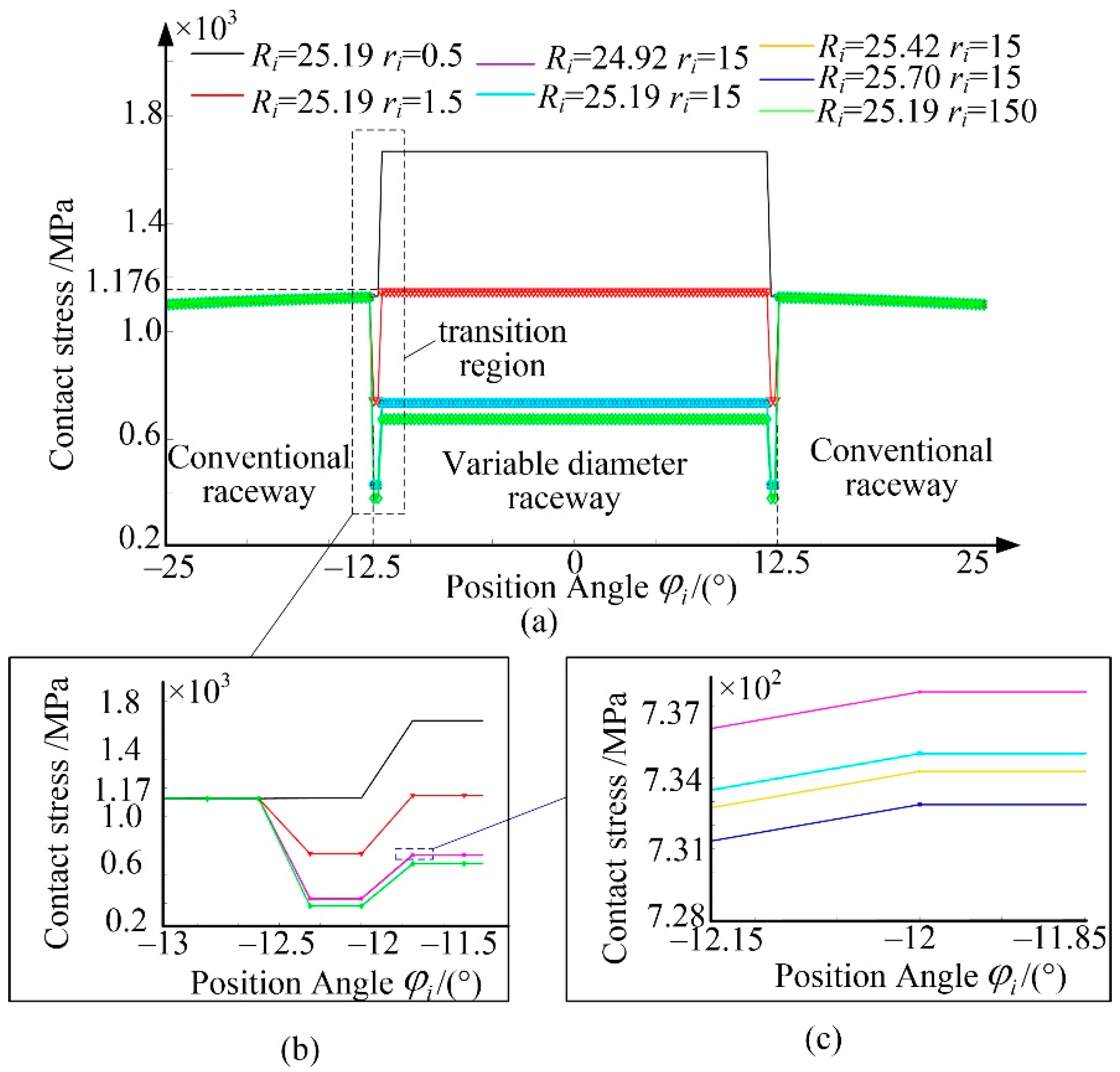

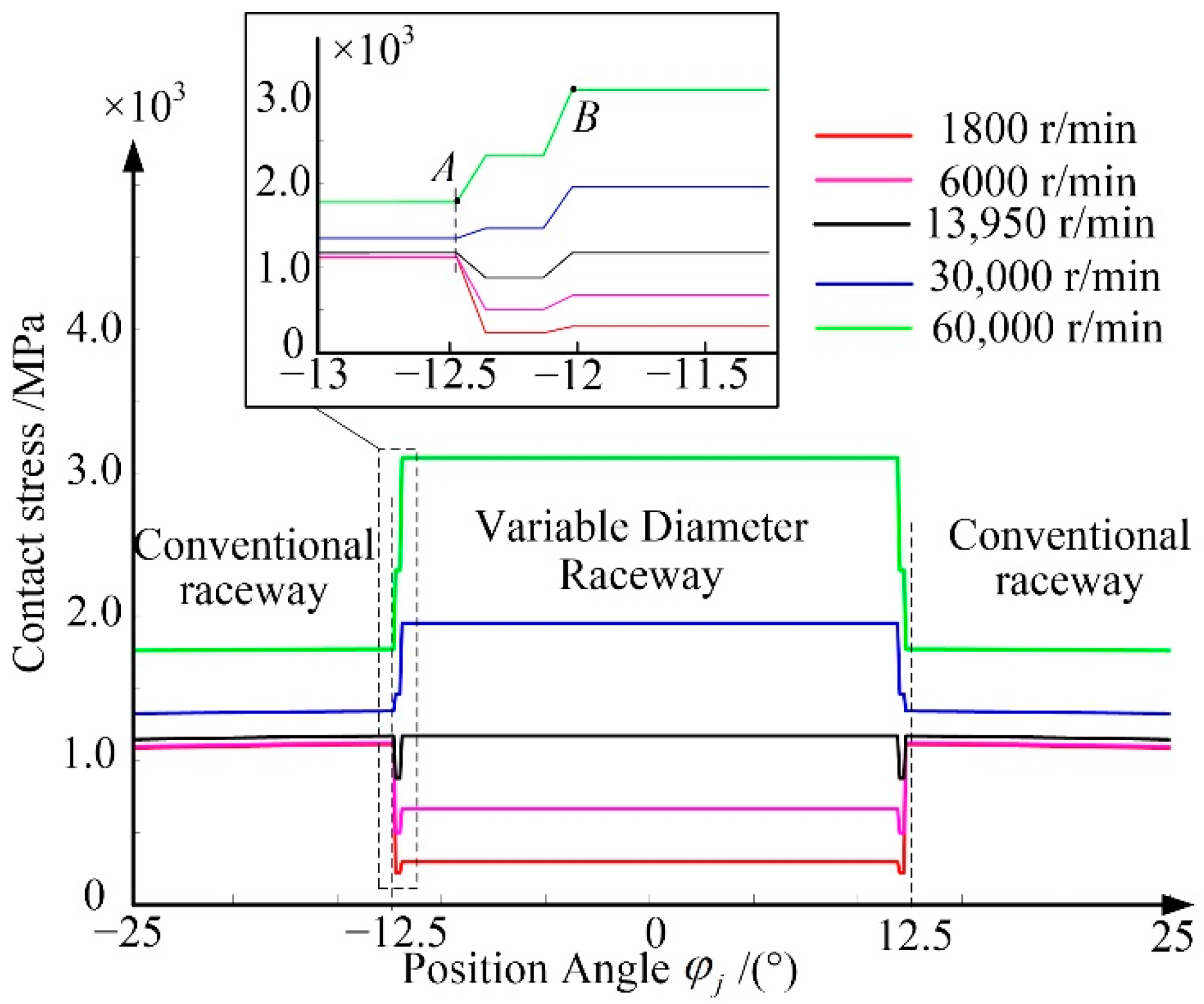

4.1. Numerical Analysis of Contact Stress

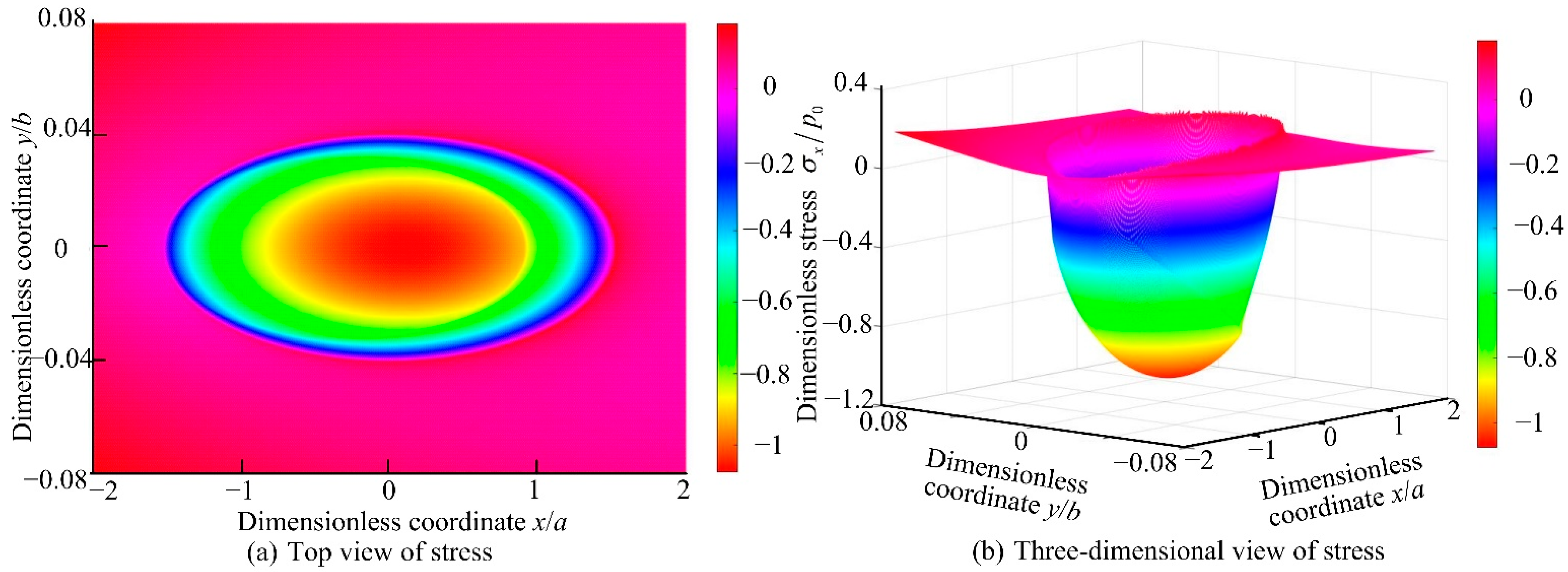

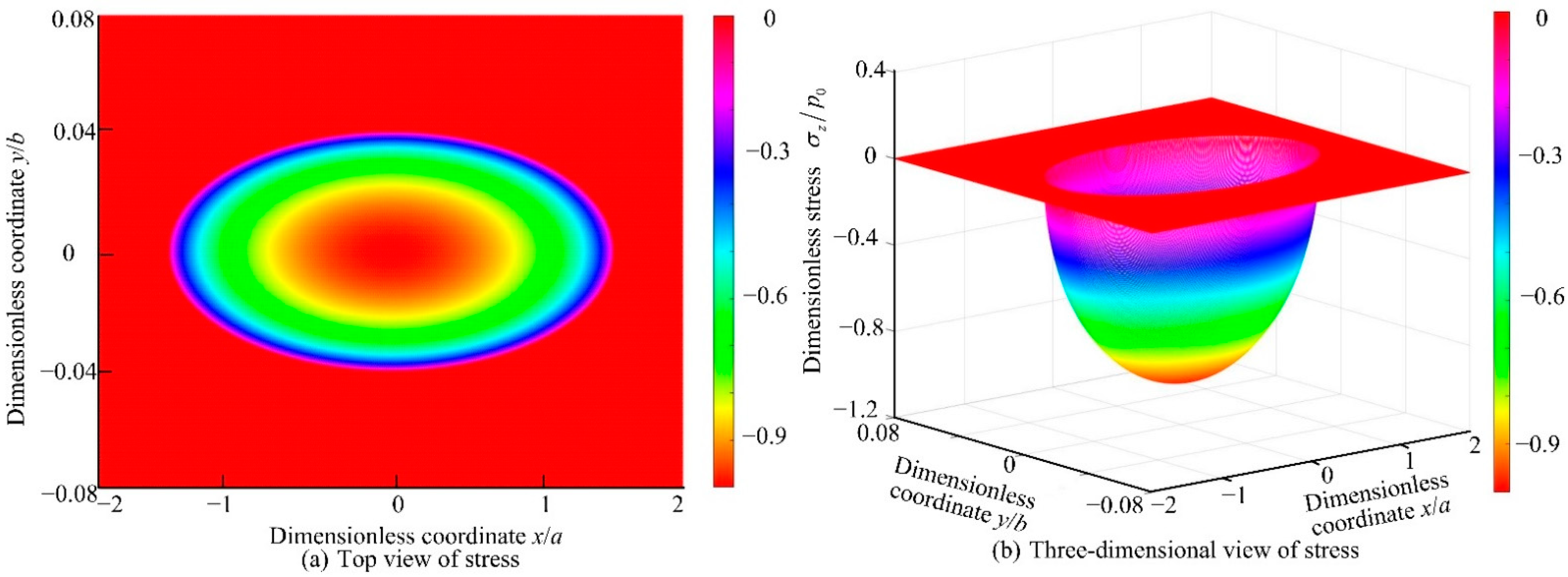

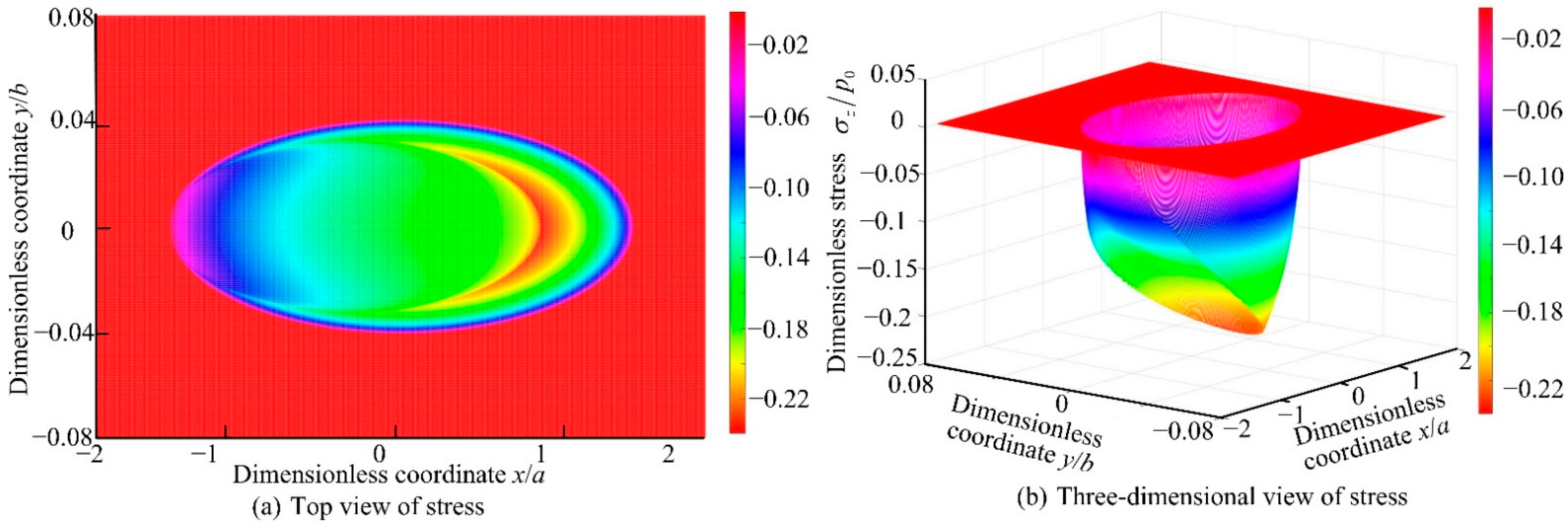

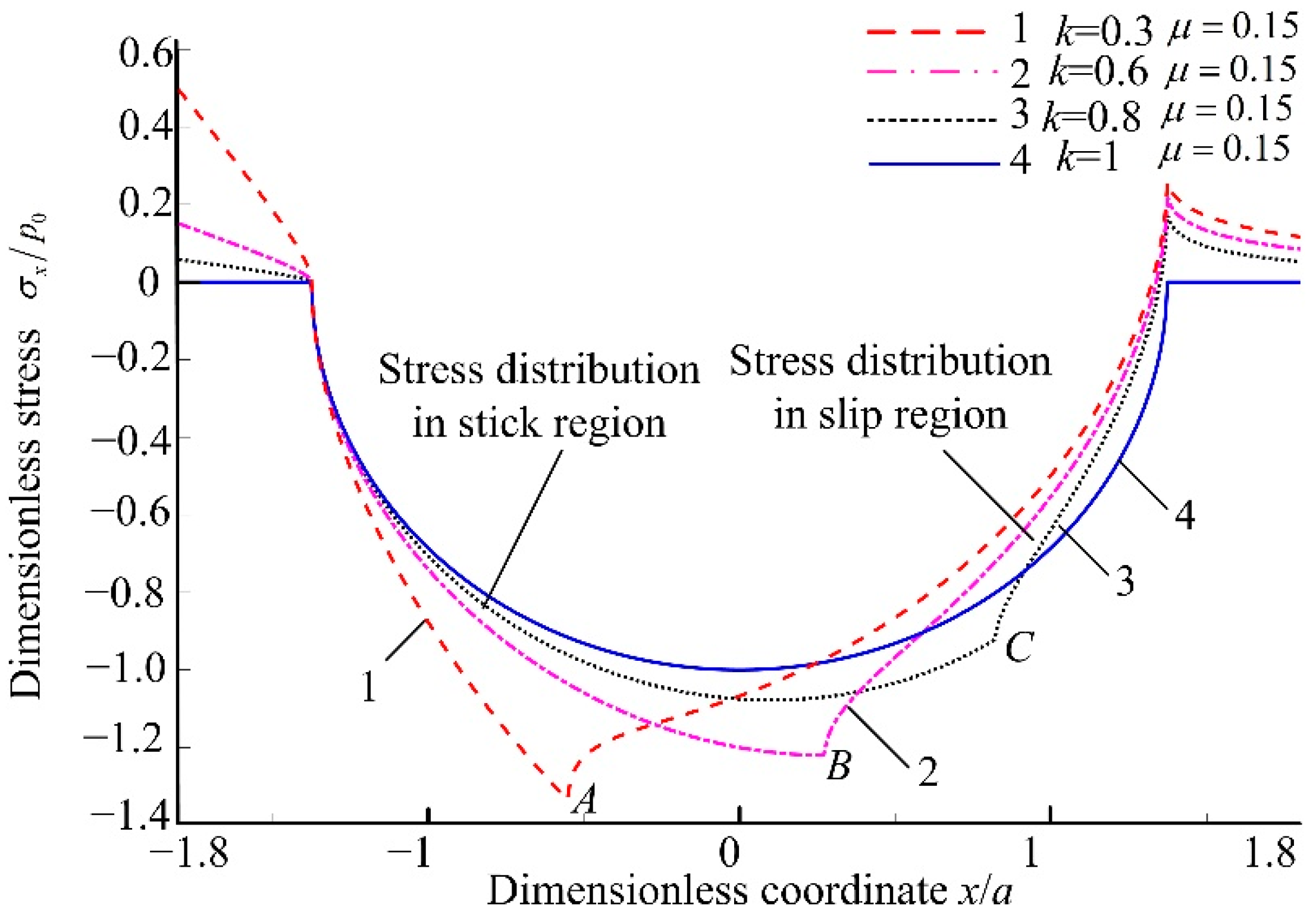

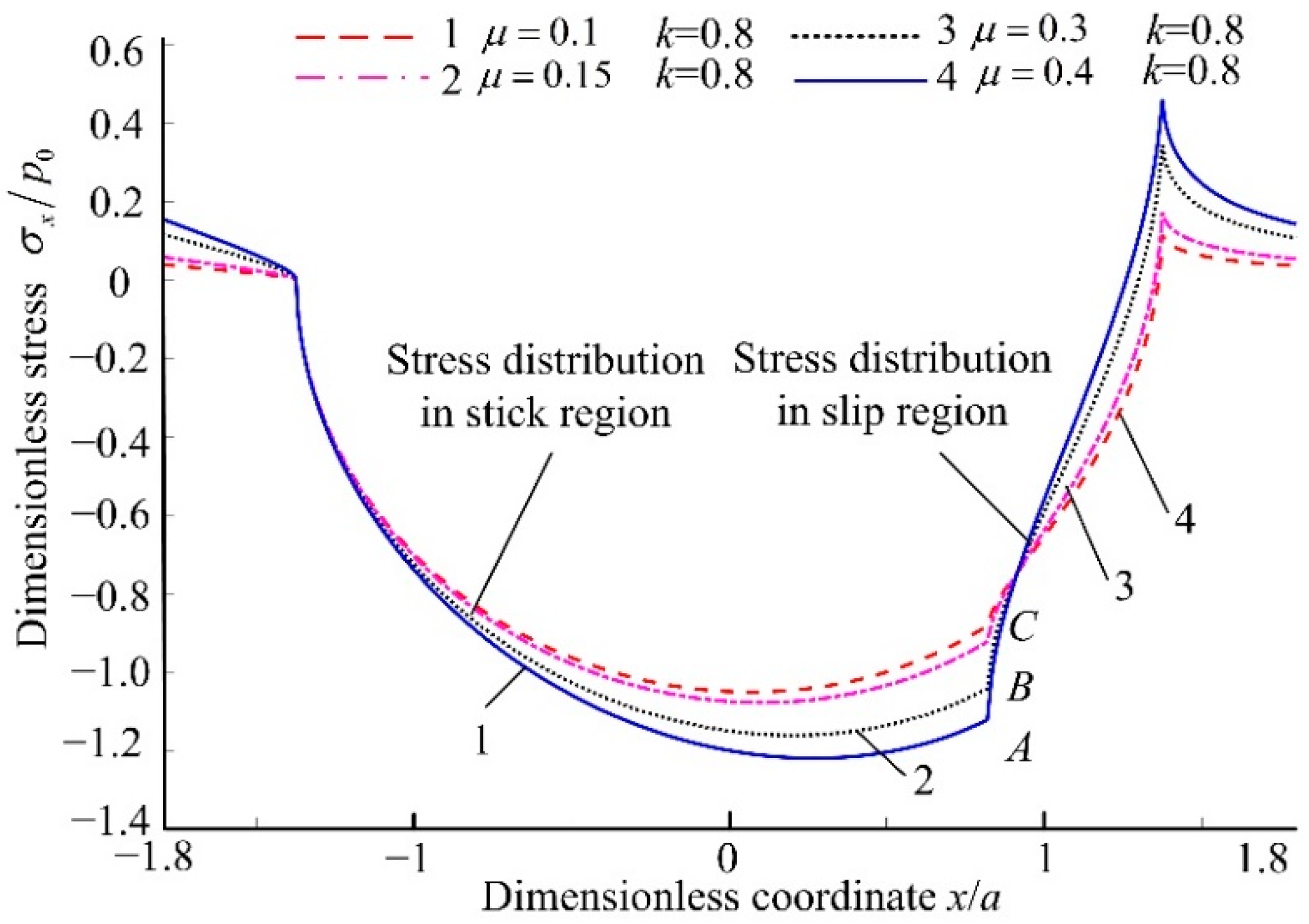

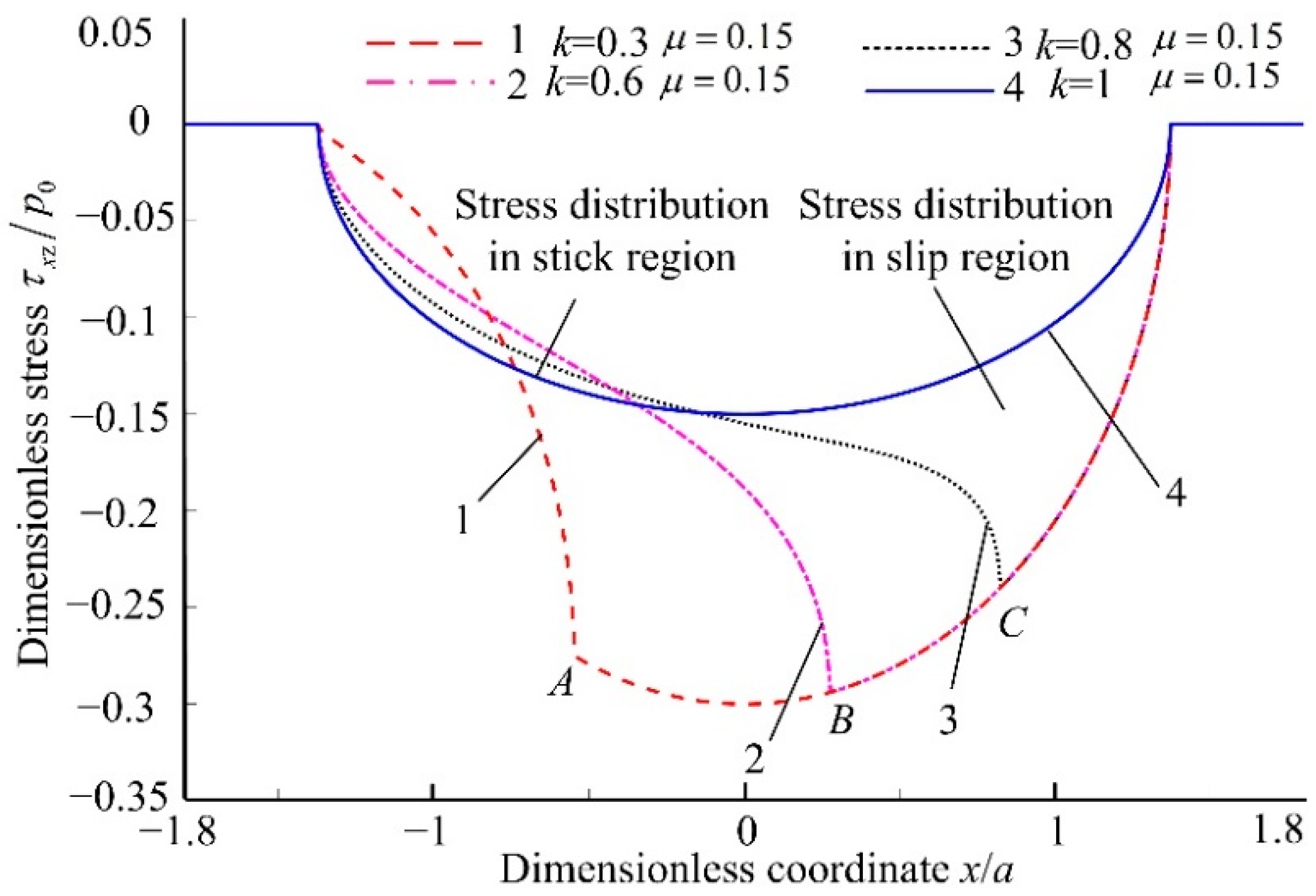

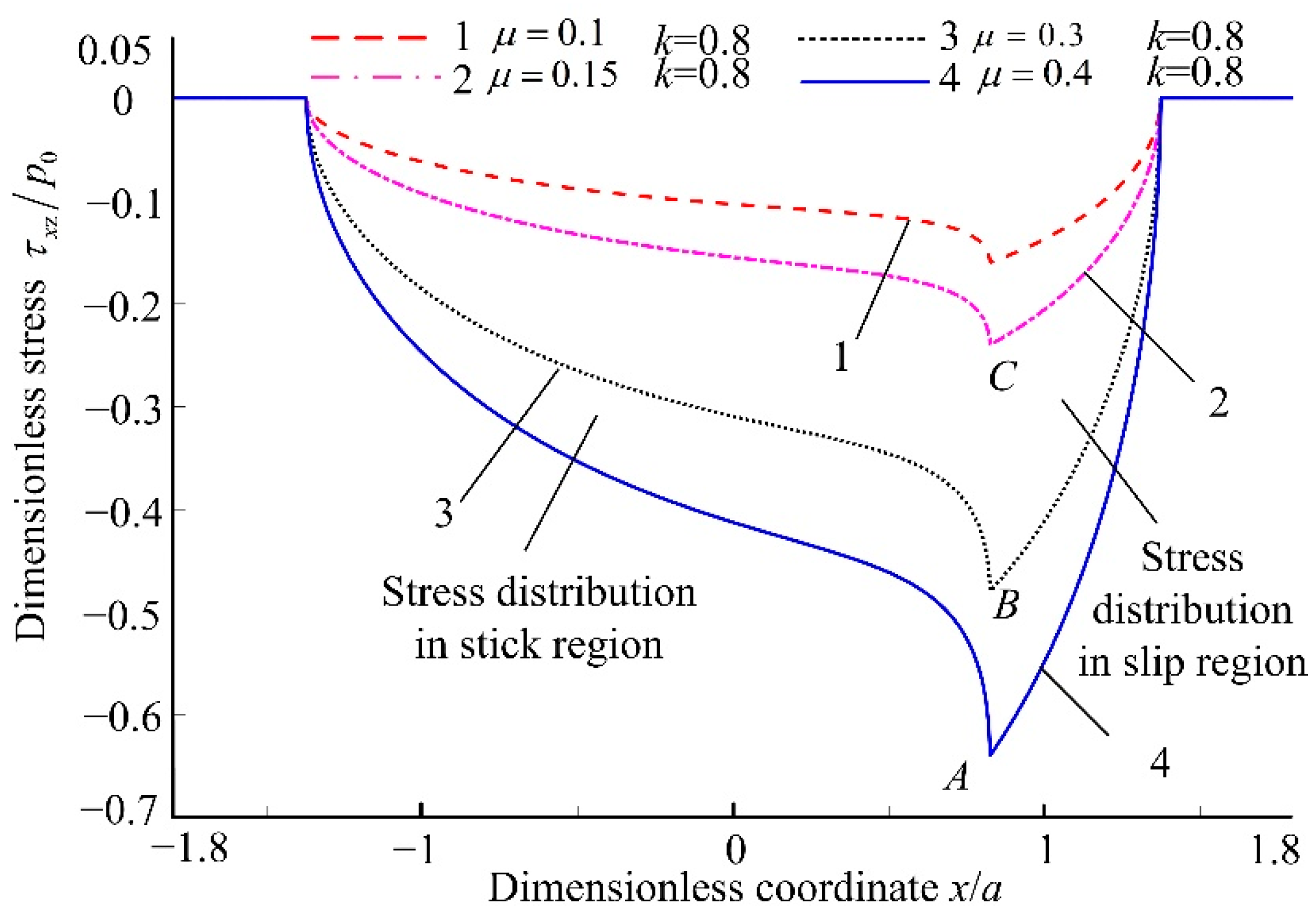

4.2. Numerical Analysis of Stress Distribution in Contact Area

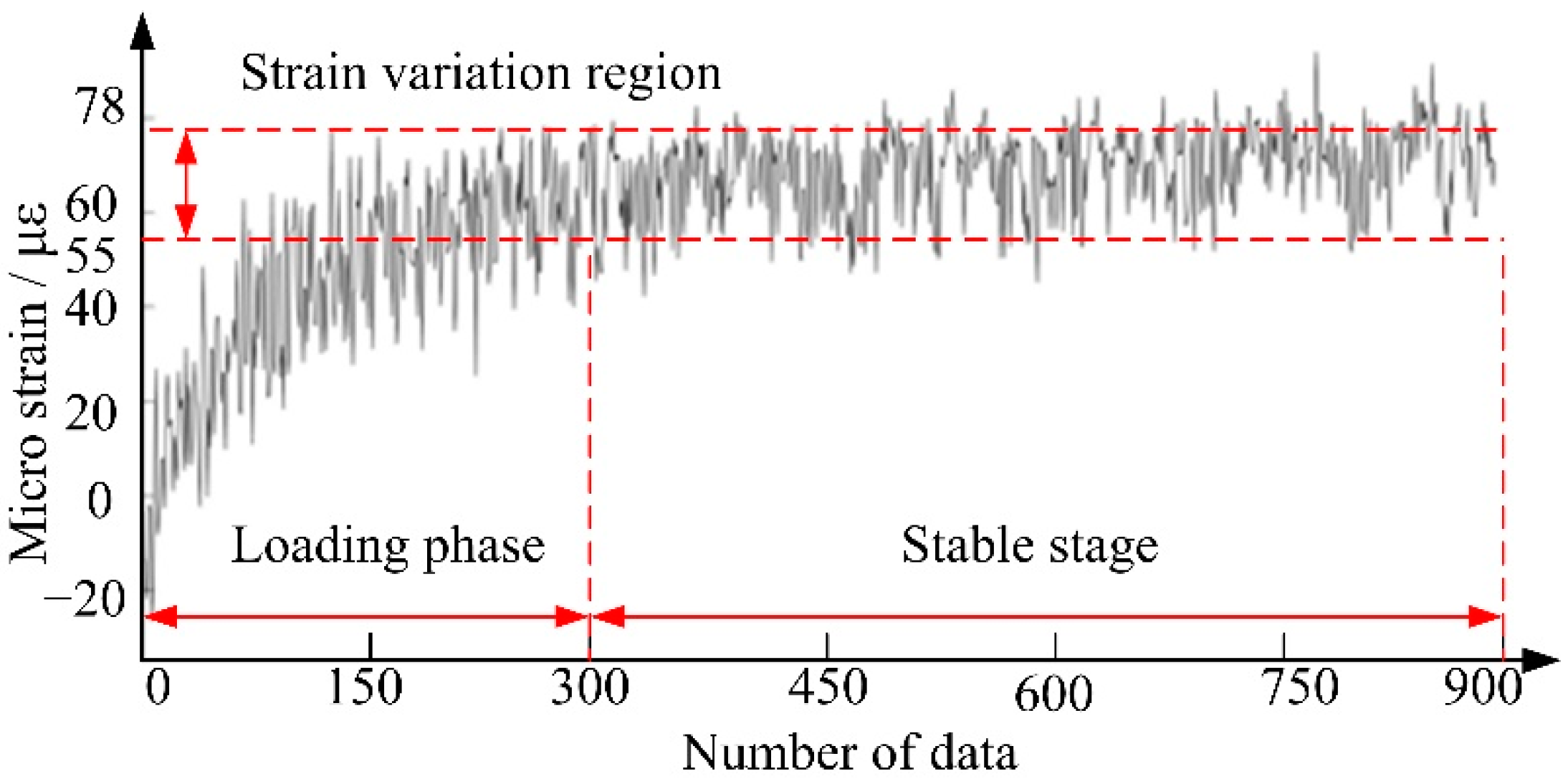

5. Experiment on Contact Characteristics of Cageless Bearing

6. Conclusions

- A new method for calculating the stress of three-dimensional nonconforming rolling contact between rolling elements and the variable diameter raceway was developed. The equations for analyzing the stress components were established. It was determined that the variable diameter raceway structure, spindle speed, friction coefficient and stick-slip coefficient are the main influencing factors of stress distribution. In addition, it was determined that the contact area is composed of two parts: the stick region and the slip region, the stress mutation often occurs at the boundary. The error of the new method for calculating is less than 15%. The correctness of the calculation method and the accuracy of the three-dimensional stress distribution model are verified, which can predict and characterize the contact stress distribution between the rolling elements and the variable diameter raceway.

- As the radius of the curvature ri increases, the contact stress distribution gradually changes from the downward curve of the opening to the upward curve of the opening. When Ri = 25.19 mm and ri = 1.5 mm, the contact stress in the conventional raceway and the variable diameter raceway is equal. As the spindle speed increases, the maximum stress of stress distribution occurs in the reducer raceway. Therefore, the larger ri should be selected in the design of the variable diameter raceway. It is recommended that the rotation speed below 13,950 r/min is beneficial to reduce the stress impact during the process of rolling elements passing through the variable diameter raceway.

- With the decrease in the friction coefficient µ and the increase in the stick-slip coefficient k, the stress mutation on the contact area of the rolling elements and variable diameter raceway reduces, which reduces the wear between the rolling element and variable diameter raceway. From the point of view of the discrete action, reducing µ and increasing the stick-slip coefficient k appropriately is beneficial to increase the service life of the variable diameter raceway.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Silayev, B.M.; Danilenko, P.A. Method of calculating high-speed rolling bearings intended for an aircraft engine based on considering the wear process. J. Frict. Wear 2015, 36, 350–354. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Yu, C. Dynamic responses after rotor drops onto a new-type active eliminating protective clearance touchdown bearing. J. Mech. Sci. Technol. 2020, 34, 2277–2288. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Q.; Wang, M.; Pan, C.; Bao, Y. Discrete theory of rolling elements for a cageless ball bearing. J. Mech. Sci. Technol. 2022, 36, 1921–1933. [Google Scholar] [CrossRef]

- Stribeck, R. Ball bearings for various loads. J. Trans. ASME 1907, 29, 420–463. [Google Scholar]

- Palmgren, A. Ball and Roller Bearing Engineering; SKF Industries Inc.: Philadelphia, PA, USA, 1959. [Google Scholar]

- Harris, T.A.; Kotzalas, M.N. Advanced Concepts of Bearing Technology: Rolling Bearing Analysis; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Ambrożkiewicz, B.; Syta, A.; Gassner, A.; Georgiadis, A.; Litak, G.; Meier, N. The influence of the radial internal clearance on the dynamic response of self-aligning ball bearings. Mech. Syst. Signal Processing 2022, 171, 108954. [Google Scholar] [CrossRef]

- Chudzik, A.; Warda, B. Effect of radial internal clearance on the fatigue life of the radial cylindrical roller bearing. Eksploat. Niezawodn. 2019, 21, 211–219. [Google Scholar] [CrossRef]

- Tomović, R. Load Calculation of the Most Loaded Rolling Element for a Rolling Bearing with Internal Radial Clearance. Appl. Sci. 2020, 10, 6934. [Google Scholar] [CrossRef]

- Qu, J.; Wang, W.; Han, H.; Liu, X. Study on Contact Analysis of High Angular Contact Ball Bearings Based on ANSYS. Mach. Des. Manuf. 2016, 8, 61–64. [Google Scholar] [CrossRef]

- Pandiyarajan, R.; Starvin, M.; Ganesh, K. Contact stress distribution of large diameter ball bearing using Hertzian elliptical contact theory. Procedia Eng. 2012, 38, 264–269. [Google Scholar] [CrossRef]

- Bozca, M. Effects of Design Parameters on Static Equivalent Stress of Radial Rolling Bearings. Acta Polytech. 2021, 61, 163–173. [Google Scholar] [CrossRef]

- Carter, F.W. On the action of a locomotive driving wheel. Proc. R. Soc. Lond. Ser. A 1926, 112, 151–157. [Google Scholar] [CrossRef]

- Reuss, M.; Sakai, T.; Matsubara, A. Modeling Approach for Estimation of Contact and Friction Behavior of Rolling Elements in Linear Bearings. Int. J. Autom. Technol. 2019, 13, 382–388. [Google Scholar] [CrossRef]

- Sen Gupta, S.K. Analytical and experimental studies of conical thrust ball bearings. Wear 1981, 69, 277–297. [Google Scholar] [CrossRef]

- Goryacheva, I.; Miftakhova, A. Modelling of the viscoelastic layer effect in rolling contact. Wear 2019, 430–431, 256–262. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, P.J.; Sun, Y.L.; An, B.; Zhang, M.; Wang, P. Analysis of wheel-rail rolling contact behavior considering curved contact patch. J. China Railw. Soc. 2021, 43, 27–36. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Shcherbakov, S.S. Spatial stress-strain state of tribofatigue system in roll–shaft contact zone. Strength Mater. 2013, 45, 35–43. [Google Scholar] [CrossRef]

- Song, X.D.; Liu, S.D.; Xu, H.L. Checking method for static load capacity of angular contact ball bearing under axial load. Bearing 2020, 7, 5–8. [Google Scholar] [CrossRef]

- Toumi, M.; Murer, S.; Bogard, F.; Bolaers, F. Numerical simulation and experimental comparison of flaw evolution on a bearing raceway: Case of thrust ball bearing. J. Comput. Des. Eng. Optim. 2018, 5, 427–434. [Google Scholar] [CrossRef]

- Lee, D.-H.; Seo, J.-W.; Kwon, S.-J.; Choi, H.-Y. Three-dimensional transient rolling contact analysis of similar elastic cylinders. Procedia Eng. 2011, 10, 2633–2638. [Google Scholar] [CrossRef][Green Version]

- Lostado, R.; Martinez, R.F.; Mac Donald, B.J. Determination of the contact stresses in double-row tapered roller bearings using the finite element method, experimental analysis and analytical models. J. Mech. Sci. Technol. 2015, 29, 4645–4656. [Google Scholar] [CrossRef]

- Kania, L. Modelling of rollers in calculation of slewing bearing with the use of finite elements. J. Mech. Mach. Theory 2006, 41, 1359–1376. [Google Scholar] [CrossRef]

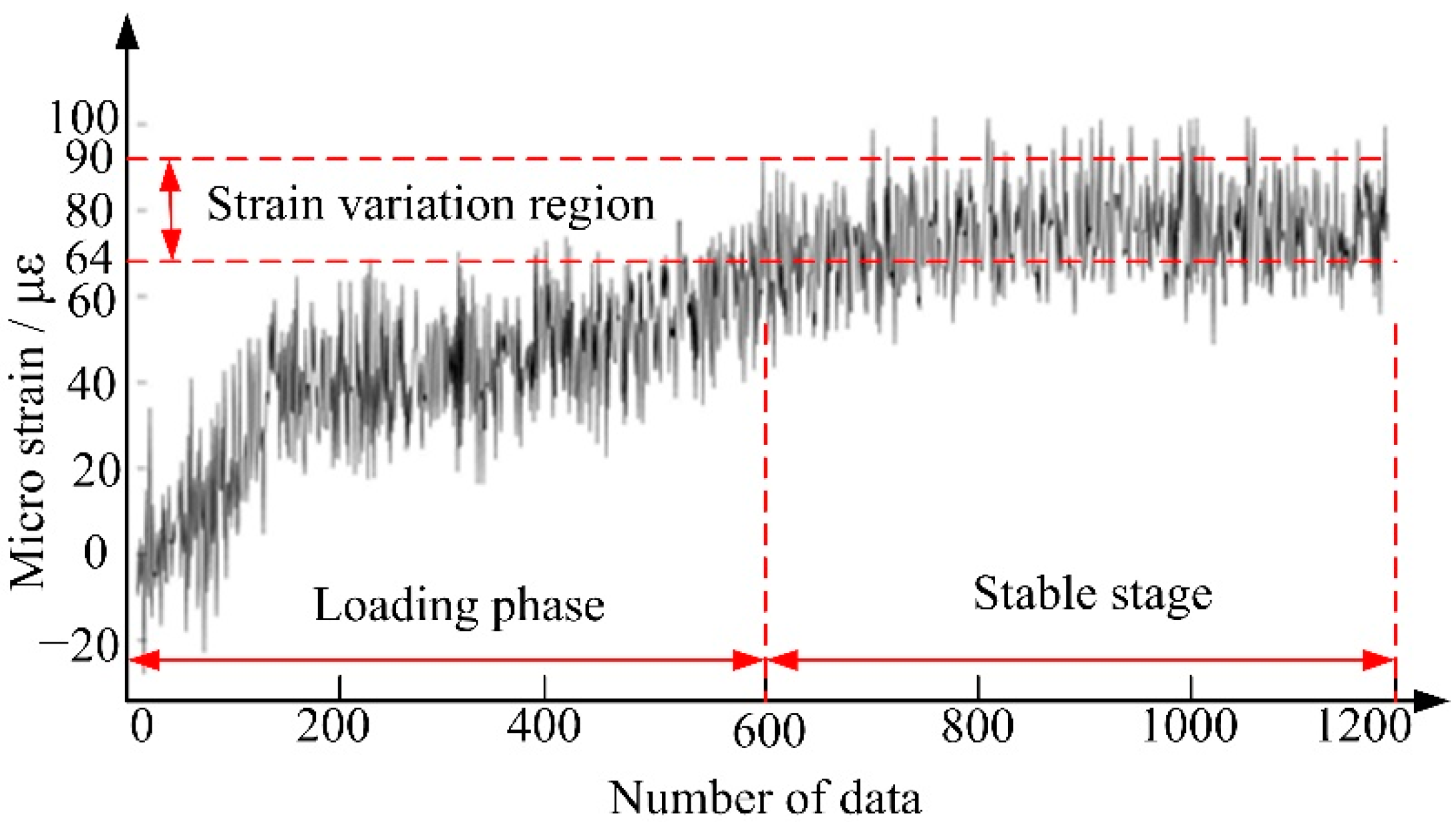

- Bian, L.; Ma, J.; Huang, Q. Research on Condition Monitoring for Slewing Bearings Based on Stain Analysis. Bearing 2015, 11, 50–53. [Google Scholar] [CrossRef]

- Nagatomo, T.; Takahashi, K.; Okamura, Y.; Kigawa, T.; Noguchi, S. Effects of load distribution on life of radial roller bearings. J. Tribol. 2012, 134, 021101. [Google Scholar] [CrossRef]

- Yang, X.; Xiao, H. Analyzing Load Case of Mill Roller Bearing with Boundary Element Method. In Proceedings of the 2009 International Conference on Measuring Technology and Mechatronics Automation, Zhangjiajie, China, 11–12 April 2009; pp. 754–757. [Google Scholar]

- Yang, X.Q. Contact Mechanics Theory and Design Analysis of Rolling Bearing; Huazhong University of Science & Technology Press: Wuhan, China, 2018. [Google Scholar]

- Ping, L.; Wang, C.; Li, L. Contact Problems of Gothic-arc Bearing. J. Nanjing Univ. Sci. Technol. 2007, 31, 458–461. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, Y.; Deng, S. Study on Load Distribution Characteristics of Cylindrical Roller Bearings with Trilobe Raceways. Bearing 2016, 9, 1–6. [Google Scholar] [CrossRef]

- Zhang, Z.; Deng, S.; Ju, H.W. Study on Processing for Non-Circular Raceway of Aerospace Trilobe Cylindrical Roller Bearings. Bearing 2019, 9, 13–17,20. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, Y.; Zhang, Y. Influence of Raceway Shape on Mechanical Properties of Four-Point Contact Ball Bearings. Bearing 2014, 4, 40–42. [Google Scholar] [CrossRef]

- Wang, J. Geometric Design and Static Stress Analysis of Deep Groove Ball Bearing with Oval Raceway. Master’s Thesis, Northeastern University, Shenyang, China, 2014. [Google Scholar]

- Singh, A.P.; Agrawal, A.; Joshi, D. Contact Mechanics Studies for an Elliptical Curvature Deep Groove Ball Bearing Using Continuum Solid Modeling based on FEM Simulation Approach. IOSR J. Mech. Civ. Eng. 2016, 13, 1–11. [Google Scholar] [CrossRef]

- Kim, S.-W.; Kang, K.; Yoon, K.; Choi, D.-H. Design optimization of an angular contact ball bearing for the main shaft of a grinder. J. Mech. Mach. Theory 2016, 104, 287–302. [Google Scholar] [CrossRef]

- Niu, R.; Xu, J.; Shao, X.; Deng, S. Mechanical Properties Analysis of Asymmetric Double Row Four-point-contact Slewing Bearing. J. Mech. Eng. 2018, 54, 177–186. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Qin, S. Design and simulation analysis of variable speed surface of cage-free bearing. J. Harbin Univ. Sci. Technol. 2021, 26, 33–39. [Google Scholar] [CrossRef]

| Parameter | Numerical | Parameter | Numerical |

|---|---|---|---|

| Inner diameter | 30 mm | X load | 0 N |

| Outer diameter | 62 mm | Y load | 500 N |

| Inner raceway diameter | 36.48 mm | Rolling element density | 3.18 g/cm3 |

| Outer raceway diameter | 55.53 mm | Bearing ring density | 7.81 g/cm3 |

| Ball diameter | 9.525 mm | Rolling element Poisson’s ratio | 0.26 |

| Inner raceway radius of curvature | 4.905 mm | Bearing ring Poisson’s ratio | 0.3 |

| Outer raceway radius of curvature | 4.953 mm | Speed | 6 K–18 K RPM |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhao, Y.; Wang, M. Analysis of Contact Stress Distribution between Rolling Element and Variable Diameter Raceway of Cageless Bearing. Appl. Sci. 2022, 12, 5764. https://doi.org/10.3390/app12125764

Wang Q, Zhao Y, Wang M. Analysis of Contact Stress Distribution between Rolling Element and Variable Diameter Raceway of Cageless Bearing. Applied Sciences. 2022; 12(12):5764. https://doi.org/10.3390/app12125764

Chicago/Turabian StyleWang, Qiyu, Yanling Zhao, and Mingzhu Wang. 2022. "Analysis of Contact Stress Distribution between Rolling Element and Variable Diameter Raceway of Cageless Bearing" Applied Sciences 12, no. 12: 5764. https://doi.org/10.3390/app12125764

APA StyleWang, Q., Zhao, Y., & Wang, M. (2022). Analysis of Contact Stress Distribution between Rolling Element and Variable Diameter Raceway of Cageless Bearing. Applied Sciences, 12(12), 5764. https://doi.org/10.3390/app12125764