Use of Treated Non-Ferrous Metallurgical Slags as Supplementary Cementitious Materials in Cementitious Mixtures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Technical Performance Assessment

2.2.2. Chemical Reactivity (R3 Test)

2.2.3. Hydration Studies

2.2.4. Mechanical Performance (Strength Activity and Strength Development)

2.2.5. Environmental Performance Assessment

2.2.6. Standards and Limitations

3. Results

3.1. Technical Performance Results

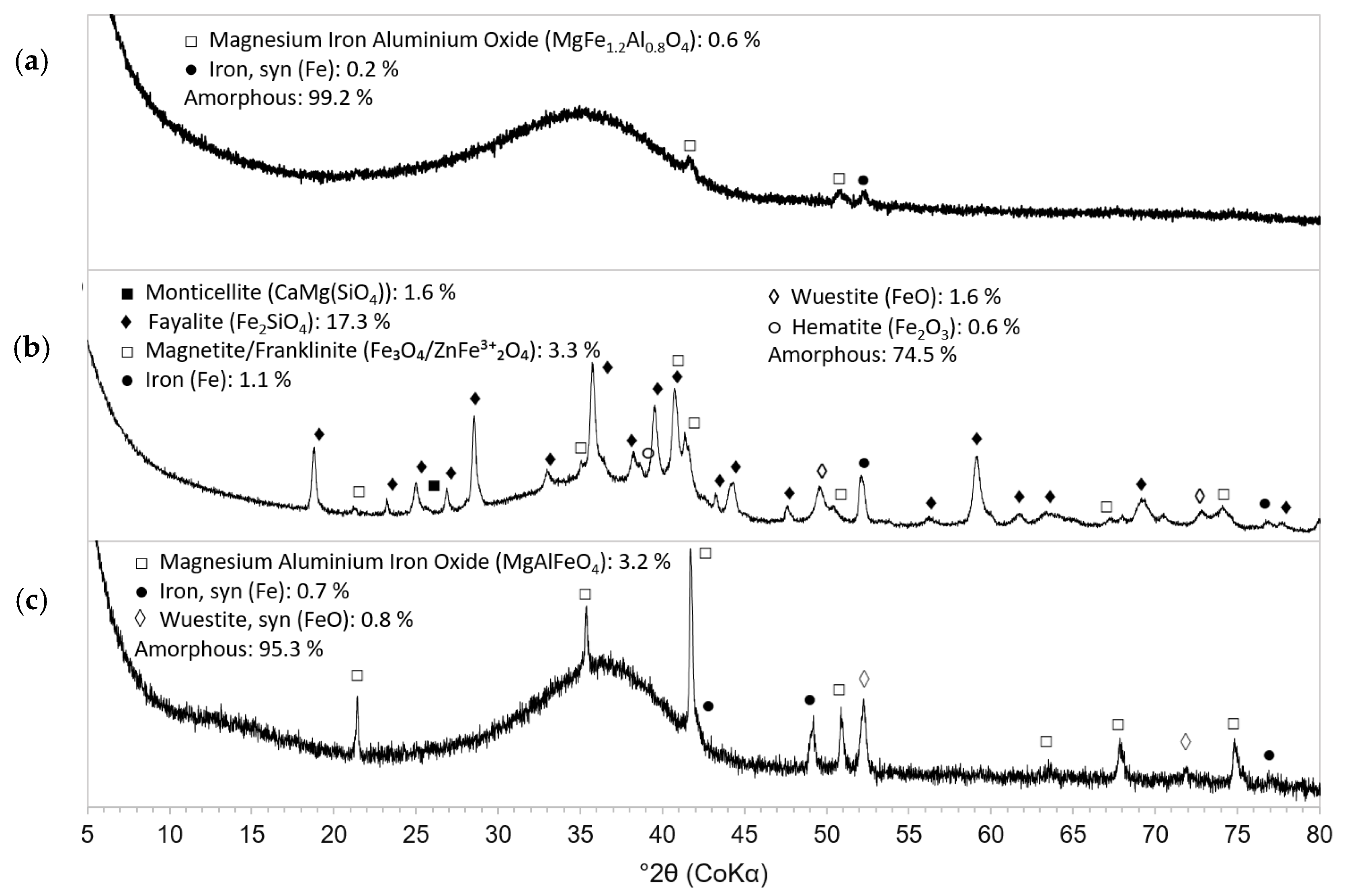

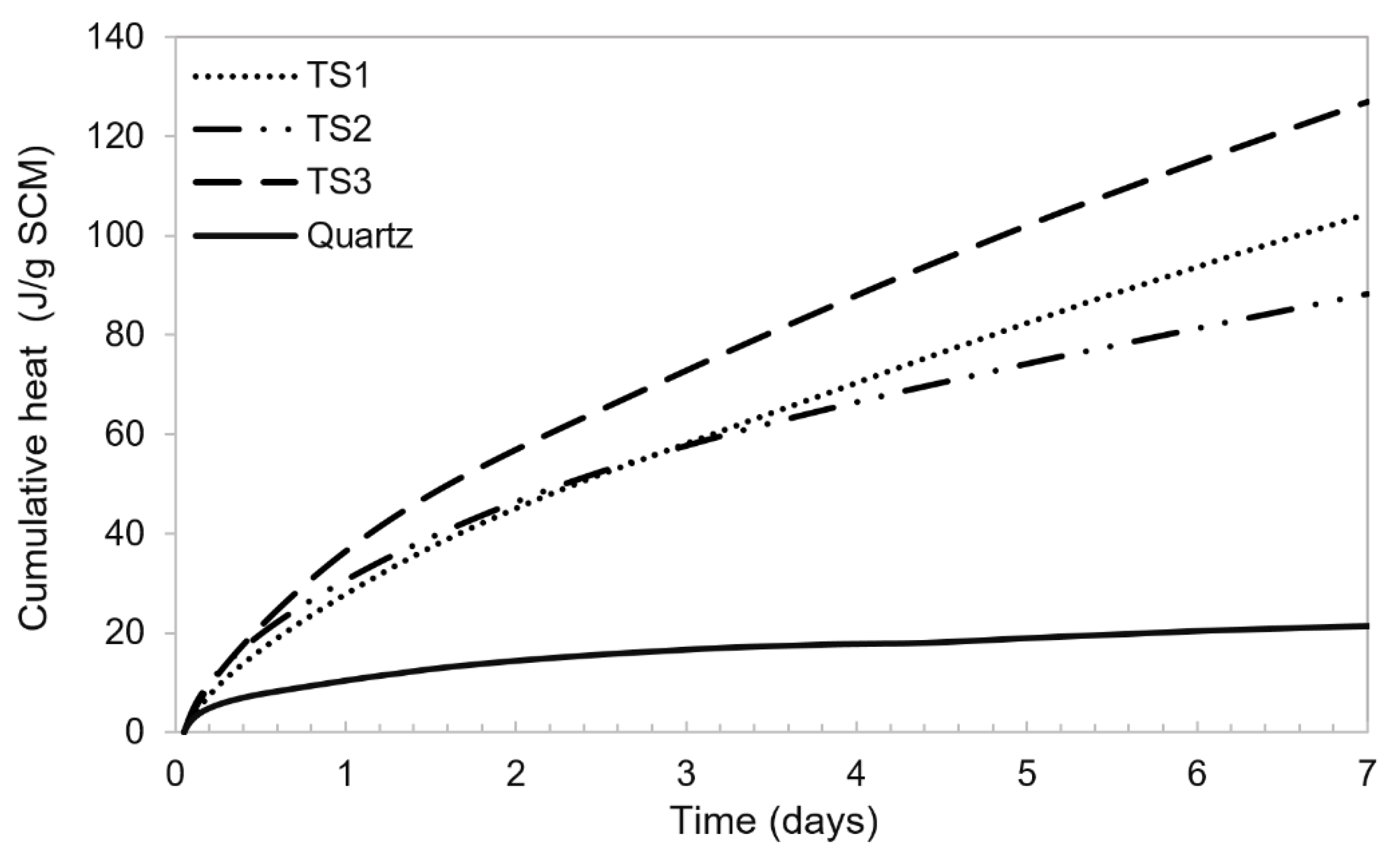

3.1.1. Chemical Reactivity

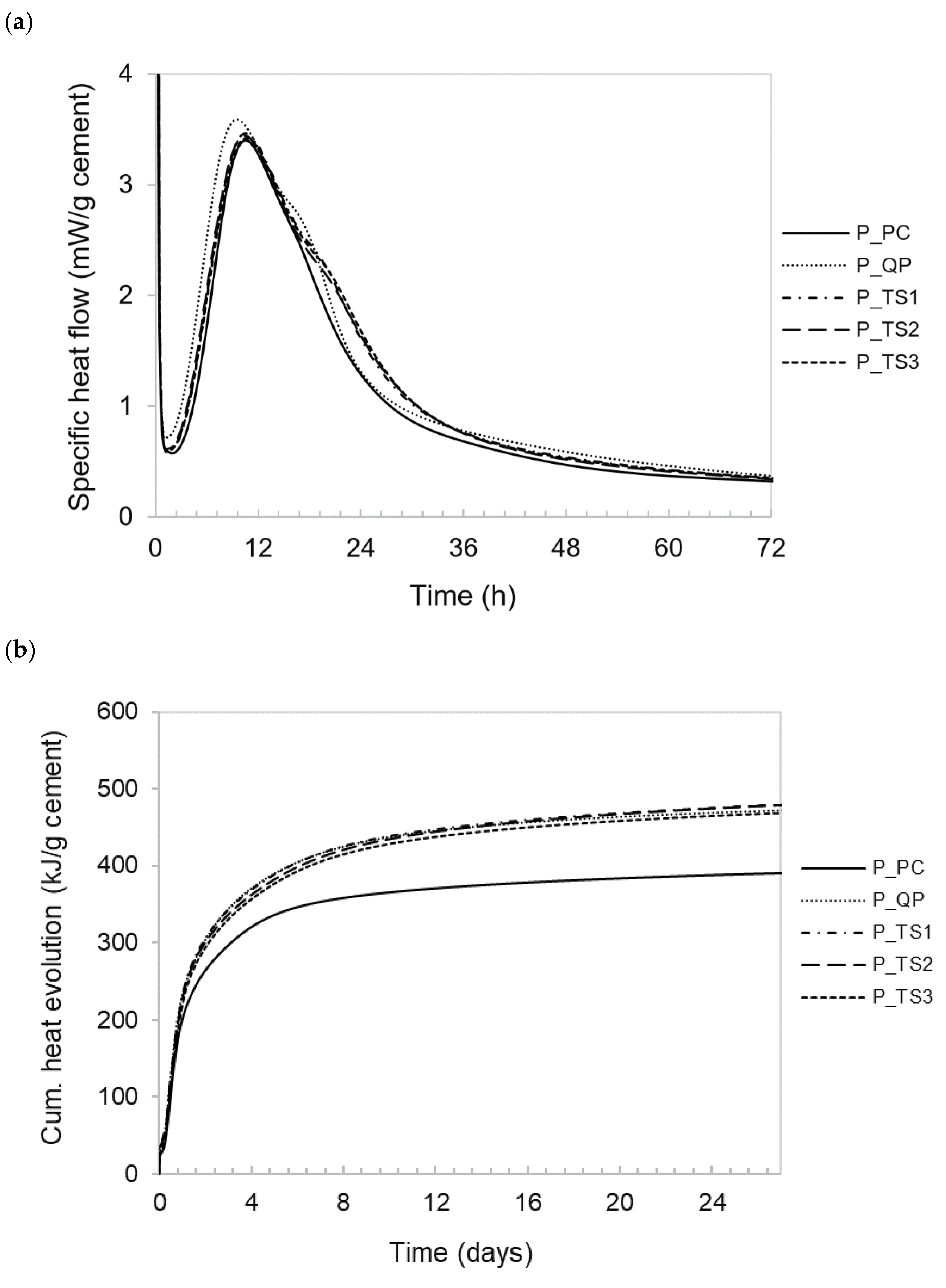

3.1.2. Calorimetry

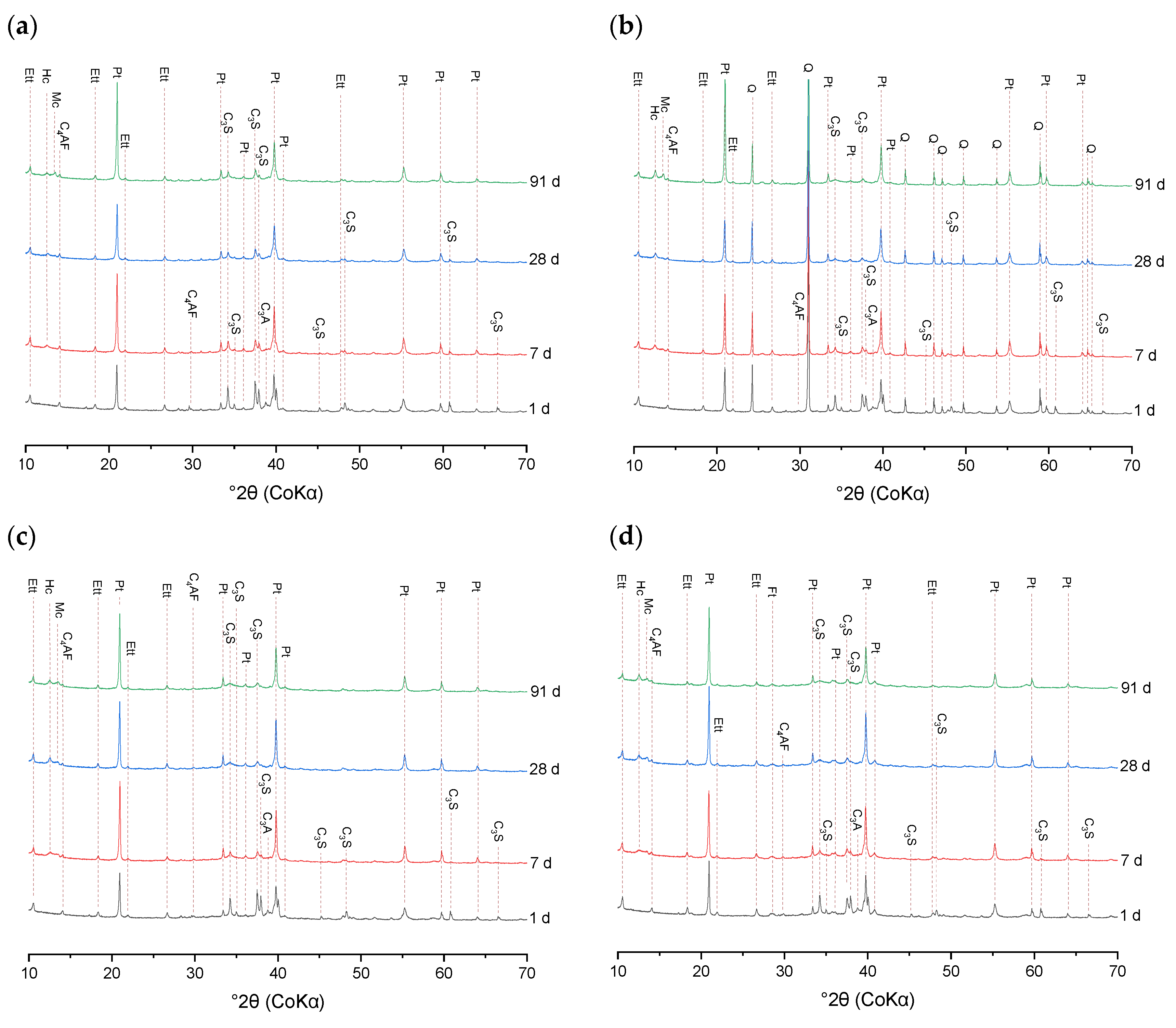

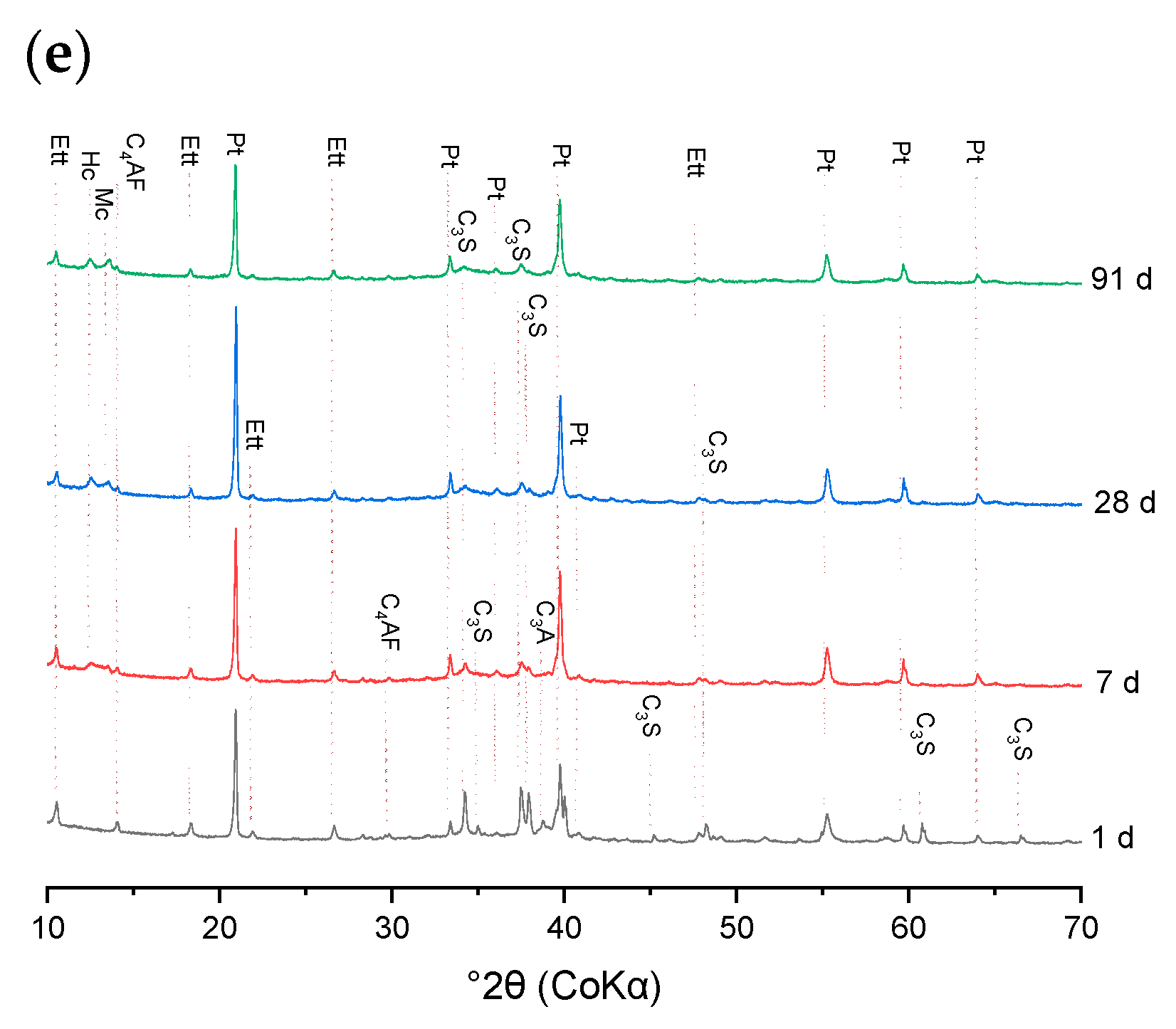

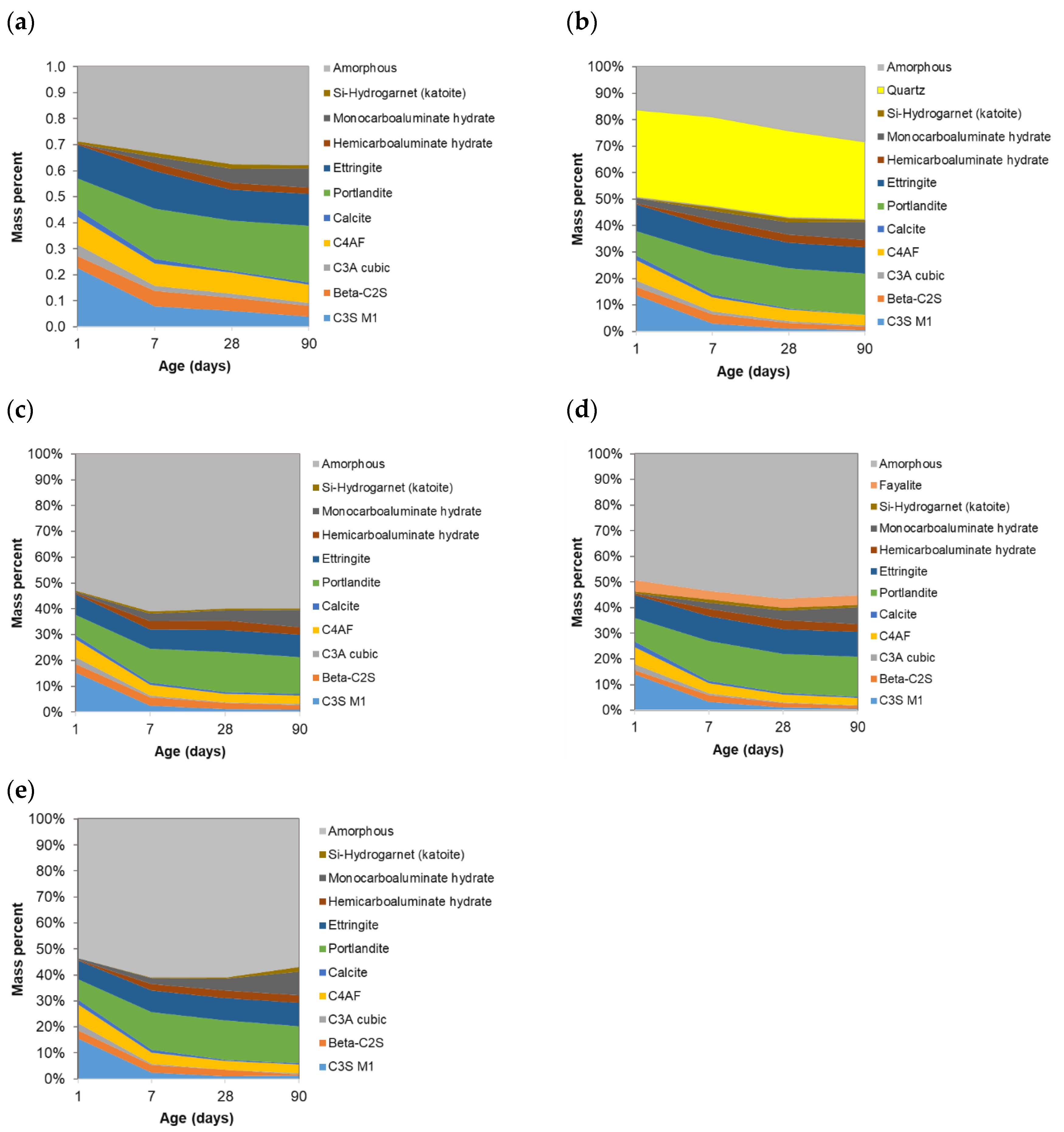

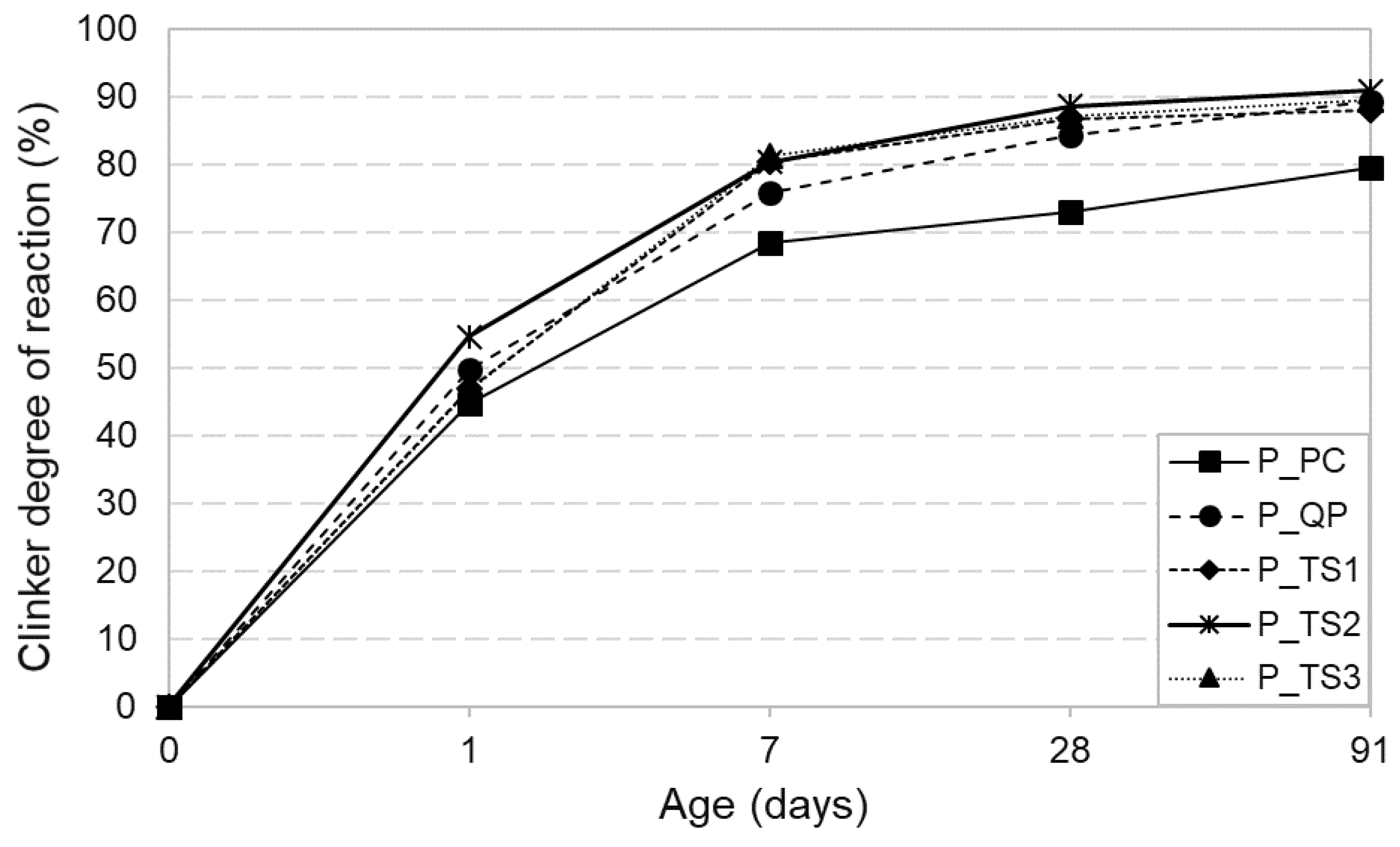

3.1.3. Phase Evolution

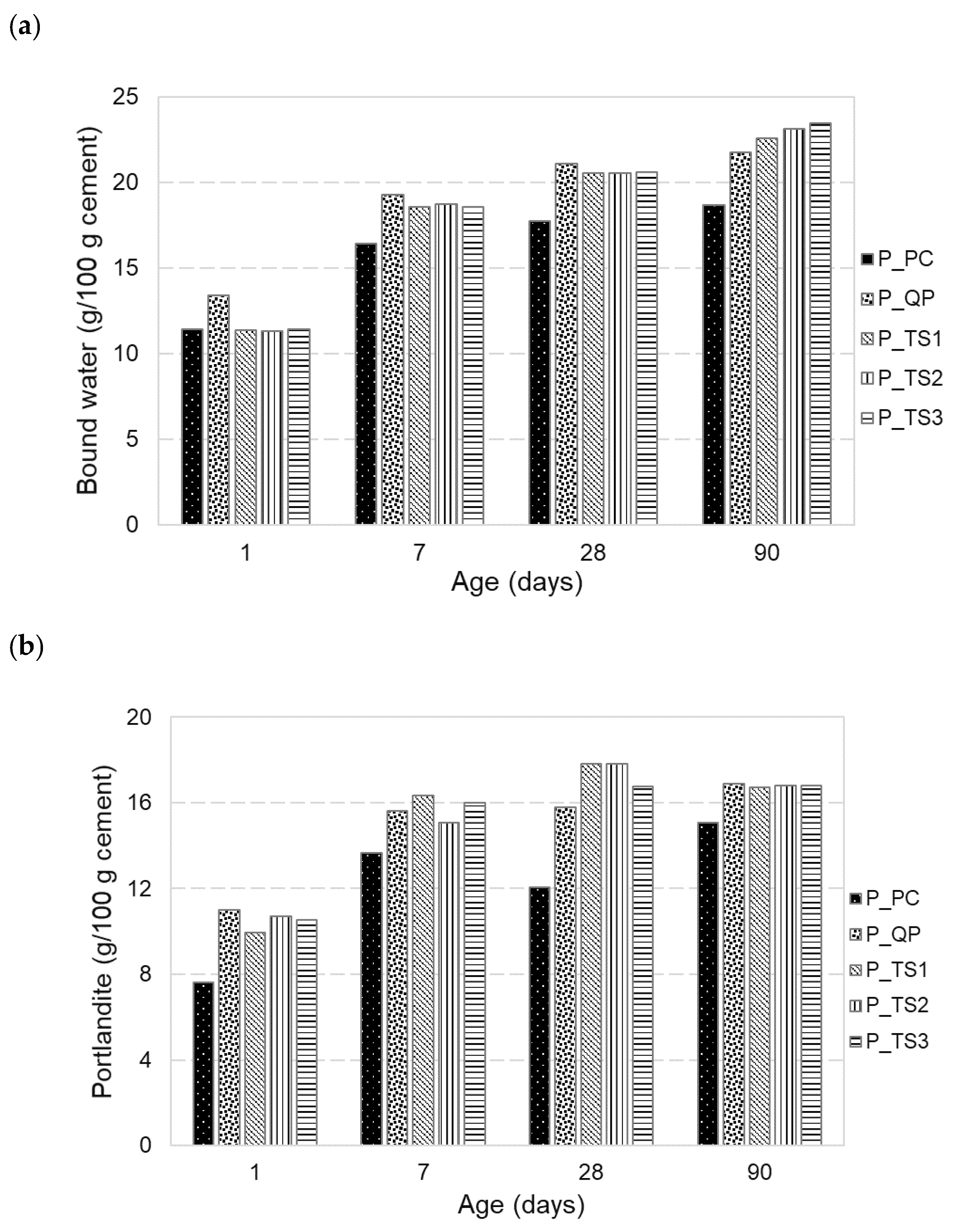

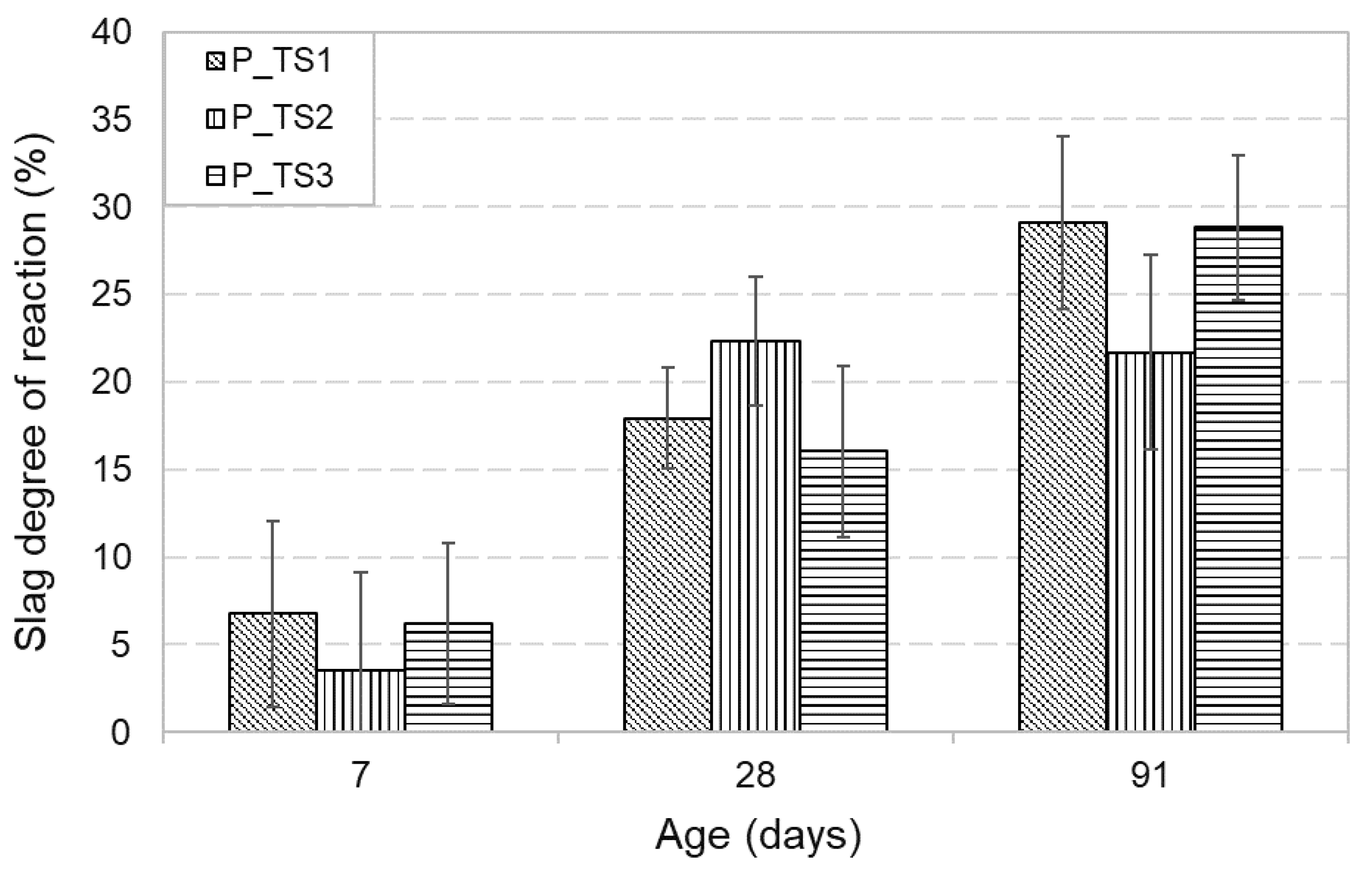

3.1.4. Thermogravimetry

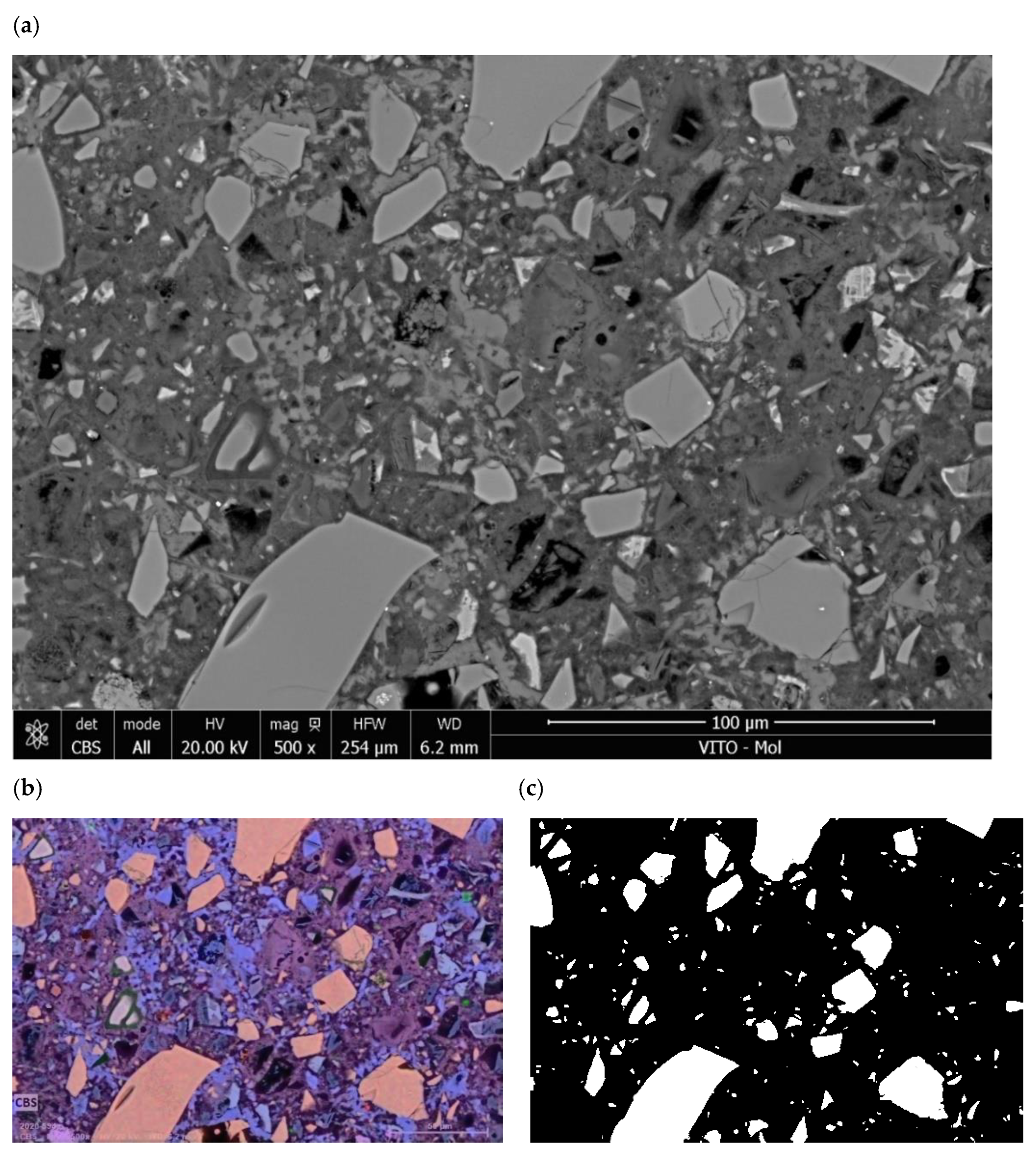

3.1.5. SEM Image Analysis

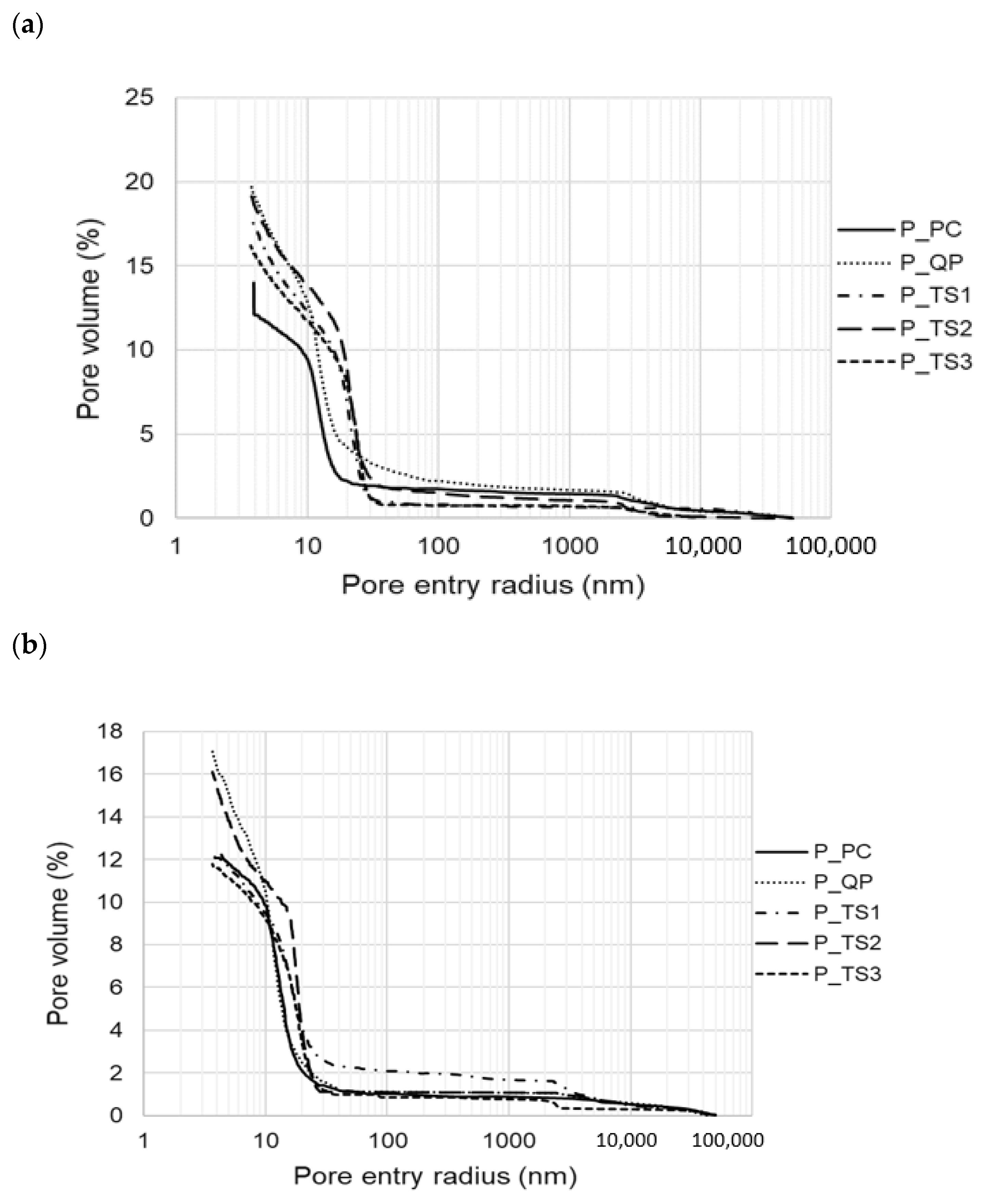

3.1.6. Porosimetry

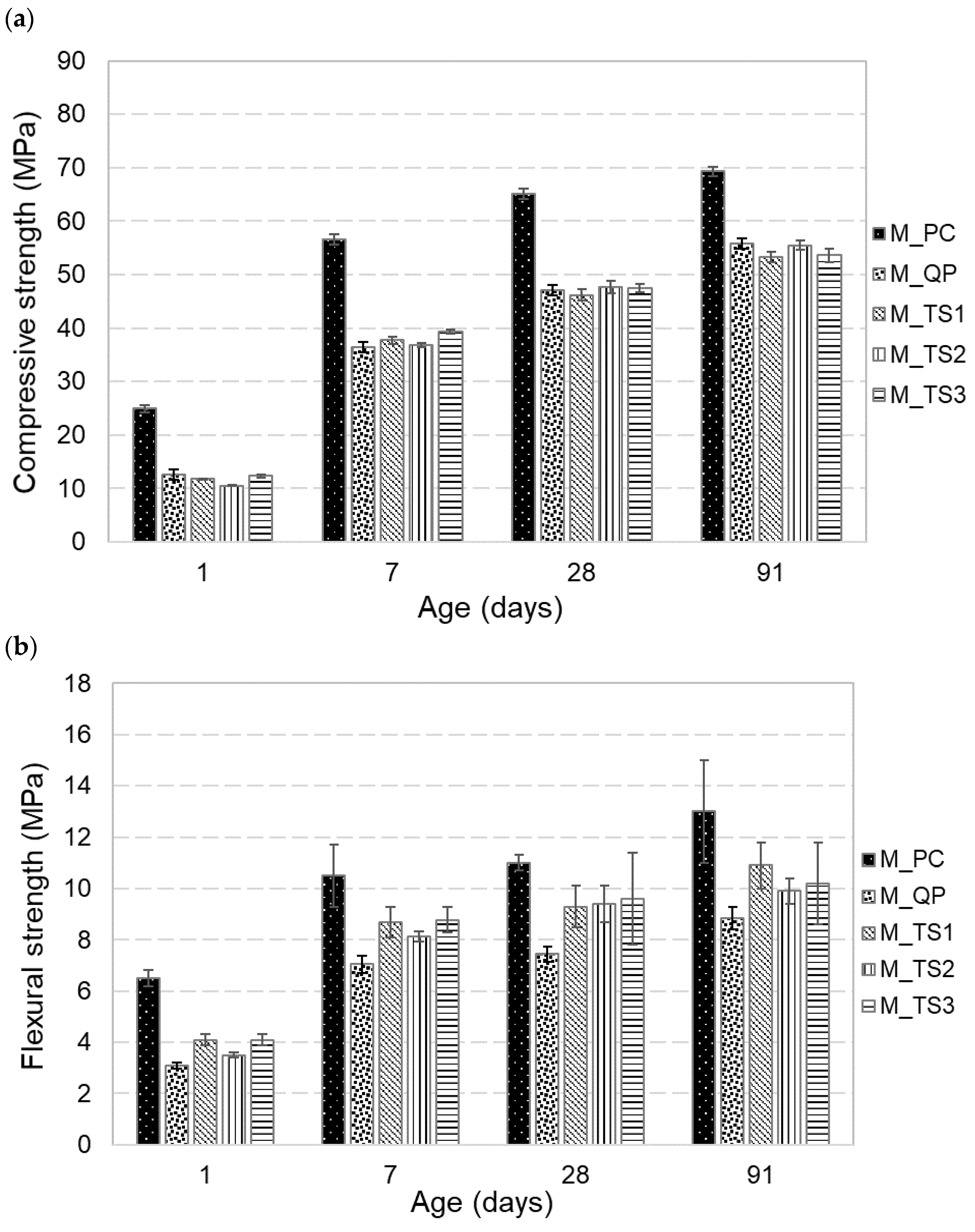

3.1.7. Mechanical Performance

3.2. Environmental Performance Results

4. Discussion

5. Conclusions

- -

- The application of a secondary thermal treatment to non-ferrous slags from the lead and copper industries can significantly reduce the amounts of heavy metals in the slags and enable their use in cementitious materials.

- -

- Such slags are primarily composed of iron silicates. Despite the differences in the source and compositions of the slags, while granulation results in a substantial increase in their amorphous content, they are only moderately reactive according to R3 and calorimetry findings.

- -

- Replacement of cement with such slags were found in all cases to result in an increase in the clinker degree of reaction in all ages, which is potentially due to the increase in the availability of water to cement grains.

- -

- TGA results also indicate an acceleration in hydration reactions when cement is partially replaced by the studied slags. However, the portlandite and bound water contents of slag-blended mixtures in the early ages found to be lower than those of mixtures containing quartz powder. This is in agreement with the calorimetry results and indicates a slight retarding effect of such slags compared to quartz.

- -

- While a notable increase in the porosity as well as coarsening of the pore size structure of cement paste mixtures was observed up to the age of 28 days as a result of cement substitution, a considerable refinement of the pore structure was detected at later ages. No such later-age refinement was observed for the pastes incorporating quartz powder.

- -

- Despite the existence of sufficient evidence for the pozzolanic reactivity of the studied slags, the compressive strength of mortars prepared by such slags were found to be similar to that of mixtures containing quartz powder at different ages. This was attributed to the lower mechanical strength and filler effect of the slag grains compared to quartz powder.

- -

- All three slags were found to satisfy the minimum strength activity and maximum leaching requirements and are thus suitable for use in concrete.

- -

- While the slags were found to satisfy the minimum technical and environmental requirements for being used in concrete, it appears that mere granulation of such slags is not sufficient for promoting their pozzolanic activity. Addition of other oxides such as calcium or aluminium oxide to boost the reactivity is recommended.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement. Build. Environ. 2011, 46, 1113–1140. [Google Scholar]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Ariño, A.M.; Mobasher, B. Effect of Ground Copper Slag on Strength and Toughness of Cementitious Mixes. ACI Mater. J. 1999, 96, 68–73. [Google Scholar]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete; Prentice Hall, Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Boddy, A.M.; Hooton, R.D.; Thomas, M.D.A. The effect of product form of silica fume on its ability to control alkali-silica reaction. Cem. Concr. Compos. 2000, 30, 1139–1150. [Google Scholar] [CrossRef]

- Atahan, H.N.; Dikme, D. Use of mineral admixtures for enhanced resistance against sulfate attack. Constr. Build. Mater. 2011, 25, 3450–3457. [Google Scholar] [CrossRef]

- Pan, D.A.; Li, L.; Tian, X.; Wu, Y.; Cheng, N.; Yu, H. A review on lead slag generation, characteristics, and utilization. Resour. Conserv. Recycl. 2019, 146, 140–155. [Google Scholar] [CrossRef]

- Gorai, B.; Jana, R.K. Characteristics and utilisation of copper slag—A review. Resour. Conserv. Recy. 2003, 39, 299–313. [Google Scholar] [CrossRef]

- Curry, K.C. Iron and Steel Slag; U.S. Geological Survey, Mineral Commodity Summaries: Reston, VA, USA, 2020.

- Piatak, N.M.; Parsons, M.B.; Seal, R.R. Characteristics and environmental aspects of slag: A review. Appl. Geochem. 2015, 57, 236–266. [Google Scholar] [CrossRef]

- Li, W.; Tang, Z.; Tam, V.; Zhao, X.; Wang, K.F. A Review on Durability of Alkali-activated System from Sustainable Construction Materials to Infrastructures. Es Mater. Manuf. 2019, 4, 2–19. [Google Scholar] [CrossRef]

- Barati, M.; Jahanshahi, S. Granulation and Heat Recovery from Metallurgical Slags. J. Sustain. Metall. 2019, 6, 191–206. [Google Scholar] [CrossRef]

- De Rojas, M.I.S.; Rivera, J.; Frias, M.; Marin, F. Use of recycled copper slag for blended cements. J. Chem. Technol. Biot. 2008, 83, 209–217. [Google Scholar] [CrossRef]

- Pontikes, Y.; Machiels, L.; Onisei, S.; Pandelaers, L.; Geysen, D.; Jones, P.T.; Blanpain, B. Slags with a high Al and Fe content as precursors for inorganic polymers. Appl. Clay Sci. 2013, 73, 93–102. [Google Scholar] [CrossRef]

- Siakati, C.; Douvalis, A.P.; Ziogas, P.; Peys, A.; Pontikes, Y. Impact of the solidification path of FeOx-SiO2 slags on the resultant inorganic polymers. J. Am. Ceram Soc. 2019, 103, 2173–2184. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, Q.; Chen, Q.; Kero, J.; Andersson, A.; Ahmed, H.; Engström, F.; Samuelsson, C. Characterization and evaluation of the pozzolanic activity of granulated copper slag modified with CaO. J. Clean. Prod. 2019, 232, 1112–1120. [Google Scholar] [CrossRef]

- Sivakumar, P.P.; Arnout, L.; Lapauw, T.; Gruyaert, E.; De Belie, N.L.; Matthys, S. Increasing the Reactivity of Modified Ferro Silicate Slag by Chemical Adaptation of the Production Process. In Proceedings of the 2nd International Conference on Sustainable Building Materials, Eindhoven, The Netherlands, 12–15 August 2019; pp. 36–46. [Google Scholar]

- Van De Sande, J.; Peys, A.; Hertel, T.; Rahier, H.; Pontikes, Y. Upcycling of non-ferrous metallurgy slags: Identifying the most reactive slag for inorganic polymer construction materials. Resour. Conserv. Recycl. 2020, 154, 104627. [Google Scholar] [CrossRef]

- Edwin, R.S.; De Schepper, M.; Gruyaert, E.; De Belie, N. Effect of secondary copper slag as cementitious material in ultra-high performance mortar. Constr Build Mater 2016, 119, 31–44. [Google Scholar] [CrossRef]

- Hallet, V.; De Belie, N.; Pontikes, Y. The impact of slag fineness on the reactivity of blended cements with high-volume non-ferrous metallurgy slag. Constr. Build. Mater. 2020, 257, 119400. [Google Scholar] [CrossRef]

- Sivakumar, P.P.; Matthys, S.; De Belie, N.; Gruyaert, E. Reactivity Assessment of Modified Ferro Silicate Slag by R3 Method. Appl. Sci. 2021, 11, 366. [Google Scholar] [CrossRef]

- Kriskova, L.; Pontikes, Y.; Pandelaers, L.; Cizer, Ö.; Jones, P.T.; Van Balen, K.; Blanpain, B. Effect of High Cooling Rates on the Mineralogy and Hydraulic Properties of Stainless Steel Slags. Metall. Mater. Trans. B 2013, 44, 1173–1184. [Google Scholar] [CrossRef]

- Matthes, W.; Vollpracht, A.; Villagrán, Y.; Kamali-Bernard, S.; Hooton, D.; Gruyaert, E.; Soutsos, M.; De Belie, N. Ground granulated blast-furnace slag. In Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–53. [Google Scholar]

- Vollpracht, A.; Brameshuber, W. Binding and leaching of trace elements in Portland cement pastes. Cem. Concr. Res. 2016, 79, 76–92. [Google Scholar] [CrossRef]

- Van der Sloot, H.A. Comparison of the characteristic leaching behavior of cements using standard (EN 196-1) cement mortar and an assessment of their long-term environmental behavior in construction products during service life and recycling. Cem. Concr. Res. 2000, 30, 1079–1096. [Google Scholar] [CrossRef]

- Saikia, N.; Cornelis, G.; Mertens, G.; Elsen, J.; Van Balen, K.; Van Gerven, T.; Vandecasteele, C. Assessment of Pb-slag, MSWI bottom ash and boiler and fly ash for using as a fine aggregate in cement mortar. J. Hazard. Mater. 2008, 154, 766–777. [Google Scholar] [CrossRef]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- Gholizadeh Vayghan, A.; Wright, J.R.; Rajabipour, F. An extended chemical index model to predict the fly ash dosage necessary for mitigating alkali–silica reaction in concrete. Cem. Concr. Res. 2016, 82, 1–10. [Google Scholar] [CrossRef]

- EN. BS EN 197-1. Cement. Composition, Specifications and Conformity Criteria for Common Cements; BSI: Brussels, Belgium, 2011. [Google Scholar]

- Avet, F.; Scrivener, K. Effect of temperature on the water content of CASH in plain Portland and blended cements. Cem. Concr. Res. 2020, 136, 106124. [Google Scholar] [CrossRef]

- Avet, F.; Snellings, R.; Alujas Diaz, A.; Ben Haha, M.; Scrivener, K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Snellings, R.; Scrivener, K.L. Rapid screening tests for supplementary cementitious materials: Past and future. Mater. Struct. 2016, 49, 3265–3279. [Google Scholar] [CrossRef]

- Li, X.; Snellings, R.; Antoni, M.; Alderete, N.M.; Haha, M.B.; Bishnoi, S.; Cizer, Ö.; Cyr, M.; De Weerdt, K.; Dhandapani, Y. Reactivity tests for supplementary cementitious materials: RILEM TC 267-TRM phase 1. Mater. Struct. 2018, 51, 1–14. [Google Scholar] [CrossRef]

- Snellings, R. X-ray powder diffraction applied to cement. In A Practical Guide to Microstructural Analysis of Cementitious Materials; Scrivener, K.L., Snellings, R., Lothenbach, B., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 107–176. [Google Scholar]

- Ronneberger, O.; Fischer, P.; Brox, T. Convolutional Networks for Biomedical Image Segmentation. In Proceedings of the 18th International Conference on Medical Image Computing and Computer-Assisted Intervention, Munich, Germany, 5–9 October 2015; pp. 234–241. [Google Scholar]

- EN. BS EN 196-1: Methods of Testing Cement—Part 1: Determination of Strength; BSI: Brussels, Belgium, 2005. [Google Scholar]

- EN. BS EN 1015-3. Methods of Test for Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Flow Table); BSI: Brussels, Belgium, 1999. [Google Scholar]

- EN. BS EN 12457-4. Characterisation of Waste. Leaching. Compliance Test for Leaching of Granular Waste Materials and Sludges. One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size below 10 mm (without or with Size Reduction); BSI: Brussels, Belgium, 2002. [Google Scholar]

- EN. EN 15167-1: Ground Granulated Blast Furnace Slag for Use in Concrete, Mortar and Grout—Part 1: Definitionhs, Specifications and Conformity Criteria; BSI: Brussels, Belgium, 2006. [Google Scholar]

- Weeks, C.; Hand, R.J.; Sharp, J.H. Retardation of cement hydration caused by heavy metals present in ISF slag used as aggregate. Cem. Concr. Compos. 2008, 30, 970–978. [Google Scholar] [CrossRef]

- Asavapisit, S.; Fowler, G.; Cheeseman, C.R. Solution chemistry during cement hydration in the presence of metal hydroxide wastes. Cem. Concr. Res. 1997, 27, 1249–1260. [Google Scholar] [CrossRef]

- Cheeseman, C.R.; Asavapisit, S. Effect of calcium chloride on the hydration and leaching of lead-retarded cement. Cem. Concr. Res. 1999, 29, 885–892. [Google Scholar] [CrossRef]

- Spooren, J.; Binnemans, K.; Björkmalm, J.; Breemersch, K.; Dams, Y.; Folens, K.; González-Moya, M.; Horckmans, L.; Komnitsas, K.; Kurylak, W. Near-zero-waste processing of low-grade, complex primary ores and secondary raw materials in Europe: Technology development trends. Resour. Conserv. Recycl. 2020, 160, 104919. [Google Scholar] [CrossRef]

- Blotevogel, S.; Ehrenberg, A.; Steger, L.; Doussang, L.; Kaknics, J.; Patapy, C.; Cyr, M. Ability of the R3 test to evaluate differences in early age reactivity of 16 industrial ground granulated blast furnace slags (GGBS). Cem. Concr. Res. 2020, 130, 105998. [Google Scholar] [CrossRef]

- Snellings, R.; Kamyab, H.; Joseph, S.; Nielsen, P.; Loots, M.; Abeele, L.V.d. Pozzolanic Reactivity of Size-Classified Siliceous Fly Ashes. In Proceedings of the 2nd International Conference of Sustainable Building Materials, Eindhoven, The Netherlands, 12–15 August 2019. [Google Scholar]

- Shi, C.; Day, R.L. Comparison of different methods for enhancing reactivity of pozzolans. Cem. Concr. Res. 2001, 31, 813–818. [Google Scholar] [CrossRef]

- Rashad, A.; Bai, Y.; Basheer, P.; Milestone, N.; Collier, N. Hydration and properties of sodium sulfate activated slag. Cem. Concr. Compos. 2013, 37, 20–29. [Google Scholar] [CrossRef]

- Joseph, S.; Snellings, R.; Cizer, Ö. Activation of Portland cement blended with high volume of fly ash using Na2SO4. Cem. Concr. Compos. 2019, 104, 103417. [Google Scholar] [CrossRef]

- Adu-Amankwah, S.; Black, L.; Skocek, J.; Haha, M.B.; Zajac, M. Effect of sulfate additions on hydration and performance of ternary slag-limestone composite cements. Constr. Build. Mater. 2018, 164, 451–462. [Google Scholar] [CrossRef]

- Adu-Amankwah, S.; Lopez, S.A.B.; Black, L. Influence of component fineness on hydration and strength development in ternary slag-limestone cements. Rilem Tech. Lett. 2019, 4, 81–88. [Google Scholar] [CrossRef]

| Oxide/Metal | Slag Source | ||||||

|---|---|---|---|---|---|---|---|

| S1 (Raw) | S2 (Raw) | S3 (Synthetic) | TS1 (Treated) | TS2 (Treated) | TS3 (Treated) | ||

| Oxide content (%) | FeO | 13.5 | 21.9 | 35.3 | 16.9 | 21.6 | 31.0 |

| SiO2 | 18.5 | 17.3 | 20.6 | 50.6 | 39.0 | 21.3 | |

| CaO | 5.64 | 7.28 | 9.66 | 9.45 | 15.8 | 9.93 | |

| Al2O3 | 4.25 | 2.15 | 2.68 | 11.0 | 11.8 | 5.67 | |

| Na2O | 7.04 | 2.72 | 0.67 | 9.32 | 5.76 | 3.06 | |

| K2O | 2.10 | 0.55 | 0.51 | 2.54 | 0.42 | 0.73 | |

| MgO | 4.21 | 0.28 | 2.82 | 5.84 | 7.96 | 0.65 | |

| ZnO | 7.19 | 10.7 | 12.9 | 0.18 | 0.03 | 1.45 | |

| CuO | 0.72 | 0.05 | 0.23 | 0.18 | 0.08 | 0.01 | |

| SO3 | 17.3 | <0.05 | 0.77 | 0.49 | 0.29 | 0.32 | |

| Metal content (%) | Pb | 3.48 | 3.86 | 4.45 | 0.001 | 0.001 | 0.075 |

| As | 0.409 | 0.505 | 0.14 | <0.001 | <0.001 | 0.006 | |

| Sn | 0.179 | 0.304 | 0.93 | 0.001 | 0.004 | 0.214 | |

| Sb | 0.037 | 0.628 | 0.54 | <0.001 | 0.001 | 0.027 | |

| Co | 0.008 | 0.011 | NA | <0.001 | <0.001 | 0.005 | |

| Materials | Characteristic Particle Sizes (µm) | True Density (g/cm3) | ||||

|---|---|---|---|---|---|---|

| Mean | Mode | D(v,10) | D(v,50) | D(v,90) | ||

| TS1: Treated S1 | 20.9 | 12.4 | 1.6 | 9.1 | 53.9 | 2.952 |

| TS2: Treated S2 | 13.4 | 5.5 | 2.1 | 6.0 | 23.0 | 3.656 |

| TS3: Treated S3 (synthetic) | 34.5 | 12.4 | 1.8 | 13.6 | 104.0 | 3.291 |

| Cement | 12.3 | 14.2 | 2.0 | 9.9 | 25.0 | 3.125 |

| Quartz powder | 9.4 | 12.4 | 2.2 | 7.5 | 19.4 | 2.650 |

| Oxide/Property | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | P2O5 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 60.9 | 17.6 | 6.38 | 3.72 | 1.5 | <0.7 | 0.307 | 1.07 | 1.84 |

| Mineral | C3S M1 | β-C2S | C3A cubic | C4AF | Anhydrite | Calcite | Quartz | Amorphous | |

| Content (%) | 59.1 | 6.0 | 5.8 | 13.4 | 5.0 | 4.0 | 0.5 | 6.2 |

| Slag (g) | Ca(OH)2 (g) | Potassium Solution (g) | CaCO3 (g) |

|---|---|---|---|

| 11.12 | 33.33 | 59.94 | 5.56 |

| Paste Label | Slag Source | Mixing Ratios (wt./wt.) | ||

|---|---|---|---|---|

| Water-to-Binder | Slag-to-Binder | Quartz-to-Binder | ||

| P_PC | – | 0.4 | 0.0 | 0.0 |

| P_QP | – | 0.4 | 0.0 | 0.3 |

| P_TS1 | TS1: Treated S1 | |||

| P_TS2 | TS2: Treated S2 | 0.4 | 0.3 | 0.0 |

| P_TS3 | TS3: Treated S3 | |||

| Mortar Label | Slag Source | Batched Masses for Preparation of Mortars (g) | ||||

|---|---|---|---|---|---|---|

| Cement | Slag | Quartz | Water | Sand | ||

| M_PC | – | 900 | – | – | 450 | 2700 |

| M_QP | – | 630 | – | 270 | 450 | 2700 |

| M_TS1 | TS1: Treated S1 | |||||

| M_TS2 | TS2: Treated S2 | 630 | 270 | – | 450 | 2700 |

| M_TS3 | TS3: Treated S3 (synthetic) | |||||

| Slag Source | 3-Day Heat (J/g SCM) | 7-Day Heat (J/g SCM) | 7-Day Bound Water (g/100 g Dried Paste) |

|---|---|---|---|

| TS1: Treated S1 | 58.0 | 104 | 3.2 |

| TS2: Treated S2 | 58.0 | 88.0 | 2.3 |

| TS3: Treated S3 (synthetic) | 73.0 | 127 | 3.3 |

| Some conventional SCMs | |||

| Blast furnace slag | 460 | 518 | 8.5 |

| Fly ash | 104 | 173 | 4.5 |

| Calcined clay | 527 | 574 | 10.4 |

| Inert material | |||

| Quartz | 16 | 21 | 1.3 |

| Parameter | P_PC (28 days) | P_QP (28 days) | P_TS1 (28 days) | P_TS2 (28 days) | P_TS3 (28 days) | P_PC (90 days) | P_QP (90 days) | P_TS1 (90 days) | P_TS2 (90 days) | P_TS3 (90 days) |

|---|---|---|---|---|---|---|---|---|---|---|

| Total cumulative volume (mm3/g) | 71 | 114 | 105 | 107 | 94 | 70 | 96 | 67 | 86.5 | 58 |

| Total specific surface area (m2/g) | 16.3 | 24.4 | 20.1 | 19.5 | 16.6 | 12.9 | 21.4 | 11.1 | 17.3 | 9.5 |

| Average pore radius (nm) | 11.9 | 11.9 | 17.5 | 19.0 | 19.9 | 12.9 | 11.2 | 16.1 | 16.9 | 16.6 |

| Total porosity (%) | 13.9 | 20.1 | 18.0 | 19.2 | 16.2 | 12.7 | 16.9 | 12.4 | 16 | 11.7 |

| Threshold pore entry radius (nm) | 15.9 | 17.4 | 27.0 | 25.8 | 28.3 | 18.1 | 17.0 | 23.0 | 1.85 | 23.9 |

| Critical pore entry radius (nm) | 12.7 | 12.5 | 22.0 | 21.9 | 23.2 | 12.7 | 12.1 | 16.5 | 2.20 | 18.5 |

| Mortar Label | Flow (%) | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 Day | 7 Days | 28 Days | 91 Days | 1 Day | 7 Days | 28 Days | 91 Days | ||

| M_PC | 81.5 | 24.9 ± 0.6 | 56.6 ± 1.0 | 65.1 ± 1.0 | 69.3 ± 0.9 | 6.5 ± 0.3 | 10.5 ± 1.2 | 11 ± 0.3 | 13.0 ± 2.0 |

| M_QP | 91.0 | 12.6 ± 0.4 | 36.5 ± 1.1 | 49.0 ± 1.3 | 55.8 ± 3.0 | 3.1 ± 0.1 | 7.0 ± 0.3 | 7.4 ± 0.2 | 8.8 ± 0.4 |

| M_TS1 | 95.5 | 11.8 ± 0.1 | 37.7 ± 0.6 | 46.2 ± 1.1 | 53.3 ± 1.0 | 4.1 ± 0.2 | 8.7 ± 0.6 | 9.3 ± 0.8 | 10.9 ± 0.9 |

| M_TS2 | 106 | 10.5 ± 0.1 | 36.8 ± 0.4 | 47.7 ± 1.2 | 55.5 ± 0.9 | 3.5 ± 0.1 | 8.1 ± 0.2 | 9.4 ± 0.7 | 9.9 ± 0.5 |

| M_TS3 | 98.5 | 12.3 ± 0.2 | 39.4 ± 0.4 | 47.5 ± 0.8 | 53.6 ± 1.2 | 4.1 ± 0.2 | 8.8 ± 0.5 | 9.6 ± 1.8 | 10.2 ± 1.6 |

| Mortar Label | Slag Source | SAI at Different Ages (Days) | |||

|---|---|---|---|---|---|

| 1 | 7 | 28 | 91 | ||

| M_QP | – | 0.50 | 0.64 | 0.75 | 0.81 |

| M_TS1 | TS1: Treated S1 | 0.47 | 0.67 | 0.71 | 0.77 |

| M_TS2 | TS2: Treated S2 | 0.42 | 0.65 | 0.73 | 0.80 |

| M_TS3 | TS3: Treated S3 | 0.49 | 0.7 | 0.73 | 0.77 |

| Standard limitation | EN 15167 | – | – | 0.70 | – |

| Mortar Label | Slag Source | As | Ba | Cr | Pb | Zn | Sb | Ni |

|---|---|---|---|---|---|---|---|---|

| M_PC | – | <0.15 | 13 | 0.2 | <0.1 | <0.1 | <0.2 | <0.05 |

| M_TS1 | TS1: Treated S1 | <0.15 | 15 | 0.52 * | <0.1 | <0.1 | <0.2 | <0.05 |

| M_TS2 | TS2: Treated S2 | <0.15 | 12 | 0.29 | <0.1 | <0.1 | <0.2 | <0.05 |

| M_TS3 | TS3: Treated S3 | <0.15 | 20 | 0.16 | <0.1 | 0.1 | <0.2 | <0.05 |

| VLAREMA limits | 0.8 | 20 | 0.5 | 1.3 | 2.8 | 1 | 0.75 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gholizadeh Vayghan, A.; Horckmans, L.; Snellings, R.; Peys, A.; Teck, P.; Maier, J.; Friedrich, B.; Klejnowska, K. Use of Treated Non-Ferrous Metallurgical Slags as Supplementary Cementitious Materials in Cementitious Mixtures. Appl. Sci. 2021, 11, 4028. https://doi.org/10.3390/app11094028

Gholizadeh Vayghan A, Horckmans L, Snellings R, Peys A, Teck P, Maier J, Friedrich B, Klejnowska K. Use of Treated Non-Ferrous Metallurgical Slags as Supplementary Cementitious Materials in Cementitious Mixtures. Applied Sciences. 2021; 11(9):4028. https://doi.org/10.3390/app11094028

Chicago/Turabian StyleGholizadeh Vayghan, Asghar, Liesbeth Horckmans, Ruben Snellings, Arne Peys, Priscilla Teck, Jürgen Maier, Bernd Friedrich, and Katarzyna Klejnowska. 2021. "Use of Treated Non-Ferrous Metallurgical Slags as Supplementary Cementitious Materials in Cementitious Mixtures" Applied Sciences 11, no. 9: 4028. https://doi.org/10.3390/app11094028

APA StyleGholizadeh Vayghan, A., Horckmans, L., Snellings, R., Peys, A., Teck, P., Maier, J., Friedrich, B., & Klejnowska, K. (2021). Use of Treated Non-Ferrous Metallurgical Slags as Supplementary Cementitious Materials in Cementitious Mixtures. Applied Sciences, 11(9), 4028. https://doi.org/10.3390/app11094028