Mechanisms and Evolution of Cracks in Prestressed Concrete Sleepers Exposed to Time-Dependent Actions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fracture Analysis and Methods

2.2. Crack Simulation Methods

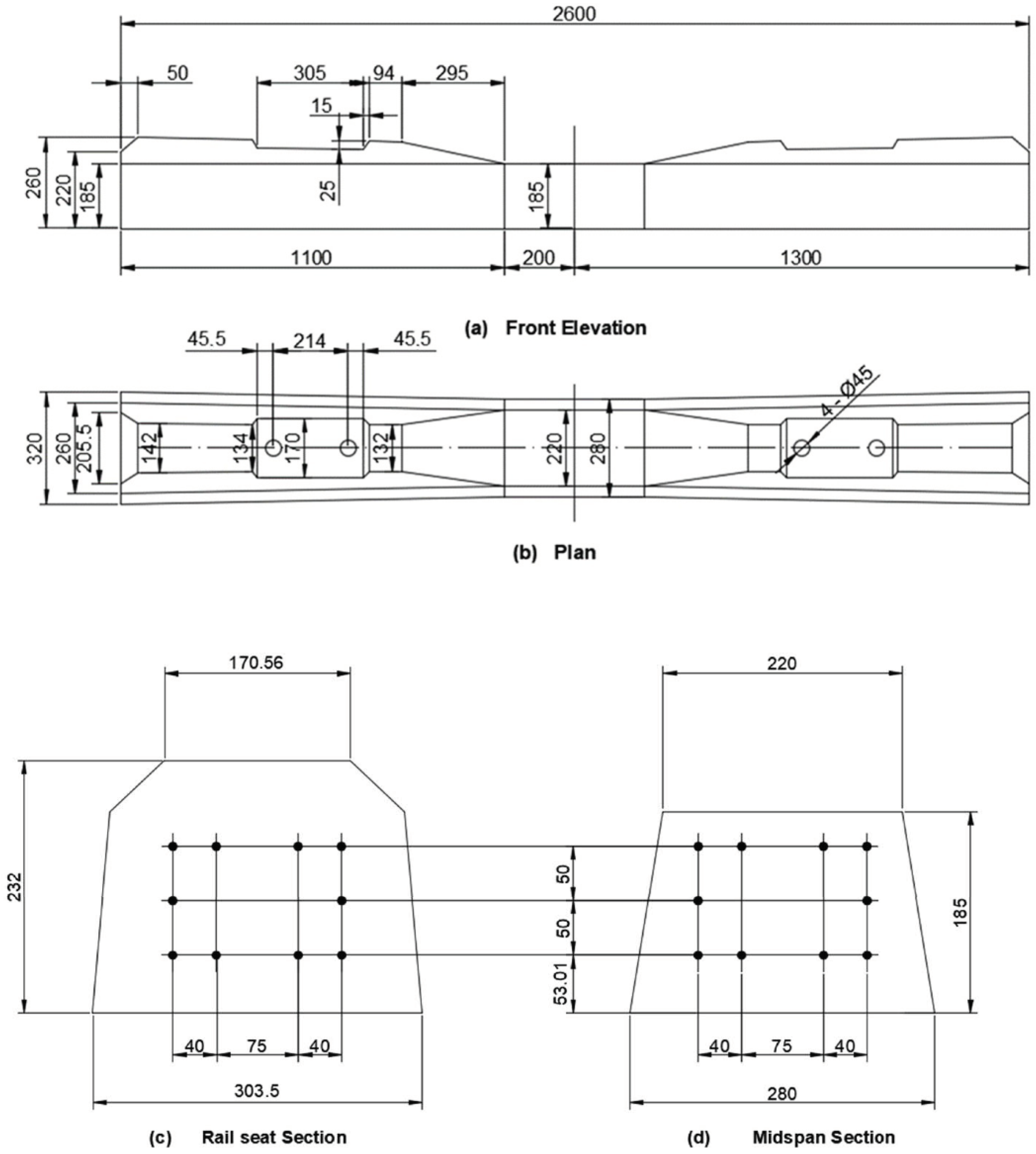

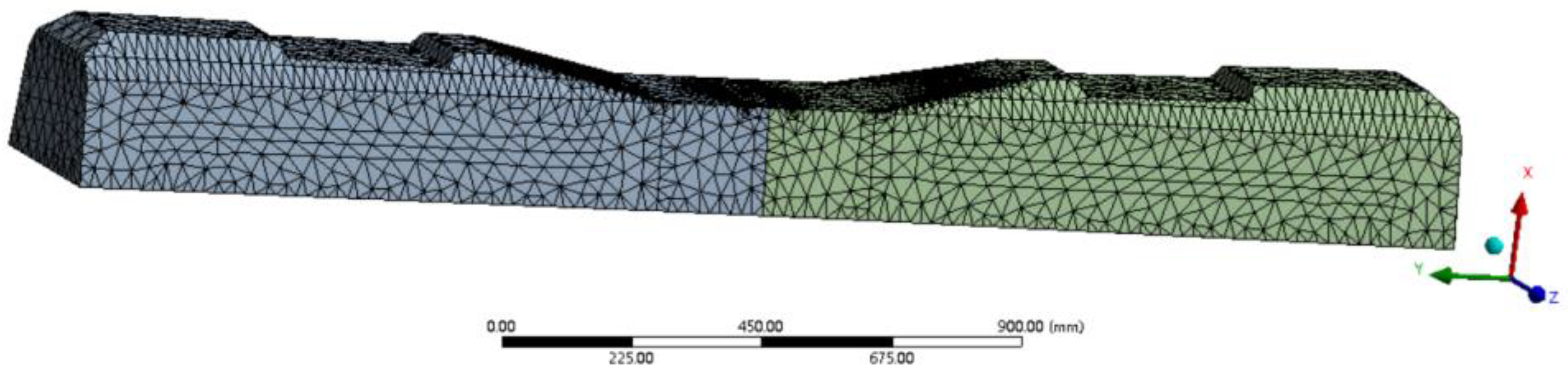

2.3. Geometric Details and Material Properties of the Prestressed Concrete Sleeper

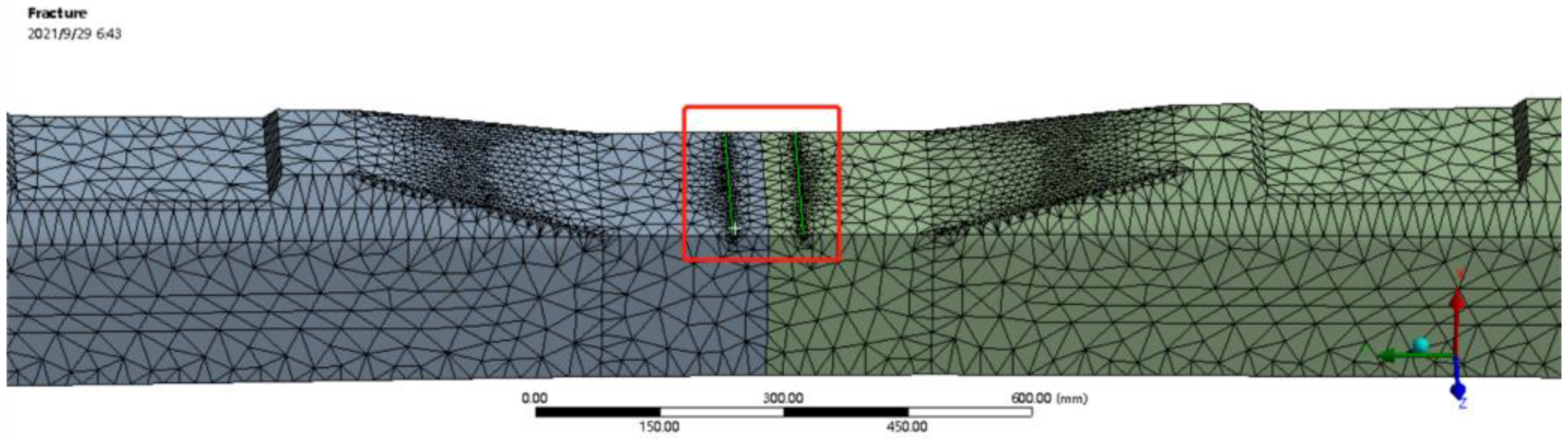

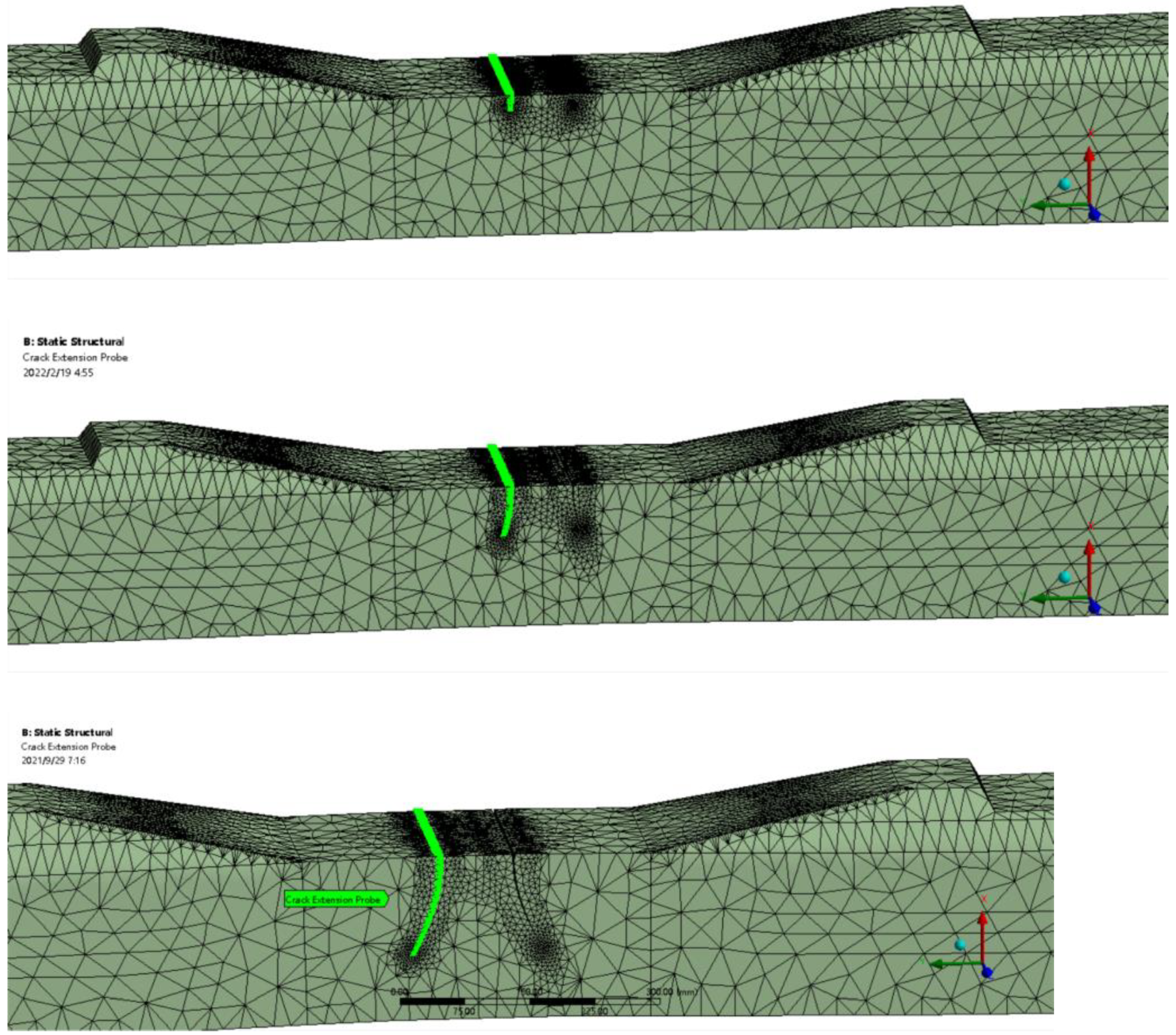

2.4. Crack Model

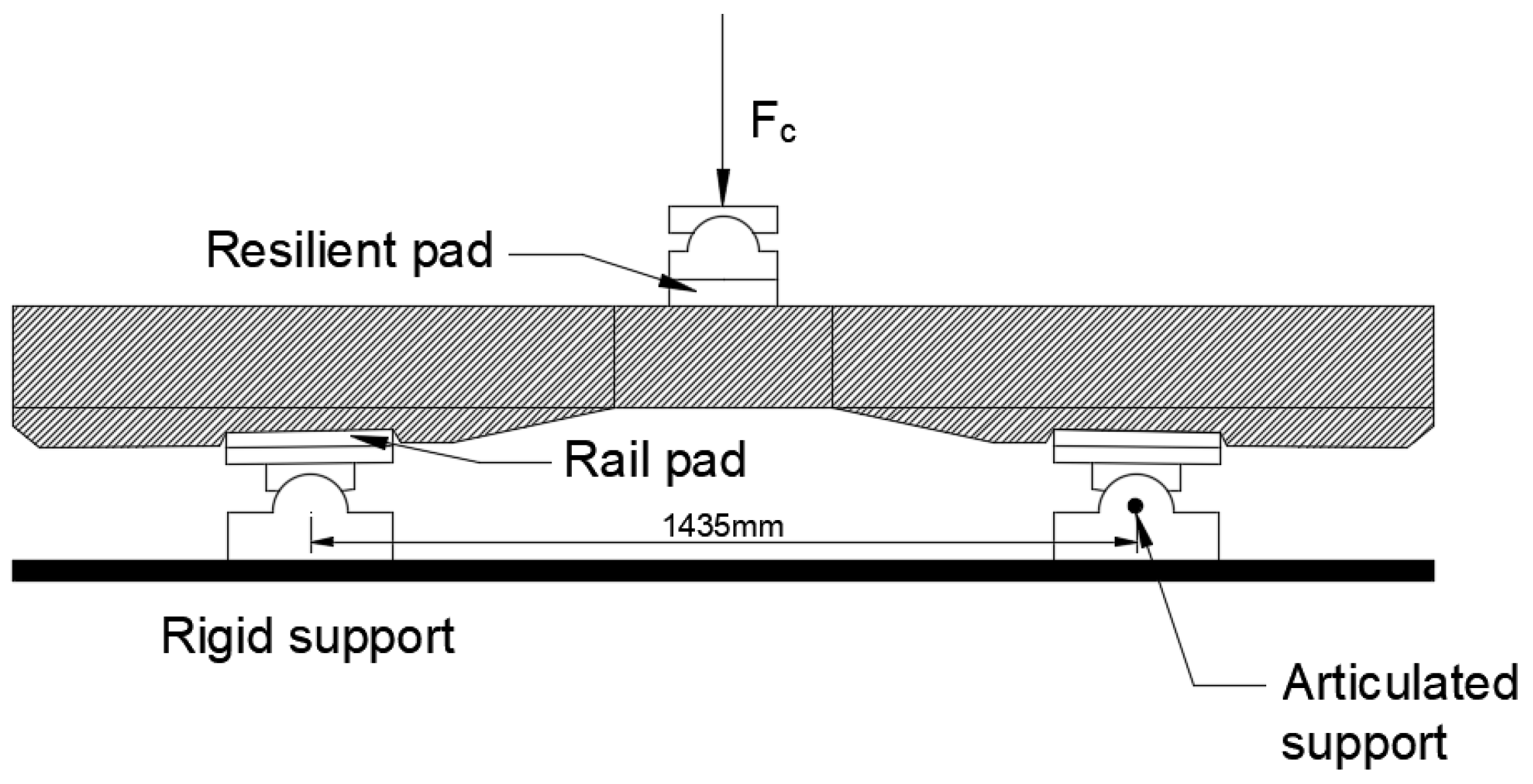

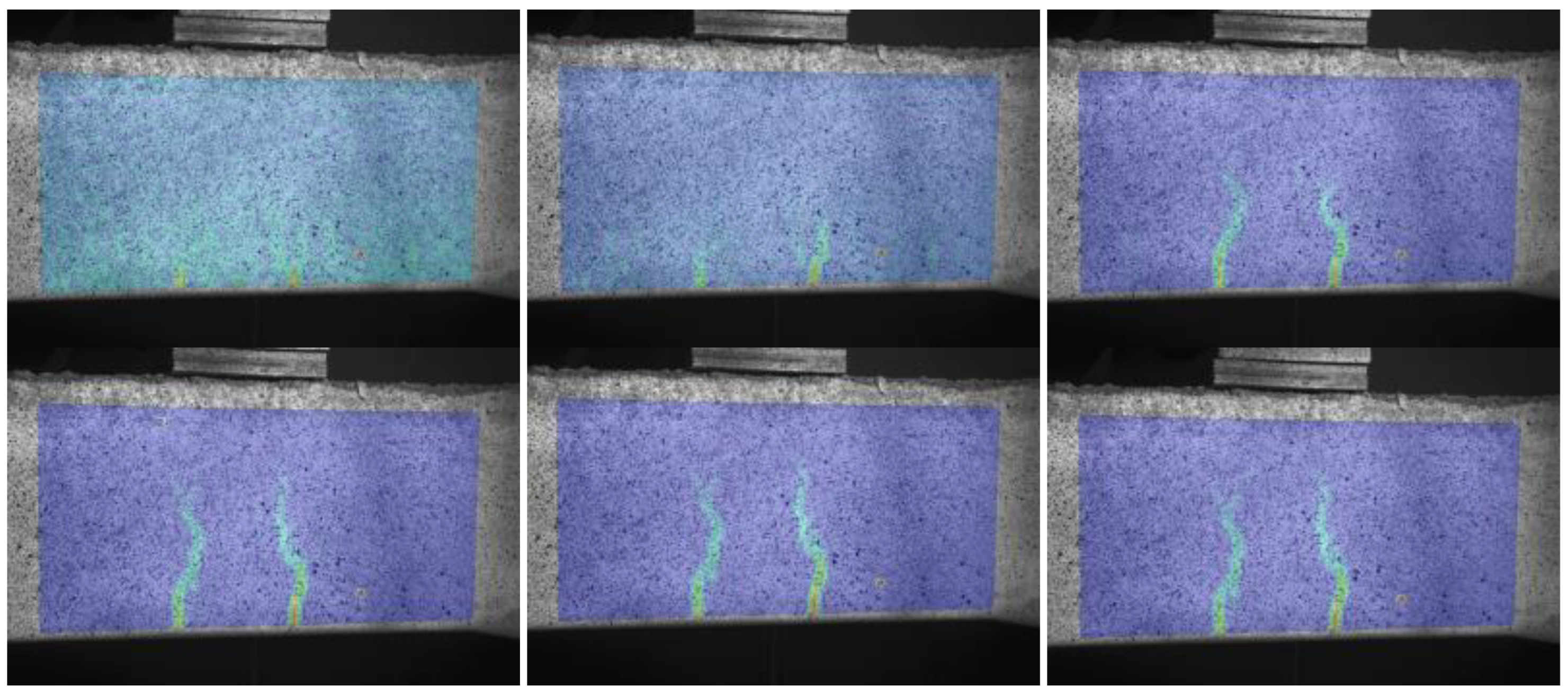

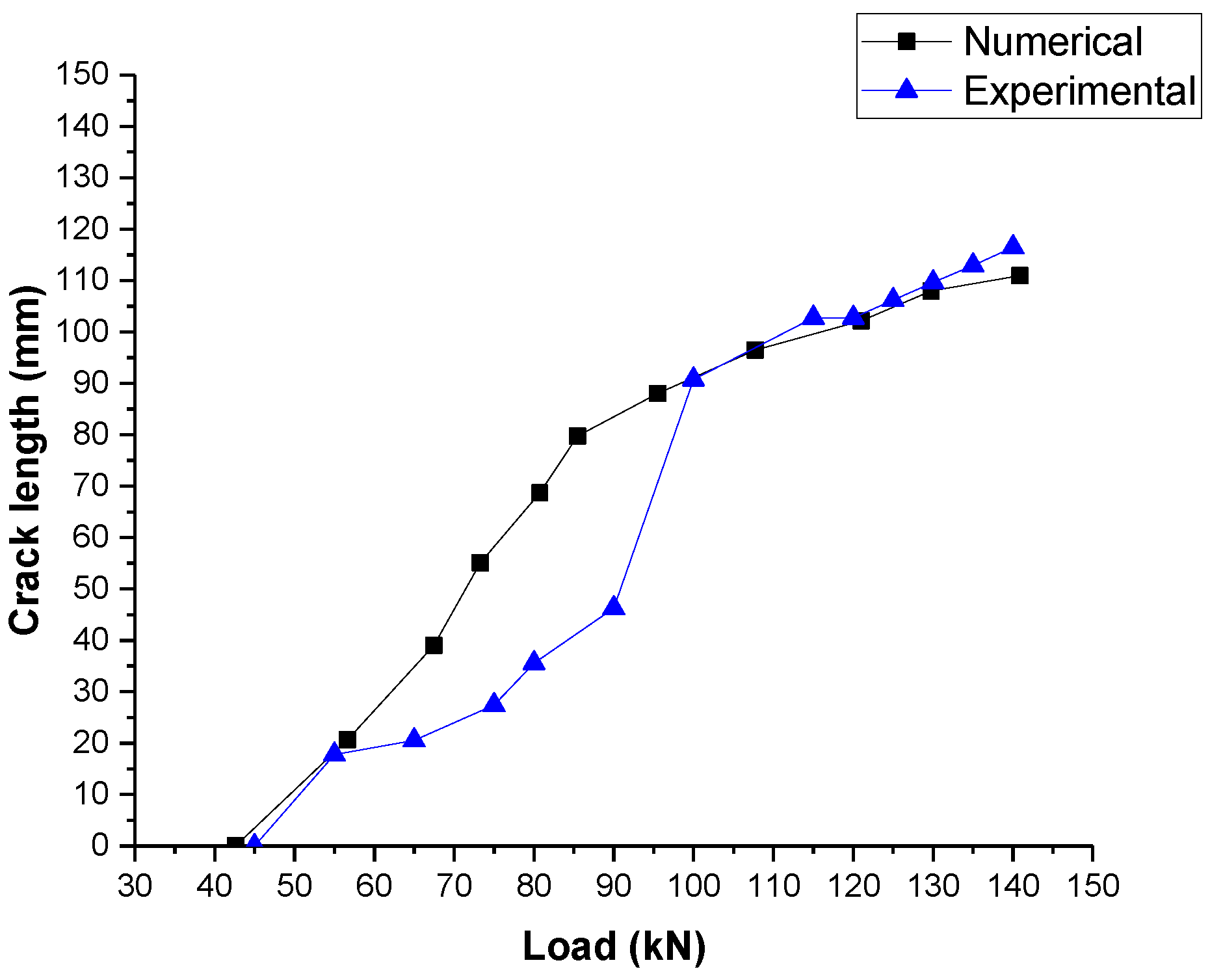

2.4.1. Experimental Test Results

2.4.2. Crack Model Validation

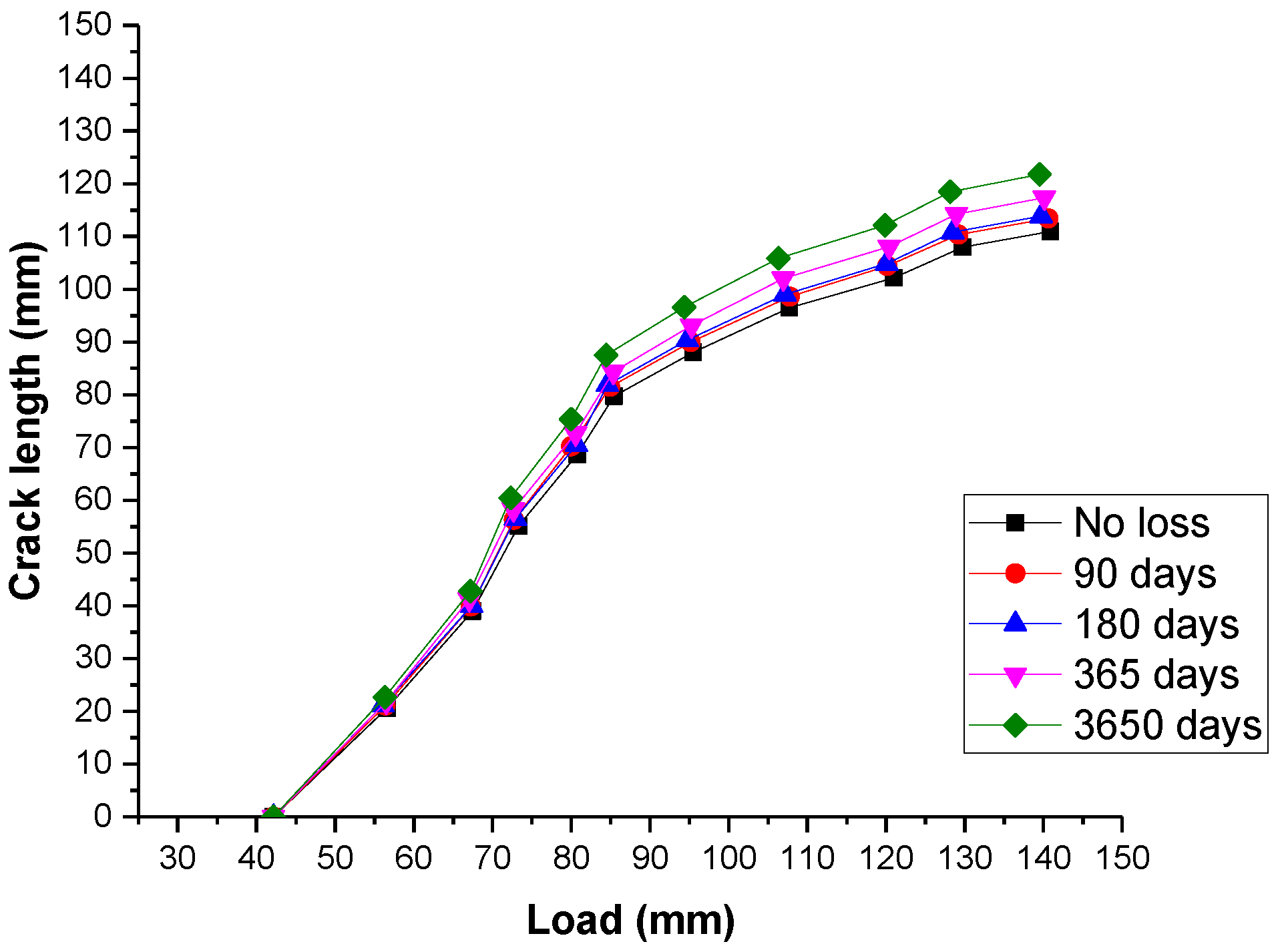

3. Crack Propagation Related to Time-Dependent Behaviour in Railway Sleepers

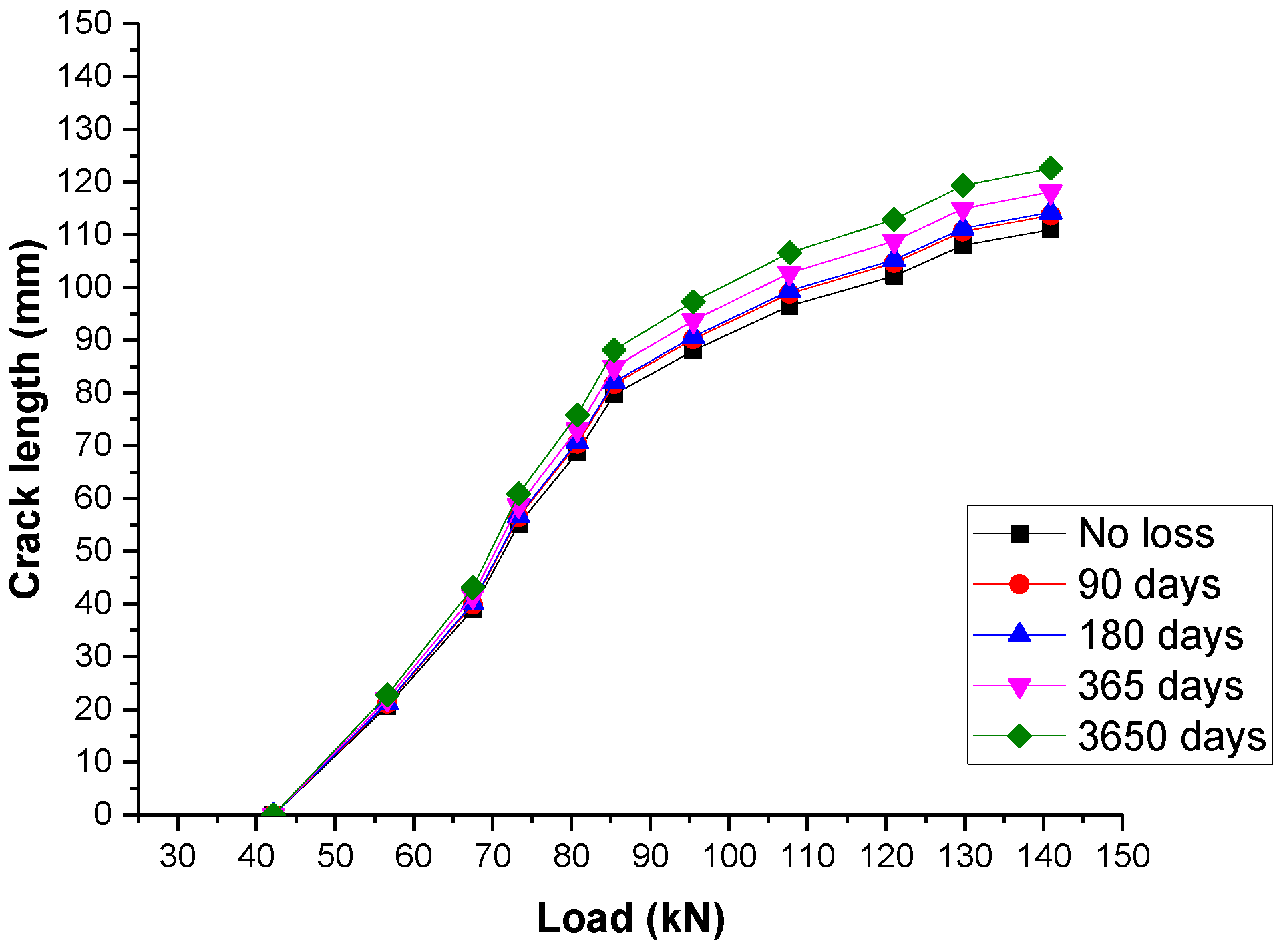

3.1. Crack Propagation Due to Creep

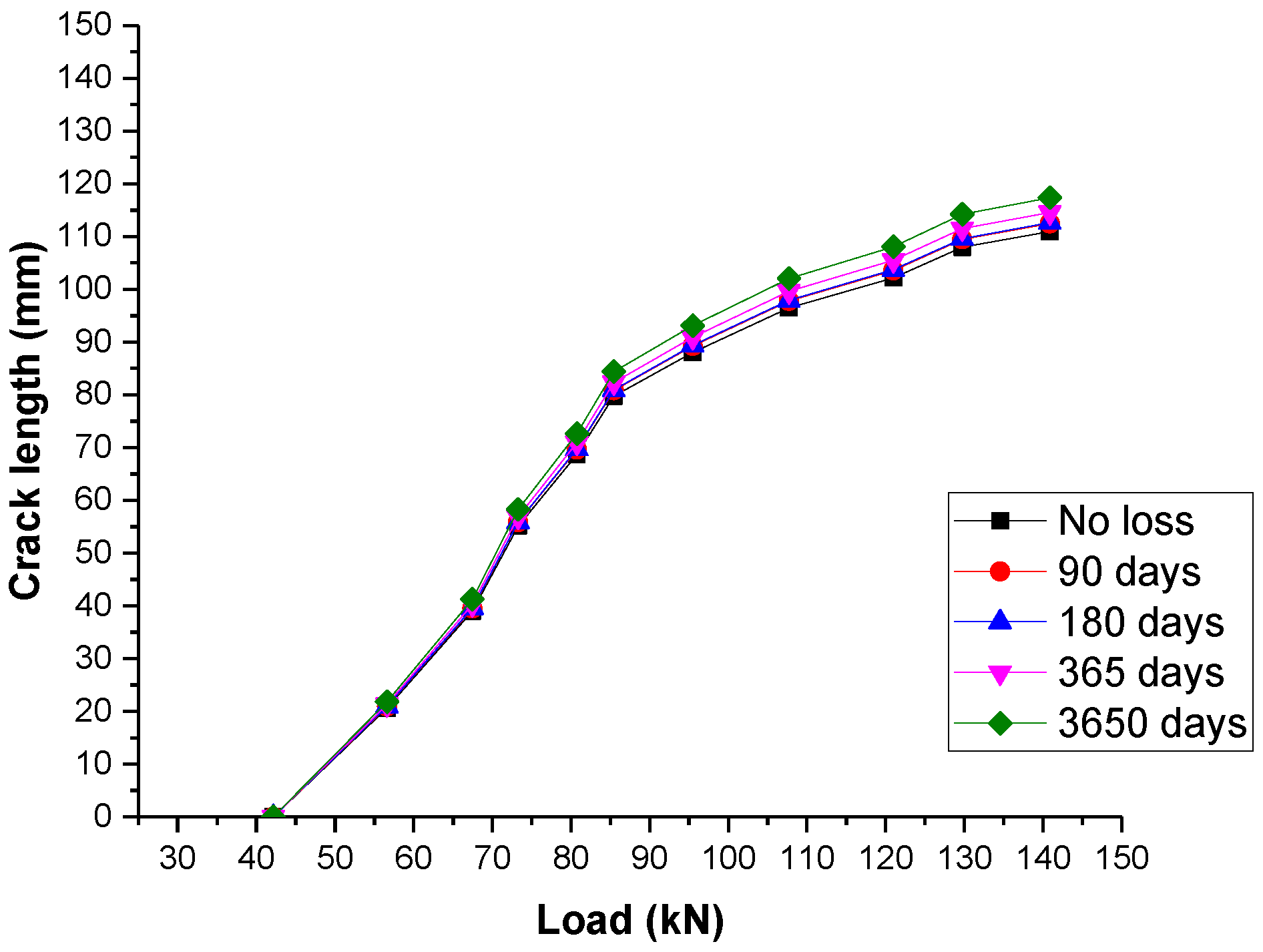

3.2. Crack Propagation Due to Shrinkage

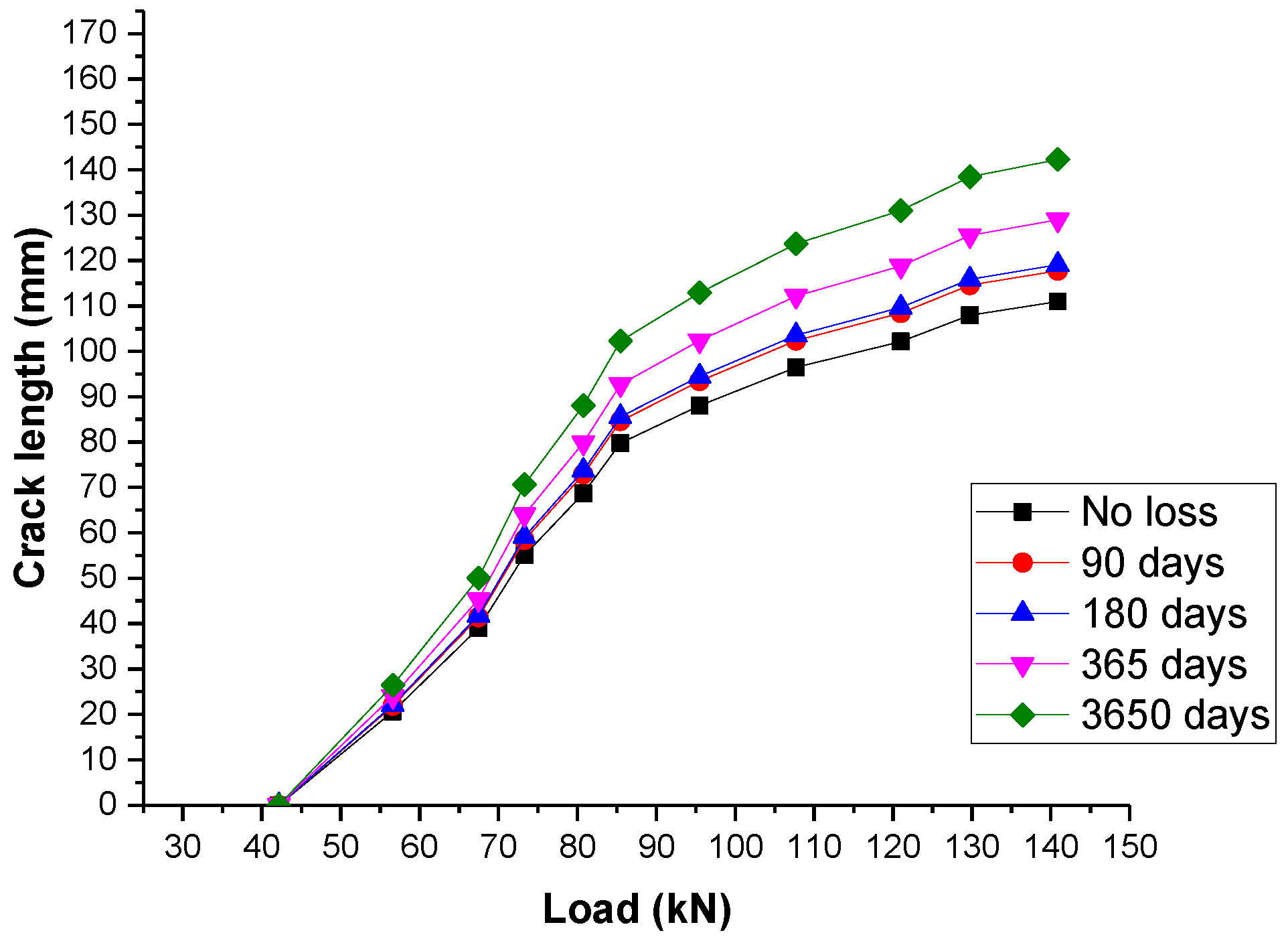

3.3. Crack Propagation Due to Relaxation

3.4. Discussion of Results

4. Conclusions

- A reasonable numerical crack model in accordance with fracture toughness theory was developed. The Separating Morphing and Adaptive Remeshing Technology (SMART) crack growth simulation method is used. This method indicates the mesh changes occur around the crack-front region only, leading to a computationally efficient solution of the crack-growth problem.

- Experimental and numerical results of crack propagation indicate the growth of cracks is sharp before 90 kN. After 90 kN, the growth of cracks slows. The structural performance of prestressed concrete sleepers is observed.

- Effects of time-dependent behaviour including creep, shrinkage and relaxation are considered in the crack propagation analysis. Loss of prestress due to time-dependent behaviour reduces crack resistance of prestressed concrete sleepers.

- It is found that the crack lengths in sleepers are greater over time subject to time-dependent behaviour under the same loads. In the long-term, this effect becomes more significant.

- Crack propagation subject to relaxation has less influence than creep and shrinkage. The effects of creep and shrinkage in crack propagation are similar to each other. This point demonstrates that the time-dependent behaviour of prestressed concrete sleepers in the concrete part has more influence than the tendon part.

- A combination of the effect of time-dependent behaviour severely reduces the crack resistance of railway sleepers. In the static capacity test, a 116 mm long crack length under 140 kN was regarded as a failure. However, in this research, crack resistance of the prestressed concrete sleeper subject to all those time-dependent behaviours decreases over time. According to the numerical results, failure can happen under 100 kN external loads over a 10-year service life.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taherinezhad, J.; Sofi, M.; Mendis, P.A.; Ngo, T.D. A review of behaviour of prestressed concrete sleepers. Electron. J. Struct. Eng. 2013, 13, 1–16. [Google Scholar]

- Li, D.; Kaewunruen, S.; You, R. Time-dependent behaviours of railway prestressed concrete sleepers in a track system. Eng. Fail. Anal. 2021, 127, 105500. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Remennikov, A.M. Impact capacity of railway prestressed concrete sleepers. Eng. Fail. Anal. 2009, 16, 1520–1532. [Google Scholar] [CrossRef]

- Esveld, C.; Esveld, C. Modern Railway Track; MRT-Productions: Zaltbommel, The Netherlands, 2001; Volume 385. [Google Scholar]

- Thun, H. Assessment of Fatigue Resistance and Strength in Existing Concrete Structures. Ph.D. Thesis, Luleå Tekniska Universitet, Luleå, Sweden, 2006. [Google Scholar]

- Remennikov, A.M.; Kaewunruen, S. Experimental load rating of aged railway concrete sleepers. Eng. Struct. 2014, 76, 147–162. [Google Scholar] [CrossRef] [Green Version]

- Van Dyk, B.J.; Dersch, M.S.; Edwards, J. International Concrete Crosstie and Fastening System Survey—Final Results; University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2012. [Google Scholar]

- Ferdous, W.; Manalo, A. Failures of mainline railway sleepers and suggested remedies—Review of current practice. Eng. Fail. Anal. 2014, 44, 17–35. [Google Scholar] [CrossRef]

- Van Hung, N.; Hung, V.V.; Viet, T.B. The effect of crack width on the service life of reinforced concrete structures. IOP Conf. Ser. Earth Environ. Sci. 2018, 143, 012044. [Google Scholar] [CrossRef]

- Murray, M.; Cai, Z. Literature Review on the Design of Railway Prestressed Concrete Sleeper. RSTA Research Report. 1998. Available online: https://ro.uow.edu.au/cgi/viewcontent.cgi?article=1382&context=engpapers&httpsredir=1&referer= (accessed on 12 February 2022).

- Kaewunruen, S. Experimental and Numerical Studies for Evaluating Dynamic Behaviour of Prestressed Concrete Sleepers Subject to Severe Impact Loading. Ph.D. Thesis, School of Civil, Mining & Environmental Engineering, University of Wollongong, Wollongong, Australia, 2007. [Google Scholar]

- Kaewunruen, S. Remennikov, A. Experimental and numerical studies of railway prestressed concrete sleepers under static and impact loads. Civ. Comput. 2007, 3, 25–28. [Google Scholar]

- Kaewunruen, S.; Remennikov, A. On the residual energy toughness of prestressed concrete sleepers in railway track structures subjected to repeated impact loads. Electron. J. Struct. Eng. 2013, 13, 41–61. [Google Scholar]

- Kaewunruen, S.; Remennikov, A.M.; Murray, M.H. Introducing a new limit states design concept to railway concrete sleepers: An Australian experience. Front. Mater. 2014, 1, 8. [Google Scholar] [CrossRef] [Green Version]

- Remennikov, A.M.; Kaewunruen, S. A review of loading conditions for railway track structures due to train and track vertical interaction. Struct. Control Health Monit. 2008, 15, 207–234. [Google Scholar] [CrossRef]

- Remennikov, A.; Murray, M.H.; Kaewunruen, S. Reliability-based conversion of a structural design code for railway prestressed concrete sleepers. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2012, 226, 155–173. [Google Scholar] [CrossRef] [Green Version]

- Domingo, L.M.; Martin, C.Z.; Avilés, C.P.; Herraiz, J.I.R. Analysis of the influence of cracked sleepers under static loading on ballasted railway tracks. Sci. World J. 2014, 2014, 363547. [Google Scholar]

- Bakharev, T.; Struble, L. Microstructural features of railseat deterioration in concrete ties. J. Mater. Civ. Eng. 1997, 9, 146–153. [Google Scholar] [CrossRef]

- Remennikov, A.; Kaewunruen, S. Resistance of railway concrete sleepers to impact loading. In Proceedings of the 7th International Conference on Shock and Impact Loads on Structures, Beijing, China, 17–19 October 2007; pp. 489–496. [Google Scholar]

- Zakeri, J.A.; Sadeghi, J. Field investigation on load distribution and deflections of railway track sleepers. J. Mech. Sci. Technol. 2007, 21, 1948–1956. [Google Scholar] [CrossRef]

- Sadeghi, J.; Barati, P. Comparisons of the mechanical properties of timber, steel and concrete sleepers. Struct. Infrastruct. Eng. 2012, 8, 1151–1159. [Google Scholar] [CrossRef]

- Li, D.; Kaewunruen, S.; Robery, P.; Remennikov, A. Creep and Shrinkage Models for Railway Prestressed Concrete Sleepers: A review. In Proceedings of the 15th East-Asia Pacific Conference on Structural Engineering and Construction: Railway Infrastructure, Xi’an, China, 11–13 October 2017. [Google Scholar]

- Li, D.; Kaewunruen, S.; Robery, P.; Remennikov, A. Long-Term Behaviours of Railway Prestressed Concrete Sleepers Due to Shortening Parameters. In Proceedings of the 15th East-Asia Pacific Conference on Structural Engineering and Construction: Railway Infrastructure, Xi’an, China, 11–13 October 2017. [Google Scholar]

- Li, D.; Kaewunruen, S.; Robery, P.; Remennikov, A.M. Parametric Studies Into Creep and Shrinkage Characteristics in Railway Prestressed Concrete Sleepers. Front. Built Environ. 2020, 6, 130. [Google Scholar] [CrossRef]

- Li, D.; Kaewunruen, S.; Robery, P.; Remennikov, A.M. Creep and Shrinkage Effects on Railway Prestressed Concrete Sleepers. In ICRT 2017: Railway Development, Operations, and Maintenance; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 394–405. [Google Scholar]

- Jokūbaitis, A.; Valivonis, J.; Marčiukaitis, G. Analysis of strain state and cracking of cocnrete sleepers. J. Civ. Eng. Manag. 2016, 22, 564–572. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Kaewunruen, S. Effect of extreme climate on topology of railway prestressed concrete sleepers. Climate 2019, 7, 17. [Google Scholar] [CrossRef] [Green Version]

- Rezaie, F.; Shiri, M.; Farnam, S. Experimental and numerical studies of longitudinal crack control for pre-stressed concrete sleepers. Eng. Fail. Anal. 2012, 26, 21–30. [Google Scholar] [CrossRef]

- Tehrani, F.M.; Serrano, R.M. Crack propagation of concrete beams prestressed with single strand tendons. J. Civ. Eng. Res. 2014, 4, 71–81. [Google Scholar]

- Farnam, S.; Rezaie, F. Simulation of crack propagation in prestressed concrete sleepers by fracture mechanics. Eng. Fail. Anal. 2019, 96, 109–117. [Google Scholar] [CrossRef]

- Jing, G.; Yunchang, D.; You, R.; Siahkouhi, M. Comparison study of crack propagation in rubberized and conventional prestressed concrete sleepers using digital image correlation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2021, 09544097211020595. [Google Scholar] [CrossRef]

- Ansys; Release 18.1; ANSYS® Academic Research Mechanical: Canonsburg, PA, USA, 2018.

- Kulakov, P.; Kutlubulatov, B.; Rubtsov1, A.; Mukhametzyanov, Z.; Afanasenko, V. The Assessment of Impact of the Crack Size on the Fracture Load of a Cylindrical Element. In Proceedings of the CEUR Workshop, Krasnoyarsk, Russia, 28 May 2021. [Google Scholar]

- Edwards, J.R.; Gao, Z.; Wolf, H.E.; Dersch, M.S.; Qian, Y. Quantification of concrete railway sleeper bending moments using surface strain gauges. Measurement 2017, 111, 197–207. [Google Scholar] [CrossRef]

- Van Dyk, B. Characterization of the Loading Environment for Shared-Use Railway Superstructure in North America. Master’s Thesis, University of Illinois at Urbana, Champaign, IL, USA, 2015. [Google Scholar]

- EN 13230-2; Railway Applications-Track-Concrete Sleepers and Bearers Part 2: Prestressed Monoblock Sleepers. European Standards: Brussels, Belgium, 2009.

- Huang, C.H.; Wu, C.H.; Lin, S.K.; Yen, T. Effect of slag particle size on fracture toughness of concrete. Appl. Sci. 2019, 9, 805. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Kaewunruen, S.; Robery, P. Early-Age Responses of Railway Prestressed Concrete Sleepers to Creep and Shrinkage. In Proceedings of the 2nd International RILEM/COST Conference on Early Age Cracking and Serviceability, Brussels, Belgium, 12–14 September 2017. [Google Scholar]

- Li, D.; Ngamkhanong, C.; Kaewunruen, S. Time-dependent topology of railway prestressed concrete sleepers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032046. [Google Scholar] [CrossRef]

- Li, D.; Ngamkhanong, C.; Kaewunruen, S. Influence of surface abrasion on creep and shrinkage of railway prestressed concrete sleepers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032040. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Ngamkhanong, C.; Kaewunruen, S. Influence of vertical holes on creep and shrinkage of railway prestressed concrete sleepers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 236, 012042. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sussman, J.M.; Matsumoto, A. Grand challenges in transportation and transit systems. Front. Built Environ. 2016, 2, 4. [Google Scholar] [CrossRef] [Green Version]

| Main Causes | Problems | Worldwide Response |

|---|---|---|

| Lateral load | Abrasion on rail-seat | 3.15 |

| Shoulder/fastening system wear or fatigue | 5.5 | |

| Vertical dynamic load | Cracking from dynamic loads | 5.21 |

| Derailment damage | 4.57 | |

| Cracking from centre binding | 5.36 | |

| Manufacturing and maintenance defects | Tamping damage | 6.14 |

| Others (e.g., manufactured defects) | 4.09 | |

| Environmental considerations | Cracking from environmental or chemical degradation | 4.67 |

| Material Properties | Basic Variables | Value |

|---|---|---|

| Concrete | Density | 2400 kg/m3 |

| Mean compressive strength | 65 MPa | |

| Tensile strength | 5.64 MPa | |

| Modulus of elasticity | 33 GPa | |

| Passion’s ratio | 0.23 | |

| Prestressing tendons | Density | 9800 kg/m3 |

| Yield strength of tendons | 1570 MPa | |

| Modulus of elasticity | 200 GPa | |

| Prestressing force | 420 kN | |

| Passion’s ratio | 0.30 |

| Load (kN) | Crack Length-1 (mm) | Crack Length-2 (mm) |

|---|---|---|

| 45 | 0 | 0 |

| 55 | 18 | 43 |

| 65 | 21 | 48 |

| 75 | 27 | 51 |

| 80 | 36 | 60 |

| 90 | 46 | 82 |

| 100 | 91 | 84 |

| 115 | 100 | 110 |

| 120 | 103 | 116 |

| 125 | 106 | 120 |

| 130 | 110 | 123 |

| 135 | 112 | 127 |

| 140 | 116 | 130 |

| Time | Creep Loss | Shrinkage Loss | Relaxation Loss | Total Loss | ||||

|---|---|---|---|---|---|---|---|---|

| (days) | (kN) | (%) | (kN) | (%) | (kN) | (%) | (kN) | (%) |

| 90 | 13.02 | 3.10 | 14.56 | 3.46 | 8.13 | 1.94 | 35.71 | 8.50 |

| 180 | 15.65 | 3.73 | 17.68 | 4.21 | 9.06 | 2.16 | 42.38 | 10.09 |

| 365 | 18.03 | 4.29 | 19.91 | 4.74 | 10.11 | 2.41 | 48.06 | 11.45 |

| 3650 | 22.08 | 5.26 | 22.29 | 5.31 | 14.48 | 3.45 | 58.86 | 14.01 |

| Loss of Prestress Due to Time-Dependent Behaviour in Days | No Loss | 90 | 180 | 365 | 3650 |

|---|---|---|---|---|---|

| Creep | 110.96 | 113.39 | 113.89 | 117.36 | 121.76 |

| Shrinkage | 110.96 | 113.68 | 114.27 | 118.13 | 122.60 |

| Relaxation | 110.96 | 112.49 | 112.64 | 114.57 | 117.37 |

| Combination of creep, shrinkage and relaxation | 110.96 | 117.76 | 119.08 | 129.00 | 142.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; You, R.; Kaewunruen, S. Mechanisms and Evolution of Cracks in Prestressed Concrete Sleepers Exposed to Time-Dependent Actions. Appl. Sci. 2022, 12, 5511. https://doi.org/10.3390/app12115511

Li D, You R, Kaewunruen S. Mechanisms and Evolution of Cracks in Prestressed Concrete Sleepers Exposed to Time-Dependent Actions. Applied Sciences. 2022; 12(11):5511. https://doi.org/10.3390/app12115511

Chicago/Turabian StyleLi, Dan, Ruilin You, and Sakdirat Kaewunruen. 2022. "Mechanisms and Evolution of Cracks in Prestressed Concrete Sleepers Exposed to Time-Dependent Actions" Applied Sciences 12, no. 11: 5511. https://doi.org/10.3390/app12115511

APA StyleLi, D., You, R., & Kaewunruen, S. (2022). Mechanisms and Evolution of Cracks in Prestressed Concrete Sleepers Exposed to Time-Dependent Actions. Applied Sciences, 12(11), 5511. https://doi.org/10.3390/app12115511