An Improved Gas Leakage Model and Research on the Leakage Field Strength Characteristics of R290 in Limited Space

Abstract

1. Introduction

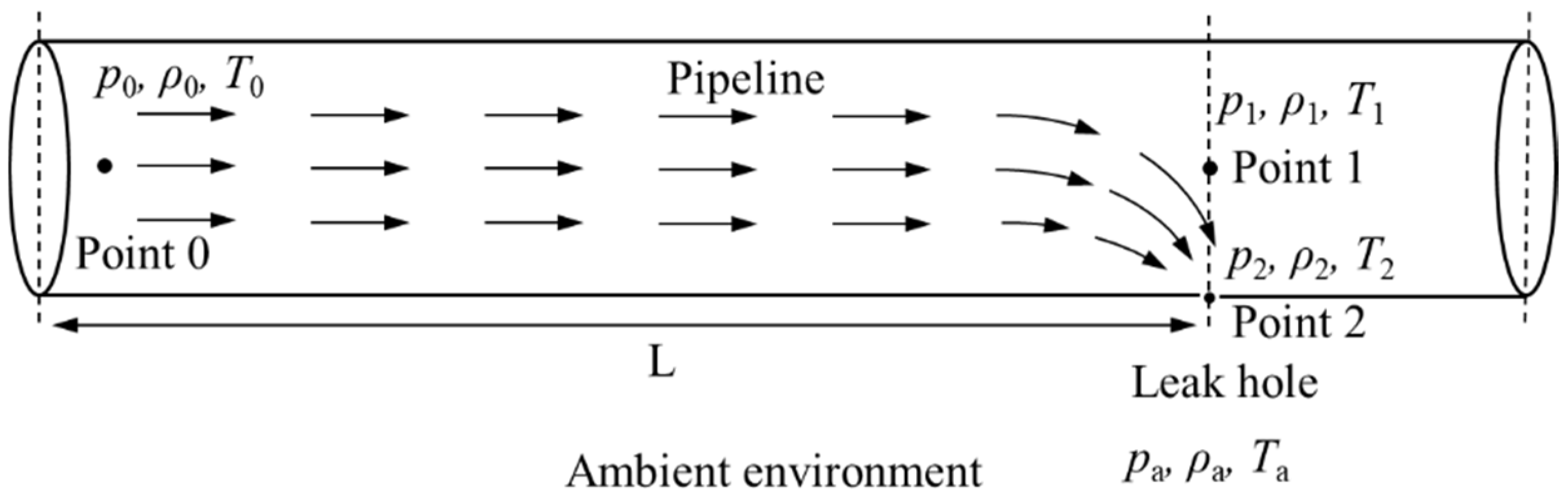

2. The Improved Gas Leakage Model of Pressure Pipeline

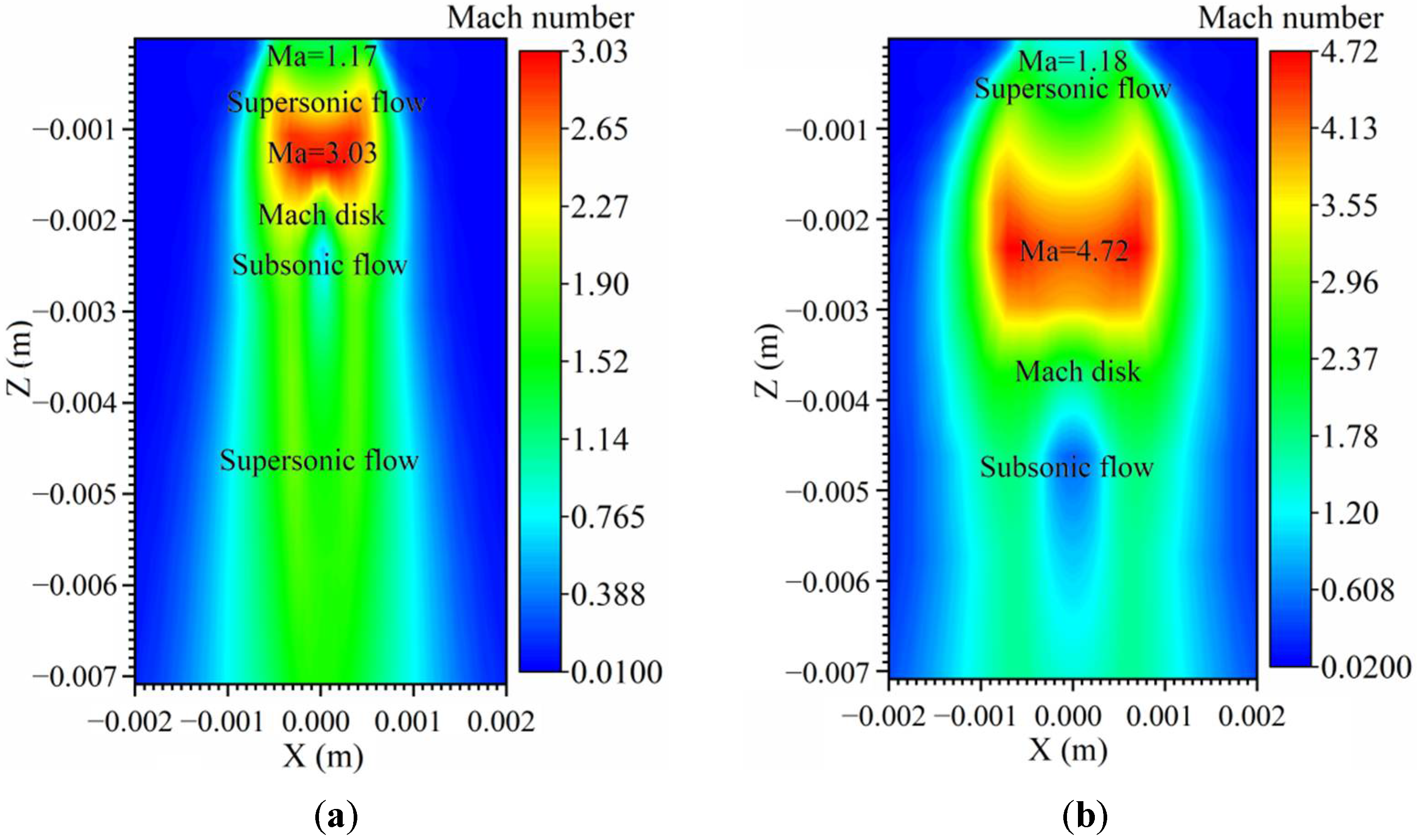

2.1. The Hole Models for Gas Leakage

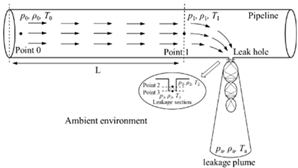

2.2. The Improved Gas Leakage Model and Its Corresponding Derivation

2.3. The Numerical Simulation

2.3.1. Governing Equations of the Diffusion Process

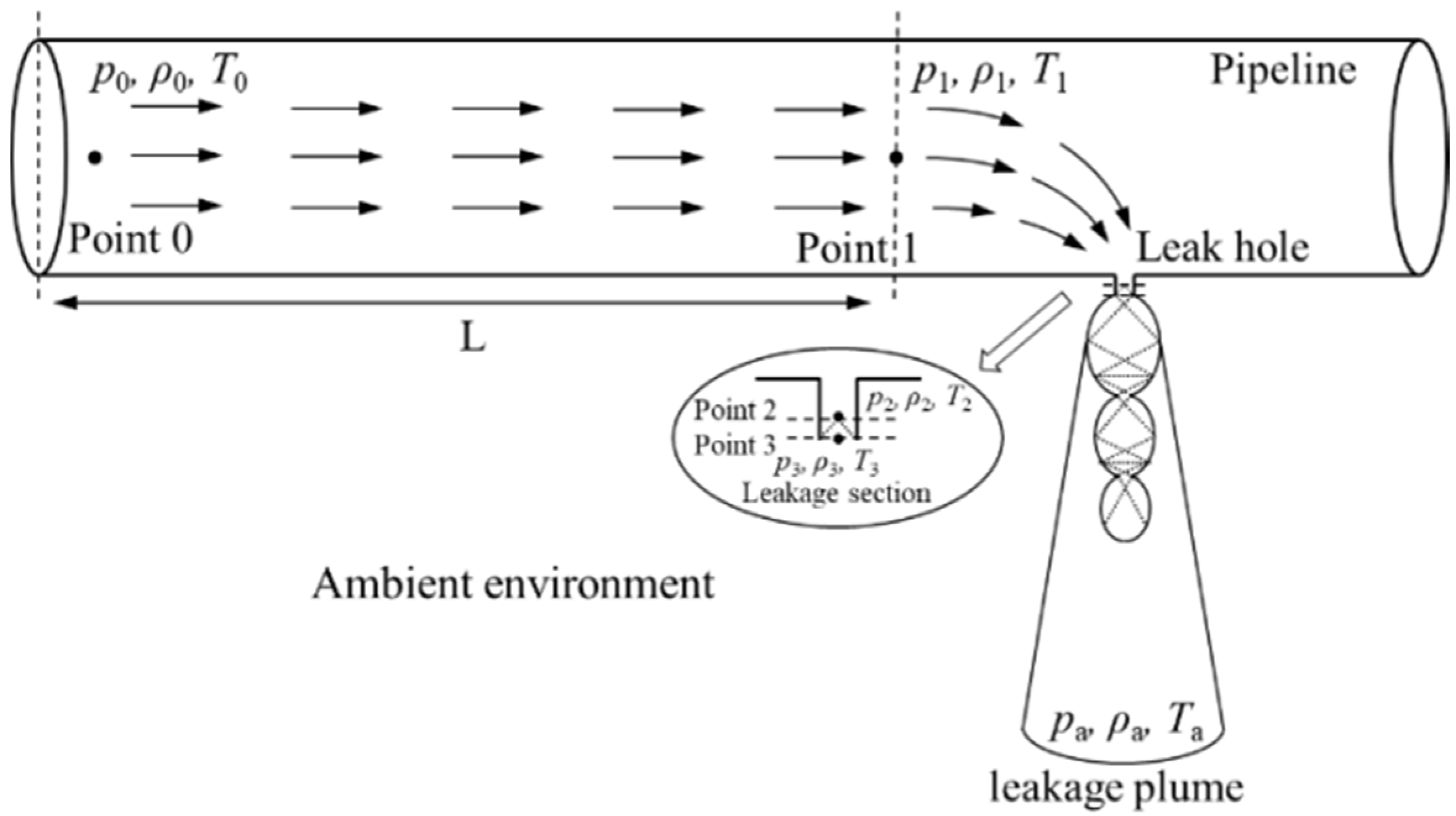

2.3.2. Geometric Model

2.3.3. Numerical Methods and Boundary Conditions

- (1)

- During the process of refrigerant leakage, compared with the change of the enthalpy value of the leaked gas, the heat transfer between the gas and the walls of the pipe and the leakage section was very small, which was neglected in the numerical model;

- (2)

- When the refrigerant leaked in the refrigeration system, the pressure inside the system changed dynamically with time. To simplify the calculation, the initial leakage pressure was assumed to be a constant value in the model;

- (3)

- In the actual leakage process, the shape of the leakage hole on the surface of the copper tube was very uncontrollable, and the leak holes with different shapes may appear. In the model, a circular hole with a constant cross-sectional area was used as an example to study;

- (4)

- During the actual leakage process, due to the heat transfer between the air and the walls in the external space, the temperature of the space fluctuated, which had a certain impact on the diffusion process of the leaked gas. In the model, the walls were insulated, and the change of external space temperature caused by this part of the heat transfer was ignored.

2.4. The Verification of the Improved Gas Leakage Model

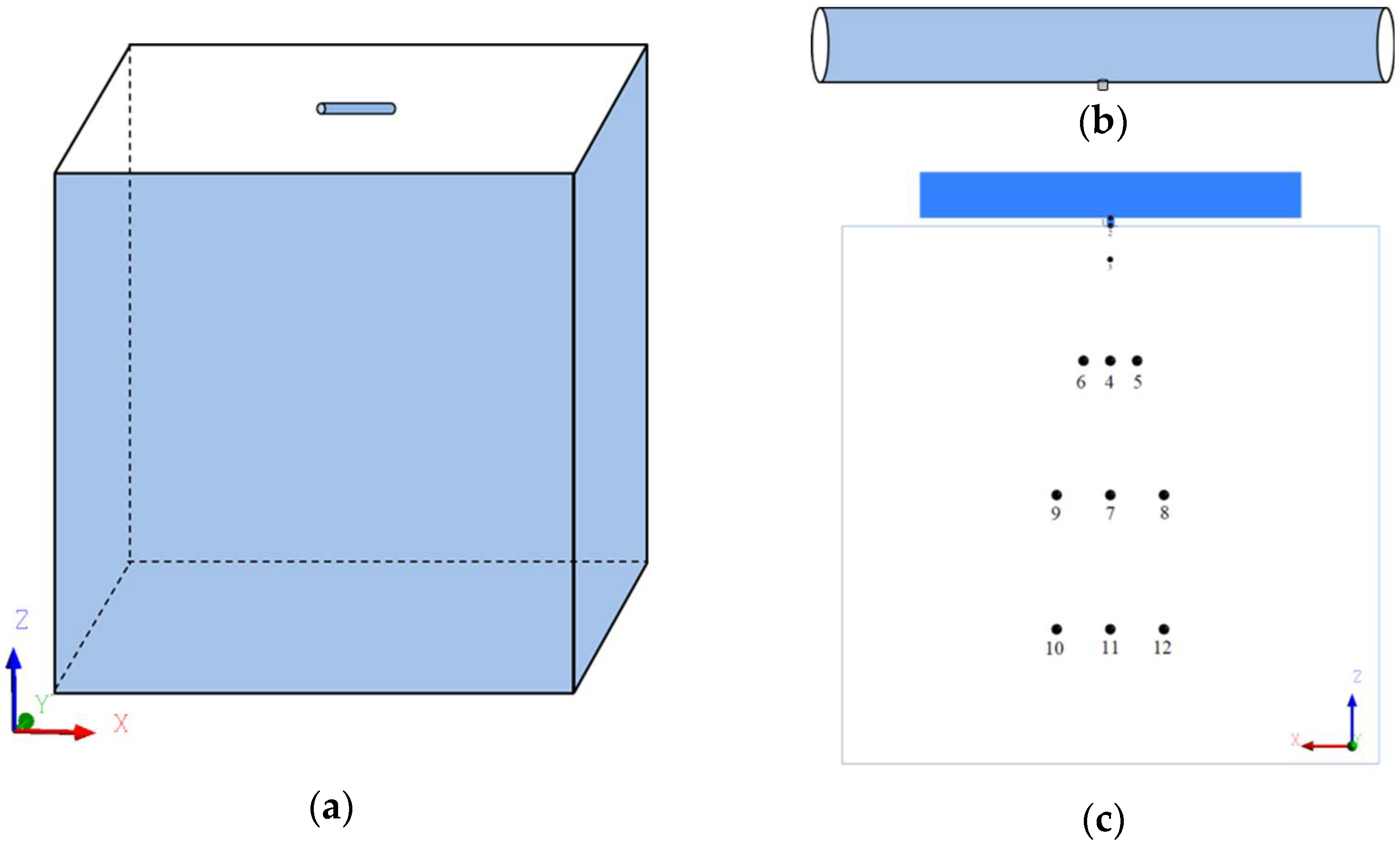

2.4.1. Comparison between Numerical and Experimental Results of the Mach Disk Position and Diameter

2.4.2. Comparison between the Numerical and Experimental Results of the Gas Concentration on the Jet Axis

3. The Results and Discussion

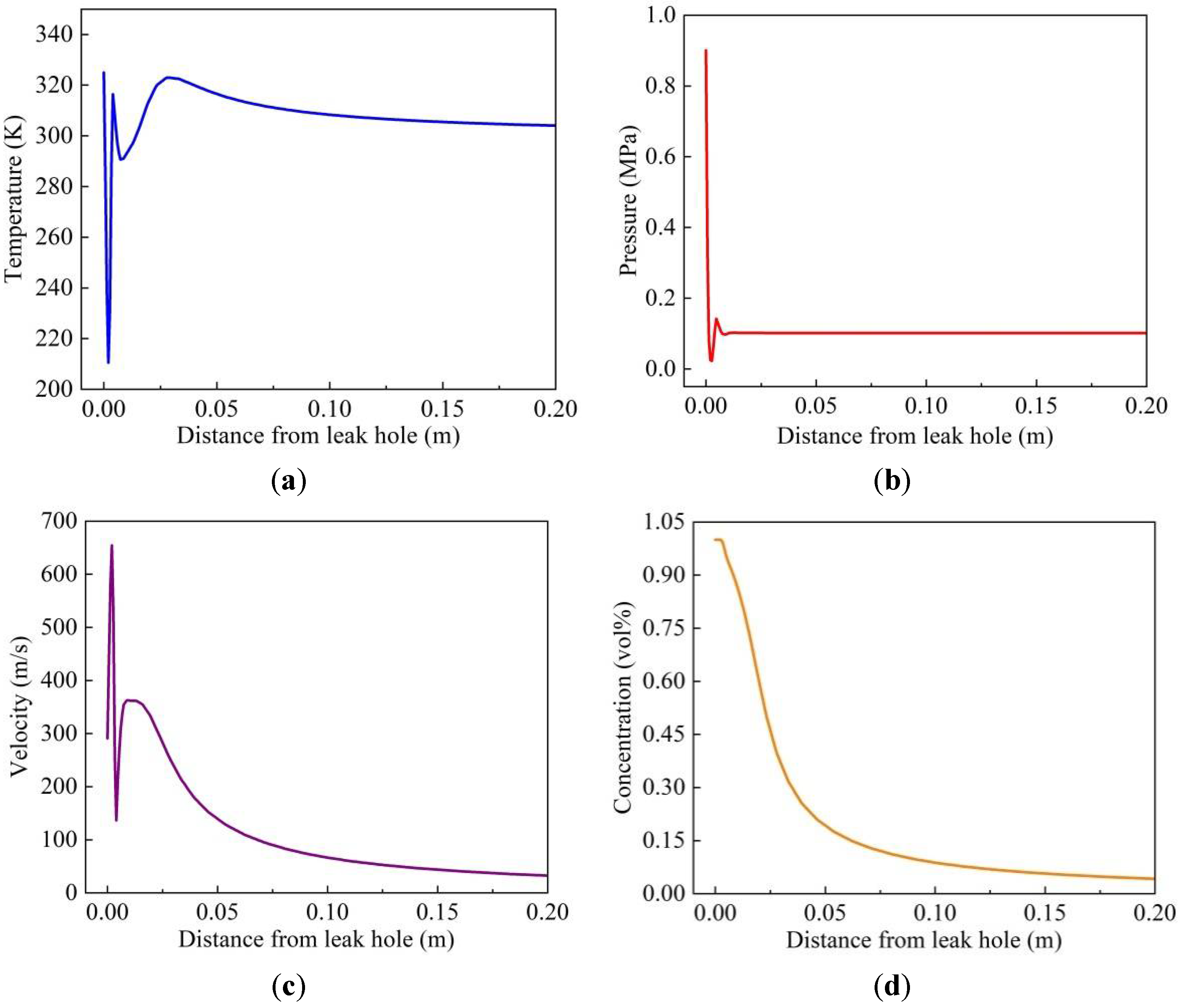

3.1. Multi-Field Coupling Characteristics of Leaked R290 in the Near-Field Flow Area

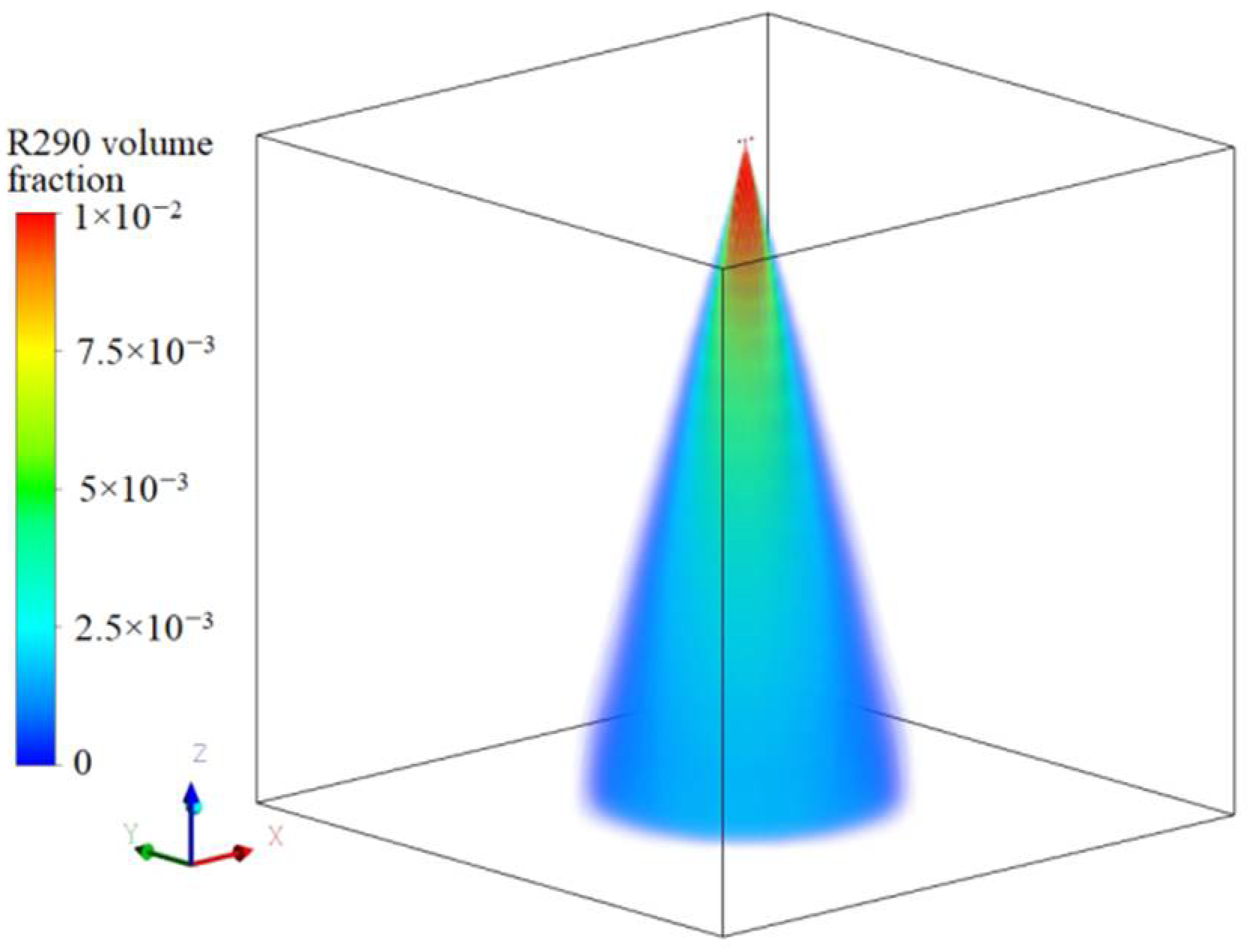

3.2. Concentration Distribution Characteristics of Leaked R290 in the Far-Field Flow Area

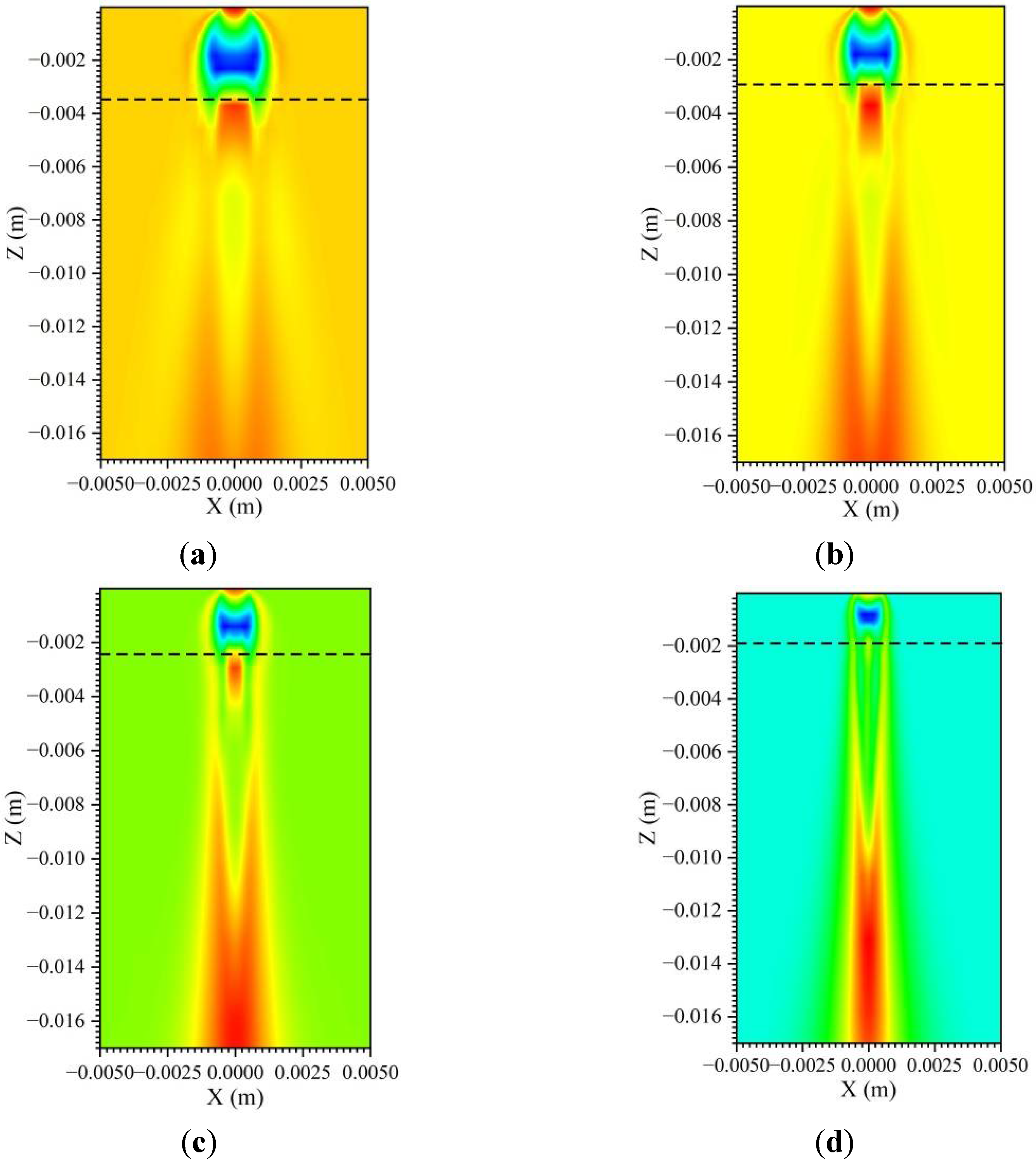

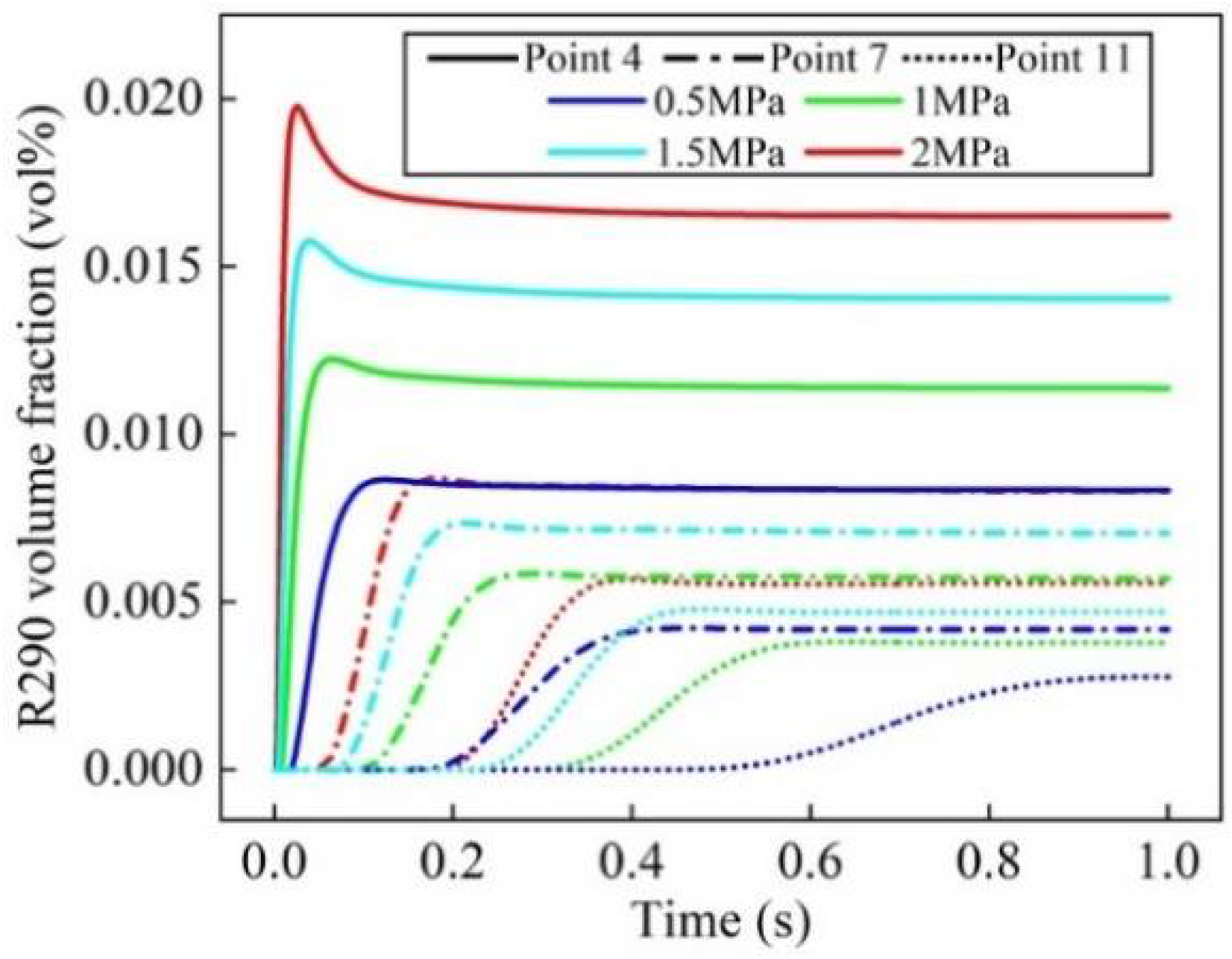

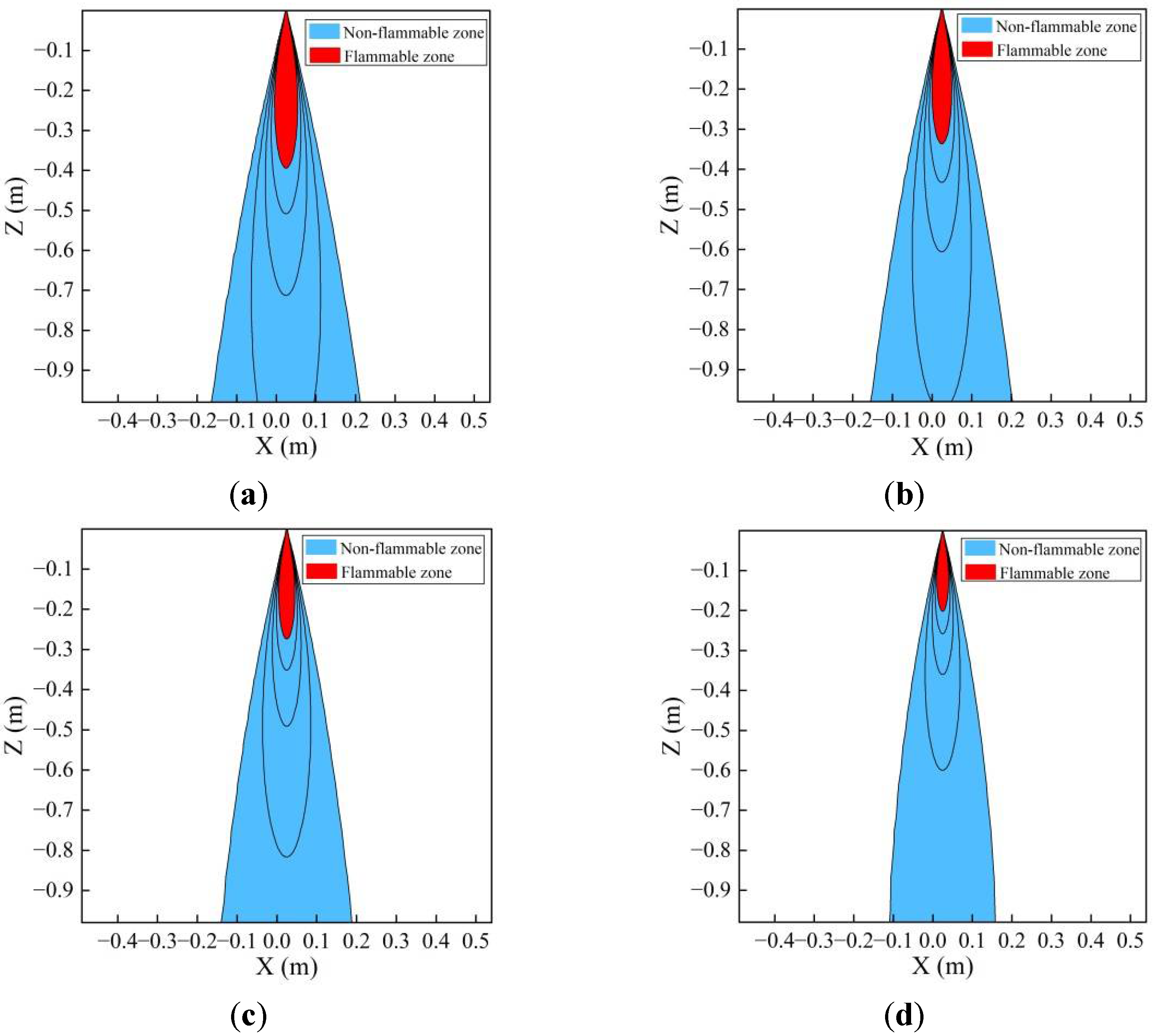

3.3. Effects of Different Initial Pressures on the Field Strength Characteristics of the Leaked R290

4. Conclusions

- (1)

- An improved gas leakage model suitable for describing refrigerant leakage in the refrigeration system was proposed, and the calculation results obtained by the improved model were compared with the experimental data from the published literature. The results found that the theoretical values of the position and circumferential diameter of the Mach disk and the concentration of the leaked gas were in good agreement with the experimental values, and the reliability of the improved gas leakage model was verified;

- (2)

- Based on the improved leakage model, the leakage and diffusion characteristics of R290 were analyzed. When the initial pressure was 2 MPa, the temperature was 360 K, the R290 gas continued to expand after it leaked into the external space, and its temperature and pressure decreased rapidly, reaching the minimum of 199.8 K and 0.013 MPa, respectively; its velocity increased rapidly, and the maximum reached 680.3 m/s. A Mach disk was formed in the flow area below the leakage hole, and the R290′s thermo-physical parameters changed abruptly through the Mach disk. After two consecutive expansion and compression processes, the temperature, pressure and the velocity of the R290 gas gradually decreased along the jet direction and, finally, the R290 gas returned to room temperature and normal pressure. In addition, the expansion and compression process of the leaked R290 gas in the local flow area caused the gas diffusion position to deviate away from the leakage hole, and the high concentration area formed by R290 increased. The formation of the Mach disk was not conducive to the diffusion of the leakage gas;

- (3)

- The initial leakage pressure had a great influence on the position and circumferential diameter of the Mach disk formed by the leaked gas. As the initial leakage pressure increased from 0.5 to 2 MPa, the distances from the Mach disk in the local flow area to the leakage hole were approximately 1.7, 2.3, 2.9 and 3.5 mm, and the circumferential diameters of the Mach disk increased accordingly. With the increase in the initial leakage pressure, the concentration response times of different measuring points were shortened (For example, the response times of the points 7 and 11 were shortened from 0.18 to 0.05 and 0.5 to 0.2 s, respectively). The flammable area formed by the leaked R290 in the external space slightly increased in the horizontal direction, the flammable area increased significantly in the vertical direction, and its ranges were within 0.2, 0.27, 0.34 and 0.4 m, and the flammable area was mainly concentrated in the local area below the leakage hole.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Q | leakage mass flow rate (kg s−1) |

| Aor | leak hole area (m2) |

| p | pressure (MPa) |

| T | temperature (K) |

| k | isentropic index |

| M | kilomolar mass (kg kmol−1) |

| R | gas constant (kJ kmol−1 K−1) |

| G | mass flow rate per cross-sectional area (kg m−2 s−1) |

| Z | compressible factor |

| f | friction coefficient of the pipe wall |

| D | pipe diameter (m) |

| Le | effective pipe length (m) |

| c | sound velocity (m s−1) |

| Ma | Mach number |

| cP | heat capacity (kJ kg−1 K−1) |

| kt | turbulent thermal conductivity (kW m−1 K−1) |

| Dt | turbulent mass diffusion coefficient (m2 s−1) |

| V | specific molar volume (m3 kmol−1) |

| g | acceleration of gravity (m s−2) |

| Greek symbols | |

| ξ | orifice loss coefficient |

| ρ | density (kg m−3) |

| μ | viscosity (kg m−1 s−1) |

| ω | mass fraction |

| σ | L-J characteristic length (angstrom) |

| Subscripts | |

| a | air |

| cr | critical |

| e | effective |

| r | refrigerant |

| t | turbulence |

| max | maximum |

| i, j | unit vector direction |

| ci | number of components |

References

- EPA GreenChill Best Practices Guidelines Commercial Refrigeration Retrofits, p6. Available online: https://www.epa.gov/greenchill/greenchill-best-practices-guidelines-commercial-refrigeration-retrofits (accessed on 8 May 2022).

- Francis, C.; Maidment, G.; Davies, G. An investigation of refrigerant leakage in commercial refrigeration. Int. J. Refrig. 2017, 74, 12–21. [Google Scholar] [CrossRef]

- Goetzler, W.; Burgos, J.; Loftus, P.J. Study of input parameters for risk assessment of 2L flammable refrigerants in residential air-conditioning and commercial refrigeration applications. ASHRAE Trans. 2014, 120, 437–448. Available online: https://eds.p.ebscohost.com/eds/pdfviewer/pdfviewer?vid=1&sid=e383e8f9-319c-4983-81b7-e7eec084fc98%40redis (accessed on 8 May 2022).

- Beshr, M.; Aute, V.; Sharma, V.; Abdelaziz, O.A.; Fricke, B.; RaderMacher, R. A comparative study on the environmental impact of supermarket refrigeration systems using low GWP refrigerants. Int. J. Refrig. 2015, 56, 154–164. [Google Scholar] [CrossRef]

- Kim, W.; Braun, J.E. Extension of a virtual refrigerant charge sensor. Int. J. Refrig. 2015, 55, 224–235. [Google Scholar] [CrossRef]

- Zaelke, D.; Borgford-Parnell, N. The importance of phasing down hydrofluorocarbons and other short-lived climate pollutants. J. Environ. Stud. Sci. 2015, 5, 75–169. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, B.; Ma, H.; Zhang, L.; Duan, C.; Liu, B.; Zhang, Y.; Chen, S.; Yang, Z. Analysis of lower GWP and flammable alternative refrigerants. Int. J. Refrig. 2021, 126, 12–22. [Google Scholar] [CrossRef]

- Gupta, S.; Pendyala, S. Flammability issue of hydrocarbons in air conditioning industry. Mater. Today Proc. 2020, 28, 2247–2250. [Google Scholar] [CrossRef]

- Levenspiel, O. Engineering Flow and Heat Exchange, 3rd ed.; Springer Science Business Media: New York, NY, USA, 2014; pp. 52–54. ISBN 978-1-4899-7453-2. [Google Scholar]

- Crowl, D.A.; Louvar, J.F. Chemical process safety: Fundamentals with applications. Ceskoslovenska Otolaryngol. 1990, 34, 169–175. [Google Scholar] [CrossRef]

- Montiel, H.; Vilchez, J.A.; Casal, J.; Arnaldos, J. Mathematical modelling of accidental gas releases. J. Hazard. Mater. 1998, 59, 211–233. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, F.; Lai, J. Steady leakage calculation model of non-isothermal long gas pipeline. J. Tianjin Univ. 2005, 38, 1115–1121. [Google Scholar] [CrossRef]

- Jo, Y.D.; Ahn, B.J. A simple model for the release rate of hazardous gas from a hole on high-pressure pipelines. J. Hazard. Mater. 2003, 97, 31–46. [Google Scholar] [CrossRef]

- Woodward, J.L.; Mudan, K.S. Liquid and gas discharge rates through holes in process vessels. J. Loss Prev. Process Ind. 1991, 4, 161–165. [Google Scholar] [CrossRef]

- Singh, M.; Patel, A.; Bajargaan, R. Study of a one-dimensional unsteady gas dynamic problem by adomian decomposition method. Int. J. Apllied Math. 2016, 29, 775–794. [Google Scholar] [CrossRef][Green Version]

- Olorunmaiye, J.A.; Imide, N.E. Computation of natural gas pipeline rupture problems using the method of characteristics. J. Hazard. Mater. 1993, 34, 81–98. [Google Scholar] [CrossRef]

- Moloudi, R.; Abolfazli Esfahani, J. Modeling of gas release following pipeline rupture: Proposing non-dimensional correlation. J. Loss Prev. Process Ind. 2014, 32, 207–217. [Google Scholar] [CrossRef]

- Colbourne, D.; Suen, K.O. Characterisation of a leak of flammable refrigerant within equipment enclosures. In Proceedings of the 11th IIR Gustav Lorentzen Conference on Natural Refrigerants, Hangzhou, China, 31 August–2 September 2014. [Google Scholar]

- Colbourne, D.; Suen, K.O. Minimum airflow rates to dilute R290 concentrations arising from leaks in room air conditioners. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Colbourne, D.; Suen, K.O. Minimum airflow rates to dilute A2L refrigerant leaks from refrigeration systems. In Proceedings of the 1st IIR International Conference on the Application of HFO Refrigerants, Birmingham, UK, 2–5 September 2018. [Google Scholar]

- Cai, D.; He, G.; Tang, W.; Huang, L. The simulation of the leaking distribution characteristics of R290 household air conditioner. In Proceedings of the 11th IIR Gustav Lorentzen Conference on Natural Refrigerants, Hangzhou, China, 31 August–2 September 2014. [Google Scholar]

- Ram Prakash, C.; Gautham, M.G.; Mohan Lal, D.; Devotta, S.; Colbourne, D. CFD simulation of HC-290 leakage from a split type room air conditioner. J. Process Mech. Eng. 2021, 235, 1989–1996. [Google Scholar] [CrossRef]

- Hu, M.; Li, J.; Liu, Z.; Li, T. Experimental and numerical simulation analysis of R-290 air conditioner leak. Int. J. Refrig. 2018, 90, 163–173. [Google Scholar] [CrossRef]

- He, G.; Hai, T.; Huang, L. The numerical simulation and analyse of leakage concentration of household air-conditioner using propane. In Proceedings of the 10th National Academic Exchange Conference on Refrigerators (Cabinets), Air Conditioners and Compressors, Qingdao, China, 29 July 2018. [Google Scholar]

- Li, Y.; Tao, J.; Han, Y.; Han, X.; Qin, J. Numerical and experimental study on the diffusion property of difluoromethane (HFC-32) in Leakage. Procedia Eng. 2014, 71, 34–43. [Google Scholar] [CrossRef][Green Version]

- Elatar, A.; Abu-Heiba, A.; Patel, V.; Edwards, K.; Baxter, V.; Abdelaziz, O.A.; Zhang, M. Evaluation of flammable volume in the case of a catastrophic leak of R-32 from a rooftop unit. Int. J. Refrig. 2018, 91, 39–45. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Liu, Y.; Huang, H.; Zhang, X.; Li, Z.; Yao, W. Influencing factors of flammable refrigerants leaking in building air- conditioning system. Procedia Eng. 2013, 62, 648–654. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Liu, Y.; Li, Z. Concentration distribution of leaking flammable refrigerants from building air conditioning system. J. Tsinghua Univ. (Sci. Technol.) 2013, 53, 1326–1333. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Y.; Zhang, H.; Yang, R.; Li, Z. Effects of ventilation intensity on leakage of flammable refrigerants of an air-conditioning System. J. Basic Sci. Eng. 2013, 21, 1157–1166. [Google Scholar] [CrossRef]

- Colbourne, D.; Suen, K.O. R290 concentrations arising from leaks in commercial refrigeration cabinets. In Proceedings of the 12th IIR Gustav Lorentzen Conference on Natural Refrigerants, Édimbourg, UK, 21–24 August 2016. [Google Scholar]

- Oreilly, H.; Kohoutek, T.; Crombie, D. An experimental and numerical study of refrigerant leaks in refrigerated transport containers. In Proceedings of the 1st IIR International Conference on the Application of HFO Refrigerants, Birmingham, UK, 2–5 September 2018. [Google Scholar]

- Oreilly, H.; Crombie, D.; Monaghan, R.F. Towards a comprehensive modelling framework for flammable refrigerant leaks in transport containers. In Proceedings of the 25th IIR International Congress of Refrigeration, Montreal, QC, Canada, 24–30 August 2019. [Google Scholar]

- Zhen, B.; Pang, J.; Yang, P.; Zhang, X. Simulation analysis of refrigerant leakage in R290 self-contained refrigerated display cabinet. J. Harbin Univ. Commer. (Nat. Sci. Ed.) 2021, 37, 50–59. [Google Scholar] [CrossRef]

- Peng, D.Y.; Robinson, D.B. A new two-constant equation of state. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Hippel, A.V. Molecular Engineering. Science 1956, 123, 315–317. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Hecht, E.; Christopher, D. Validation of a reduced-order jet model for subsonic and underexpanded hydrogen jets. Int. J. Hydrogen Energy 2016, 41, 1348–1358. [Google Scholar] [CrossRef]

| Model Leakage Process | The Current Hole Model | The Improved Gas Leakage Model | |

|---|---|---|---|

| The schematic figure |  |  | |

| Similarity | The transport process | The same model and solution method were used. | |

| Difference | The leakage process | The gas pressure at the outlet of the leakage section was directly assumed based on the given critical pressure ratio formula. | The relationship between the gas flow parameters and the flow section was established, and the gas state parameters at point two can be solved. |

| The expansion process | The change in the gas state parameters in the interval from the leakage port in the pipeline to the outer wall of the pipeline was ignored. | The expansion process of the gas in the leakage section was considered, and the state parameters of the gas at the outlet of the leakage section can be obtained. | |

| Measuring Point | Coordinates (m) | Measuring Point | Coordinates (m) |

|---|---|---|---|

| point 1 | (0.025, 0, 0) | point 7 | (0.025, 0, −1) |

| point 2 | (0.025, 0, −0.001) | point 8 | (−0.175, 0, −1) |

| point 3 | (0.025, 0, −0.01) | point 9 | (0.225, 0, −1) |

| point 4 | (0.025, 0, −0.5) | point 10 | (0.225, 0, −1.5) |

| point 5 | (−0.075, 0, −0.5) | point 11 | (0.025, 0, −1.5) |

| point 6 | (0.125, 0, −0.5) | point 12 | (−0.175, 0, −1.5) |

| Numerical Model | Method or Initial Value |

|---|---|

| Turbulence model | SST k-omega |

| Leakage gas | R290 |

| Density | |

| Viscosity | |

| Thermal conductivity | |

| Diffusion coefficient | |

| Initial leakage pressure P0 (MPa) | 0.5, 1, 1.5 and 2 |

| Initial leakage temperature T0 (K) | 360 |

| Pressure of the external space Pa (kpa) | 101.325 |

| Temperature of the external space Ta (K) | 300 |

| Solver | Pressure-based, transient |

| Solution method | Coupled |

| Models | Parameter | Pressure (MPa) | Temperature (K) | Velocity (m/s) |

|---|---|---|---|---|

| Initial leakage value | 1 | 300 | 0 | |

| Hole model | Critical leakage value | 0.53 | 249.32 | 1206.31 |

| Maximum leakage mass flow (g/s) | 0.48 | |||

| Improved leakage model | Leakage section outlet | 0.40 | 234.32 | 1371.85 |

| Leakage mass flow (g/s) | 0.41 | |||

| Initial leakage value | 3 | 300 | 0 | |

| Hole model | Critical leakage value | 1.58 | 249.04 | 1213.71 |

| Maximum leakage mass flow (g/s) | 1.44 | |||

| Improved leakage model | Leakage section outlet | 1.18 | 233.53 | 1381.14 |

| Leakage mass flow (g/s) | 1.24 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhou, P.; Zhuang, Y.; Wu, X.; Liu, Y.; Han, X.; Chen, G. An Improved Gas Leakage Model and Research on the Leakage Field Strength Characteristics of R290 in Limited Space. Appl. Sci. 2022, 12, 5657. https://doi.org/10.3390/app12115657

Li Y, Zhou P, Zhuang Y, Wu X, Liu Y, Han X, Chen G. An Improved Gas Leakage Model and Research on the Leakage Field Strength Characteristics of R290 in Limited Space. Applied Sciences. 2022; 12(11):5657. https://doi.org/10.3390/app12115657

Chicago/Turabian StyleLi, Yalun, Peixu Zhou, Yuan Zhuang, Xilei Wu, Ying Liu, Xiaohong Han, and Guangming Chen. 2022. "An Improved Gas Leakage Model and Research on the Leakage Field Strength Characteristics of R290 in Limited Space" Applied Sciences 12, no. 11: 5657. https://doi.org/10.3390/app12115657

APA StyleLi, Y., Zhou, P., Zhuang, Y., Wu, X., Liu, Y., Han, X., & Chen, G. (2022). An Improved Gas Leakage Model and Research on the Leakage Field Strength Characteristics of R290 in Limited Space. Applied Sciences, 12(11), 5657. https://doi.org/10.3390/app12115657