Abstract

Directed energy deposition (DED) is an additive manufacturing process used in manufacturing free form geometries, repair applications, coating and surface modification, and fabrication of functionally graded materials. It is a process in which focused thermal energy is used to fuse materials by melting. Thermal effects can cause distortions and defects on the parts during the DED process, therefore they should be evaluated and taken into account during the manufacturing of products. Melting pool control and DED bead geometries should be defined properly as well. In this work, an Artificial Neural Network model has been applied considering the DED process parameters in order to predict the geometrical patterns and create a local reinforced product as a hybrid manufacturing technology. Although lots of studies are available on topology optimization for manufacturing methods such as casting, extrusion, and powder bed fusion, topology optimization for the DED process is not widely taken into consideration to predict the design geometrical patterns. DOE RSM and ANN approaches were applied in this study to predict convenient dimensions, topology based geometrical patterns of local stiffeners and heat source power optimizing the energy, total mass, and peak force results of the hybrid part. A single bead track deposition is simulated in terms of validation of the numerical heat source model, and cross-sections of the beads are analysed. A cross-member structure is manufactured using the DED device and the structure is correlated under the three point bending physical conditions on test bench. It has been investigated that locally reinforced cross beam has much more energy absorption and peak force values than plain model. The results showed that the proposed NN-GA is a promising approach to generate the topology based geometrical patterns and process parameters which can be used to create a local reinforced product as hybrid manufacturing technologies.

1. Introduction

In recent years, additive manufacturing has grown more and more as its features provide design freedom, consolidation, customization of products, manufacturing-on-demand, weight reduction, and reduced human effects. Additive manufacturing (AM) is playing a significant role in diversified sectors such as aerospace, energy, oil and gas, automotive, medical, tool and die, and consumer goods. Directed energy deposition (DED) is one of the AM technologies. The DED process is described as “additive manufacturing process in which focused thermal energy is used to fuse materials by melting [1,2,3,4].

In industries such as aerospace, defence, automotive, tooling, and conventional machining manufacturing processes are unsustainable as they generate much more scrap material. DED can reduce material waste, energy consumption, production cost, and working hours. It can be used in the production of large parts with the possibility of powder or wire feeding using both robotic and gantry systems. It offers the opportunity to create hybrid products as well. It has a broad range of applications in manufacturing free form geometries, repair applications, coating and surface modification, and the fabrication of functionally graded materials, and it is an especially significant process in the manufacture of large parts, which is not appropriate in terms of installation on powder bed fusion device tables in the aerospace industry, such as rocket cases and big structural cross brackets [5]. Altıparmak et al. [6] reviewed that hybrid AM processes could be employed for large-scale multi-materials and/or different raw materials locally for different sections of aerospace components, in order to better tailor the component to engineering requirements as a future study. Hybrid processes have been found effective at minimising or eliminating defects occurring in AM, achieving better mechanical properties and functionality of the final parts and improving the process performance as well.

The recent literature has investigated whether the DED process is available for creating hybrid parts. Yang et al. [7] offered a solid foundation for a wide application of hybrid DED incorporating layer-by-layer deposition and thermal milling processes to achieve complex structural parts such as closed impellers. The thermal milling process was applied after each deposition, which not only maintained the relatively high temperature of the part but also improved the surface quality with a pre-set height for the next deposition step. Godec et al. [8] observed the combination of different additive manufacturing technologies on a space part which has smaller and more suitable dimensions for powder bed technologies. They investigated samples of a hybrid SLM/DED AM-processed Inconel 718 and the hybrid process created a complex and different microstructure combining two different AM processes. In order to produce small size hybrid part, SLA can create an alternative solution with a low density heat input. It is a cost-effective AM solution for small-scale components with high build speed and resolution from photo-curable resin [9]. Almonti et al. [10] developed a small-size hybrid component using non-metallic biobase materials such as PCM within SLA process. Compound structures filled with different typologies of PCM were realised and thermally characterised to design a modular prototype that can be used for thermal storage. It was found that the heating process is predominant within the heating system using ANoVA analysis.

In the state-of-the-art, topology optimization techniques, a useful tool for weight reduction and part optimization, do not work properly for such AM processes, as all AM methods need to have their own dedicated design rules and requirements applied. Additionally, there is no widespread and extensive knowledge on topology optimization for the DED process in order to create a hybrid part production in the literature. Considering the difficulties in bringing topology optimization based designs into reality with conventional manufacturing methodologies, one naturally agrees to the idea of employing AM for their realizations [11]. Primo et al. [12] carried out a simple C-clip component using classical topology approach (TA), lattice approach (LA), and the hybrid approach as a smart mix of the TA and LA considering printing time as the process constraint in order to create a highly complex truss structure and evaluate which of the advantages are offered by their integration.

On the other hand, the interest and attentions among researchers on the applicability of AM in remanufacturing has increased. However, there is a lack of systematic approaches based on artificial intelligence for optimization purposes [13]. Artificial neural networks and optimization algorithms are applied as surrogate models to predict the hardpoints as the surrogate-based optimization method plays an essential role in the optimization processes, especially when the optimization model is established based on computational modelling complexities and uncertainties [14]. Xinbo et al. [15] overviewed ANN approaches in terms of application area in AM whole chain. They pointed out that process parameters for DED methods such as LMD and WAAM are laser power, scanning speed, powder feeding rate, bead width, bead height, and centre distance of adjacent deposition paths. Ohyung et al. [16] applied ANN to define the classification of melt-pool images with different heat source power for selective laser melting which is the one of PBF technologies. It was seen that the classification model could be utilized to infer the location to cause the unexpected alteration of microstructures or separate the defective products non-destructively. Zuowei et al. [17] used ANN in order to predict the geometric deviations for fused deposition modelling, classifying the process images as well. Marrey et al. [18] presented a framework for the PBF process parameters optimization by mapping the ultimate quality of a fabricated part into the process parameters and material properties. The effects of laser power and scan speed on the microstructure and porosity of SS 316L fabricated parts were investigated in their first phase studies. They carried out an ANN application in order to suggest the optimized process parameters according to the desired ultimate quality of an ordered part manufactured via PBF method. Manjunath et al. [19] optimized the process parameters to obtain microstructure without porosity and good interfacial bonding between the substrate and the deposition. Taguchi’s L9 method was used for optimization experiments and the explored ranges of powder feed rate, laser power, and laser scan speed. The microstructure and microhardness of the built specimens were studied.

The objective of this work is to examine the potentiality offered by the integration of the two structures (plain metal and DED structures) to improve the final part property such as the specific energy absorption considering the optimum peak force and total mass constraints within mapping the process parameters on the ultimate properties of to-be-fabricated parts. This will help to fill the existing gap for development of the DED hybrid product, which includes the contributing and controllable design and process parameters. This research conducts a product and process optimization study of a simple test case geometry (semi cross large metal component), where structural topology optimization has been applied using an artificial neural network and genetic algorithms based on the design of feasible DED bead structure geometries and heat source power. A computational efficient approach is developed for constructing a surrogate model for problems where both inputs and outputs are high-dimensional and nonlinear using small training data set.

2. Numerical Modelling and Validation

2.1. DED Process Design Constraints

DED can be a “powder blown” or “wire feed” AM process that uses a laser beam or a heat source to melt metal powder/wire and deposit it on the surface of a suitable material. The laser/heat source creates a melt pool and the powder/wire is blown or fed into the melt pool with the help of inert gas. The powder or wire melts as it enters the melt pool, thus increasing the volume of the melt pool. As the laser or heat source moves through the liquid, it solidifies and creates a trace of material. Parts can be created by placing overlapping tracks in a parallel direction to form a layer, and then creating multiple layers to create the desired geometry. In industrial applications, PBF technologies have usually limited work table dimensions to lower than 400 mm × 400 mm, otherwise it cannot offer hybrid manufacturing. In cases during hybrid products needing large width or length dimensions, DED can facilitate and optimize costs for manufacturing processes [20,21,22].

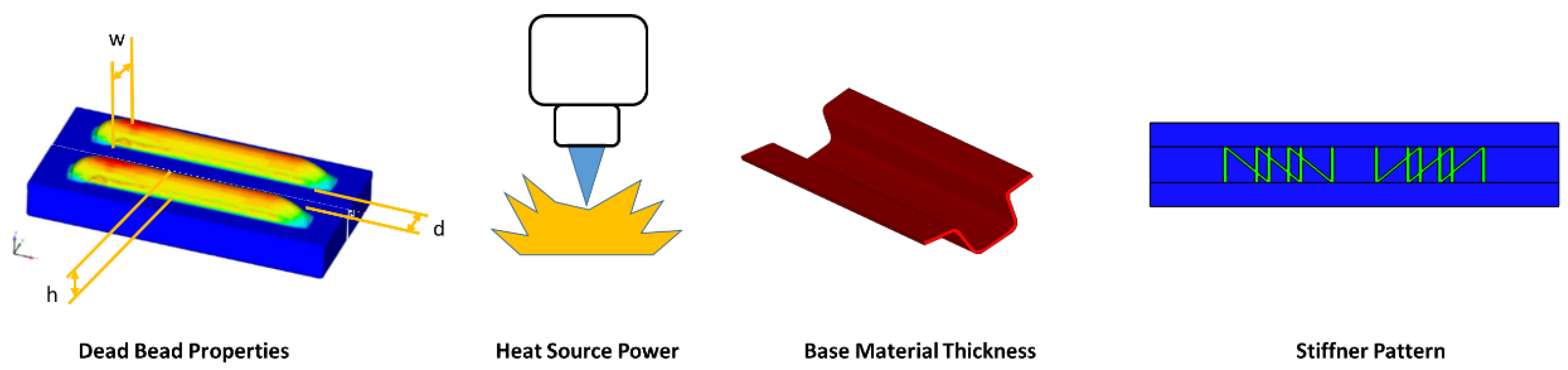

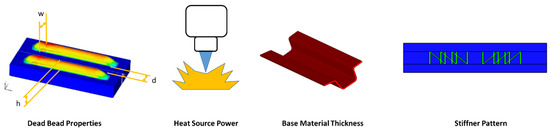

Various optimization studies with different methodologies have been investigated by researchers in the literature. Response surface approximation, radial basis functions, Kriging, and artificial neural networks (ANN) are widely used for surrogate modelling. The response surface approximation is a useful method for design optimization problems with high mathematical complexity [23]. The response surface approximation employs a sequence of designed experiments to find an ideal answer. Radial basis functions have the high prediction characteristics of highly non-linear approximation models [24]. The radial basis function method operates by describing itself by the distance from its origin. Kriging is a useful and flexible method for creating a metamodel of simulated response surfaces with various functional structures [25]. Kriging is an approach of interpolation based on a Gaussian procedure controlled by primary covariances. ANN method is a powerful method that can produce complex relationships between nonlinear design variables [26]. For this reason, in this research the ANN method has been preferred in order to optimize the specific energy absorption considering peak force and total mass according to the design parameters which have a significant influence on the performance of semi cross metal parts as shown in Figure 1.

Figure 1.

Design variables.

2.2. Heat Source Modelling

Thermal effects can cause distortions and defects such as strength and contact loss between the layers or main material/substrate as the DED process has focused thermal energy used to fuse materials by melting [27]. Therefore, they should be evaluated and taken into account during the design for components manufactured by DED, in order to prevent any strength loss caused by residual strains and stresses on the component after the process. Melting pool control and DED bead geometries should also be defined properly.

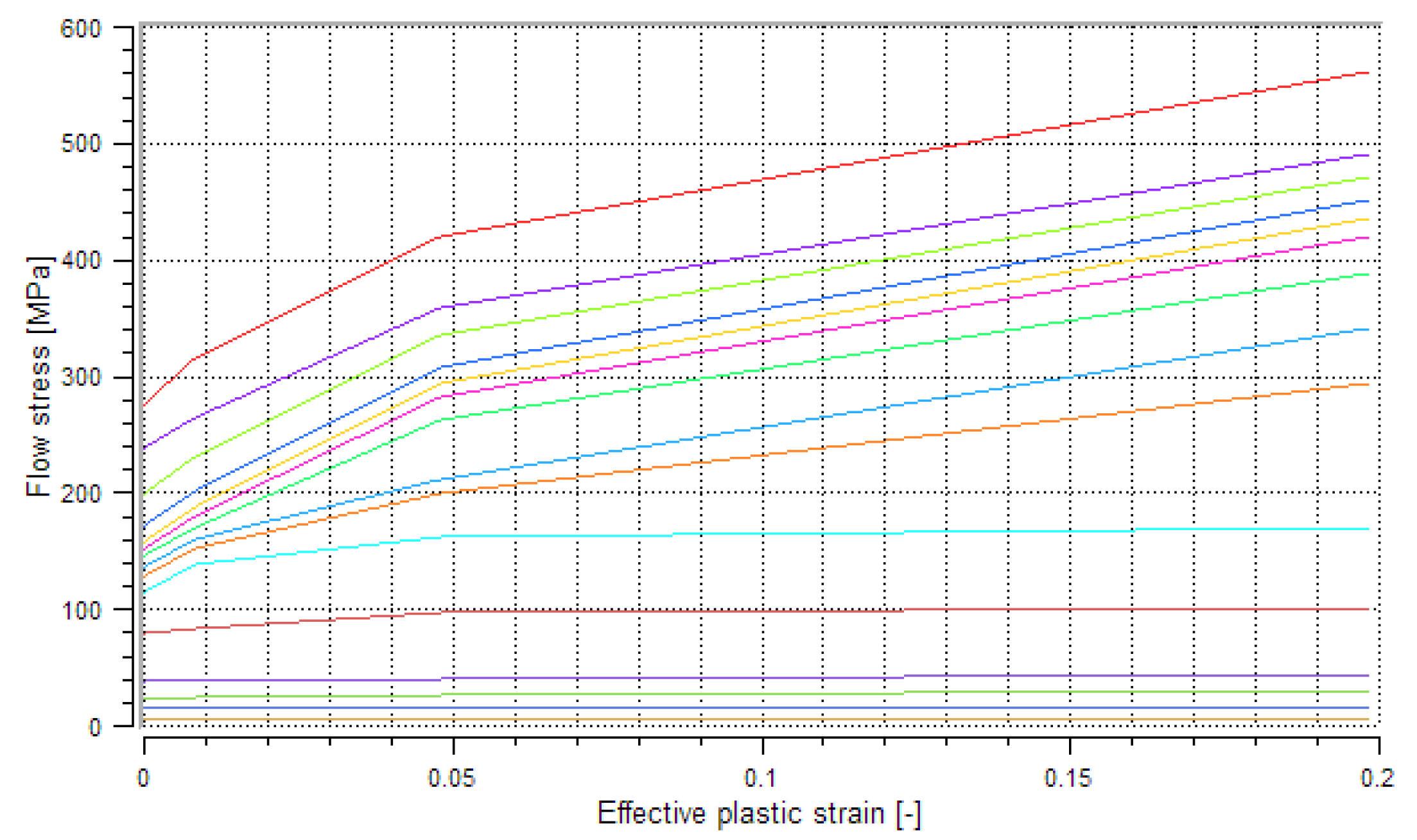

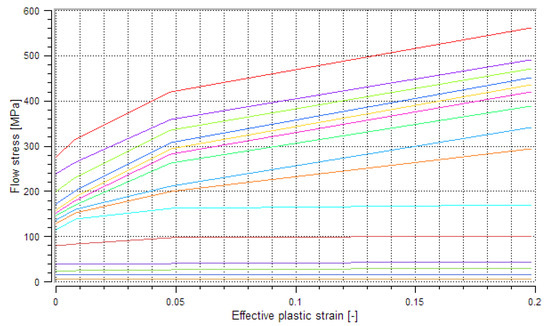

Modelling of thermo-mechanical behaviour is a significant part of the numerical analysis of the DED process. DED simulation has been performed supposing a welding approach. It is carried out on Simufact Welding Software as it provides possibilities to model heat treatment processes, variations of cooling and unclamping setups, as well as mechanical loading of welded structures. Additionally, it has a capability to define residual stresses and map thermal process effects on the part using flow curves of materials. 316L material is described as DED material with its chemical composition in Table 1 and its flow curves (see Figure 2) from software material database.

Table 1.

Chemical composition of DED material (316L).

Figure 2.

Flow Curves of DED Material (316L).

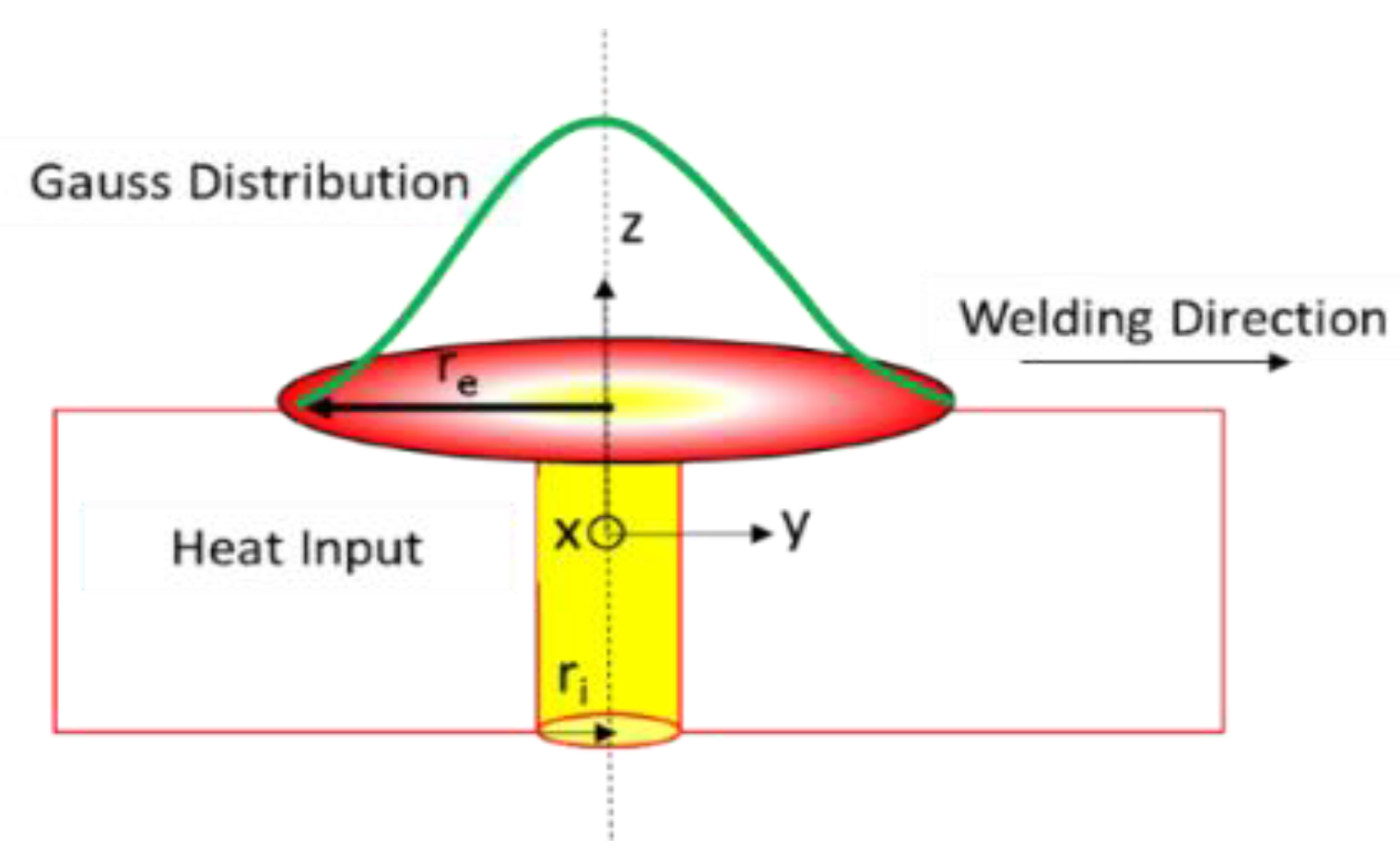

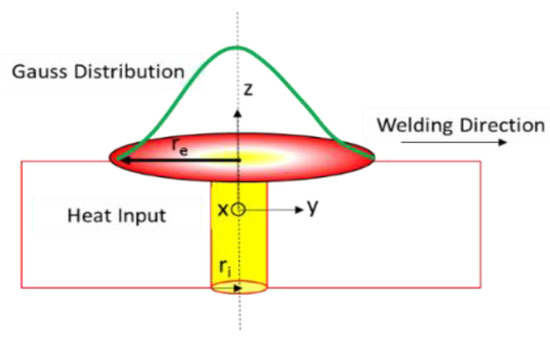

The heat source is described in the numerical model as a volume and surface distributed heat source, which consists of a Gauss surface distribution of the heat input and a constant heat distribution cylinder. An illustration of the described heat source model can be seen in Figure 3.

Figure 3.

Heat source modelling.

For the general Gaussian distribution, the surface flux (W·mm−2) is expressed in the first equation [28];

where (W·mm−2) is the maximum flux, r (mm) is the radial distance from the centre of the heat source, and (mm−2) is the distribution width coefficient. For the particular case of laser beam welding, the heat flux is expressed as shown in the second equation:

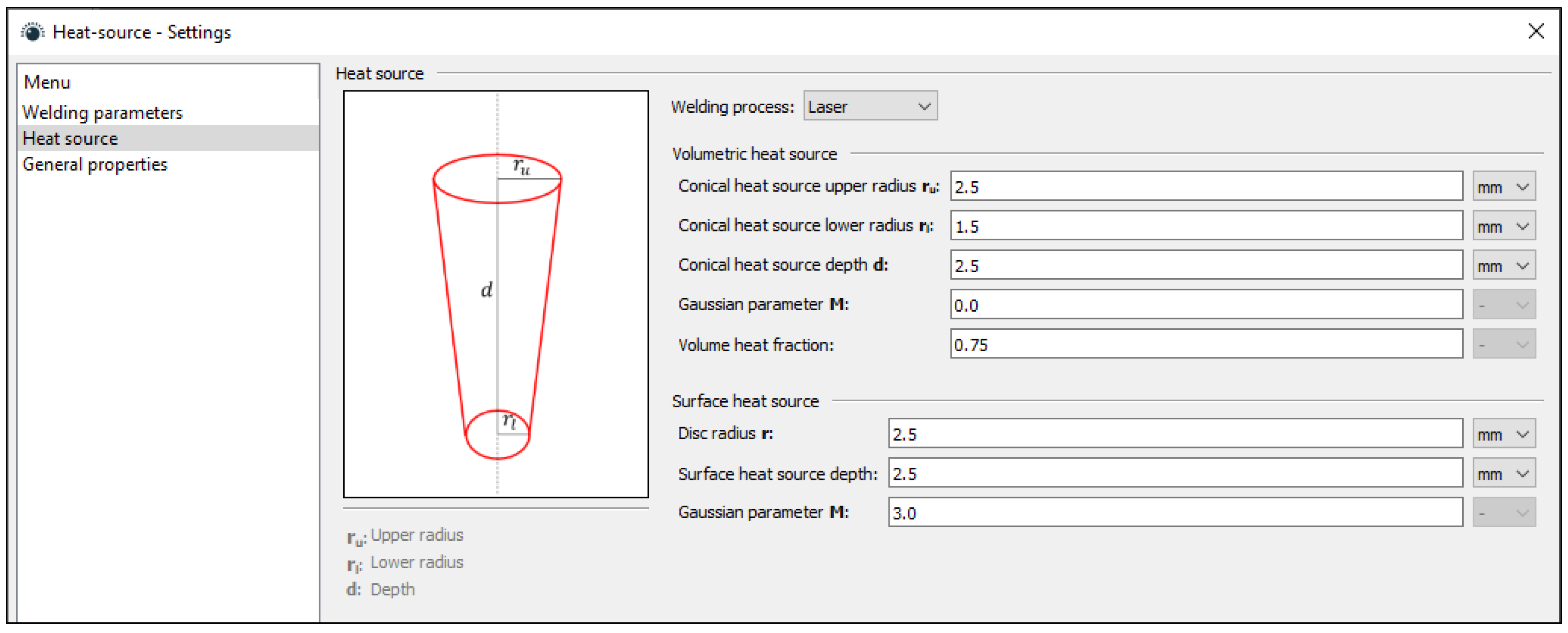

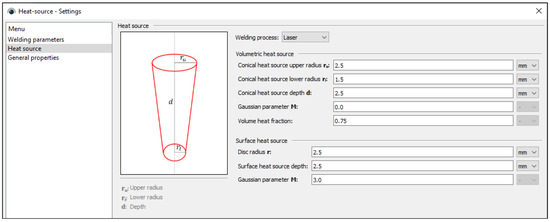

where is the process efficiency, is the power in (W), and is the focus radius [28]. A DED simulation model has been performed based on the experimental laser parameters. Heat source parameters used in the analysis are displayed in Figure 4.

Figure 4.

Heat source parameters.

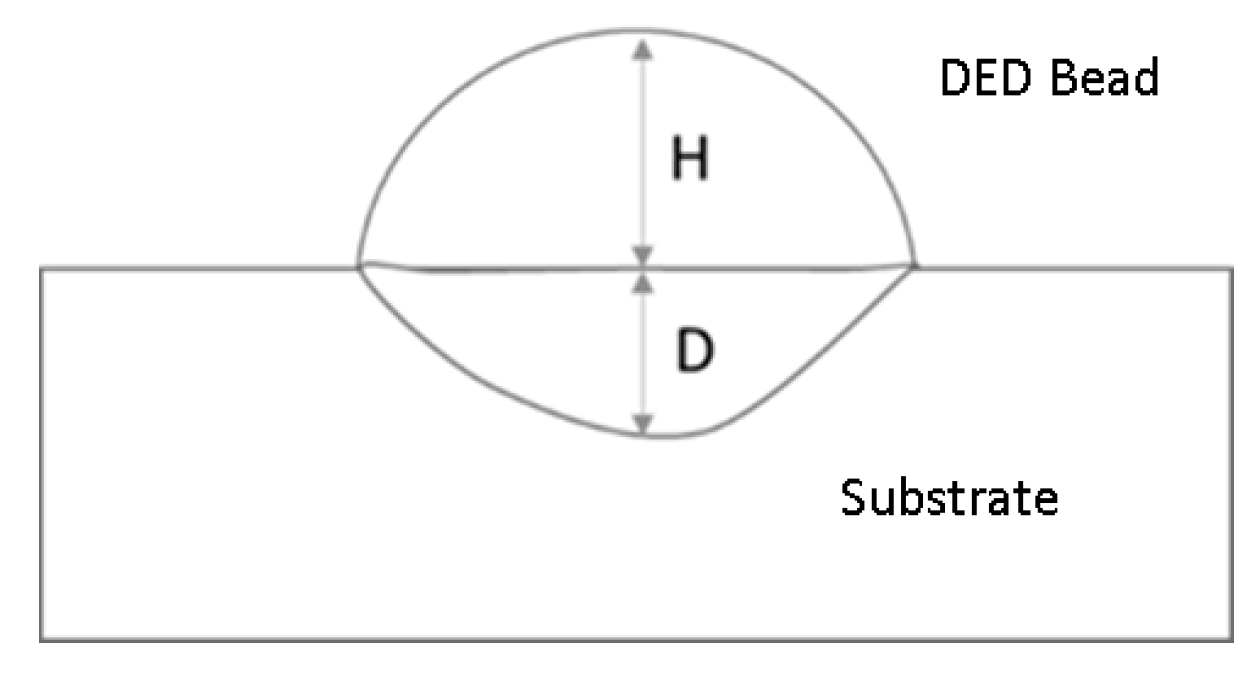

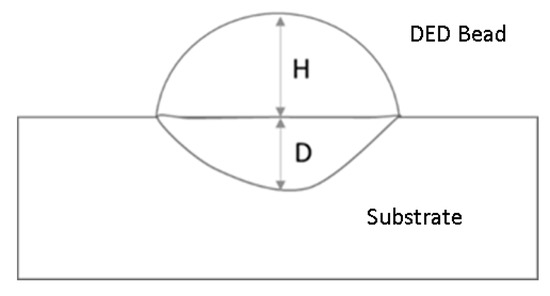

Dilution is one of the most critical parameters for DED process performance. It is a dimensional parameter and is defined by the ratio between the melt pool penetration depth below the substrate and the sum of melt pool penetration depth and deposited height for a single track. It is calculated as shown in Equation (3);

where (%) is the dilution percentage or dilution ratio, is melt pool penetration depth below the substrate, and (mm) is deposited single height. These definitions are shown in Figure 5.

Figure 5.

Dilution measurement definitions.

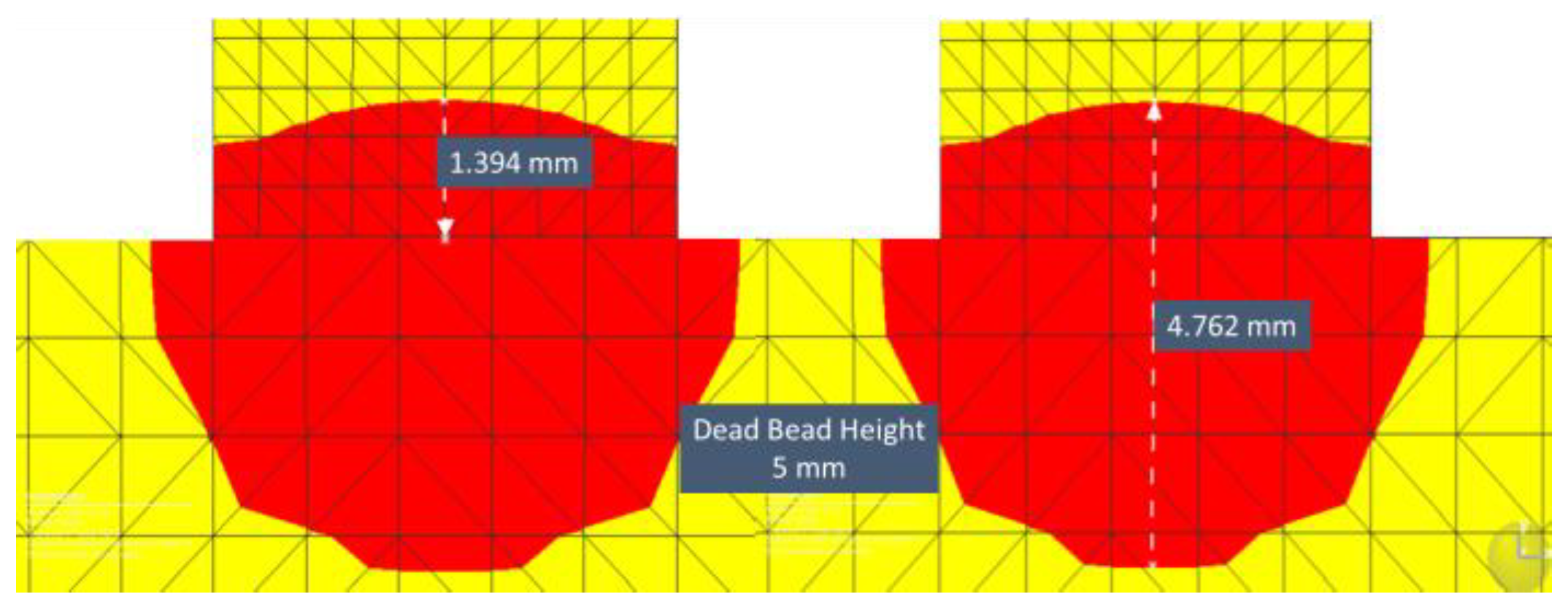

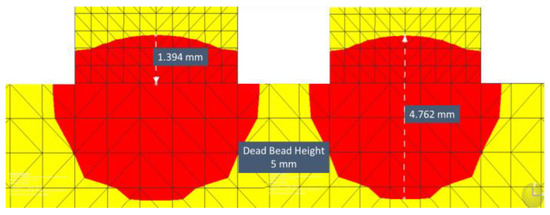

Dilution simulation has been performed with three different Heat Source Powers, 1100, 1300, and 1500 Watt. On the other hand, 2 different scan velocities have been preferred as 8 and 12 mm/sn, keeping the dead bead height at a constant value of 5 mm.

Brick elements are used for the CAE model in order to validate the heat source approach for the DED process. The advantage of using this type of element is the increase in the accuracy of the discretization. Some results for dilution are shown in Figure 6 under 1500 Watt, 12 mm/sn condition.

Figure 6.

Dilution simulation result.

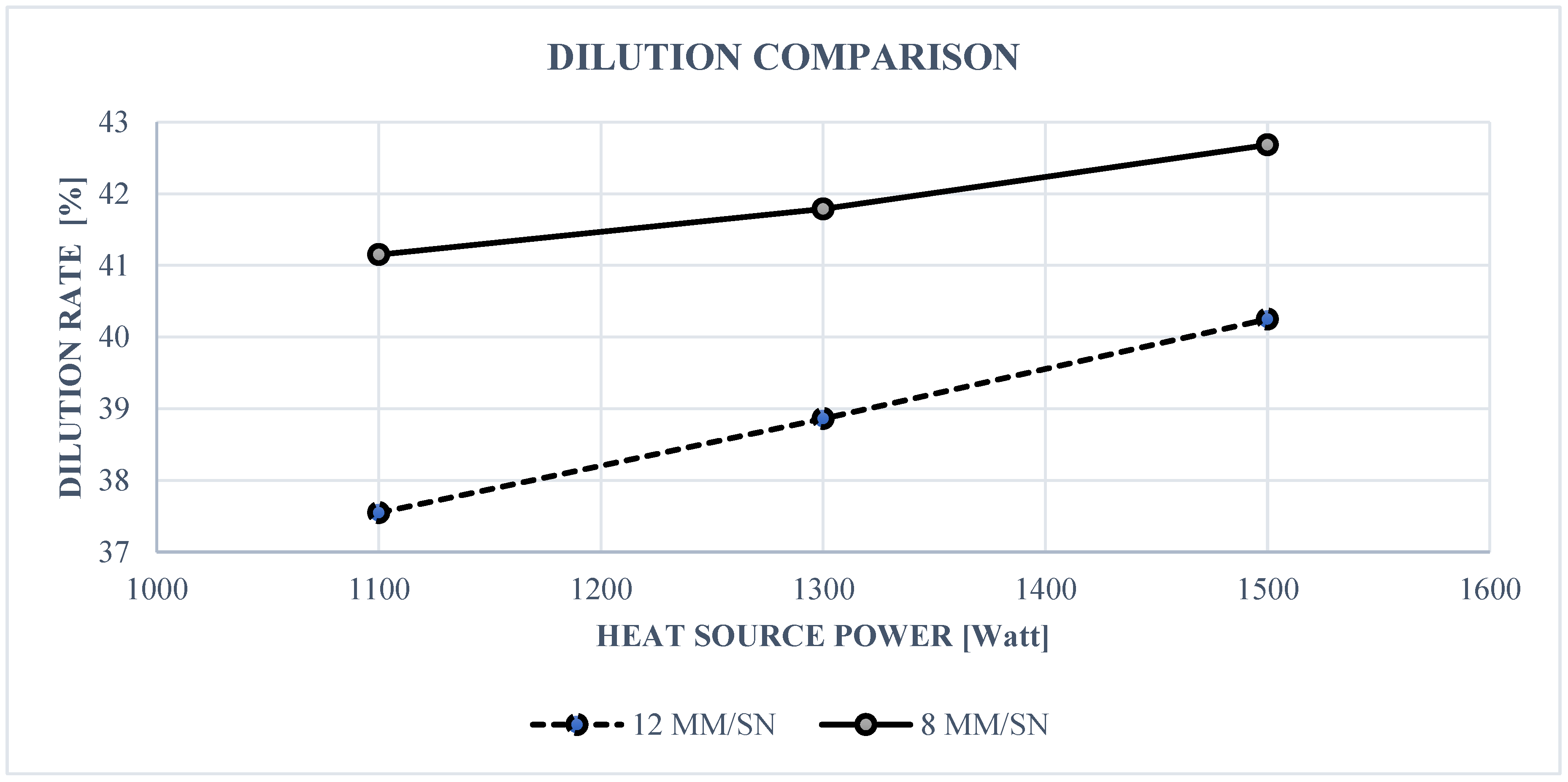

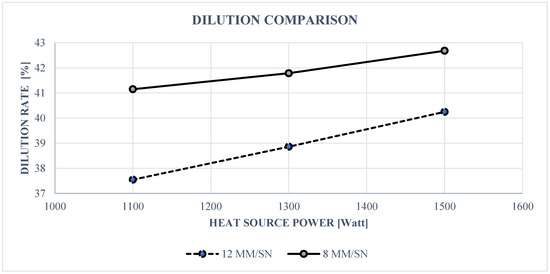

The heat source simulation model for the dilution rate is established, and the results have been gathered from these approaches within Table 2. The rationality of the model is compared by academic studies. Comparison study shows a parallel inclination between measured results physically and estimated dilution rates using simulation shown in Figure 7 [29].

Table 2.

Dilution results.

Figure 7.

Comparison of effects of heat source on dilution rate with different scanning velocities.

2.3. CAE Modelling of Hybrid DED Product

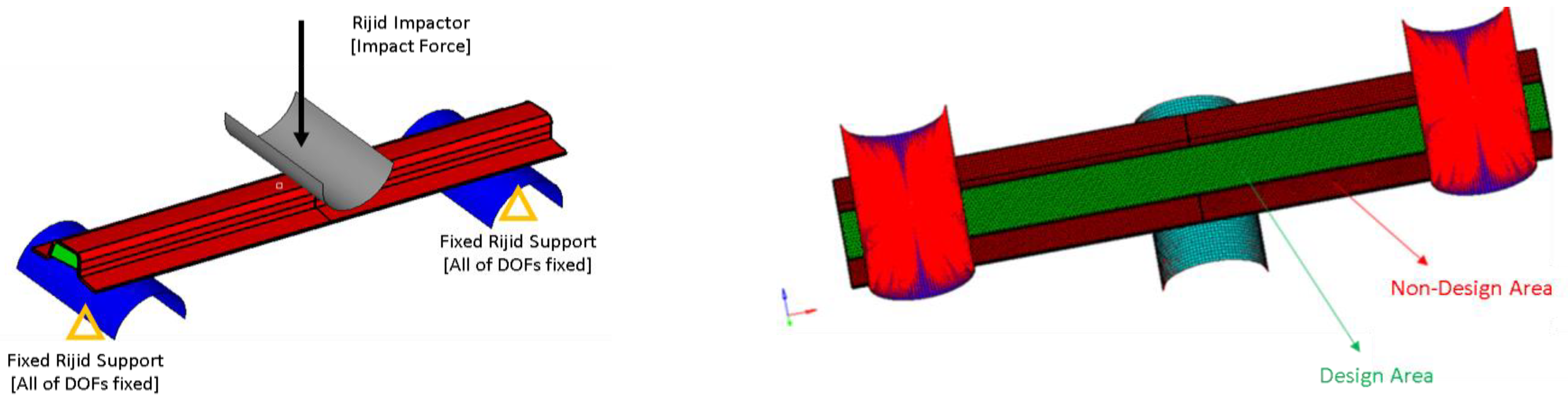

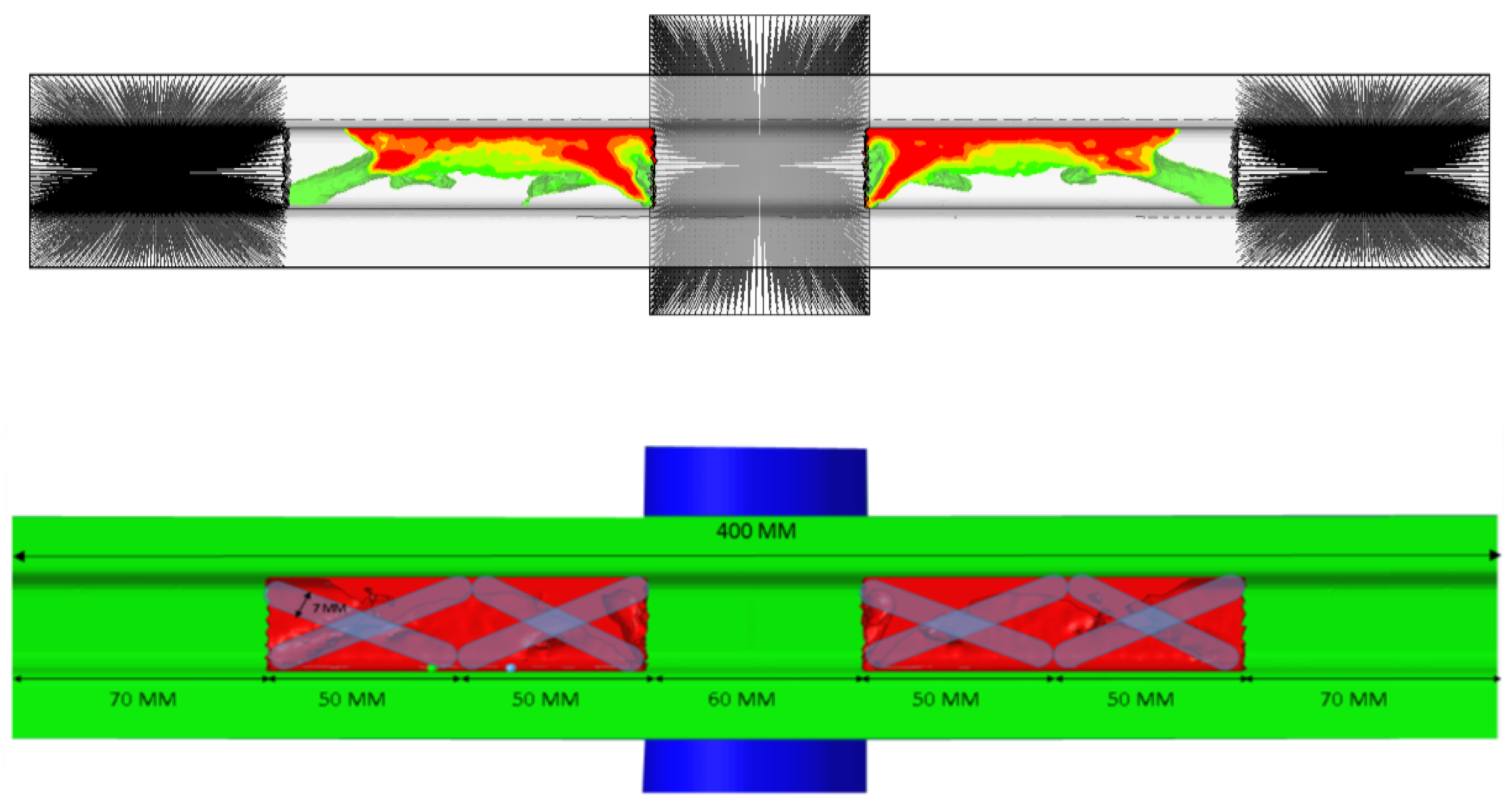

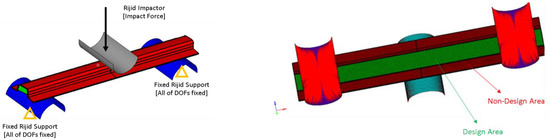

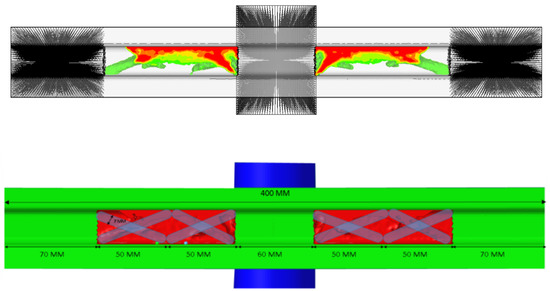

After the heat source model creation phase, in order to initialize a semi cross hybrid DED part, design volume has been created for topology optimization as shown in Figure 8. The topology optimization model has been evaluated under three point bending conditions.

Figure 8.

Boundary conditions and optimization model for cross model.

The base material is defined as a non-design area, and inside of the cross is described as a design area, namely changeable zone in terms of creating local stiffeners on the parts. Topology results have been obtained as shown in Figure 9. After this step, the structure should be derived and redesigned considering topology optimization results. It has been redesigned defined as Table 2.

Figure 9.

Topology optimization and redesign of the part.

Structural strength analysis has been carried out taking the thermomechanical results obtained from the DED simulation into account. Therefore, this means all thermal effects from the DED process can be included mapping on the parts during structural simulation.

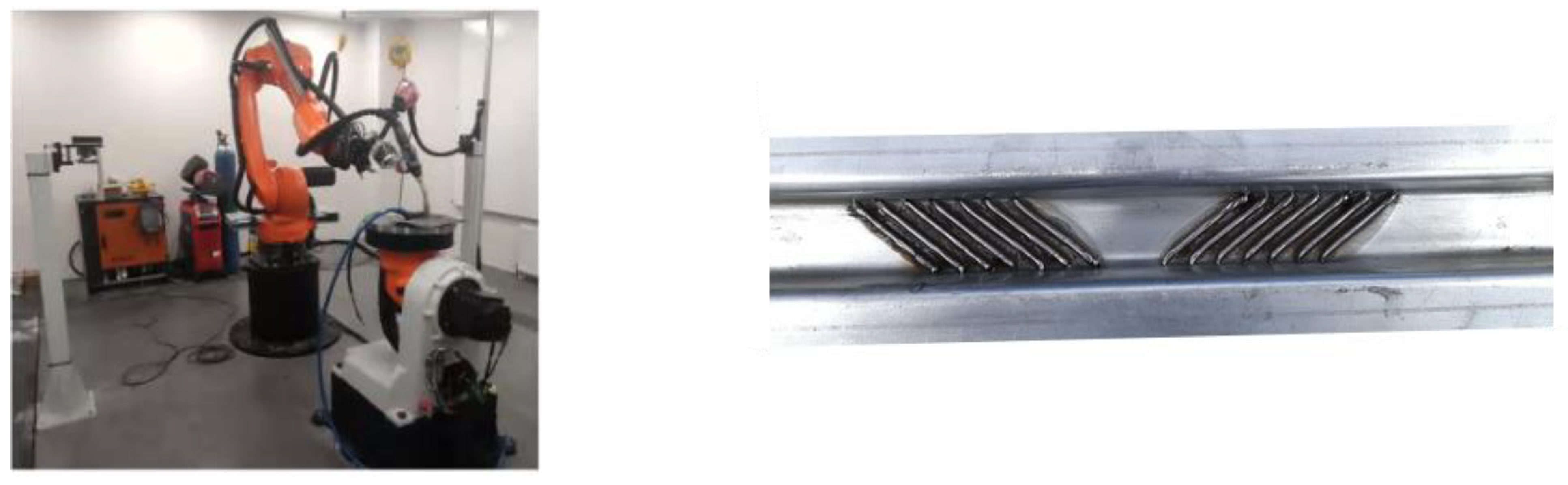

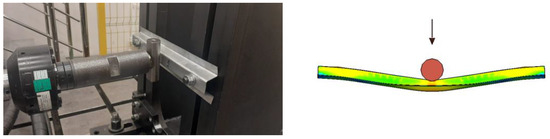

2.4. Manufacturing and Physical Tests

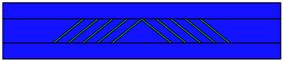

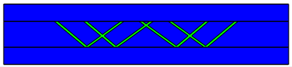

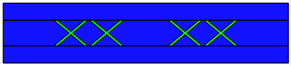

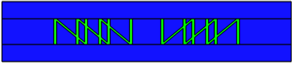

The DED machine concept used for manufacturing is based on a six-axis robot assembled on a table with a working range using a 2500 mm × 1000 mm plane. A semi cross part with semi cross left pattern has been selected from Table 3 and produced as shown in Figure 10.

Table 3.

Pattern types for redesign of the hybrid cross part.

Figure 10.

DED machine and hybrid cross part.

All CAE models are established on the Simufact Welding Software which uses the finite element method to calculate the global and local impact of heat input on the DED hybrid assembly. Only mass calculation is performed using CAD data. Overall, 355 MPa Grade Steel Material with 1.1 mm thickness is used in the simulations and the physical tests. Chemical composition of base material is defined as in Table 4.

Table 4.

Chemical composition of base material (355 Grade Steel).

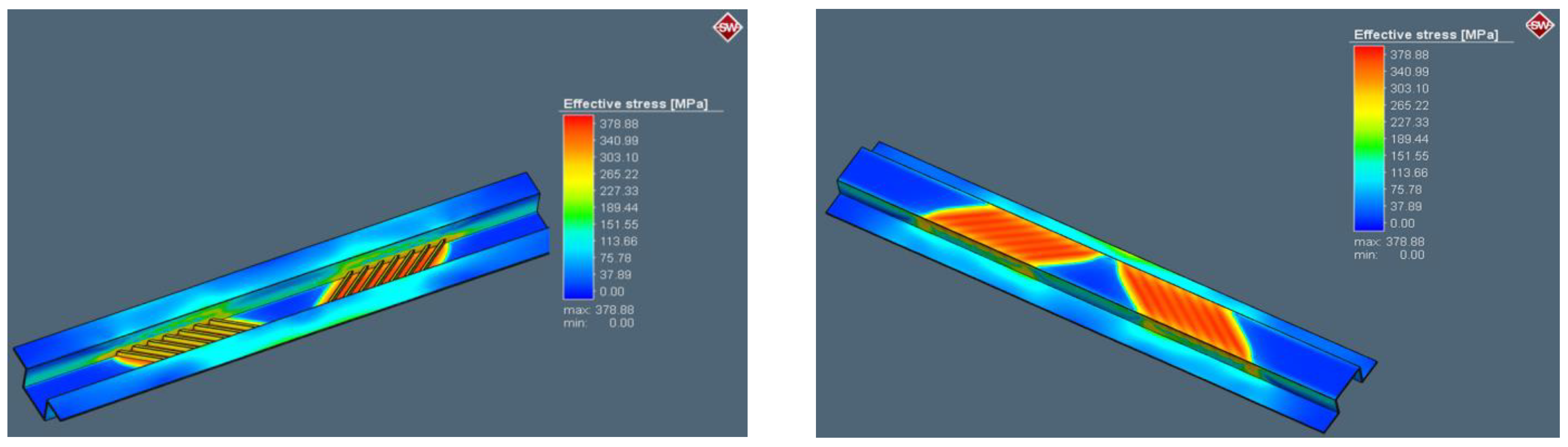

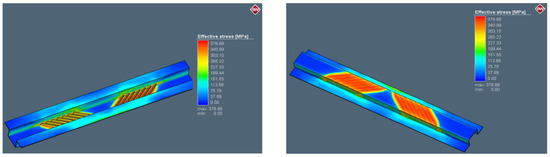

The DED process involves the generation of heat produced by the heat source power. As a result of the generated heat, the deposited surfaces in contact soften. In addition to this, DED simulation software is used to correlate the results with the product manufactured via DED machine physically (see Figure 11).

Figure 11.

DED process simulation (residual stresses after deposition).

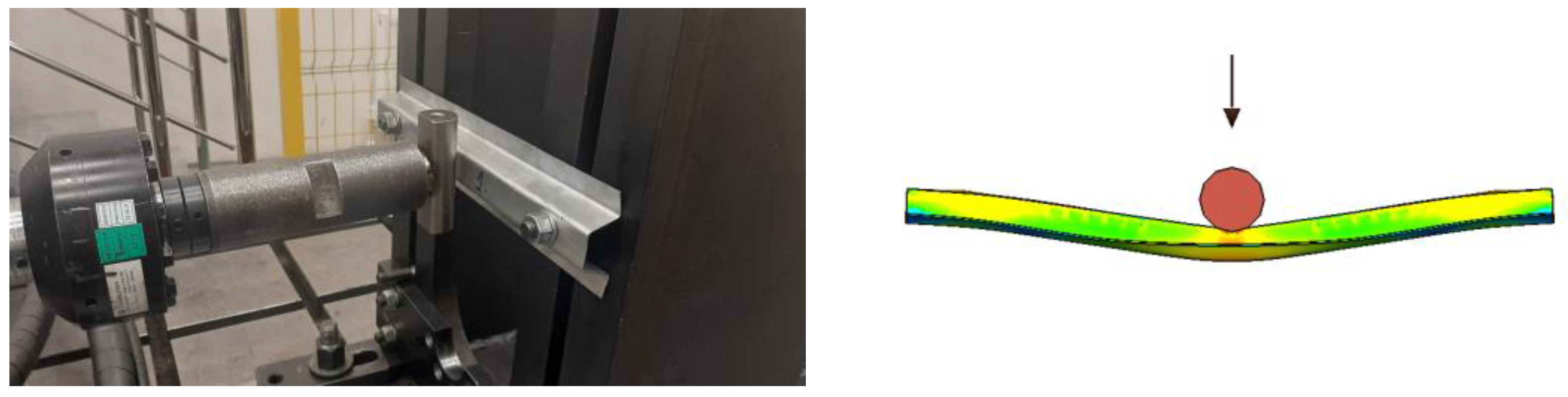

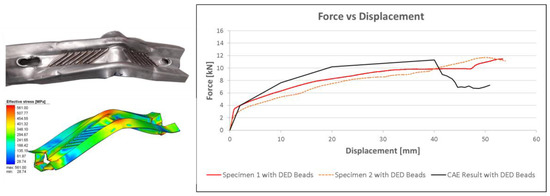

Finally, the hybrid product has been subjected to an imposed displacement using a mechanical durability test system physically and evaluated on the same software mapping the DED process results onto the part, as shown in Figure 12.

Figure 12.

Schematic of physical and numeric models for three point bending test.

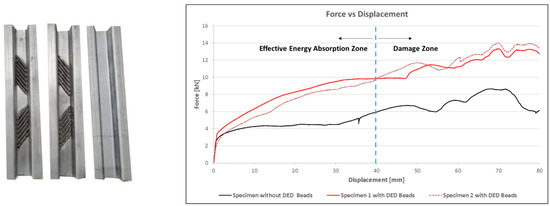

2.5. Evaluation of the Results

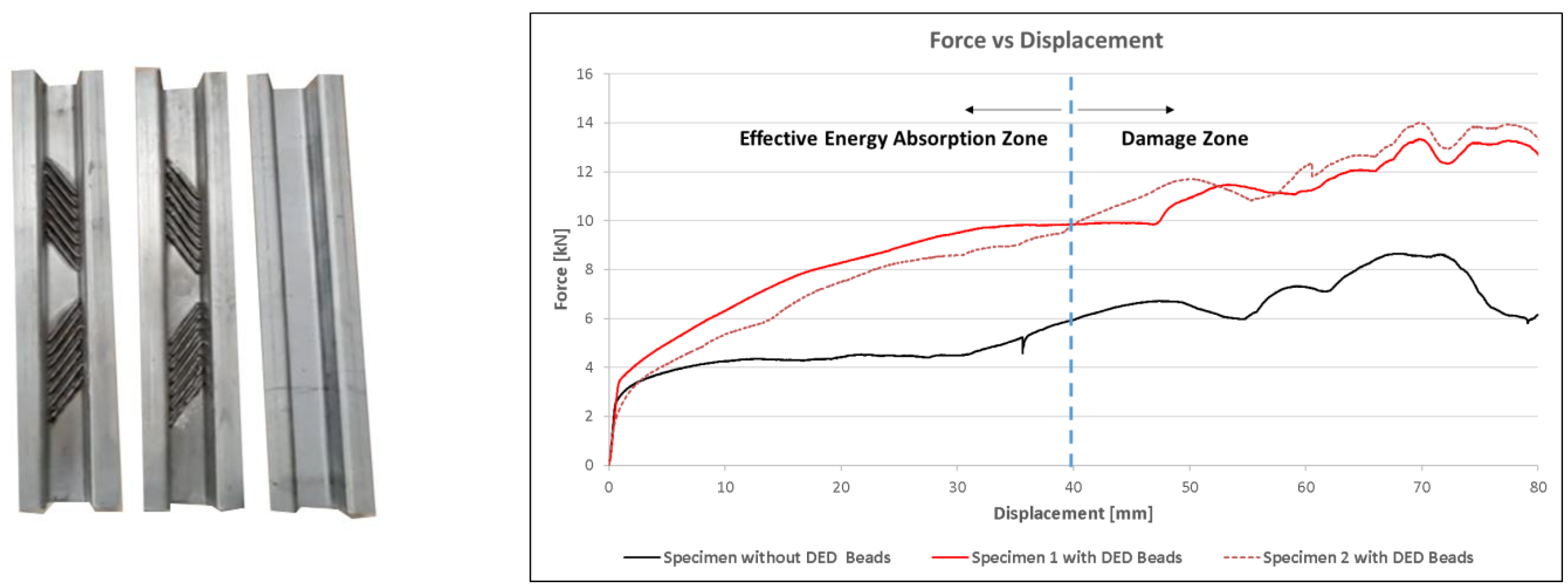

In this phase, 1 plain product and 2 hybrid products within semi-cross left pattern have been manufactured and forced physically as an imposed displacement via an actuator which has a maximum 50 kN load capacity. Results and prototypes are described in Figure 13. Energy absorption values have been compared under the effective energy absorption zone due to the suffering of the parts in the damage zone with instability. It points out that added DED beads on the part can provide a 76% increase in energy absorption value and a 66% increase in peak force. It has been seen that performance increase may lead to weight reduction using the DED process with an optimization study on energy and peak force.

Figure 13.

Test specimens and physical test results.

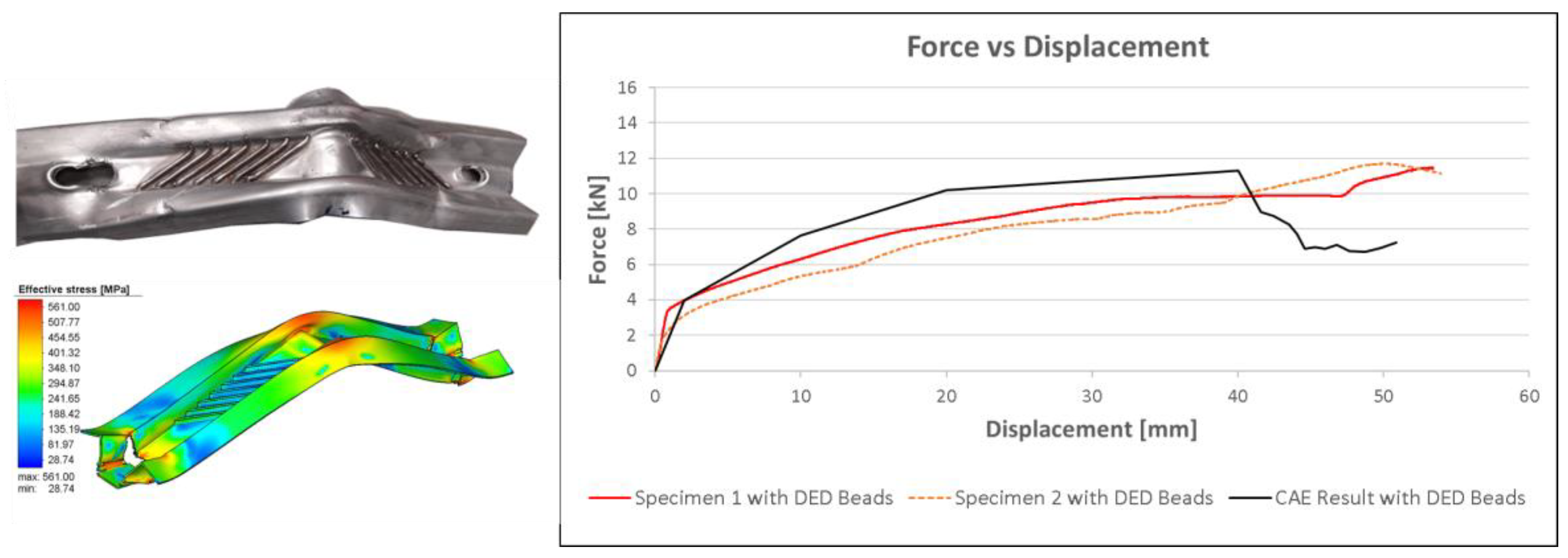

On the other hand, when the CAE results are compared with the real test results, it seems that numerical models for both heat source and structural simulation cases are working properly along the effective energy absorption zone shown in Figure 14. After this correlation, studies can be continued by creating DOE tables and ANN codes.

Figure 14.

Comparison of the results.

3. Artificial Neural Networks and Optimization

A neural network is a mathematical model of how the brain works neurologically. It mathematically models the nerve cells to imitate the brain’s process of learning. A neural network is structured with interconnected items called neurons included in layers, input and output data are necessary for neural network modelling. ANN is a more effective technique than DOE RSM as it can learn from previous data sets and it can approximate practically any non-linear functions [30]. In this research, ANN and DOE RSM are both used as surrogate models to predict and optimize the topology based geometric patterns and process parameters. The experimental results related to DOE RSM studies are taken and used as the input set for neural network models. The ANN approach is usually presented to solve the problems requiring assumptions and constraints based on experience by the trial-and-error method of experts in design and manufacturing. In this section, ANN studies will be investigated taking the DED process parameters into the account. Firstly, DOE tables have been created according to input parameters with their levels, as follows in Table 5 and Figure 1.

Table 5.

Inputs and outputs.

Five levels are determined for each of the six input parameters. On the other hand, considering the Taguchi table in Table 6, the number of experiments required for five levels of six parameters is created as 25 data. The DOE table is given in Table 7.

Table 6.

Taguchi DOE table [31].

Table 7.

Parameters with Taguchi for ANN.

However, Taguchi tables have been created, and Latin Hypercube Sampling has been used in order to find the intermediate values and evaluate and obtain more accurate results for each input. Latin hypercube sampling (LHS) is very efficient for estimating mean values and standard deviations. Latin hypercube sampling is suggested as a tool to improve the efficiency of different important sampling methods for structural reliability analysis [32]. The LHS table is given in Table 8.

Table 8.

Parameters with Latin Hypercube Sampling for ANN.

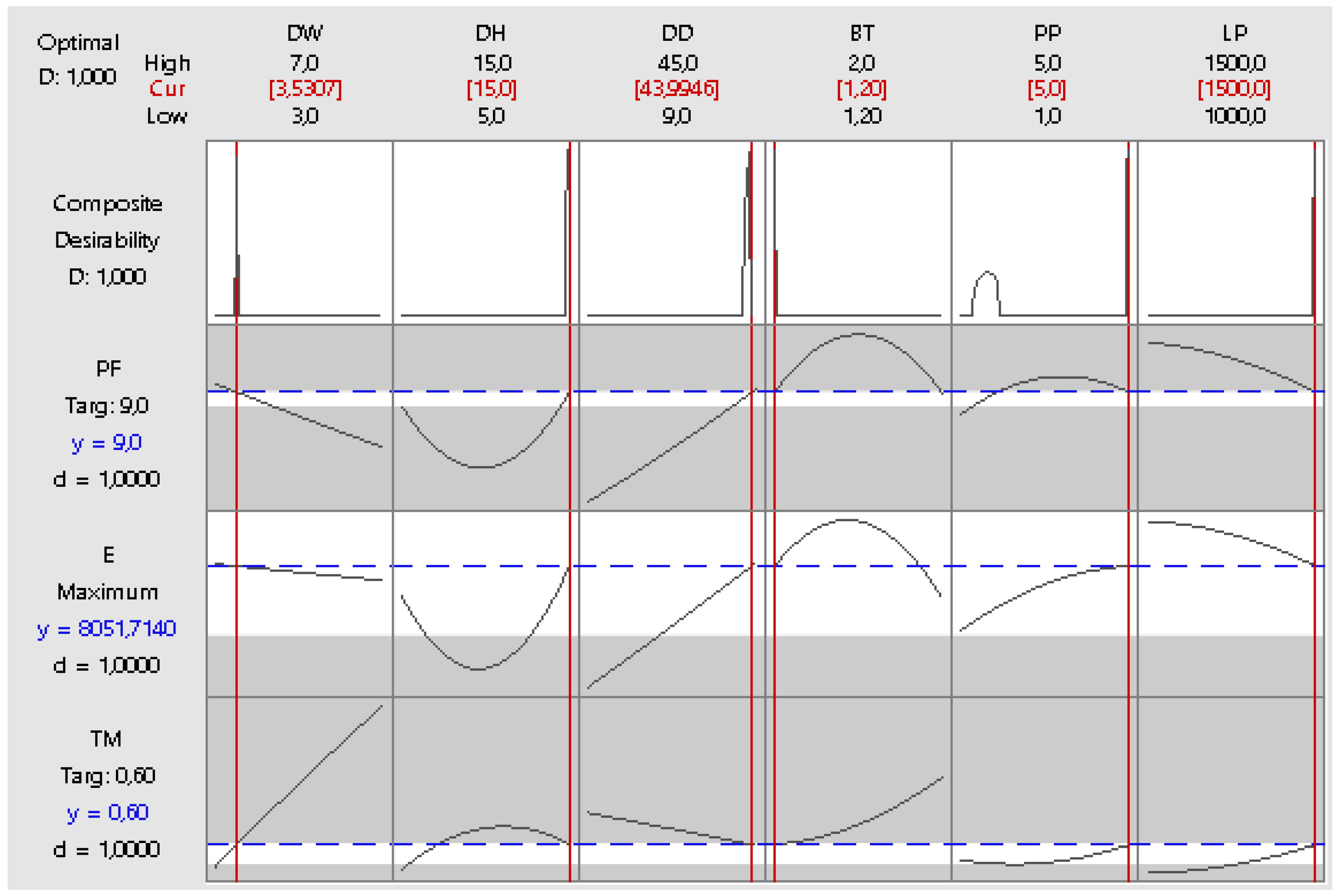

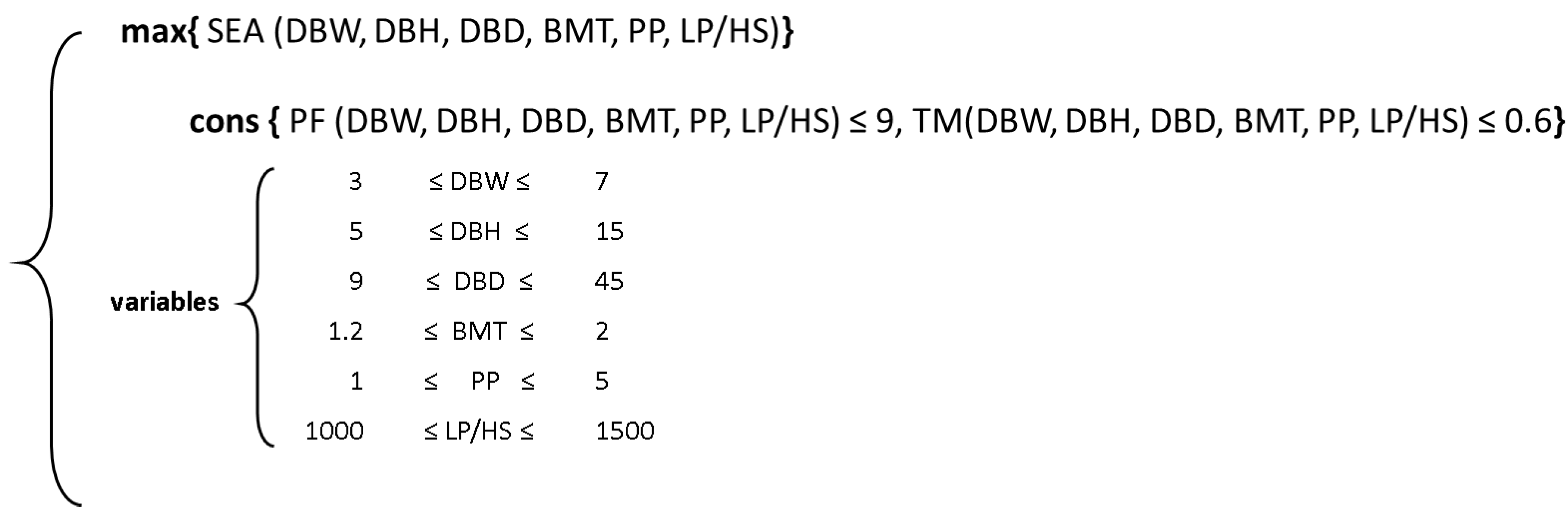

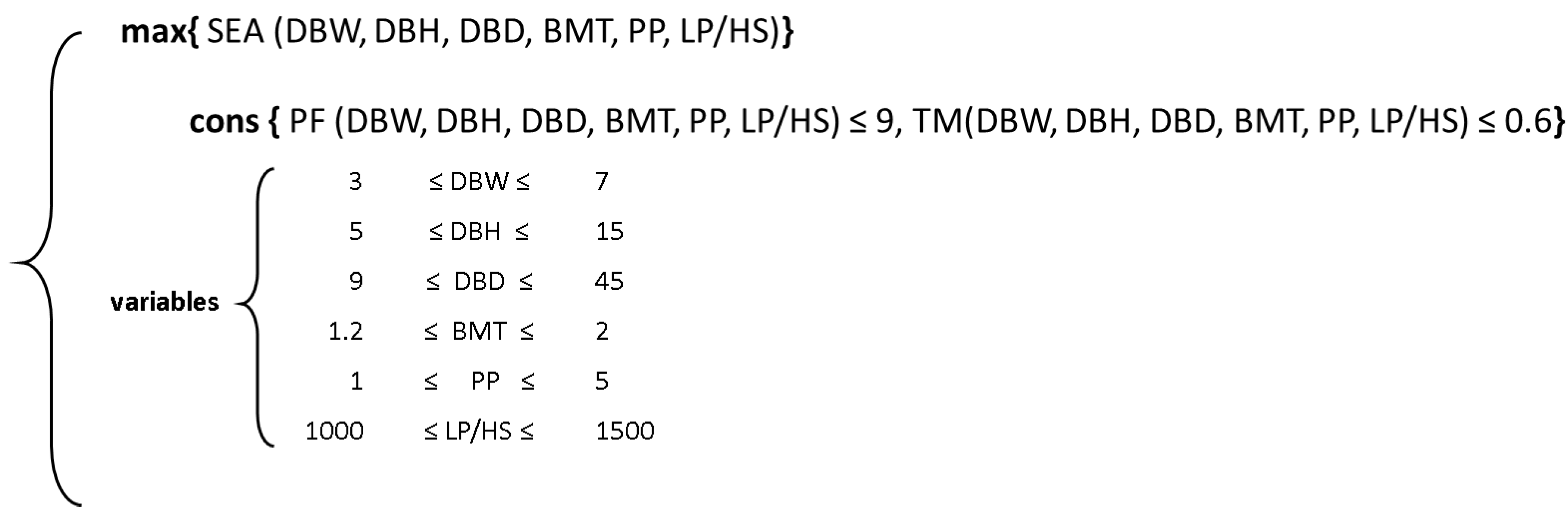

To evaluate the influence of each parameter in a three point bending performance, a response surface method (DOE RSM) analysis was performed. DOE RSM flow has been performed considering the constraints of the variables as follows;

Figure 15 shows how the input parameters effect the outputs in terms of structural performance mapping the thermal process contributions on the part. The data showed in Table 9 were obtained from the DOE RSM approach to optimize the input parameters.

Figure 15.

Relationship results between input parameters and outputs via DOE RSM.

Table 9.

DOE RSM optimization results of design and process parameters.

Table 10 shows that the DOE RSM approach evaluates the small data set for total mass and energy with over 20% correlation error. On the other hand, it estimates the peak force acceptable correlation error when it is compared with energy and total mass results relatively.

Table 10.

DOE RSM Prediction of force, energy dissipation and total mass.

Artificial Neural Network Application

In this study, a semi cross Hybrid DED component will be optimized using the multi-physical approach with both process and structural three point bending analysed as a thermomechanic couple. Thermomechanic analyses generally require high CPU time. As a result of this situation, using thermomechanic analyses directly is not reasonable in the optimization process. On the other hand, ANN can be used as an artificial intelligence-based approximation technique in order to reduce the computational cost and enhance optimization efficiency and the approximation accuracy for modelling complex systems with computational difficulties.

Recently, ANN has been applied to various engineering areas due to its benefits and efficiency in some aspects, such as acknowledging and learning the relations between inputs and outputs with no demand for any precise relation, regardless of the system linearity or nonlinearity, and the high tolerance to the noise in the data and measurement errors. In this study, the ANN method is proposed to develop metamodels of objective and constraint functions [33].

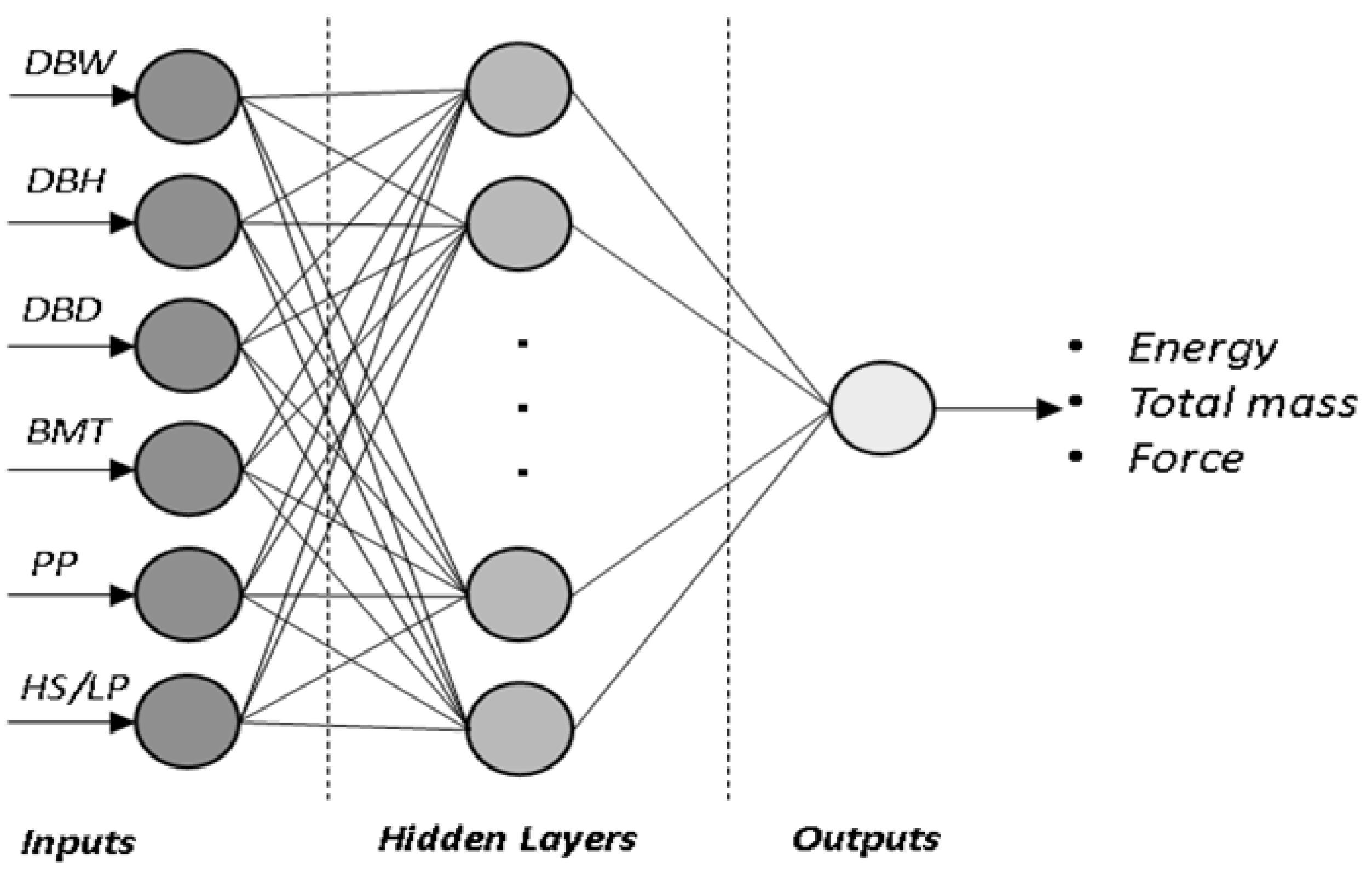

Within the scope of this study, the ANN method is proposed to develop metamodels of objective and constraint functions to predict the optimum design parameters of the semi cross hybrid component with a dimension of 400 mm including the DED process parameter effects. ANNs are computer algorithms inspired by the computational abilities of interconnected neurons in the brain. The ANN method is based on the synaptic connections between biological neuron cells and these cells. The general architecture of an ANN is composed of a collection of connected neurons associated with three kinds of layers: the input layer, the hidden layer(s), and the output layer [34,35].

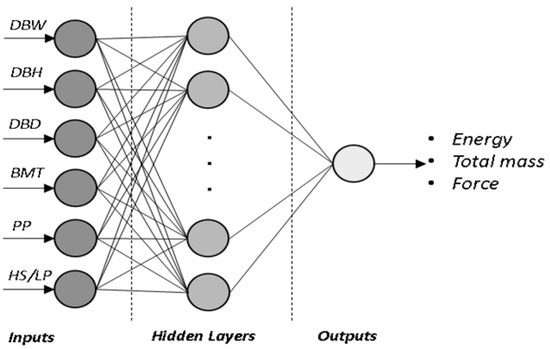

The structure of the ANN used in this paper is pointed out in Figure 16. ANN structure is composed of three layers network. MATLAB is utilized for developing a suitable generalized feedforward ANN for metamodeling objective and constraint functions. Pearson correlation coefficient (R) and mean square error (MSE) values are examined to find the best ANN structure [36].

Figure 16.

The architecture of Artificial Neural Network (ANN).

ANN structures are constituted by 36 data points which receive 25 of the input data from Taguchi and 11 via LHS method. All the results of these data are obtained from DED simulations. The learning rate is determined as starting from 0.01 and increasing in 0.01 steps up to 1. Some researchers investigated the number of neurons up to 30 and between 4 and 12 number of neurons gave the best R values and lowest MSE [33,34,35,36]. Thus, the number of neurons is defined between 1 and 30 in this study. The training functions, Levenberg–Marquardt and Scaled conjugate gradient backpropagation, which are MATLAB built-in training algorithms, are chosen. Parameters used in ANN structures are given in Table 11.

Table 11.

Artificial neural network (ANN) parameters.

A hold-out technique for cross-validation is used by partitioning the data into two segments, which are the data used for the validation test and the other for training the neural network model [31,32]. This technique is preferred as the data set is small, at almost 30 data. In total, 70%, 15%, and 15% of data points are used for training, testing, and validation, respectively. In order to find the optimum ANN structure, a nested loop is designed using the learning rate, number of neurons, and different training functions. The ANN model and predictions are saved when the Pearson correlation coefficient (R) of the test is higher than 0.965, as well as finding better MSE values throughout the cycle. The reason for choosing MSE besides the R-value is to prevent over-fitting and increase accuracy. Thus, in this study, the hold-out technique is employed to evaluate the learning algorithm of the present neural network model. The present neural network model offers an ANN model with higher prediction ability. The pseudocode of the optimum ANN model is presented in Algorithm 1.

| Algorithm 1. Matlab codes for Artificial Neural Network. |

| 1·Input: Design Variables [DBW,DBH,DBD,BMT,PP,LP], Targets [TM, SEA, PF] 2·MSE_init = 100,000; 3·training_types = [“trainlm”,“trainscg”]; 4· for learning_rate = 0.01:0.01:1 5· for trainFcns = 1:2 6· create neural network = feedforward 7· train network 8· test network 9· if R_Test > 0.965 and MSE < MSE_init 10· MSE_init=MSE 11· save network 12· else 13· end 14· end 15· end 16·end |

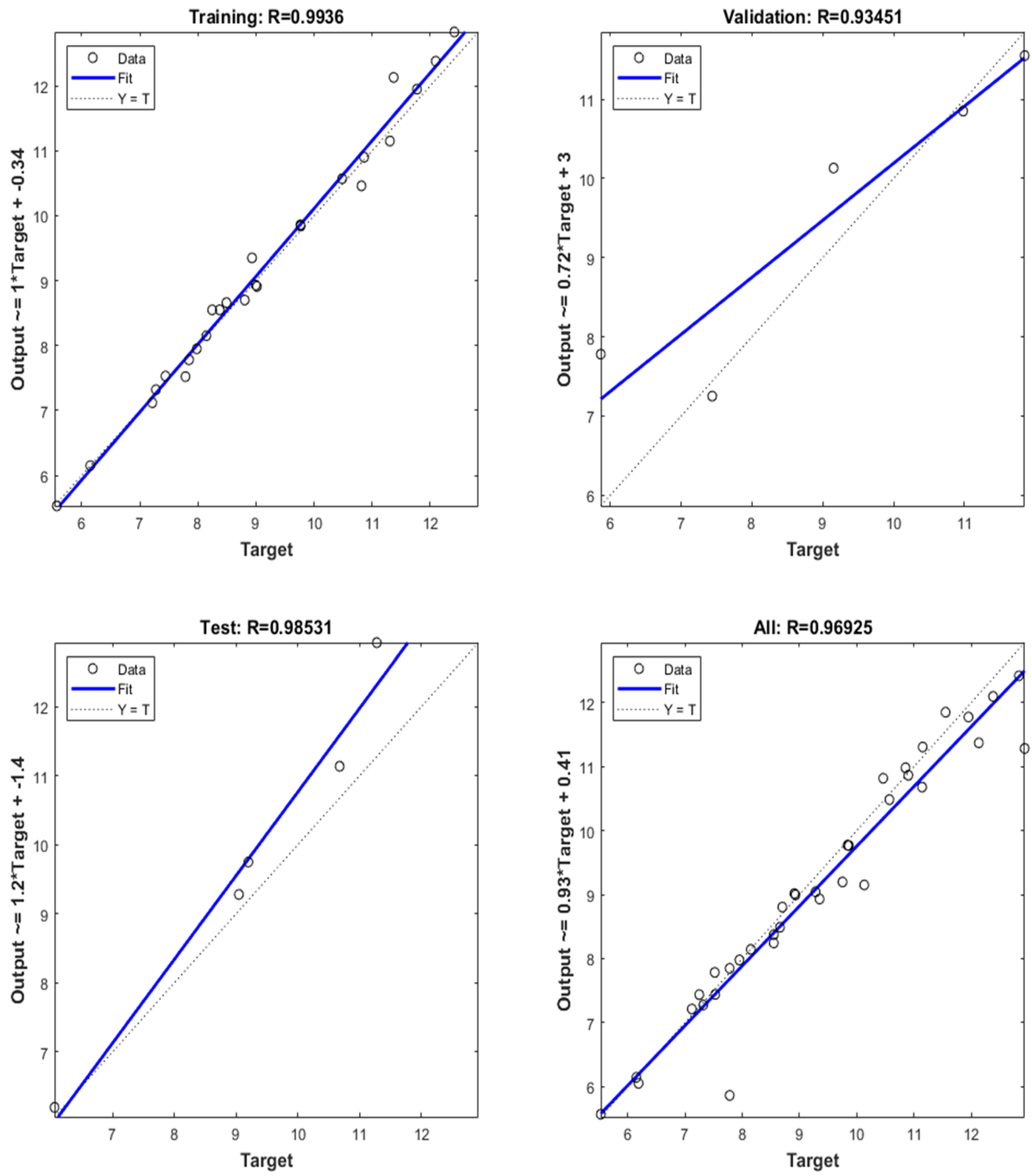

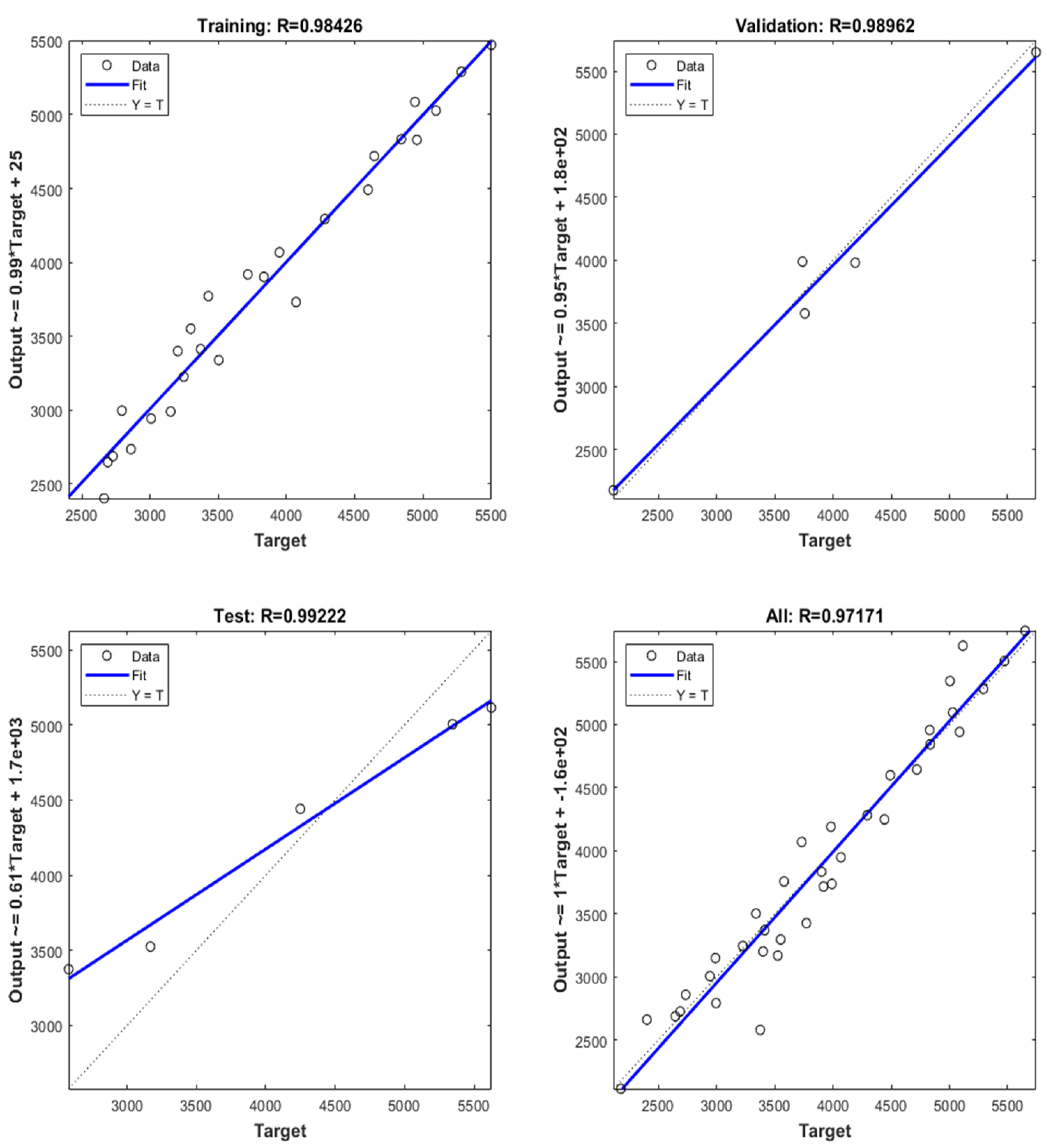

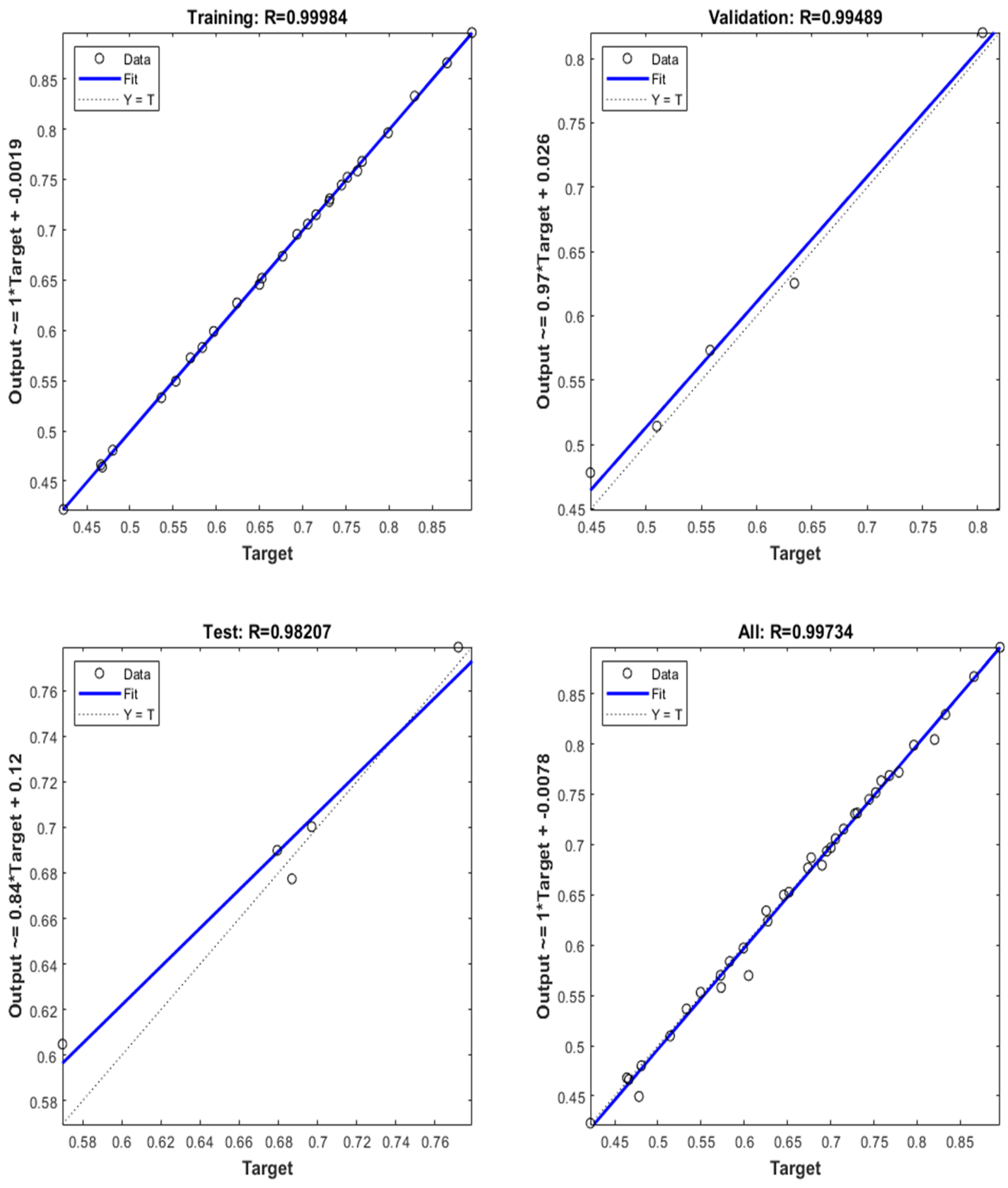

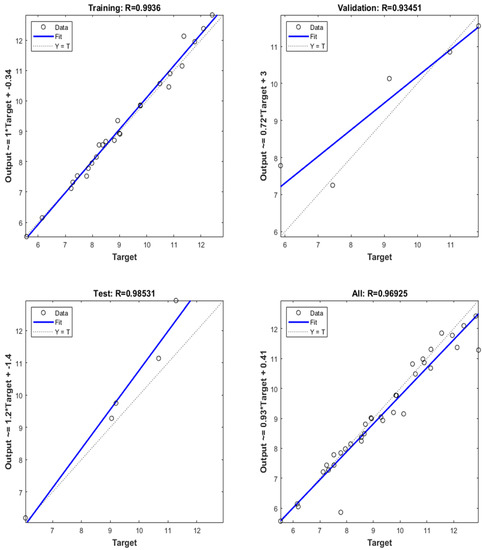

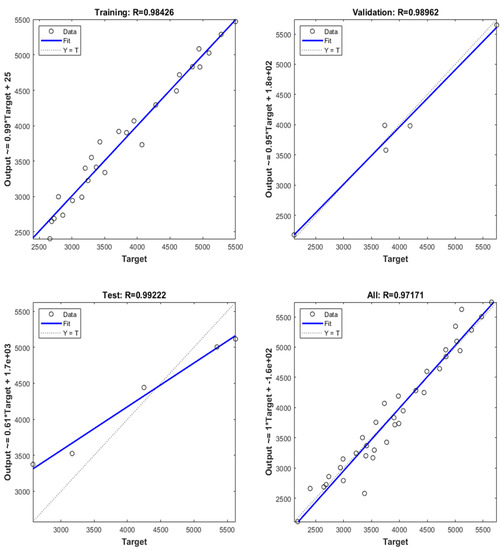

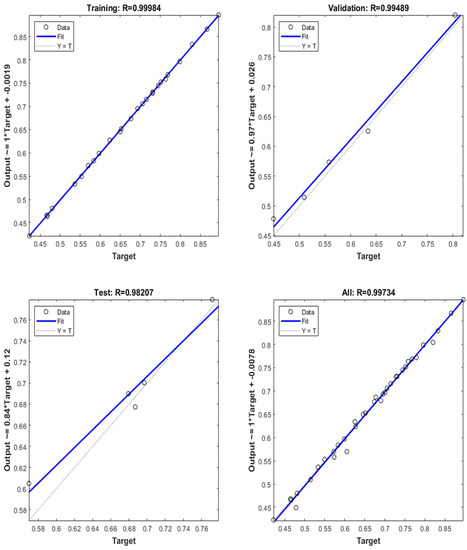

The R-value curves of the best ANN structures obtained as a result of the loop are given in Figure 17, Figure 18 and Figure 19 for Peak Force, Specific Energy Absorption, and Total Mass, respectively. An R-value close to 1 indicates that the established model has high accuracy.

Figure 17.

The R-value curves of the best artificial neural network (ANN) structures of Peak Force.

Figure 18.

The R-value curves of the best artificial neural network (ANN) structures of Specific Energy Absorption.

Figure 19.

The R-value curves of the best artificial neural network (ANN) structures of Total Mass.

The smallest R-values for Specific Energy Absorption and Total Mass are 0.97171 and 0.98207, respectively, so they have a high correlation. Although the smallest R-value for Peak Force is 0.93451 in validation, as it is a high nonlinear problem with the heat input and flow curves used for the material discretization difficulties in the analysis, it offers a sufficient validation.

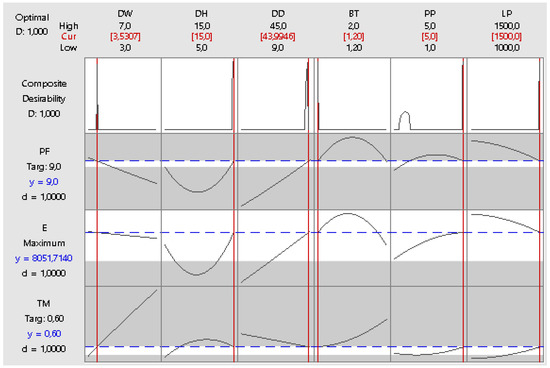

In this research, optimization of the hybrid DED semi cross part is carried out with a genetic optimization algorithm. GA is one of the evolutionary optimization methods that work using mechanisms similar to evolutionary mechanisms observed in nature [37].

Under the constraints which are defined for the DOE RSM approach, the genetic algorithm estimates the input parameters as shown in Table 12. As a next step, these input parameters, obtained via genetic algorithm, were evaluated following the steps in a DED process simulation, mapping DED results into structural analysis, three point bending simulation, and comparison of the results. Results were calculated with validated CAE analysis as defined in Table 13. It is observed that the ANN + GA approach presents acceptable results, with over 80% correlation for each outputs investigated in this research.

Table 12.

ANN + GA optimization results of design and process parameters.

Table 13.

ANN prediction of force, energy dissipation, and total mass.

Table 14 points out that, under the same constraints and conditions, the ANN + GA approach gives the better results for energy and total mass estimation. Besides this, the performance of DOE RSM on the prediction of the peak force is more reliable than the ANN + GA approach results.

Table 14.

DOE RSM and NN + GA comparison.

4. Conclusions

The objective of this research was to introduce an approach for the integration of the two structures to improve the properties of the final part, such as the specific energy absorption, considering the optimum peak force and total mass constraints for the DED hybrid product. A computationally efficient approach is developed for constructing a DOE RSM and neural network based surrogate model for problems where both inputs and outputs are high-dimensional and nonlinear, using a small training data set. The proposed approach helps to fill the existing gap for development of the DED hybrid product, which includes the contributing and controllable design and process parameters.

ANN + GA optimization approach is presented to increase the prediction for the specific energy absorption value of the semi cross hybrid DED part considering peak force and total mass constraints with a small data set to decrease the computation time and production costs. ANN models can predict the effects of the different variables, such as the DED bead height, width, and distance, base material thickness, pattern type, and heat source power on the performance of a cross member part with an acceptable and good accuracy to predict the inputs and outputs. The proposed ANN + GA model offers a surrogate model with higher prediction ability than DOE RSM method for energy and total mass. On the other hand, the DOE RSM approach gives the closed prediction for peak force values. This study demonstrates that the ANN-based optimization approach can be used in design optimization studies on the hybrid products manufactured via the DED process.

In this study, a locally reinforced semi cross part is manufactured using the proposed approach. As a result of the physical test on the bench after hybrid DED cross prototypes, it has been found that locally reinforced cross beam has much more energy absorption and peak force values than plain model, with a performance increase of over 65%. It is seen that the proposed NN-GA is a promising approach to generate the topology based geometrical patterns and process parameters which can be used to create a local reinforced product as hybrid manufacturing technologies.

The presented techniques in this study have some limits. In the case of other alloys, such as titanium alloys, the error may increase. For the same specific energy density, more material melts for titanium based alloys in comparison with iron-based alloys. It may be necessary to redefine the heat source model according to melt pool shapes and obtain the flow curves as suitable in order to correlate CAE model with the physical results.

Author Contributions

Conceptualization, M.Ç., E.İ.A. and F.Ö.; methodology, M.Ç., E.İ.A. and F.Ö.; software, M.Ç.; validation, M.Ç.; formal analysis, M.Ç.; investigation, M.Ç.; resources, M.Ç., E.İ.A. and F.Ö.; data curation, M.Ç.; writing—original draft preparation, M.Ç.; writing—review and editing, M.Ç., E.İ.A. and F.Ö.; visualization, M.Ç.; supervision, F.Ö.; project administration, M.Ç. and F.Ö.; funding acquisition, M.Ç. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Tubitak and Coşkunöz Holding [2244 Industrial Doctorate Programme No: 119C059]; and by Tubitak, Eureka, Eureka Smart Cluster and Coşkunöz Holding [grant agreement number 9190007].

Acknowledgments

The authors would like to express their sincere gratitude to Tubitak and Coşkunöz Holding which offers its software and hardware infrastructure.

Conflicts of Interest

The authors declare that there are no conflicts of interest to disclose.

Nomenclature

| ANN | Artificial Neural Network |

| DED | Directed Energy Deposition |

| DBW | DED Bead Width |

| DBD | DED Bead Distance |

| PP | Powder/Bead Pattern |

| HS/LP | Heat Source/Laser Power |

| SEA | Specific Energy Absorption |

| Cons | Constraints |

| LHS | Latin Hypercube Sampling |

| AM | Additive Manufacturing |

| TA | Topology Approach |

| RSM | Responce Surface Method |

| DOF | Degree of Freedom |

| CFD | Computational Fluid Dynamics |

| GA | Genetic Algorithm |

| DBH | DED Bead Height |

| BMT | Base Material Thickness |

| PF | Peak Force |

| TM | Total Mass |

| MSE | Mean Squared Error |

| Fig | Figure |

| PBF | Powder Bed Fusion |

| PCM | Phase Change Material |

| LA | Lattice Approach |

| DOE | Design of Experiment |

References

- Diegel, O.; Nordin, A.; Motte, D. A Practical Guide to Design for Additive Manufacturing, 1st ed.; Springer Series in Advanced Manufacturing; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Zhang, Y.; Jarosinski, W.; Jung, Y.G.; Zhang, J. Additive manufacturing processes and equipment. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 39–51. [Google Scholar] [CrossRef]

- Milewski, J.O. Additive Manufacturing of Metals: From Fundamental Technology to Rocket Nozzles, Medical Implants, and Custom Jewelry, 1st ed.; Springer Series in Materials Science, 258; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- ISO/ASTM 52900; Additive Manufacturing—General Principles—Terminology. International Organization for Standardization: Geneva, Switzerland, 2018. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:dis:ed-2:v1:en (accessed on 10 February 2022).

- Piscopo, G.; Iuliano, L. Current research and industrial application of laser powder directed energy deposition. Int. J. Adv. Manuf. Technol. 2022, 119, 6893–6917. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. Int. J. Lightweight Mater. Manuf. 2021, 4, 246–261. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Li, C.; Wen, X.; Sun, J. Mechanical performance of 316 L stainless steel by hybrid directed energy deposition and thermal milling process. J. Mater. Process. Technol. 2021, 291, 117023. [Google Scholar] [CrossRef]

- Godec, M.; Malej, S.; Feizpour, D.; Donik, Č.; Balažic, M.; Klobčar, D.; Pambaguian, L.; Conradi, M.; Kocijan, A. Hybrid additive manufacturing of Inconel 718 for future space applications. Mater. Charact. 2021, 172, 110842. [Google Scholar] [CrossRef]

- Suryatal, B.K.; Sarawade, S.S.; Deshmukh, S.P. Fabrication of medium scale 3D components using stereolithography system for rapid prototyping. J. King Saud Univ. Eng. Sci. 2021, in press. [Google Scholar] [CrossRef]

- Almonti, D.; Mingione, E.; Tagliaferri, V.; Ucciardello, N. Design and analysis of compound structures integrated with bio-based phase change materials and lattices obtained through additive manufacturing. Int. J. Adv. Manuf. Technol. 2022, 119, 149–161. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, W.; Quan, D.; Shi, G.; Tang, L.; Hou, Y.; Breitkopf, P.; Zhu, J.; Gao, T. From Topology Optimization Design to Additive Manufacturing: Today’s Success and Tomorrow’s Roadmap. Arch. Comput. Methods Eng. 2020, 27, 805–830. [Google Scholar] [CrossRef]

- Primo, T.; Calabrese, M.; Del Prete, A.; Anglani, A. Additive manufacturing integration with topology optimization methodology for innovative product design. Int. J. Adv. Manuf. Technol. 2017, 93, 467–479. [Google Scholar] [CrossRef]

- Abd Aziz, N.; Adnan, N.A.A.; Abd Wahab, D.; Azman, A.H. Component design optimisation based on artificial intelligence in support of additive manufacturing repair and restoration: Current status and future outlook for remanufacturing. J. Clean. Prod. 2021, 296, 126401. [Google Scholar] [CrossRef]

- Bulut, E.; Albak, E.İ.; Sevilgen, G.; Öztürk, F. Prediction and optimization of the design decisions of liquid cooling systems of battery modules using artificial neural networks. Int. J. Energy Res. 2022, 46, 7293–7308. [Google Scholar] [CrossRef]

- Qi, X.; Chen, G.; Li, Y.; Cheng, X.; Li, C. Applying Neural-Network-Based Machine Learning to Additive Manufacturing: Current Applications, Challenges, and Future Perspectives. Elsevier Eng. 2019, 5, 721–729. [Google Scholar] [CrossRef]

- Kwon, O.; Kim, H.G.; Ham, M.J.; Kim, W.; Kim, G.H.; Cho, J.H.; Kim, N.I.; Kim, K. A deep neural network for classification of melt-pool images in metal additive manufacturing. J. Intell. Manuf. 2020, 31, 375–386. [Google Scholar] [CrossRef]

- Zhu, Z.; Ferreira, K.; Anwer, N.; Mathieu, L.; Guo, K.; Qiao, L. Convolutional Neural Network for geometric deviation prediction in additive manufacturing. Procedia CIRP 2020, 91, 534–539. [Google Scholar] [CrossRef]

- Marrey, M.; Malekipour, E.; El-Mounayri, H.; Faierson, E.J. A Framework for Optimizing Process Parameters in Powder Bed Fusion (PBF) Process Using Artificial Neural Network (ANN). Procedia Manuf. 2019, 34, 505–515. [Google Scholar] [CrossRef]

- Manjunath, B.N.; Vinod, A.R.; Abhinav, K.; Verma, S.K.; Sankar, M.R. Optimisation of process parameters for deposition of colmonoy using directed energy deposition process. Mater. Today Proc. 2020, 26, 1108–1112. [Google Scholar] [CrossRef]

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Piscopo, G.; Salmi, A.; Atzeni, E. Influence of high-productivity process parameters on the surface quality and residual stress state of AISI 316L components produced by directed energy deposition. J. Mater. Eng. Perform. 2021, 30, 6691–6702. [Google Scholar] [CrossRef]

- Hou, S.; Li, Q.; Long, S.; Yang, X.; Li, W. Multiobjective optimization of multi-cell sections for the crashworthiness design. Int. J. Impact Eng. 2008, 35, 1355–1367. [Google Scholar] [CrossRef]

- Fang, H.; Rais-Rohani, M.; Liu, Z.; Horstemeyer, M.F. A comparative study of metamodeling methods for multiobjective crashworthiness optimization. Comput. Struct. 2005, 83, 2121–2136. [Google Scholar] [CrossRef]

- Xiong, Y.; Chen, W.; Apley, D.; Ding, X. A non-stationary covariance-based Kriging method for metamodelling in engineering design. Int. J. Numer. Methods Eng. 2007, 71, 733–756. [Google Scholar] [CrossRef]

- Kazi, M.-K.; Eljack, F.; Mahdi, E. Design of composite rectangular tubes for optimum crashworthiness performance via experimental and ANN techniques. Compos. Struct. 2022, 279, 114858. [Google Scholar] [CrossRef]

- Wahab, D.A.; Azman, A.H. Additive Manufacturing for Repair and Restoration in Remanufacturing: An Overview from Object Design and Systems Perspectives. Processes 2019, 7, 802. [Google Scholar] [CrossRef] [Green Version]

- Goldak, J.; Akhlagi, M. Computational Welding Mechanics; Springer: Ottawa, ON, Canada, 2005. [Google Scholar]

- Xi, W.; Song, B.; Zhao, Y.; Yu, T.; Wang, J. Geometry and dilution rate analysis and prediction of laser cladding. Int. J. Adv. Manuf. Technol. 2019, 103, 4695–4702. [Google Scholar] [CrossRef]

- MathWorks. Neural Network. Available online: https://www.mathworks.com/discovery/neural-network.html (accessed on 21 March 2022).

- Mohamed, S.A.N.; Zainudin, E.S.; Sapuan, S.M.; Deros, M.A.M.; Arifin, A.M.T. Integration of Taguchi-Grey relational analysis technique in parameter process optimization for rice husk composite. BioResources 2019, 14, 1110–1126. [Google Scholar]

- Olsson, A.; Sandberg, G.; Dahlblom, O. On Latin hypercube sampling for structural reliability analysis. Struct. Saf. 2003, 25, 47–68. [Google Scholar] [CrossRef]

- Rahman, A.A.; Zhang, X. Prediction of oscillatory heat transfer coefficient for a thermoacoustic heatexchanger through artificial neural network technique. Int. J. Heat. Mass Transfer. 2018, 124, 1088–1096. [Google Scholar] [CrossRef]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.E.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef] [Green Version]

- Agatonovic-Kustrin, S.; Beresford, R. Basic concepts of artificial neural network (ANN) modeling and its application in pharmaceutical research. J. Pharm. Biomed. Anal. 2000, 22, 717–727. [Google Scholar] [CrossRef]

- Demirezen, G.; Fung, A.S.; Deprez, M. Development and optimization of artificial neural network algorithms for the prediction of building specific local temperature for HVAC control. Int. J. Energy Res. 2020, 44, 8513–8531. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).