Abstract

In addition to the conventional laboratory tests of input materials and construction mixtures, the technically correct design of pavement structure involves more frequent functional tests of the input materials and mixtures. Our study summarizes findings from a long-term monitoring of pavement on selected road sections with lower traffic intensity. The research involved the comparison of resilient moduli as a design parameter of unbound pavement base layers’ unbound granular materials (UGMs), determined in a laboratory by a test device for a cyclical triaxial test and in situ by impact load test using a falling weight deflectometer (FWD). In particular, the resilient moduli determined in the laboratory by a cyclic triaxial test (Mr,CTT) were compared with the real values of resilient moduli measured by FWD (Mr,FWD). A new, unique, and innovative FWD device was used to determine the Mr,FWD of the UGMs. The innovation lay in the dual-axis deflection measurement—measurement performed not just in the axis parallel to the road, but also in the axis in the transversal direction. It was found that, especially on roads with lower traffic load, such dual-axis (spatial) determination of Mr,FWD moduli was of great importance because it often allowed the identification of local pavement sections with low bearing capacities, especially at the edges, which have a significantly lower value of Mr,FWD.

1. Introduction

Currently, the most commonly used materials in the base and subbase layers of a pavement designed to support asphalt mix layers are known as the unbound granular materials (UGMs). The unbound granular layers and the subgrade of a pavement structure provide a significant support for the structure as a whole. Hence, the mechanical properties of these materials are important for the overall performance of the structure [1].

A proper characterization of UGMs and subgrade soils is essential in the design and rehabilitation of pavement structures. The characteristics of the individual materials are of extreme importance during the design of pavement structures, and this includes the determination of optimum moisture content, grain size distribution, resilient modulus, and permanent deformation of all the materials that are to be used during the construction. Pavement layers formed by granular materials demonstrate a non-linear, time-dependent, and elastoplastic response under traffic loading. On the other hand, traditional elasticity theories consider the response of granular materials as linear-elastic, which requires a resilient modulus and Poisson’s ratio. The parameters that influence the behavior of UGMs and fine-grained soils under repeated loads are stress level, density, gradation, fines content, grain size, aggregate type, particle shape, and moisture content or matric suction. The resilient modulus is mostly influenced by the level of applied stresses and the amount of moisture content in the material [2,3,4].

The resilient modulus is an important mechanical characteristic widely used for the analysis and design of pavements. Therefore, the determination of the resilient modulus of pavement materials is of vital importance for any mechanistically based design/analysis procedure for pavements. A laboratory resilient modulus test and a falling weight deflectometer (FWD) test are usually used to obtain the resilient modulus of a subgrade. However, the difference between the resilient moduli obtained from these two methods is considerably large due to the fact that these tests are conducted under quite different conditions [5,6,7,8].

Comprehensive research in this field is provided in [9]. A comparison was made between resilient moduli obtained from (i) a conventional small-scale resilient modulus test, (ii) a large-scale model experiment (LSME), and (iii) a falling weight deflectometer (FWD) in the field. The elastic moduli were back-calculated from the FWD data using the program MODULUS. The reasonable correspondence between the elastic moduli measured at different scales was obtained when empirical corrections were made for strain amplitude using a backbone curve for granular materials and by matching stress levels.

The differences between the back-calculated MR values of various types of roadbed soils and those obtained in the laboratory were presented and discussed in [10]. It was shown that the laboratory test results corresponded very well to the back-calculated ones. It was also shown that the MR of the roadbed soils was more or less constant, whether the soils were supporting flexible or rigid pavements.

Planning a pavement rehabilitation is based on pavement structure diagnostics, by which it is possible to determine the extent of pavement disruption as well as the cause of the disruption and thus subsequently remove this cause [11,12].

Possible causes of disruption include:

- Overall pavement structure—good-quality layers of insufficient thickness;

- Material of pavement structure layers—unsuitable, damaged, or poor-laying [13].

The above-mentioned disruptions of existing pavements can be prevented in the case of unbound mixtures in base layers by the functional testing of the resilient moduli using a cyclical triaxial device (Mr,CTT). The most frequently used test to determine the bearing capacity of the entire pavement structure is the impact load test with determination of the resilient moduli (Mr,FWD) [14,15,16].

The optimal solution is to design unbound mixtures for base pavement layers by functional testing so that it subsequently fulfills the requirements for the entire structure during control tests performed later [17].

The objective of the research described in this study was to find utilization for the adjustment of the frame (holder of geophones) of FWD and to describe the optimal way of designing UGMs by performance testing, which more accurately simulates the load on the tested base layers. Another objective was to find correlations between bearing-capacity characteristics derived using:

- A cyclic triaxial test according to EN 13286-7 standard;

- Non-destructive testing of the bearing capacity using FWD from real pavement structures on test sections using the designed UGMs [18];

- A method of 3D-bearing capacity testing by the adjusted measuring frame of the FWD device [19].

2. Monitored Sections and Methods

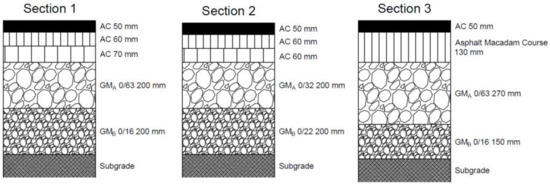

Data regarding the determination of bearing capacity at the monitored sections were analyzed in order to compare Mr,CTT and Mr,FWD and the development of the measuring frame of FWD. The following monitored sections were selected for research purposes (see Figure 1 and Table 1):

Figure 1.

Pavement structure schemes.

Table 1.

Pavement structures of the monitored roads.

- Test section 1 (road II/379), length 1639 m, two-line road of width 11.5 m.

- Test section 2 (road III/6401), length 751 m, two-line road of width 7.5 m.

- Test section 3 (road III/3785), length 364 m, two-line road of width 7.5 m.

The standard design and assessment of unbound mixtures do not commonly include functional (performance) testing of the pavement base and subbase layers. In addition to the common laboratory tests of gradation, compactability, and water and frost resistance, the individually designed mixtures were also subjected to experimental functional tests to determine the modulus in accordance with the EN 13286-7 standard. This European standard is intended specifically for testing UGMs. The resilient modulus Mr,CTT was determined after a constant curing period of the testing specimens. Before the actual determination of Mr,CTT, the properties of the used building materials were determined.

The properties of UGMs were verified in a CTT. The Mr,CTT of the compacted cylindrical testing specimens was determined, taking into account the assumed number of standard axles based on the conditions for designing flexible pavements [20].

The measurement of the pavement’s bearing capacity was performed using the FWD deflectometer Sweco. The bearing capacity measurement was performed during different seasons and various weather conditions. Material samples taken from the probes focused especially on unbound base layers.

The Mr,CTT determination was performed using CTT (see Figure 2). The course of the Mr,CTT of the compacted UGMs was monitored and determined using FWD.

Figure 2.

CTT device.

The bearing capacity was determined using FWDs. The dynamic tests (drop of weight through bumpers to loading plate) simulated the passing of a heavy vehicle at a speed of 60 km/h. At the same time, the values of deflection from sensors (geophones) deployed on the longitudinal frame to a distance of up to 2500 mm from the center of the loading plate were recorded.

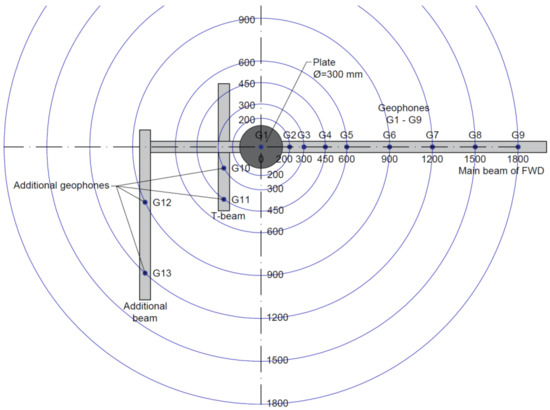

In order to be able to gather information about the transversal course of deformation as well, the standard FWD frame was equipped with a transversal frame with four additional sensors. These sensors recorded the values of deflection in the transversal direction and allowed us to make a comparison of the shape of deflection bowl in 3D and calculate the modulus of the structural layers or half-space in both directions to describe the pavement stiffness also close to the edge of the structure (see Figure 3).

Figure 3.

Layout of an auxiliary cross frame.

The PRIMAX FWD trailer by Sweco was mounted on a double-axle trailer. It was independent of the towing vehicle. The operator controlled all FWD functions from the PC, which was placed in the towing vehicle.

The standard trailer-mounted FWD was supplied with a personal computer, Windows FWD software, time-history module, transport lock, DMI (Distance Meter Indicator) integrated in the software, three temperature sensors, four-split loading plate, nine geophones in the longitudinal direction, and four geophones in the transversal direction. The impact loading applied to the pavement was 50 kN. The scheme of the load frame, including the position of the geophones, is provided in Figure 4.

Figure 4.

Scheme of the frame.

A back-calculation software for road data analysis was used for data treatment. However, the files generated from the equipment can be applied in any other back-calculation program.

We used the Primax design system from SWECO based on the following theory: When a force is transmitted to a load plate, this results in a deflection of the road surface—a “deflection bowl”. The deflection is the largest at the center of the plate and decreases as the distance from the center becomes greater. The layer stiffness in a road structure is also called the E-modulus of a layer.

Based on this theory, the shape of a deflection bowl is symmetrical, and deflections measured using a standard beam normally positioned parallel with the horizontal axis of the communication should be equivalent also in the transversal direction in the case of ideal structures. If the measured deflections at geophones are larger than those in the transversal beam, it means that the structure is less durable in this direction, either due to a smaller thickness of the structure layers or their lower quality, or due to greater disruption of these layers. By comparing the deflections at the same distance from the loading plate in horizontal and transversal direction, one can determine the differences in pavement durability in that particular direction. We are currently in the process of verifying the adjusted setup of the evaluation software so that we can directly compare the elasticity moduli (E-moduli) of the structure layers of an n-layered system in transversal and horizontal direction.

The calculation of a road surface deflection is based on the theory of elasticity and the method of equivalent thickness, as framed by engineers Messrs. J. M. Kirk and N. Odemark on the basis of Boussinesq’s equations. The deflection is the sum of the deformation in the layers and the subgrade. The deformation of one layer is linearly elastic, i.e., the deformation is directly proportional to the force and the thickness of the layer, but inversely proportional to the stiffness of the layer. The deformation of the subgrade is calculated from the stress and stiffness.

In accordance with the Czech national standards, sampling at national and regional communications is required every 25 m. During special measurements or in the case of severely damaged communications, the distance between two subsequent measuring points can be up to 5 m in a traffic lane.

3. Results

The obtained results can be divided into several focus sections.

3.1. Assessment of UGM Mixtures

A commonly used parameter for the evaluation of the bearing capacity is the deflection line parallel to the direction of traffic flow. This, however, might not provide ideal information about the bearing capacity of the entire pavement structure area. When evaluating the properties of the test sections, significant differences have been observed in the bearing capacity of the pavement. When considering the bearing capacity, the pavement structure is non-homogeneous in the transversal direction. For this reason, attention was paid to the development and modification of the test device. The deflectometer was upgraded by an auxiliary cross frame capable of measuring deflection also in the transversal direction from the measuring point. The following tables (Table 2 and Table 3) describe the test results of functional tests, i.e., the cyclic triaxial test and CBR test. A comparison of Mr,CTT was performed in relation to the changes in moisture of the unbound mixture tested (see Figure 5) since a variable moisture state was expected across the pavement width. Table 2 and Table 3 therefore show the Mr,CTT determined at various moisture contents. It was possible to make specific comparisons of the calculated and measured values of the elasticity moduli of the GMs. The results show that the proposed Mr,CTT testing for unbound mixtures in base layers and the control of the non-destructive testing by impact load test with determination of Mr,FWD are the most optimal systems for the assessment of suitability of used GMs.

Table 2.

Average Mr,CTT values and approximate values of CBR for subbase layers of the monitored road sections.

Table 3.

Average Mr,CTT values and approximate values of CBR for base layers of the monitored road sections.

Figure 5.

Specimens for CTT: GM 0/22 (left); GM 0/32 (right).

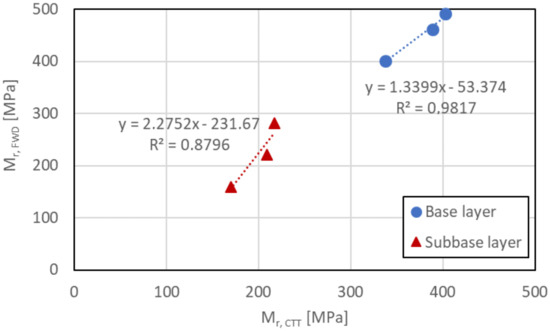

3.2. Relationship between Mr,CTT and Mr,FWD

The relationship between Mr,CTT and Mr,FWD is given in Table 4 and Figure 6 at the current natural moisture content, sampled from the edge of the pavement where higher moisture content can be expected.

Table 4.

Determined elasticity moduli of layers at the monitored sections at natural material humidity during the time of measurement.

Figure 6.

Relationship between Mr,CTT and Mr,FWD of materials from the base and subbase layer.

The average Mr,CTT value for GMA was 350 MPa. The measured values varied from 315 to 403 MPa. The bearing capacity of GMA was especially affected by the gradation of the mixture with the fine particle content. The average elasticity modulus of GMB was 200 MPa. Some values, however, were below 100 MPa. The reason for this rapid decrease in bearing capacity of GMB was typically the increase in moisture content. Another reason was most likely the penetration of the lower unbound layer with a fine-grain base, especially in the case of pavements with a current lifespan longer than 5 years.

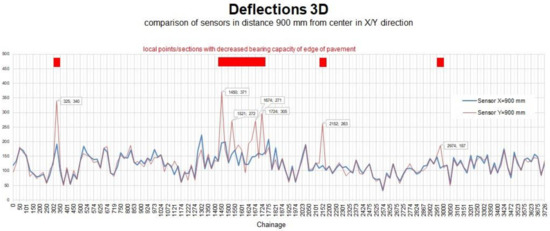

3.3. The Benefit of the Innovated FWD in Determination of Mr,FWD

The FWD device used for the determination of bearing capacity is capable of measuring in the axis of the traffic line or in the outer track of the wheels. In some cases of pavement disruptions, especially spatial deformations of pavement edges, the measured values of deflection determined in longitudinal direction do not correspond to the edges of the pavement. In situations where this is due to changes in the pavement structure (gradual historical widening) or changes of the parameters, specifically those of the base layer and subbase layer, there is a significant decrease or fluctuation of the bearing capacity of the structure layers. This phenomenon brings about the non-homogeneity of the pavement base layer or subbase layer characteristics, and this can directly affect the optimum planning of maintenance and rehabilitations or the reconstructions of the entire road section. An auxiliary cross frame added to FWD allows the gathering of information about changes of the parameters in transversal directions, in particular the bearing capacity of the structure layers. This allows for better description of the causes of disruption of pavement edges.

Searching for places with lower bearing capacity of the base layer and surface of a pavement allows, for example, a direct comparison of the measured pavement deflection by a sensor 900 mm away from the roadway center in the longitudinal and transversal directions. When a positive difference is found, the lower parameters of these layers can be expected, and closer attention should be paid in these cases during further diagnostic process (tests and laboratory material analysis) or special rehabilitation actions to be planned for these sections (see Figure 7).

Figure 7.

Comparison of sensors in distance 900 mm from center in X/Y direction.

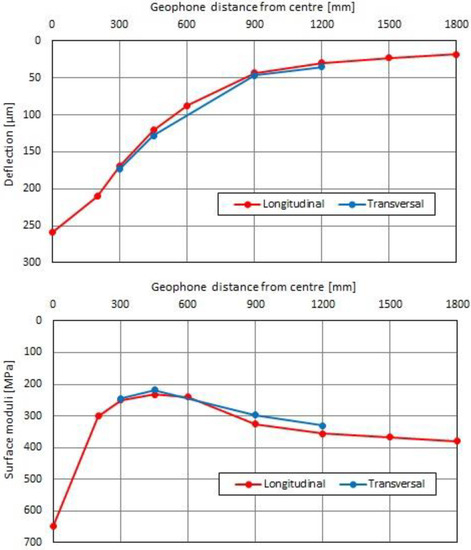

Another possible use of the data from such modified FWD is to draw up a detailed analysis of the course of the deflection bowl and surface moduli at selected measuring points. Such data can then be used either to determine the homogeneity or non-homogeneity of the bearing capacity parameters of specific structure layers in the longitudinal and transversal directions or to allow focusing on layers which negatively affect the overall bearing capacity of the pavement (see Figure 8).

Figure 8.

Deflection bowl and values of surface moduli obtained from innovative FWD device.

4. Discussion

Our results show that it was possible to compare the values of the determined Mr,CTT with the real values of Mr,FWD at selected road sections with a lower traffic load, which often suffer from the problem of low bearing capacity at their edges. Thanks to the use of this new, unique, innovative FWD device consisting of a dual-axis system of moduli measurements, it was always possible to find the spots with lower bearing capacity of the pavement edges. Materials sampled from these spots were then subjected to a cyclic compression test, and, indeed, lower parameters of Mr,CTT were found. During subsequent testing of these samples, a higher level of moisture was also determined, and thus the cause of the pavement edge disruptions was revealed.

5. Conclusions

Based on the described research, it can be concluded that:

- A strong correlation was found between Mr,CTT and Mr,FWD for both base layers as well as subbase layers.

- The indicative values of CBRsat were also determined. For the monitored unbound mixtures, they ranged between 117% and 231%.

- The values of Mr,CTT and Mr,FWD for the subbase layers are comparable.

- Using the innovative FWD device, it is possible to reveal locally non-durable points at the edge of the pavement during pavement diagnostics.

- It was verified that the innovative FWD device was usable specifically for pavements with lower traffic load, at which the problematic durability of the pavement edges can be assumed.

- Additionally, during the phase of deflections evaluation, it was possible to label a point as non-durable if there were differences in deflections in the horizontal and transversal directions larger than approximately 20%. This criterion can be used in technical regulations dealing with pavement diagnostics during their reconstructions.

An auxiliary cross frame can have various uses in the measurement of durability. It provides advantages when enlarging the width of roads with various pavement structures in the cross section or in pavements with neglected maintenance from the perspective of correct drainage function.

Author Contributions

Conceptualization, D.S. and L.M.; methodology, M.V., P.H. and O.D.; software, R.K. (Robert Kaderka), J.S. and P.V.; validation, D.S., P.H., O.D., L.M. and M.V.; formal analysis, M.V. and K.S.; investigation, K.S.; resources, P.H. and O.D.; data curation, M.V. and R.K. (Radek Komenda); writing—original draft preparation, D.S., P.H., O.D., L.M., R.K. (Robert Kaderka), R.K. (Radek Komenda), J.S., P.V., K.S. and M.V.; writing—review and editing, D.S., P.H., O.D., L.M., R.K. (Robert Kaderka), R.K. (Radek Komenda), J.S., P.V., K.S. and M.V.; visualization, R.K. (Radek Komenda), J.S., P.V. and K.S.; supervision, M.V.; project administration, O.D.; funding acquisition, D.S., P.H. and O.D. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the Technology Agency of the Czech Republic with Project CK01000158 “Use of higher amounts of reclaimed material in asphalt mixtures with PmB bitumen”, Project CK03000169 “Development of road construction layers with optimized grain size replacing insufficient aggregate fractions”, and Project TH04030342 “Recycled building materials for transport infrastructure construction”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Erlingsson, S.; Rahman, S.; Salour, F. Characteristic of unbound granular materials and subgrades based on multi stage RLT testing. Transp. Geotech. 2017, 13, 28–42. [Google Scholar] [CrossRef]

- Cetin, A.; Kaya, Z.; Cetin, B.; Aydilek, A.H. Influence of laboratory compaction method on mechanical and hydraulic characteristics of unbound granular base materials. Road Mater. Pavement Des. 2014, 15, 220–235. [Google Scholar] [CrossRef]

- Mousa, R.; Gabr, A.; Arab, M.; Azam, A.M.; Arab, M.G.; Azam, A.; El-Badawy, S. Resilient Modulus for Unbound Granular Materials and Subgrade Soils in Egypt Model for Prediction of Resilient Modulus Incorporating Matric Suction for Recycled Unbound Granular Materials. View Project 4th International Jordan Conference View project Resilient Modulus for Unbound Granular Materials and Subgrade Soils in Egypt. 2017. Available online: https://www.researchgate.net/publication/316521210 (accessed on 15 October 2021).

- Adu-Osei, A. Characterization of Unbound Granular Layers in Flexible Pavements (Sponsored by the Aggregates Foundation for Technology, Research and Education.). Available online: https://repositories.lib.utexas.edu/bitstream/handle/2152/35440/502-3.pdf?sequence=2&isAllowed=y (accessed on 15 October 2021).

- Ji, R.; Siddiki, N.; Nantung, T.; Kim, D. Evaluation of resilient modulus of subgrade and base materials in indiana and its implementation in MEPDG. Sci. World J. 2014, 2014, 372838. [Google Scholar] [CrossRef] [PubMed]

- Quinta-Ferreira, M.; Fung, E.; Andrade, P.S.; Branco, F.C. In-place evaluation of a limestone base course modulus, using a van-integrated falling weight deflectometer (FWD) and the GeoGauge (SSG). Road Mater. Pavement Des. 2012, 13, 817–831. [Google Scholar] [CrossRef]

- Rahim, A.; Asce, A.M.; George, K.P.; Asce, H.M. Falling Weight Deflectometer for Estimating Subgrade Elastic Moduli. Transp. Eng. 2003, 129, 100–107. [Google Scholar] [CrossRef]

- Saleh, M. Utilisation of the deflectograph data to evaluate pavement structural condition of the highway network. Road Mater. Pavement Des. 2016, 17, 136–152. [Google Scholar] [CrossRef]

- Tanyu, B.F.; Kim, W.H.; Edil, T.B.; Benson, C.H. Comparison of Laboratory Resilient Modulus with Back-Calculated Elastic Moduli from Large-Scale Model Experiments and FWD Tests on Granular Materials. Symp. Pap. 2003, 1437, 191–208. Available online: https://www.astm.org/stp12532s.html (accessed on 15 October 2021).

- Dawson, T.A.; Baladi, G.Y.; Sessions, C.P.; Haider, S.W. Backcalculated and Laboratory-Measured Resilient Modulus Values. Transp. Res. Rec. 2009, 2094, 71–78. [Google Scholar] [CrossRef]

- Stehlik, D.; Varaus, M.; Hyzl, P. Monitoring of experimental sections with recycled waste materials. In Proceedings of the 5th International Conference on Structural Engineering, Mechanics and Computation, Cape Town, South Africa, 2–4 September 2013. [Google Scholar]

- Stehlik, D.; Dasek, O.; Hyzl, P.; Coufalik, P.; Krcmova, I.; Varaus, M. Pavement construction using road waste building material—From a model to reality. Road Mater. Pavement Des. 2015, 16, 314–329. [Google Scholar] [CrossRef]

- Salour, F.; Erlingsson, S. Investigation of a pavement structural behaviour during spring thaw using falling weight deflectometer. Road Mater. Pavement Des. 2013, 14, 141–158. [Google Scholar] [CrossRef]

- Elshaer, M.; Ghayoomi, M.; Daniel, J.S. The role of predictive models for resilient modulus of unbound materials in pavement FWD-deflection assessment. Road Mater. Pavement Des. 2020, 21, 374–392. [Google Scholar] [CrossRef]

- Rocha, S.; Tandon, V.; Nazarian, S. Falling Weight Deflectometer Fleet: Repeatability and Reproducibility. Road Mater. Pavement Des. 2004, 5, 215–238. [Google Scholar] [CrossRef]

- Mehta, Y.; Asce, A.M.; Roque, R.; Asce, F. Evaluation of FWD Data for Determination of Layer Moduli of Pavements. J. Mater. Civ. Eng. 2003, 15, 25–31. [Google Scholar] [CrossRef]

- Islam, K.M.; Gassman, S.; Rahman, M.M. Field and Laboratory Characterization of Subgrade Resilient Modulus for Pavement Mechanistic-Empirical Pavement Design Guide Application. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 921–930. [Google Scholar] [CrossRef]

- Horak, E.; Maina, J. Structural number determined with the falling weight deflectometer and used as benchmark methodology Advanced numerical modeling View project Permeability of Hot Mix Asphalt View project. IEEE Proc. Hong Kong 2014. [Google Scholar] [CrossRef]

- Pożarycki, A.; Górnaś, P.; Wanatowski, D. The influence of frequency normalisation of FWD pavement measurements on backcalculated values of stiffness moduli. Road Mater. Pavement Des. 2019, 20, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Hyzl, P.; Varaus, M.; Stehlik, D.; Zdralek, P. Experience with triaxial loading systems for the testing of road construction materials. In Proceedings of the 7th International Rilem Symposium Atcbm09 on Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece, 27–29 May 2009; pp. 909–926. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).