Mathematical Description of Changes of Dried Apple Characteristics during Their Rehydration

Abstract

:1. Introduction

- mathematical description of changes of dried apples characteristics (mass gain, volume increase, dry matter loss, rehydration indices, and colour) during their rehydration;

- application of the empirical models used in the literature, ANNs, and models not yet used for the description of the rehydration process;

- development of equations to calculate the constants of applied rehydration models;

- investigation of the effect of drying and rehydration conditions on changes of dried apple characteristics.

2. Materials and Methods

- for slices, L = s;

- for cubes, L−2 = 3 s−2;

- for the mass gain and the volume increase

- for the dry matter loss.

- for the Peleg model

- for the Pilosof–Boquet–Batholomai model

- for the Singh and Kulshrestha model

+ a8Tr2 + a9Tdvd + a10TdL + a11TdTr + a12vdL + a13vdTr + a14LTr,

- Index RI1 (in kgreh/kgdry):

- Index RI2 (in kgreht/kgraw):

- water absorption capacity WAC:

3. Results and Discussion

- for lightness L*

- for yellowness b*

- for hue angle h*

- for chroma C*

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rasooli Sharabiani, V.; Kaveh, M.; Abdi, R.; Szymanek, M.; Tanaś, W. Estimation of Moisture Ratio for Apple Drying by Convective and Microwave Methods Using Artificial Neural Network Modeling. Sci. Rep. 2021, 11, 12. [Google Scholar] [CrossRef] [PubMed]

- Boy, V.; Mlayah, S.; Giblaine, M.; Lemée, Y.; Lanoisellé, J.L. A Case Study of Turbulent Free Jet Flows Issuing from Rectangular Slots on Process Performances and Quality of Hot-Air-Dried Apple. Processes 2021, 9, 1900. [Google Scholar] [CrossRef]

- Rojas-Graü, M.A.; Soliva-Fortuny, R.; Martín-Belloso, O. Effect of Natural Antibrowning Agents on Color and Related Enzymes in Fresh-Cut Fuji Apples as an Alternative to the Use of Ascorbic Acid. J. Food Sci. 2008, 73, 267–272. [Google Scholar] [CrossRef] [PubMed]

- Guz, T.; Rydzak, L.; Domin, M. Influence of Selected Parameters and Different Methods of Implementing Vacuum Impregnation of Apple Tissue on Its Effectiveness. Processes 2020, 8, 428. [Google Scholar] [CrossRef] [Green Version]

- Tulej, W.; Głowacki, S. Modeling of the Drying Process of Apple Pomace. Appl. Sci. 2022, 12, 1434. [Google Scholar] [CrossRef]

- Arendse, W.; Jideani, V. Effects of Some Weak Acids and Moringa Oleifera Leaf Extract Powder on the Colour of Dried Apple. Processes 2022, 10, 206. [Google Scholar] [CrossRef]

- Royen, M.J.; Noori, A.W.; Haydary, J. Experimental Study and Mathematical Modeling of Convective Thin-Layer Drying of Apple Slices. Processes 2020, 8, 1562. [Google Scholar] [CrossRef]

- Ghanem, N.; Mihoubi, D.; Bonazzi, C.; Kechaou, N.; Boudhrioua, N. Drying Characteristics of Lemon By-Product (Citrus Limon. v. Lunari): Effects of Drying Modes on Quality Attributes Kinetics’. Waste Biomass Valorization 2020, 11, 303–322. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Fatemi, H.; Khalife, E.; Witrowa-Rajchert, D.; Nowacka, M. Effect of Pretreatments on Convective and Infrared Drying Kinetics, Energy Consumption and Quality of Terebinth. Appl. Sci. 2021, 11, 7672. [Google Scholar] [CrossRef]

- Sagar, V.R.; Suresh Kumar, P. Recent Advances in Drying and Dehydration of Fruits and Vegetables: A Review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [Green Version]

- Ertekin, C.; Firat, M.Z. A Comprehensive Review of Thin-Layer Drying Models Used in Agricultural Products. Crit. Rev. Food Sci. Nutr. 2017, 57, 701–717. [Google Scholar] [CrossRef] [PubMed]

- Menon, A.; Stojceska, V.; Tassou, S.A. A Systematic Review on the Recent Advances of the Energy Efficiency Improvements in Non-Conventional Food Drying Technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Dadan, M.; Nowacka, M. The Assessment of the Possibility of Using Ethanol and Ultrasound to Design the Properties of Dried Carrot Tissue. Appl. Sci. 2021, 11, 689. [Google Scholar] [CrossRef]

- Chupawa, P.; Gaewsondee, T.; Duangkhamchan, W. Drying Characteristics and Quality Attributes Affected by a Fluidized-Bed Drying Assisted with Swirling Compressed-Air for Preparing Instant Red Jasmine Rice. Processes 2021, 9, 1738. [Google Scholar] [CrossRef]

- Jeevarathinam, G.; Pandiselvam, R.; Pandiarajan, T.; Preetha, P.; Balakrishnan, M.; Thirupathi, V.; Kothakota, A. Infrared Assisted Hot Air Dryer for Turmeric Slices:Effect on Drying Rate and Quality Parameters. LWT 2021, 144, 111258. [Google Scholar] [CrossRef]

- Jeevarathinam, G.; Pandiselvam, R.; Pandiarajan, T.; Preetha, P.; Krishnakumar, T.; Balakrishnan, M.; Thirupathi, V.; Ganapathy, S.; Amirtham, D. Design, Development, and Drying Kinetics of Infrared-assisted Hot Air Dryer for Turmeric Slices. J. Food Process Eng. 2021, e13876. [Google Scholar] [CrossRef]

- Delfiya, D.S.A.; Prashob, K.; Murali, S.; Alfiya, P.V.; Samuel, M.P.; Pandiselvam, R. Drying Kinetics of Food Materials in Infrared Radiation Drying: A Review. J. Food Process Eng. 2021, e13810. [Google Scholar] [CrossRef]

- Pravitha, M.; Manikantan, M.R.; Ajesh Kumar, V.; Beegum, S.; Pandiselvam, R. Optimization of Process Parameters for the Production of Jaggery Infused Osmo-Dehydrated Coconut Chips. LWT 2021, 146, 111441. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Tak, Y.; Olum, E.; Sujayasree, O.J.; Tekgül, Y.; Çalışkan Koç, G.; Kaur, M.; Nayi, P.; Kothakota, A.; Kumar, M. Advanced Osmotic Dehydration Techniques Combined with Emerging Drying Methods for Sustainable Food Production: Impact on Bioactive Components, Texture, Color, and Sensory Properties of Food. J. Texture Stud. 2021, 26. [Google Scholar] [CrossRef]

- Srinivas, Y.; Mathew, S.M.; Kothakota, A.; Sagarika, N.; Pandiselvam, R. Microwave Assisted Fluidized Bed Drying of Nutmeg Mace for Essential Oil Enriched Extracts: An Assessment of Drying Kinetics, Process Optimization and Quality. Innov. Food Sci. Emerg. Technol. 2020, 66, 102541. [Google Scholar] [CrossRef]

- Zhang, Y.; Pandiselvam, R.; Zhu, H.; Su, D.; Wang, H.; Ai, Z.; Kothakota, A.; Khaneghah, A.M.; Liu, Y. Impact of Radio Frequency Treatment on Textural Properties of Food Products: An Updated Review. Trends Food Sci. Technol. 2022, 124, 154–166. [Google Scholar] [CrossRef]

- Maldonado, S.; Arnau, E.; Bertuzzi, M.A. Effect of Temperature and Pretreatment on Water Diffusion during Rehydration of Dehydrated Mangoes. J. Food Eng. 2010, 96, 333–341. [Google Scholar] [CrossRef]

- Moreira, R.; Chenlo, F.; Chaguri, L.; Fernandes, C. Water Absorption, Texture, and Color Kinetics of Air-Dried Chestnuts during Rehydration. J. Food Eng. 2008, 86, 584–594. [Google Scholar] [CrossRef]

- Giraldo, G.; Vázquez, R.; Martín-Esparza, M.; Chiralt, A. Rehydration Kinetics and Soluble Solids Lixiviation of Candied Mango Fruit as Affected by Sucrose Concentration. J. Food Eng. 2006, 77, 825–834. [Google Scholar] [CrossRef]

- Silva, B.G.; Fileti, A.M.F.; Foglio, M.A.; Rosa, P.D.T.V.; Taranto, O.P. Effects of Different Drying Conditions on Key Quality Parameters of Pink Peppercorns (Schinus terebinthifolius Raddi). J. Food Qual. 2017, 2017, 3152797. [Google Scholar] [CrossRef] [Green Version]

- Szumny, A.F.A.; Gutiérrez-Ortízac, Á.A.C.-B. Composition of Oregano Essential Oil (Origanum vulgare) as Affected by Drying Method. J. Food Eng. 2010, 98, 240–247. [Google Scholar]

- Boateng, I.D.; Yang, X.-M.; AlyTahanya, A.A.; Li, Y. Drying Methods Affect Organoleptic and Physicochemical Properties of Rehydrated Ginkgo Seed Slices. Ind. Crops Prod. 2021, 160, 113166. [Google Scholar] [CrossRef]

- Seguí, L.; Fito, P.J.; Fito, P. A Study on the Rehydration Ability of Isolated Apple Cells after Osmotic Dehydration Treatments. J. Food Eng. 2013, 115, 145–153. [Google Scholar] [CrossRef]

- Górnicki, K. Modelling of Selected Vegetables and Fruits Rehydration Process; Wydawnictwo SGGW: Warsaw, Poland, 2011. (In Polish) [Google Scholar]

- Górnicki, K.; Kaleta, A.; Winiczenko, R.; Chojnacka, A.J.M. Some Remarks on Modelling of Mass Transfer Kinetics during Rehydration of Dried Fruits and Vegetables. In Mass Transfer-Advances in Sustainable Energy and Environment Oriented Numerical Modeling; Nakaima, H., Ed.; InTech: Rijeka, Croatia, 2013. [Google Scholar]

- Phukasmas, P.; Songsermpong, S. Instant Rice Process Development: Effect of Rice Cooking Methods on the Quality of Jasmine Instant Rice Dried by Industrial Microwave Oven. J. Microbiol. Biotechnol. Food Sci. 2019, 9, 330–334. [Google Scholar] [CrossRef]

- Bochnak-Niedźwiecka, J.; Świeca, M. Quality of New Functional Powdered Beverages Enriched with Lyophilized Fruits-Potentially Bioaccessible Antioxidant Properties, Nutritional Value, and Consumer Analysis. Appl. Sci. 2020, 10, 3668. [Google Scholar] [CrossRef]

- Nisoa, M.; Wattanasit, K.; Tamman, A.; Sirisathitkul, Y.; Sirisathitkul, C. Microwave Drying for Production of Rehydrated Foods: A Case Study of Stink Bean (Parkia speciosa) Seed. Appl. Sci. 2021, 11, 2918. [Google Scholar] [CrossRef]

- Fijalkowska, A.; Nowacka, M.; Witrowa-Rajchert, D. The Physical, Optical and Reconstitution Properties of Apples Subjected to Ultrasound before Drying. Ital. J. Food Sci. 2017, 29, 343–356. [Google Scholar]

- Santos, K.C.; Guedes, J.S.; Rojas, M.L.; Carvalho, G.R.; Augusto, P.E.D. Enhancing Carrot Convective Drying by Combining Ethanol and Ultrasound as Pre-Treatments: Effect on Product Structure, Quality, Energy Consumption, Drying and Rehydration Kinetics. Ultrason. Sonochem. 2021, 70, 105304. [Google Scholar] [CrossRef] [PubMed]

- Rojas, M.L.; Silveira, I.; Augusto, P.E.D. Ultrasound and Ethanol Pre-Treatments to Improve Convective Drying: Drying, Rehydration and Carotenoid Content of Pumpkin. Food Bioprod. Process. 2020, 119, 20–30. [Google Scholar] [CrossRef]

- Aral, S.; Bese, A.V. Convective Drying of Hawthorn Fruit (Crataegus spp.): Effect of Experimental Parameters on Drying Kinetics, Color, Shrinkage, and Rehydration Capacity. Food Chem. 2016, 210, 577–584. [Google Scholar] [CrossRef] [PubMed]

- Pieczywek, P.M.; Kozioł, A.; Konopacka, D.; Cybulska, J.Z.A. Changes in Cell Wall Stiffness and Microstructure in Ultrasonically Treated Apple. J. Food Eng. 2017, 197, 8. [Google Scholar] [CrossRef]

- Sacilik, K.; Elicin, A.K. The Thin Layer Drying Characteristics of Organic Apple Slices. J. Food Eng. 2006, 73, 281–289. [Google Scholar] [CrossRef]

- Doymaz, İ. Drying Kinetics, Rehydration and Colour Characteristics of Convective Hot-Air Drying of Carrot Slices. Heat Mass Transf.-Stoffuebertragung 2017, 53, 25–35. [Google Scholar] [CrossRef]

- Taiwo, K.A.; Angersbach, A.; Knorr, D. Influence of High Intensity Electric Field Pulses and Osmotic Dehydration on the Rehydration Characteristics of Apple Slices at Different Temperatures. J. Food Eng. 2002, 52, 185–192. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Lemus-Mondaca, R.; Bilbao-Sáinz, C.; Fito, P.; Andrés, A. Effect of Air Drying Temperature on the Quality of Rehydrated Dried Red Bell Pepper (var. Lamuyo). J. Food Eng. 2008, 85, 42–50. [Google Scholar] [CrossRef]

- Aslam, J.; Latif, W.; Wasif, M.; Hussain, I.; Javaid, S. Comparison of Regression and Neural Network Model for Short Term Load Forecasting: A Case Study. In Proceedings of the The 1st International Conference on Energy, Power and Environment, Gujrat, Pakistan, 11–12 November 2021; p. 29. [Google Scholar]

- Ramzi, M.; Kashaninejad, M.; Salehi, F.; Sadeghi Mahoonak, A.R.; Ali Razavi, S.M. Modeling of Rheological Behavior of Honey Using Genetic Algorithm–Artificial Neural Network and Adaptive Neuro-Fuzzy Inference System. Food Biosci. 2015, 9, 60–67. [Google Scholar] [CrossRef]

- Momenzadeh, L.; Zomorodian, A.; Mowla, D. Experimental and Theoretical Investigation of Shelled Corn Drying in a Microwave-Assisted Fluidized Bed Dryer Using Artificial Neural Network. Food Bioprod. Process. 2011, 89, 15–21. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Prithviraj, V.; Manikantan, M.R.; Beegum, P.P.S.; Ramesh, S.V.; Padmanabhan, S.; Kothakota, A.; Mathew, A.C.; Hebbar, K.B.; Mousavi Khaneghah, A. Central Composite Design, Pareto Analysis, and Artificial Neural Network for Modeling of Microwave Processing Parameters for Tender Coconut Water. Meas. Food 2022, 5, 100015. [Google Scholar] [CrossRef]

- Srikanth, V.; Rajesh, G.K.; Kothakota, A.; Pandiselvam, R.; Sagarika, N.; Manikantan, M.R.; Sudheer, K.P. Modeling and Optimization of Developed Cocoa Beans Extractor Parameters Using Box Behnken Design and Artificial Neural Network. Comput. Electron. Agric. 2020, 177, 105715. [Google Scholar] [CrossRef]

- Kothakota, A.; Pandiselvam, R.; Siliveru, K.; Pandey, J.P.; Sagarika, N.; Srinivas, C.H.S.; Kumar, A.; Singh, A.; Prakash, S.D. Modeling and Optimization of Process Parameters for Nutritional Enhancement in Enzymatic Milled Rice by Multiple Linear Regression (MLR) and Artificial Neural Network (ANN). Foods 2021, 10, 2975. [Google Scholar] [CrossRef]

- Sopade, P.A.; Xun, P.Y.; Halley, P.J.; Hardin, M. Equivalence of the Peleg, Pilosof and Singh–Kulshrestha Models for Water Absorption in Food. J. Food Eng. 2007, 78, 730–734. [Google Scholar] [CrossRef]

- Ugolik, M.; Lech, W.; Kulawik, K. Varieties of Apple Trees; Plantpress: Cracow, Poland, 1996. (In Polish) [Google Scholar]

- Sinha, N.K. Apples. In Handbook of Fruits and Fruit Processing; Hui, Y.H., Ed.; Blackwell Publishing: Ames, IA, USA, 2006. [Google Scholar]

- Luikov, A.V. Analytical Heat Diffusion Theory; Academic: New York, NY, USA, 1968. [Google Scholar]

- Górnicki, K.; Kaleta, A. Drying Curve Modelling of Blanched Carrot Cubes under Natural Convection Condition. J. Food Eng. 2007, 82, 160–170. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Some Remarks on Evaluation of Drying Models of Red Beet Particles. Energy Convers. Manag. 2010, 51, 2967–2978. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K.; Winiczenko, R.; Chojnacka, A. Evaluation of Drying Models of Apple (var. Ligol) Dried in a Fluidized Bed Dryer. Energy Convers. Manag. 2013, 67, 179–185. [Google Scholar] [CrossRef]

- Horwitz, W. (Ed.) Official Methods of Analysis of AOAC International; AOAC Int.: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Mazza, G. Dehydration of Carrots: Effects of Pre-Drying Treatments on Moisture Transport and Product Quality. Int. J. Food Sci. Technol. 2007, 18, 113–123. [Google Scholar] [CrossRef]

- Winiczenko, R.; Górnicki, K.; Kaleta, A.; Martynenko, A.; Janaszek-Mańkowska, M.; Trajer, J. Multi-Objective Optimization of Convective Drying of Apple Cubes. Comput. Electron. Agric. 2018, 145, 341–348. [Google Scholar] [CrossRef]

- Saguy, I.S.; Marabi, A.; Wallach, R. Liquid Imbibition during Rehydration of Dry Porous Foods. Innov. Food Sci. Emerg. Technol. 2005, 6, 37–43. [Google Scholar] [CrossRef]

- Peleg, M. An Empirical Model for the Description of Moisture Sorption Curves. J. Food Sci. 1988, 53, 1216–1219. [Google Scholar] [CrossRef]

- Pilosof, A.M.R.; Boquet, R.; Bartholomai, G.B. Kinetics of Water Uptake by Food Powders. J. Food Sci. 1985, 50, 278–279. [Google Scholar] [CrossRef]

- Singh, P.B.N.; Kulshrestha, S.P. Kinetics of Water Sorption by Soybean and Pigeonpea Grains. J. Food Sci. 1987, 52, 1538–1541. [Google Scholar] [CrossRef]

- Lewis, W.K. The Rate of Drying of Solid Materials. Ind. Eng. Chem. 1921, 13, 427–432. [Google Scholar] [CrossRef]

- Henderson, S.M.; Pabis, S. Grain Drying Theory, I. Temperature Effect on Drying Coefficient. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Page, G. Factors Influencing the Maximum Rates of Air-Drying Shelled Corn in Thin Layer. Masters Thesis, Purdue University, West Lafayette, IN, USA, 1949; pp. 1–4. [Google Scholar]

- Overhults, D.G. Drying Soybeans with Heated Air. Trans. ASAE 1973, 16, 112–113. [Google Scholar] [CrossRef]

- Ergün, K.; Çalışkan, G.; Dirim, S.N. Determination of the Drying and Rehydration Kinetics of Freeze Dried Kiwi (Actinidia deliciosa) Slices. Heat Mass Transf. 2016, 52, 2697–2705. [Google Scholar] [CrossRef]

- Rafiq, A.; Chowdhary, J.; Hazarika, M.K.; Makroo, H.A. Temperature Dependence on Hydration Kinetic Model Parameters during Rehydration of Parboiled Rice. J. Food Sci. Technol. 2015, 52, 6090–6094. [Google Scholar] [CrossRef] [Green Version]

- Deng, Y.; Luo, Y.; Wang, Y.; Yue, J.; Liu, Z.; Zhong, Y.; Zhao, Y.; Yang, H. Drying-Induced Protein and Microstructure Damages of Squid Fillets Affected Moisture Distribution and Rehydration Ability during Rehydration. J. Food Eng. 2014, 123, 23–31. [Google Scholar] [CrossRef]

- Link, J.V.; Tribuzi, G.; Laurindo, J.B. Improving Quality of Dried Fruits: A Comparison between Conductive Multi-Flash and Traditional Drying Methods. LWT–Food Sci. Technol. 2017, 84, 717–725. [Google Scholar] [CrossRef]

- Benseddik, A.; Azzi, A.; Zidoune, M.N.; Khanniche, R.; Besombes, C. Empirical and Diffusion Models of Rehydration Process of Differently Dried Pumpkin Slices. J. Saudi Soc. Agric. Sci. 2019, 18, 401–410. [Google Scholar] [CrossRef]

- Rhim, J.W.; Koh, S.; Kim, J.M. Effect of Freezing Temperature on Rehydration and Water Vapor Adsorption Characteristics of Freeze-Dried Rice Porridge. J. Food Eng. 2011, 104, 484–491. [Google Scholar] [CrossRef]

- Harnkarnsujarit, N.; Kawai, K.; Watanabe, M.; Suzuki, T. Effects of Freezing on Microstructure and Rehydration Properties of Freeze-Dried Soybean Curd. J. Food Eng. 2016, 184, 10–20. [Google Scholar] [CrossRef]

- Basunia, M.A.; Abe, T. Thin-Layer Drying Characteristics of Rough Rice at Low and High Temperatures. J. Stored Prod. Res. 2005, 41, 163–173. [Google Scholar] [CrossRef]

- Markowski, M.; Zielinska, M. Kinetics and Water Absorption and Soluble-Solid Loss of Hot-Air-Dried Carrots during Rehydration. Int. J. Food Sci. Technol. 2011, 46, 1122–1128. [Google Scholar] [CrossRef]

- Schanda, J. (Ed.) Colorimetry: Understanding the CIE System; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Feng, H.; Tang, J. Microwave Finish Drying of Diced Apples in a Spouted Bed. J. Food Sci. 2006, 63, 679–683. [Google Scholar] [CrossRef]

- Nadian, M.H.; Rafiee, S.; Golzarian, M.R. Real-Time Monitoring of Color Variations of Apple Slices and Effects of Pre-Treatment and Drying Air Temperature. J. Food Meas. Charact. 2016, 10, 493–506. [Google Scholar] [CrossRef]

- Boeckx, J. Regulation of the Respiratory Metabolism of Apple during (Dynamic) Controlled Atmosphere Storage. Ph.D. Thesis, Katholieke Universiteit Leuven, Leuven, Belgium, 2018. [Google Scholar]

- Contreras, C.; Martín-Esparza, M.E.; Chiralt, A.; Martínez-Navarrete, N. Influence of Microwave Application on Convective Drying: Effects on Drying Kinetics, and Optical and Mechanical Properties of Apple and Strawberry. J. Food Eng. 2008, 88, 55–64. [Google Scholar] [CrossRef]

| Model No. | Model Equation | Model Name | References |

|---|---|---|---|

| (1) | * | Peleg | [60] |

| (2) | Pilosof–Boquet–Batholomai | [61] | |

| (3) | Sing and Kulshrestha | [62] | |

| (4) | Lewis (Newton) | [63] | |

| (5) | Henderson–Pabis | [64] | |

| (6) | Page | [65] | |

| (7) | Modified Page | [66] |

| Model No. | Model Name | Variable | SSE | R2 | Adjusted R2 | RMSE |

|---|---|---|---|---|---|---|

| (1) | Peleg | mass gain | 0.0488–0.6590 | 0.9597–0.9966 | 0.9578–0.9964 | 0.0570–0.1910 |

| volume increase | 0.0203–0.4924 | 0.8622–0.9950 | 0.8631–0.9946 | 0.0430–0.1496 | ||

| dry matter loss | 0.0018–0.0385 | 0.9329–0.9976 | 0.9299–0.9974 | 0.0116–0.0454 | ||

| (2) | Pilosof–Boquet–Batholomai | mass gain | 0.0488–0.6590 | 0.9597–0.9966 | 0.9578–0.9963 | 0.0570–0.1910 |

| volume increase | 0.0203–0.4924 | 0.8622–0.9950 | 0.8531–0.9946 | 0.0430–0.1496 | ||

| dry matter loss | 0.0018–0.0385 | 0.9329–0.9976 | 0.9299–0.9974 | 0.0116–0.0454 | ||

| (3) | Singh and Kulshrestha | mass gain | 0.0488–0.6592 | 0.9597–0.9966 | 0.9578–0.9963 | 0.0570–0.1910 |

| volume increase | 0.0203–0.5129 | 0.8452–0.9950 | 0.8349–0.9946 | 0.0430–0.1527 | ||

| dry matter loss | 0.0018–0.0385 | 0.9329–0.9973 | 0.9299–0.9966 | 0.0116–0.0452 | ||

| (4) | Lewis (Newton) | mass gain | 0.0763–0.2210 | 0.8840–0.9481 | 0.8840–0.9481 | 0.0738–0.1064 |

| volume increase | 0.0671–0.3131 | 0.8071–0.9492 | 0.8071–0.9492 | 0.0731–0.1326 | ||

| dry matter loss | 0.0501–0.2417 | 0.8398–0.9672 | 0.8398–0.9672 | 0.0646–0.1183 | ||

| (5) | Henderson–Pabis | mass gain | 0.0660–0.1952 | 0.8997–0.9549 | 0.8930–0.9519 | 0.0580–0.1033 |

| volume increase | 0.0610–0.2440 | 0.8327–0.9538 | 0.8215–0.9513 | 0.0636–0.1276 | ||

| dry matter loss | 0.0476–0.2741 | 0.8590–0.9688 | 0.8523–0.9660 | 0.0652–0.1142 | ||

| (6) | Page | mass gain | 0.0037–0.0582 | 0.9541–0.9981 | 0.9520–0.9970 | 0.0143–0.0619 |

| volume increase | 0.0022–0.2092 | 0.8686–0.9983 | 0.8598–0.9982 | 0.0142–0.1130 | ||

| dry matter loss | 0.0050–0.2267 | 0.8834–0.9969 | 0.8778–0.9966 | 0.0195–0.1039 | ||

| (7) | Modified Page | mass gain | 0.0027–0.0843 | 0.9541–0.9981 | 0.9520–0.9980 | 0.0143–0.0619 |

| volume increase | 0.0022–0.2092 | 0.8686–0.9983 | 0.8598–0.9982 | 0.0142–0.1130 | ||

| dry matter loss | 0.0050–0.2267 | 0.8834–0.9969 | 0.8778–0.9966 | 0.0195–0.1039 |

| Model No. | Model Name | Parameter Equations |

|---|---|---|

| (1) | Peleg | A1 = 0.087419 − 2.2 × 10−5·Td2 + 0.02319·L2 − 1.8·10−5·Tr2 + 0.00422·Td·vd − 0.08602·vd·L A2 = 0.329564 + 2.97 × 10−5·Td2 − 0.00178·Td·vd + 0.00042·Td·L + 0.0339644·vd·L − 0.00125·L·Tr |

| (2) | Pilosof–Boquet–Batholomai | A3 = 3.045997 − 0.00028·Tr2 + 0.014144·Td·vd − 0.00385·Td·L − 0.31729·vd·L + 0.011896·L·Tr A4 = 0.280897 + 0.04096·L2 − 5.5 × 10−5·Tr2 |

| (3) | Singh and Kulshrestha | A5 = 2.252442 + 0.021388·Td − 0.00031·Tr2 − 0.00693·Td·L − 0.0265·vd·L + 0.013017·L·Tr A6 = 4.083154 + 0.001954·Tr2 − 0.04949·L·Tr |

| (4) | Lewis (Newton) | k = 2.327949 + 0.001058·Tr2 − 0.02735·L·Tr |

| (5) | Henderson–Pabis | k = 1.940489 + 0.000939·Tr2 − 0.02355·L·Tr a = 0.895178 + 7.94 × 10−6·Td·Tr |

| (6) | Page | k = 0.72067 + 0.00015·Tr2 n = 0.612353 − 9.7 × 10−6·Tr2 |

| (7) | Modified Page | k = 2.20413 + 0.001114·Tr2 − 0.02795·L·Tr n = 0.513102 + 0.000599·Td·L − 1.5·10−5·Td·Tr |

| Model No. | Model Name | Parameter Equations |

|---|---|---|

| (1) | Peleg | A1 = 0.432052 + 0.0144·L2 − 5.7 × 10−5·Tr2 A2 = 0.064866 + 0.003357·vd2 + 0.042058·L2 − 3.6 × 10−5·Tr2 |

| (2) | Pilosof–Boquet–Batholomai | A3 = 1.797968 − 0.00243·L·Tr A4 = 0.33569 + 0.043488·L2 − 6.2 × 10−5·Tr2 |

| (3) | Singh and Kulshrestha | A5 = 1.351868 − 0.00028·Tr2 − 0.00101·Td·vd +0.000959·Td·Tr − 0.01163·L·Tr A6 = 3.563119 + 0.001701·Tr2 + 0.058523·Td·vd − 0.00208·Td·Tr − 1.22396·vd·L |

| (4) | Lewis (Newton) | k = 1.968387 + 0.000829·Tr2 − 0.02088·L·Tr |

| (5) | Henderson–Pabis | k = 1.622107 + 0.000699·Tr2 − 0.01724·L·Tr a = 0.914742 |

| (6) | Page | k = 1.367971 + 0.0004·Tr2 − 0.01023·L·Tr n = 0.623547 − 7.1 × 10−6·Tr2 |

| (7) | Modified Page | k = 1.797016 + 0.000814·Tr2 − 0.01995·L·Tr n = 0.623556 − 7.1 × 10−6·Tr2 |

| Model No. | Model Name | Parameter Equations |

|---|---|---|

| (1) | Peleg | A1 = 1.199471 + 0.03494·L2 − 0.01674·Td·vd + 0.000595·Td·Tr + 0.345962·vd·L − 0.0122·L·Tr A2 = −0.09904 + 0.105514·L2 + 0.018807·Td·vd − 8.7 × 10−5·Td·Tr − 0.38681·vd·L |

| (2) | Pilosof–Boquet–Batholomai | A3 = 0.65515 − 0.00546·L2 − 2.9·10−5·Tr2 + 0.003547·Td·vd − 0.07355·vd·L + 0.00107·L·Tr A4 = −0.02683 + 0.063203·L2 + 0.018608·Td·vd − 5.4 × 10−5·Td·Tr − 0.38314·vd·L |

| (3) | Singh and Kulshrestha | A5 = 0.658516 + 0.003843·Td·vd − 0.07913·vd·L A6 = 3.234311 − 0.00966·Td·L + 0.000608·Td·Tr |

| (4) | Lewis (Newton) | k = 2.388268 − 0.06332·L2 |

| (5) | Henderson–Pabis | k = 1.048803 + 0.000156·Tr2 a = 0.825358 − 4.6·10−5·Tr2 8.45 × 10−5·Td·Tr |

| (6) | Page | k = 1.353281 − 0.02825·L2 + 6.64 × 10−5·Tr2 n = 0.510797 + 0.005854·L2 |

| (7) | Modified Page | k = 1.098296 + 0.00019·Tr2 n = 0.510797 + 0.005854·L2 |

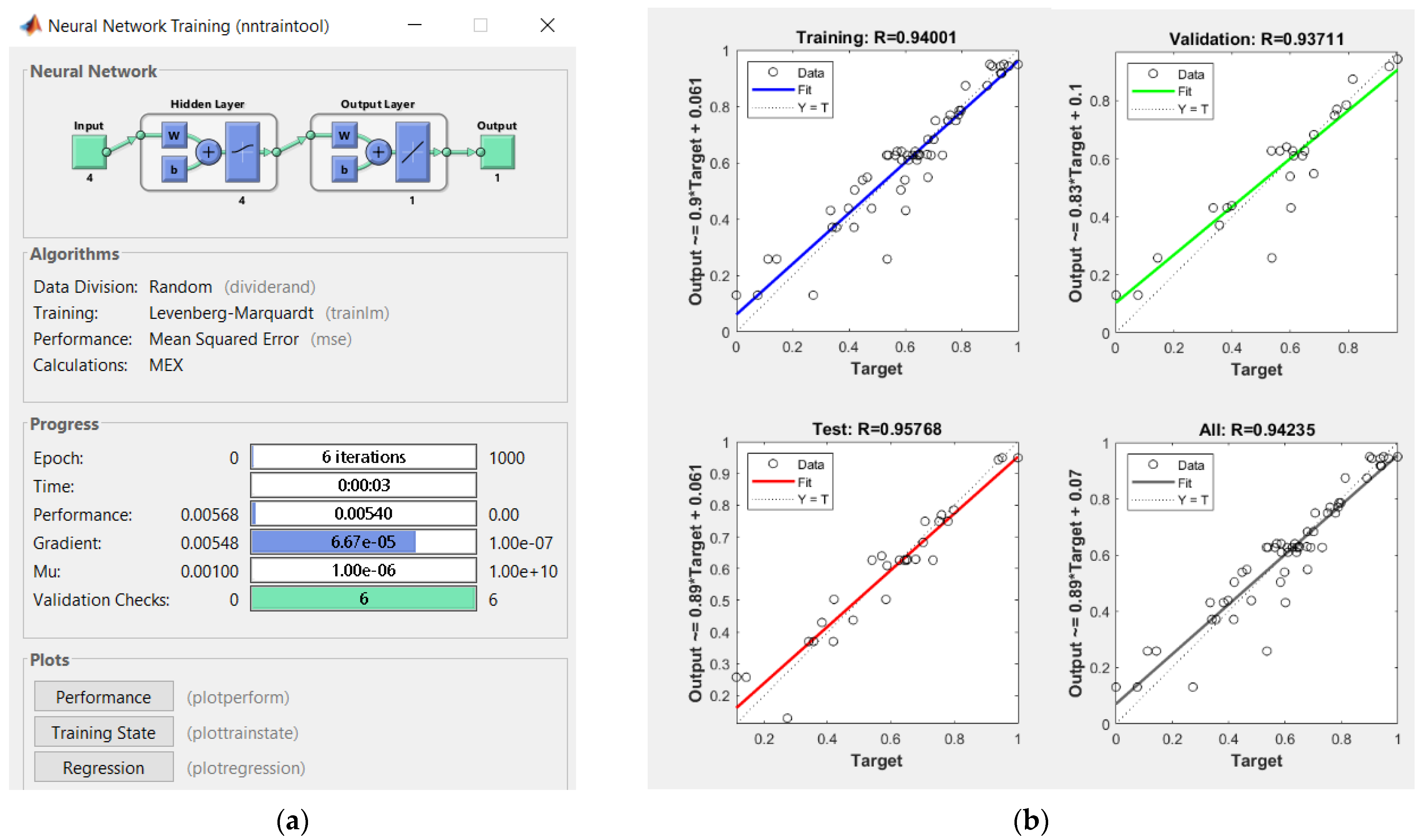

| Rehydration Index | Weights and Biases between Input and Hidden Layer | Weights and Biases between Hidden and Output Layer | ||||||

|---|---|---|---|---|---|---|---|---|

| No. | Weights | Bias | Weights | Bias | ||||

| RI1 | i | D1i | D2i | D3i | D4i | Di | Wi | Bi |

| 1 | 0.76302 | −4.30465 | 6.1141 | 4.1011 | 3.2308 | 3.8703 | −1.0468 | |

| 2 | −0.18017 | 5.2373 | −2.251 | −9.0609 | −0.41154 | 0.46843 | ||

| 3 | −5.4656 | 2.1371 | −5.5557 | 4.6212 | −1.931 | 4.4227 | ||

| 4 | −8.7999 | 2.4317 | −0.35888 | 3.979 | 0.66115 | −6.7914 | ||

| RI2 | 1 | −1.8885 | 2.0685 | 1.1286 | −0.37259 | −2.3498 | 3.0742 | 0.79132 |

| 2 | 0.50806 | 0.55895 | −7.7709 | −0.84271 | 0.62434 | −2.1788 | ||

| 3 | −3.4158 | −0.11008 | −10.5825 | −1.202 | 0.85564 | 8.3004 | ||

| 4 | 0.32057 | −4.9892 | 2.4163 | −5.1056 | 1.52 | 3.3142 | ||

| WAC | 1 | −0.32603 | −0.53705 | −0.88337 | 2.8526 | −2.0969 | −1.0055 | 0.42304 |

| 2 | 9.2834 | −46.5133 | −60.2563 | 122.4035 | 0.81527 | 7.7133 | ||

| 3 | −22.1376 | −52.8683 | 0.59559 | 19.7618 | 0.54159 | −62.5777 | ||

| Rehydration Index | R | RMSE | χ2 |

|---|---|---|---|

| RI1 | 0.9424 | 0.0756 | 0.0065 |

| RI2 | 0.9376 | 0.0787 | 0.0070 |

| WAC | 0.9270 | 0.0802 | 0.0070 |

| Rehydration Index | Omitted Parameter | R | RMSE | χ2 |

|---|---|---|---|---|

| RI1 | Td | 0.76 (2) * | 0.34 (1) | 0.130 (1) |

| vd | 0.84 (4) | 0.14 (4) | 0.021 (4) | |

| Tr | 0.78 (3) | 0.15 (3) | 0.026 (3) | |

| L | 0.21 (1) | 0.29 (2) | 0.096 (2) | |

| RI2 | Td | 0.79 (3) | 0.18 (2) | 0.035 (2) |

| vd | 0.84 (4) | 0.13 (4) | 0.020 (4) | |

| Tr | 0.78 (2) | 0.15 (3) | 0.026 (3) | |

| L | 0.45 (1) | 0.23 (1) | 0.062 (1) | |

| WAC | Td | 0.76 (2) | 0.14 (2) | 0.022 (2) |

| vd | 0.85 (4) | 0.12 (4) | 0.016 (4) | |

| Tr | 0.82 (3) | 0.14 (3) | 0.021 (3) | |

| L | 0.30 (1) | 0.21 (1) | 0.048 (1) |

| Variable | SSE | R2 | Adjusted R2 | RMSE |

|---|---|---|---|---|

| L* | 0.0077–0.2359 | 0.6306–0.9889 | 0.6306–0.9889 | 0.0394–0.2068 |

| b* | 0.0009–0.5514 | 0.3516–0.9986 | 0.3516–0.9986 | 0.0177–0.3031 |

| h* | 0.0105–0.6388 | 0.2601–0.9865 | 0.2601–0.9865 | 0.0419–0.3574 |

| C* | 0.0012–0.6660 | 0.3611–0.9980 | 0.3611–0.9980 | 0.0241–0.3085 |

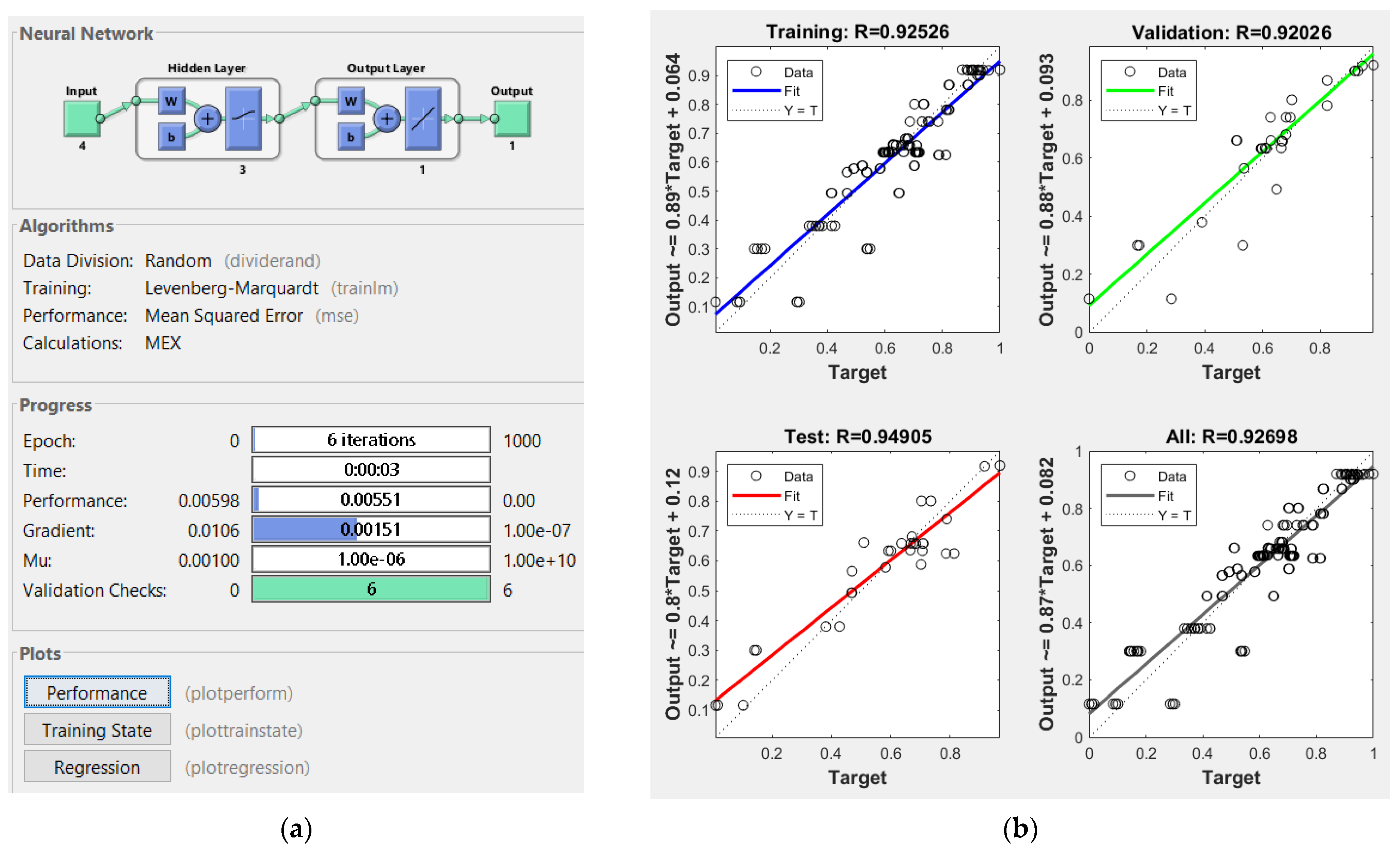

| No. | Weights and Biases between Input and Hidden Layer | Weights and Biases between Hidden and Output Layer | ||||||

|---|---|---|---|---|---|---|---|---|

| Weights | Bias | Weights | Bias | |||||

| i | D1i | D2i | D3i | D4i | D5i | Di | Wi | Bi |

| 1 | −0.3936 | 0.068912 | 7.7881 | −0.37068 | −0.29036 | −4.083 | 9.4829 | 4.3014 |

| 2 | 5.5244 | 3.3242 | 0.99513 | −1.4537 | −2.1599 | 1.3043 | −1.7557 | |

| 3 | 5.143 | −0.15515 | 5.6857 | −2.9232 | −7.4673 | 0.73944 | −3.9588 | |

| 4 | −0.67089 | −5.7064 | 2.1326 | 0.36501 | 2.9711 | 0.87002 | −3.3684 | |

| 5 | −4.0698 | 3.8803 | 2.1008 | 1.5752 | 3.0415 | 0.7498 | 1.5977 | |

| 6 | 2.7802 | 5.5689 | 3.5537 | −2.3719 | −3.6688 | −1.6085 | −2.9859 | |

| 7 | 0.13428 | −0.70078 | 0.3338 | −7.8718 | 1.8079 | −0.83412 | 4.0532 | |

| 8 | 7.6823 | 0.47277 | −0.4144 | 8.8348 | 6.2643 | −0.78616 | 5.2191 | |

| Parameter | All Parameters Considered | Omitted L | Omitted Td | Omitted vd | Omitted Tr | Omitted t | |

|---|---|---|---|---|---|---|---|

| Statistical Test Method | |||||||

| R | 0.9048 | 0.1395 | 0.4424 | 0.4482 | 0.4859 | 0.6721 | |

| RMSE | 0.0567 | 0.2654 | 0.2953 | 0.1980 | 0.1246 | 0.1022 | |

| R2 | 0.8187 | 0.0195 | 0.1957 | 0.2009 | 0.2361 | 0.4517 | |

| Adjusted R2 | 0.8177 | 0.0143 | 0.1915 | 0.1967 | 0.2321 | 0.4488 | |

| SSE | 0.0573 | 0.1332 | 0.1207 | 0.1203 | 0.1176 | 0.0996 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Górnicki, K.; Kaleta, A.; Kosiorek, K. Mathematical Description of Changes of Dried Apple Characteristics during Their Rehydration. Appl. Sci. 2022, 12, 5495. https://doi.org/10.3390/app12115495

Górnicki K, Kaleta A, Kosiorek K. Mathematical Description of Changes of Dried Apple Characteristics during Their Rehydration. Applied Sciences. 2022; 12(11):5495. https://doi.org/10.3390/app12115495

Chicago/Turabian StyleGórnicki, Krzysztof, Agnieszka Kaleta, and Krzysztof Kosiorek. 2022. "Mathematical Description of Changes of Dried Apple Characteristics during Their Rehydration" Applied Sciences 12, no. 11: 5495. https://doi.org/10.3390/app12115495

APA StyleGórnicki, K., Kaleta, A., & Kosiorek, K. (2022). Mathematical Description of Changes of Dried Apple Characteristics during Their Rehydration. Applied Sciences, 12(11), 5495. https://doi.org/10.3390/app12115495