Spectroscopic Approach for the On-Line Monitoring of Welding of Tanker Trucks

Abstract

:1. Introduction

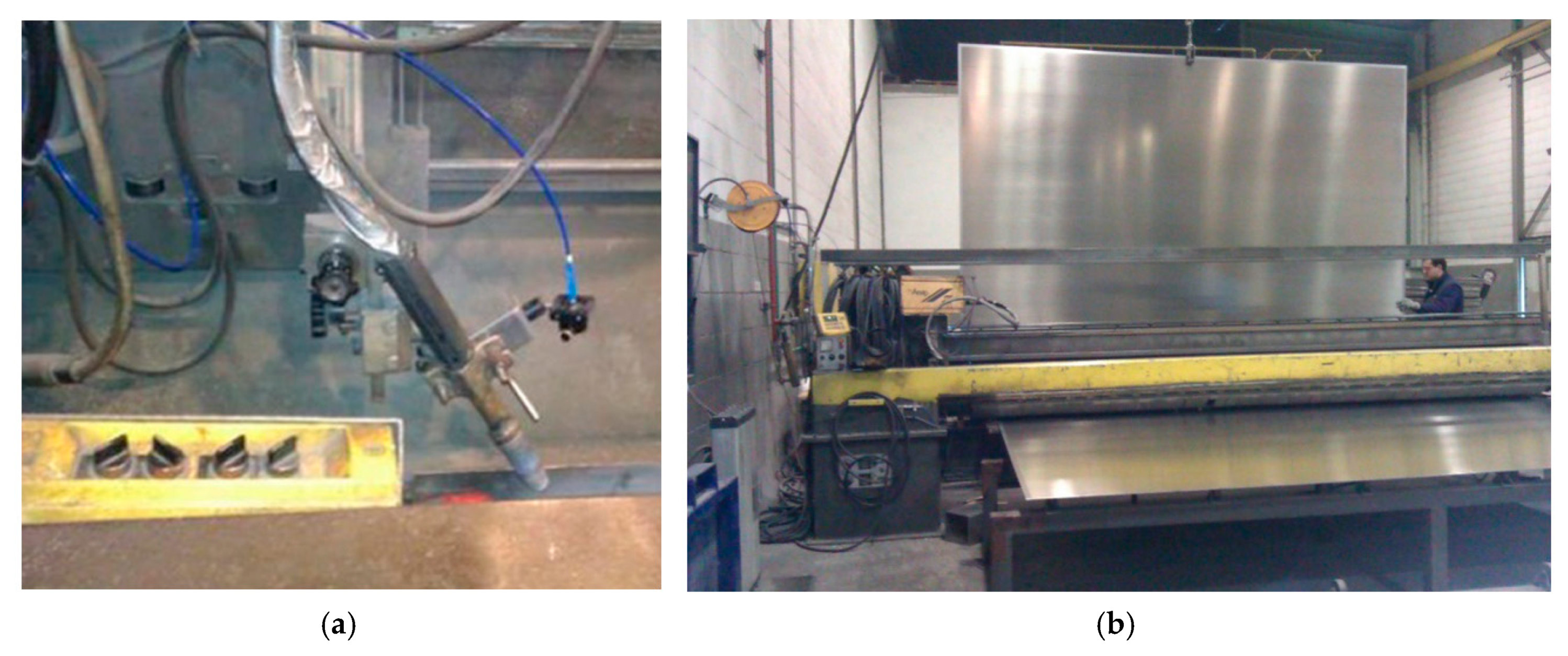

2. Materials and Methods

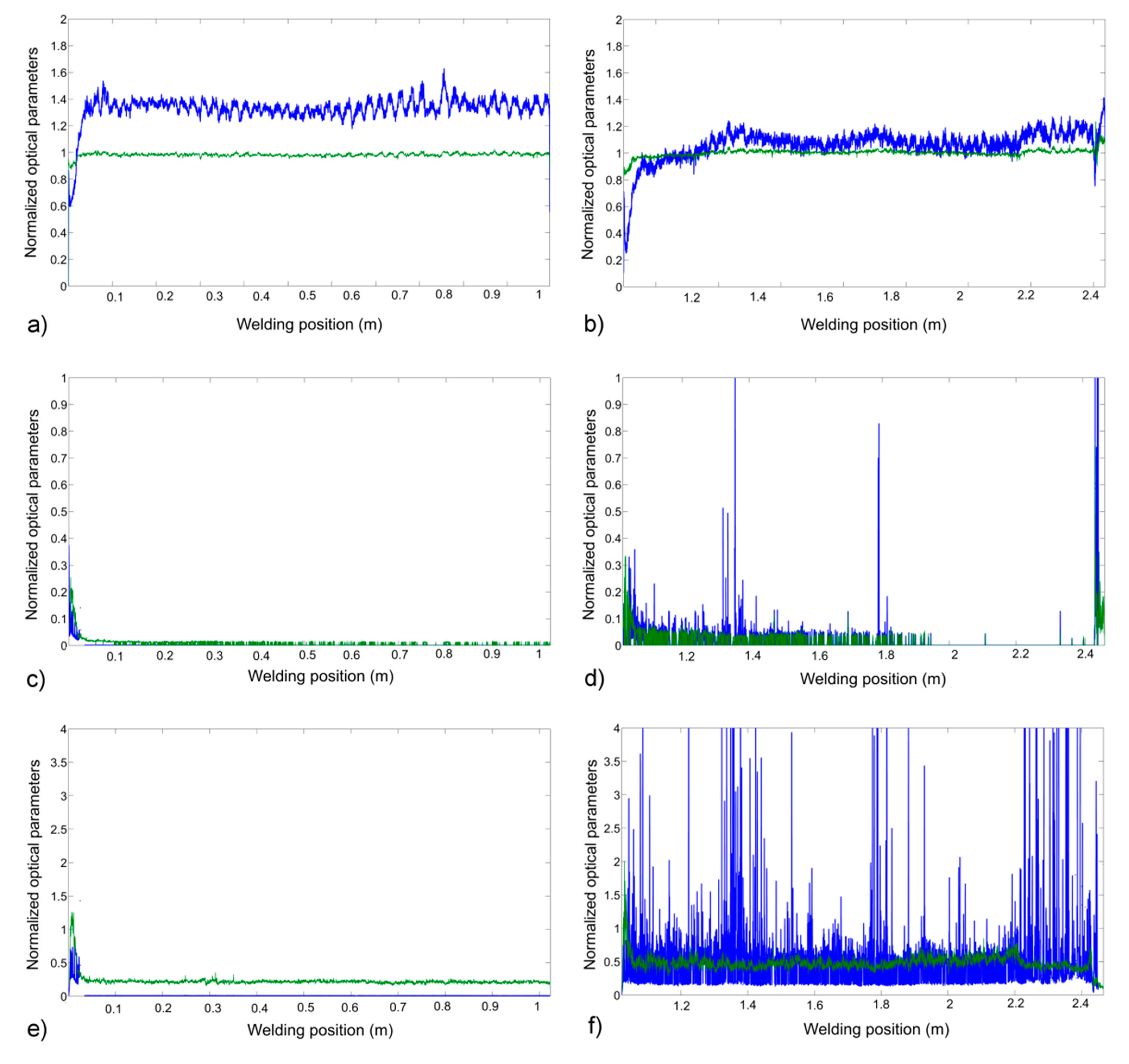

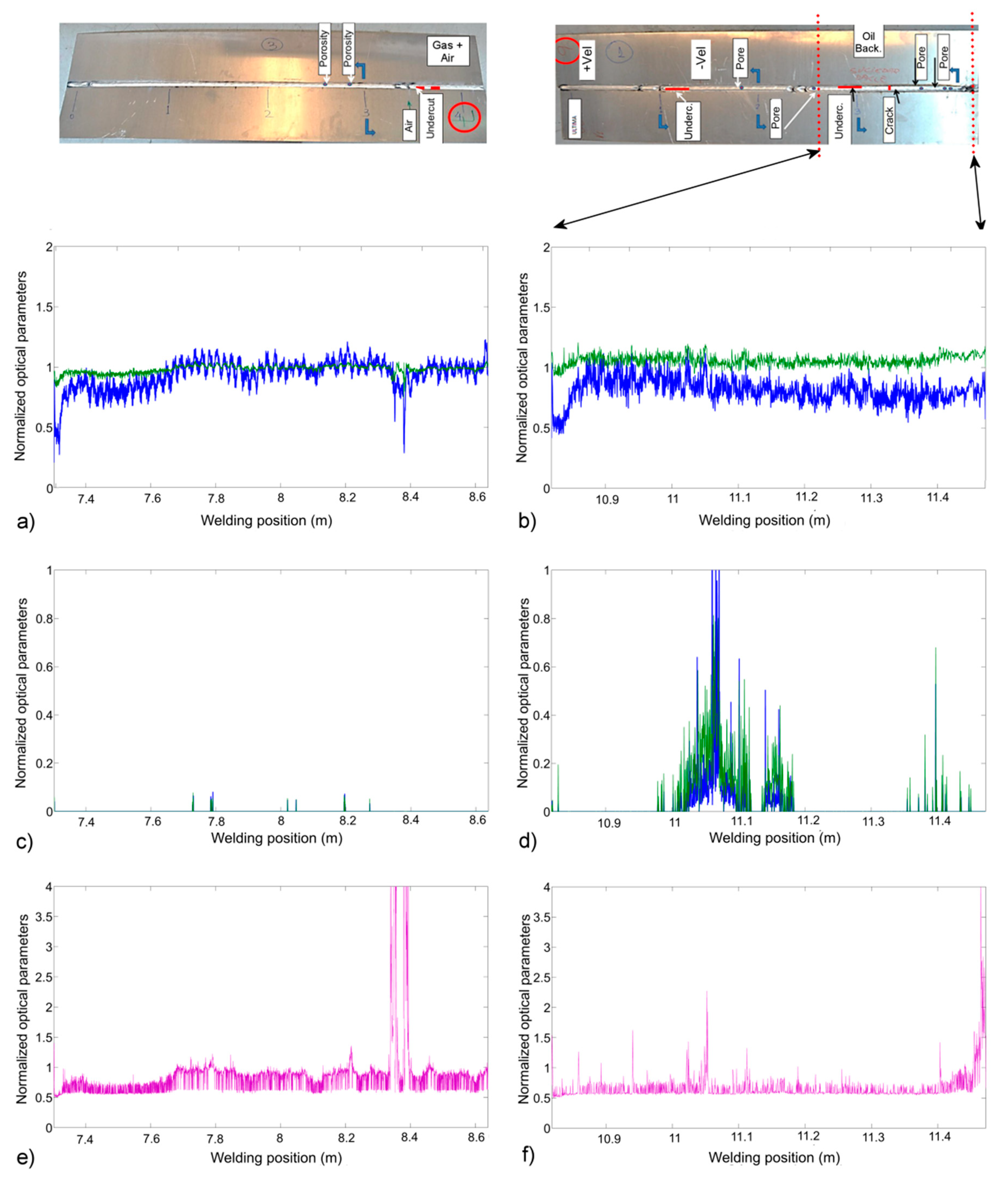

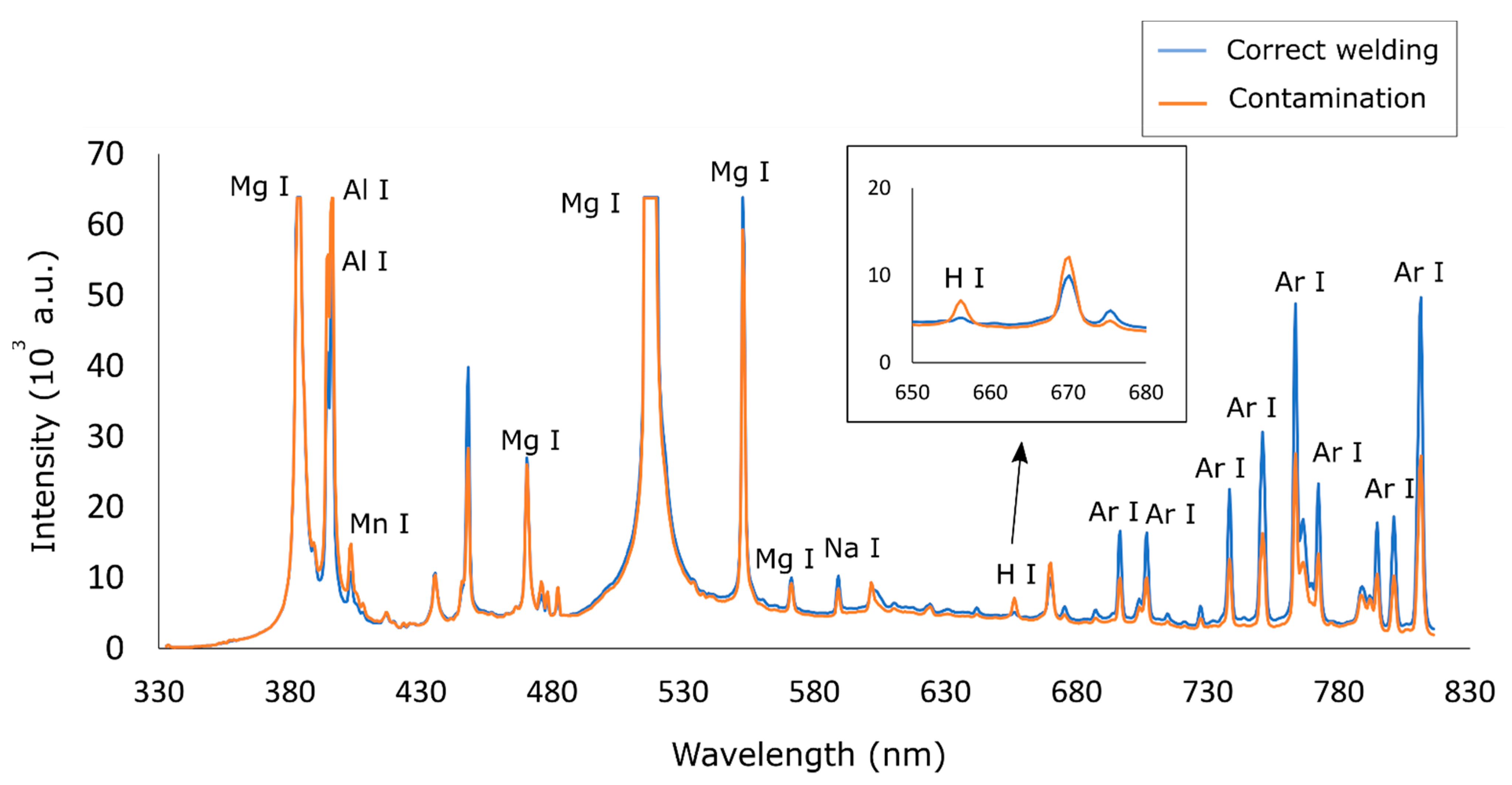

3. Experimental Results and Discussion

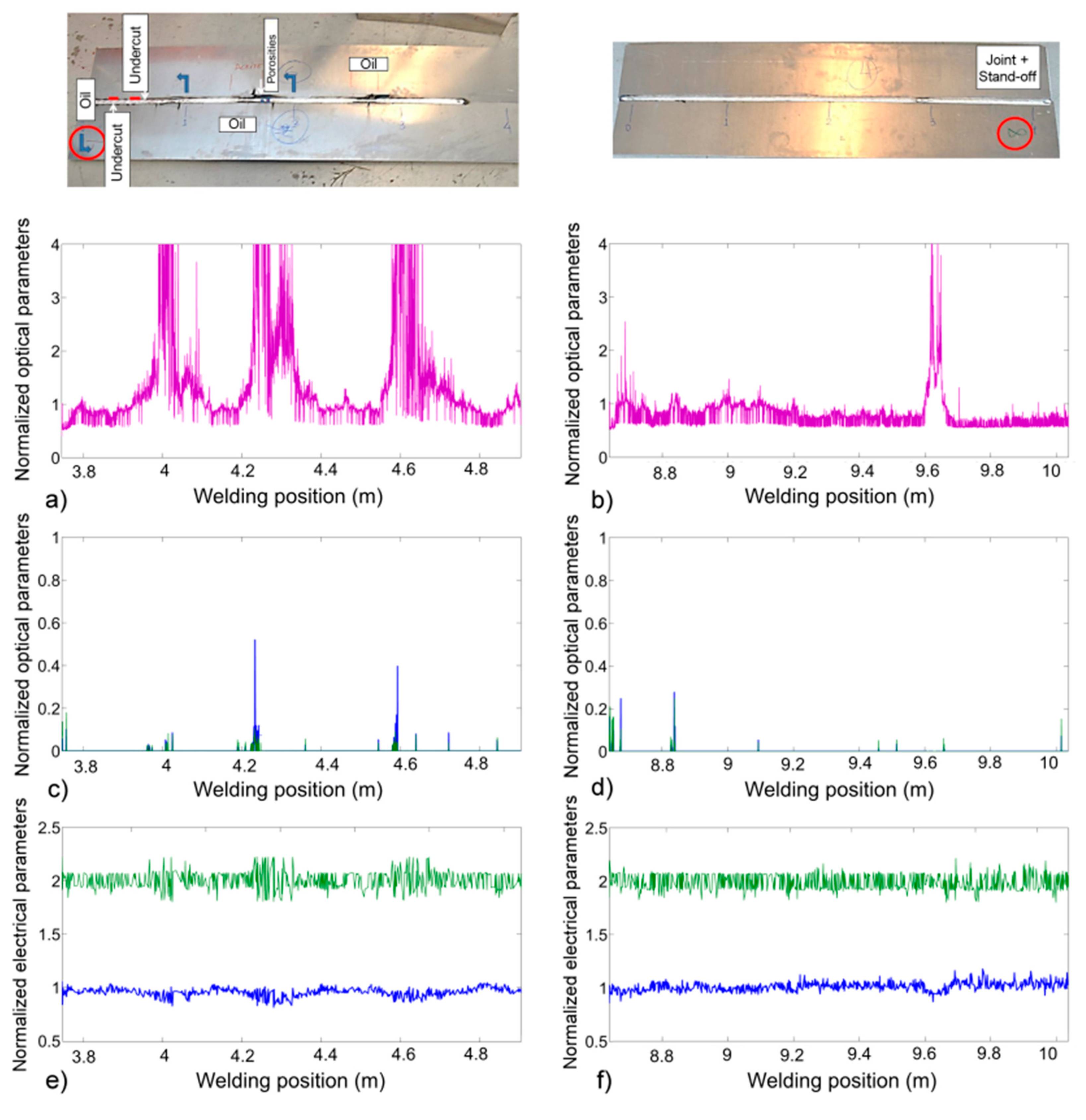

3.1. Field Trials

3.2. In-Line Production Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kovacevic, R.; Zhang, Y.; Li, L. Monitoring of Weld Joint Penetrations Based on Weld Pool Geometrical Appearance. Weld. J. Res. Suppl. 1996, 75, 317–329. [Google Scholar]

- Abdullah, B.; Smith, J.S.; Lucas, W.; Lucas, J.; Abdul Malek, M. Monitoring of TIG welding using laser and diode illumination sources: A comparison study. In Proceedings of the 2008 International Conference on Electronic Design, Penang, Malaysia, 1–3 December 2008; pp. 1–4. [Google Scholar]

- Das, B.; Pal, S.; Bag, S. Monitoring of friction stir welding process using weld image information. Sci. Technol. Weld. Jt. 2016, 21, 317–324. [Google Scholar] [CrossRef]

- Speka, M.; Matteï, S.; Pilloz, M.; Ilie, M. The infrared thermography control of the laser welding of amorphous polymers. NDT E Int. 2008, 41, 178–183. [Google Scholar] [CrossRef]

- Makwana, P.; Goecke, S.F.; De, A. Real-time heat input monitoring towards robust GMA brazing. Sci. Technol. Weld. Jt. 2019, 24, 16–26. [Google Scholar] [CrossRef]

- Yang, M.; Bai, R.; Zheng, H.; Qi, B. Temperature monitoring and calibration in Ti–6Al–4V molten pool with pulsed arc welding. Sci. Technol. Weld. Jt. 2020, 25, 369–376. [Google Scholar] [CrossRef]

- Gu, H.; Duley, W. A statistical approach to acoustic monitoring of laser welding. J. Phys. D 1996, 29, 556. [Google Scholar] [CrossRef]

- Rodriguez-Cobo, L.; Mirapeix, J.; Ruiz-Lombera, R.; Cobo, A.; López-Higuera, J.M. Fiber Bragg grating sensors for on-line welding diagnostics. J. Mater. Process. Technol. 2014, 214, 839–843. [Google Scholar] [CrossRef]

- Sun, A.; Kannatey-Asibu, E.; Gartner, M. Monitoring of laser weld penetration using sensor fusion. J. Laser Appl. 2002, 14, 114–121. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, H.; Xu, Y.; Zhong, J.; Lv, N.; Chen, S. Multisensor-based real-time quality monitoring by means of feature extraction, selection and modeling for Al alloy in arc welding. Mech. Syst. Signal Process. 2015, 60, 151–165. [Google Scholar] [CrossRef]

- Ancona, A.; Spagnolo, V.; Lugara, P.M.; Ferrara, M. Optical Sensor for real-time Monitoring of CO2 Laser Welding Process. Appl. Opt. 2001, 40, 6019–6025. [Google Scholar] [CrossRef]

- Sibillano, T.; Ancona, A.; Berardi, V.; Lugarà, P.M. Real-time monitoring of laser welding by correlation analysis: The case of AA5083. Lasers Eng. 2007, 45, 1005–1009. [Google Scholar] [CrossRef]

- Garcia-Allende, P.B.; Mirapeix, J.; Conde, O.M.; Cobo, A.; Lopez-Higuera, J.M. Defect detection in arc-welding processes by means of the line-to-continuum method and feature selection. Sensors 2009, 9, 7753–7770. [Google Scholar] [CrossRef] [PubMed]

- Taparli, U.A.; Jacobsen, L.; Griesche, A.; Michalik, K.; Mory, D.; Kannengiesser, T. In situ laser-induced breakdown spectroscopy measurements of chemical compositions in stainless steels during tungsten inert gas welding. Spectrochim. Acta B At. Spectrosc. 2018, 139, 50–56. [Google Scholar] [CrossRef]

- Taparli, U.A.; Kannengiesser, T.; Cieslik, K.; Mory, D.; Griesche, A. In situ chemical composition analysis of a tungsten-inert-gas austenitic stainless steel weld measured by laser-induced breakdown spectroscopy. Spectrochim. Acta B At. Spectrosc. 2020, 167, 105826. [Google Scholar] [CrossRef]

- Lin, J.; Yang, J.; Huang, Y.; Lin, X. Defect identification of metal additive manufacturing parts based on laser-induced breakdown spectroscopy and machine learning. Appl. Phys. B 2021, 127, 173. [Google Scholar] [CrossRef]

- Yu, H.; Xu, Y.; Song, J.; Pu, J.; Zhao, X.; Yao, G. On-line monitor of hydrogen porosity based on arc spectral information in Al–Mg alloy pulsed gas tungsten arc welding. Opt. Laser Technol. 2015, 70, 30–38. [Google Scholar] [CrossRef]

- Devletian, J.H.; Wood, W. Factors Affecting Porosity in Aluminum Welds—A Review; Bulletin (Welding Research Council (U.S.)) Series; Welding Research Council, United Engineering Center: New York, NY, USA, 1983; pp. 1–18. [Google Scholar]

- Mirapeix, J.; Ruiz-Lombera, R.; Valdiande, J.J.; Rodriguez-Cobo, L.; Anabitarte, F.; Cobo, A. Defect detection with CCD-spectrometer and photodiode-based arc-welding monitoring systems. J. Mater. Process. Technol. 2001, 211, 2132–2139. [Google Scholar] [CrossRef]

- Bebiano, D.; Alfaro, S.C. A weld defects detection system based on a spectrometer. Sensors 2009, 9, 2851–2861. [Google Scholar] [CrossRef] [Green Version]

- Cobo, A.; Mirapeix, J.; Linares, F.; Piney, J.A.; Solana, D.; Lopez-Higuera, J.M. Spectroscopic sensor system for quality assurance of the tube-to-tubesheet welding process in nuclear steam generators. IEEE Sens. J. 2007, 7, 1219–1224. [Google Scholar] [CrossRef]

- Sibillano, T.; Ancona, A.; Berardi, V.; Schingaro, E.; Basile, G.; Lugara, P. Optical detection of conduction/keyhole mode transition in laser welding. J. Mater. Process. Technol. 2007, 191, 364–367. [Google Scholar] [CrossRef]

- Ferrara, M.; Ancona, A.; Lugara, P.M.; Sibilano, M. Online quality monitoring of welding processes by means of plasma optical spectroscopy. In Advanced High-Power Lasers and Applications, International Society for Optics and Photonics; SPIE: Bellingham, WA, USA, 2000; Volume 3888, pp. 750–758. [Google Scholar]

- Sforza, P.; de Blasiis, D. On-line optical monitoring system for arc welding. NDT E Int. 2002, 35, 37–43. [Google Scholar] [CrossRef]

- Mirapeix, J.; Cobo, A.; Fuentes, J.; Davila, M.; Etayo, J.M.; Lopez-Higuera, J.M. Use of the plasma spectrum rms signal for arc-welding diagnostics. Sensors 2009, 9, 5263–5276. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mirapeix, J.; Ruiz-Lombera, R.; Valdiande, J.J.; Lopez-Higuera, J.M. Colorimetric analysis for on-line arc-welding diagnostics by means of plasma optical spectroscopy. IEEE Sens. J. 2015, 16, 3465–3471. [Google Scholar] [CrossRef] [Green Version]

- Robertson, A.R. Computation of correlated color temperature and distribution temperature. J. Opt. Soc. Am. 1968, 58, 1528–1535. [Google Scholar] [CrossRef]

- Rodriguez-Cobo, L.; Ruiz-Lombera, R.; Conde, O.M.; López-Higuera, J.M.; Cobo, A.; Mirapeix, J. Feasibility study of Hierarchical Temporal Memories applied to welding diagnostics. Sens. Actuator A Phys. 2013, 204, 58–66. [Google Scholar] [CrossRef]

- Alfaro, S.C.; Mendonça, D.d.S.; Matos, M.S. Emission spectrometry evaluation in arc welding monitoring system. J. Mater. Process. Technol. 2006, 179, 219–224. [Google Scholar] [CrossRef]

- Yilbas, B.; Hassan, G.; Ali, H.; Al-Aqeeli, N. Environmental dust effects on aluminum surfaces in humid air ambient. Sci. Rep. 2017, 7, 45999. [Google Scholar] [CrossRef] [Green Version]

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.1400 | 0.1880 | 0.0480 | 0.3490 | 4.6730 | 0.0020 | 0.0020 | 0.0180 | -- |

| Weld Trial Nº | Study Parameter | Defects (X-ray) |

|---|---|---|

| 1 | Correct welding | Undercuts/Ex. penetration |

| 2 | Correct welding | Undercuts/Porosities |

| 3 | Water inclusion | Undercuts/Porosities |

| 4 | Oil inclusion | Undercuts/Porosities |

| 5 | Solvent inclusion | Porosities/Ex. penetration |

| 6 | Welding current/Feed Wire Speed | Porosities |

| 7 | Gas flow rate/Dry compressed air | Undercuts/Porosities |

| 8 | Joint preparation/Stand-off distance | -- |

| 9 | Process speed/Water and oil inclusions (backing) | Undercuts/PorositiesEx. Penetration/Cracks |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valdiande, J.J.; Rodriguez-Cobo, L.; Cobo, A.; Lopez-Higuera, J.M.; Mirapeix, J. Spectroscopic Approach for the On-Line Monitoring of Welding of Tanker Trucks. Appl. Sci. 2022, 12, 5022. https://doi.org/10.3390/app12105022

Valdiande JJ, Rodriguez-Cobo L, Cobo A, Lopez-Higuera JM, Mirapeix J. Spectroscopic Approach for the On-Line Monitoring of Welding of Tanker Trucks. Applied Sciences. 2022; 12(10):5022. https://doi.org/10.3390/app12105022

Chicago/Turabian StyleValdiande, Jose J., Luis Rodriguez-Cobo, Adolfo Cobo, José Miguel Lopez-Higuera, and Jesús Mirapeix. 2022. "Spectroscopic Approach for the On-Line Monitoring of Welding of Tanker Trucks" Applied Sciences 12, no. 10: 5022. https://doi.org/10.3390/app12105022

APA StyleValdiande, J. J., Rodriguez-Cobo, L., Cobo, A., Lopez-Higuera, J. M., & Mirapeix, J. (2022). Spectroscopic Approach for the On-Line Monitoring of Welding of Tanker Trucks. Applied Sciences, 12(10), 5022. https://doi.org/10.3390/app12105022